1. Introduction

Relative humidity (RH) and temperature are the two most important environmental parameters in many applications, such as monitoring the living conditions of manned spacecrafts, controlling specific chemical reactions, and managing certain hazardous article warehouse. Compared with electronic hygrometers, optical fiber humidity sensors have the advantages of electromagnetic interference resistance, high sensitivity, quick response and so on [

1,

2,

3]. Several kinds of fiber RH sensors have been reported, such as those based on tapered fiber [

4,

5], Mach-Zehnder interferometers [

6,

7,

8], Fabry-Perot interferometers (FPI) [

9,

10], optical fiber Bragg gratings [

11,

12], and microfiber knot resonators [

13]. However, these RH sensors lack the ability to measure the temperature simultaneously. Relative humidity is defined as the percentage of current water vapor pressure to the saturated water vapor pressure at the same temperature [

14]. This means that in order to ensure the accuracy of RH measurement, the corresponding temperature must be measured at the same time. In 2022, Li et al. [

15] proposed an optical fiber sensor based on cascaded C-shaped Fabry-Perot interferometers to measure RH and temperature simultaneously. However, the fabrication of the sensor is complex.

In this paper, a RH and temperature simultaneous measurement sensor with a very simple structure is proposed. The sensor was fabricated by curing two kinds of ultraviolet (UV) glue with different refractive indexes (RIs) to form two layers of polymer films with different thicknesses on the end face of a fiber patch cord. Thus, a cascaded Fabry-Perot interferometer (FPI) was formed. The change of the surrounding RH only influences the RI of the exterior layer, whereas temperature change affects the RIs of both layers. By solving a set of quadratic equations, RH and temperature can be demodulated simultaneously. The Vernier effect has also been utilized to enhance the sensitivity [

16,

17,

18].

2. Sensor Fabrication and Working Principle

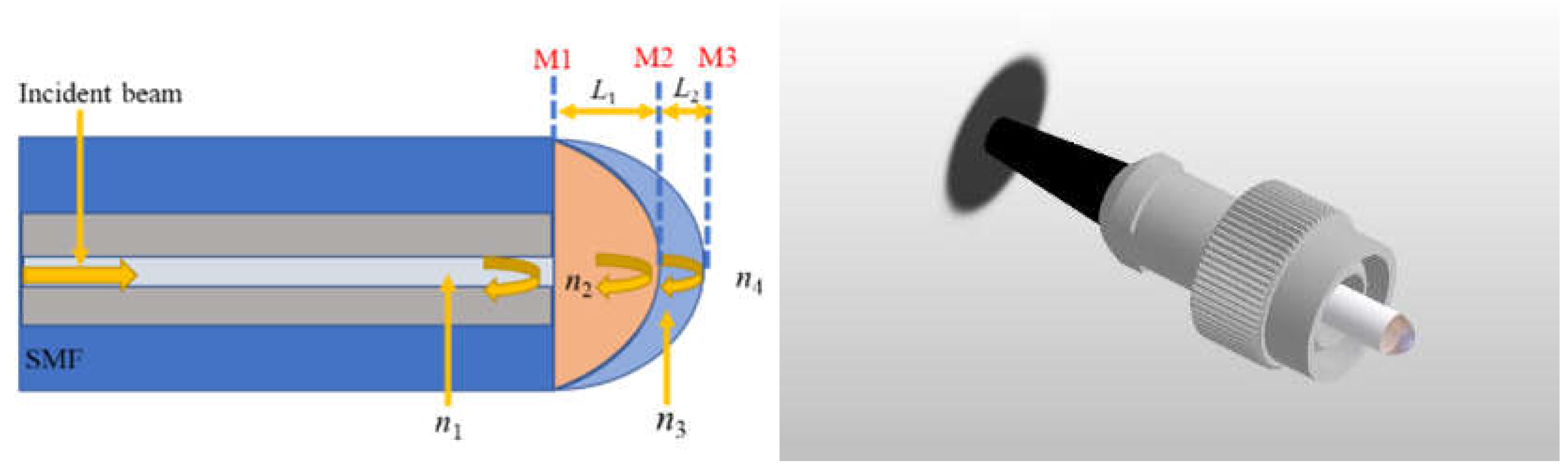

The schematic diagram and a 3D illustration of the sensor are shown in

Figure 1. Two polymer films were fabricated directly on the end face of a polished fiber patch cord with a FC connector. The fiber in the patch cord is standard singlemode fiber (SMF). In order to ensure a RI difference as large as possible and optimize the visibility of the interference spectrum, the UV glues of the first layer and second layer were choose to be PC 373 LD (Luvantix ADM inc.) and the NOA 144 (Norland Products inc.). The corresponding RIs are

and

, respectively. The fabrication process is as follows:

