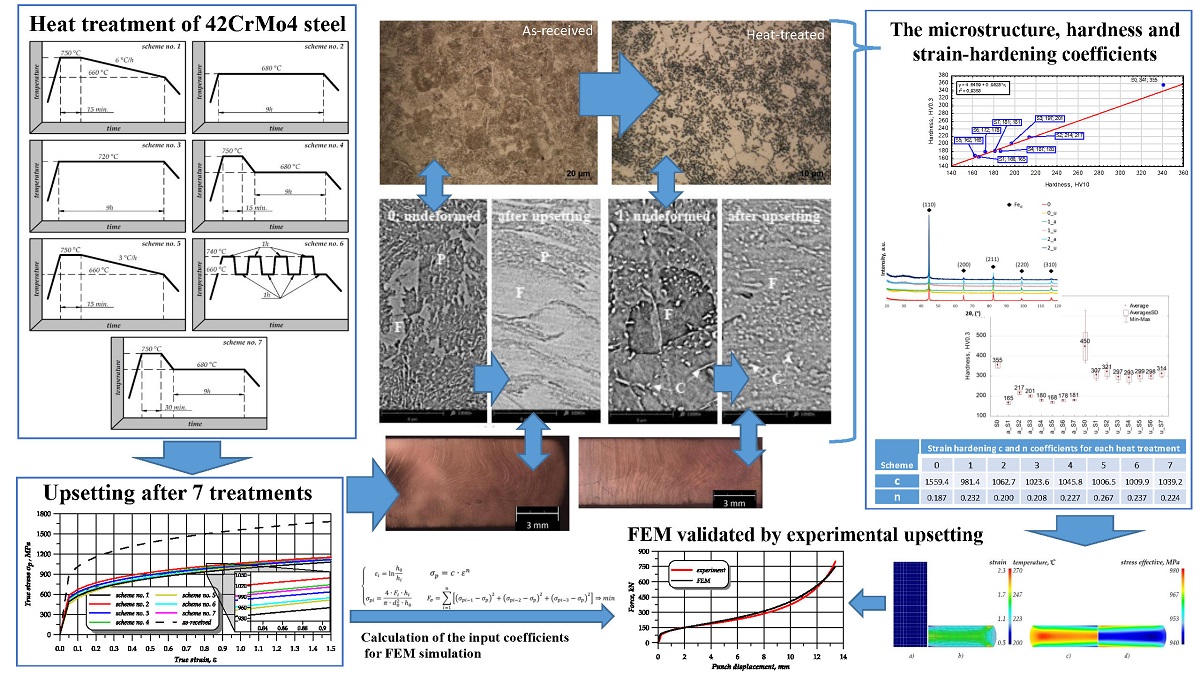

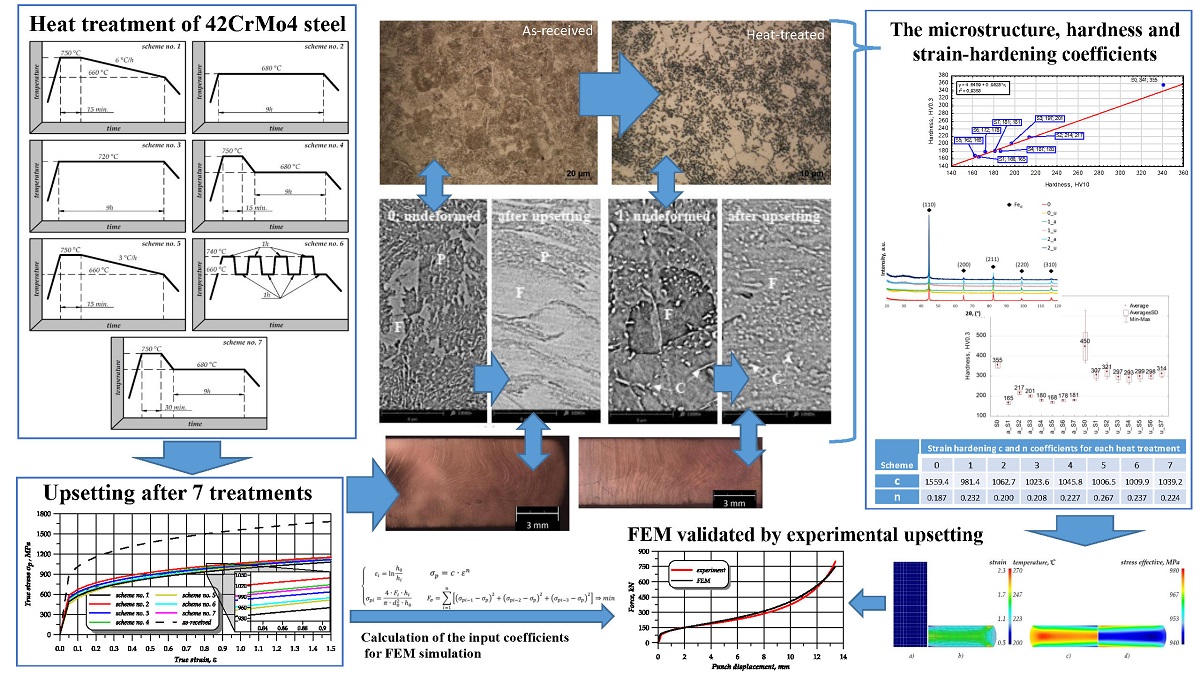

The study presents the effect of annealing process parameters on the microstructure, hardness and strain hardening coefficients i.e., the strength coefficient c and the strain hardening exponent n, of 42CrMo4 steel. Seven selected annealing time-temperature schemes are examined for superior steel formability in cold metal forming conditions. The c and n coefficients are first determined in experimental upsetting of annealed samples and then used in FEM simulations of the upsetting process. The results demonstrate that the strain hardening coefficients (c and n) depend on the employed annealing scheme. Compared to the as-received sample, the annealing process reduces the true stress and effectively decrease the hardness of 42CrMo4 steel, improves microstructural spheroidization and, consequently, facilitates deformability of this material. The annealing schemes relying on heating the material to 750 °C and its subsequent slow cooling lead to the highest decrease in hardness ranging from 162 to 168HV. Results obtained with the SEM-EDS, LOM and XRD methods lead to the conclusion that the employed heat treatment schemes cause the initial ferritic-pearlitic microstructure to develop granular and semi-lamellar precipitation of cementite enriched with Mo and Cr in the ferrite matrix. In addition, the annealing process affects the growth of α-Fe grains. The highest cold hardening rate, and thus formability, is obtained for the annealing scheme producing the lowest hardness. The results of FEM simulations are positively validated by experimental results. Obtained results are crucial for further numerical simulations and experimental research connected with developing new cold metal forming methods for producing parts made of 42CrMo4 steel.