1. Introduction

NASA/ESA/CSA’s James Webb telescope is about to be launched to its intended orbit on single barrel three stage pencil rocket from south France. This project is claimed to be most sophisticated in history of science and thus have suffered various delays owing to its complexity, sophistication and difficulties encountered during design, material selection manufacturing and fabrication. Let aside, it had agglomerated to be of 10 billion $ - most expensive experiment in history of science. No record exists about reverse calculations of intended orbit, payload deployed in intended orbit, its relationship with trajectory till point of launch on earth (recently shifted with a strong assumption that it will not affect any of afore and after-mentioned), mechanical design, architecture, materials selection, and manufacturing based on this. There were already open questions and now a closer look at material selection and its properties in proposed conditions have revealed even more bigger problems. Fundamental materials properties and selection criteria are entirely ignored so much so that it is very probable that this most expensive assembly will split into pieces during ascent inside or outside of faring of rocket. This study critically examines this and highlight fundamental mechanisms (slip system) which crucially dictate material selection, manufacturing, finishing, assembly, and application.

2. Brittleness, Crystallography, Deformation, and Fracture of Beryllium

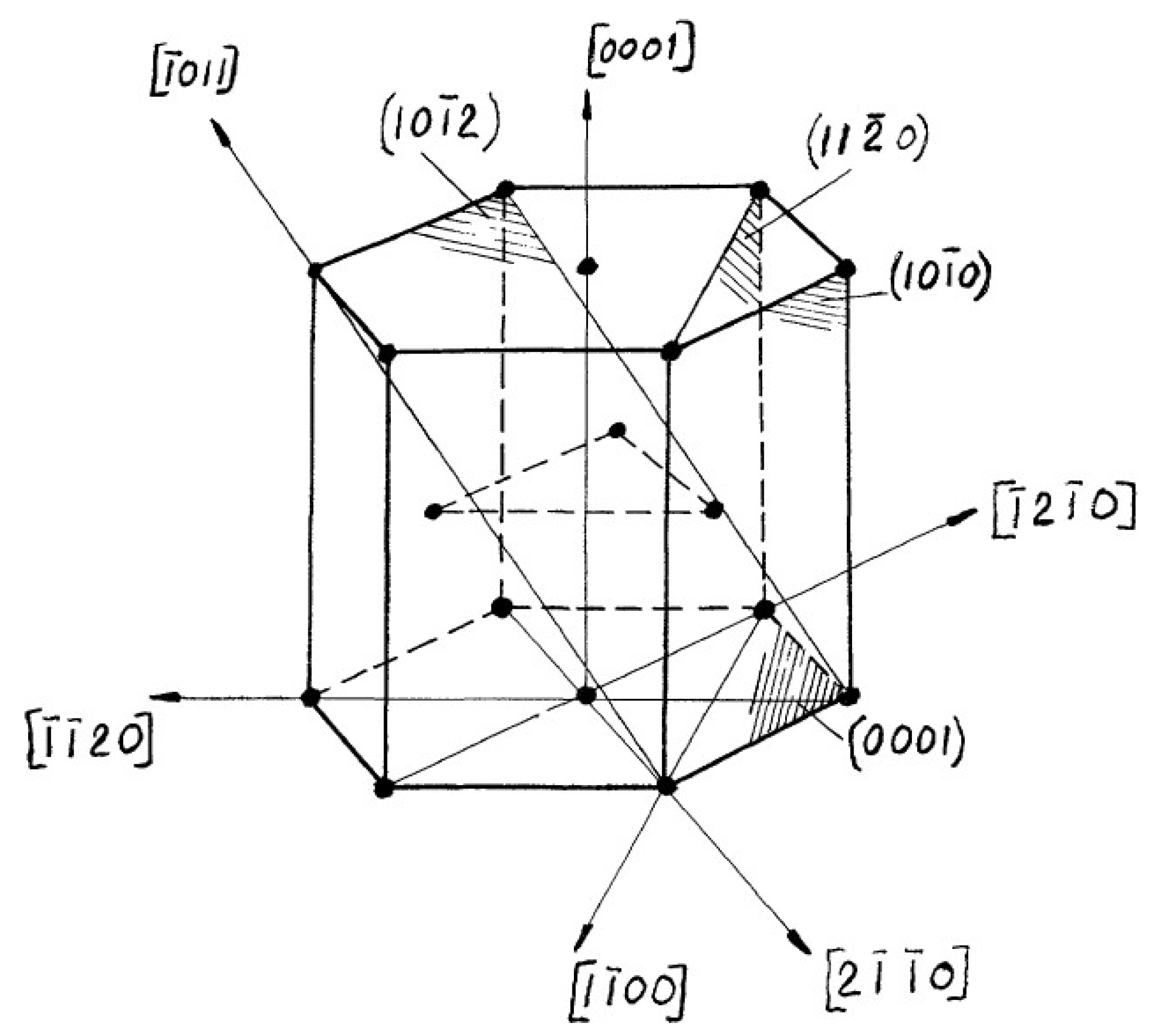

Beryllium is a hexagonal close packed (hcp) crystal structure metal. It is brittle at room temperature [

1] and its brittleness increases as temperature is lowered [

2]. It has three main slip systems (0001), {11̅00} and {11̅0𝑋} namely basal, prismatic, and pyramidal and there is only one slip direction <112̅0> [

3,

4] (

Figure 1).

