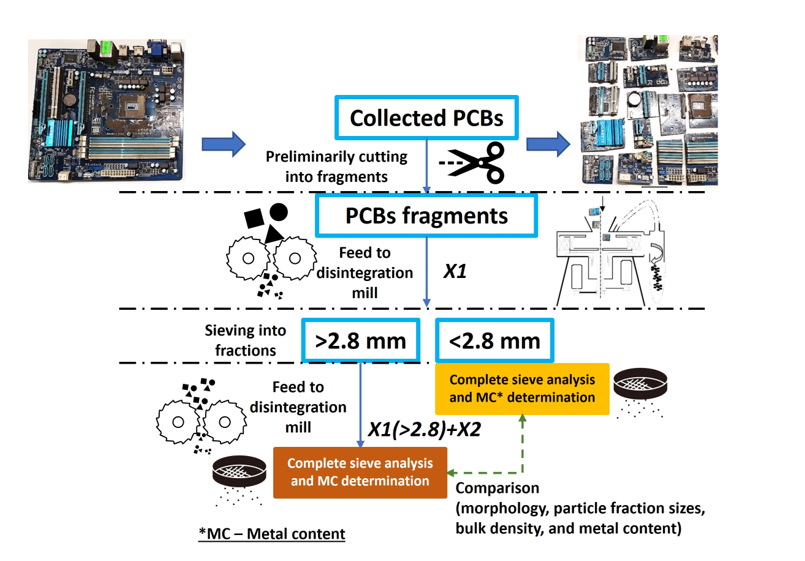

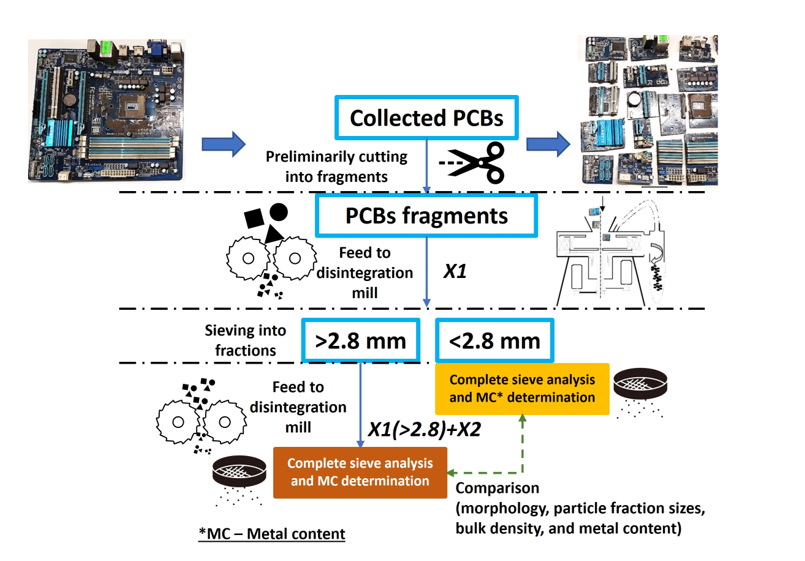

Various metals and semiconductors containing Printed Circuit Boards (PCBs) are abundant in any electronic device equipped with controlling and computing features. These devices inevitably constitute E-waste after the end of service life. The typical construction of PCBs includes mechanically and chemically resistive materials, which significantly reduce the reaction rate or even avoid accessing chemical reagents (dissolvents) to target metals. Additionally, the presence of relatively reactive polymers and compounds from PCBs requires high energy consumption and reactive supply due to the formation of undesirable and sometimes environmentally hazardous reaction products. Preliminarily milling PCBs into powder is a promising method for increasing the reaction rate and avoiding liquid and gaseous emissions. Unfortunately, current state-of-the-art milling methods also lead to the presence of significantly more reactive polymers still adhered to milled target metal particles. This paper aims to find a novel single and two-stage disintegration-milling approach that can provide the formation of metal-rich particle size fractions. The morphology, particle fraction sizes, bulk density, and metal content in produced particles were measured and compared. Research results show the highest bulk density (up to 6.8 g·cm-3) and total metal content (up to 95.2 wt. %) in finest sieved fractions after the single-step milling of PCBs. Therefore, the concentrations of about half tested metallic elements are higher in the single milled specimen and with lower adhered plastics concentrations, as compared to double milled specimens.