Copyright © 2021-2023 R. V. Lapshin, published under Creative Commons Attribution

1. Introduction

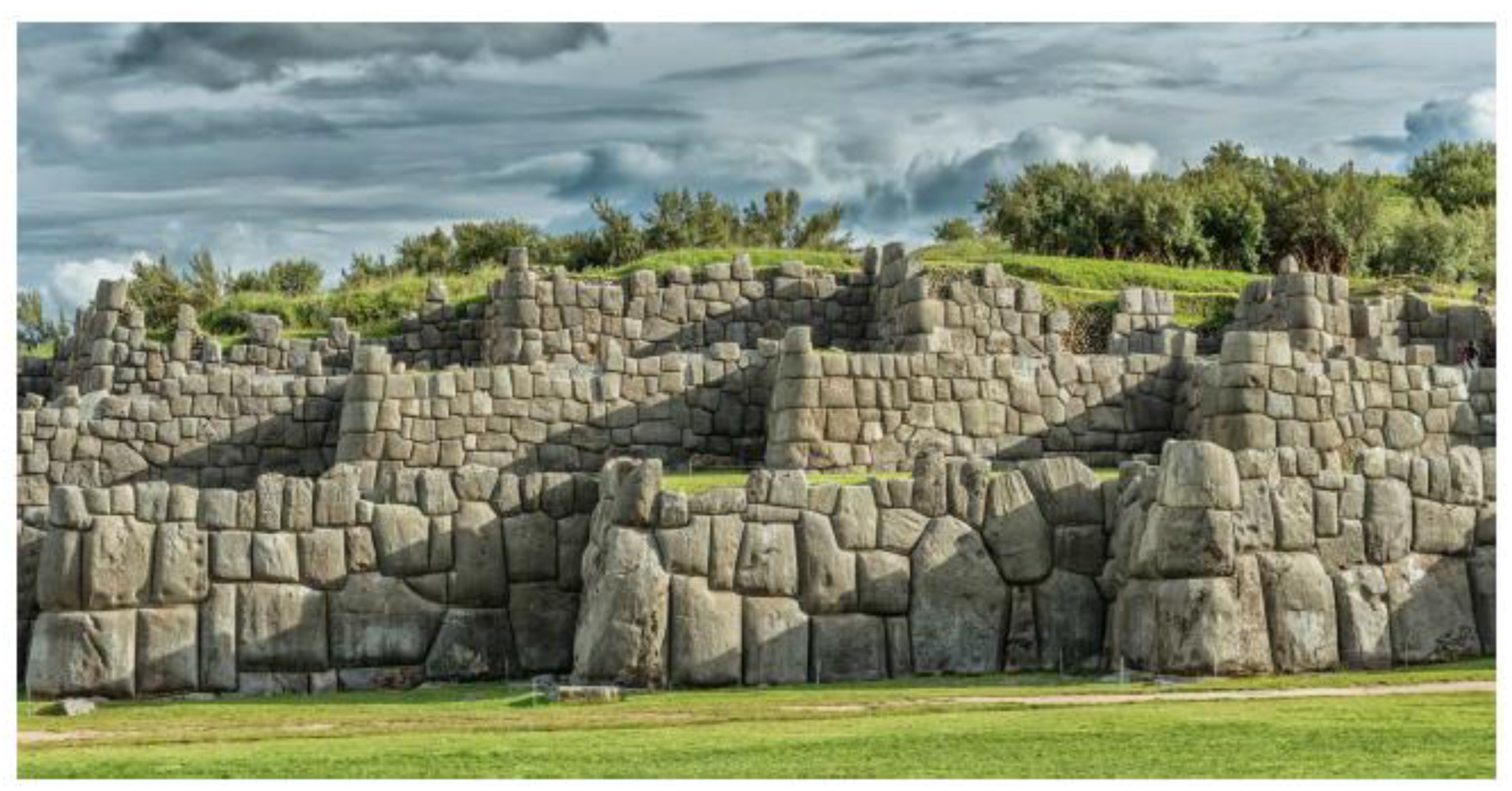

Polygonal masonry is a type of masonry made of natural stone. Stones having an initially arbitrary shape are processed in such a way that form irregular polygons tightly adjacent to each other on the front side of the structure.1 It should be noted that the name “polygonal masonry” is largely conditional. The fact is that there are many structures classified as polygonal in which stone “polygons” have curved sections besides the linear ones. A feature of the polygonal masonry is that it does not require a building mortar (dry masonry). The polygonal masonry possesses sufficient strength and stability to withstand moderate earthquakes.2,3,4,5

In the present paper, a polygonal masonry in the megalithic structures located on the territory of modern Peru is under consideration. The main attention is paid to the masonry consisting of large stone blocks weighing from several hundred kilograms to several tons fitted close to each other almost without a gap between curved surfaces of large area. The remaining simpler types of polygonal masonry, when the stones are small6 or the mating surfaces are almost flat,6,7 or the stones contact each other over a small area,7 or there are significant gaps between the stones, are quite correspond to the long-known methods of stone processing and, therefore, they do not require any special explanation.

Since mortar is not used in the polygonal masonry, to ensure integrity of a structure, significant static friction forces should act in addition to the mechanical locking between the stone blocks of the masonry. The static friction force depends on the stone-by-stone static friction coefficient, weight of the stone block and the microrelief in the contact area of the surfaces. Since the friction coefficient is determined mainly by the properties of the used material, it cannot be changed for chosen rock. Although the contact area does not affect the value of the static friction force practically, however, its increasing (especially between the lower and upper faces of the blocks) allows to distribute the block weight more evenly without using mortar that reduces local stresses and thus decreases probability of wall cracking and stone crushing.

In the long term, a large contact area can provide effective mineralization (filling) of the gap in the contact area with penetrating aqueous mineral solutions (see

Section 3.3), which further increases the strength, cohesion, and stability of the masonry. It is known that masonry using mortar is stronger when the mortar layer is thinner with equal adhearance to all other requirements.

8 Thus, the type of the polygonal masonry under consideration, in which the mineralization (monolithing) of the gap between the stones tightly adjacent to each other takes place, provides maximum strength of the masonry and, in this regard, brings it closer to the theoretical strength limit. The only thing that cannot be reached in such masonry is a good bonding8 of the blocks due to widely varying shape and sizes of the used stone blocks.

Obviously, the larger the vertical size of the stone blocks, the smaller is the number of courses of the polygonal masonry for a given wall height. Moreover, it is known that increasing the height of a stone block increases its bending resistance abruptly (in proportion to powers of two).8 As a result, those polygonal masonry turns out to be stronger which stone blocks have a greater height. Thus, to achieve the high strength and stability of the polygonal structure, it is necessary to use as heavy (large size) stone blocks as possible, maximize the contact area of the adjacent blocks, and obtain a certain microrelief in the contact area of the surfaces of the adjacent blocks.

It follows from the foregoing that the concept feature of the polygonal masonry is the use of large, heavy stone blocks weighing from several hundred kilograms to several tons. The Peruvian polygonal masonry is usually applied for erection of load-bearing walls of the first floor or retaining walls intended for slope strengthening. A dry polygonal masonry of small blocks does not provide adequate strength and stability of the structure. The polygonal masonry from large blocks with large gaps was made by simple transferring of sizes. More advanced polygonal masonry of large blocks contacting tightly with each other over a curved surface of large area required applying new, more complex techniques for block mating (see

Section 2.3) as well as invention of special contrivances. The article describes two such possible contrivances – a topography translator (see

Section 2.11) and more complex 3D-pantograph

9 (see

Section 2.1,

Section 2.6,

Section 2.7,

Section 2.8,

Section 2.9 and

Section 2.10). In addition, the article provides several methods to use these devices, it explains advantages and disadvantages of these methods, and their areas of applicability.

The main building materials of those years were boulders and blocks of rock of random (arbitrary) shape. As a rule, this building material did not need to be extracted (broken out in quarries), since it was initially presented everywhere in the form of multi-meter deposits of mountain debris formed at the foot of the mountains as a result of fallings and landslides. In most cases, this material did not even need to be transported from anywhere, since construction took place usually at those locations where the stone material was already in great abundance. If a megalithic structure was located on top of a mountain, then the construction material was taken (broken out) here on the site. That is why, for example, the top of the mountain, where the Machu Picchu complex of buildings is located, is cut off, while the tops of the neighboring mountains, where no one lives, are sharp.

At first, the boulders are being examined. While detecting visible cracks, the boulder is split along the crack. If the boulder consisted of, say, two parts connected by a comparatively narrow bridge, the boulder was split across this narrow bridge. The boulder surfaces were roughly pretreated with a sledgehammer to obtain stone billets of a simpler shape. In particular, too prominent sharp corners were removed.

In general, a polygonal masonry is not something unprecedented, such masonry has been used in Europe since antiquity.5,10 In the Peruvian version, only the quality of the curved interfaces is striking, which is not easy to repeat even in our time.11 The methods suggested by both the scientific-engineering community6,11,12,13,14,15,16 and enthusiasts17,18,19,20,21 for fabrication of the Peruvian polygonal masonry do not explain all the observed features and/or are often far from a reality.

The methods of polygonal masonry fabrication proposed by the author are based on the use of a reduced clay model and 3D-pantograph9 (see

Section 2.1, 2.6-2.10), topography translator (see

Section 2.11), and replicas12 (see

Section 2.3, 2.6). The main tools for stone processing are a hammer and steel chisel (in practice, a set of chisels of different types made of hardened steel). Besides the hammer and chisel, to work effectively with stone blocks, another simple tool is needed that many often forget about, this is a steel crowbar. The use of the topography translator, reduced clay model and pantograph provides not only the well-known unique appearance and high quality of masonry of large blocks, but also allows to significantly increase the productivity of the builders. Only due to the high productivity it became possible to carry out the volumes of the polygonal construction revealed in Peru for an acceptable time, engaging a reasonable amount of labor force.

If we closely look at the shape of the stones in the masonry, at the sites of their almost perfect fitting, then there is a feeling that the stones were not processed mechanically but were sculpted (see

Section 3.1). In this regard, many researchers mistakenly decided that the stones were sculpted or cast from a certain plastic mixture – artificial granite, concrete, geopolymeric concrete, lime, rock softened by heating, and so on.

18-21 In this regard, the question immediately arises: why produce an expensive plastic mixture when there is a lot of ready-to-use material around – natural stone of arbitrary shape? What is even more unclear is: why should plastic mixture be given such complex shapes? Why not make a limited range of standard concrete blocks with locking elements, for example? Nevertheless, sculpting really took place during the polygonal construction, but it was sculpting of a reduced model of the future stone block from clay, not the sculpting of the stone block itself. Further, using a 3D-pantograph, the “sculpture” was simply transferred to a stone block with the enlargement set in the pantograph by means of a hammer and chisel.

There are other arguments against the plastic version. For example, the backside of many blocks is a ragged stone; there is no plastic mixture flowed into the interblock spaces inside the masonry; the stone blocks have veinlets and other features inherent in natural stone.

22 Unlike clay, concrete,18 lime, and artificial granite are not suitable for hand modeling. Therefore, the blocks cast from these materials will have flat interface surfaces, as well as flat front and back sides, determined by the flat panels of the formwork used. Thus, if, for example, smooth L- or U-shaped recesses are present in the masonry, then, most likely, this masonry was not fabricated by the casting method generally accepted in construction (see also

Section 2.2).

Any products obtained by casting/sculpting21 shrink during the drying process. The shrinkage of modern concrete can reach 3%, lime shrinkage is noticeably greater. The casting shrinkage leads to casting size decrease, warping (shape distortion) and to cracking, as a result. Thus, the presence of cracks can be one of the casting hallmarks. The shrinkage-induced casting size decrease, in turn, leads to interblock gaps. Since the initial shape of the blocks in the polygonal masonry is irregular, the shrinkage in addition turns out to be non-uniform. Accordingly, the gaps resulting from such shrinkage will be non-uniform too (nonparallel, see Ref. 19).

Thus, even if the blocks are cast sequentially one after another “in-place”,18,19 waiting each time for the end of the shrinkage (ideal case), it is still not possible to completely eliminate gaps between the blocks. For the reinforcement-free concrete block with modest sizes of 50×50 cm (width×height) having typical average shrinkage coefficient of modern concrete of 1.5%, the gap between the blocks makes 7.5 mm (!). The larger are the sizes of the blocks, the greater is the value of their shrinkage, and, accordingly, the larger is the resulting gap.

The shrinkage can be reduced by using steel reinforcement and/or adding crushed stones of hard rock to the concrete mix. To hide the use of crushed stones, the front side of the blocks should be covered with a plaster layer. Surely, there are also quite expensive shrinkage-free concretes (shrinkage coefficient 0.1%), but this invention is relatively recent. Thus, additional signs of the concrete technologies will be: reinforcement, crushed stone inclusions, a layer of plaster. When, according to a number of signs, we see that some blocks of a polygonal masonry are made by casting/sculpting of a concrete-like material, that, unfortunately, takes place in many known Peruvian monuments, before us are either a fake of recent times or unsuccessful repair/restoration.23