Mostly, under normal room temperature conditions and somewhat zero and near zero temperatures, basal plane is active and responsible for plasticity and fracture of this metal (5𝜎𝑏 = 𝜎𝑝 i.e. 5 times the stress at basal plane is required to start slip on prismatic plane. Typical 𝜎𝑏= 1.4 Kg / mm

2). However, at moderately high temperature, prismatic slip system is activated and result in deformation and fracture of metal while pyramidal only become active at very high temperatures [

5]. This is very quick, and metal fails in brittle manner. Since application is cryogenic and involve thermal cycling, most likely this will happen. Other deformation mechanisms such as twinning, and cleavage are also activated under certain conditions. Twining plane is found out to be {112̅0}and twining occurs by shear along <111̅0> direction. Above 400

oC two more twining planes are found to activate shear namely {101̅1} and {101̅3}. Cleavage is found to occur primarily along basal plane (0001) and along secondary prism planes {11̅20}. Cleavage along twinning planes has also been observed. Role of c/a ratio for deformation modes and slip mechanisms reveal that Be lies in the middle of metals with hcp structure and found to be most brittle with well defined modes and slip mechanisms. For it, at its c/a ratio, tendency to slip by prismatic slip is high (despite high critical resolved shear stress) rendering metal less ductile and more brittle. It also offers much higher friction stress for motion of dislocations on basal plane as compared to its counterparts (Zn or Cd) (undesirable). A friction stress is due to lattice defects, impurity atoms, precipitates, and Peierls-Nabarro force of lattice itself. A high Peierls-Nabarro force implies inherent high slip resistance. Impurities in solid solutions can be reduced by purification of metals (inapplicable for Be (by condensation)) [6-8]). Thus, brittleness of Be is unavoidable. Another important factor which determines the inherent brittleness of Be is its very low value of Poisson Ratio (< 0.1) [

9]. Decreasing grain size imparts slight ductility in Be. However, it has its own extrinsic (process dependent) limitations. Alloying seems not be affect ductility. Only limited enhancement in strength is achieved.

3. Ductile to Brittle Transition Temperature (DBTT)

Ductile to brittle temperature of Be is shown to be a function of composition and thermal treatment (temperature range) [