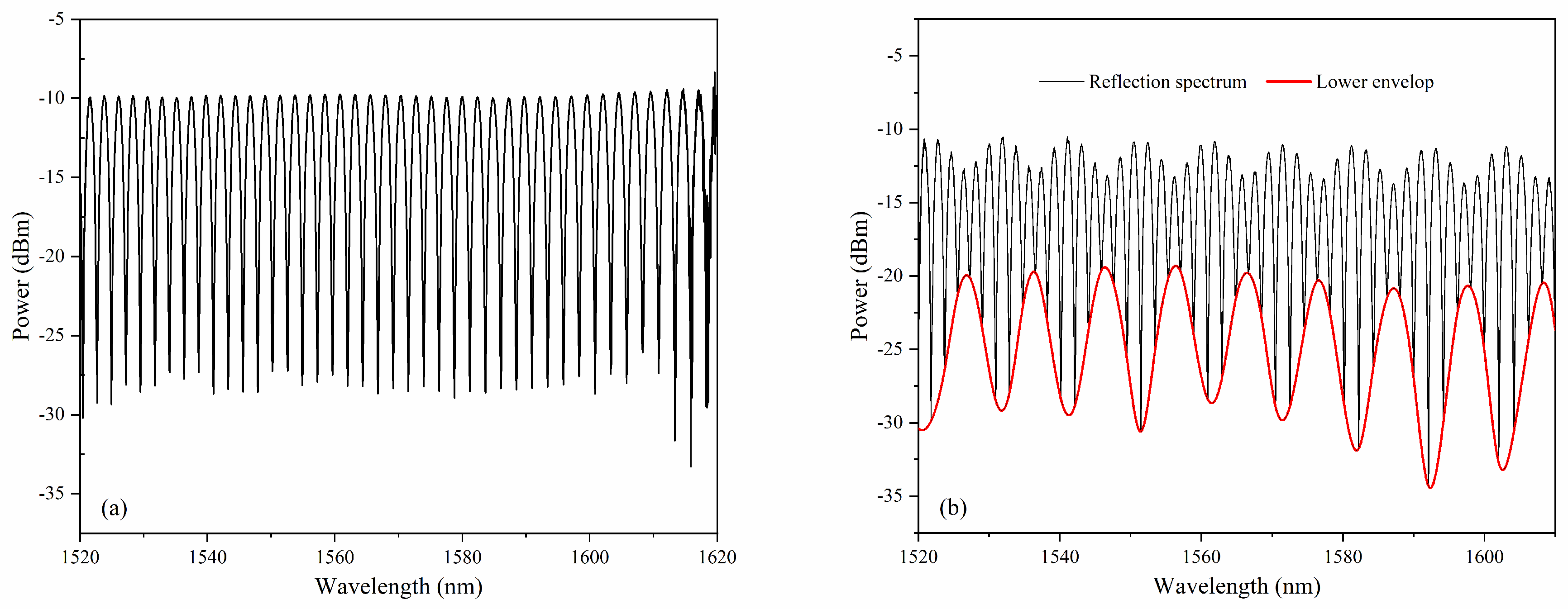

Firstly, a drop of the low RI glue was dropped on a slide. Then, the end face of the fiber patch cord was shallowly dipped into it vertically. A hemispherical film would be formed on the end face after the fiber was moved up, due to surface tension of the glue. During the whole process, the reflection spectrum was monitored in real-time by an optical spectrum analyzer (ADVANTEST Q8384). If the thickness of the film needs to be slightly adjusted, the connector can be turned bottom-up. Under the combined action of the viscosity of the glue and gravity, the thickness of the film will change slowly. When the desired spectrum was observed on the OSA, the UV light source was tuned on to cure the glue quickly. The reflection spectrum after the curing of the first layer is show in

Figure 2 (a). It can be seen that the peak-valley difference is about 20 dB.