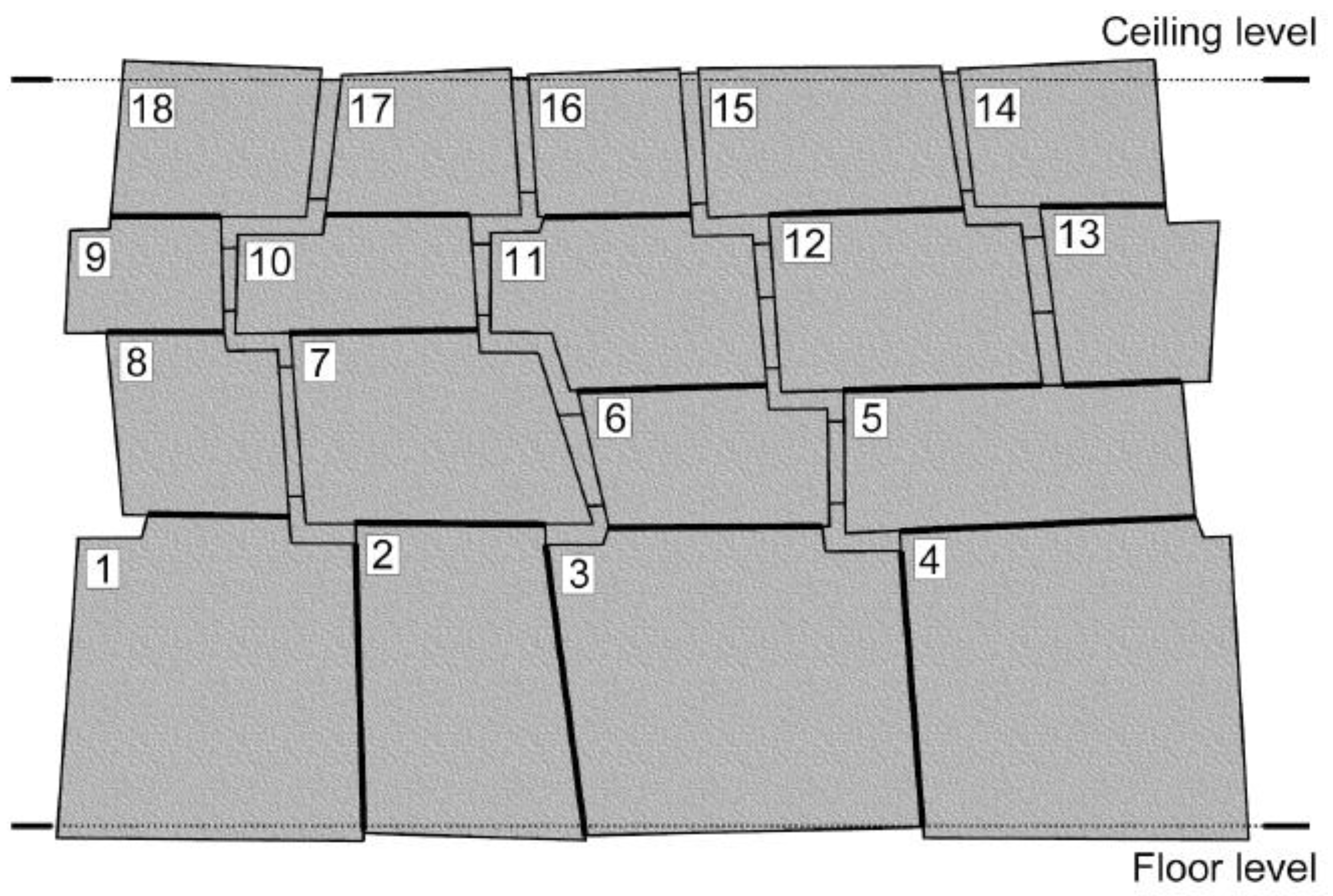

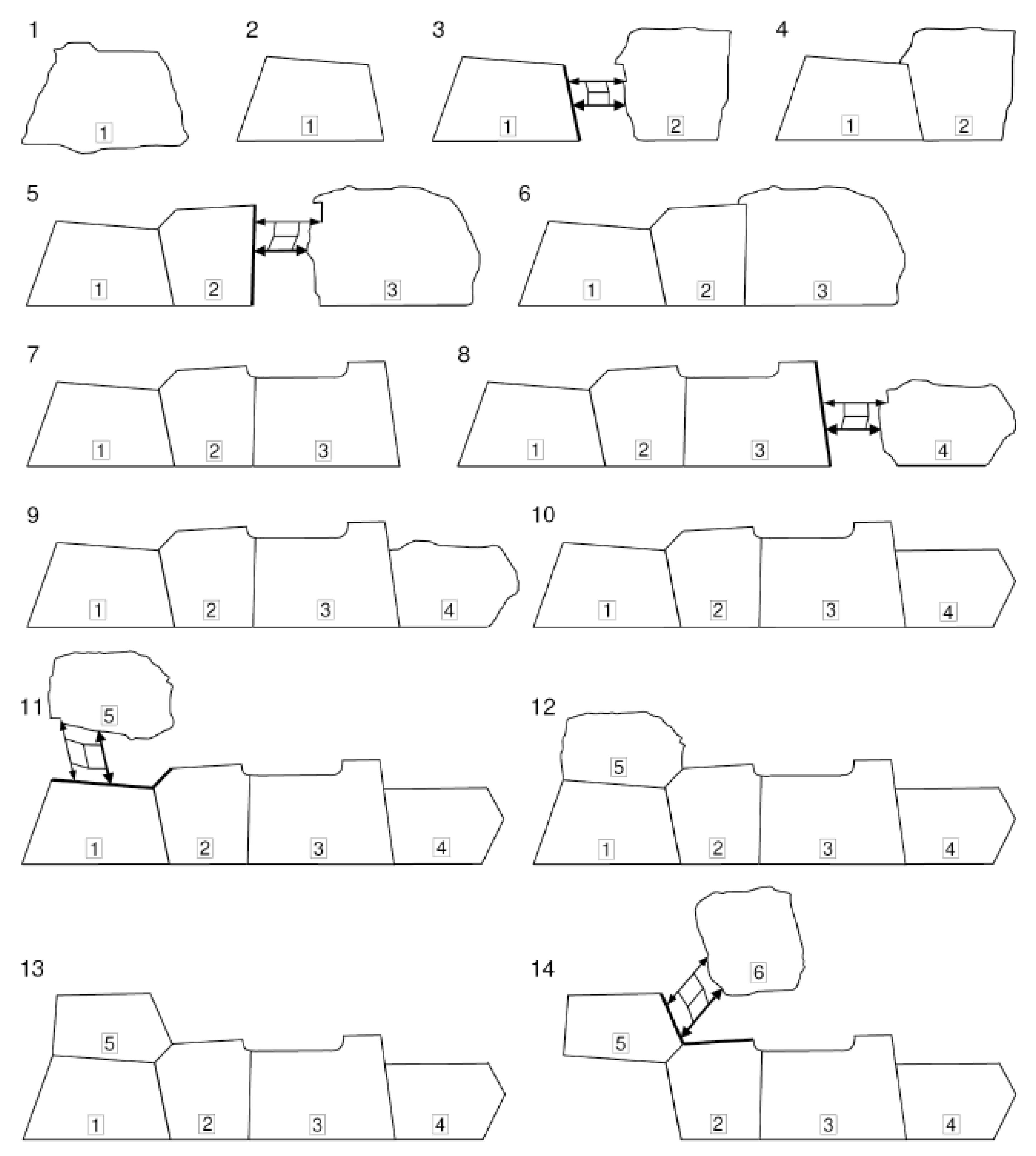

Figure 1 shows an approximate view of the cast polygonal masonry of blocks tightly-abutted to each other. First, the large blocks are cast. After shrinkage termination, the polygonal masonry is assembled from the large blocks sequentially block by block (numbers in the figure show block installation order). After installing each course of the large blocks, small (compensatory) spaces between the large blocks are filled with concrete (before casting, a thin layer of material is coated on the hardened concrete to prevent adhesion of the fresh concrete with the hardened one

18,19). If necessary, the installation of large blocks resting on a still missing compensation insert is carried out using small wedging stones. Note that the polygonal masonry obtained according to the described technology may not be completely dismountable in some cases.

It is seen from the presented procedure that the interface surfaces in the polygonal masonry obtained by casting should be close to planes and the masonry itself should have a rather specific appearance (see

Figure 1). Large non-edge blocks in such masonry are in conditional contact with neighboring large blocks with only two of their sides – the base and top side; contacts of the rest (lateral) sides occur through the small blocks with a small shrinkage of their own. The small blocks are designed to compensate for the shrinkage-related size reductions and shape changes of the large blocks. Only this approach allows to reduce to a minimum (but not to zero) the gaps between the concrete blocks obtained by casting.

The disadvantage of the presented masonry is a rather weak bonding of the blocks. The insufficiently good bonding of the blocks results in separation of the masonry into loosely connected “posts”.8 In

Figure 1, such posts are formed by the blocks 1-8-9-18, 2-7-10-17, 3-6-11-16, and 4-5-12-13-14-15. Moreover, local posts (blocks 12-15 and 13-14) may form within the posts. All this affects the strength and stability of the proposed type of the polygonal masonry negatively.

The more sides a large concrete block has, the more the compensating inserts are required, accordingly, the more complex the formwork used is. Since there are no triangular blocks in the Peruvian polygonal masonry, the simplest shape of the block in this case is a conditional quadrilateral. The conditional quadrilateral occurs if one ignores changes in the shape of a large polygonal block related to the recesses for the compensation blocks in its body. Since a masonry similar to one shown in

Figure 1 was not found in Peru, the methods of casting into a formwork were not used for fabrication of the polygonal walls from the blocks tightly-abutted to each other.

In the article, besides the mechanical treatment of stones by means of a hammer and steel chisel, the method is also proposed that allows casting large polygonal blocks into a mold (see

Section 2.2). In this case, the tight abutment of polygonal masonry blocks is achieved due to high casting accuracy (small shrinkage). According to this technology, the typical signs of the casting are: a solid/hollow core made of cheap concrete-like material and a comparatively thin shell made of more expensive artificial granite.

By the time the Europeans conquered the South America, the Indians did not know either iron tools or a wheel or a potter’s wheel, did not have draft animals, did not own the technology of brick firing, and did not possess a written language. Peru is a mountainous country, thus, it is impossible to grow large volumes of agricultural products there simply because of acute shortage of sown areas suitable for agriculture. The acute shortage of agricultural land, in fact, became the reason for the large-scale construction of the terraces24 on the mountain slopes, especially at that moment of the Peruvian history, when the arrived Europeans have launched large-scale mining of gold and silver. A town (civilization), let alone an empire, cannot arise without a developed agriculture. The developed agriculture implies the food production in commodity quantities.

On himself, a peasant is able to plow a vegetable garden from which only his family will feed. To feed several families of townspeople, the peasant needs to use agricultural machines of those years – horses or oxen, as well as agricultural implements to those “machines”. In order to deliver food and raw materials (to craftsmen) in the town, transport machines of those years – carts and wagons drawn by horses or oxen, at least mules and roads were required. Agricultural and transport machines of those years – horses need “fuel” to work, a lot of fuel. Therefore, a part of the scarce land will have to be taken away for grazing and for fodder grain cultivation.

Since the towns in Peru could not self-originate for the above reasons, then an empire could not arise in Peru. The Inca Empire is a fiction, a myth, it never existed (see

Section 3.5). In certain natural and climatic conditions, human settlements in the form of a village can exist indefinitely. The first towns in Peru appeared only when European settlers arrived there. The settlers brought the iron tools, wheeled transportation, horses, cereal crops, modern for that time weapons, agriculture and handicraft technologies, written language; introduced money and commodity-money relations, built the roads and bridges.

25,26

Taking into account the above arguments, one can conclude that only the builders who came from Europe could erect the polygonal structures under consideration in the article (see

Section 3.5, 3.6). Unlike the Indians, these builders had all the necessary tools, mechanisms, and skills for the large-scale construction. The marks of this large-scale stone construction are visible everywhere – Catholic cathedrals, monasteries, palaces, villas, a lot of urban and industrial buildings, bridges, roads.

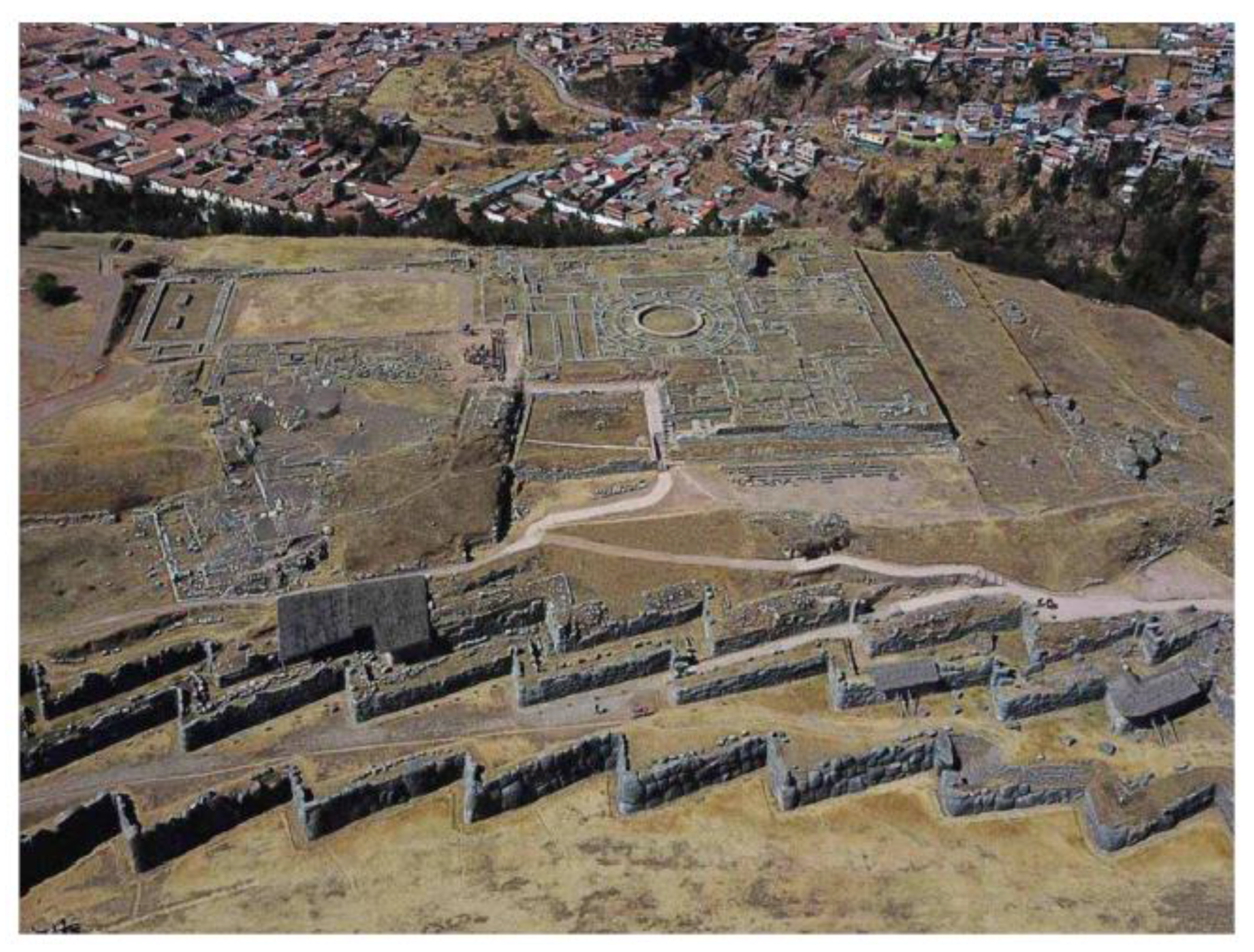

27 In particular, the famous Fortress Sacsayhuaman is an example of early star fortresses that survived to our time (see

Section 3.6).

Any large-scale construction always implies the existence of an economy corresponding to this scale. Therefore, the article additionally explains what the economy of Peru was based on in those years (see

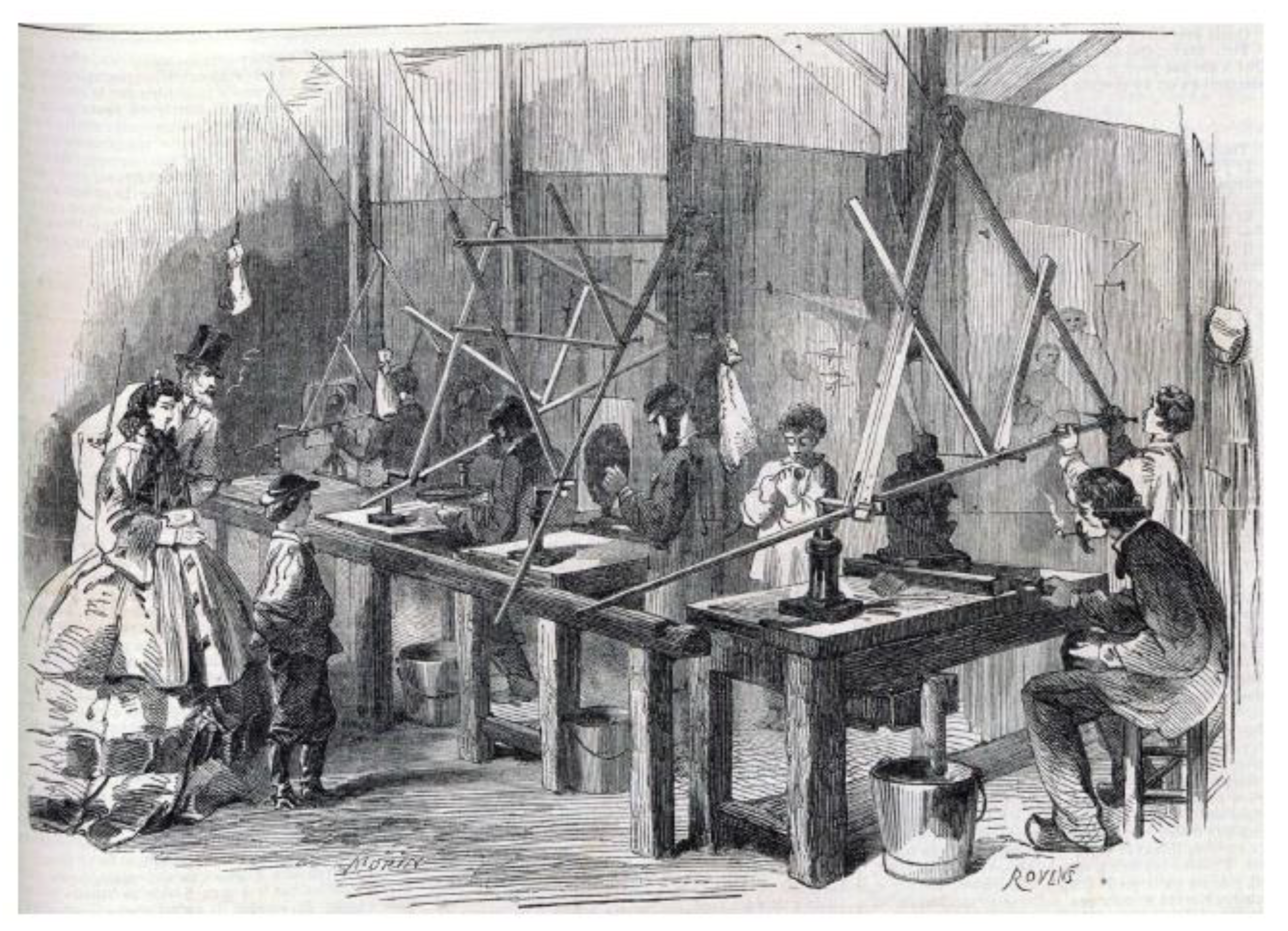

Section 3.5). As machines coping-scaling three-dimensional objects are known since the beginning of the 18th century (see

Section 3.4), the polygonal structures under consideration should be dated around this time.

