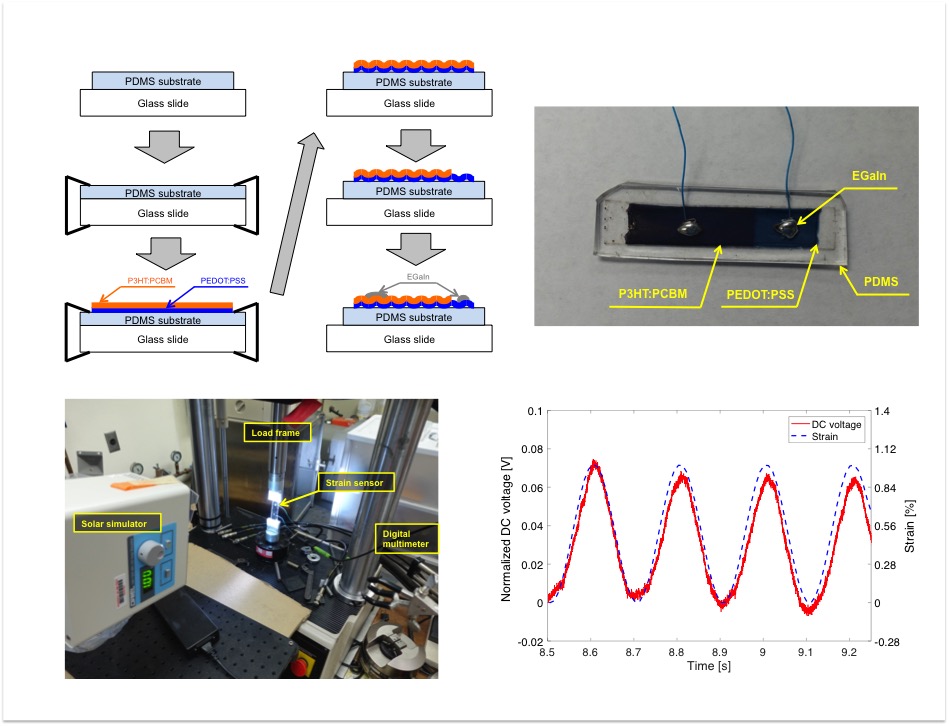

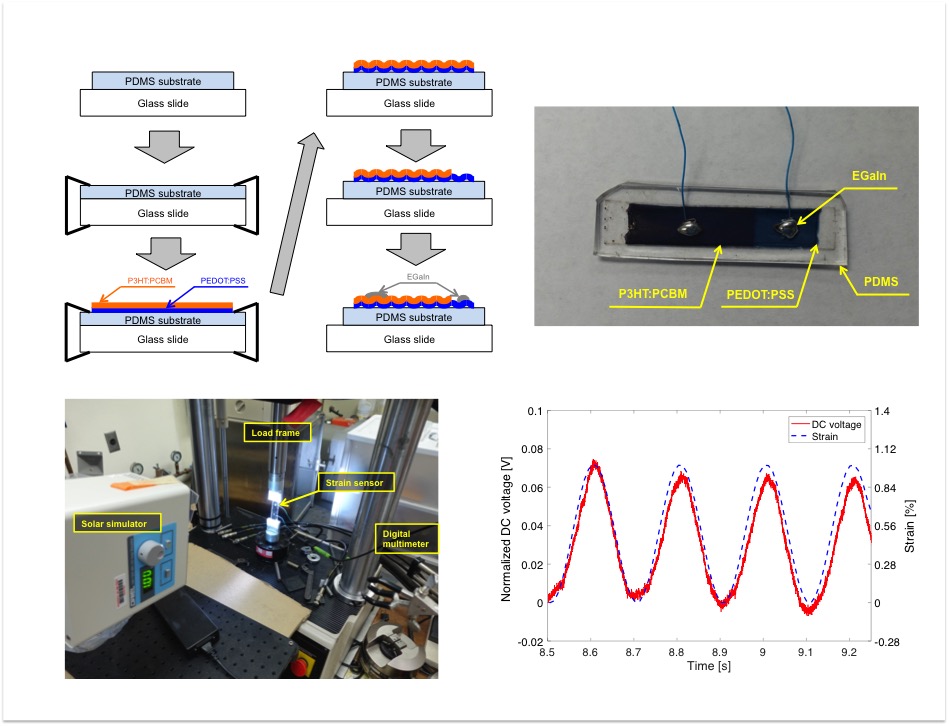

In this study, a flexible strain sensor is devised using corrugated poly(3-hexylthiophene) (P3HT) thin film. In the previous studies, the P3HT-based photoactive thin film was shown to generate direct current (DC) under broadband light, and the generated DC voltage varied with applied tensile strain. Yet, the mechanical resiliency and strain sensing range of the P3HT-based thin film strain sensor were limited due to relatively more brittle thin film constituent—poly(3,4-ethylenedioxythiophene)-polystyrene(sulfonate) (PEDOT:PSS) conductive thin film as a bottom electrode. To address this issue, it is aimed to design mechanically resilient strain sensor using corrugated thin film constituents. Buckling is induced to form corrugation in the thin films by applying pre-strain to the substrate, where the thin films are deposited, and releasing the pre-strain afterwards. It is known that corrugated thin film constituents exhibit different optical and electronic properties from non-corrugated ones. Therefore, to optimize design of the flexible strain sensor, it was studied to understand how the applied pre-strain and thickness of the PEDOT:PSS thin film affect the optical and electrical properties. Also, pre-strain effect on light absorptivity of the corrugated P3HT-based thin films was studied. In addition, strain effect was investigated on the optical and electrical properties of the corrugated thin film constituents. Finally, flexible strain sensors are fabricated by following the design guideline, which is suggested from the studies on the corrugated thin film constituents, and DC voltage strain sensing capability was validated. As a result, flexible strain sensor exhibited tensile strain sensing range up to 5% at frequency up to 15 Hz with maximum gage factor ~7.