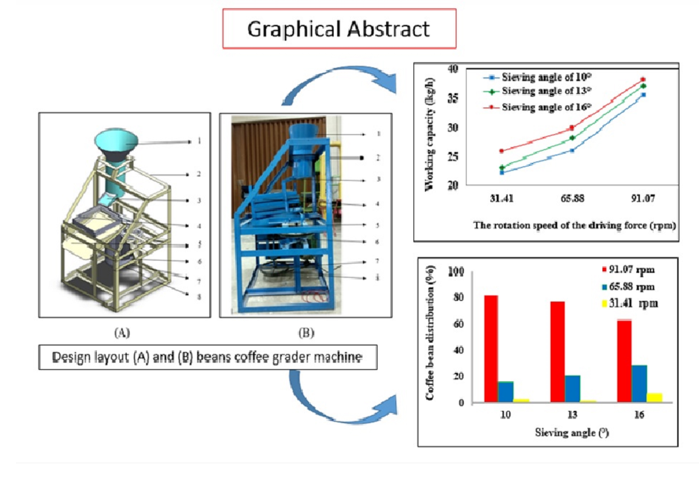

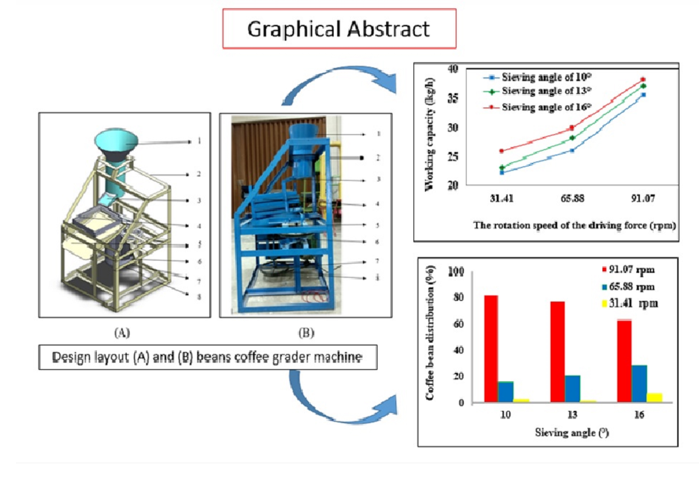

Nowadays, some coffee production centers are still classification manually, so it requires a very long time, a lot of labor, and expensive operational costs. Therefore, the purpose of this research was to design and performance of the coffee bean classifier that can accelerate the process of classification beans. The classifier used consists of three main parts, namely the frame, driving force, and sieves. Research parameters include classifier work capacity, power, specific energy, classification distribution and effectiveness, and efficiency. The results showed that the best operating conditions of the coffee bean classifier was found at a rotational speed of 91.07 rpm and a 16° sieves angle with a classifier working capacity of 38.27 kg/h, the distribution of the seeds retained in the first sieve was 56.77 %, the second sieves was 28.12%, and the third sieves was 15.11%. The efficiency of using a classifier was found at a rotating speed of 91.07 rpm and a sieves angle of 16°. This classifier was simple in design, easy to operate, and can sort coffee beans into three classification, namely small, medium, and large.