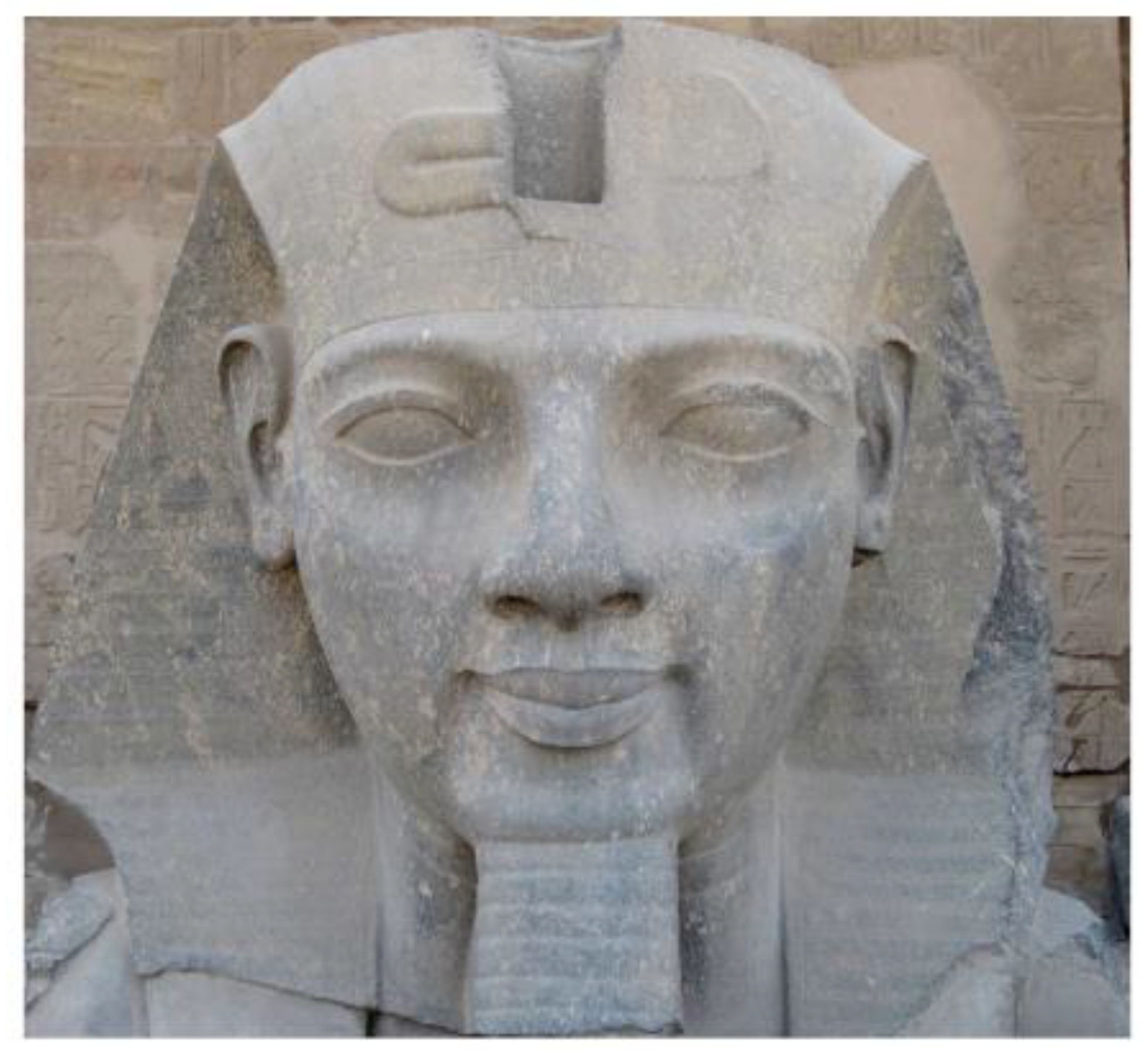

Section 3.8 shows that some “Ancient” Egyptian statues of pharaohs could be made using the casting technology described in

Section 2.2. Also,

Section 3.8 explains how, by performing a slight modification of the 3D-pantograph design, it is possible to fabricate the “Ancient” Egyptian statues of pharaohs, which left and right halves have a high enough degree of mirror symmetry.

2. Tools, contrivances and methods of fabrication of the polygonal masonry

2.1. Clay model shape transfer on a stone billet by means of a 3D-pantograph

According to the proposed method, first, as consistent with a sketch, the clay model of a structure is made in a reduced scale which blocks form a polygonal masonry. Let us assume for a certainty that the structure is just a wall of one block thickness. Small polygonal blocks of the planned shape are sculpted from clay. The sizes of these blocks correspond to the sizes, say, of a basketball or so. The surface interfaces are additionally formed by pressing the blocks into each other. To reduce shrinkage, a solid core of suitable shape – a stone or a piece of dry clay is put inside the clay blocks.

The model of the wall is assembled from the raw model blocks. During the assembly, some material is laid between the blocks that prevents the blocks from sticking to each other during the drying-solidification process. To reduce the influence of the shrinkage effect, the bottom course is dried first, then the next course, and so on. If necessary, the wall is given the required slope (see

Section 2.6). During the drying shrinkage process, the model blocks are matched more closely under their own weight and with small corrections of the builder. If a shrinkage-resulted gap appears between the model blocks, it is eliminated by putting clay layers of a necessary thickness.

After model wall solidification, it is disassembled. Now “magic” began. The Medieval European builders transferred the surface topography from a small model clay block to a large stone billet of suitable sizes and shape with a specified scale using a 3D-pantograph,9 a hammer, and a steel chisel.

The pantograph is a simple hinge-lever device based on a parallelogram mechanism.

28 A 2D-pantograph allows to proportionally enlarge/reduce a flat drawing.

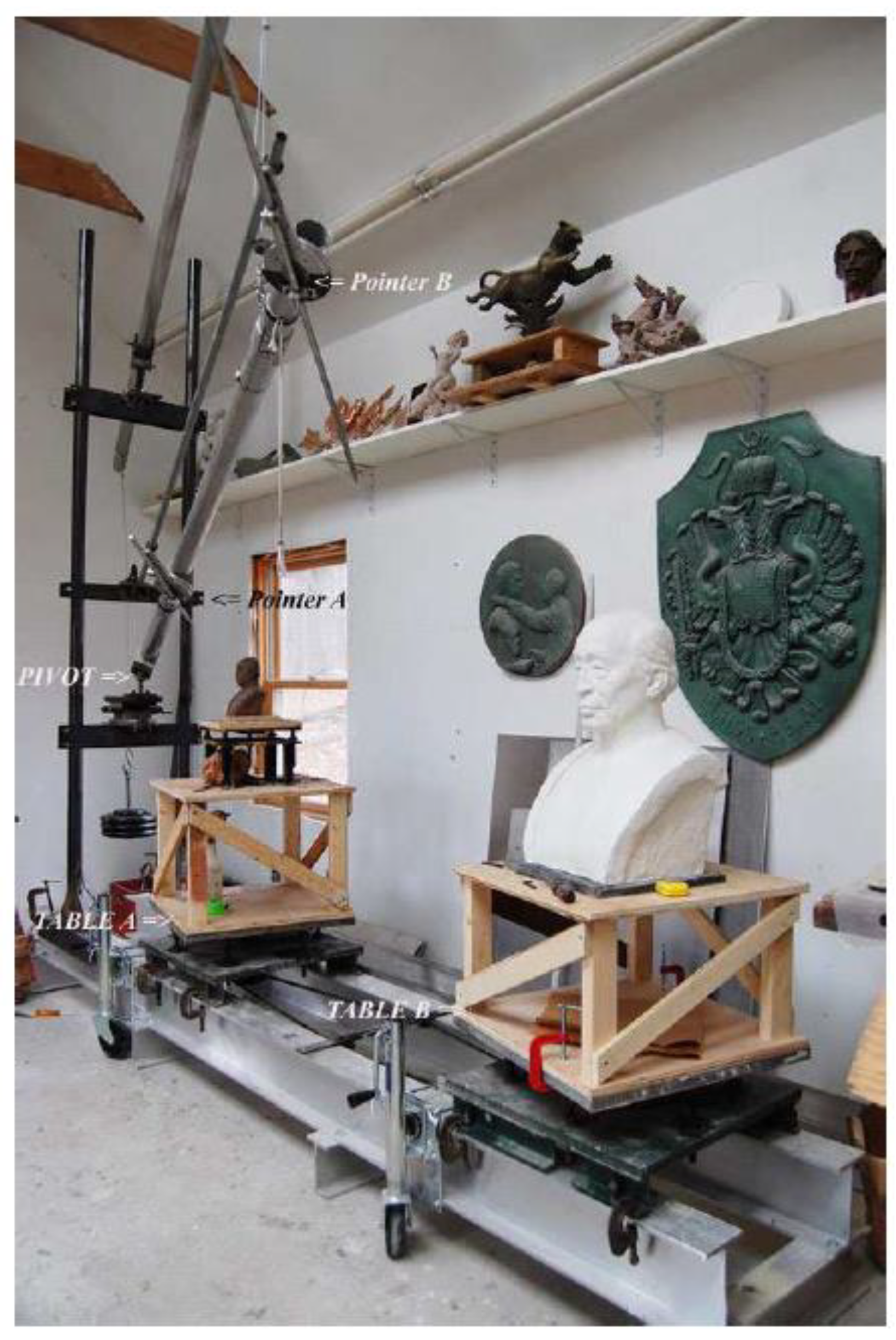

28,29 Being a logical advancement of the 2D-pantograph, a more complicated 3D-pantograph

30,31 (see

Figure 2) allows to proportionally enlarge/reduce a space figure, for example, a statue. In our case, using the 3D-pantograph, the enlarged copy of a small clay model of the block is obtained by processing the stone billet with a hammer and chisel.

The parallelogram mechanism is located on a boom of the 3D-pantograph. Due to cylindrical hinges, the parallelogram mechanism can freely rotate around the boom. The boom is attached to a frame using a ball joint (Pivot in

Figure 2). The boom has a counterweight. A sharp probe (Pointer A in

Figure 2) is fixed on one arm of the parallelogram mechanism, a sharp pointer (a part actually similar to the probe; Pointer B in

Figure 2) – on the other arm. If one touches the clay model with the probe, the pointer will show where the corresponding point of the enlarged copy is located in the space. The enlargement coefficient is set by the appropriate adjustment of the arms of the lever system. The model and its enlarged copy are located each on their rotary platform (Table A and Table B, respectively) backside down. Due to a chain transmission, the platforms can be synchronously rotated around their vertical axes, putting different sides of the model/copy under the probe/pointer.

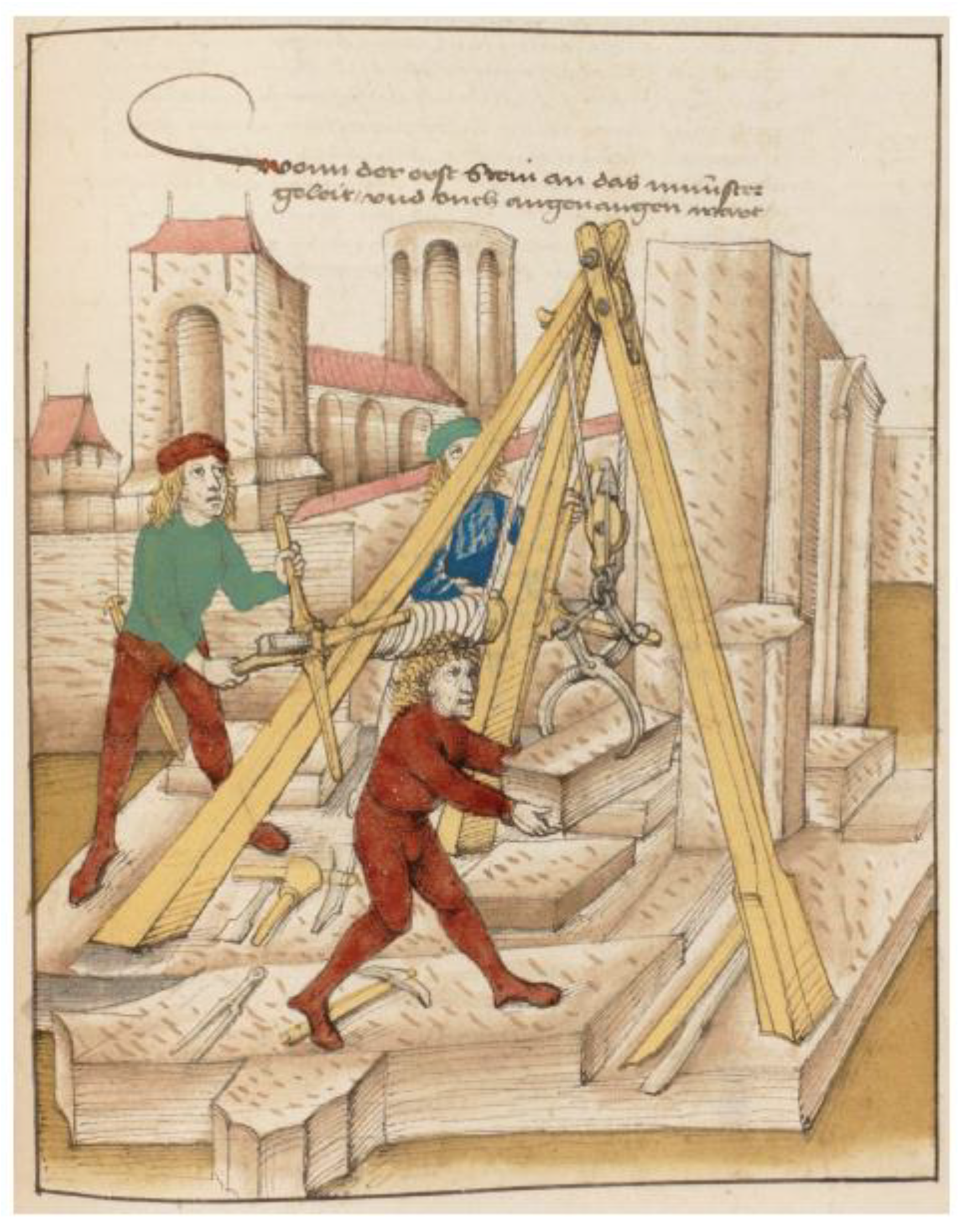

Ill. 1.

Medieval builders use a tripod with blocks and tackles and with a winch to lift stone blocks. The picture is from a 15th century manuscript. To hold the stone block, a block tongs are used. With the help of the tripod, it is possible not only to lift a stone block but also to move (drag) it in the horizontal plane.

Ill. 1.

Medieval builders use a tripod with blocks and tackles and with a winch to lift stone blocks. The picture is from a 15th century manuscript. To hold the stone block, a block tongs are used. With the help of the tripod, it is possible not only to lift a stone block but also to move (drag) it in the horizontal plane.

