Submitted:

10 February 2023

Posted:

10 February 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

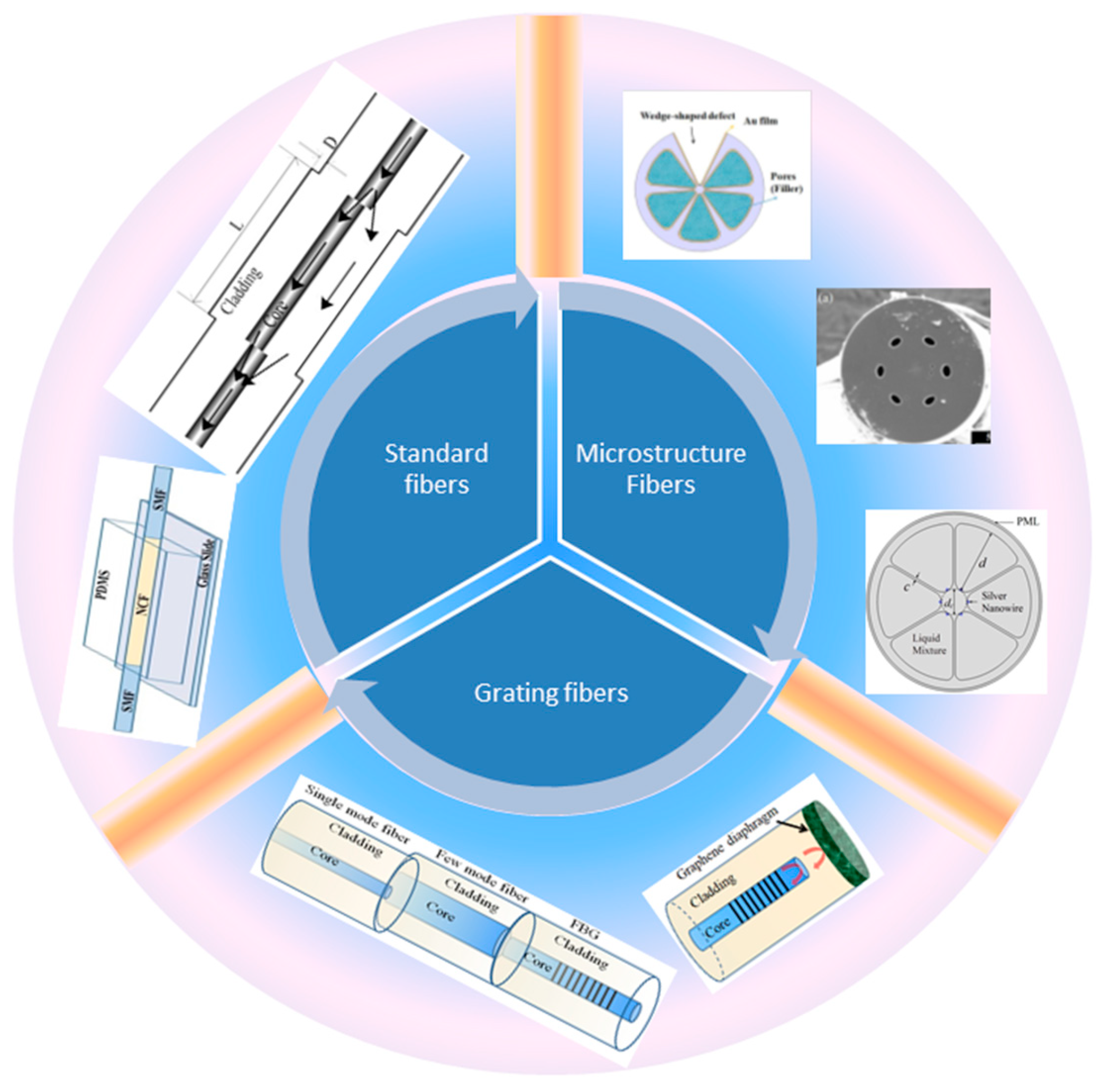

2. Microstructure Optical Fiber (MOF):

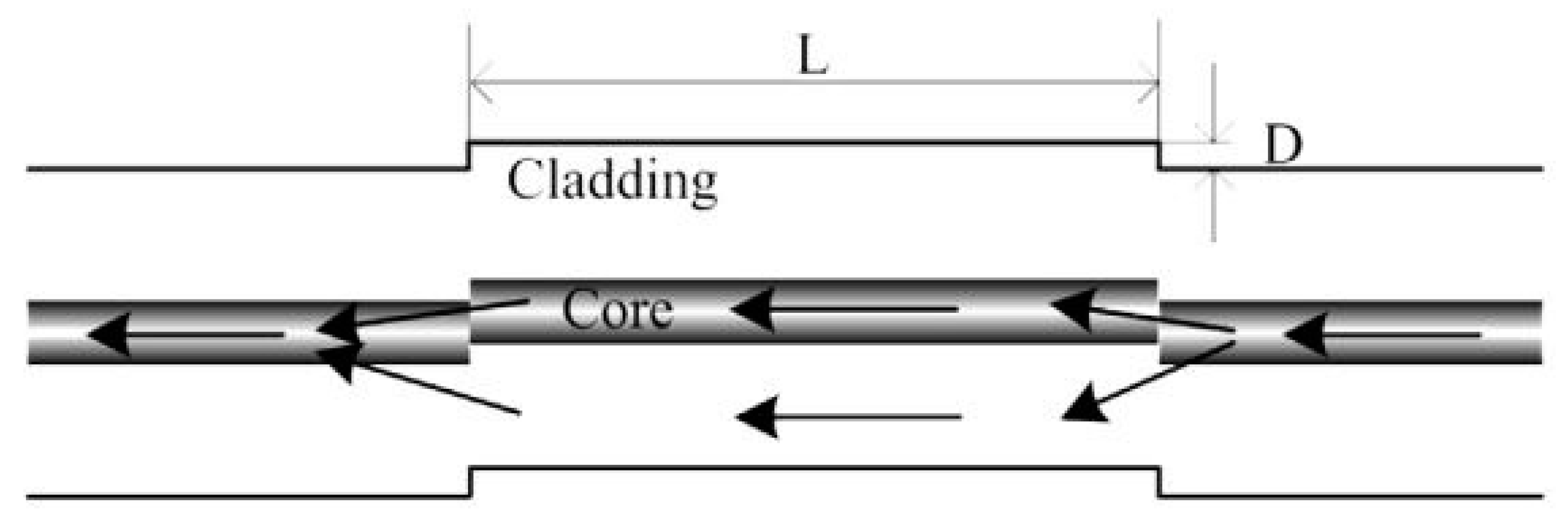

3. Standard Fiber

4. Grating Based Fiber

5. Future Prospects and Challenges:

6. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ma, S.; Xu, Y.; Pang, Y.; Zhao, X.; Li, Y.; Qin, Z.; Liu, Z.; Lu, P.; Bao, X. Optical Fiber Sensors for High-Temperature Monitoring: A Review. Sensors 2022, 22, 5722. [CrossRef]

- Childs, P.R.N.; Greenwood, J.R.; Long, C.A. Review of temperature measurement. Rev. Sci. Instrum. 2000, 71, 2959–2978. [CrossRef]

- Yang, S.; Homa, D.; Heyl, H.; Theis, L.; Beach, J.; Dudding, B.; Acord, G.; Taylor, D.; Pickrell, G.; Wang, A. Application of Sapphire-Fiber-Bragg-Grating-Based Multi-Point Temperature Sensor in Boilers at a Commercial Power Plant. Sensors 2019, 19, 3211. [CrossRef]

- Willsch, M.; Bosselmann, T.; Flohr, P.; Kull, R.; Ecke, W.; Latka, I.; Fischer, D.; Thiel, T. Design of fiber optical high temperature sensors for gas turbine monitoring.In Proccedings of the 20th International Conference on Optical Fibre Sensors, 2009, Edinburgh, UK, 5–9 October 2009; Volume 7503, p. 75037R. [CrossRef]

- Atkins, R.A.; Gardner, J.H.; Gibler, W.N.; Lee, C.E.; Oakland, M.D.; Spears, M.O.; Swenson, V.P.; Taylor, H.F.; McCoy, J.J.; Beshouri, G. Fiber-optic pressure sensors for internal combustion engines. Appl. Opt. 1994, 33, 1315–1320. [CrossRef]

- Watson, J.; Castro, G. A review of high-temperature electronics technology and applications. J. Mater. Sci. Mater. Electron. 2015, 26, 9226–9235. [CrossRef]

- Gao, S.; Wang, L.; Feng, C. Multi-spectral pyrometer for gas turbine blade temperature measurement. Proc. SPIE 9202, Photonics Applications for Aviation, Aerospace, Commercial and Harsh Environments V, Eds.; 2014; p. 920217. [CrossRef]

- Zhang, L.; Zhu, Y.; Jiang, M.; Wu, Y.; Deng, K.; Ni, Q. Body Temperature Monitoring for Regular COVID-19 Prevention Based on Human Daily Activity Recognition. Sensors 2021, 21, 7540. [CrossRef]

