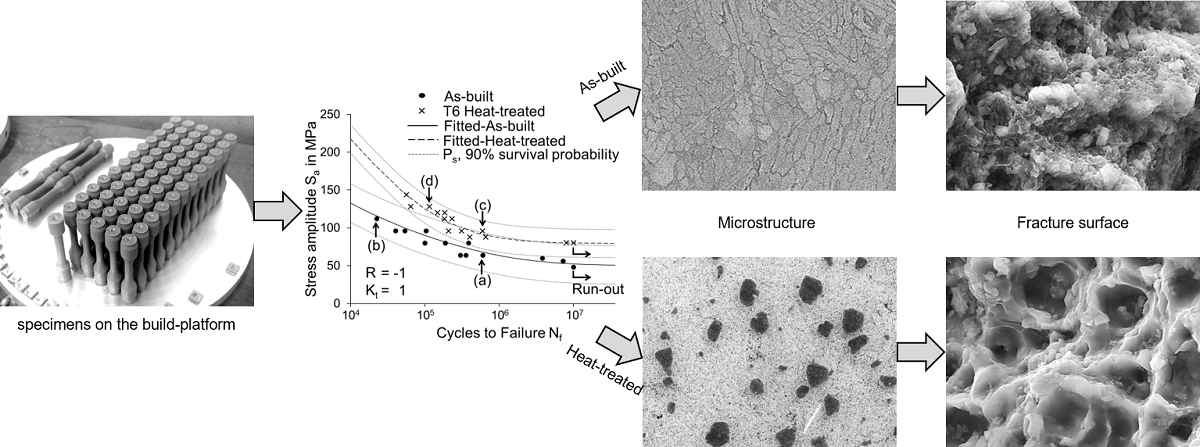

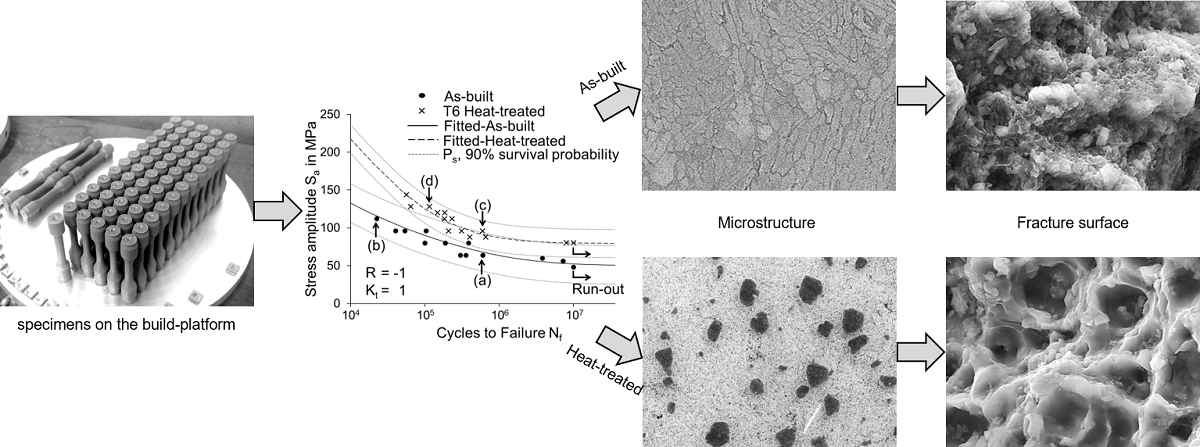

This study aims to identify an optimal heat-treatment parameter set for an additively manufactured AlSi10Mg alloy in terms of increasing the hardness and eliminating the anisotropic microstructural characteristics of the alloy in as-built condition. Furthermore, the influence of these optimized parameters on the fatigue properties of the alloy investigated. In this respect, microstructural characteristics of an AlSi10Mg alloy manufactured by Laser-Based Powder Bed Fusion in non-heat-treated and heat-treated conditions were investigated. Their static and dynamic mechanical properties were evaluated, and fatigue behavior was explained by a detailed examination of fracture surfaces. Much of the microstructure in the non-heat-treated condition was composed of columnar grains oriented parallel to the build direction. Further analysis revealed a high fraction of pro-eutectic α-Al. Through heat-treatment, the alloy was successfully brought to its peak-hardened condition, while eliminating the anisotropic microstructural features. Yield strength and ductility increased simultaneously after heat-treatment, which is due to the relief of residual stresses, preservation of refined grains, and introduction of precipitation strengthening. The fatigue strength, calculated at 10^7 cycles, improved as well after heat-treatment and finally detailed fractography reviled that a more ductile fracture mechanism has happened in the heat-treated condition compared to the non-heat-treated condition.