1. Introduction

One of The Goals of Sustainable Development were set up in 2015 by the United Nations General Assembly is the fight against hunger, which includes ensuring food security [1, 2]. An important problem threatening food safety is the formation of biofilms and the spread of pathogenic bacteria in the premises for the production and storage of food, as well as on equipment for its transportation [3, 4]. Processing of production shops with formulations based on low molecular weight antibiotics may not lead to the desired result, since some biocides have low adhesion to the treated surfaces and, as a result, require frequent renewal. In addition, bacteria can rapidly develop resistance to low molecular weight biocides [5, 6]. Polymers have proven themselves as new antibacterial functional coatings. As a rule, in such cases, the polymers are the matrix for low molecular weight biocides, which give the coating durability, but do not have an antibacterial effect on their own [7]. Also, in most research works, such coatings are the product of a complex and expensive synthesis [8].

It is important to create affordable and cheap antibacterial compositions. In this regard, special attention should be paid to coatings from interpolyelectrolyte complexes (IPECs) [9]. Biocidal compositions based on IPEC with a predominance of cationic groups have regions with free charged groups capable of providing a biocidal effect and adhesion to hydrophilic surfaces, as well as hydrophobic regions that increase adhesion to hydrophobic surfaces and make it possible to modify such systems with low molecular weight antibacterial agents.

Most of the works aimed at the creation of biocidal coatings from IPEC investigate coatings obtained by layer-by-layer deposition [10, 11, 12]. However, the most promising from a practical point of view is the method of obtaining a coating by applying a prepared solution of water-soluble IPEC onto a substrate. It has been found that polydiallyldimethylammonium chloride (PDADMAC) and sodium polystyrene sulfonate (PSS) coatings can be prepared from a ready solution of the complex on various types of surfaces, both hydrophilic and hydrophobic, and that such coatings are resistant to water wash-off. Such coatings are of great interest, since, as is known from the literature, PDADMAC itself has a high biocidal activity [13, 14]. Thus, coatings based on PDADMAC with PSS with an included antibiotic will have both washout resistance and dual biocidal action.

However, there is a big question about the optimal degrees of polymerization of polymers required to create such coatings. In particular, the main task is to establish the role of the molecular weight of the predominant polycation in the complex - PDADMAC.

In this paper, we will try to consider the main properties of coatings based on PDADMAC with different molecular weights and make an assumption about the choice of the degree of polymerization for creating stable antibacterial coatings.

2. Materials and Methods

2.1. Materials

The samples of polydiallyldimethylammonium chloride (PDADMAC) with average molecular mass M = 400–500 kDa (PDADMAC400), M = 200–300 kDa (PDADMAC300) and M < 100 kDa (PDADMAC100) were used as received from Sigma-Aldrich (St. Louis, MO, USA).

Glass cover slips with an area of 3.24 cm2 were used in the experiments to wash-off the polymer films. Glass slides with an area of 19.76 cm2 were used to study the moisture saturation and adhesive properties of coatings. Cleaning and preparation of the glass surfaces was carried out as follows: the substrate was dipped in methanol and vigorously shaken for a minute. After that, the glass was treated with 1 M KOH solution, then washed with bidistilled water and dried. Bidistilled water with conductivity 0.05 μS/cm was used in all the experiments.

2.5. Methods

PDADMAC Coatings Wash-Off Procedure. Freshly cleaned substrate (glass coverslip) with 3.24 cm2 area was weighed. The 200 μL aliquote of the 20 mg/mL solution of polymer was deposited on the substrate so that all the area was covered with the solution. The sample was left to dry overnight. The prepared sample was weighted once again and the mass of the film was calculated as the difference between the masses of substrate with film and bare substrate. Each cycle of wash-off was as follows: 200 μL of water was applied to the glass, with coating, so that it completely covered the surface of the film. After two minutes of incubation the liquid was eliminated and the sample was left to dry. The sample was weighted and the mass loss was calculated. The experiments were carried out at a relative humidity of 15-20%.