- Costanzo, S.; Flores, A. A Non-Contact Integrated Body-Ambient Temperature Sensors Platform to Contrast COVID-19. Electronics 2020, 9, 1658. [CrossRef]

- Bielska, S.; Sibinski, M.; Lukasik, A. Polymer temperature sensor for textronic applications. Mater. Sci. Eng. B 2009, 165, 50–52. [CrossRef]

- Wawrzynczyk, D.; Bednarkiewicz, A.; Nyk, M.; Strek, W.; Samoc, M. Neodymium(iii) doped fluoride nanoparticles as non-contact optical temperature sensors. Nanoscale 2012, 4, 6959–6961. [CrossRef]

- Kus, A.; Isik, Y.; Cakir, M.C.; Coşkun, S.; Özdemir, K. Thermocouple and Infrared Sensor-Based Measurement of Temperature Distribution in Metal Cutting. Sensors 2015, 15, 1274–1291. [CrossRef]

- Jun, S.; Kochan, O. Investigations of Thermocouple Drift Irregularity Impact on Error of their Inhomogeneity Correction. Meas. Sci. Rev. 2014, 14, 29–34. [CrossRef]

- Nie, B.; He, X.; Zhang, C.; Li, X.; Li, H. Temperature measurement of gas explosion flame based on the radiation thermometry. Int. J. Therm. Sci. 2014, 78, 132–144. [CrossRef]

- Pathak, A.; Viphavakit, C. A review on all-optical fiber-based VOC sensors: Heading towards the development of promising technology. Sensors Actuators A: Phys. 2022, 338, 113455. [CrossRef]

- Mollah, A.; Islam, S.R.; Yousufali; Abdulrazak, L.F.; Hossain, M.B.; Amiri, I. Plasmonic temperature sensor using D-shaped photonic crystal fiber. Results Phys. 2020, 16, 102966. [CrossRef]

- Wang, Z.; Chen, D.; Yang, X.; Liang, S.; Sun, X. Temperature sensor of single-mode-no-core-single-mode fiber structure coated with PDMS. Opt. Fiber Technol. 2021, 68, 102793. [CrossRef]

- Liao, C.R.; Wang, D.N. Review of femtosecond laser fabricated fiber Bragg gratings for high temperature sensing. Photon- Sensors 2012, 3, 97–101. [CrossRef]

- Wildner, W.; Drummer, D. A Fiber Optic Temperature Sensor Based on the Combination of Two Materials With Different Thermo-Optic Coefficients. IEEE Sensors J. 2015, 16, 688–692. [CrossRef]

- R. Kashyap, Fiber Bragg Gratings (Elsevier, Amsterdam, 1999).

- Mizuno, Y.; Zou, W.; He, Z.; Hotate, K. Proposal of Brillouin optical correlation-domain reflectometry (BOCDR). Opt. Express 2008, 16, 12148–12153. [CrossRef]

- A.H. Hartog, An Introduction to Distributed Optical Fibre Sensors (CRC Press, Boca Raton, FL, 2017).

- G. Rajan (ed.) Optical Fiber Sensors: Advanced Techniques and Applications (CRC Press, Boca Raton, FL, 20154).

- H. Alemohammad, Opto-Mechanical Fiber Optic Sensors: Research, Technology, and Applications in Mechanical Sensing (Elsevier, Amsterdam, 2018).

- P. Russell, “Photonic crystal fibers,” Science 299, 358–362 (2003).

- J. C. Knight, “Photonic crystal fibres,” Nature 424, 847–851 (2003).

- Larsen, T.T.; Bjarklev, A.; Hermann, D.S.; Broeng, J. Optical devices based on liquid crystal photonic bandgap fibres. Opt. Express 2003, 11, 2589–2596. [CrossRef]

- Du, F.; Lu, Y.-Q.; Wu, S.-T. Electrically tunable liquid-crystal photonic crystal fiber. Appl. Phys. Lett. 2004, 85, 2181–2183. [CrossRef]

- Haakestad, M.; Alkeskjold, T.; Nielsen, M.D.; Scolari, L.; Riishede, J.; Engan, H.; Bjarklev, A. Electrically tunable photonic bandgap guidance in a liquid-crystal-filled photonic crystal fiber. IEEE Photon- Technol. Lett. 2005, 17, 819–821. [CrossRef]

- Alkeskjold, T.T.; Bjarklev, A.; Hermann, D.S.; Anawati, A.; Broeng, J.; Li, J.; Wu, S.-T.; Lægsgaard, J.; Anawati All-optical modulation in dye-doped nematic liquid crystal photonic bandgap fibers. Opt. Express 2004, 12, 5857–5871. [CrossRef]

- Steinvurzel, P.; Eggleton, B.; de Sterke, C.; Steel, M. Continuously tunable bandpass filtering using high-index inclusion microstructured optical fibre. Electron. Lett. 2005, 41, 463–464. [CrossRef]

- Alkeskjold, T.T.; Bjarklev, A. Electrically controlled broadband liquid crystal photonic bandgap fiber polarimeter.. Opt. Lett. 2007, 32, 1707–1709. [CrossRef]

- Qian, W.; Zhao, C.-L.; Wang, Y.; Chan, C.C.; Liu, S.; Jin, W. Partially liquid-filled hollow-core photonic crystal fiber polarizer. Opt. Lett. 2011, 36, 3296–3298. [CrossRef]

- Jha, R.; Villatoro, J.; Badenes, G.; Pruneri, V. Refractometry based on a photonic crystal fiber interferometer. Opt. Lett. 2009, 34, 617–619. [CrossRef]

- Li, B.; Sheng, Z.; Wu, M.; Liu, X.; Zhou, G.; Liu, J.; Hou, Z.; Xia, C. Sensitive real-time monitoring of refractive indices and components using a microstructure optical fiber microfluidic sensor. Opt. Lett. 2018, 43, 5070–5073. [CrossRef]

- Canales, A.; Jia, X.; Froriep, U.P.; Koppes, R.A.; Tringides, C.M.; Selvidge, J.; Lu, C.; Hou, C.; Wei, L.; Fink, Y.; et al. Multifunctional fibers for simultaneous optical, electrical and chemical interrogation of neural circuits in vivo. Nat. Biotechnol. 2015, 33, 277–284. [CrossRef]

- Li, X.; Lin, S.; Liang, J.; Zhang, Y.; Oigawa, H.; Ueda, T. Fiber-Optic Temperature Sensor Based on Difference of Thermal Expansion Coefficient Between Fused Silica and Metallic Materials. IEEE Photon- J. 2011, 4, 155–162. [CrossRef]

- Reyes-Vera, E.; Cordeiro, C.M.B.; Torres, P. Highly sensitive temperature sensor using a Sagnac loop interferometer based on a side-hole photonic crystal fiber filled with metal. Appl. Opt. 2017, 56, 156–162. [CrossRef]

- Yang, H.; Wang, S.; Wang, X.; Wang, J.; Liao, Y. Temperature Sensing in Seawater Based on Microfiber Knot Resonator. Sensors 2014, 14, 18515–18525. [CrossRef]

- Lu, Y.; Wang, M.T.; Hao, C.J.; Zhao, Z.Q.; Yao, J.Q. Temperature Sensing Using Photonic Crystal Fiber Filled With Silver Nanowires and Liquid. IEEE Photon- J. 2014, 6, 1–7. [CrossRef]

- Reyes-Vera, E.; Gómez-Cardona, N.D.; Chesini, G.; Cordeiro, C.M.B.; Torres, P. Temperature sensibility of the birefringence properties in side-hole photonic crystal fiber filled with Indium. Appl. Phys. Lett. 2014, 105. [CrossRef]

- Qian, W.; Zhao, C.-L.; He, S.; Dong, X.; Zhang, S.; Zhang, Z.; Jin, S.; Guo, J.; Wei, H. High-sensitivity temperature sensor based on an alcohol-filled photonic crystal fiber loop mirror. Opt. Lett. 2011, 36, 1548–1550. [CrossRef]

- Chesini, G.; Osorio, J.H.; Serrao, V.A.; Franco, M.A.R.; Cordeiro, C.M.B. Metal-Filled Embedded-Core Capillary Fibers as Highly Sensitive Temperature Sensors. IEEE Sensors Lett. 2018, 2, 1–4. [CrossRef]

- Xie, J.; Xu, B.; Li, Y.; Kang, J.; Shen, C.; Wang, J.; Jin, Y.; Liu, H.; Ni, K.; Dong, X.; et al. High-sensitivity temperature sensor based on a droplet-like fiber circle.. Appl. Opt. 2014, 53, 4085–4088. [CrossRef]

- Qian, W.; Zhao, C.-L.; He, S.; Dong, X.; Zhang, S.; Zhang, Z.; Jin, S.; Guo, J.; Wei, H. High-sensitivity temperature sensor based on an alcohol-filled photonic crystal fiber loop mirror. Opt. Lett. 2011, 36, 1548–1550. [CrossRef]

