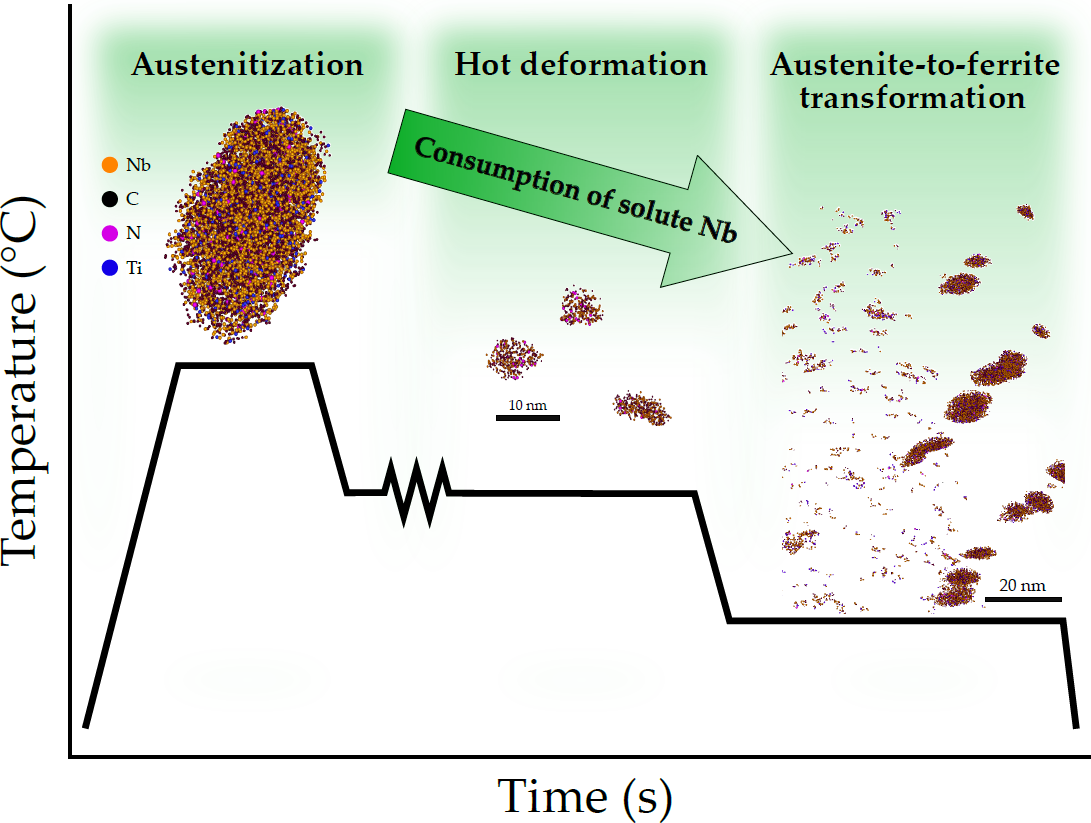

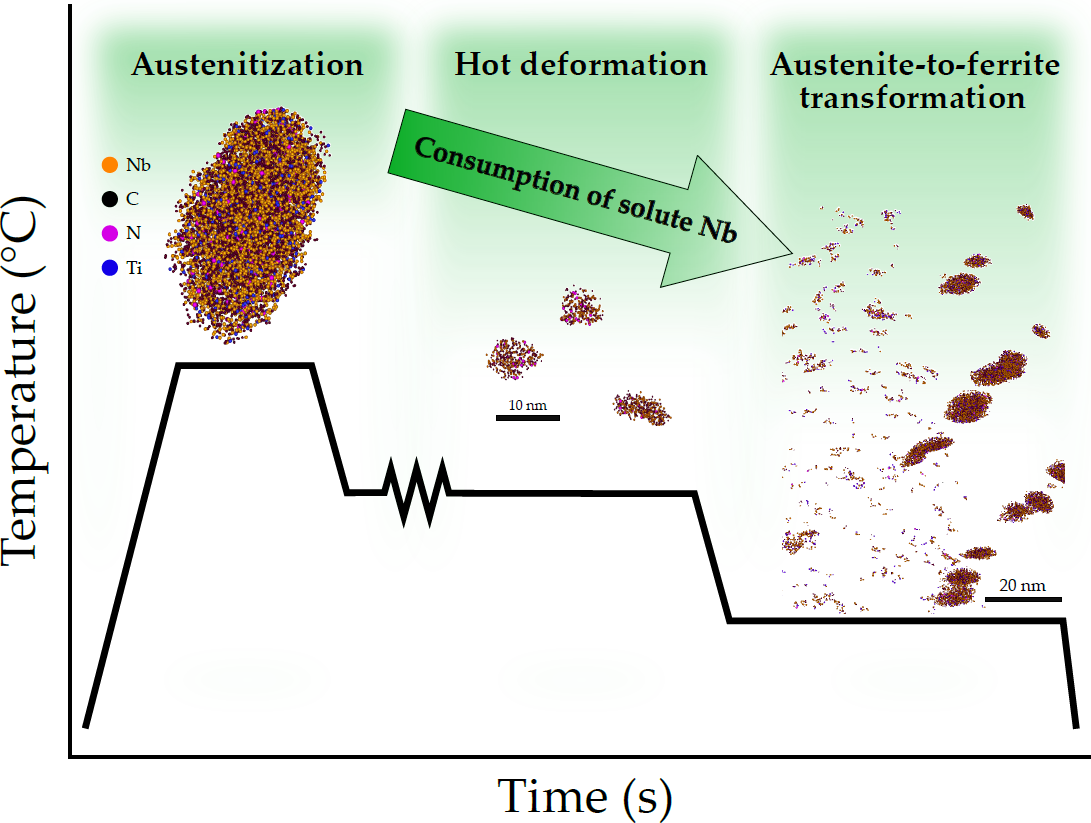

Microalloying of low carbon steel with niobium (Nb) and titanium (Ti) is standardly applied in high-strength low-alloy (HSLA) steels enabling austenite conditioning during thermo-mechanical controlled processing (TMCP), which results in pronounced grain refinement in the finished steel. The metallurgical effects of microalloying elements are related solute drag and precipitate particle pinning, both acting on the austenite grain boundary thereby delaying or suppressing recrystallization of the deformed grain. In that respect it is important to better understand the precipitation kinetics as well as the precipitation sequence in a typical Nb-Ti-microalloyed steel. Various characterization methods have been utilized in this study for tracing microalloy precipitation after simulating different austenite TMCP conditions in a Gleeble apparatus. Atom probe tomography (APT), scanning transmission electron microscopy in a focused ion beam equipped scanning electron microscope (STEM-on-FIB) and electrical resistivity measurements provide complementary information on the precipitation status and are correlated with each other. It will be demonstrated that accurate electrical resistivity measurements can monitor the general consumption of solute microalloys (Nb) during hot working which was complemented by APT measurements of the steel matrix. On the other hand, STEM revealed that a large part of Nb-containing particles during hot working are co-precipitated with titanium during cooling from the austenitizing temperature. Precipitates that form during cooling or isothermal holding can be distinguished from strain-induced precipitates by corroborating STEM measurements with APT results. APT specifically allows obtaining detailed information about the chemical composition of precipitates as well as the distribution of elements inside the particle. Electrical resistivity measurement, on the contrary, provides macroscopic information on the progress of precipitation and can be calibrated by APT. The current paper highlights the complementarity of these methods and shows first results within the framework of a larger study on strain-induced precipitation.