PDADMAC Coatings Moisture Saturation Research. Freshly cleaned substrate (glass slide) with 19.76 cm2 area was weighed. The 1220 μL aliquote of the 20 mg/mL solution of polymer was deposited on the substrate so that all the area was covered with the solution. The sample was left to dry overnight in an oven with 5% relative humidity. The prepared sample was weighted once again, the mass of the film was calculated as the difference between the masses of substrate with film and bare substrate, and this value was used as a reference. Then the sample was kept in a chamber with different relative humidity of the environment for 24 hours and weighed again. The weight gain of the coating after incubation in the environment with controlled humidity was used to estimate the capacity of the polymer coating to absorb water from air.

The gravimetry analyzes were made using precise balances VLA-120 M by Gosmetr (Saint Petersburg, Russia).

PDADMAC Coatings Adhesive Properties Research. Freshly cleaned substrate (glass slide) with 19.76 cm2 area was weighed. The aliquote of the 20 mg/mL solution of polymer was deposited on the substrate so that all the area was covered with the solution. Two minutes later, the polymer solution was removed and the substrate was washed with bidistilled water. Then, the glass slide was also covered with pre-cleaned glass from above and dried for 24 hours. After complete drying, the adhesive properties of the polycations were evaluated by the stress required to separate the two glass substrates. The experiments were carried out at a relative humidity of 15-20%. The adhesive properties were evaluated by dynamometry on a tensile testing machine by Metrotest (Moscow, Russia).

Estimation of minimal inhibitory concentrations (MIC) of PDADMAC. The estimation of MIC values was made for Gram-positive bacterias B. subtilis in LB medium and in Tryptic Soy Broth (TBS) medium. The last one medium is favorable for the biofilm formation. The MICs in LB and TSB medium were determined using a broth microdilution assay [15]. The cell concentration was adjusted to approximately 5 × 105 cells/ml. The tested compound was serially diluted twofold in a 96-well microplate (100 μl per well). The microplates were covered and incubated at 37 °C with shaking. The OD600 of each well was measured, and the MIC was assigned as the lowest concentration of the tested compound that resulted in no growth after 16–20 h. Bacterial cell growth was measured at 590 nm using a microplate reader (VICTOR X5 Light Plate Reader, PerkinElmer, Waltham, MA, USA).

Statistical analysis. The average results of at least five experiments are presented as mean values.