The second layer was coated with the same procedure with the NOA 144. After coating the second layer, the reflection spectrum is show in

Figure 2(b). The envelop is formed by the Vernier effect of the cascaded FPIs.

As depicted in

Figure 1(a), Fresnel reflections from the three interfaces (M1, M2, and M3) forms three FPIs, i.e., FPI1 formed by M1 and M2, FPI2 formed by M2 and M3, and FPI3 formed by M1 and M3. The corresponding cavity length of the FPIs are

,

, and

, respectively. The electric field of the reflected beam can be expressed as [

17]:

Where

is the input electric field,

and

are the round-trip phase shift of FPI1 and FPI2, which can be expressed as:

and [

19]

where

and

are the transmission loss of FPI1 and FPI2, respectively, and

,

, and

are the reflection coefficients of M1, M2 and M3, which can be expressed as:

where

,

,

and

are the RIs of core of the SMF, low-RI polymer film, high-RI polymer film, and air, respectively, as shown in

Figure 1.

The relative intensity of the reflected beam can be expressed as:

The free spectrum range (FSR) of a single FPI can be expressed as:

where

is the frequency of the interference spectrum, which is the reciprocal of FSR.

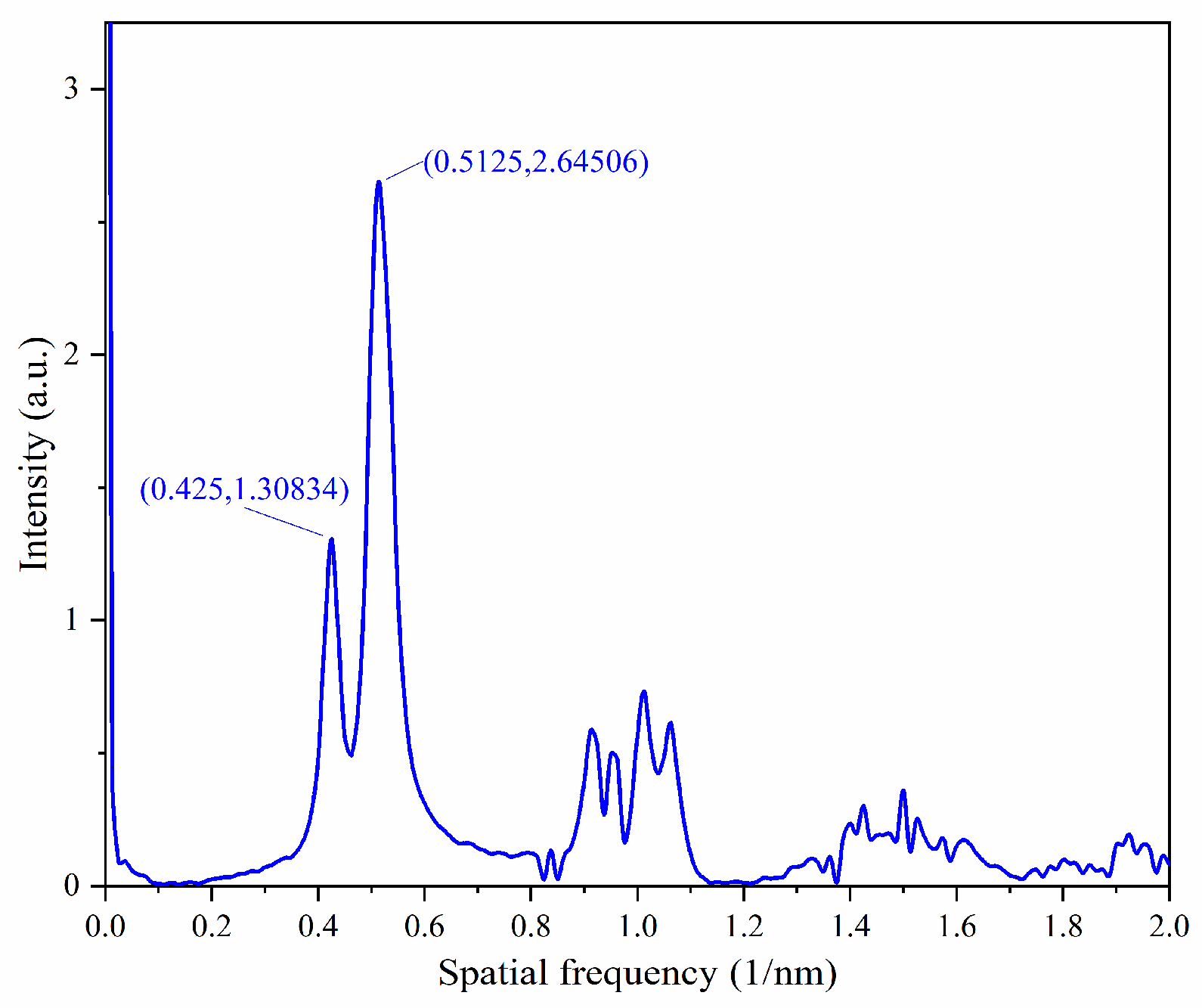

The Fast Fourier Transformation (FFT) of the reflection spectrum is shown in

Figure 3. It can be seen that the reflected beam is the superposition of two components with a small difference in frequency. The corresponding cavity lengths are 369.9μm and 442.5μm.This means that the reflection spectrum is mainly composed of the FPI1 and FPI3 [

17]. The length of the FPI2, i.e.,

L2 = 72.6 μm. Therefore, the FSR of the periodic envelope can be expressed as:

where

is the FSR of FPI1;

is the FSR of FPI3. Compared with a signle FPI3, the sensitivity is amplified

M times due to the Vernier effect, where

M can be expressed as follows

Clearly,

M is determined by the ratio of the optical path length of FPI1 and FPI2. For the sensor fabricated previously,

M is about 5.86. For FPI3, the center wavelength of the

mth dip of the interference fringes can be expressed as:

Because FPI1 is insensitive to RH, the RH shifts the spectrum mainly through the change of

and

. The humidity sensitivity

can be expressed as follows

The RH sensitivity is a combined effect of the RI and length change of the FPI2, after the film absorbs the water molecules. The temperature

can be deduced in a similar way, but now both cavities are sensitive to temperature. It can be expressed as follows

The temperature sensitivity is resulted from the thermal expansion and thermal optical effect of the polymer films.