A minimum size of the model clay block depends on the size of the stone block under fabrication and is determined by the error of the pantograph mechanism ultimately. The size of the model block is also determined by how convenient it is for one or two workers to handle (sculpt, correct, carry, install, shift, turn, etc.) such a block. The modern 3D-pantographs used by sculptors

30,31 (see

Figure 2) allow enlargement of the object model by up to 6 times. Thus, by a clay block model size, say, 50×50×50 cm, which can be made hollow to reduce its weight and shrinkage, the stone blocks up to 3×3×3 m can be processed on the not very large pantograph.

It should be noted that by installing a stone billet on the pantograph, the clay model of the block suitable for this billet can be quickly selected. This feature is extremely useful exactly in the case of the polygonal type of masonry, since in such masonry, initial stone blocks often have a complicated shape that requires a lot of preliminary measurements while selecting a billet.

After the mentioned copying process with the specified scale, the wall of stone blocks is assembled without any adjustments using sleds, rollers, levers, steel crowbars, pulleys,32 blocks and tackles,33 winches,34 and cranes35 of the time.14,15,36,37,38,39 As an example, Ill. 1 shows a picture from the 15th century manuscript,40 where medieval builders lift stone blocks using a tripod equipped with blocks and tackles and with a winch. With the help of this tripod, it is possible not only to lift a stone block but also to move (drag) the block in the horizontal plane. To do this, alternately, the stone block is lowered on the ground, the tripod is moved by a short distance, and the stone block is raised above the ground again.

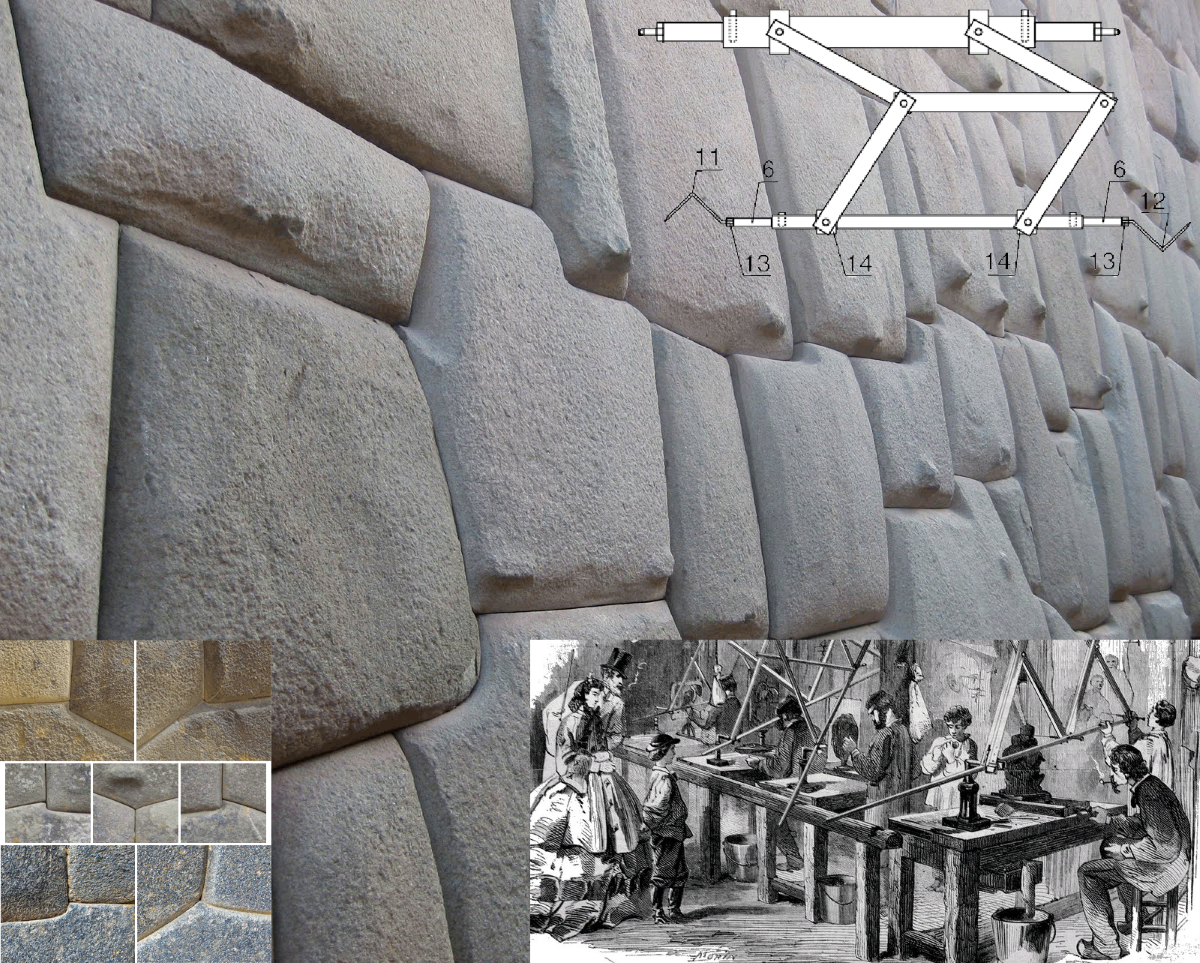

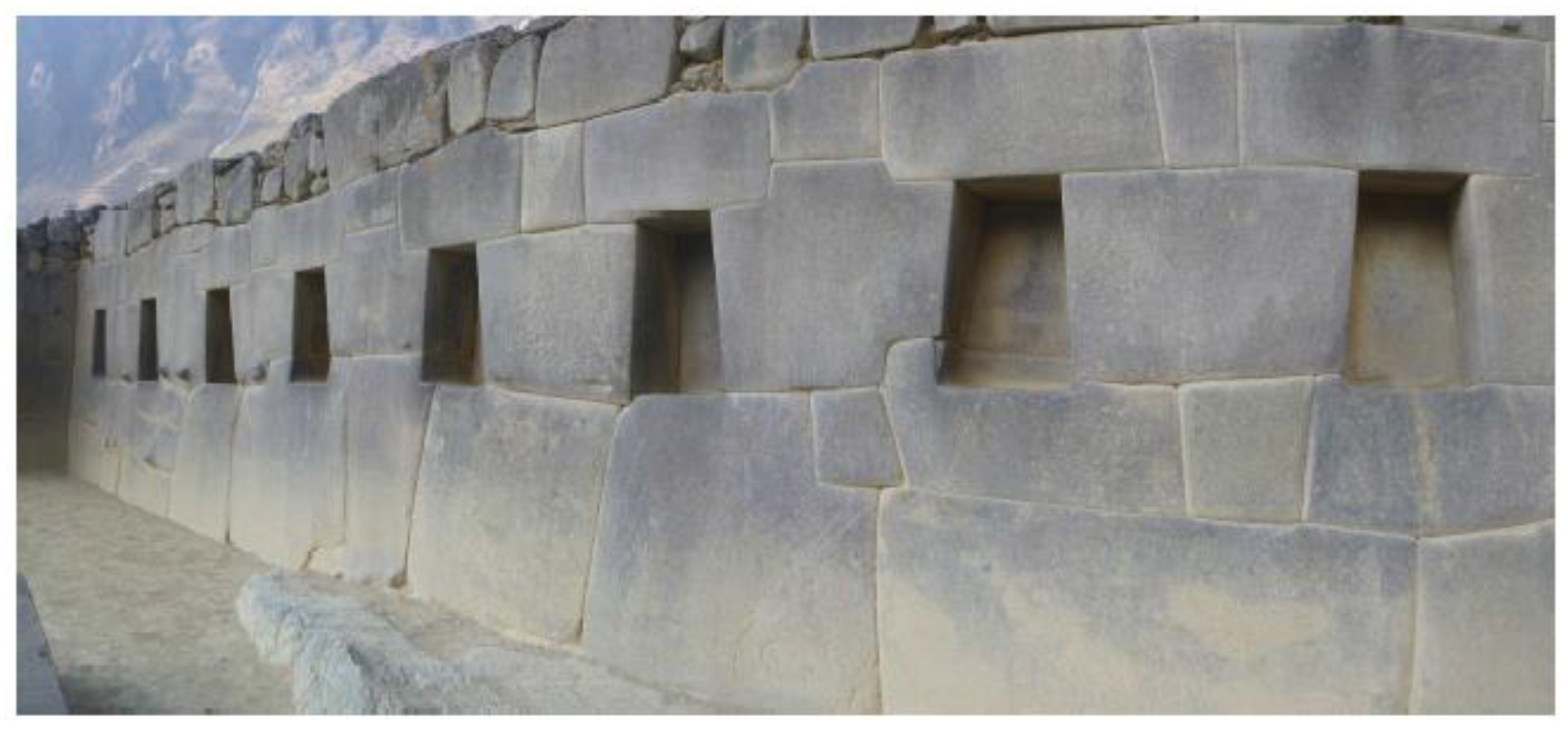

Photo. 1.

Cusco (V. M. Soroka, 2021).

Photo. 1.

Cusco (V. M. Soroka, 2021).

The front side of a stone block can be copied from the front side of its clay model, but it can be dressed or refined after the polygonal structure assembly. Processing of the backsides of the stone blocks is carried out after assembling a bearing wall. The backside of a retaining wall is not processed in any way. Blocks forming an outer wall corner should be placed with the most lengthy front face down on the pantograph to provide access to the side faces being processed. In such stone blocks, the front face, inaccessible for processing during copying, is dressed after the final assembly of the corner section of the wall.

When a polygonal masonry is built on a leveled reinforced ground, the first course is formed of not large stone blocks having a flat base, which are processed by the corresponding clay models. The stone blocks of the second course are usually noticeably larger than the blocks of the first course (see Photos. 1-5, for example). Why is that? Why are the large blocks of the second course not put on the equally large or even larger blocks? There should be good reasons for such a masonry arrangement. Indeed, the higher a large heavy block is located, the higher is its gravity center, the less stable is the wall. Moreover, the load bearing capacity of small stones is less than that of large ones.

As an example, let us consider the wall on the Hatunrumiyoc street in Cusco (see Photos. 1-5). Since the street has a slope, one might think that the small stones in the base of the large blocks of the wall are needed to account for this slope. However, there are sections of the polygonal masonry in this wall, where one course of stones splits into two or two courses merge into one. For example, in Photo. 1, moving from left to right, the second and the third courses merge into single course – the second course; and the fourth course splits into two courses – the third and the fourth. Thus, we see that the street slope could always be taken into account using the technique of masonry course merging/splitting.

Photo. 2.

Cusco (V. M. Soroka, 2021).

Photo. 2.

Cusco (V. M. Soroka, 2021).

In fact, everything is quite simple. By using the not large blocks of the first course, it is possible to take up the side gaps between the large stone blocks of the second course completely, i. e., correctly locate the latter relative to each other. Only provided that the relative position of the large blocks of the second course is correct, the rest blocks located above can be installed with minimal gaps. The adjustment of the side gaps between the large blocks of the second course becomes simpler when the masonry of the first course consists of 1.5-2 blocks by width.

Now, even if the ground would subside under one of the not large blocks of the first course, the neighbor not large blocks of the first course will continue to hold the located above large block of the second course in a predetermined spatial position. Only pressure acting on these blocks will increase. However, this is not a problem since the margin of compressive strength in any stone material is much greater than the margin of bending strength.8 Thus, the gap caused by the ground subsidence will increase over a small area under the large block of the second course only. The occurring bending force in the large block of the second course is far from a critical value provided that the height of the block is sufficient.8 Having the large block with sufficient height, the gap occurring under the block does not result in increasing the side gap and gap above the block because of no bending.

If a single extended block is put in the first course instead of the several not large blocks, then a bending (extension) force will inevitably occur in such a block, when the ground subsided under it, and the gap increase will take place over the entire length of the block, and unequally. In some cases, such a block can act as a turning out lever. The occurrence of the unequal gap will cause the spread of unequal gaps higher up in the masonry. As a result, the uneven weight distribution of the stone blocks will occur in this section of the polygonal masonry, which, in turn, would cause formation of a network of bend and shear stresses and, as a consequence, higher probability of cracks and stone crumbling in the wall.

Photo. 3.

Cusco (S. N. Kozintsev, photo.sirano.info).

Photo. 3.

Cusco (S. N. Kozintsev, photo.sirano.info).

The use of the not large stone blocks in the first course is one more confirmation that the wall of the polygonal blocks of the type under consideration was not built course after course with fitting the stones in-place (see

Section 2.11),13 but it was fabricated by a reduced clay model and then it was only assembled. During the course-after-course construction, the first course of the masonry would always consist of the largest stone blocks, since according to this approach, both the mounting surface for the next stone block and this stone block itself are successively made in-place.

Note that it is difficult to process not large stones in the first masonry course with a hammer and chisel while precise fitting since it is not easy to ensure the stone immobility due to its low weight. A micro-displacement of the stone occurs each time when a hammer strikes by a chisel. Therefore, it is possible that the not large stone blocks in the first masonry course could initially represent a single extended block of small height, which was split into several parts after interface copying with the pantograph. The locations, where the block was divided into parts, were chosen so that the bonding8,41 of masonry blocks would not deteriorate.

If the base of the not large stone blocks of the first course stands out of the general aesthetics of a particular polygonal masonry, then it can be hidden by a layer of soil (see Photos. 5, 10). The soil under the masonry weight will be compacted and the not large stones-wedges of the first course can crack and crumble, then the masonry will slide apart. To prevent such event, hard wedging stones having no visible defects should be used and not in one but in several places; the soil under the building should be strengthened;13 after laying the first two courses, the work on this site should be stopped and the masonry should be observed for some time, etc.

Photo. 4.

Cusco (V. M. Soroka, 2021).

Photo. 4.

Cusco (V. M. Soroka, 2021).

When a polygonal masonry is erected on a bedrock, the bedrock is pre-prepared. For example, L- or U-shaped recesses are fabricated in the bedrock. Next, clay replicas are taken by the pre-prepared section of the rock. To further correctly locate the model blocks of the first course relative to each other, marks are put with a narrow object on the front and back sides of the clay replicas along a horizontally stretched construction cord. After drying, the replicas are removed from the bedrock and put in the pantograph in place of a stone billet (Table B in

Figure 2). Using the pantograph, the surface of the interface with the bedrock and the marks are transferred from the clay replicas on the reduced clay model blocks of the first course. The obtained reduced model blocks of the first course are dried.

To avoid bottom surface damage of the model blocks of the first course, the model blocks are put in beds with a flat base by pressing into raw clay bars. The correct mutual positions of the model blocks of the first course at construction site of the model wall are adjusted by the above marks by adding soil and installing small wedging stones under the beds of these blocks.

As a rule, the polygonal structures in Peru have no sections that differ by weight significantly. In cases when one part of a polygonal structure rests on a bedrock, and the other part rests on an ordinary, albeit reinforced, ground, unacceptable stresses may occur in the polygonal structure. These stresses originate from the settling of the building part erected on the ground. Due to differences in the foundations of the different parts of the structure, the similar stresses caused by different thermal expansion42 of the foundations may also occur. In the above cases, a settlement/expansion joint8,41 should be provided in the polygonal structure. The settlement/expansion joint stretches from the base of the masonry to its top point. The joint provides vertical slipping of the stone blocks of the structure part located on the ground, relative to its other more stable part rested on the bedrock.

Photo. 5.

Cusco (V. M. Soroka, 2021).

Photo. 5.

Cusco (V. M. Soroka, 2021).

The proposed method of geometry transfer from a small clay model to a large stone block using a 3D-pantograph does not require a detailed drawing of the block geometry (for comparison, see the modern approach presented in Ref. 11, which uses high-tech means of design, measurement, manufacturing, and control). The builder should actually sculpt approximately the block and its interface with the neighboring blocks in accordance to a general idea of the sketch with his own hands (and applying tools such as spatulas, straighteners, scrapers, wire loops, and the like); then put this block in the model wall, where it would be finally fitted to the neighboring model blocks under its own weight and with small corrections of the builder. No precise dimensions need to be held here.

2.2. Pantograph application for fabrication of the polygonal masonry blocks by casting

Using the proposed method, it is also possible to obtain large blocks of concrete,43 geopolymeric concrete,44 lime, artificial granite45,46,47,48 and other materials by casting them into a mold. Using the pantograph, the reduced clay model of a block is enlarged to the desired size. The enlarged clay model is made hollow to reduce weight and shrinkage. Next, a mold is fabricated by the enlarged clay model.