10]. For a commercially pure grade, it is 100 – 200

oC [

11]. Below figure (

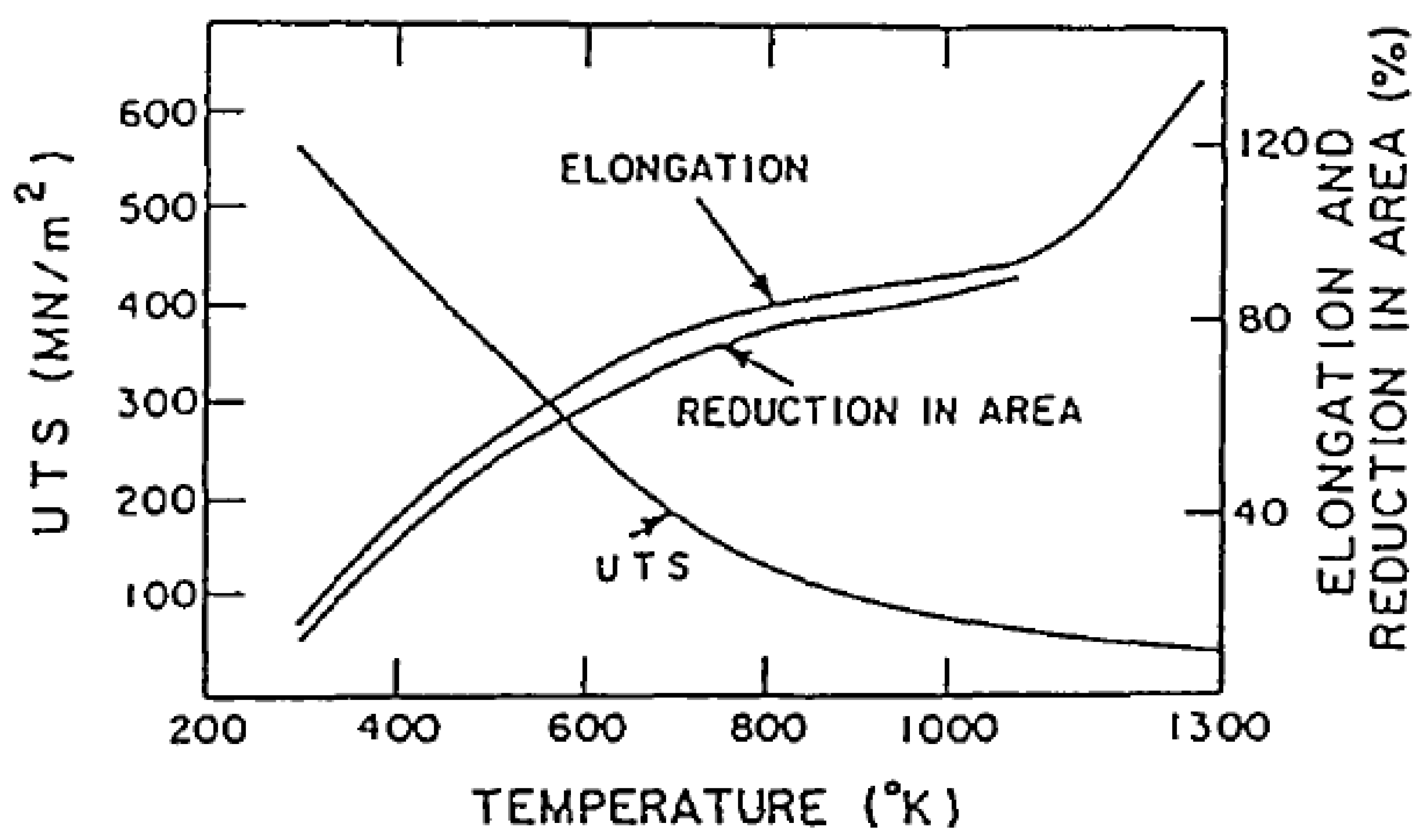

Figure 2) shows the variation of UTS, elongation and reduction in area for a wrought, fine grained, high purity beryllium product over a temperature range of 300 – 1000

oC [

11]. It can be easily observed that UTS which is a measure of strength not stiffness decreases as temperature increases. Elongation (usually represented as percentage) and reduction in area (which is measure of former) increase with increase in temperature. This is due to ability of material to toughen at the expense of strength.

