Preprint

Article

Residual Stress, Phase, Microstructure and Mechanical Property Enhancement of Ultrafine Bainitic Steel through Laser Shock Processing

Altmetrics

Downloads

1094

Views

501

Comments

1

supplementary.pdf (464.18KB )

This version is not peer-reviewed

Submitted:

27 April 2018

Posted:

27 April 2018

You are already at the latest version

Alerts

Abstract

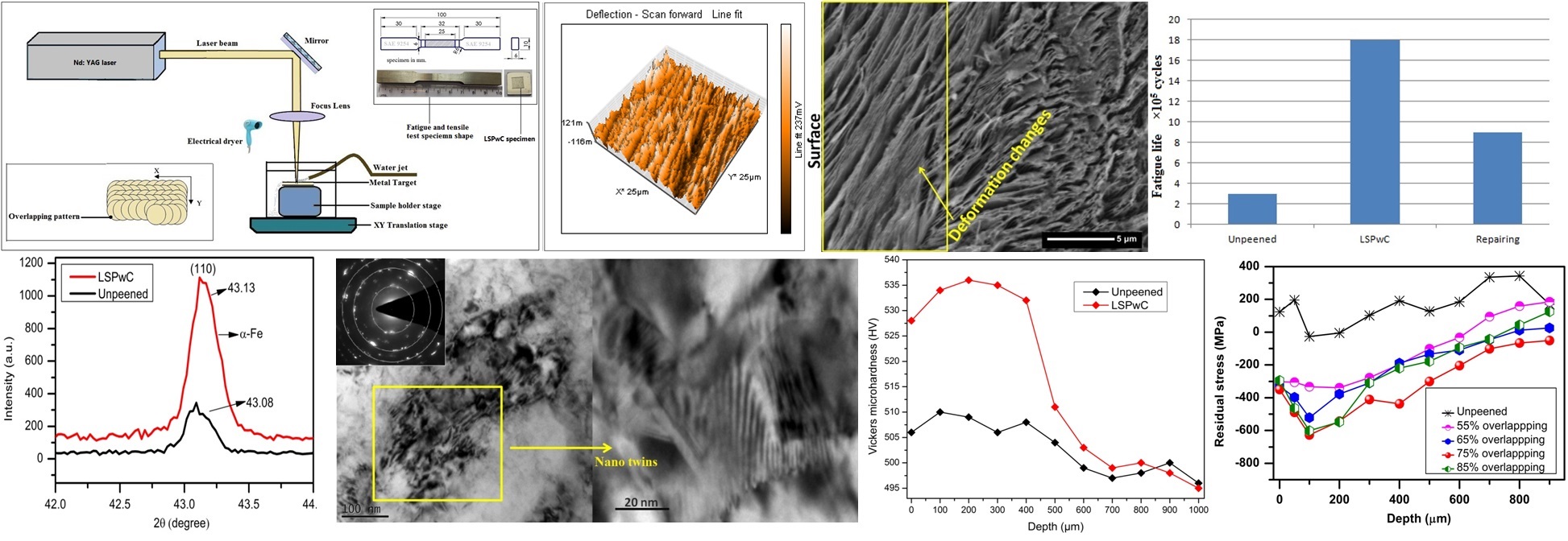

The study proposes laser shock peening without a coating of high strength ultrafine bainitic steel to mitigating the fatigue failures for automotive and structural engineering applications. Laser pulse density of 2500 pulses/cm2 (75% overlapping) was optimised based on the induced residual stresses for employing the wide range of characterisations. The roughness and topographic results showed that surface roughening was controlled by tuning the laser pulse density. The High-Resolution X-ray Diffraction analysis confirmed the lattice misorientation resulting peak shift and the trend towards martensite phase transformations. The electron microscopic micro/nanostructure analyses revealed the grain refinement features such as nano-twins, micro shear bands and shear cells. The work hardening depth and nanomechanical properties were significantly enhanced. A fully reversed (R= -1) high-cycle fatigue tests extended the lifespan by an average of fifteen times than the untreated. Also, it has potential to repair the structural components effectively.

Keywords:

Subject: Engineering - Mechanical Engineering

Copyright: This open access article is published under a Creative Commons CC BY 4.0 license, which permit the free download, distribution, and reuse, provided that the author and preprint are cited in any reuse.

MDPI Initiatives

Important Links

© 2024 MDPI (Basel, Switzerland) unless otherwise stated