3. Results

3.1. Wash-off Resistance Study

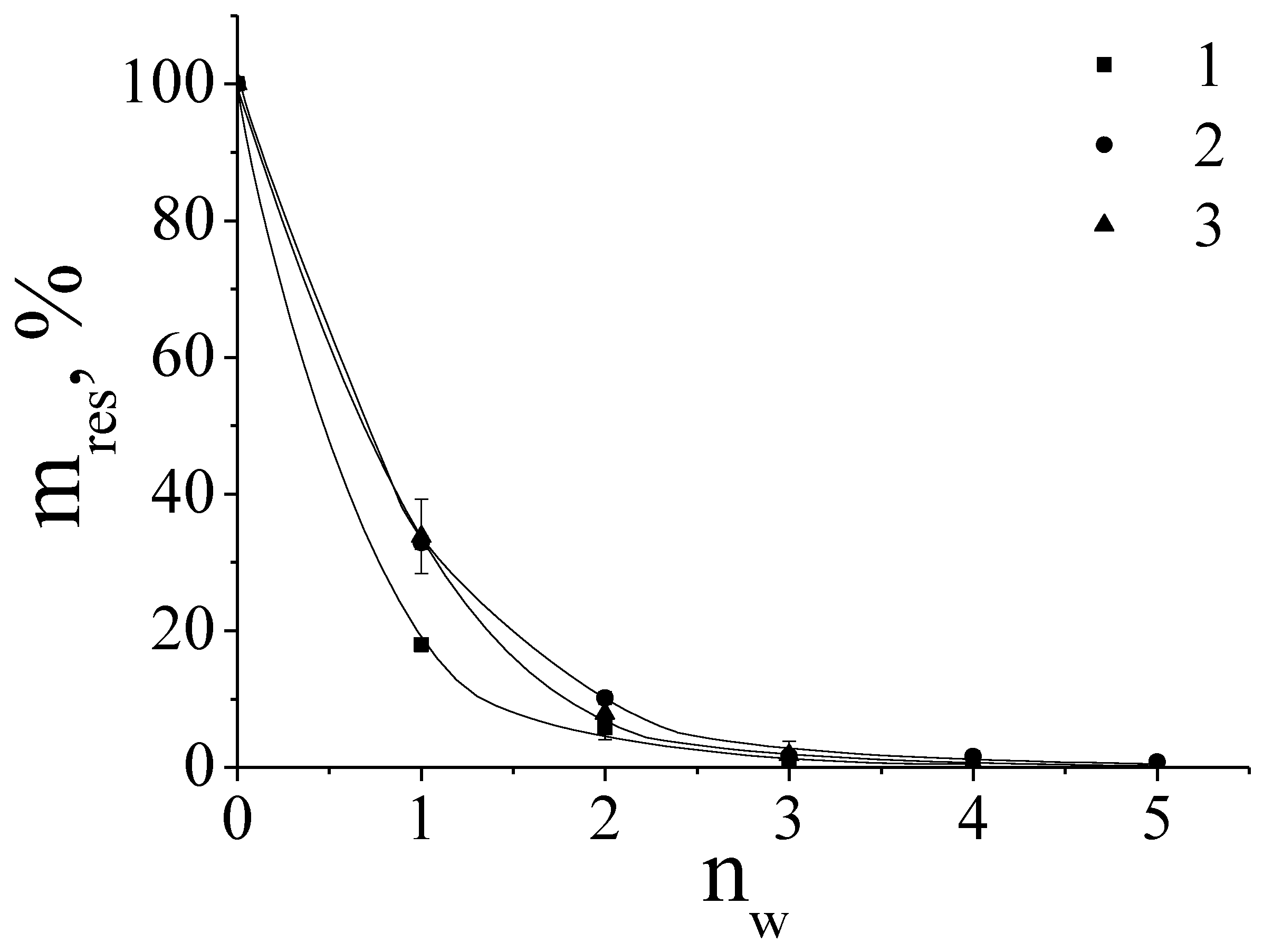

The resistance of the polymers films towards wash-off with water was monitored by the weight loss of the sample. The results are presented in

Figure 1. For the PDADMAC200 and PDADMAC400, about 65% of weight loss was observed after the first wash-off cycle and almost all polycation had vanished after four cycles of the wash-off. In contrast, the PDADMAC100 lost about 80% of its coating mass after the first wash-off cycle.