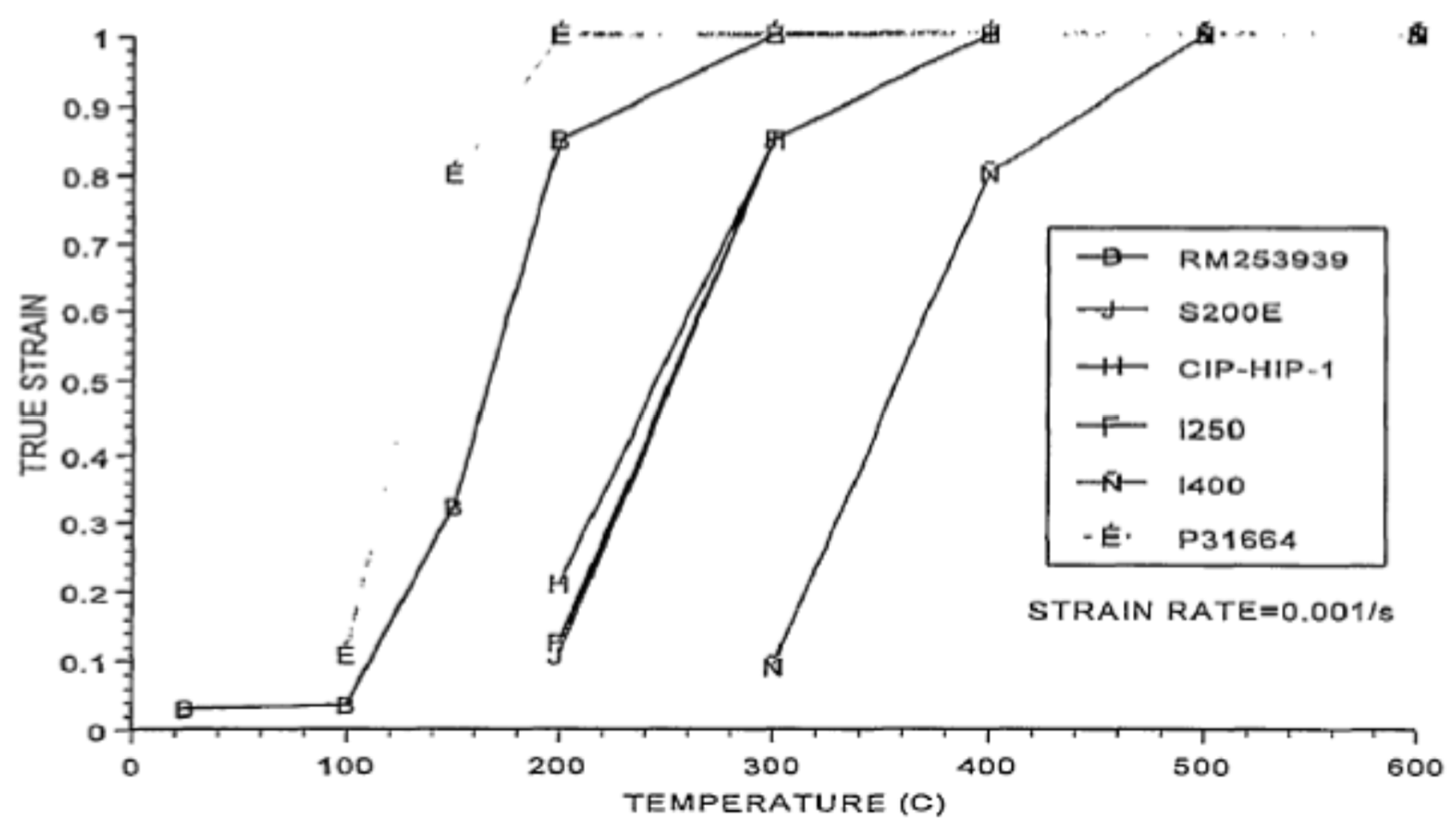

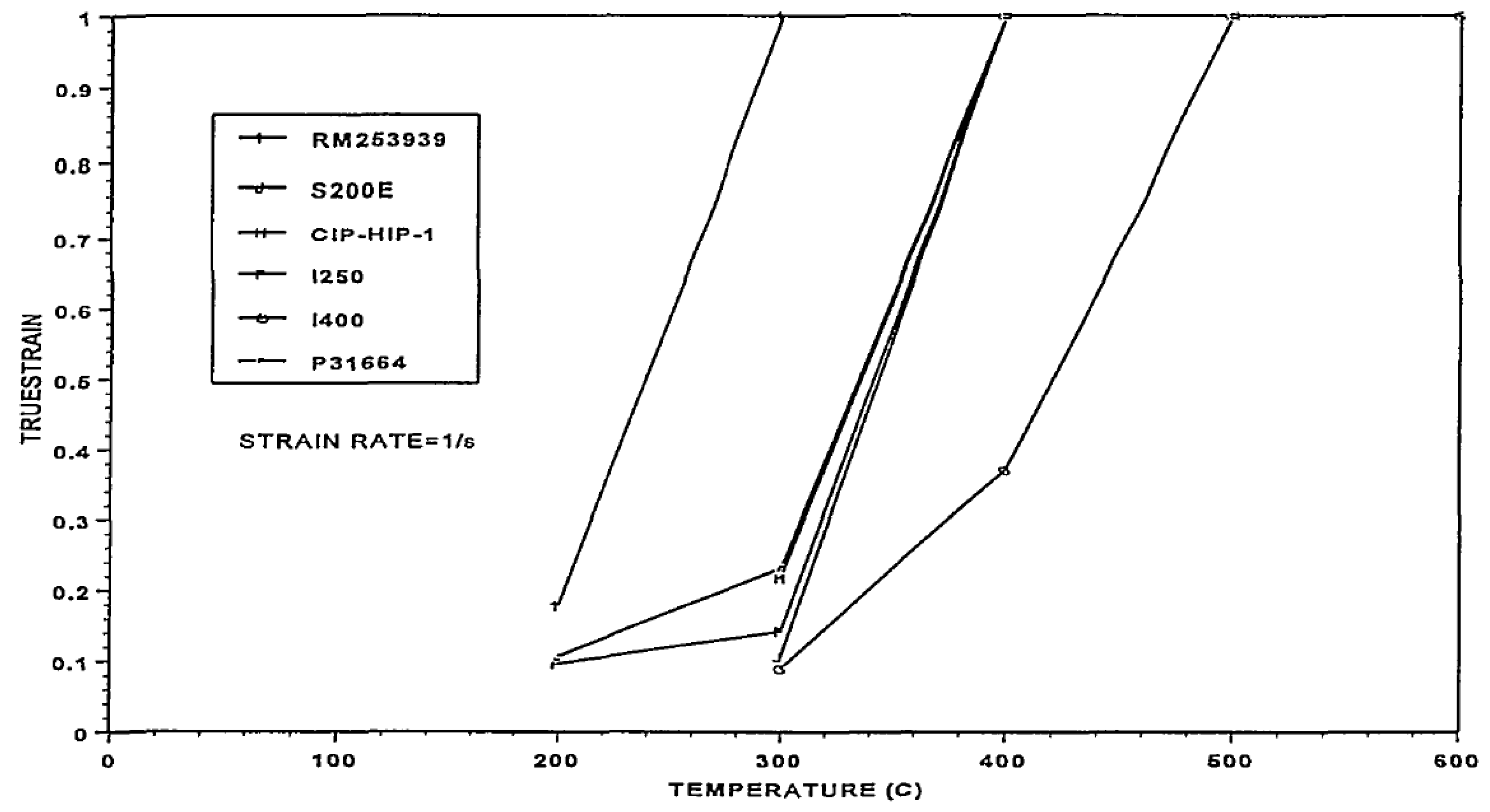

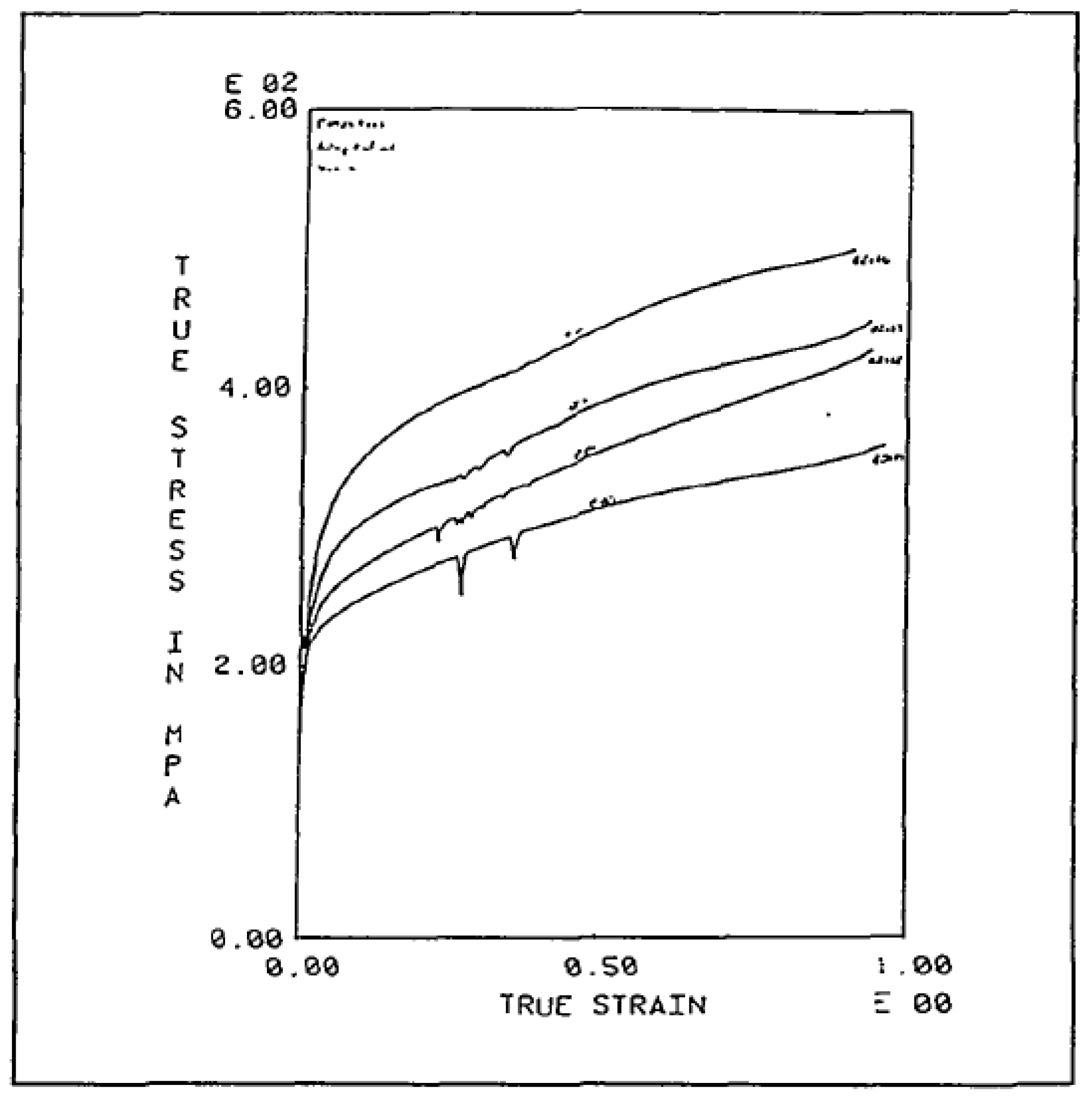

This DBTT is a strong function of strain rate [

12]. Following two figures (

Figure 3 and

Figure 4), shows effect of two different strain rates namely 0.001 and 1 s

-1 on DBTT of various Be samples. In both cases, true strain, or reduction in sample height at which failure occurs is plotted against temperature from 1000

oC (upper limit) to DBTT.

It can be easily inferred all materials tested at 0.001 / s strain rate failed from tensile hoop stresses and cracked along the compression specimen surface. DBTT range is from 400 to 100

oC. Strongest material exhibits highest DBTT [

2,

12,

13]. In case of

Figure 4 (strain rate 1 / s), lower limit of DBBT is raised to 200 with same upper limit of 400C. Fracture mode also slightly changed from tensile hoop stress fracture to adiabatic shear band failure at 45

o. Yield point variations were observed in various grades bearing various compositions. Flow stress and shape of flow curves varies considerably with grades due to variation in alloy content, size and distribution of BeO particles, aging precipitates, and grain size (

Figure 5).

