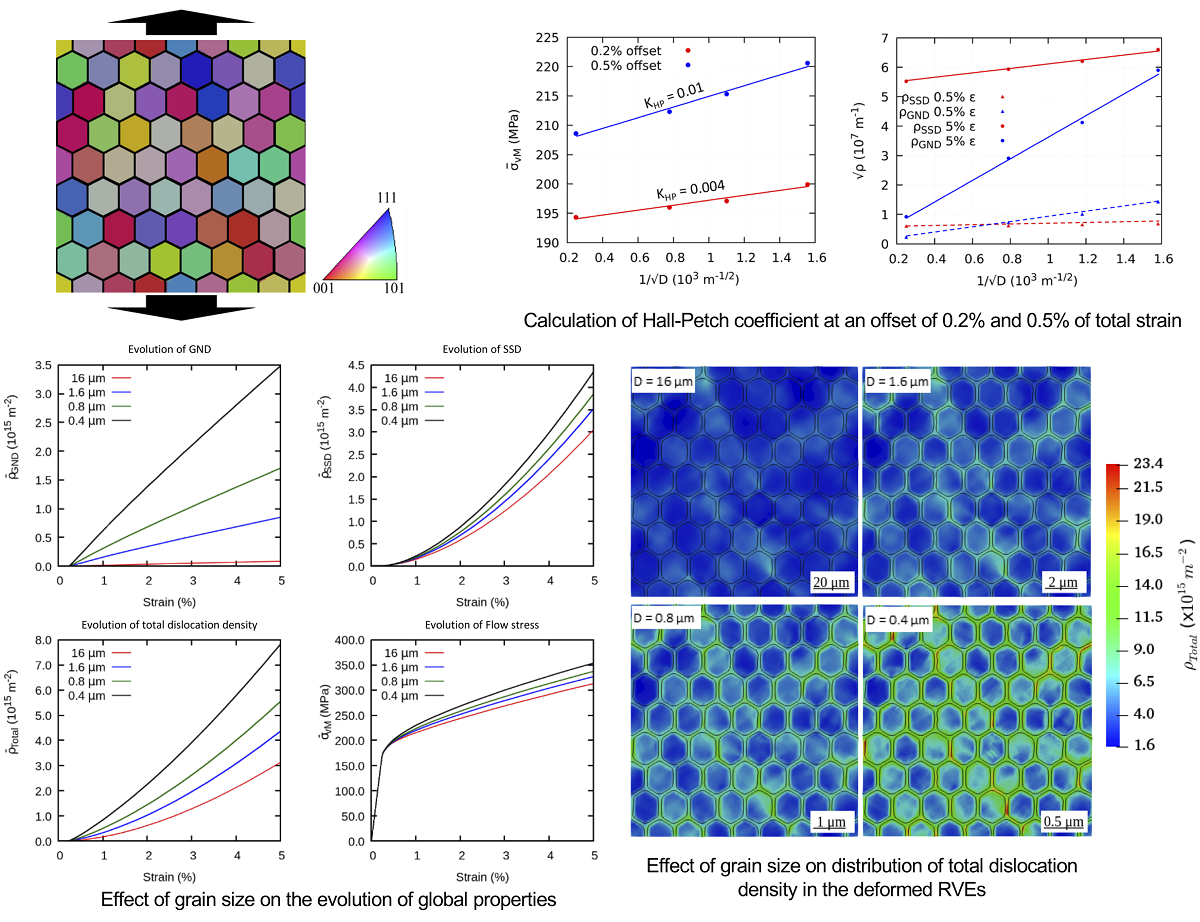

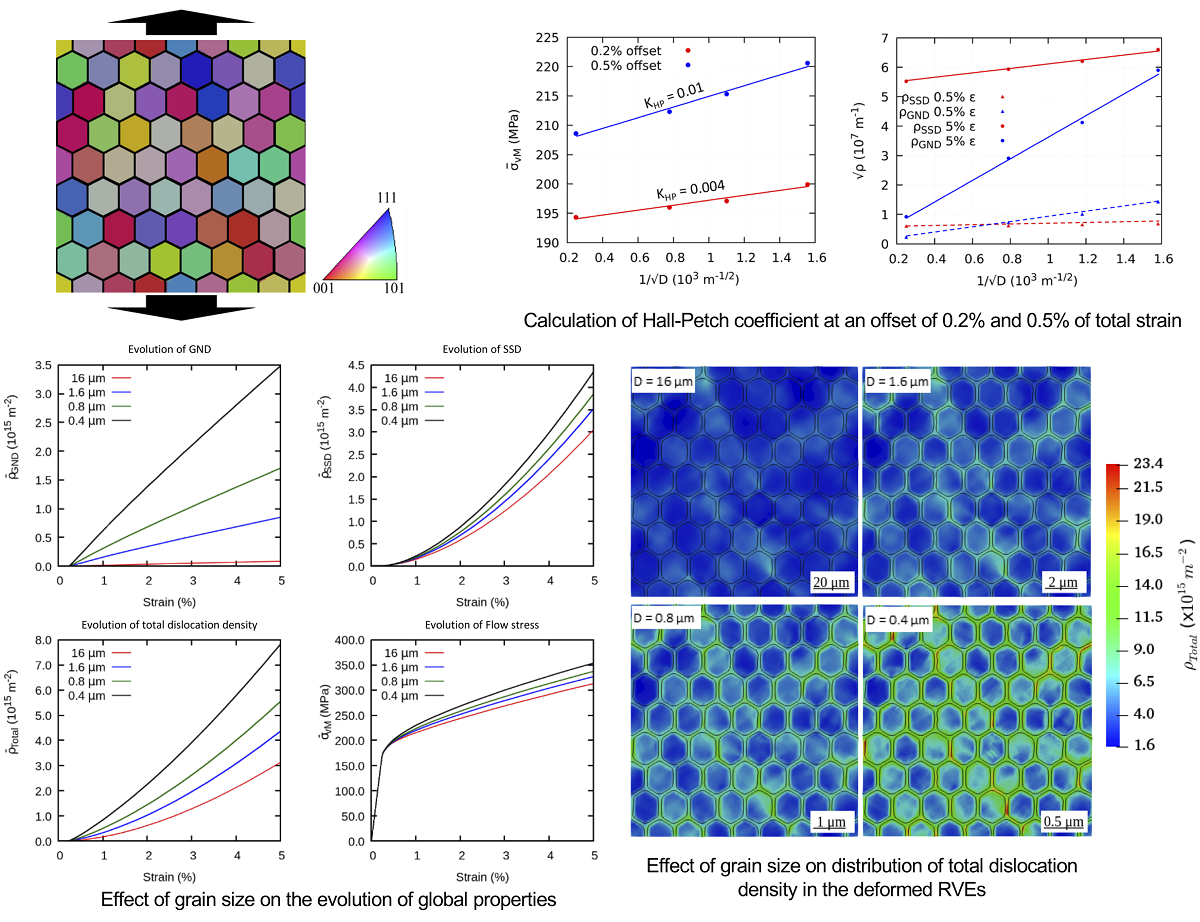

One ambitious objective of Integrated Computational Materials Engineering (ICME) is to shorten the materials development cycle by using computational materials simulation techniques at different length scales. In this regard, the most important aspects are the prediction of the microstructural evolution during material processing and the understanding of the contributions of microstructural features to the mechanical response of the materials. One possible solution to such a challenge is to apply the Phase Field (PF) method because it can predict the microstructural evolution under the influence of different internal or external stimuli, including deformation. To accomplish this, it is necessary to take into account plasticity or, specifically, non-homogeneous plastic deformation, which is particularly important for investigating the size effects in materials emerging at the micron length scale. In this work, we present quasi-2D simulations of plastic deformation in a face centred cubic system in a finite strain formulation. Our model consists of dislocation-based strain gradient crystal plasticity implemented into a PF code. We apply this model to study the influence of grain size on the mechanical behavior of polycrystals, which includes dislocation storage and annihilation. Furthermore, the initial state of the material before deformation is also considered. The results show that a dislocation-based strain gradient crystal plasticity model can capture the Hall-Petch effect in many aspects. The model reproduced the correct functional dependence of the flow stress of the polycrystal on grain size without assigning any special properties to the grain boundaries. However, the predicted Hall-Petch coefficients are significantly smaller than those found typically in experiments. In any case, we found a good qualitative agreement between our findings and experimental results.