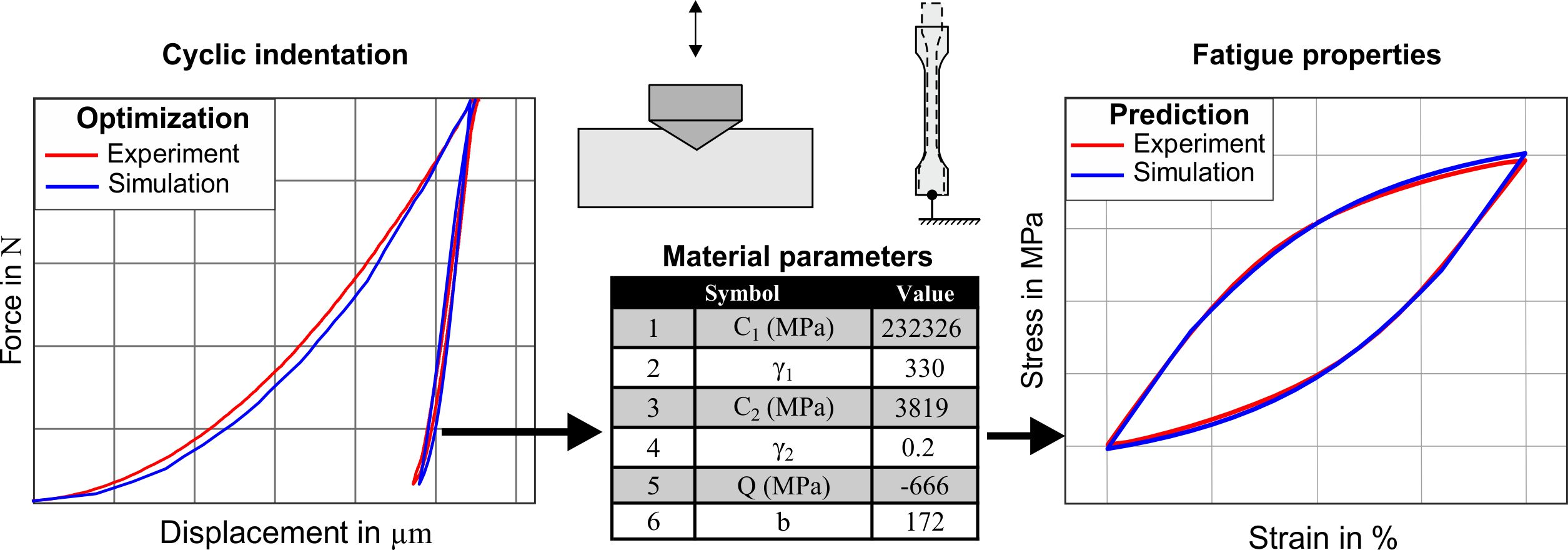

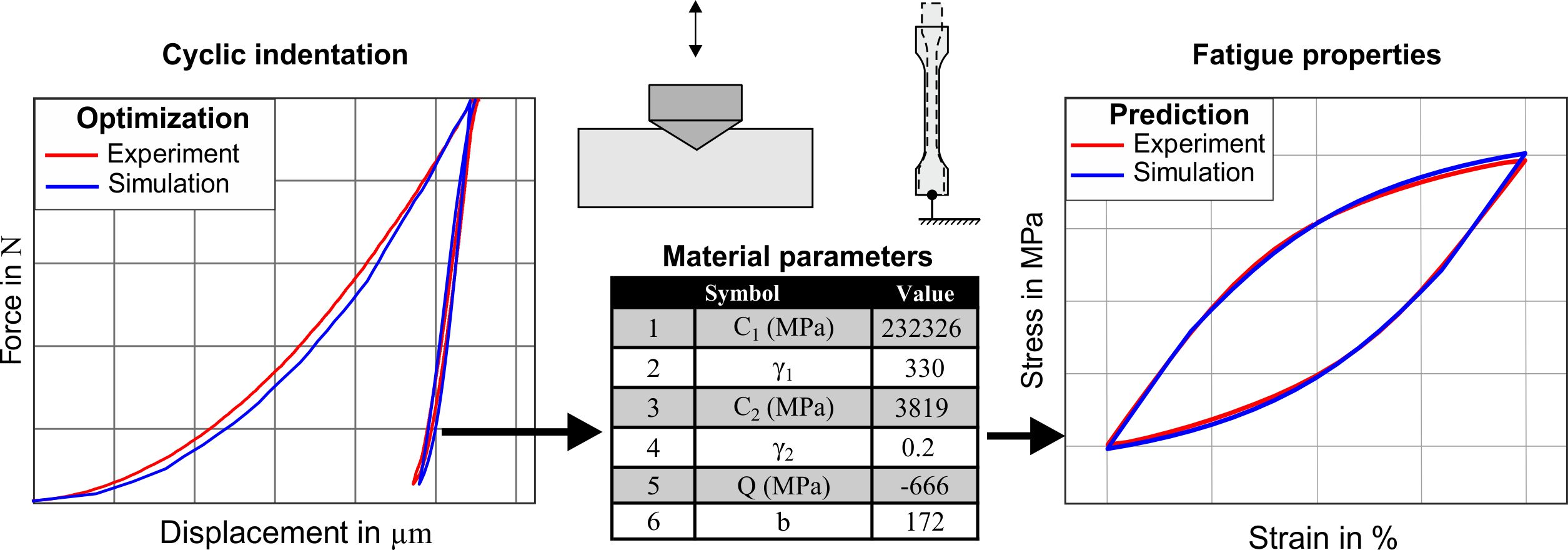

The application of instrumented indentation to assess material properties like Young’s modulus and micro-hardness has become a standard method. In recent developments, indentation experiments and simulations have been combined to inverse methods, from which further material parameters as yield strength, work hardening rate, and tensile strength can be determined. In this work, an inverse method is introduced by which material parameters for cyclic plasticity, i.e. kinematic hardening parameters, can be determined. To accomplish this, cyclic Vickers indentation experiments are combined with finite element simulations of the indentation with unknown material properties, which are then determined by inverse analysis. To validate the proposed method, these parameters are subsequently applied to predict the uniaxial stress-strain response of a material with success. The method has been validated successfully for a quenched and tempered martensitic steel and for technically pure copper, where an excellent agreement between measured and predicted cyclic stress-strain-curves has been achieved. Hence, the proposed inverse method based on cyclic nanoindentation, as a quasi-non-destructive method, could complement or even substitute the resource-intensive conventional fatigue testing in the future for some applications.