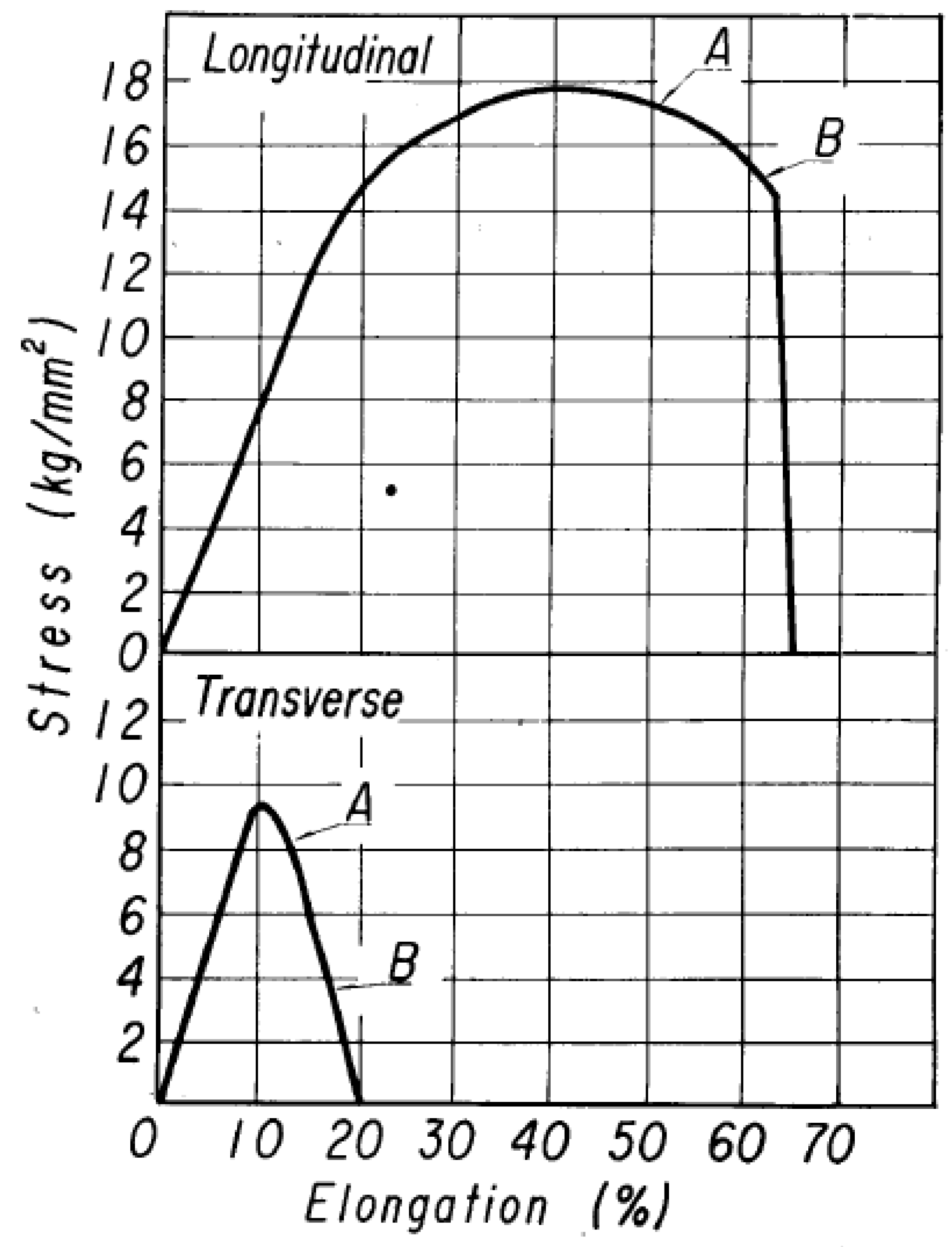

3.1. Anisotropy

DBTT is highly anisotropic [

13]. This is accounted by measuring its value in a rolled sheet subjected to tensile testing. It showed inferior tensile ductility in transverse direction to those in longitudinal direction in the temperature range of 100 – 400

oC. Even annealing after words does not improve much (

Figure 6).

