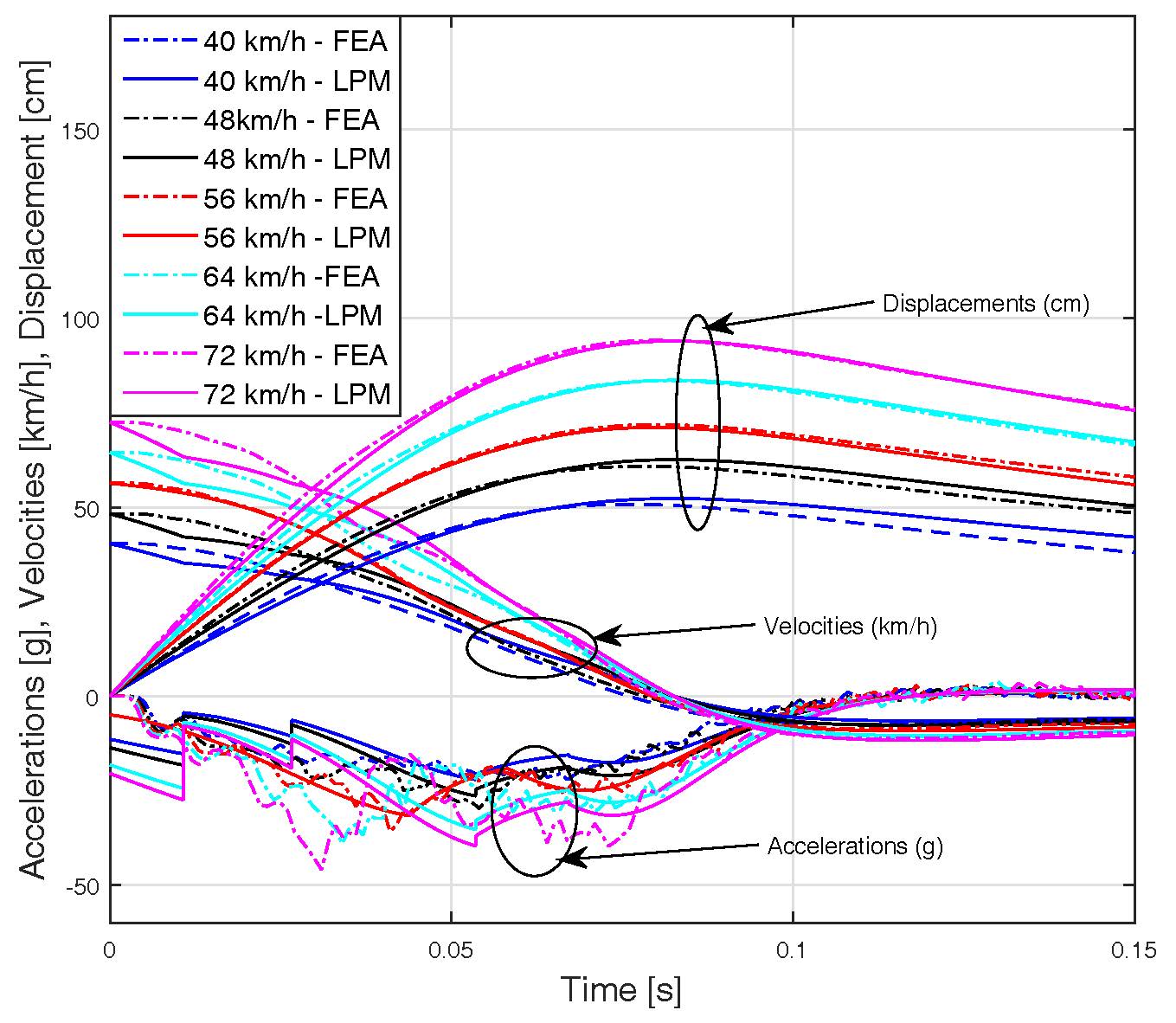

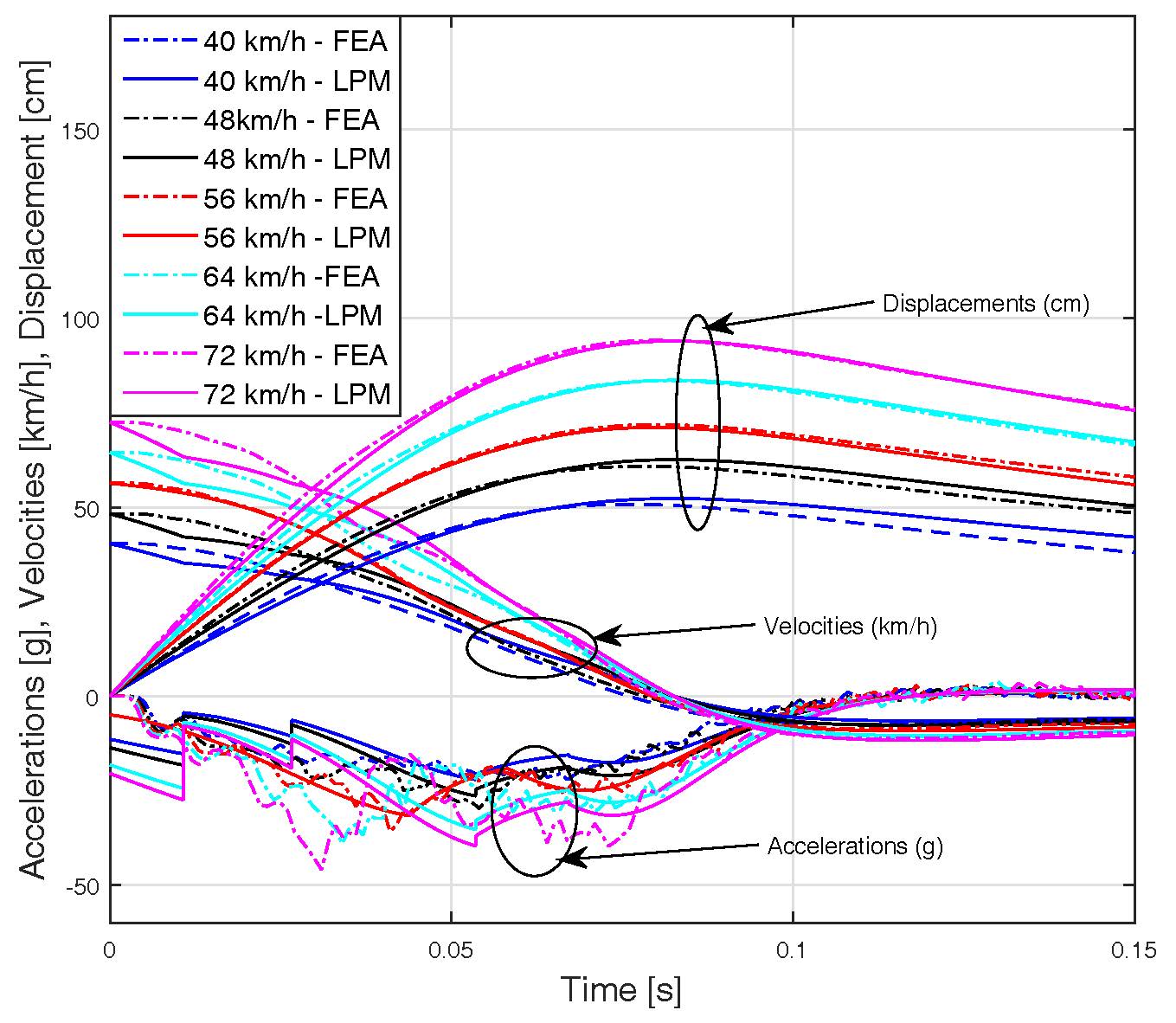

Estimating the vehicle crashworthiness parameters experimentally is expensive and time consuming. For these reasons different modelling approaches are utilized to predict the vehicle behaviour and reduce the need for full-scale crash testing. The earlier numerical methods used for vehicle crashworthiness analysis were based on the use of lumped parameters models (LPM), a combination of masses and nonlinear springs interconnected in various configurations. Nowadays, the explicit nonlinear finite element analysis (FEA) is probably the most widely recognized modelling technique. Although informative, finite element models (FEM) of vehicle crash are expensive both in terms of man-hours put into assembling the model and related computational costs. A simpler analytical tool for early analysis of vehicle crashworthiness could greatly assist the modelling and save time. In this paper a simple piecewise LPM composed of a mass-spring-damper system, is used to estimate the vehicle crashworthiness parameters, focusing on the dynamic crush and the acceleration severity index (ASI). The model is first calibrated against a full-scale crash test and a FEM, post-processed with the LS-DYNA software, at an impact velocity of 56 km/h. The genetic algorithm is used to calibrate the model by estimating the piecewise lumped parameters (stiffness and damping of the front structure of the vehicle). After calibration, the LPM is applied to a range of velocities (40, 48, 64 and 72 km/h). The predictions for crashworthiness parameters from the LPM were compared with the predictions from the FEA and the results are much similar. It is shown that the LPM can assist in crash analysis, since LPM has some predictive capabilities and requires less computation time in comparison with the explicit nonlinear FEA.