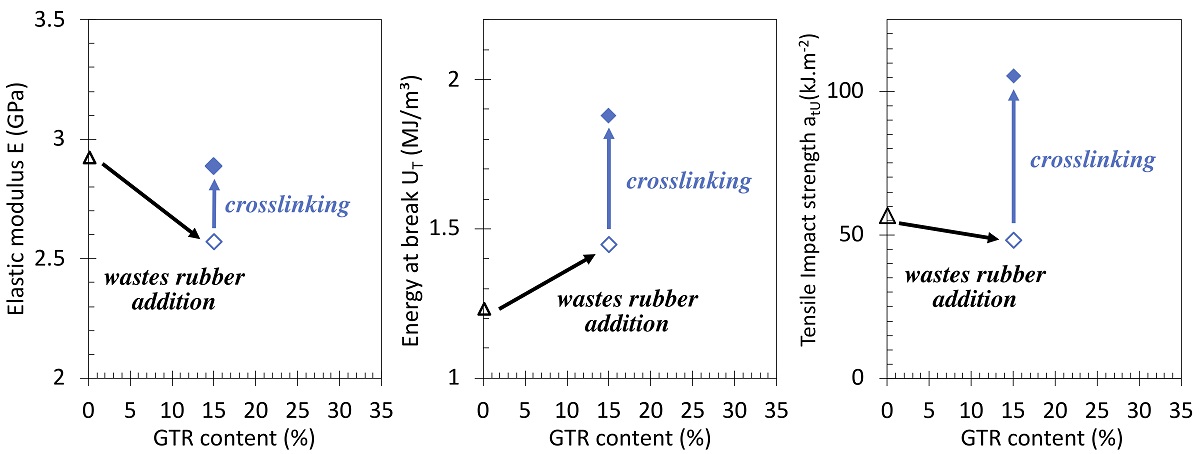

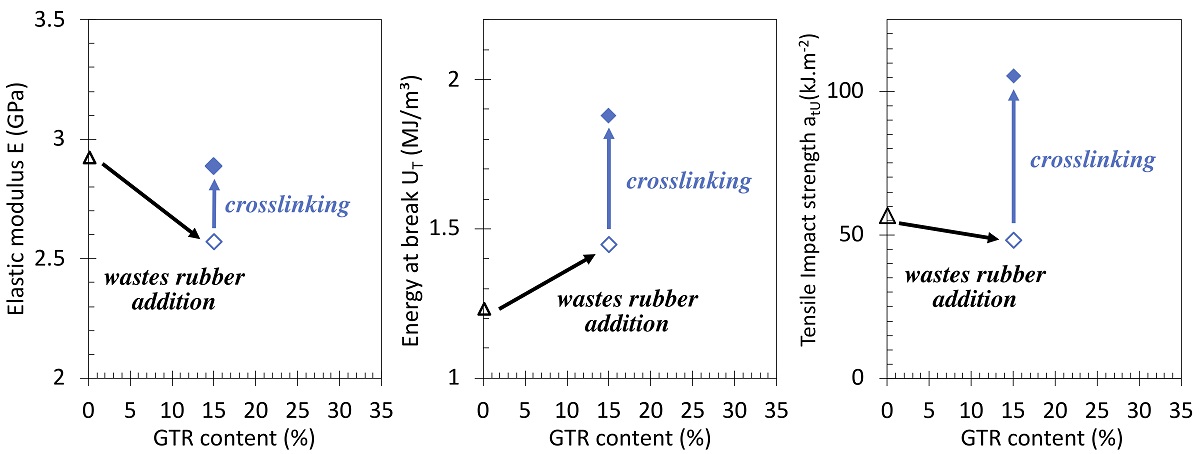

Poly (Lactic Acid) (PLA) / Ground Tire Rubber (GTR) blends using Dicumyl peroxide (DCP) as a crosslinking agent were prepared as a route to recycle wastes rubber from the automotive industry. The GTR were exposed to grinding and exhibited mechanical damage, traduced at the rubber network scale by chains scission and/or chemical cross-links breakage. Such damage is accompanied by a decrease of 80% of the rubber chains network density of the initial tire buffing but found independent on the type of grinding (cryogenic, dry ambient) or on the GTR size (from <400 µm to <63 µm). Moreover, the finest sieved GTR contain the largest the amount of reinforcing elements (carbon black, clay) that can be advantageously used in PLA/GTR blends. The melt-blending of these finest GTR particles obtained by cryo-grinding at an amount of 15 wt.% and in presence of the crosslinking agent (DCP), resulted in an optimum improvement of the ductility, energy at break and impact strength of the PLA/GTR blends as compared to neat PLA, while maintaining its stiffness. The results were attributed to (i) the good dispersion of the fine GTR particles into the PLA matrix, (ii) the partial re-crosslinking of the GTR particles and co-crosslinking at PLA/GTR interface and (iii) the presence of reinforcing carbon black into the GTR particles and clay particles dispersed into the PLA matrix.