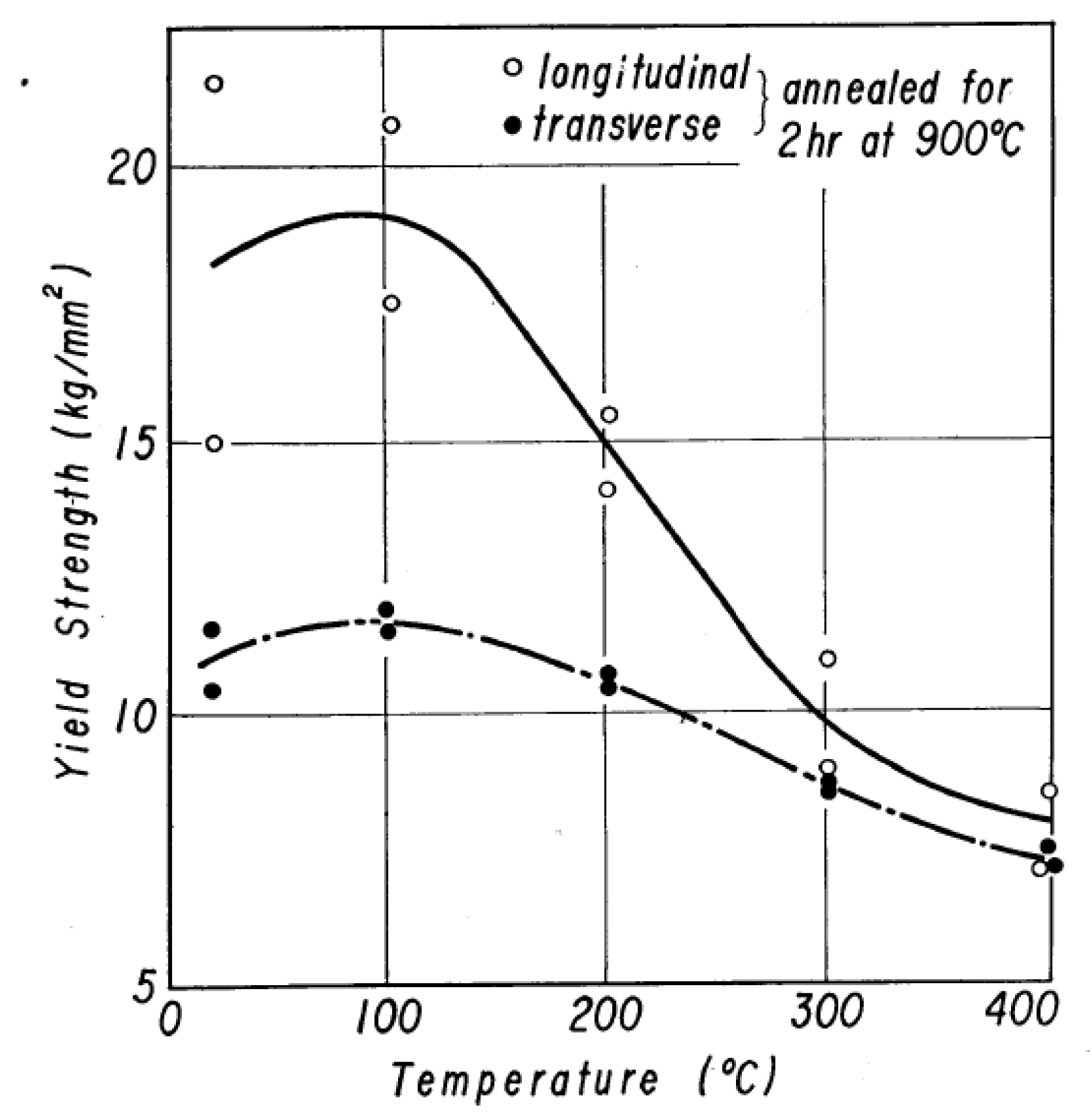

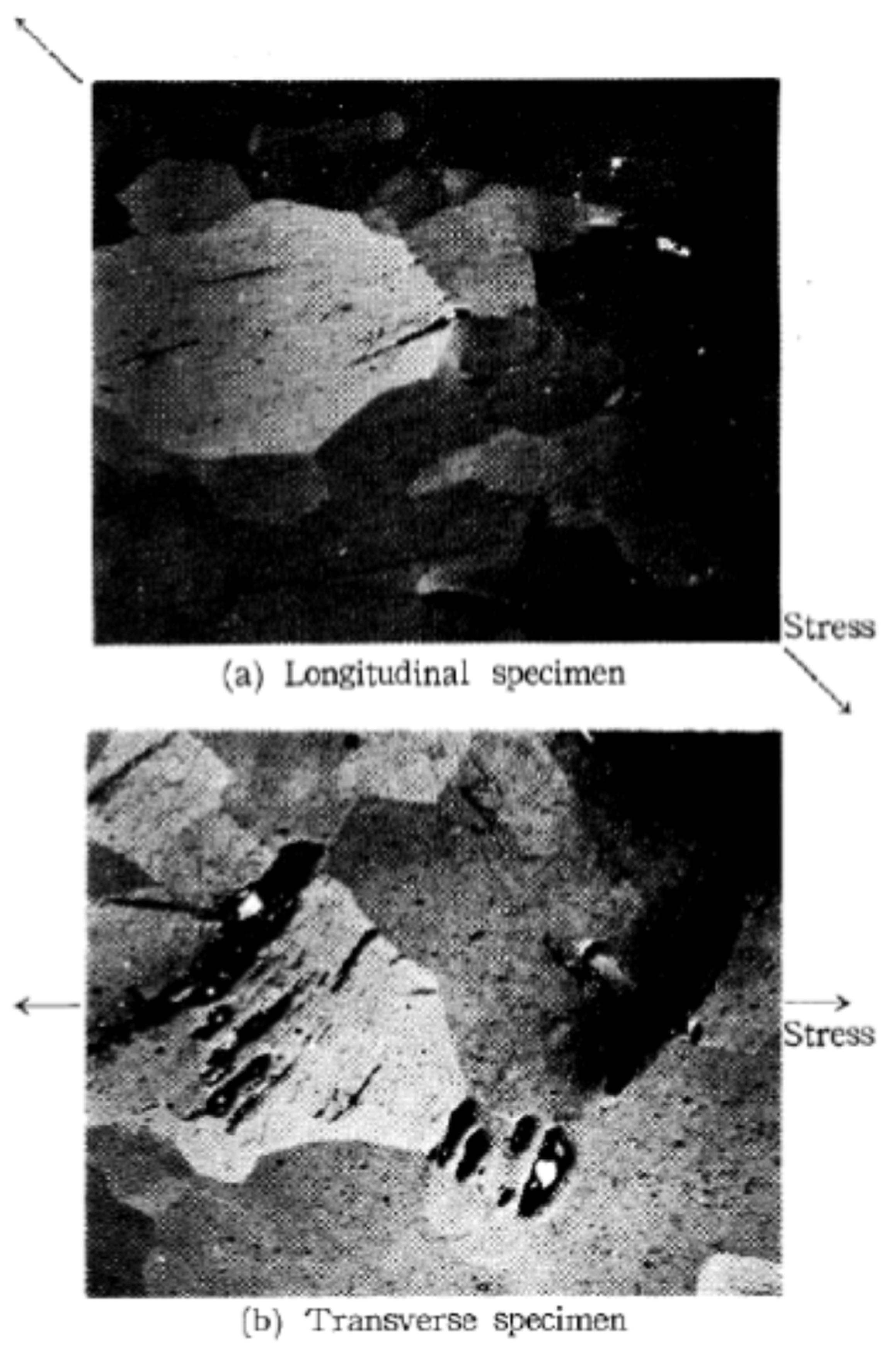

It can be easily observed that mechanical properties (Y.S, UTS and Percentage elongation) are considerably low along transverse direction. Following figure (

Figure 7) shows variation of yield strength with testing temperature for Be Sheets followed by their microstructures in

Figure 8a,b.

Trans granular cracks are easily observable in specimens which were strained till point A in Fig 6.

4. Conclusions

Following conclusion may be drawn

Beryllium is a hexagonal close packed (hcp) crystal structure metal. It is brittle at room temperature and its brittleness increases as temperature is lowered.

There are certain preferred planes along which deformation occurs by virtue of slip mechanisms. These are basal plane (0001), prismatic {11̅00} and pyramidal {11̅0𝑋}. Slip direction being one only <112̅0>.

Mostly slip occurs along basal plane, occasionally along prismatic at higher temperature and higher shear stress value (usually when stress for this (prismatic stress) exceeds critical resolved shear stress at basal plane (𝜎𝑏= 1.4 Kg / mm2)) while pyramidal plane is activated at very high temperatures only.

DBTT is highly anisotropic. Its lower value is observed along transverse direction with trnsgranular cracks as compared to longitudinal direction.

References

- Lagerberg, G., Metallurgical viewpoints on the brittleness of beryllium. 1960: Sweden. p. 24.

- Lott, L.A. LITERATURE SURVEY: PHYSICAL PROPERTIES OF LITHIUM AND BERYLLIUM AT LOW TEMPERATURES. 1967.

