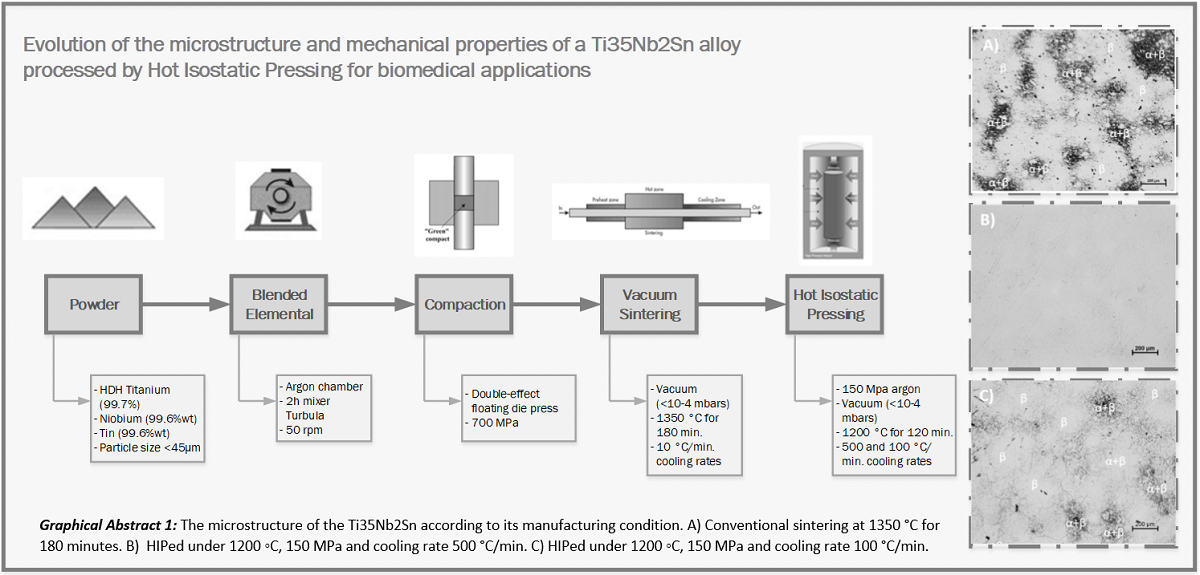

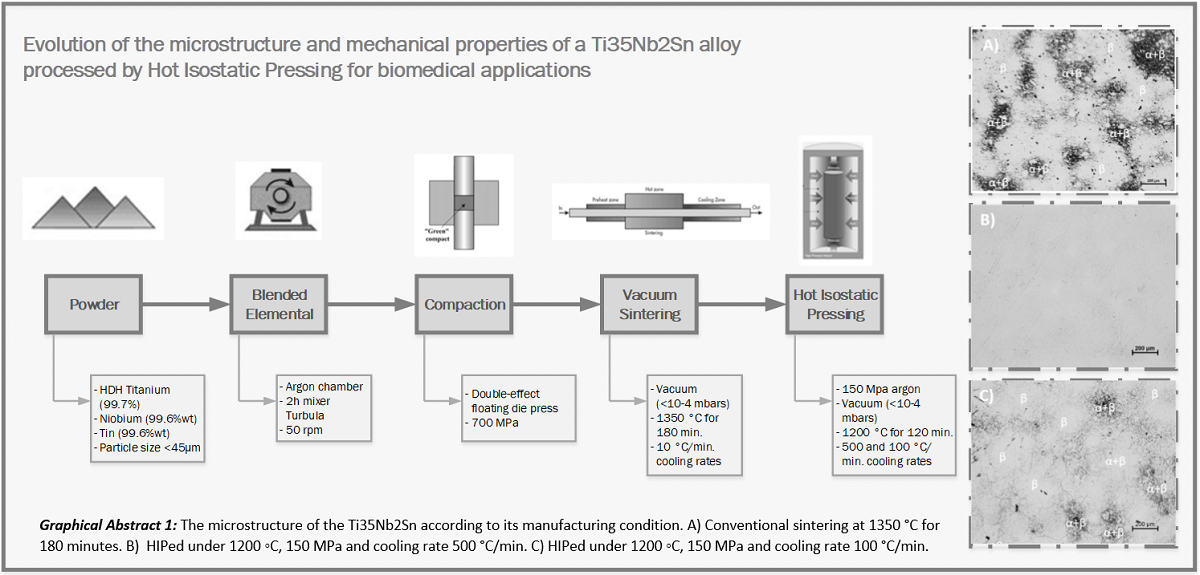

The influence of the hot isostatic pressing (HIP) post-processing step on structural and phase changes, porosity healing and mechanical strength in a powder metallurgy Ti35Nb2Sn alloy was studied. Powders were pressed at room temperature at 750 MPa, and then sintered at 1,350°C in a vacuum for 3 h. The standard HIP process at 1,200°C and 150 MPa for 3 h was performed to study its effect on a Ti35Nb2Sn powder metallurgy alloy. The influence of the HIP process and cold rate on density, microstructure, the quantity of interstitial elements, mechanical strength and Young's modulus was investigated. HIP post-processing for 2 h at 1,200°C and 150 MPa led to greater porosity reduction and a marked retention of the β phase at room temperature. The slow cooling rate during the HIP process affected phase stability, with a large amount of α”-phase precipitate, which decreased the titanium alloy’s yield strength.