- Hu, D.J.J.; Lim, J.L.; Cui, Y.; Milenko, K.; Wang, Y.; Shum, P.P.; Wolinski, T. Fabrication and Characterization of a Highly Temperature Sensitive Device Based on Nematic Liquid Crystal-Filled Photonic Crystal Fiber. IEEE Photon- J. 2012, 4, 1248–1255. [CrossRef]

- Chen, T.; Wang, Q.; Chen, R.; Zhang, B.; Jewart, C.; Chen, K.P.; Maklad, M.; Swinehart, P.R. Distributed high-temperature pressure sensing using air-hole microstructural fibers. Opt. Lett. 2012, 37, 1064–1066. [CrossRef]

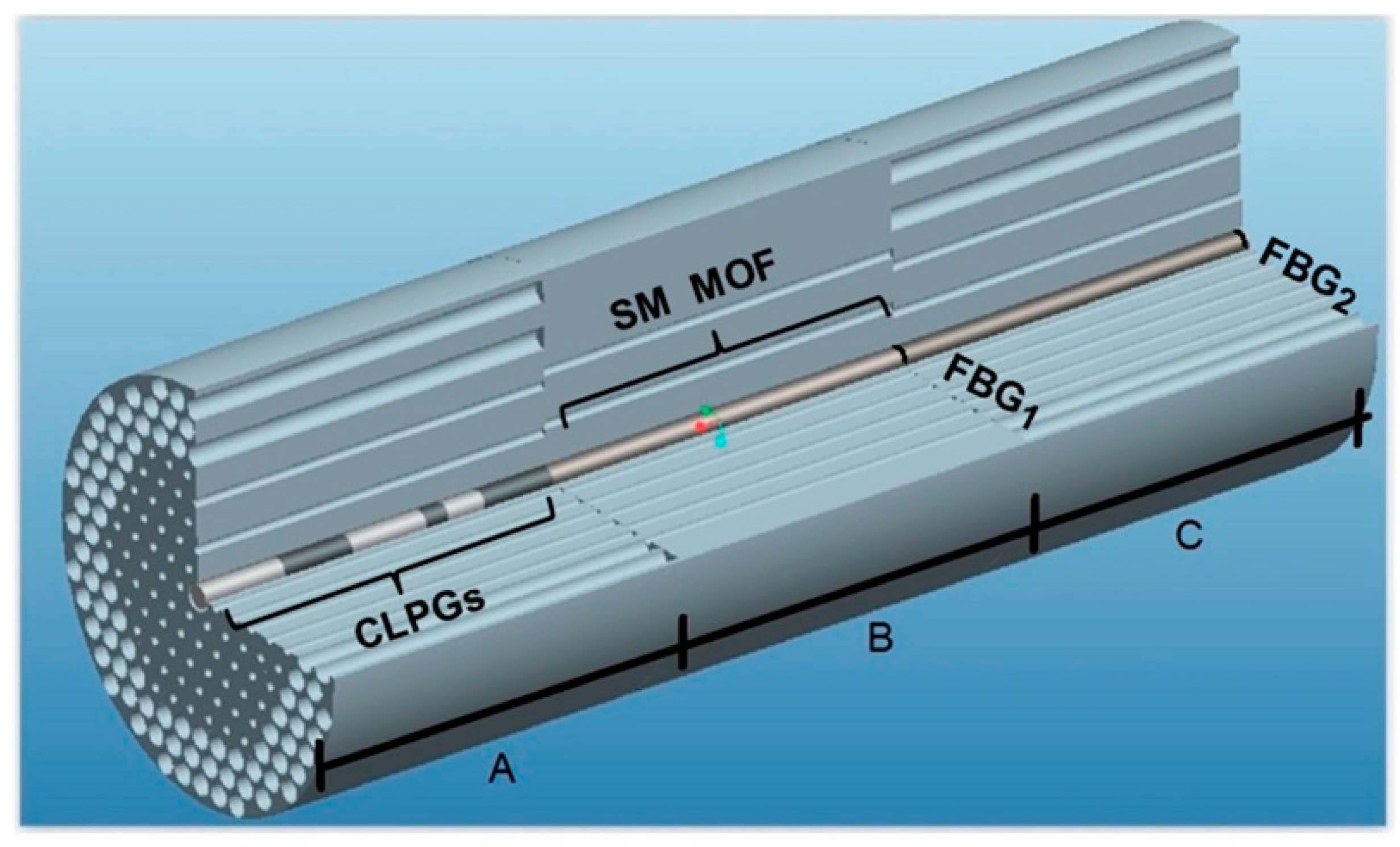

- Xiaolei Li, Qizhen Sun, Duan Liu, Ruibing Liang, Jiejun Zhang, Jianghai Wo, Perry Ping Shum, and Deming Liu, “Simultaneous wavelength and frequency encoded microstructure based quasi-distributed temperature sensor” OPTICS EXPRESS, 20(11), 12076-12084, 2012.

- Tan, X.; Geng, Y.; Li, X.; Gao, R.; Yin, Z. High temperature microstructured fiber sensor based on a partial-reflection-enabled intrinsic Fabry–Perot interferometer. Appl. Opt. 2013, 52, 8195–8198. [CrossRef]

- Poulton, C.G.; Schmidt, M.A.; Pearce, G.J.; Kakarantzas, G.; Russell, P.S. Numerical study of guided modes in arrays of metallic nanowires. Opt. Lett. 2007, 32, 1647–1649. [CrossRef]

- Hou, J.; Bird, D.; George, A.; Maier, S.; Kuhlmey, B.; Knight, J.C. Metallic mode confinement in microstructured fibres. Opt. Express 2008, 16, 5983–5990. [CrossRef]

- Schmidt, M.A.; Sempere, L.N.P.; Tyagi, H.K.; Poulton, C.G.; Russell, P.S.J. Waveguiding and plasmon resonances in two-dimensional photonic lattices of gold and silver nanowires. Phys. Rev. B 2008, 77, 033417. [CrossRef]

- Sazio, P.J.A.; Amezcua-Correa, A.; Finlayson, C.E.; Hayes, J.R.; Scheidemantel, T.J.; Baril, N.F.; Jackson, B.R.; Won, D.-J.; Zhang, F.; Margine, E.R.; et al. Microstructured Optical Fibers as High-Pressure Microfluidic Reactors. Science 2006, 311, 1583–1586. [CrossRef]

- J. A. Harrington, “A review of IR transmitting, hollow waveguides,” Fiber Integr. Opt. 19, 211–227 (2000).

- F.C. Favero et al., “Microstructure fiber interferrometer as sensitive temperature measurement,” Photonic Sensor, 3, 208-213 (2013).

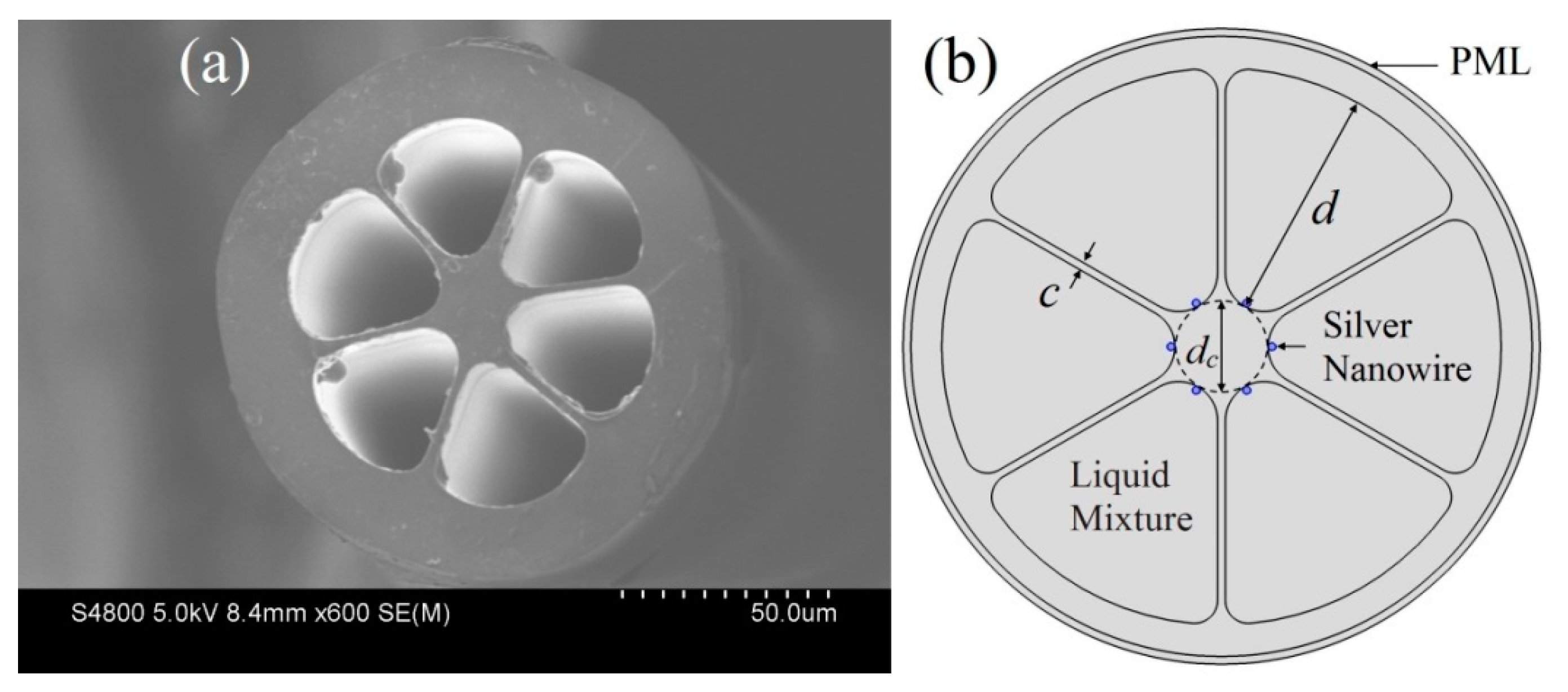

- Luan, N.; Wang, R.; Lv, W.; Lu, Y.; Yao, J. Surface Plasmon Resonance Temperature Sensor Based on Photonic Crystal Fibers Randomly Filled with Silver Nanowires. Sensors 2014, 14, 16035–16045. [CrossRef]