3. Experimental Results and Discussion

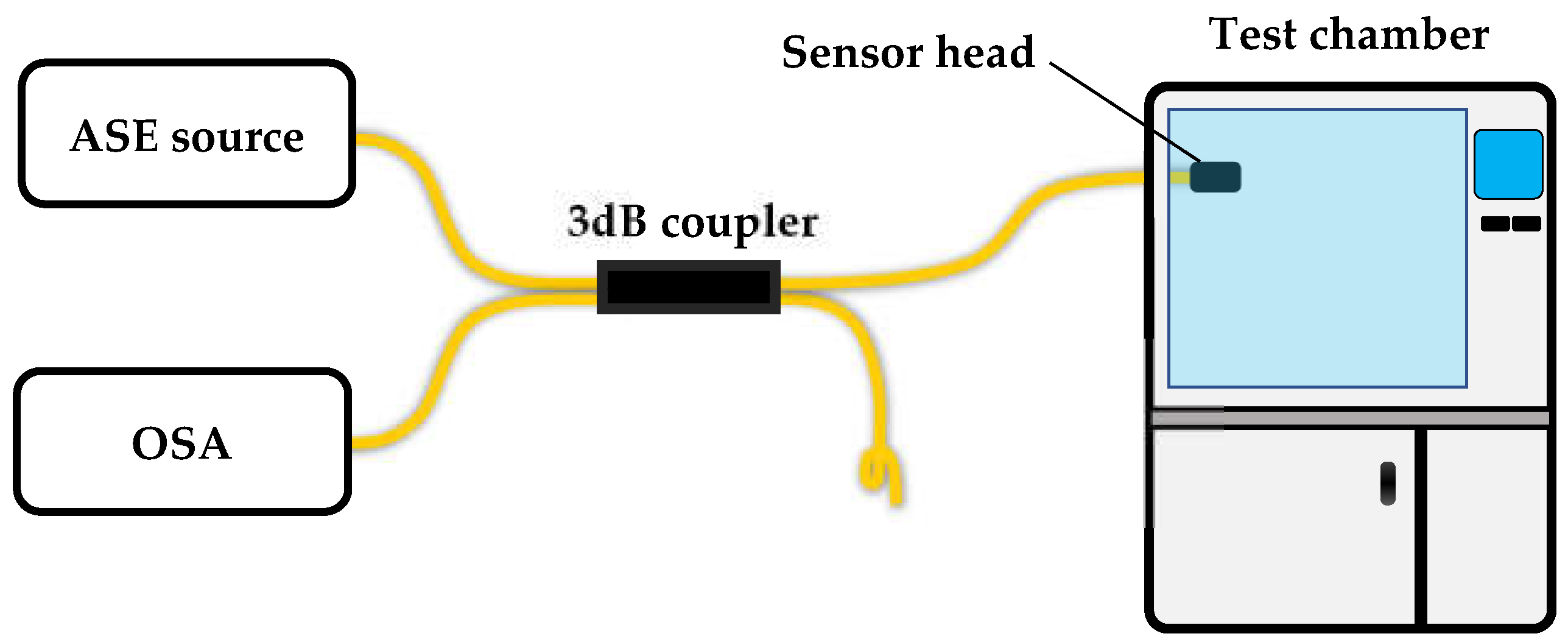

The experimental setup is shown in

Figure 4. The sensor was fabricated directly on the FC connector surface of one arm of a 2×2 3 dB coupler. The idle arm was tightly tied to suppress reflection. On the other side of the coupler, one arm was connected to a C+L band ASE light source and the other arm was connected to the optical spectrum analyzer (OSA, resolution 0.01nm). The sensor head was placed into a test chamber (SETH-A-040U) with a RH resolution of 1% and temperature resolution of 0.1°C. During the experiment, the temperature was tuned from 15 °C to 40 °C with a step of 5 °C. At each temperature, the RH was tuned from 20% to 90% with a step of 10%. The temperature range is mainly restricted by the characteristics of the UV glue. We found in this range the sensor has a good repeatability.

3.1. Humidity Response of the Sensor

As an example,

Figure 5 (a) shows spectra at RH values of 20%, 60%, and 80%, respectively, under the temperature of 30°C. In the spectral range, there plenty of peaks and dips on the envelope of the spectrum. Theoretically each of them can be tracked to demodulate the measurand. To investigate their difference, the peaks at 1545.1 nm and 1585.8 nm under the initial RH was examined. The wavelength of these peaks as a function of RH are plotted in

Figure 5(b) and (c), respectively. Firstly, we can see that the character wavelengths shift to the longer wavelength with the increasing of RH. Secondly, the

-RH relationship is nonlinear, which can be fitted very well with a quadratic polynomial. Thirdly, by taking the first-order derivative of the fitting equations shown in the figure, we can conclude: the sensitivity at a longer wavelength is higher than that at a shorter wavelength; and the RH sensitivity is linearly increasing with the RH. These features are common to other interferometric fiber sensors [

20,

21]. Thus, choosing a character wavelength at a longer wavelength is helpful to increase the sensitivity of the sensor. The highest RH sensitivities in the experimental range are 378.6 pm/RH and 387.3 pm/RH for the two peaks in the RH range.