Since shrinkage has a significant effect on the value of the interblock gap, it is desirable to make the cast blocks hollow to reduce shrinkage. Moreover, the cast blocks can be made of two components – a core (solid or hollow) of cheap concrete and a comparatively thin outer shell (“plaster” layer) of more expensive artificial granite. First, the core is cast. Then, after the end of the shrinkage, a fairly thin shell is cast over the core. Shrinkage of the shell is insignificant due to its small thickness. To ensure the strength and durability of the shell, its coefficient of thermal expansion (CTE)42 should be as close as possible to the CTE of the concrete core.49

The enlarged clay models for hollow/solid core and for the outer shell are fabricated by the same reduced clay model of the block using the pantograph set to the appropriate enlargement factor. To increase adhesion of the shell to the core, radial grooves are made on the front surface of the enlarged core model, which continue on the side surfaces. The grooves are made either directly by the pantograph pointer (Pointer B), or by a wire loop attached to the pointer. Despite exfoliations on the granite blocks of some Peruvian structures that are similar to the described outer shell (see Photos. 1-3, 5 and 15), the thicknesses of these exfoliations are small and thus these exfoliations should rather be attributed to the results of natural stone destruction50 or unsuccessful restoration/conservation23.

Although the proposed casting method is able to provide the polygonal masonry fabrication from large blocks tightly-abutted to each other, it is much more laborious in comparison with the mechanical processing method. The fact is that, besides the reduced model, this casting method requires additional fabrication of two more clay full-sized models of the block at least, followed by fabrication of two molds by these models – one for the concrete core, the other for the shell of artificial granite. To get a hollow core, one more full-sized clay model with minimal details is required, and one more casting mold is required in one of the fabrication alternatives.

Applying the 3D-pantograph to the reduced clay model and to an impression of its front face, it is possible to directly (i. e., without making intermediate full-sized clay models) fabricate the full-sized casting molds since the shape of the stone blocks used in polygonal masonry is quite simple (unlike a human sculpture, for example). To do this, an imprint of the front face of the reduced clay model is made in a clay pancake. After imprint solidification, the clay model is placed in its imprint and this packet is installed on its rotary platform (Table A in

Figure 2) facedown. The clay billet for a full-sized casting mold is installed on the rotary platform of the enlarged model (Table B) with the open part (corresponds to the backside of the cast block) up.

First, with the 3D-pantograph, the side surfaces of the model (block base, top side, left and right sides) are transferred to the inner side surfaces of the casting mold. To transfer the side surfaces, a Π-shaped (in the vertical plane) pointer is installed in the pantograph instead of the conventional pointer; the tip of the Π-shaped pointer is directed opposite to the tip of the conventional pointer. After copying-scaling the side surface, the reduced clay model is removed from its imprint and the front face is transferred from the imprint onto the bottom of the casting mold by the 3D-pantograph equipped with the conventional straight pointer. If a split casting mold consisting of several parts is used, then the transfer of the model shape begins by transferring the imprint surface to the base (bottom) of the casting mold. Then the model is placed in the imprint and sequentially abutting the side parts of the casting mold to its base, the model side surfaces are transferred to the inner surfaces of these parts with the pantograph.

The casting method suggested can be simplified and made cheaper using a roughly mechanically processed natural stone as the core, which shape approximately repeats the shape of the final product in a reduced scale. However, in this case, the shell will have an unequal thickness, which, in turn, may affect the constancy of the gaps between the blocks (because of the non-uniform shrinkage). The required stone block acting as a core can be fabricated either simply by basic dimensions or by the reduced clay model using the pantograph. In the method under consideration, the backside of the cast block may not have an outer shell layer at all since in most buildings, taking up a gap between the blocks or taking care of the product appearance is not necessary at this location.

Since stone blocks in a polygonal masonry experience a weight load from several tons to several tens of tons, under certain circumstances, say, during tremors caused by an earthquake, the destruction of the outer hard but fragile shell of artificial granite may occur. The listed features show that although the presented casting method is capable to provide the desired result (small gaps), it is too complex and expensive for construction purposes, and it does not guarantee the necessary structure durability in the earthquake-prone region.

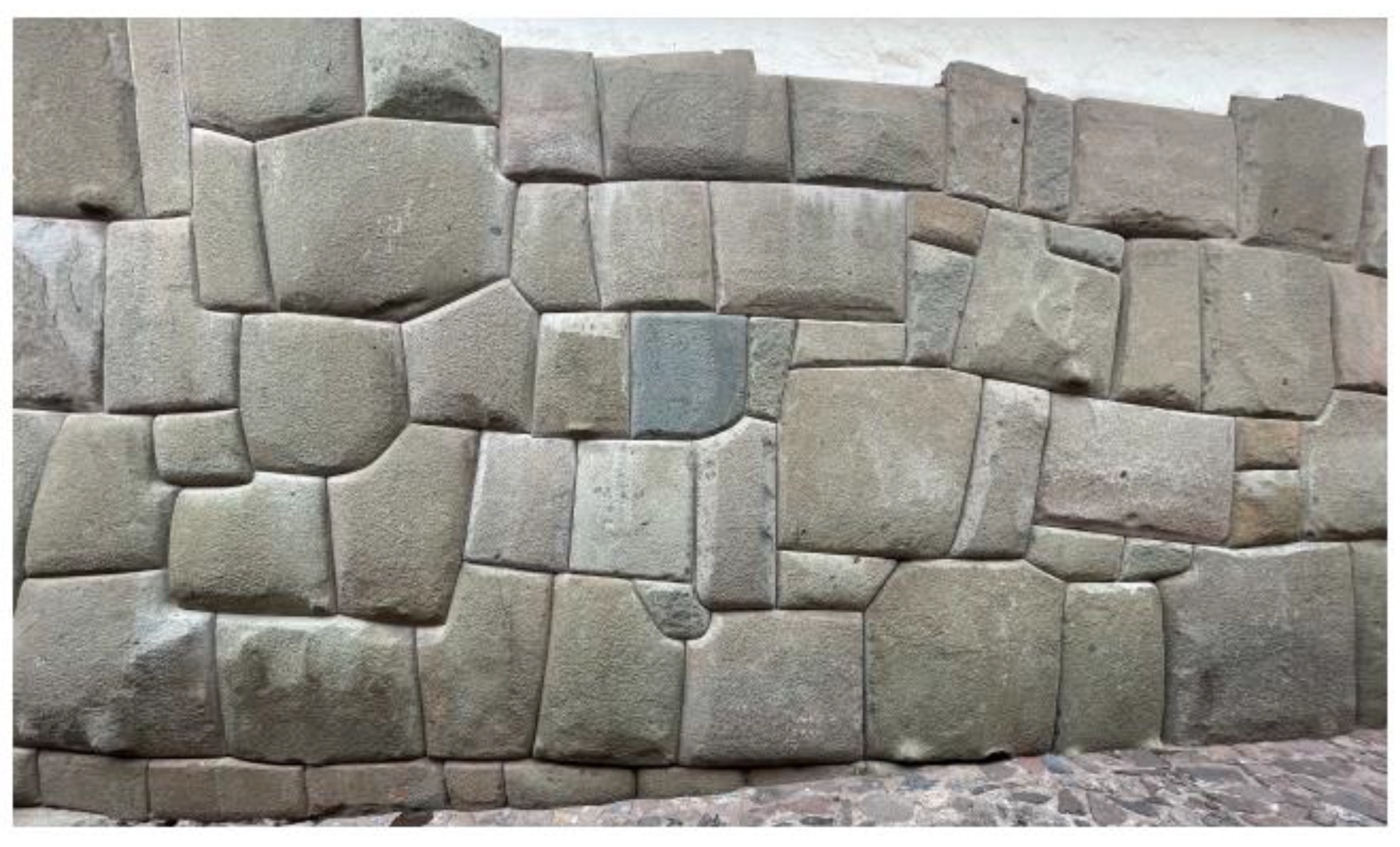

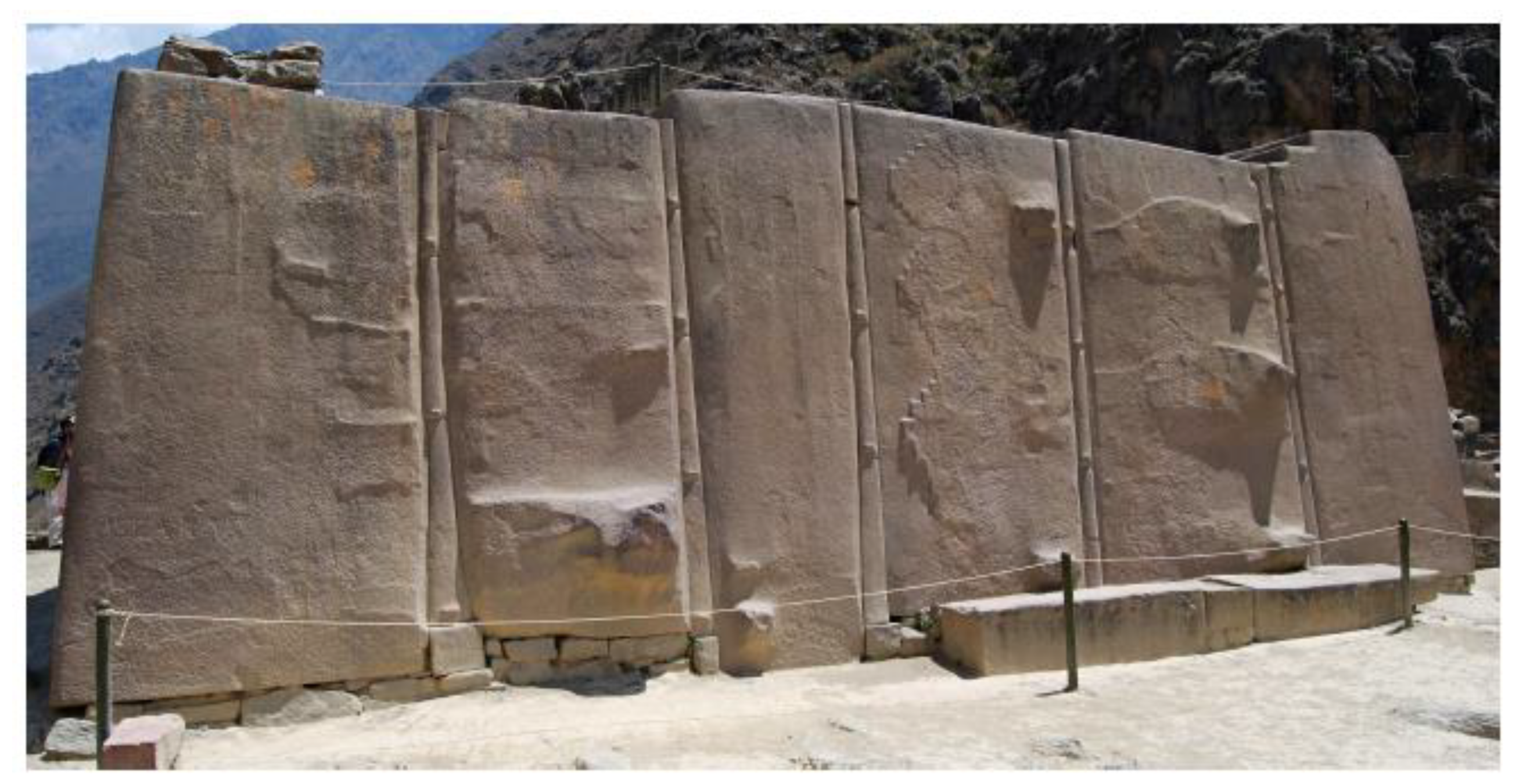

Photo. 8.

Ollantaytambo (C. Boudou, 2013).

Photo. 8.

Ollantaytambo (C. Boudou, 2013).

2.3. Usage of replicas

2.3.1. Replica-pancake

Not very complicated interfaces between large stone blocks are fabricated using replicas. A “pancake” of a constant thickness is pressed/rolled out of the clay. The raw pancake is put on a stone block, the surface of which should be replicated (the stone surface is previously covered with a composition that prevents clay sticking). After solidification, the replica-pancake is taken off. Periodically applying the obtained low weight replica-pancake to a heavy mating stone block, the excess material is gradually removed at the contact areas until full fitting of the replica to the block.

The smaller the relief to be transferred, the thinner the replica-pancake should be. In practice, the replica-pancake is able to transfer only comparatively smooth changes of a stone surface. While attempting to transfer small details, the replica-pancake becomes too thin, thus, it already bends under its own weight and breaks easily. In order to avoid the bending and prevent accidental damage during stone block processing, a fragile and still rather thin replica-pancake after separation from the original surface should be attached to some kind of a substrate-holder. By using the replica-pancake, it is impossible to transfer accurately the relief such as steep hills/pits since folds are formed in the replica's body. The folds result in changes of replica thickness, and, hence, the distortion of the copied topography. In general, the advantage of the replica-pancake is its simplicity; the disadvantage is a rather high error.

Since the replica-pancake is comparatively thin, its transversal shrinkage is not significant. Unlike the replica of replica described below, the transversal shrinkage in the replica-pancake cannot be corrected later in any way. To prevent the shrinkage-related longitudinal deformation, the material of the replica-pancake should have a small shrinkage coefficient and/or the replica-pancake should be pressed somehow against the original surface during the drying process. The replica-pancake should be pressed in such a way that its thickness would remain the same at any point. One can press the replica-pancake by putting an imprint of the original surface pre-made in a clay bar between a weight and the replica-pancake. The last improvement brings us close to the replica of the replica method discussed below.