- Luan, N.-N.; Wang, R.; Lu, Y.; Yao, J.-Q. Simulation of surface plasmon resonance temperature sensor based on liquid mixture-filling microstructured optical fiber. Opt. Eng. 2014, 53, 67103. [CrossRef]

- Youfu, G.; Xuejin, L.; Xiaoling, T.; Yuanlong, D.; Xueming, H. Compact and Ultrasensitive Temperature Sensor With a Fully Liquid-Filled Photonic Crystal Fiber Mach-Zehnder Interferometer. IEEE Sens. J. 2014, 14, 167–170.

- Du, Y.; Qiao, X.; Rong, Q.; Yang, H.; Feng, D.; Wang, R.; Hu, M.; Feng, Z. A Miniature Fabry–Pérot Interferometer for High Temperature Measurement Using a Double-Core Photonic Crystal Fiber. IEEE Sensors J. 2013, 14, 1069–1073. [CrossRef]

- Ding, W.-H.; Jiang, Y. Miniature Photonic Crystal Fiber Sensor for High-Temperature Measurement. IEEE Sensors J. 2013, 14, 786–789. [CrossRef]

- Lopez-Aldaba, A.; Pinto, A.M.R.; Lopez-Amo, M.; Frazão, O.; Santos, J.L.; Baptista, J.M.; Baierl, H.; Auguste, J.-L.; Jamier, R.; Roy, P. Experimental and Numerical Characterization of a Hybrid Fabry-Pérot Cavity for Temperature Sensing. Sensors 2015, 15, 8042–8053. [CrossRef]

- Scarcia, W.; Palma, G.; Falconi, M.C.; De Leonardis, F.; Passaro, V.M.N.; Prudenzano, F. Electromagnetic Modelling of Fiber Sensors for Low-Cost and High Sensitivity Temperature Monitoring. Sensors 2015, 15, 29855–29870. [CrossRef]

- Pérez-Herrera, R.; André, R.; Silva, S.; Becker, M.; Schuster, K.; Kobelke, J.; Lopez-Amo, M.; Santos, J.; Frazão, O. Simultaneous measurement of strain and temperature based on clover microstructured fiber loop mirror. Measurement 2015, 65, 50–53. [CrossRef]

- Revathi, S.; Inabathini, S.R.; Pal, J. Pressure and temperature sensor based on a dual core photonic quasi-crystal fiber. Optik 2015, 126, 3395–3399. [CrossRef]

- Lopez-Aldaba, A.; Pinto, A.M.R.; Lopez-Amo, M.; Frazão, O.; Santos, J.L.; Baptista, J.M.; Baierl, H.; Auguste, J.-L.; Jamier, R.; Roy, P. Experimental and Numerical Characterization of a Hybrid Fabry-Pérot Cavity for Temperature Sensing. Sensors 2015, 15, 8042–8053. [CrossRef]

- Liu, Q.; Li, S.; Chen, H.; Li, J.; Fan, Z. High-sensitivity plasmonic temperature sensor based on photonic crystal fiber coated with nanoscale gold film. Appl. Phys. Express 2015, 8, 46701. [CrossRef]

- Liu, Q.; Li, S.; Chen, H.; Fan, Z.; Li, J. Photonic Crystal Fiber Temperature Sensor Based on Coupling Between Liquid-Core Mode and Defect Mode. IEEE Photon- J. 2015, 7, 1–9. [CrossRef]

- Wang, Q.; Du, C.; Zhang, J.; Lv, R.; Zhao, Y. Sensitivity-enhanced temperature sensor based on PDMS-coated long period fiber grating. Opt. Commun. 2016, 377, 89–93. [CrossRef]

- Liu, C.; Wang, F.; Lv, J.; Sun, T.; Liu, Q.; Fu, C.; Mu, H.; Chu, P.K. A highly temperature-sensitive photonic crystal fiber based on surface plasmon resonance. Opt. Commun. 2016, 359, 378–382. [CrossRef]

- Du, C.; Wang, Q.; Zhao, Y.; Li, J. Highly sensitive temperature sensor based on an isopropanol-filled photonic crystal fiber long period grating. Opt. Fiber Technol. 2017, 34, 12–15. [CrossRef]

- Warren-Smith, S.C.; Nguyen, L.V.; Lang, C.; Ebendorff-Heidepriem, H.; Monro, T.M. Temperature sensing up to 1300°C using suspended-core microstructured optical fibers. Opt. Express 2016, 24, 3714–3719. [CrossRef]

- Nguyen, L.V.; Warren-Smith, S.C.; Ebendorff-Heidepriem, H.; Monro, T.M. Interferometric high temperature sensor using suspended-core optical fibers. Opt. Express 2016, 24, 8967–77. [CrossRef]

- Reyes-Vera, E.; Cordeiro, C.M.B.; Torres, P. Highly sensitive temperature sensor using a Sagnac loop interferometer based on a side-hole photonic crystal fiber filled with metal. Appl. Opt. 2017, 56, 156–162. [CrossRef]

- Li, S.; Xia, L.; Chen, Z.; Yu, J.; Guan, H.; Lu, H.; Zhong, Y. Colloidal crystal cladding fiber based on side-polished fiber and its temperature sensing. Opt. Quantum Electron. 2017, 49, 1–10. [CrossRef]

- Xu, Y.; Lu, P.; Chen, L.; Bao, X. Recent Developments in Micro-Structured Fiber Optic Sensors. Fibers 2017, 5, 3. [CrossRef]

- Woyessa, G.; Fasano, A.; Markos, C.; Stefani, A.; Rasmussen, H.K.; Bang, O. Zeonex microstructured polymer optical fiber: fabrication friendly fibers for high temperature and humidity insensitive Bragg grating sensing. Opt. Mater. Express 2016, 7. [CrossRef]

- Yang, C.X.; Lu, Y.; Liu, L.B.; Yao, J. Fiber ring laser temperature sensor based on liquid-filled photonic crystal fiber. J. Sci. IEEE Sens. J. 2017, 99, 6948–6952.

- Wang, Y.; Huang, Q.; Zhu, W.; Yang, M.; Lewis, E. Novel optical fiber SPR temperature sensor based on MMF-PCF-MMF structure and gold-PDMS film. Opt. Express 2018, 26, 1910–1917. [CrossRef]