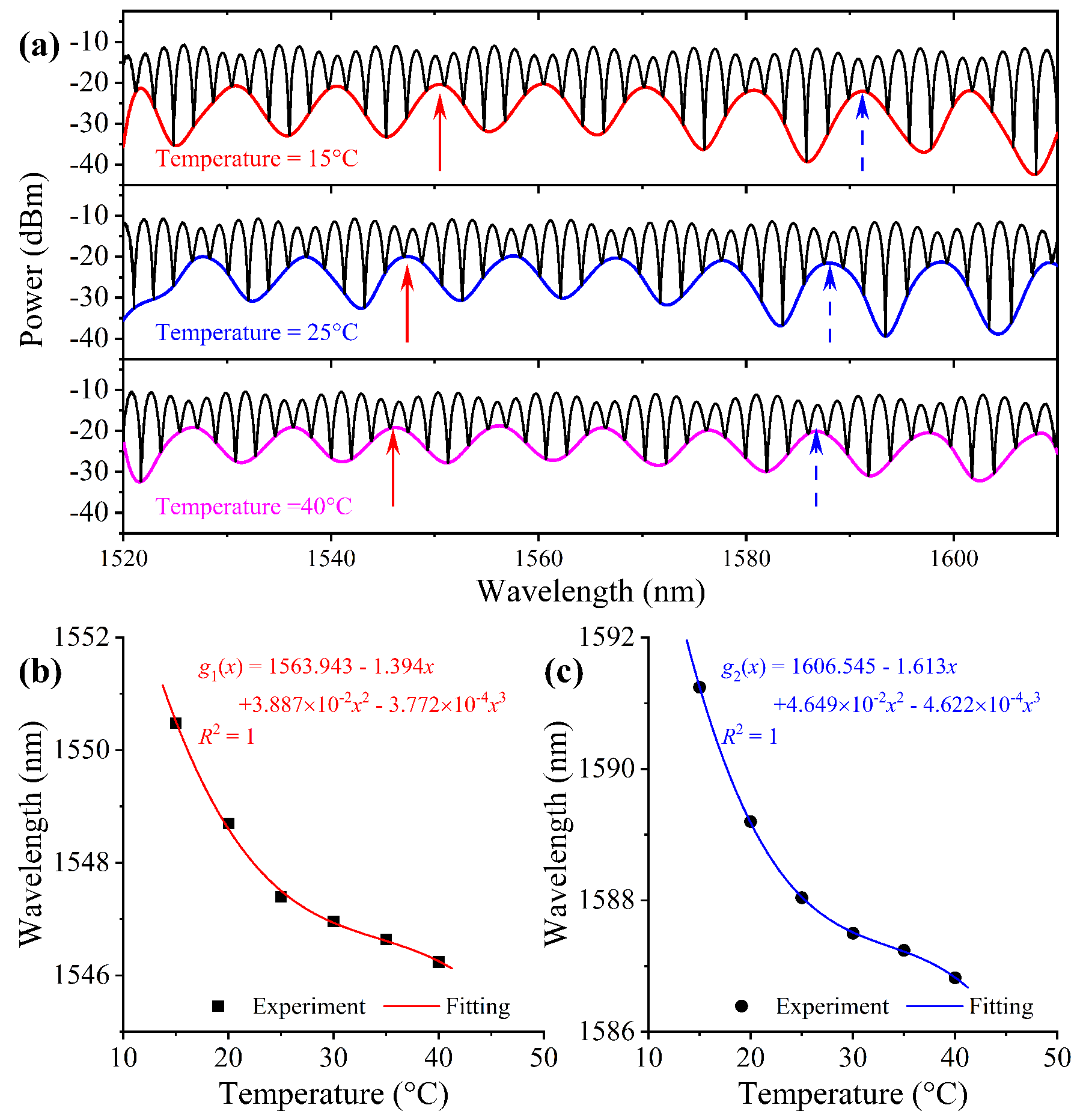

3.2. Temperature Response of the Sensor

Figure 6 (a) shows three typical spectra at 15 °C, 25 °C, and 40 °C, when the RH is 20%. We can see that, contrary to the RH response, blue shift occurs when the temperature increases.

Figure 6(b) and (c) are the

-

T relationship obtained from the two peaks as indicated in

Figure 6(a). Obviously, the

-

T relationship is nonlinear and the longer wavelength peak has a higher temperature sensitivity. The curves can be perfectly fitted with a cubic polynomial. We believe the temperature response, as well as the RH response discussed previously, is closely related to the property of the UV glues selected to make the film. Thus, sensors with specific materials need to be calibrated specifically, but the working principle should be in common as long as the same design is used. The highest temperature sensitivities in the experimental range are -482.5 pm/°C and -533.0 pm/°C for the two peaks in the temperature range.

3.3. Simultaneous mearment method

Because both the humidity and temperature response of the sensor are nonlinear, as reveled by the above experimental results, it is required that two feature wavelengths be characterized in the calibration of the sensor, in order to demodulate the two measurands simultaneously. After calibration, fitting functions as shown in

Figure 5 and

Figure 6 can be obtained. Then, the wavelength shifts of the two peaks under the combined influence of temperature and humidity can be expressed as:

Where 20% and 30 °C are the RH and temperature at which the sensor was calibrated. This is a set of two equation in two unknowns. With the measured and , temperature and RH can be obtained by solving Eq.(12).

