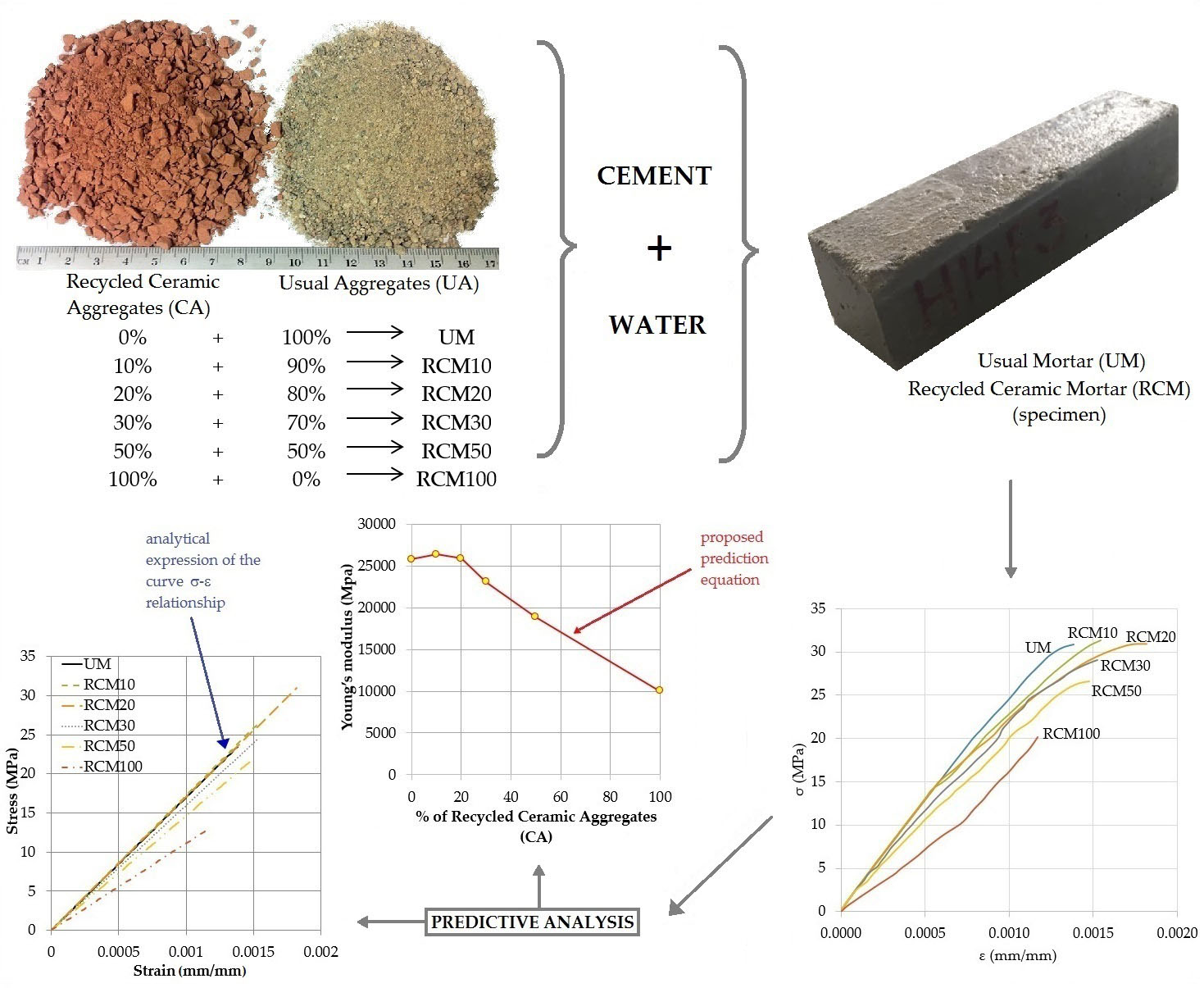

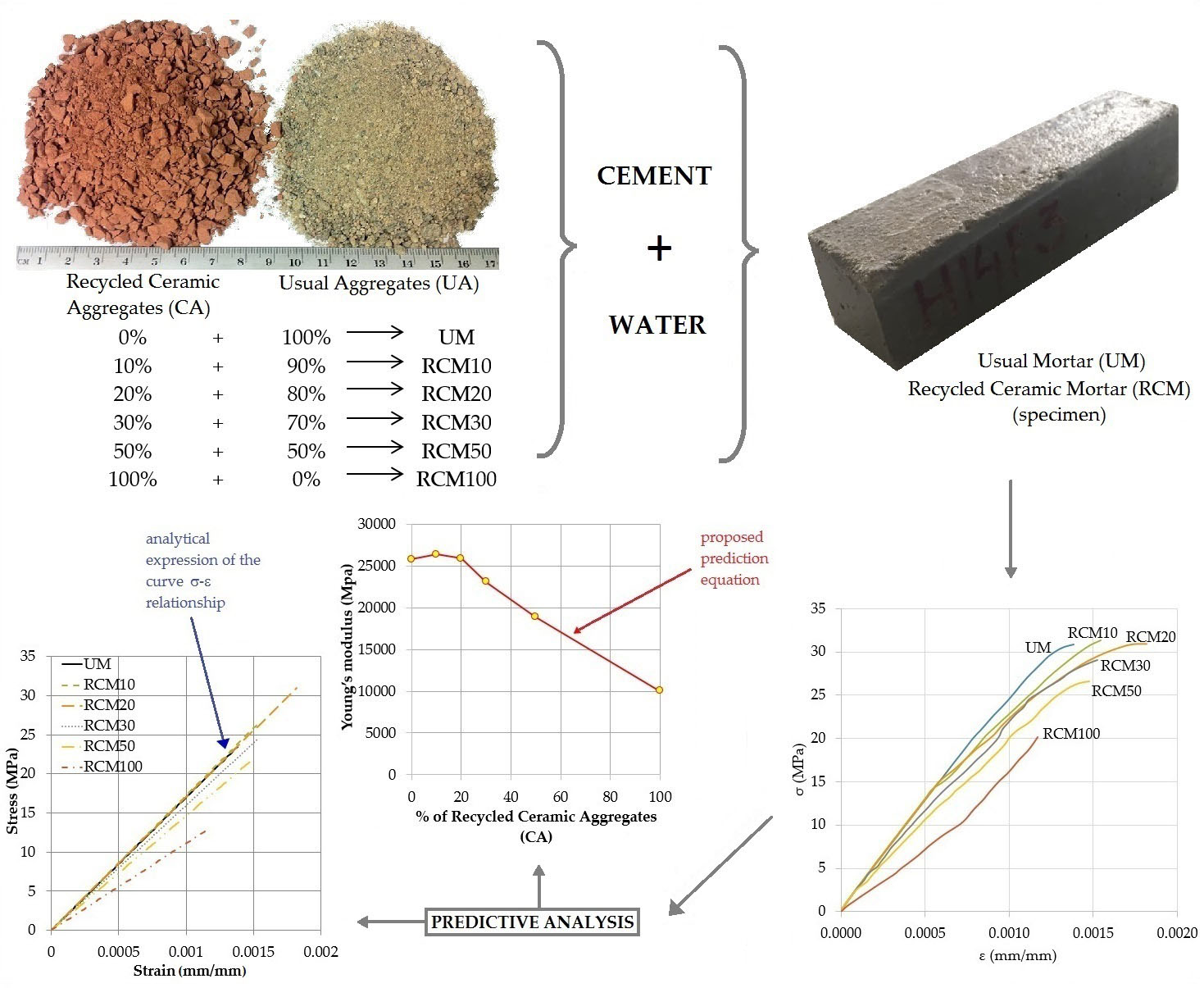

The difficult current environmental situation, caused by construction industry residues containing ceramic materials could be improved by using these materials as recycled aggregates in mortars, with their processing causing a reduction in their use in landfill, contributing to recycling and also minimizing the consumption of virgin materials. Although some research is currently being carried out into recycled mortars, little is known about their stress-strain (σ-ε); therefore this work will provide the experimental results obtained from recycled mortars with recycled ceramic aggregates (with contents of 0, 10, 20, 30, 50 and 100%), such as: the density, the compression strength, as well as the σ-ε curves representative of their behavior. The values obtained from the analysis process of the results are those of: σ (elastic ranges and failure maximum), ε (elastic ranges and failure maximum), and Resilience and Toughness; in order to finally obtain, through numerical analysis, the equations to predict their behavior (related to their recycled content). At the end of the investigation it is established that mortars with recycled ceramic aggregate contents of up to 20% could be assimilated just like mortars with the usual aggregates, and the prediction equations produced could be used in cases of similar applications.