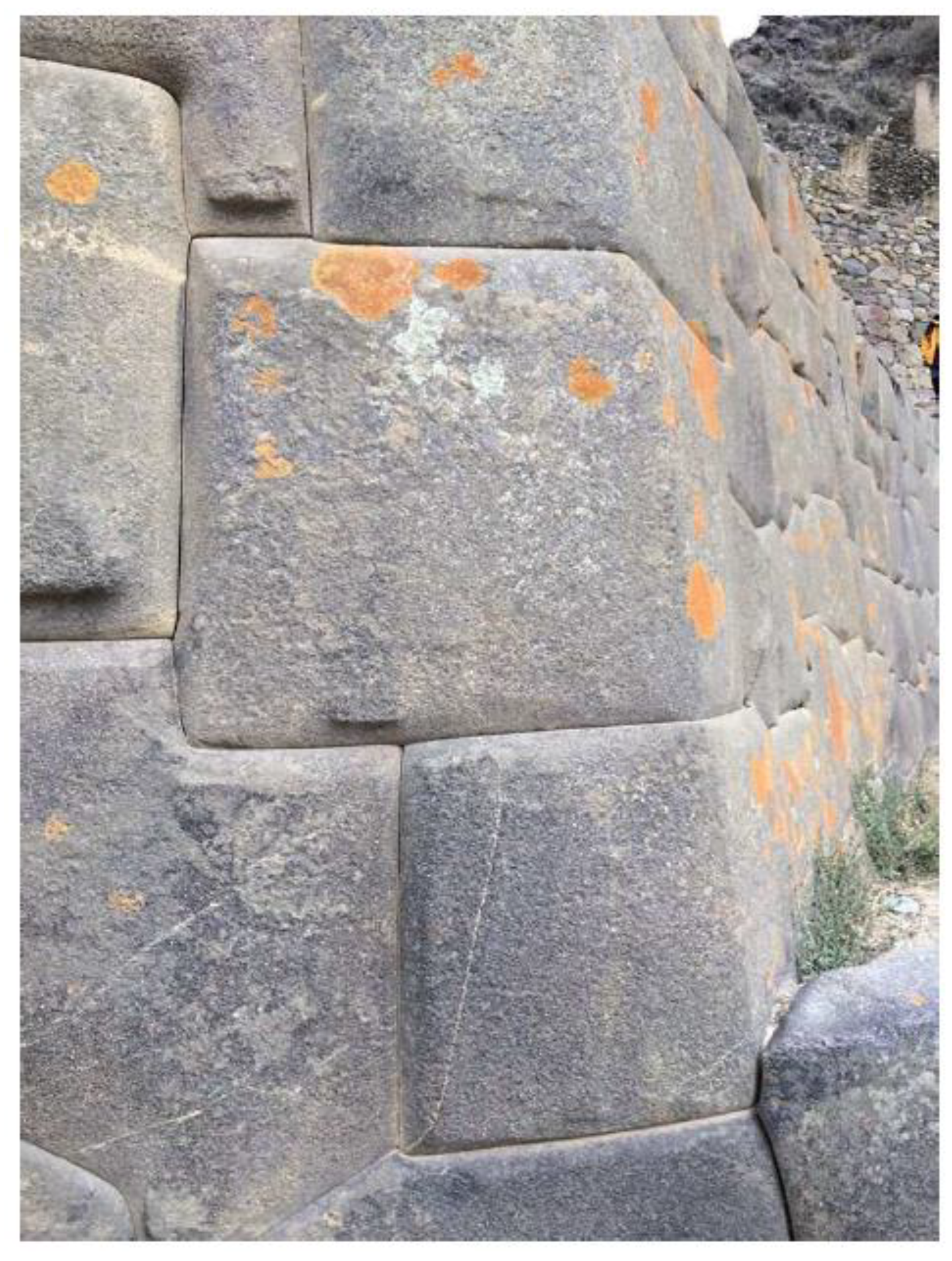

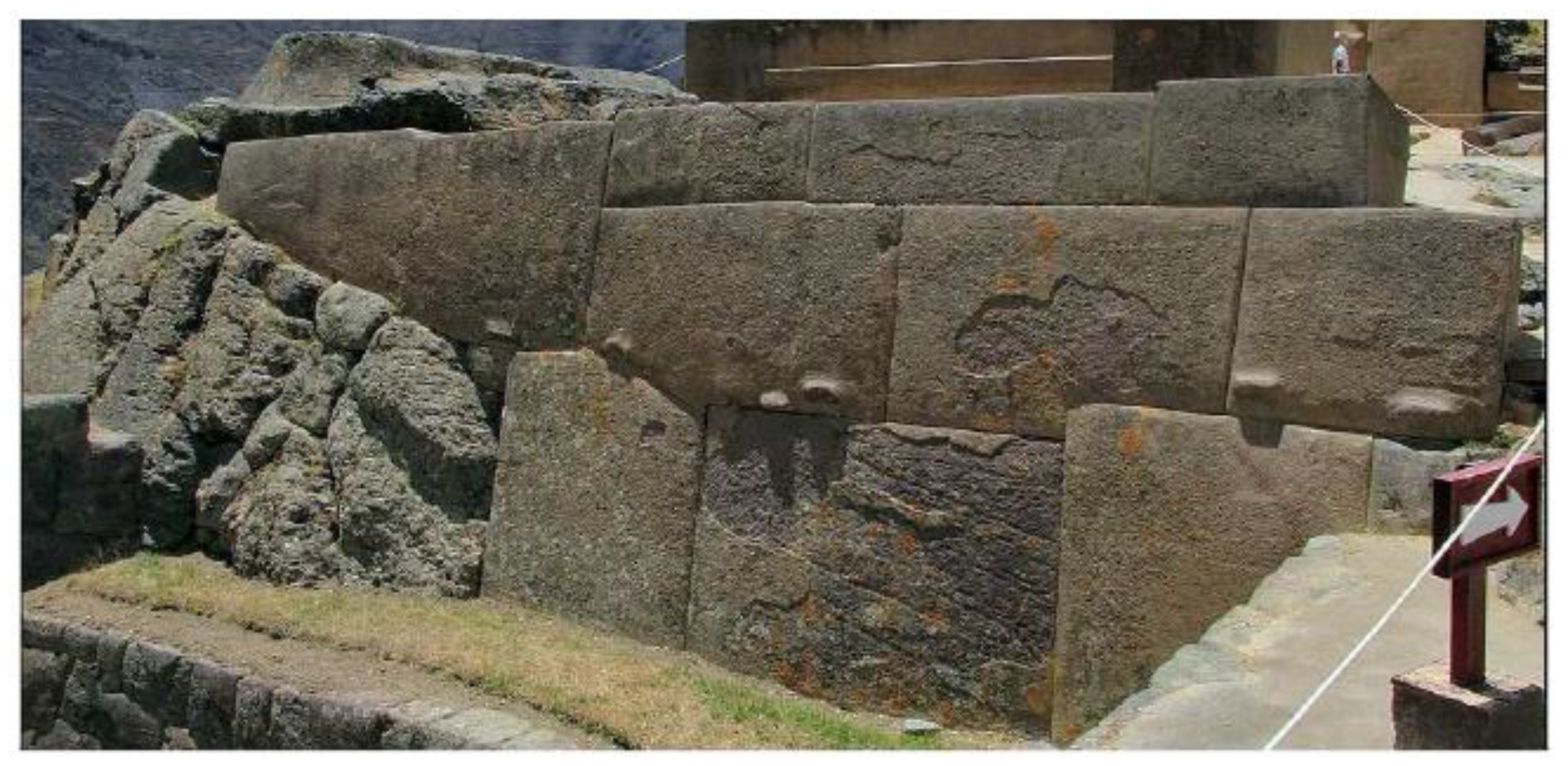

Photo. 9.

Ollantaytambo (B. Foerster, 2009, hiddenincatours.com).

Photo. 9.

Ollantaytambo (B. Foerster, 2009, hiddenincatours.com).

2.3.2. Replica of replica

If a higher accuracy of the relief transfer is required than the replica-pancake is capable to provide, then a replica of the replica is produced. First, by applying a raw clay bar to the selected area of the stone block, an imprint of its surface is made. After solidification, another imprint is made in raw clay by the obtained replica. After drying, the replica of the replica is further used as a copy of the surface area of the stone block when making the mating part of the stone masonry.

In another method, a clay rim is installed along the perimeter of the selected area of the stone block, after that the formed container is filled with gypsum. After solidification, the obtained replica is imprinted in a raw clay or, having installed a rim on the replica, one fill the formed container with gypsum (the surface of the gypsum mold is pre covered with a substance preventing binding of the poured gypsum to the gypsum mold). After drying, the resulting replica of the replica is further used as a copy of the surface area of the stone block when making the mating part of the stone masonry.

The replicas were also used in the sites where the stone structures of large blocks were abutted upon rocks. The replica was taken from a pre-prepared rock section and then applied to the processing stone block or, vice versa, the replica was taken from a processed stone block and then applied to the processing rock. It all depended on what was more convenient in each particular case. Since very large stone blocks are like rocks – they being extremely difficult to move, the replicas were also used for joining large blocks to very large blocks and very large blocks to other very large blocks.

Photo. 10.

Temple of Ten Niches, Ollantaytambo (P. Adams, 2012, manboyinthepromisedlanddotcom.wordpress.com).

Photo. 10.

Temple of Ten Niches, Ollantaytambo (P. Adams, 2012, manboyinthepromisedlanddotcom.wordpress.com).

The larger are the sizes of a stone block, the larger and heavier are the replicas fabricated by it. Therefore, beginning from a certain size of the stone block, replicas have to be taken from separate sections of the stone block. To ensure the correct mutual position of the replicas on the processed mating surface of the block/rock, the sections of the neighboring replicas should be partially overlapped.

The disadvantages of the replicas are: a higher interface error of adjacent blocks in comparison with the pantograph and a higher fabrication laboriousness in comparison with the reduced block model. One of the sources of a replica of the replica error is clay/gypsum shrinkage. The shrinkage-related error of the replica-replica is twice that of a single replica. To reduce the shrinkage-caused error of the replica-replica, a thin layer of raw clay is applied to the replica; after that the replica is pressed against the original. As a result, raw clay fills the voids, after that the replica and the original are separated, then the replica is dried. Next, the similar operations are performed with the replica-replica. If necessary, the process is repeated.

The advantage of the replica is that just one of the mating surfaces of the adjacent blocks is processed upon a model (replica); the original surface is processed arbitrarily (independently). In contrast to the replica, it is necessary to process both mating surfaces by the model in the pantograph method. There are no arbitrarily processed surfaces in the pantograph method.

2.4. The main problem

What does a stonemason has to continuously do while fabricating blocks fitted to each other through a complicated profile? The stonemason has to repeatedly apply one stone to another in order to determine the areas where the excess material should be removed. When the stones are small, it is easy to do.6 But how to do this, and quickly and precisely, when the weight of the stones is hundreds of kilograms or even several tons? The suggested methods just allow us to solve this problem. It is no longer necessary to repeatedly move a heavy mating block during processing.

2.5. What else was the clay model of the object needed for?

It is always extremely useful:

to have a small model of the object consisting of many parts of a complicated shape connected to each other in a complicated way;

to turn each block in hands;

to evaluate proportions more precisely;

to correct the blocks if something is disliked in their shape or fitting;

to assemble/disassemble the model wall to check the fundamental possibility of assembling the object containing locking elements;

to assemble/disassemble the model wall to analyze the operations for moving, installing and mounting, heavy stone blocks;

to see in advance how the object will look after the end of construction.

In those days, architects and builders had no computers to rotate a component in three-dimensional space on a monitor screen or, creating a virtual reality, wander around the future construction long before its erection. Even in our time, the making of scale models in architecture and planning did not lose its relevance.

It is well-known that the region, where the polygonal masonry was used, is earthquake-prone.2,3,4,5. Therefore, by creating a model of the building with lock blocks and shaking it, one could see how the object would behave in an earthquake, after that make appropriate corrections to the project, if necessary. Other methods did not simply exist in those times, calculations were rough, and the intuition and experience could fail.

Photo. 11.

Temple of Ten Niches, Ollantaytambo (A. Fuchs, 2008, sy-akka.de/ wordpress). Pay attention to the symmetrical arrangement of the blocks in the masonry.

Photo. 11.

Temple of Ten Niches, Ollantaytambo (A. Fuchs, 2008, sy-akka.de/ wordpress). Pay attention to the symmetrical arrangement of the blocks in the masonry.

As shown above, both the concrete castings and the clay models have a shrinkage. Clay shrinkage makes 2-3%.43 Consequently, the shrinkage-caused gaps should occur between the blocks of the polygonal masonry in both cases. Then what is the advantage of the clay model? The fact is that if the shrinkage-caused gaps occur in the clay model of the wall, these gaps can always be repaired by putting a thin clay layers on the clay model blocks where needed. In this case, any requirements related to the strength and durability of the added clay layers are simply not applicable, since the clay model is just an auxiliary element of the construction process not experiencing heavy loads, which is thrown away after a short use.

But it is useless to cover a concrete casting with a thin concrete layer of several millimeters thick, since the adhesion of this layer with the casting will not be strong enough and this layer will fall off or fail very soon under weight load and weather conditions. A thicker layer can be applied to the concrete casting covering the entire casting surface rather than a separate region (see

Section 2.2). This layer will adhere better, but the construction technology for such layer formation is too complicated and expensive.

Thus, the signs of a recent construction (casting) and/or unsuccessful restoration23 (Fortress Sacsayhuaman, the Tarawasi complex) are: cracks in blocks, traces of concrete mortar application, layered structure of disintegrated blocks (including the so-called “melted” stones), large gaps between blocks and non-parallelism of these gaps, falling apart polygonal masonry, failure to completely demount the masonry.

On the upper faces of a number of demounted stone blocks in Ollantaytambo, characteristic L- and U-shaped recesses for the bases of the blocks installed over draw attention.6,13 Some of these recesses spread over two or even three adjacent blocks thereby providing bonding8 of the blocks. According to the rules of stable equilibrium, the recesses ensure that the blocks would return to their initial position in the event of a small earthquake-caused horizontal displacement. The recesses under consideration in the upper faces of the blocks and the corresponding protruding parts at the bottom faces of the blocks installing over are fabricated while sculpturing the clay model.

2.6. What are the advantages of the pantograph over a replica?

When we apply a replica to a processing extensive surface of complicated topography, we do not clearly see where and how much material should be removed. Therefore, when using the replica, we should stain it by something, say, chalk or charcoal, and, applying it to the processing surface area, slightly rub it to mark the locations, where stone material should be removed. Remember, what a dentist does after filling the tooth. He puts a piece of carbon paper on the filling and asks to close your mouth and slightly rub it with teeth. After that, the dentist removes a little bit of the filling material in the marked place. Then he repeats the process several times until the teeth when closing would take the correct position.

When working with the pantograph, the sharp probe (Pointer A) is applied to the clay model, and the sharp pointer (Pointer B), which is mechanically connected to the probe by means of the parallelogram mechanism, is applied to the processing surface of a billet. In contrast to the replica, due to the small area of the probe and pointer, the topography measurement is actually carried out in a surface point, and it is clearly visible in what exact point; the entire surface is completely open.

Photo. 13.

Ollantaytambo (I. Otkalo, 2015, peru-info.me).

Photo. 13.

Ollantaytambo (I. Otkalo, 2015, peru-info.me).

Moreover, the pantograph allows one to clearly determine the thickness of the material to be removed at any point to which the pointer is directed (see also

Section 2.11.2). Therefore, the excess material can be removed for significantly fewer attempts. All these result in increasing productivity abruptly. The highest productivity is achieved when two people work with the pantograph. One person by the pantograph pointer shows a location (point) on the stone billet and reports the thickness of material that should be removed at this point, and the other person with the hammer and chisel removes the specified amount of the material.

Another advantage of the pantograph in comparison with the replica is that it is much faster, more accurate and easier to touch the clay model of the block with the almost weightless probe (the device is balanced by a counterweight) than to apply the relatively heavy replica to the stone billet, and then in addition to slightly rub with this replica by the billet.

Also, the pantograph allows to easily keep proportions set by an architect, that, in case of the replicas, have to be done by eye by spending a long time selecting billets of suitable sizes. Imagine that you need to accurately fit a structure into some unchangeable or difficult-to-change dimensions, say, between two rocky outcrops or into a cave. To do this, it is enough to measure the distance between the rocky outcrops and the size of the model, then divide first by second and set the obtained enlargement factor in the pantograph.

What else does the use of the clay model blocks and the pantograph give? Let it be required to make the outer side of the wall with a slope. To do this, it is sufficient to lay the raw clay model of the wall on the back side, install the stops setting the required slope, put a flat panel on top of the front side, and allocate above suitable weights. Instead of the weights, tightening clamps can be used. After some time, the clay model of the wall will be deformed properly. In the method, the specified angle can be kept very accurately along the whole length of the wall.

2.7. Reverse approach: clay model creation by a stone billet, formation of the interface surface and its transfer on the stone billet

According to the method described above, first, a reduced clay model was created by a sketch, and then the stone billet was selected for each block of the model. This approach allows us to repeat many times a section of the wall (if necessary, at different scales) using the same clay model each time (see a probable example of such masonry in Ref. 51). The drawback of the method is the large volume of the chipped off material of the stone billet. The analysis shows that a reverse method was mainly used for the polygonal masonry.

In the reverse method, first, a reduced clay model is created by a stone billet of arbitrary shape using the 3D-pantograph. To do this, a piece of raw clay is impaled on a pointed, say, three- or four-sided metal pin located in the center of the rotating platform intended for a model (Table A in

Figure 2). Due to this pin, the model can be removed from the pantograph at any time and precisely returned to its original position.

As before, the clay model and the stone billet are put on the pantograph with their backsides down. The exception is the wall corner blocks forming an outer corner (see Photo. 7). These blocks should be placed with the most lengthy front face down on the pantograph to provide access to the side faces to be processed. In such stone blocks, the front face, inaccessible for processing during copying, is dressed after the final assembly of the corner section of the wall.

Clay is added to those places of the model where it is not enough. Removal of clay excess is carried out directly with the metal pointer (Pointer A in

Figure 2; instead of a tip, a suitable tool can be attached to the pointer, for example, a wire loop, cutter, scraper, etc.) of the pantograph, which probe (Pointer B) moves over the surface of the stone billet block vertically up, then a small turn of the platform with the billet (Table B) around the vertical axis, then down, again a small turn, again up, etc.30 Owing to the pantograph, creation of the clay model body by the stone billet does not take much time.