3.2. Estimation of Moisture Saturation of Coatings

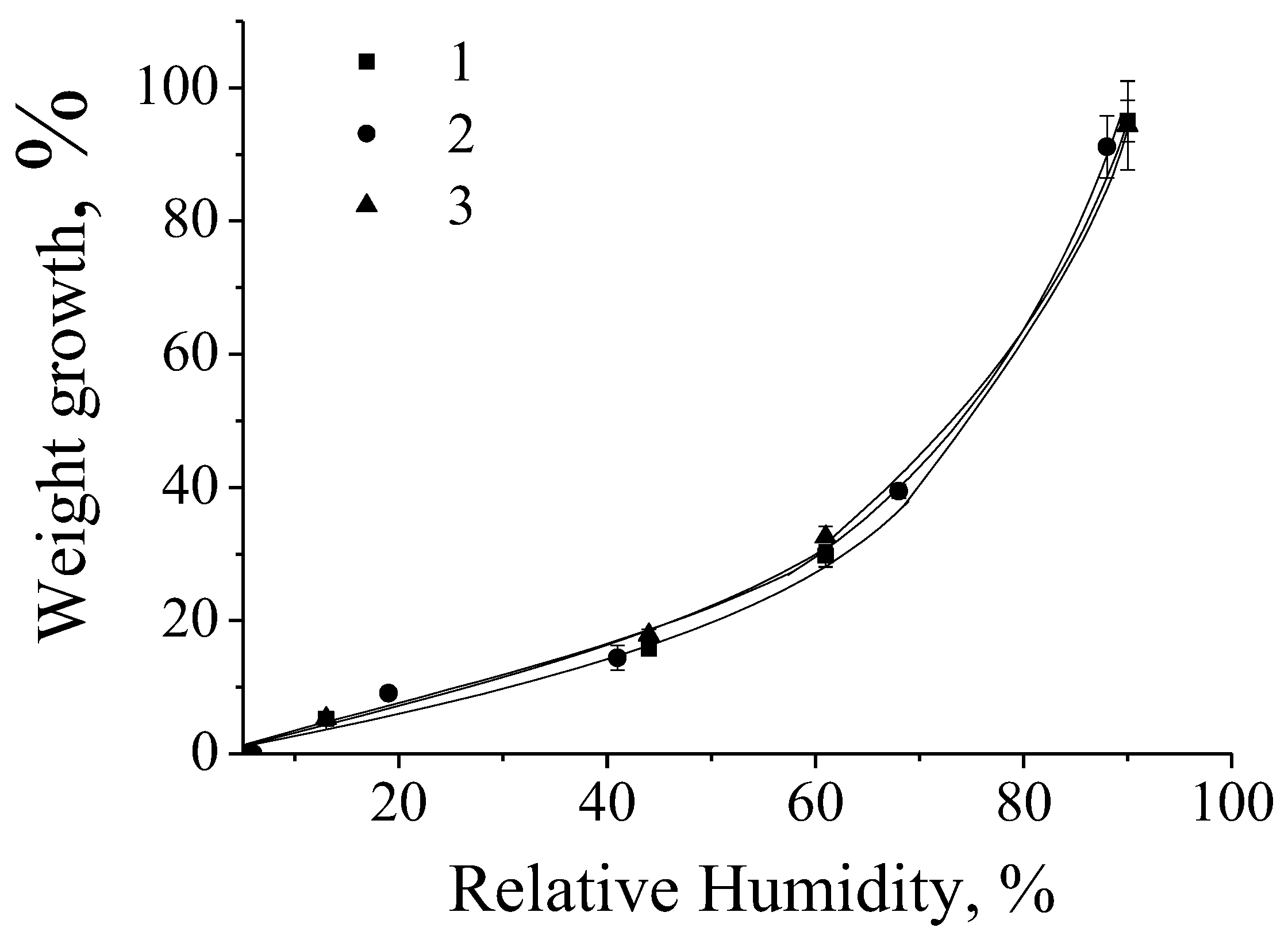

Further, an ability of the PDADMAC coating to absorb water from environment was tested. The results are presented in

Figure 2. It has been established that an increase in humidity from 15 to 70% leads to a gradual increase in the weight of the coating from 5 to 40%. The curves completely coincided for polymers of different molecular weights. The film adsorbed on the glass surface did not change its shape during the experiment.