4. Conclusions

In conclusion, a fiber sensor for the simultaneous measurement of RH and temperature has been proposed and experimentally investigated in this paper. The sensor was fabricated by simply curing two kinds polymer films with different RIs and thicknesses on the end face of FC path cord. Simultaneous of the two measurands was accomplished by calibrating two feature wavelengths on the envelope of the reflection spectrum and then solving a set of nonlinear equations. The sensor employs the advantage of the Vernier effect to enhance the sensitivity. For the sensor fabricated in this paper, the highest RH and temperature achieved in the experimental range are 387.3 pm/%RH and -533.0 pm/°C, respectively. The sensor can find applications in monitoring RH and temperature of special environment, such as that of manned crafts, chemical reactions, and explosive warehouse, etc.

Author Contributions

Conceptualization, Q.H. and T.Z.; methodology, Q.H; validation, T.Z. and Z.L.; investigation, T.Z.; resources, Q.H.; data curation, Z. L.; writing—original draft preparation, T.Z.; writing—review and editing, Q.H.; supervision, Z.C.; project administration, Q.H.; funding acquisition, J.J. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the National Key Research and Development Program of China under Grant 2022YFF0706003, and the National Natural Science Foundation of China under Grant 62175179.

Data Availability Statement

Not applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Shimura, Y.; Suzuki, Y.; Morisawa, M. Improving Measurement Range of a Swellable Polymer-Clad Plastic Fiber Optic Humidity Sensor by Dye Addition. Sensors 2022, 22, 6315. [Google Scholar] [CrossRef] [PubMed]

- Xiang, S.; You, H.; Miao, X.; Niu, L.; Yao, C.; Jiang, Y.; Zhou, G. An Ultra-Sensitive Multi-Functional Optical Micro/Nanofiber Based on Stretchable Encapsulation. Sensors 2021, 21, 7437. [Google Scholar] [CrossRef] [PubMed]

- Rao, X.; Zhao, L.; Xu, L.K.; Wang, Y.H.; Liu, K.; Wang, Y.; Chen, G.R.Y.; Liu, T.Y.; Wang, Y.P. Review of Optical Humidity Sensors. Sensors 2021, 21, 61. [Google Scholar] [CrossRef] [PubMed]

- Batumalay, M.; Lokman, A.; Ahmad, F.; Arof, H.; Ahmad, H.; Harun, S.W. Tapered Plastic Optical Fiber Coated With HEC/PVDF for Measurement of Relative Humidity. IEEE Sens. J. 2013, 13, 4. [Google Scholar] [CrossRef]

- Li, J.; Liu, X.; Sun, H.; Wang, L.; Zhang, J.; Deng, L.; Ma, T. An Optical Fiber Sensor Coated with Electrospinning Polyvinyl Alcohol/Carbon Nanotubes Composite Film. Sensors 2020, 20, 6996. [Google Scholar] [CrossRef] [PubMed]

- Lokman, A.; Arof, H.; Harun, S.W.; Harith, Z.; Rafaie, H.A.; Nor, R.M. Optical Fiber Relative Humidity Sensor Based on Inline Mach-Zehnder Interferometer With ZnO Nanowires Coating. IEEE Sens. J. 2016, 16, 312–316. [Google Scholar] [CrossRef]

- Cheng, X.; Hu, J.H.; Zhu, K.; Zhao, Z.Y. High-resolution polymer optical fibre humidity sensor utilizing single-passband microwave photonic filter. Measurement 2021, 179, 8. [Google Scholar] [CrossRef]

- Wang, Z.H.; Li, L.Q.; Wang, M.J.; Ma, Q.Q.; Lou, Y.; Wu, Q.; Peng, B.J. Fiber Core-Offset Humidity Sensor Based on Graphene Oxide Characteristics. IEEE Photonics J. 2021, 13, 9. [Google Scholar] [CrossRef]

- Vaz, A.; Barroca, N.; Ribeiro, M.; Pereira, A.; Frazao, O. Optical Fiber Humidity Sensor Based on Polyvinylidene Fluoride Fabry-Perot. IEEE Photonics Technol. Lett. 2019, 31, 549–552. [Google Scholar] [CrossRef]

