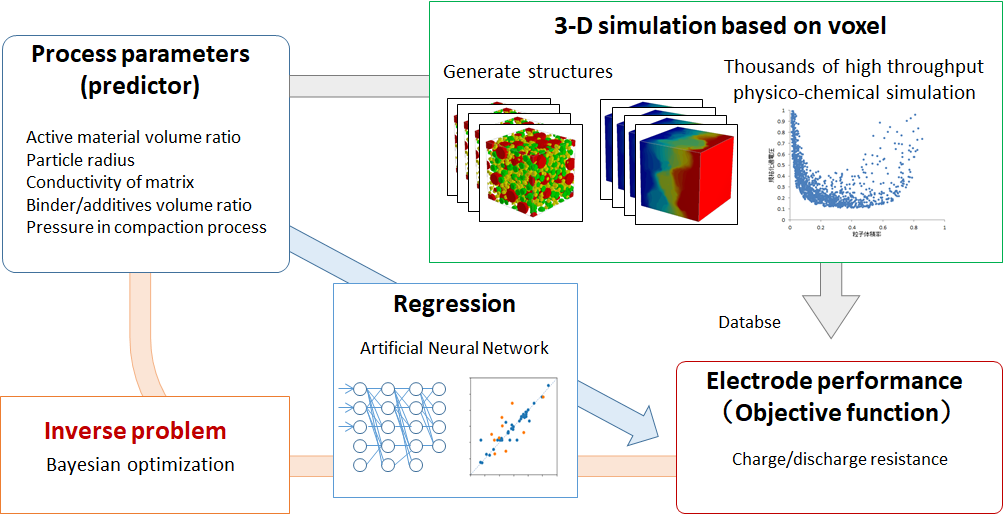

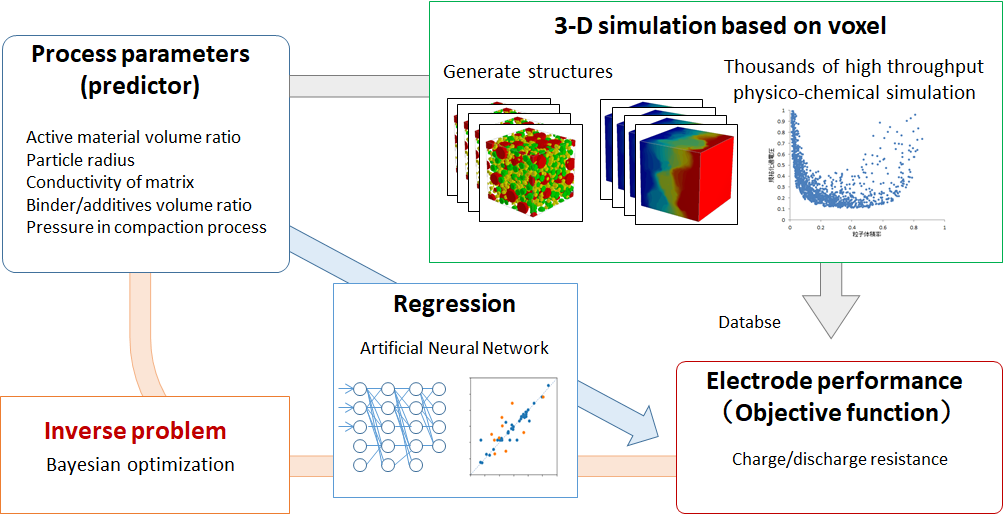

We have proposed a data-driven approach for designing mesoscale porous structures of Li-ion battery electrode with three-dimensional virtual structures and machine learning techniques. Over 2,000 artificial 3D structures assuming positive electrode composed of random packed spheres as active material particles are generated, and charge/discharge resistance has been evaluated using simplified Physico-chemical model. In this model, resistance from Li diffusion in active material particles (diffusion resistance), transfer resistance of Li+ in electrolyte (electrolyte resistance) and reaction resistance on the interface between active material and electrolyte are simulated based on mass balance of Li, Ohm’s law in and linearized Butler-Volmer equation, respectively. Using these simulation results, regression models via Artificial Neural Network (ANN) have been created in order to predict charge/discharge resistance from porous structure features. In this study, porosity, active material particle size and volume fraction, pressure in the compaction process, electrolyte conductivity, and binder volume fraction are adopted as features, associated with controllable process parameters for manufacturing battery electrode. As results, the predicted electrode resistance by ANN regression model is good agreement with the simulated values. Furthermore, sensitivity analysis and optimization of the process parameters have been carried out. The proposed data-driven approach could be a solution as a guiding principle for manufacturing battery electrode.