3.3. Study of Adhesive Properties

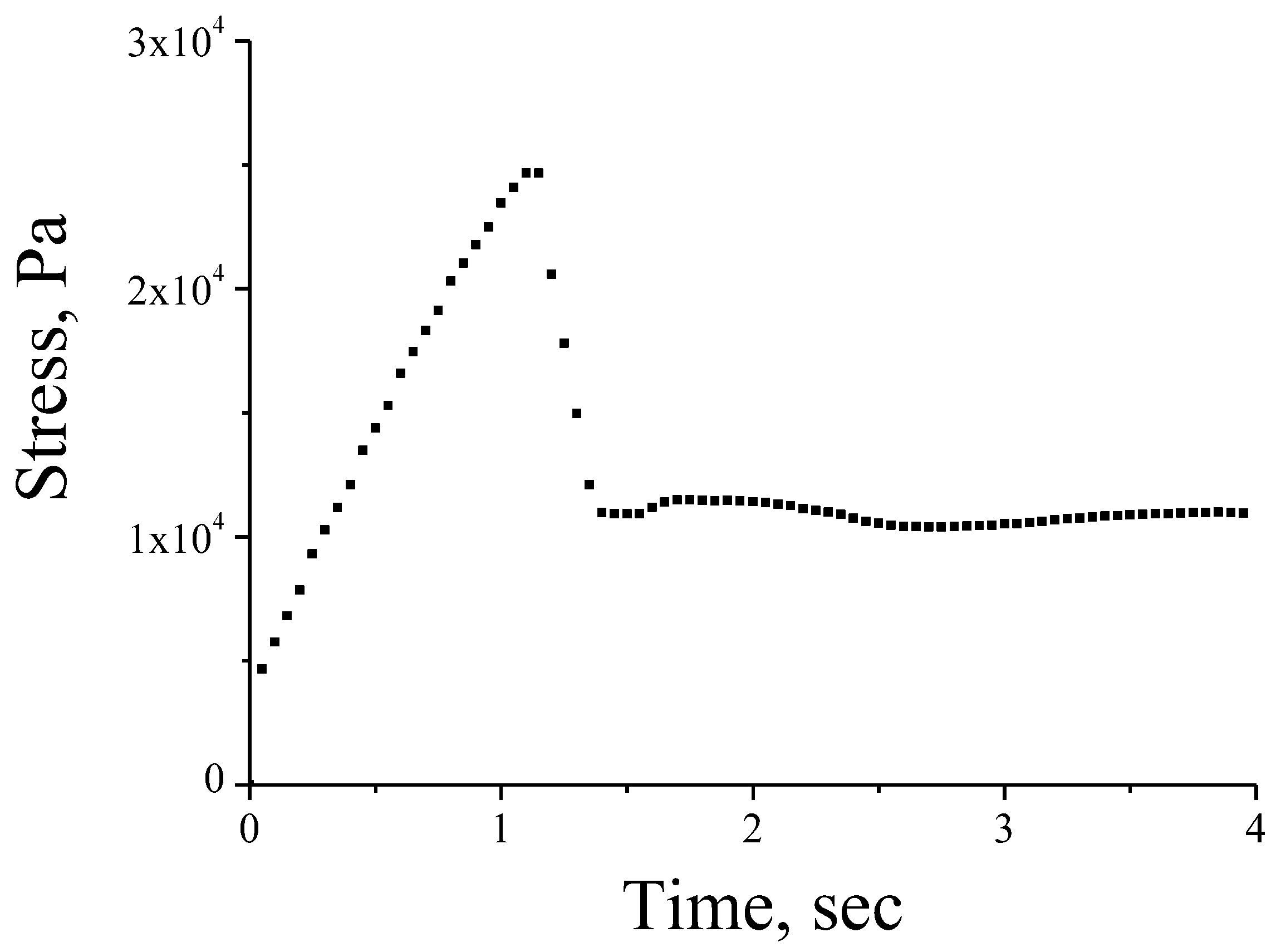

To evaluate the adhesive properties of coatings formed from PDADMAC of different molecular weights, the dynamometry method was used.

Figure 3 shows a typical stress versus time curve for the polycation under investigation. The maximum value of the applied stress (peak value) was taken as the characteristics of the adhesive properties of the PDADMAC coating. The mean values of the stress measurements are summarized in

Table 1. No significant difference in adhesive properties was found for the coatings prepared from all studied polycations.

3.4. Evaluation of the Antibacterial Activity of Polycations

The estimation of minimal inhibition concentration (MIC) - the minimum concentration of PDADMAC of different molecular weights at which bacterial growth is completely inhibited - was measured. The results are presented in

Table 2. It was found that the polycations of the presented degrees of polymerization exhibit the same antibacterial activity.

4. Discussion

Deposition of the water solution of PDADMAC on the surface of hydrophilic glass results in the formation of a polymer coating. It can be seen that for PDADMAC with masses 200 kDa and more, the profile of the mass loss curve upon washing off remains practically identical. While for the oligomeric fraction with a mass less than 100 kDa, the bulk of the polymer film is removed during the first 2 wash-off cycles. Apparently, this is due to the large diffusion coefficients of small macromolecules, which are able to both dissolve faster in water and move faster in the bulk of the swollen film. However, for all three PDADMAC fractions, the main weight loss is observed after three washing cycles. Thus, for the preparation of formulations based on PDADMAC, it is desirable to use polymers with a molecular weight above 200 kDa. It was also found by dynamometry that a change in the molecular weight of PDADMAC has practically no effect on the adhesive properties.

It is known that polyelectrolytes are very hygroscopic and coatings obtained from them are capable of high water absorption [16]. It is necessary to evaluate the ability of PDADMAC coatings to absorb water from the environment in order to assess the adequacy of the perception of the results of gravimetric analysis of wash-off resistance. PDADMAC was demonstrated to adsorb on a glass surface with formation of the polymer film, which could absorb up to 40% water related to its dry weight from an environment having relative humidity up to 70%. This absorption did not change the integrity and shape of the PDADMAC coating. It should be noted that at a relative humidity of over 70%, water drops were visible on the polymer coating. However, after being placed in a low humidity chamber, the film then acquired its initial form and integrity. Since the gravimetric evaluation of the resistance to wash-off was carried out at a relative humidity in the room below 20%, we can state the reliability of the results obtained.