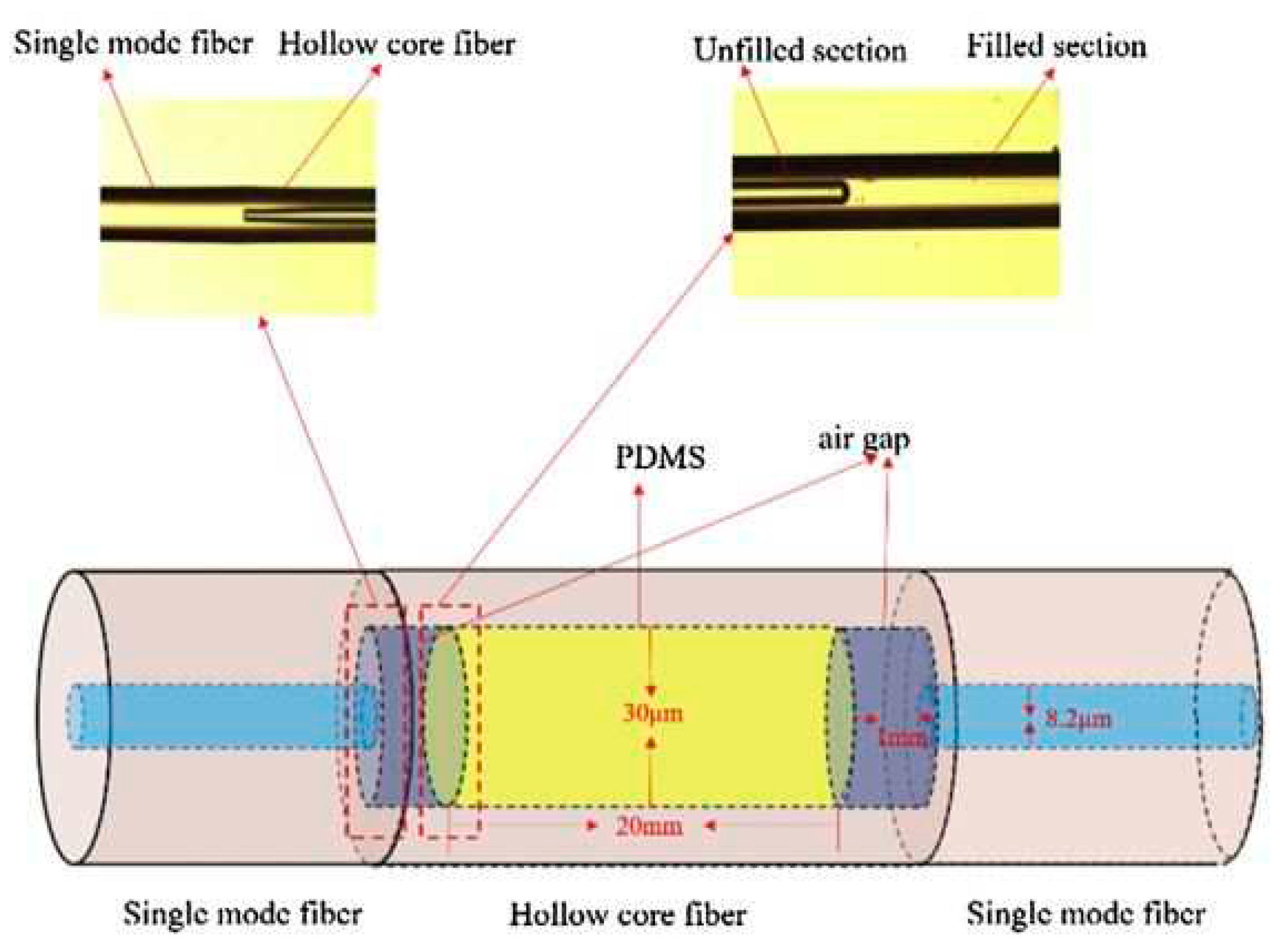

- Gao, H.; Hu, H.; Zhao, Y.; Li, J.; Lei, M.; Zhang, Y. Highly-sensitive optical fiber temperature sensors based on PDMS/silica hybrid fiber structures. Sensors Actuators A: Phys. 2018, 284, 22–27. [CrossRef]

- Korganbayev, S.; Min, R.; Jelbuldina, M.; Hu, X.; Caucheteur, C.; Bang, O.; Ortega, B.; Marques, C.; Tosi, D. Thermal Profile Detection Through High-Sensitivity Fiber Optic Chirped Bragg Grating on Microstructured PMMA Fiber. J. Light. Technol. 2018, 36, 4723–4729. [CrossRef]

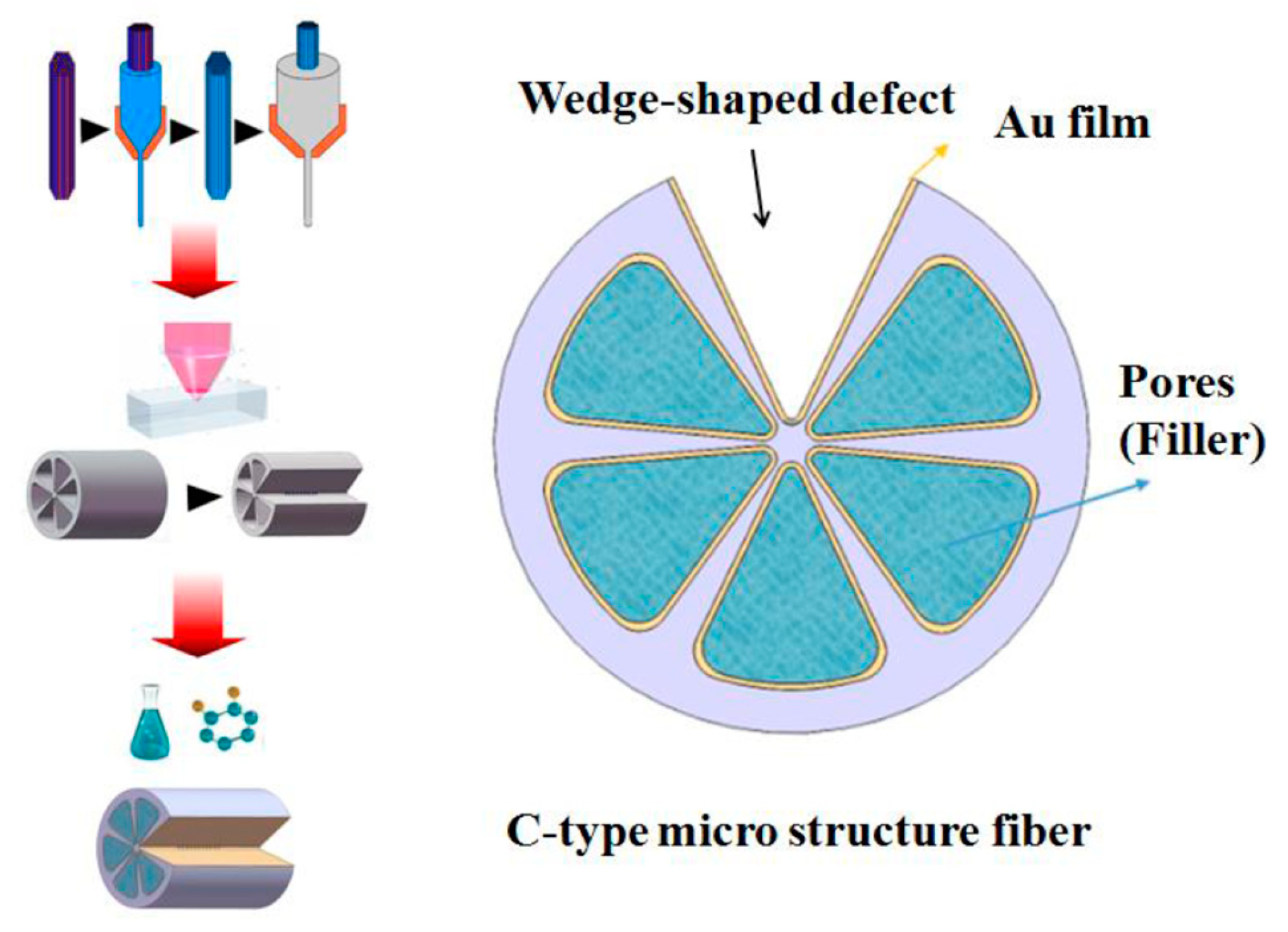

- Zhao, Y.; Wu, Q.-L.; Zhang, Y.-N. Theoretical analysis of high-sensitive seawater temperature and salinity measurement based on C-type micro-structured fiber. Sensors Actuators B: Chem. 2018, 258, 822–828. [CrossRef]

- Lopez-Aldaba, A.; Auguste, J.-L.; Jamier, R.; Roy, P.; Lopez-Amo, M. Simultaneous Strain and Temperature Multipoint Sensor Based on Microstructured Optical Fiber. J. Light. Technol. 2017, 36, 910–916. [CrossRef]

- Liu, Y.-G.; Liu, X.; Ma, C.-J.; Zhou, Y.-M. Micro-structured optical fiber sensor for simultaneous measurement of temperature and refractive index. Opt. Fiber Technol. 2018, 41, 168–172. [CrossRef]

- Zhao, L.; Han, H.; Lian, Y.; Luan, N.; Liu, J. Theoretical analysis of all-solid D-type photonic crystal fiber based plasmonic sensor for refractive index and temperature sensing. Opt. Fiber Technol. 2019, 50, 165–171. [CrossRef]

- Su, H.; Zhang, Y.; Ma, K.; Zhao, Y.; Wang, J. High-temperature sensor based on suspended-core microstructured optical fiber. Opt. Express 2019, 27, 20156–20164. [CrossRef]

- Zhao, L.; Zhang, Y.; Chen, Y.; Wang, J. Composite cavity fiber tip Fabry-Perot interferometer for high temperature sensing. Opt. Fiber Technol. 2019, 50, 31–35. [CrossRef]

- Ma, M.; Chen, H.; Zhang, W.; Li, S.; Jing, X. Temperature sensor based on a Sagnac interferometer using a liquid crystal-filled microstructured optical fiber. Mater. Res. Express 2019, 6, 085205. [CrossRef]

- Zhao, J.; Zhao, Y.; Bai, L.; Zhang, Y.-N. Sagnac Interferometer Temperature Sensor Based on Microstructured Optical Fiber Filled with Glycerin. Sensors Actuators A: Phys. 2020, 314. [CrossRef]

- Abdullah, H.; Mitu, S.A.; Ahmed, K. Magnetic Fluid-Injected Ring-Core-Based Micro-structured Optical Fiber for Temperature Sensing in Broad Wavelength Spectrum. J. Electron. Mater. 2020, 49, 4969–4976. [CrossRef]