- Petch, N.J. and E. Wright, The Plasticity and Cleavage of Polycrystalline Beryllium. II. The Cleavage Strength and Ductility Transition Temperature. Proceedings of the Royal Society of London. Series A, Mathematical and Physical Sciences, 1980. 370(1740): p. 29-39. [CrossRef]

- Zhong, J.M., et al., Micro-yield behavior and mechanism of beryllium metal. 2004. 14: p. 1637- 1641.

- Goldberg, A., et al., Physical Metallurgy of Beryllium, in Beryllium Chemistry and Processing, E.E. Vidal, et al., Editors. 2009, ASM International. p. 0.

- Rengstorff, G.W.P., et al., High-purity Metals. 1966: Defense Metals Information Center, Battelle Memorial Institute.

- Commission, U.S.A.E., U.S.E. Research, and D. Administration, Nuclear Science Abstracts. 1959: Oak Ridge Directed Operations, Technical Information Division.

- Goldberg, A., Beryllium Manufacturing Processes. 2006: United States.

- Pugh, S., XCII. Relations between the elastic moduli and the plastic properties of polycrystalline pure metals. The London, Edinburgh, and Dublin Philosophical Magazine and Journal of Science, 1954. 45(367): p. 823-843. [CrossRef]

- Abeln, S.P., R. Field, and M.C. Mataya, Elevated temperature stress strain behavior of beryllium powder product. 1995: United States. p. 33.

- Henshall, G.A., S.G. Torres, and J.E. Hanafee, The elevated temperature tensile properties of S- 200E commercially pure beryllium. 1995: United States. p. 106-121.

- Conrad, H. and F.W. Cooke, The effects of temperature and strain rate on the strength of beryllium sheet. Metallurgical Transactions, 1971. 2(5): p. 1307-1313.

- Tsuya, K., Anisotropy of the Ductile-Brittle Transition Behavior of Beryllium Sheets. Journal of the Japan Institute of Metals, 1966. 30(4): p. 372-376.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).