At the next stage, a prototype of the wall is assembled from the obtained clay model blocks. The blocks still have no mating surfaces. Taking into account the sizes and the shape of the blocks, each block location is defined in the wall prototype. An architect-builder approximately layouts the contours of the future interfaces on the clay model of the wall, which should reflect: a conceived style, ensure stability of the created polygonal masonry, and minimize the labor of processing of the mounting surfaces. Further on, according to the accepted layout, the clay is cut out in the model block regions by which the blocks will adjoin each other.

Next, the wall model is being assembled from the obtained model blocks. By small corrections, the blocks are matched more precisely to each other. If the block model was occasionally damaged during the manipulations, the shape of the model in any location can always be restored by placing the block model back on the pantograph (on the above indicated pin) and by comparing with the shape of the original stone billet. Then the wall is being dried. First, the bottom course is dried, then the next one, and so on. During the drying shrinkage process, the model blocks are matched more closely under their own weight and with small corrections of the builder. If a shrinkage-resulted gap appears between the model blocks, it is eliminated by putting clay layers of the corresponding thicknesses on the model blocks at their interface.

At the final stage, the model wall is being disassembled. A clay model of a block is put back on the pantograph (on the above indicated pin) and the mounting sites are transferred on the stone billet corresponding to this model block using the hammer and chisel.

In the described method, the stone block is installed in the pantograph at least twice. To accurately return the stone block to its initial position, two lines radially diverging from the center of the platform (Table B) can be plotted on the platform. At the first installation of the stone block, alignment marks are applied to the surface of the stone with paint in the places where the lines come out from under the block. Processing of the backsides of the stone blocks is carried out after assembling a bearing wall.

2.8. Several more advantages of the pantograph

The use of the reduced clay model and pantograph allows block fabrication directly in the quarry where the stones are extracted.6,13 As a result, the already finished stone blocks are delivered from the quarry to the construction site. This approach significantly reduces the weight of the transported blocks and overall cargo traffic. Moreover, such organization excludes a large amount of construction debris on the construction site, which needs to be also transported somewhere after all.

Both the pantograph method and the replica method use auxiliary elements. In the pantograph method, these are the clay model blocks; in the replica method, these are the replicas themselves. To mate stone blocks in the replica method, the side surface of the block must be divided into several overlapping sections, each of which requires its own replica. If you mentally attach to the side surface of a non-edge stone block all the replicas made for it and by it, you will get a kind of a wheel, i. e., a fairly massive formation. If a replica of replica is used, then there will be two such “wheels” already. Thus, it is necessary to fabricate one “wheel” of replicas for each non-edge block in the replica of replica method. Let us compare such a “wheel” of replicas with the small model blocks in the pantograph-based method. The advantages of the pantograph are obvious.

2.9. Method combining elements of the replica, clay model and pantograph methods

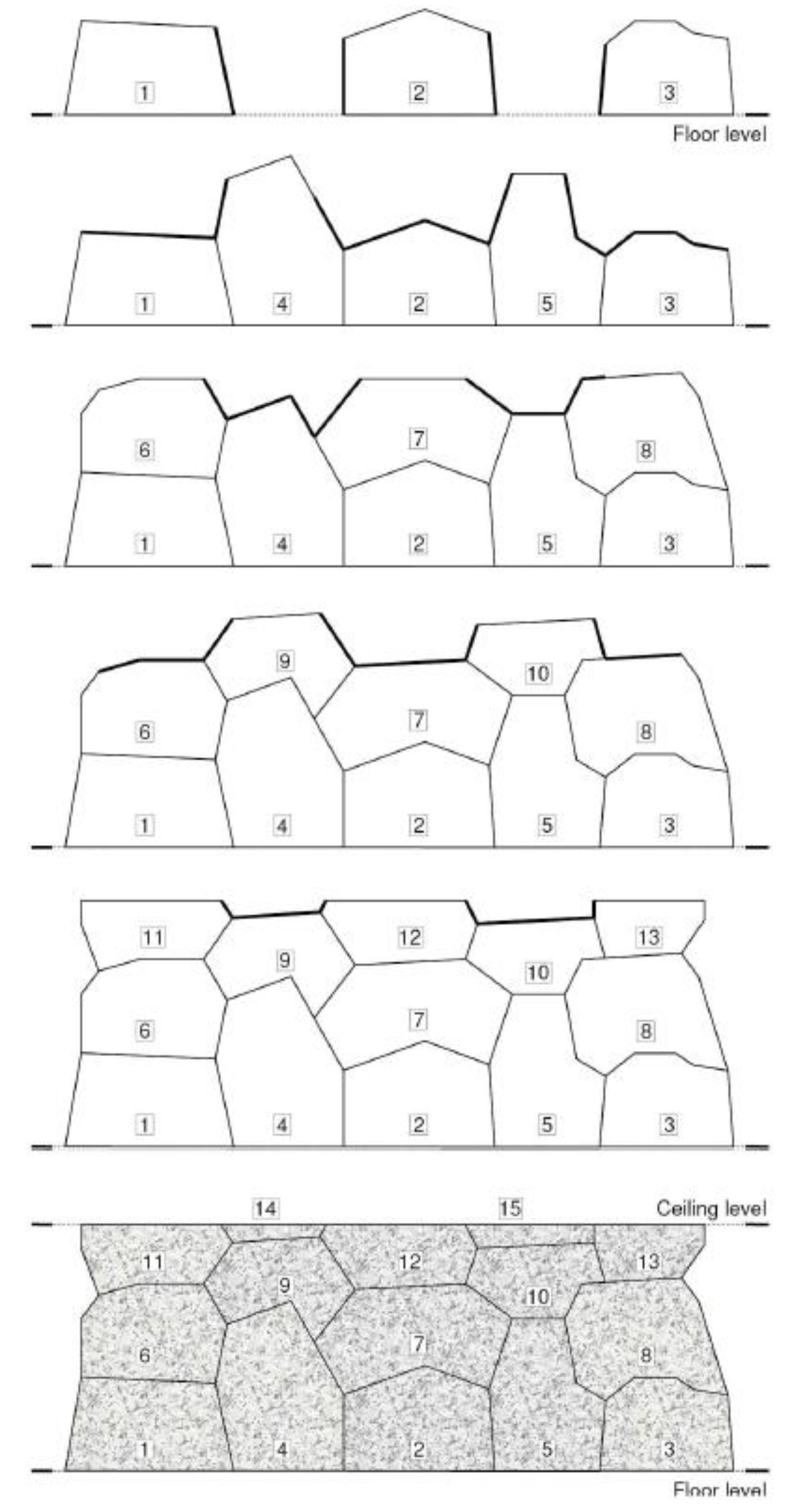

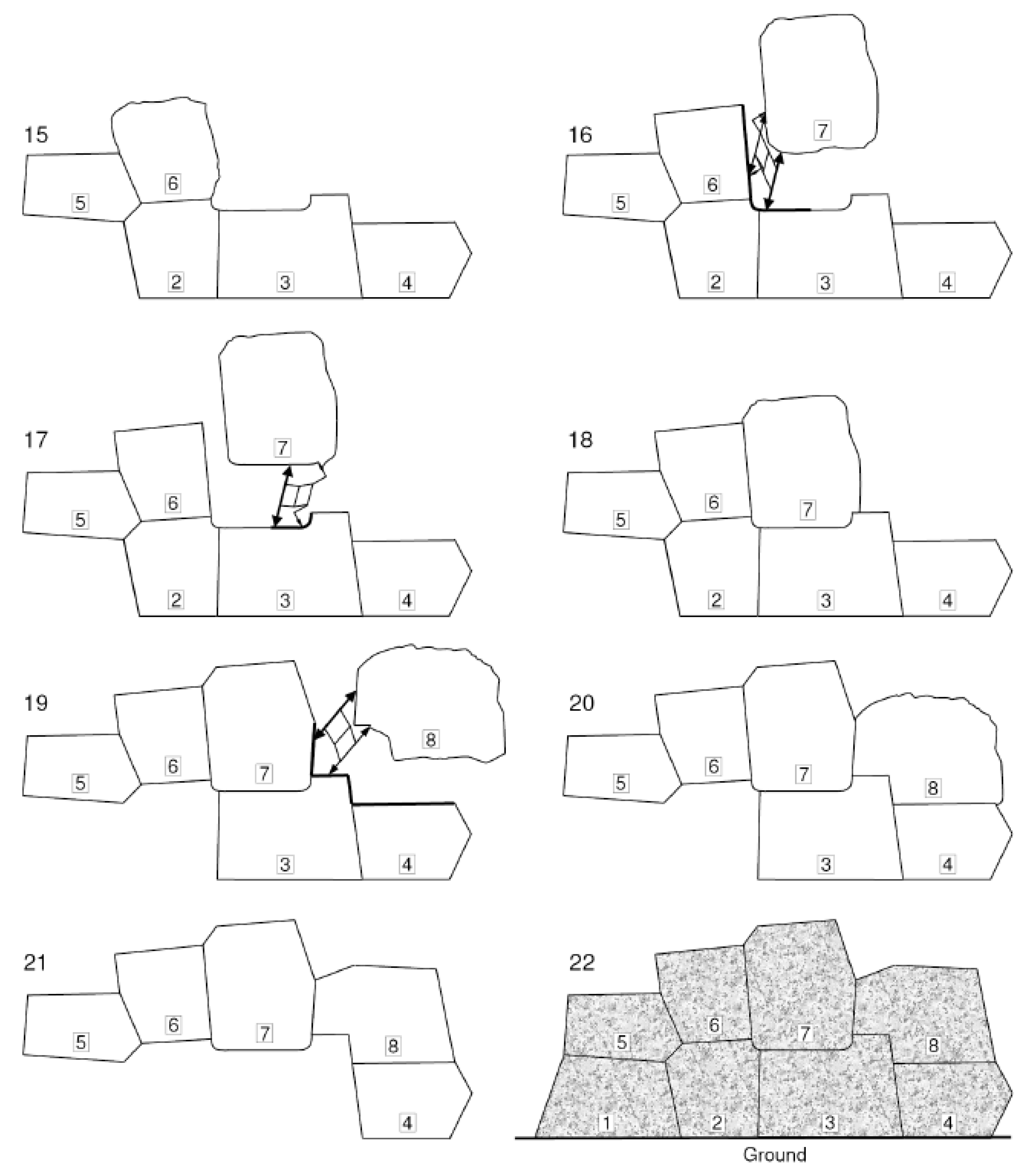

In the beginning, every second stone block of the first course is installed on the site of the future structure (see

Figure 3). The empty positions between these blocks will be occupied by stone blocks, which will be fitted in-place to these initially installed blocks at the next stage using a full-sized clay model and the 3D-pantograph. The heights of the stone blocks installed between the initial blocks should be approximately two times the heights of the initial blocks. The base surfaces of the initially installed stone blocks are pre-treated properly to ensure their stability.

Besides the prepared base, the initially installed blocks have finally processed side faces also. Processing of the side faces is straightening of a complicated initial shape of the stone billet by surfaces close to the planes with the hammer and chisel. The slopes of the side faces of the initially installed blocks to the bases of these blocks should not exceed 90°, if possible, in order to facilitate the subsequent installation of the adjacent blocks. The similar rule is applied later for every second block of the subsequent courses of the polygonal masonry.

Next, the space between the initially installed blocks is filled with clay. Actually, clay models of the blocks are created at the scale 1:1 in the spaces between the initial blocks. The side surfaces of these models contacting at the left and right with the side surfaces of the initial blocks are, in fact, their replicas. To decrease weight of the full-sized clay models and reduce their shrinkage deformations during drying, the models are made hollow. If a shrinkage-resulted gap appears between the initial stone block and the clay model, it is eliminated by putting a raw clay layer of suitable thickness on the clay model.

After drying, the clay model of the block is removed from the structure and installed in the pantograph in the model place (Table A). The corresponding stone billet is installed in the copy place (Table B). The pantograph is adjusted to the scale 1:1 (at the given scale, the placement of the model and the copy in the pantograph is only determined by operation convenience). If necessary, one can quickly check the matching of the selected stone billet to the model with the pantograph.

Photo. 14.

Wall of Six Monoliths, Ollantaytambo (P. Špindler, 2008, commons.wikimedia. org). Most likely, the Wall is built using the method combining elements of the methods of replica, clay model, and 3D-pantograph. The small stones under the megaliths indicate that the Wall seems to have been once reassembled, and possibly moved.

Photo. 14.

Wall of Six Monoliths, Ollantaytambo (P. Špindler, 2008, commons.wikimedia. org). Most likely, the Wall is built using the method combining elements of the methods of replica, clay model, and 3D-pantograph. The small stones under the megaliths indicate that the Wall seems to have been once reassembled, and possibly moved.

Next, the interface surfaces are transferred from the full-sized clay model to the stone billet using the pantograph, hammer and chisel, as described above. After transferring the interface surfaces, the rest (arbitrary) faces are formed on the remaining side surface of the stone billet. Processing of these faces is straightening of the complicated initial shape of the stone billet by surfaces close to the planes. Further, these faces will no longer be processed. The stone block obtained this way is finally put in its position in the polygonal masonry.

Having finished the first course, the next one is produced in the same way. As in the above methods, the stone blocks of an arbitrary shape are used in the described method as building material. The method provides a good vertical bonding of the blocks and a satisfactory horizontal one. Since the method has no a full-fledged clay model of the structure, to put together the original stone blocks well and thereby minimize the amount of material to be chipped off during processing, it is desirable to preliminarily lay out the stone blocks on the ground with the backside down, one next to the other.

The method disadvantage is the high laboriousness associated with the fabrication of the clay model of the block in the scale 1:1. Nevertheless, in comparison with the replica-replica method, this method is capable of providing a higher accuracy of the interface between the contacting surfaces when it is necessary. As in the replica cases, about half of the side surface of the stone blocks is processed arbitrarily in this method.

The Wall of Six Monoliths at Ollantaytambo (see Photo. 14) consisting of one conditional course was constructed according to the described method most likely. Leaving aside the architectural appearance of the monument for a while, let us ask the question: why are the monoliths not connected to each other directly, but require intermediate inserts (shims)? The fact is that the use of replicas on such extended contact areas of the side surfaces of the monoliths is unable to provide a zero gap. Therefore, the intermediate inserts were needed to connect the monoliths.

To emphasize the gigantic dimensions of the monoliths, the inserts should significantly differ from the monoliths in width. Since fabrication and installation of a single narrow monolith-high insert is even more difficult technical task than the direct fitting of the neighboring monoliths, the intermediate inserts were divided into 3-5 separate parts. Each insert was fabricated in-place and installed sequentially one after another – first, a row (conditional) of the lowest inserts, then the next row of inserts, etc. During wall assembly, some of the intermediate inserts were lowered on their place from top to bottom, some were installed from the front or back side of the wall.

Photo. 15.

Ollantaytambo (E. Berzin, 2020, allenatore.livejournal.com).

Photo. 15.

Ollantaytambo (E. Berzin, 2020, allenatore.livejournal.com).

One should pay attention to the small stones on which the monoliths rest. These stones ensure taking up the side gaps between the monoliths and the lowest narrow vertical inserts (see

Section 2.1). However, the considered method of block joining does not need such position adjustment, since fabrication of the intermediate inserts here is carried out in-place. It follows that the Wall of Six Monoliths was once reassembled and may have been originally located in other place. The need for reassembly could arise due to insufficiently thorough preparation of the monument basement or in connection with blocks that are falling apart after an earthquake, etc. Apparently, at the final construction stage, the small stones in the base of the reassembled monument were supposed to be hidden by a floor level.

2.10.“ Planetary” pantograph for use in construction

The modern 3D-pantographs used by sculptors have two synchronously rotating platforms. A model is installed on one platform (see Table A in

Figure 2), and the enlarged copy of the model is installed on the other platform (Table B). Usually the enlarged copy is hollow, so the weight of the copy is not high, as a rule. The reinforced platform of such pantograph applied for construction purposes is able to withstand stone billets weighing up to 700 kg.