- Su, D.; Qiao, X.G.; Rong, Q.Z.; Sun, H.; Zhang, J.; Bai, Z.Y.; Du, Y.Y.; Feng, D.Y.; Wang, Y.P.; Hu, M.L.; et al. A fiber Fabry-Perot interferometer based on a PVA coating for humidity measurement. Opt. Commun. 2014, 311, 107–110. [Google Scholar] [CrossRef]

- Swanson, A.J.; Raymond, S.G.; Janssens, S.; Breukers, R.D.; Bhuiyan, M.D.H.; Lovell-Smith, J.W.; Waterland, M.R. Investigation of polyimide coated fibre Bragg gratings for relative humidity sensing. Meas. Sci. Technol. 2015, 26, 9. [Google Scholar] [CrossRef]

- Saini, P.K.; Prakash, O.; Kumar, J.; Purbia, G.S.; Mukherjee, C.; Dixit, S.K.; Nakhe, S.V. Relative humidity measurement sensor based on polyvinyl alcohol coated tilted fiber Bragg grating. Meas. Sci. Technol. 2021, 32, 11. [Google Scholar] [CrossRef]

- Le, A.D.D.; Han, Y.G. Relative Humidity Sensor Based on a Few-Mode Microfiber Knot Resonator by Mitigating the Group Index Difference of a Few-Mode Microfiber. J. Lightwave Technol. 2018, 36, 904–909. [Google Scholar] [CrossRef]

- Wang, B.; Tian, J.J.; Hu, L.; Yao, Y. High Sensitivity Humidity Fiber-Optic Sensor Based on All-Agar Fabry-Perot Interferometer. IEEE Sens. J. 2018, 18, 4879–4885. [Google Scholar] [CrossRef]

- Li, F.; Li, X.G.; Zhou, X.; Zhang, Y.N.; Lv, R.Q.; Zhao, Y.; Xie, L.S.; Nguyen, L.V.; Ebendorff-Heidepriem, H.; Warren-Smith, S.C. Simultaneous Measurement of Temperature and Relative Humidity Using Cascaded C-shaped Fabry-Perot interferometers. J. Lightwave Technol. 2022, 40, 1209–1215. [Google Scholar] [CrossRef]

- Hou, L.Y.; Zhao, C.L.; Xu, B.; Mao, B.N.; Shen, C.Y.; Wang, D.N. Highly sensitive PDMS-filled Fabry-Perot interferometer temperature sensor based on the Vernier effect. Appl. Optics 2019, 58, 4858–4865. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, X.X.; Lv, R.Q.; Li, G.L.; Zheng, H.K.; Zhou, Y.F. Highly Sensitive Reflective Fabry-Perot Magnetic Field Sensor Using Magnetic Fluid Based on Vernier Effect. IEEE Trans. Instrum. Meas. 2021, 70, 8. [Google Scholar] [CrossRef]

- Li, Y.; Zhao, C.; Xu, B.; Wang, D.; Yang, M. Optical cascaded Fabry–Perot interferometer hydrogen sensor based on vernier effect. Opt. Commun. 2018, 414, 166–171. [Google Scholar] [CrossRef]

- Shi, J.; Xu, D.; Xu, W.; Wang, Y.; Yan, C.; Zhang, C.; Yan, D.; He, Y.; Tang, L.; Zhang, W.; et al. Humidity Sensor Based on Fabry–Perot Interferometer and Intracavity Sensing of Fiber Laser. J. Lightwave Technol. 2017, 35, 4789–4795. [Google Scholar] [CrossRef]

- Chen, Y.; Han, Q.; Liu, T.; Xiao, H. Wavelength Dependence of the Sensitivity of All-Fiber Refractometers Based on the Singlemode–Multimode–Singlemode Structure. IEEE Photonics J. 2014, 6, 1–7. [Google Scholar] [CrossRef]

- Chen, Y.; Han, Q.; Liu, T.; Lü, X. Self-temperature-compensative refractometer based on singlemode–multimode–singlemode fiber structure. Sensors and Actuators B: Chemical 2015, 212, 107–111. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).