It is known that increase of molecular weight of the polymers of the same structure could decrease or increase their biocidal activity [17,18]. In this work we discuss the behavior of PDADMAC with relatively high degrees of polymerizations. Minimum inhibitory concentrations of PDADMAC of different molecular weights were determined. It was found that the same concentration of inhibition of bacterial growth was observed for all the samples. It is important to stress that for the large-scale application of the polymers as biocide coatings it is assumed to use commercial available polymers. For the PDADMAC produced for the flocculation and oil production processes typical molecular weights are hundreds of kDA [19]. So, the findings about role of the molecular weights of PDADMAC molecules under investigation in this paper could be applied to the industrial samples of polymers.

5. Conclusions

Thus, it can be concluded that polycations can be used to create biocidal compositions based on IPEC in a wide range of molecular weights. However, an important factor is that during the formation of the complex, the degree of polymerization of the polycation should exceed the degree of polymerization of the polyanion [20]. However, it is desirable that the molecular weight of PDADMAC should exceed 100 kDa- otherwise the polycation forms coatings that are weakly resistant to washing off. At the same time the adhesive properties of the coatings and antibacterial properties of PDADMAC were demonstrated to be almost independent on molecular weight of polymers.

Thus, when choosing a polycation for creating antibacterial coatings, the best option from a practical and functional point of view is to choose polymers with a higher degree of polymerization, but this requirement is not mandatory.

Author Contributions

Conceptualization, A.V.S.; formal analysis, V.A.P. and A.V.S.; investigation, V.A.P. and A.V.S.; data V.A.P.; writing, A.V.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by Ministry of Science and Higher Education of the Russian Federation, project No. 075-15-2020-775.

Data Availability Statement

Not applicable.

Acknowledgments

This research was funded by Ministry of Science and Higher Education of the Russian Federation, project No. 075-15-2020-775.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Rafael Pérez-Escamilla, Food Security and the 2015–2030 Sustainable Development Goals: From Human to Planetary Health: Perspectives and Opinions, Curr. Dev. in Nutr. 2017, 1, 7, e000513.

- López-Gálvez, F.; Gómez, P.A.; Artés, F.; Artés-Hernández, F.; Aguayo, E. Interactions between Microbial Food Safety and Environmental Sustainability in the Fresh Produce Supply Chain. Foods 2021, 10, 1655. [Google Scholar] [CrossRef] [PubMed]

- Kathryn A Whitehead, Joanna Verran Formation, architecture and functionality of microbial biofilms in the food industry Curr. Opin. Food Sci. 2015 Volume 2, Pages 84-91.

- Toushik, S.H.; Roy, A.; Alam, M.; Rahman, U.H.; Nath, N.K.; Nahar, S.; Matubber, B.; Uddin, M.J.; Roy, P.K. Pernicious Attitude of Microbial Biofilms in Agri-Farm Industries: Acquisitions and Challenges of Existing Antibiofilm Approaches. Microorganisms 2022, 10, 2348. [Google Scholar] [CrossRef] [PubMed]

- de Brito, F.A.E.; de Freitas, A.P.P.; Nascimento, M.S. Multidrug-Resistant Biofilms (MDR): Main Mechanisms of Tolerance and Resistance in the Food Supply Chain. Pathogens 2022, 11, 1416. [Google Scholar] [CrossRef] [PubMed]

- Ejaz, H.; Junaid, K.; Yasmeen, H.; Naseer, A.; Alam, H.; Younas, S.; Qamar, M.U.; Abdalla, A.E.; Abosalif, K.O.A.; Ahmad, N.; Bukhari, S.N.A. Multiple Antimicrobial Resistance and Heavy Metal Tolerance of Biofilm-Producing Bacteria Isolated from Dairy and Non-Dairy Food Products. Foods 2022, 11, 2728. [Google Scholar] [CrossRef] [PubMed]

- P. Dimitrakellis, G.D. Kaprou, G. Papavieros, D.C. Mastellos, V. Constantoudis, A. Tserepi, E. Gogolides,Enhanced antibacterial activity of ZnO-PMMA nanocomposites by selective plasma etching in atmospheric pressure,Micro and Nano Engineering, 2021, 13, 100098.