- Wang, M.; Chen, H.; Jing, X.; Li, S.; Ma, M.; Zhang, W.; Zhang, Y. Temperature sensor based on modes coupling effect in a liquid crystal-filled microstructured optical fiber. Optik 2020, 219. [CrossRef]

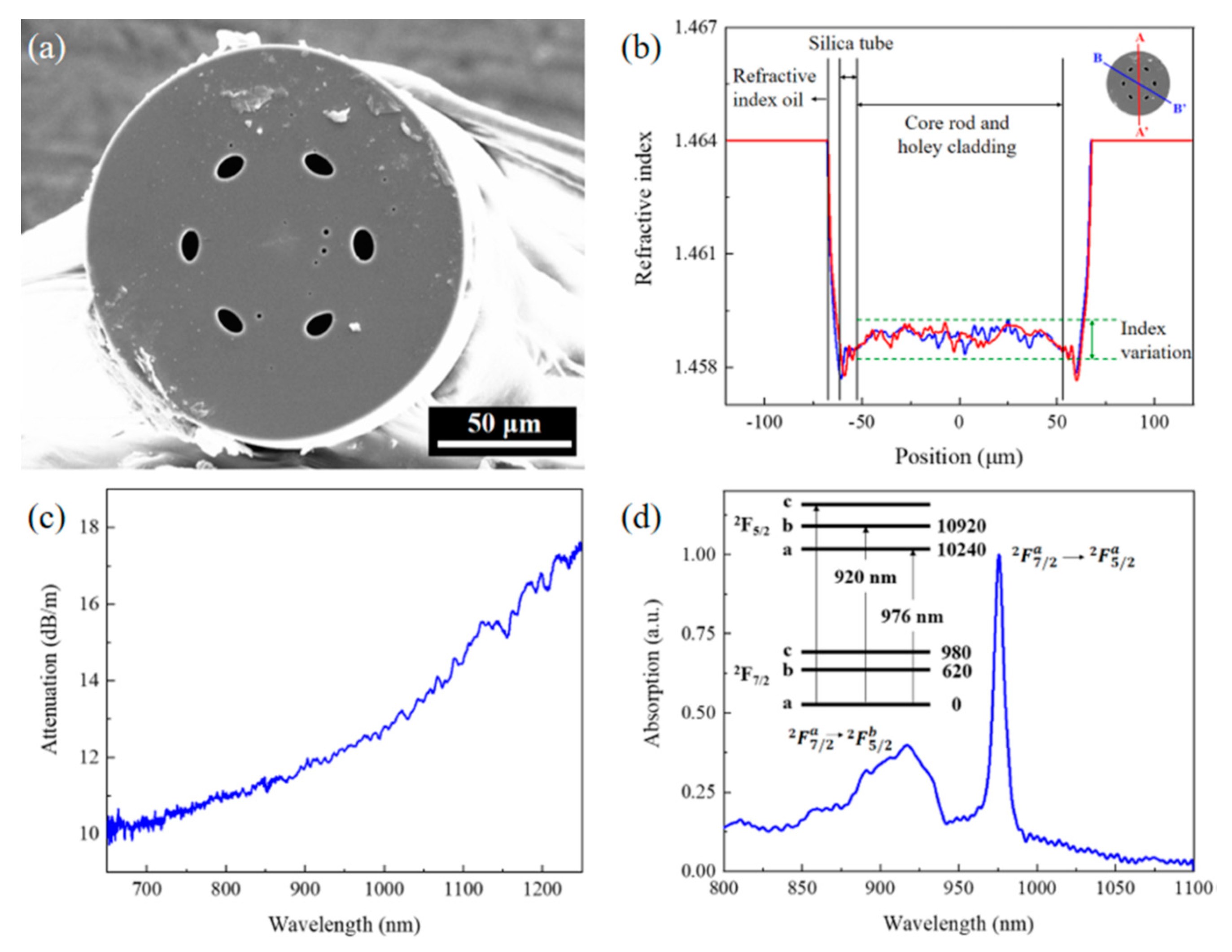

- Zheng, B.; Yang, J.; Qi, F.; Wang, J.; Zhang, X.; Wang, P. Fabrication of Yb-doped silica micro-structured optical fibers from UV-curable nano-composites and their application in temperature sensing. J. Non-Crystalline Solids 2021, 573. [CrossRef]

- Li, H.; Li, S.; Wang, S.; Zhang, S. Theoretical analysis of a microstructured fiber temperature sensor based on a Sagnac interferometer with a wide temperature measurement range. Photon- Nanostructures - Fundam. Appl. 2020, 43, 100858. [CrossRef]

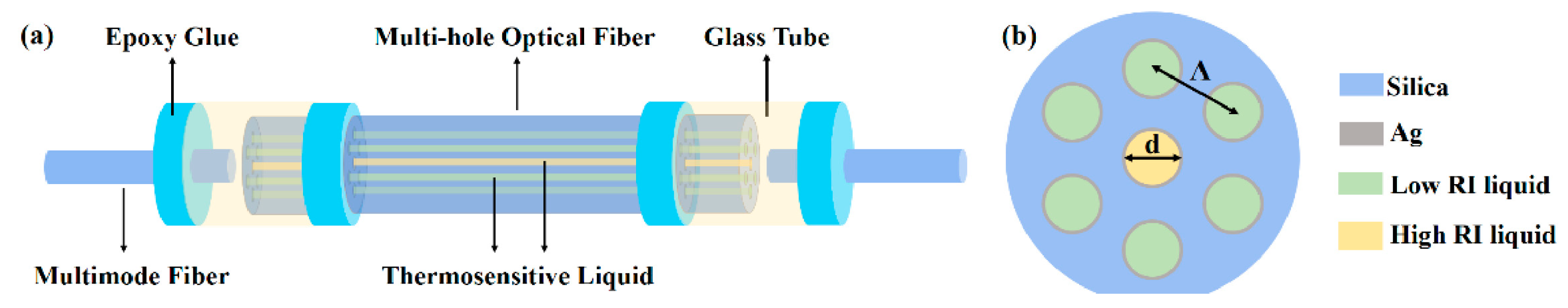

- Li, S.; Zhang, S.; Guo, Y.; Li, H.; Wang, Y.; Zhou, X.; Cheng, T. Experiment and Analysis of Temperature Sensing of Microstructured Fiber with Silver and PDMS Films. Sensors 2022, 22, 1447. [CrossRef]

- Chen, X.; Yan, X.; Zhang, X.; Wang, F.; Suzuki, T.; Ohishi, Y.; Cheng, T. Highly sensitive nonlinear temperature sensor based on soliton self-frequency shift technique in a microstructured optical fiber. Sensors Actuators A: Phys. 2021, 334, 113333. [CrossRef]

- Liang, Y.; Zhang, H.; Huang, B.; Liu, B.; Lin, W.; Sun, J.; Wang, D. Ultrahigh-sensitivity temperature sensor based on resonance coupling in liquid-infiltrated side-hole microstructured optical fibers. Sensors Actuators A: Phys. 2021, 334, 113358. [CrossRef]

- Zhang, X.; Xu, Y.; Zhu, X.-S.; Shi, Y.-W. Surface plasmon resonance temperature sensor with tunable detection range based on a silver-coated multi-hole optical fiber. Opt. Express 2022, 30, 48091–48102. [CrossRef]

- Wildner, W.; Drummer, D. A Fiber Optic Temperature Sensor Based on the Combination of Two Materials With Different Thermo-Optic Coefficients. IEEE Sensors J. 2015, 16, 688–692. [CrossRef]

- Wang, K.; Mizuno, Y.; Kishizawa, K.; Toyoda, Y.; Lee, H.; Ichige, K.; Kurz, W.; Dong, X.; Jakobi, M.; Koch, A.W. Temperature sensing based on multimode interference in polymer optical fibers: sensitivity enhancement by PC-APC connections. Jpn. J. Appl. Phys. 2022, 61, 118001. [CrossRef]

- Sun, X.; Zhang, L.; Zeng, L.; Hu, Y.; Duan, J.-A. Micro-bending sensing based on single-mode fiber spliced multimode fiber Bragg grating structure. Opt. Commun. 2021, 505, 127513. [CrossRef]

