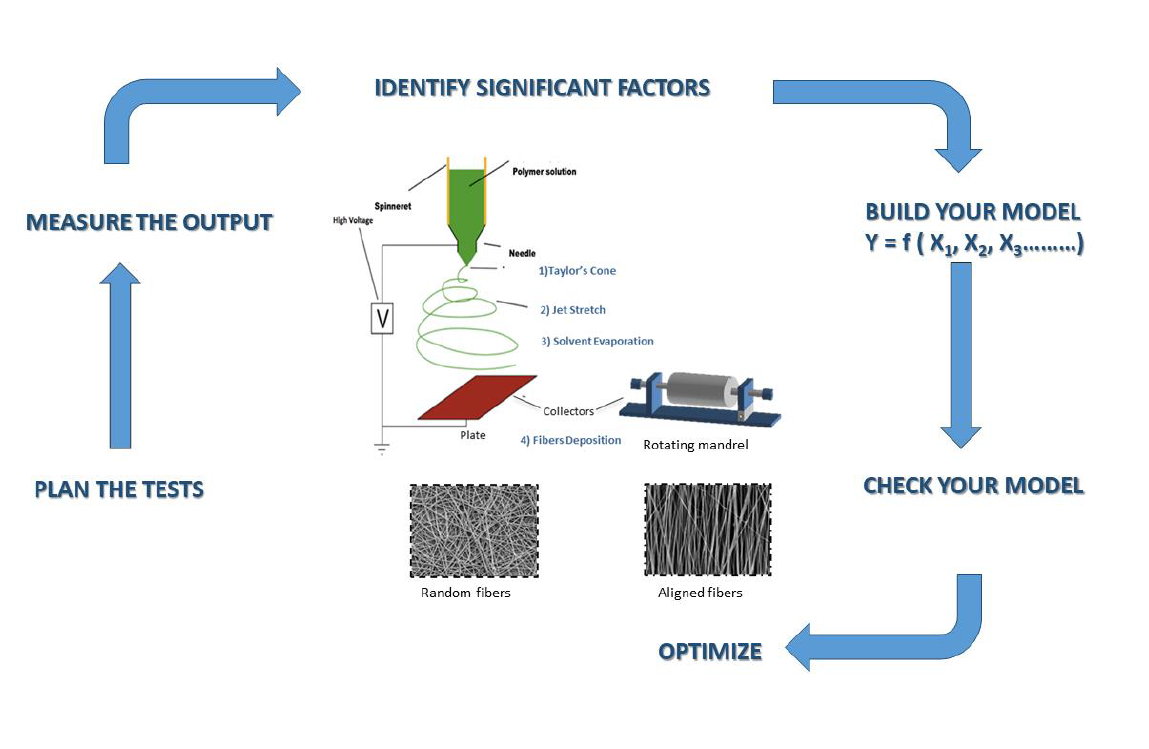

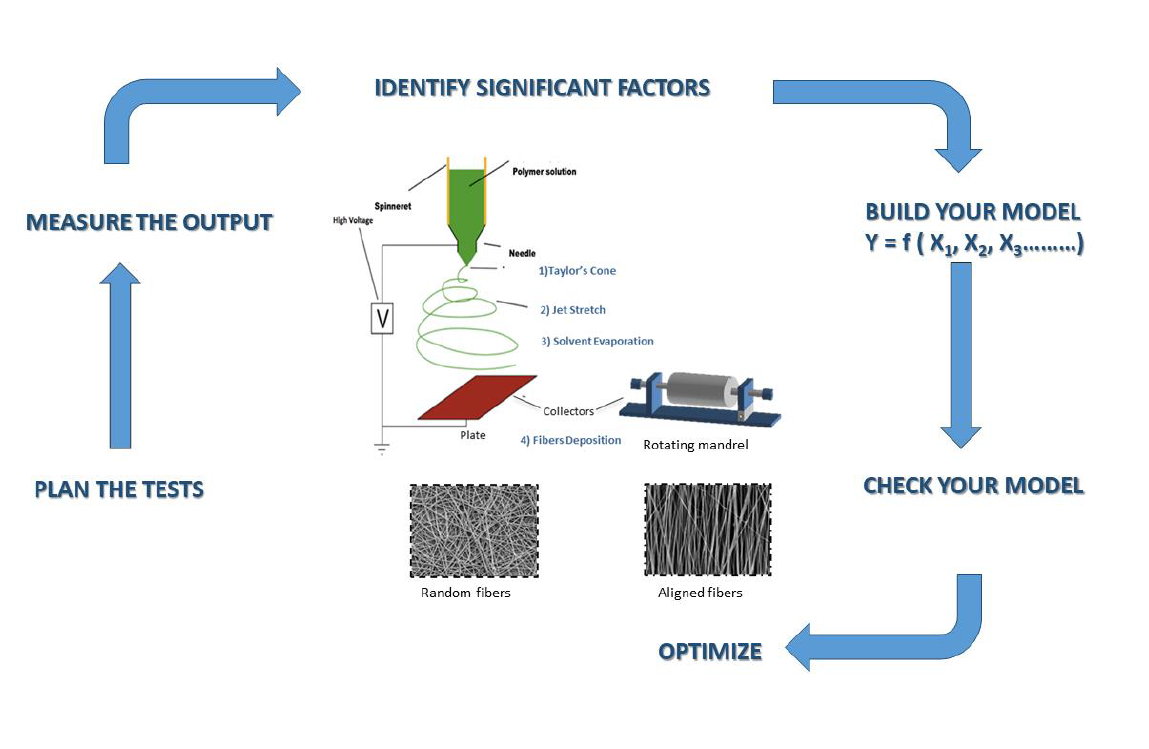

Electrospinning is known to be an effective and straightforward technique to fabricate polymer non woven matrices made of nano and microfibers. Micro patterned morphology of electrospun matrices results to be outmost advantageous in the biomedical field, since it is able to mimic extracellular matrix (ECM), and favors cell adhesion and proliferation. Controlling electrospun fibers alignment is crucial for the regenerative purposes of certain tissues, such as neuronal and vascular. In this study we investigated the impact of electrospinning process parameters on fiber alignment in tubular nanofibrous matrices made of Poly (L-lactide-co-ε-caprolactone) (PLA-PCL); a Design of Experiments (DoE) approach is here proposed in order to statistically set up the process parameters. The DoE was studied keeping constants the previously set material and environmental parameters; voltage, flow rate and mandrel rotating speed were the process parameters here investigated as variables. Orientation analysis was based on ImageJ and plugin Orientation J analysis of SEM images. The results show that voltage combined with flow rate has significant impact on electrospun fiber orientation, and the greatest orientation is achieved when all the three input parameters (voltage, flow rate and mandrel rotation speed) are at their maximum value.