- Isopencu, G.; Mocanu, A. Recent Advances in Antibacterial Composite Coatings. Coatings 2022, 12, 1504. [Google Scholar] [CrossRef]

- Mkrtchyan, K.V.; Pigareva, V.A.; Zezina, E.A.; Kuznetsova, O.A.; Semenova, A.A.; Yushina, Y.K.; Tolordava, E.R.; Grudistova, M.A.; Sybachin, A.V.; Klimov, D.I.; Abramchuk, S.S.; Yaroslavov, A.A.; Zezin, A.A. Preparation of Biocidal Nanocomposites in X-ray Irradiated Interpolyelectolyte Complexes of Polyacrylic Acid and Polyethylenimine with Ag-Ions. Polymers 2022, 14, 4417. [Google Scholar] [CrossRef] [PubMed]

- Mahmoud H.M.A. Shibraen, Omar M. Ibrahim, Rabie A.M. Asad, Shuguang Yang, M.R. El-Aassar,Interpenetration of metal cations into polyelectrolyte-multilayer-films via layer-by-layer assembly: Selective antibacterial functionality of cationic guar gum/ polyacrylic acid- Ag+ nanofilm against resistant E. coli, Colloids Surf. A Physicochem. Eng. Asp., 2021, 610, 125921.

- Fabiana Zarpelon, Deise Galiotto, Cesar Aguzzoli, Larissa Nardini Carli, Carlos Alejandro Figueroa, Israel Jacob Rabin Baumvol, Giovanna Machado, Janaina da Silva Crespo, Marcelo Giovanela,Removal of coliform bacteria from industrial wastewaters using polyelectrolytes/silver nanoparticles self-assembled thin films, J. Environ. Chem. Eng. 2016, 4(1), 137–146.

- Xinrui Liu, Yunqian Li, Shanji Li, Yu-Chien Lin, Veronica Lynn Li, Yun-Hsuan Chen, Chingpo Lin, Murugan Keerthi, Shao-Ju Shih, Ren-Jei Chung,Polyelectrolyte multilayer coatings for short/long-term release of antibacterial agents, Surf. Coat. Technol., 2020, 393.

- Pigareva, V.A.; Senchikhin, I.N.; Bolshakova, A.V.; Sybachin, A.V. Modification of Polydiallyldimethylammonium Chloride with Sodium Polystyrenesulfonate Dramatically Changes the Resistance of Polymer-Based Coatings towards Wash-Off from Both Hydrophilic and Hydrophobic Surfaces. Polymers 2022, 14, 1247. [Google Scholar] [CrossRef] [PubMed]

- Misin, V.M., Zezin, A.A., Klimov, D.I. et al. Biocidal Polymer Formulations and Coatings. Polym. Sci. Ser. B 2021, 63, 459–469.

- Wiegand I, Hilpert K, Hancock REW. Agar and broth dilution methods to determine the minimal inhibitory concentration (MIC) of antimicrobial substances. Nat Protoc. 2008, 3(2),163–175.

- Vladislava A. Pigareva, Daria A. Stepanova, Anastasia V. Bolshakova, Valeria I. Marina, Ilya A. Osterman, Andrey V. Sybachin, Hyperbranched Kaustamin as an antibacterial for surface treatment, Mendeleev Communications, 2022, 32, 4, 561-563.

- Akgül, Cahit & Mehmet, Yildirim. Molecular weight dependent antistaphylococcal activities of oligomers/polymers synthesized from 3-aminopyridi. J SERB CHEM SOC 2010, 75. 104-104.

- Ikeda, T., Hirayama, H., Yamaguchi, H., Tazuke, S., & Watanabe, M. (1986). Polycationic biocides with pendant active groups: molecular weight dependence of antibacterial activity. Antimicrob. Agents Chemother. 1986, 30, 132–136.

- https://snf.com/industry/oil-gas/applications/drilling/.

- Izumrudov, V.A., Parashchuk, V.V. & Sybachin, A.V. Unusual behavior of saline solutions of polyelectrolyte complexes containing guest oligomers. Polym. Sci. Ser. B 2006, 48, 78–79.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).