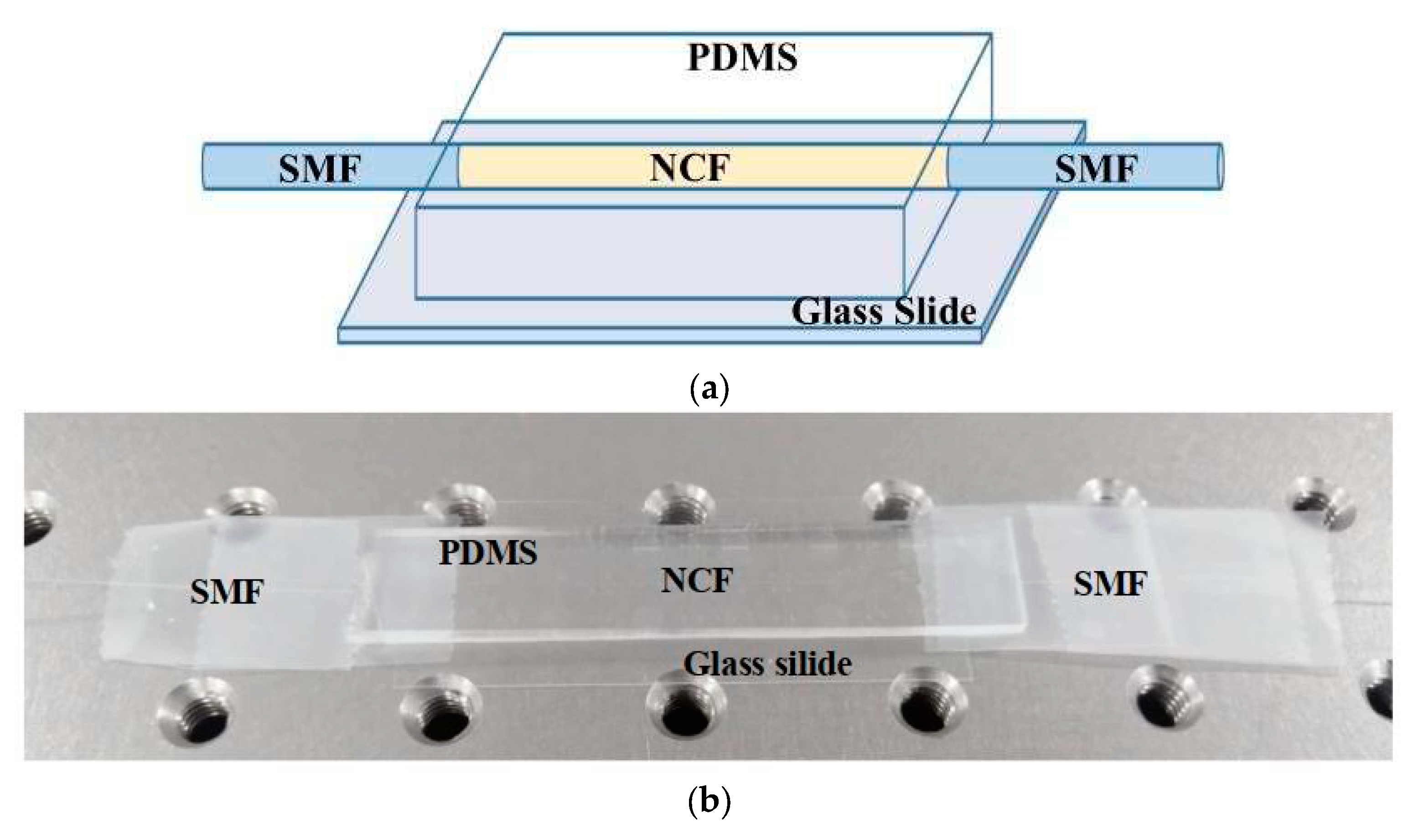

- Wang, Z.; Chen, D.; Yang, X.; Liang, S.; Sun, X. Temperature sensor of single-mode-no-core-single-mode fiber structure coated with PDMS. Opt. Fiber Technol. 2021, 68, 102793. [CrossRef]

- Li, X.; Tan, J.; Li, W.; Yang, C.; Tan, Q.; Feng, G. A high-sensitivity optical fiber temperature sensor with composite materials. Opt. Fiber Technol. 2022, 68, 102821. [CrossRef]

- Huang, Q.; Wang, Y.; Zhu, W.; Lai, T.; Peng, J.; Lyu, D.; Guo, D.; Yuan, Y.; Lewis, E.; Yang, M. Graphene–Gold–Au@Ag NPs-PDMS Films Coated Fiber Optic for Refractive Index and Temperature Sensing. IEEE Photon- Technol. Lett. 2019, 31, 1205–1208. [CrossRef]

- Gao, H.; Hu, H.; Zhao, Y.; Li, J.; Lei, M.; Zhang, Y. Highly-sensitive optical fiber temperature sensors based on PDMS/silica hybrid fiber structures. Sensors Actuators A: Phys. 2018, 284, 22–27. [CrossRef]

- Cai, L.; Liu, Y.; Hu, S.; Liu, Q. Optical fiber temperature sensor based on modal interference in multimode fiber lengthened by a short segment of polydimethylsiloxane. Microw. Opt. Technol. Lett. 2019, 61, 1656–1660. [CrossRef]

- Peng, X.; Cha, Y.; Zhang, H.; Li, Y.; Ye, J. Light intensity modulation temperature sensor based on U-shaped bent single-mode fiber. Optik 2017, 130, 813–817. [CrossRef]

- Wildner, W.; Drummer, D. A Fiber Optic Temperature Sensor Based on the Combination of Two Materials With Different Thermo-Optic Coefficients. IEEE Sensors J. 2015, 16, 688–692. [CrossRef]

- Noor, M.Y.M.; Azmi, A.I.; Abdullah, A.S.; Supa'At, A.S.M.; Kassim, N.M.; Ibrahim, M.H.; Ngajikin, N.H. High Sensitivity of Balloon-Like Bent MMI Fiber Low-Temperature Sensor. IEEE Photonics Technol. Lett. 2015, 27, 1989–1992. [CrossRef]

- Hao, X.; Tong, Z.; Zhang, W.; Cao, Y. A fiber laser temperature sensor based on SMF core-offset structure. Opt. Commun. 2015, 335, 78–81. [CrossRef]

- Kumar, M.; Kumar, A.; Tripathi, S.M. A comparison of temperature sensing characteristics of SMS structures using step and graded index multimode fibers. Opt. Commun. 2013, 312, 222–226. [CrossRef]

- Yang, R.; Yu, Y.-S.; Xue, Y.; Chen, C.; Wang, C.; Zhu, F.; Zhang, B.-L.; Chen, Q.-D.; Sun, H.-B. A Highly Sensitive Temperature Sensor Based on a Liquid-Sealed S-Tapered Fiber. IEEE Photon- Technol. Lett. 2013, 25, 829–832. [CrossRef]

- Tan, X.; Geng, Y.; Li, X.; Gao, R.; Yin, Z. High temperature microstructured fiber sensor based on a partial-reflection-enabled intrinsic Fabry–Perot interferometer. Appl. Opt. 2013, 52, 8195–8198. [CrossRef]

- A.K. Mallik, A. Kumar, G. Gupta and A. Bhatnagar, "Single mode fiber-optic temperature sensor fabricated using wet etching," 2012 International Conference on Fiber Optics and Photonics (PHOTONICS), 2012, pp. 1-3.

- Cao, Z.; Zhang, Z.; Ji, X.; Shui, T.; Wang, R.; Yin, C.; Zhen, S.; Lu, L.; Yu, B. Strain-insensitive and high temperature fiber sensor based on a Mach–Zehnder modal interferometer. Opt. Fiber Technol. 2014, 20, 24–27. [CrossRef]

- Leal-Junior, A.; Frizera-Neto, A.; Marques, C.; Pontes, M.J. A Polymer Optical Fiber Temperature Sensor Based on Material Features. Sensors 2018, 18, 301. [CrossRef]

- Leal-Junior, A.; Casas, J.; Marques, C.; Pontes, M.J.; Frizera, A. Application of Additive Layer Manufacturing Technique on the Development of High Sensitive Fiber Bragg Grating Temperature Sensors. Sensors 2018, 18, 4120. [CrossRef]

- Chiavaioli, F.; Gouveia, C.A.J.; Jorge, P.A.S.; Baldini, F. Towards a Uniform Metrological Assessment of Grating-Based Optical Fiber Sensors: From Refractometers to Biosensors. Biosensors 2017, 7, 23. [CrossRef]

- Hill, K.O.; Fujii, Y.; Johnson, D.C.; Kawasaki, B.S. Photosensitivity in optical fiber waveguides: Application to reflection filter fabrication. Appl. Phys. Lett. 1978, 32, 647–649. [CrossRef]

- Rahman, B.M.A.; Viphavakit, C.; Chitaree, R.; Ghosh, S.; Pathak, A.K.; Verma, S.; Sakda, N. Optical Fiber, Nanomaterial, and THz-Metasurface-Mediated Nano-Biosensors: A Review. Biosensors 2022, 12, 42. [CrossRef]

- Zaynetdinov, M.; See, E.M.; Geist, B.; Ciovati, G.; Robinson, H.D.; Kochergin, V. A Fiber Bragg Grating Temperature Sensor for 2–400 K. IEEE Sensors J. 2015, 15, 1908–1912. [CrossRef]

- Hsiao, T.-C.; Hsieh, T.-S.; Chen, Y.-C.; Huang, S.-C.; Chiang, C.-C. Metal-coated fiber Bragg grating for dynamic temperature sensor. Optik (Stuttg) 2016, 127, 10740–10745. [CrossRef]