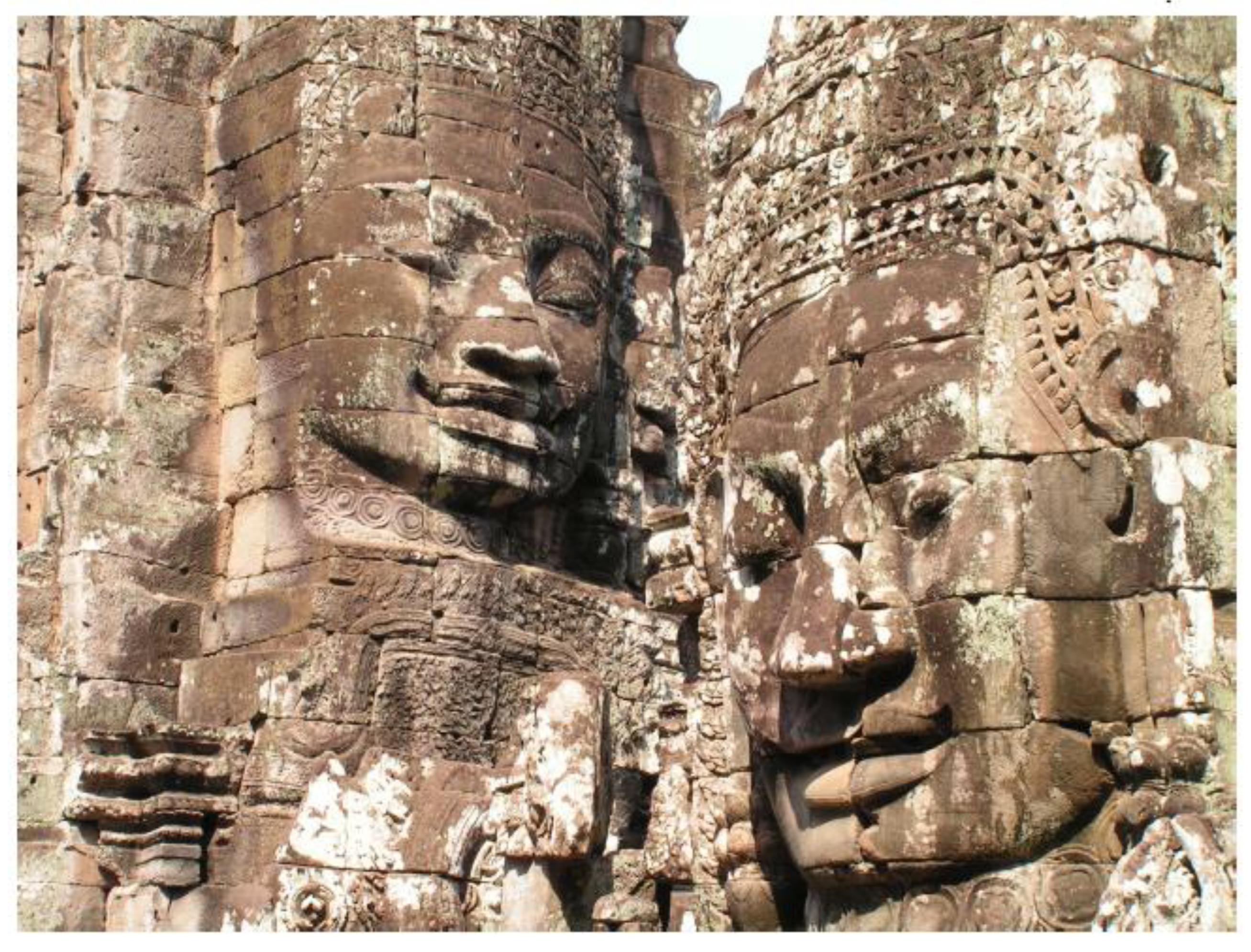

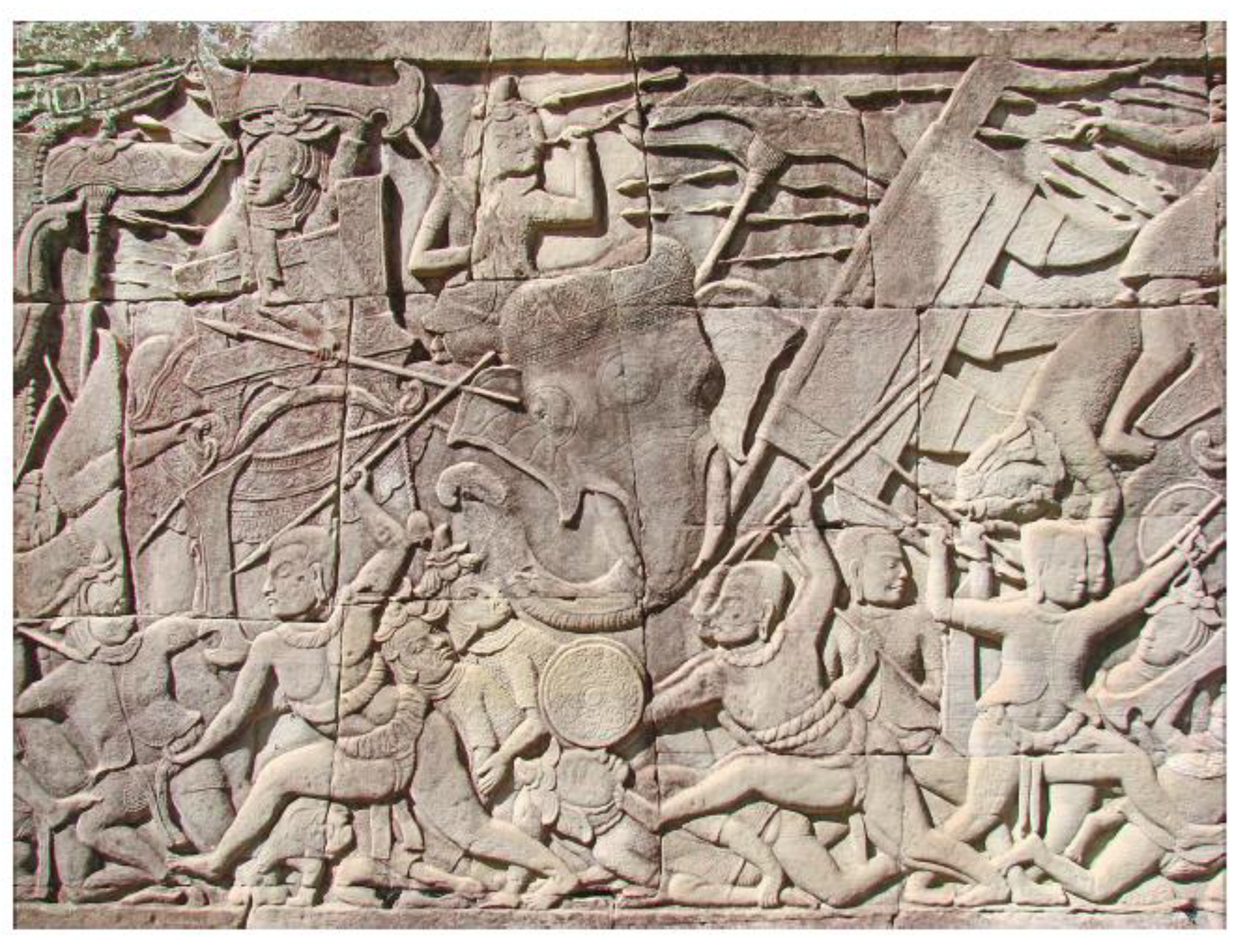

When a sculpture is large and heavy, its model can be divided into several parts. An enlarged stone copy can be fabricated for each such part; then a large sculpture is assembled from the obtained enlarged copies of these parts. Apparently, the polygonal Face Towers of the Cambodian temple complex Angkor

52 were made using this technology (see Photo. 16). However, this is not our case. Regarding to the Face Towers, it is worth noting that they have symmetry, which, in turn, may indicate the use of a 3D-pantograph for their fabrication (see

Section 3.8).

The modern 3D-pantograph is not suitable for working with large and heavy stone billets. Instead of the existing design, one can offer the following “planetary” pantograph. The heavy stone billet in such pantograph is simply installed on a plane site and the frame, to which the pantograph boom and the platform with the model are attached, is turning during work in the horizontal plane around the stationary standing billet. As the frame turns, the model also turns around its vertical axis at the required angle (actually retains its original orientation in the space) using an appropriate mechanism. One revolution of the support point (Pivot in

Figure 2) of the pantograph boom around the stationary billet corresponds to one revolution of the model around its axis.

Photo. 16.

The polygonal Face Towers of the Angkor temple complex, Cambodia (D. Wilmot, 2005,

www.flickr.com/photos/david_wilmot). According to the proposed technology, the reduced clay model of a Face Tower consisted of a number of parts forming a polygonal masonry. For each part of the clay model, an enlarged stone copy was produced using the 3D-pantograph. The Face Tower was assembled from the enlarged stone copies of these parts. The Face Towers have symmetry, which may also speak in favor of using a 3D-pantograph for their fabrication.

Photo. 16.

The polygonal Face Towers of the Angkor temple complex, Cambodia (D. Wilmot, 2005,

www.flickr.com/photos/david_wilmot). According to the proposed technology, the reduced clay model of a Face Tower consisted of a number of parts forming a polygonal masonry. For each part of the clay model, an enlarged stone copy was produced using the 3D-pantograph. The Face Tower was assembled from the enlarged stone copies of these parts. The Face Towers have symmetry, which may also speak in favor of using a 3D-pantograph for their fabrication.

Due to the large sizes of the construction pantograph, the mechanism synchronizing rotation of the model with the rotation of the frame around the stationary billet turns out to be cumbersome and heavy. To simplify design and reduce cost of the planetary construction pantograph as well as to decrease a backlash-related error, any mechanism can be abandoned at all. To do this, just divide the round site on which the billet is rested and the model platform by the same number of sectors with a step equal to, say, 10°. Now, after rotating the pantograph frame around the billet by one sector, for example, counterclockwise, one just needs to manually rotate the model by one sector clockwise during the work. The frame and model rotation discontinuity is leveled by the operation of the parallelogram mechanism located on the boom.

In contrast to the existing pantograph, the planetary pantograph occupies more space, and the person using the pantograph has to move while working along with the turning frame around the billet. These features can be attributed to the shortcomings of the planetary pantograph, which, however, are not critical at all in the construction field.

2.11. Topography translator based on the double parallelogram mechanism

One can suggest a plain mechanical device – a topography translator (see

Figure 4), which, in the case of a comparatively simple polygonal masonry, allows to perform quite acceptable joining of the surfaces of the adjacent stone blocks in-place. The comparatively simple polygonal masonry is a masonry that does not require the preliminary fabrication of an object model. The blocks in such masonry have a comparatively simple shape, they are joined to each other mainly along the side surface (backsides of the blocks are not processed, as a rule) using simple L- or U-shaped recesses, and do not contain complex three-dimensional locking elements. To process the stone blocks using the topography translator, both the mating blocks are put on the ground on their backsides. Thus, the side surface (base, top side, and side faces of the blocks) to be processed would be arranged vertically in this method.

First, the mating area of the surface of the first block is subjected to an arbitrary processing. During the processing, the surface in this area is made smoothly changing, close to a plane. Such a surface is obtained when a stonemason makes a flat surface manually “by eye” without deviation control of the treated surface from the plane in any way.

Then, near the first block, a second stone block is put. The second stone block is located so that the surface areas under the fitting are opposite each other. The distance between the blocks is set such (60-80 cm) that a stonemason can accommodate between the blocks and is capable to work with a hammer and chisel in the space between these blocks without much trouble. Next, the proposed topography translator is installed between the blocks as a strut, so the stonemason can use it to transfer the inversed topography of the surface area of the first block previously processed in an arbitrary manner to the second block.

In general, the lateral surface of a stone block is a set of the mentioned conditionally flat surface sections. The conditionally flat sections can adjoin each other forming a sharp boundary, or they can pass into each other quite smoothly as in the reciprocal parts of the L-shaped recesses. The U-shaped recesses are reduced to a pair of counter-located L-shaped recesses. Further, let us describe in more detail the translator and the stone block processing sequence based on its application.

2.11.1. Topography translator design

The topography translator consists of two parallel rods connected to each other by means of a double parallelogram mechanism (see

Figure 4). The double parallelogram mechanism belongs to the hinge-lever guiding mechanisms, and has two degrees of freedom and consists of seven links such that AB=A'B'=BC=B'C' and AA'=BB'=CC'.28 In the translator under consideration, the rod bodies are part of the double parallelogram mechanism. The rod with a bigger cross-section will be called a carrying rod; the rod with a smaller cross-section will be called a measuring rod. Using a telescopic or other joint, the length of the rods can be changed roughly by sliding in and out the edge sections along the rod. After the end of the rough adjustment of the rod lengths, the relative positions of the edge sections are fixed with pins.

Tip-supports are screwed in into the ends of the carrying rod, and by unscrewing them one can fix the translator rod securely like a strut on the processed area between the mating stone blocks. Pointed tips are screwed in into the both ends of the measuring rod. The pointed tip directed to the pre-treated surface of the first block will be called a probe; and the pointed tip directed to the processing surface of the second block will be called a pointer. By screwing in/out the threaded pointed tips, the length of the measuring rod is set precisely. The set positions of the supports and the pointed tips are fixed with lock-nuts.

If the carrying rod is installed as a strut between the blocks perpendicular to the mating surfaces, then the flat foot supports are used (see

Figure 4a). If the carrying rod is installed as a strut with a significant tilt to the mating surfaces, then the pointed supports are used (see

Figure 4b). In the latter case, before installing the carrying rod, small recesses are made in the stones at the installation locations of the supports. The recesses are necessary to prevent slipping of the carrying rod supports.

Since the translator have to transfer the spatial topography of the surface, and the double parallelogram mechanism has only two degrees of freedom, the parallelogram mechanism is attached to the carrying rod through cylindrical hinges. Thus, due to the cylindrical hinges of the carrying rod, the measuring rod together with the double parallelogram mechanism can rotate freely around the carrying rod. Such rotation makes it possible to “readout” the transferred topography by the probe of the measuring rod around the installation position of the carrying rod.

2.11.2. Order of operation with the topography translator

If the carrying rod of the translator is installed near the location of the longest distance between the blocks, then the longest distance is set in the measuring rod in-place, and the topography transfer starts from this location. Generally, the carrying rod can be installed at any location which is convenient for the stonemason. In practice, it is often convenient to install the carrying rod closer to a block edge, and to begin topography transfer (translation) from there.

After installing the carrying rod and setting the necessary length of the measuring rod, the probe tip of the measuring rod is brought into the contact with the pre-treated surface of the first stone block (shown in the figure on the left). As a result, the pointer tip of the measuring rod will show the point on the counter processing surface of the second block (shown in the figure on the right), where the stonemason should chip off material.

If one made the translator pointer sinkable into the retractable section of the measuring rod, spring-loaded, and equipped with a scale and an indicator (these elements are not shown in the figure) then a stonemason will know how much material should be chipped off at this point. The similar pointer device can also be used in the design of the 3D-pantograph. Thus, having information about the amount of material to be removed at each surface point, the stonemason performs the work in fewer chippings significantly improving his productivity.

The highest productivity is achieved when two people operate with the translator. One person with the translator pointer shows the location (point) on the stone block under processing and says the thickness of material that should be removed at this point, and the other person using the hammer and chisel removes the specified amount of the material.

The main purpose of the double parallelogram mechanism is to ensure the strict parallelism of the movement of the measuring rod. From the above description, it can be seen that the translator under consideration provides the same result on a separate mating section as the 3D-pantograph adjusted to the scale 1:1.

Translator accuracy is determined by gaps in the hinges and by bending deformations of the structural elements of the mechanism. To ensure structure rigidity, the bars and hinges used in the parallelograms have the appropriate cross-section sizes and stiffeners (not shown in the figure). To increase structure rigidity, besides the mentioned parallelogram mechanisms, additional identical parallelogram mechanisms can be used by attaching them both in parallel and in series (along the rods).