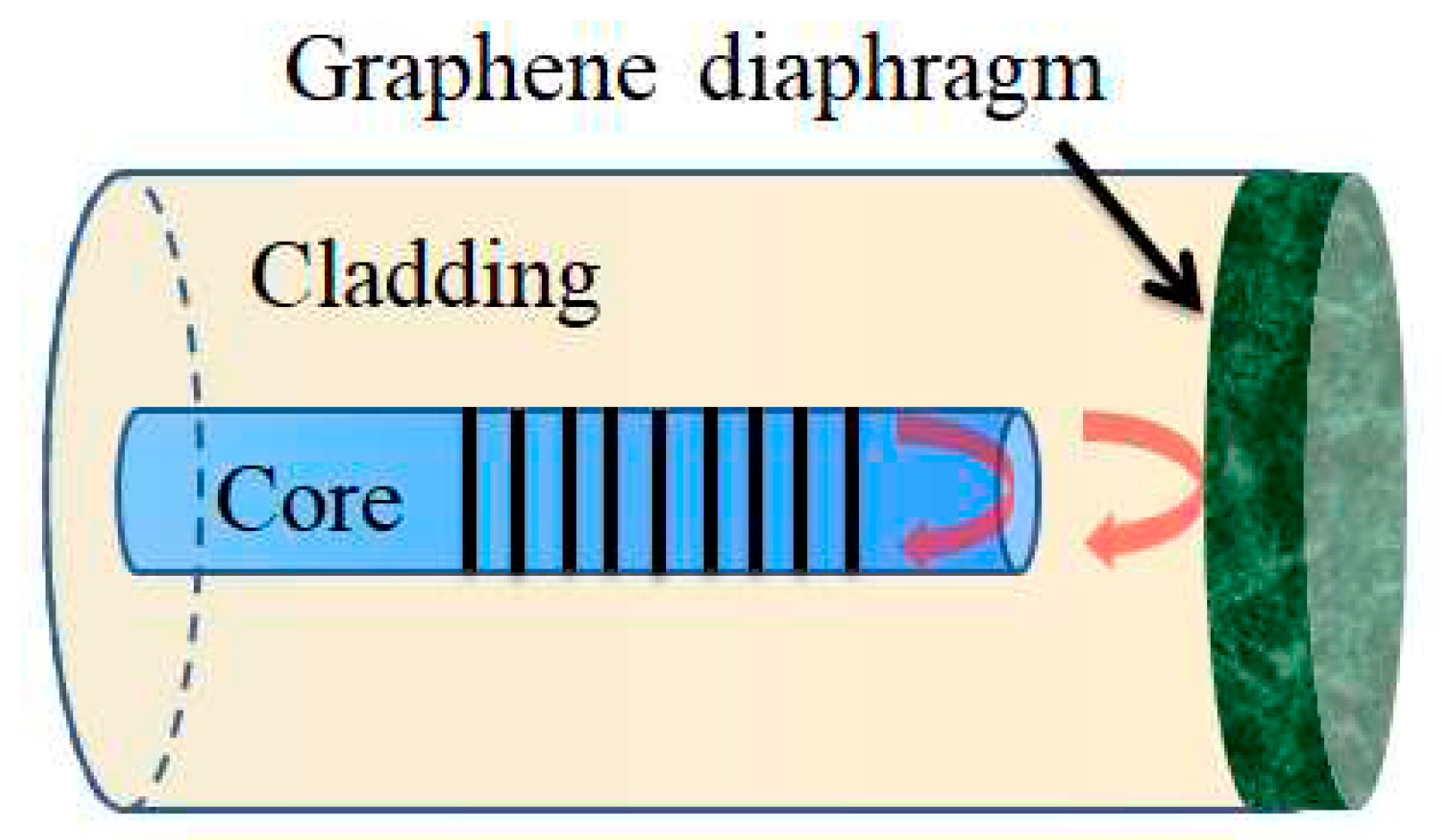

- Dong, N.; Wang, S.; Jiang, L.; Jiang, Y.; Wang, P.; Zhang, L. Pressure and Temperature Sensor Based on Graphene Diaphragm and Fiber Bragg Gratings. IEEE Photon- Technol. Lett. 2017, 30, 431–434. [CrossRef]

- Jasmi, F.; Azeman, N.H.; Bakar, A.A.A.; Zan, M.S.D.; Badri, K.H.; Su'Ait, M.S. Ionic Conductive Polyurethane-Graphene Nanocomposite for Performance Enhancement of Optical Fiber Bragg Grating Temperature Sensor. IEEE Access 2018, 6, 47355–47363. [CrossRef]

- Cheng, P.; Wang, L.; Pan, Y.; Yan, H.; Gao, D.; Wang, J.; Zhang, H. Fiber Bragg grating temperature sensor of cladding with SrTiO3thin film by pulsed laser deposition. Laser Phys. 2019, 29, 025107. [CrossRef]

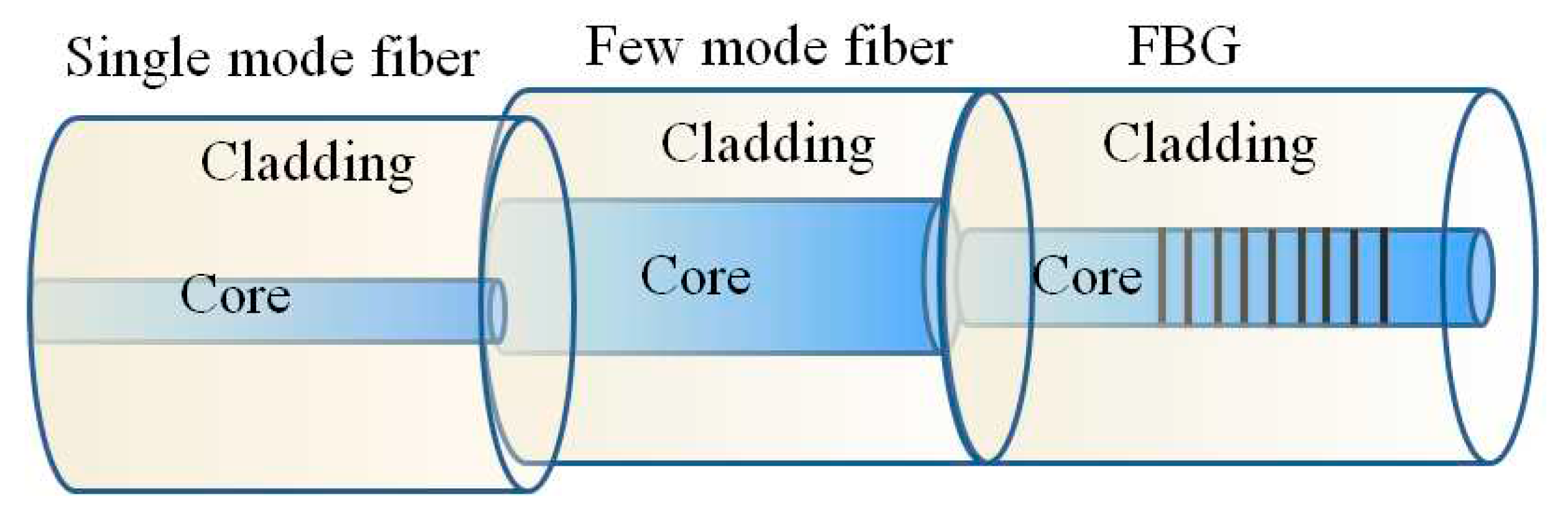

- Gao, X.; Ning, T.; Zhang, C.; Xu, J.; Zheng, J.; Lin, H.; Li, J.; Pei, L.; You, H. A dual-parameter fiber sensor based on few-mode fiber and fiber Bragg grating for strain and temperature sensing. Opt. Commun. 2020, 454, 124441. [CrossRef]

- Chen, Q.; Wang, D.N.; Gao, F. Simultaneous refractive index and temperature sensing based on a fiber surface waveguide and fiber Bragg gratings. Opt. Lett. 2021, 46, 1209–1212. [CrossRef]

- Esposito, F.; Campopiano, S.; Iadicicco, A. Miniaturized Strain-Free Fiber Bragg Grating Temperature Sensors. IEEE Sensors J. 2022, 22, 16898–16903. [CrossRef]

- Fu, H.; Wang, S.; Chang, H.; You, Y. A high resolution and large range fiber Bragg grating temperature sensor with vortex beams. Opt. Fiber Technol. 2020, 60, 102369. [CrossRef]

- Li, G.; Ji, L.; Li, G.; Su, J.; Wu, C. High-resolution and large-dynamic-range temperature sensor using fiber Bragg grating Fabry-Pérot cavity. Opt. Express 2021, 29, 18523–18529. [CrossRef]

- He, J.; Xu, X.; Du, B.; Xu, B.; Chen, R.; Wang, Y.; Liao, C.; Guo, J.; Wang, Y.; He, J. Stabilized Ultra-High-Temperature Sensors Based on Inert Gas-Sealed Sapphire Fiber Bragg Gratings. ACS Appl. Mater. Interfaces 2022, 14, 12359–12366. [CrossRef]

- Guo, Q.; Zhang, Z.-D.; Zheng, Z.-M.; Pan, X.-P.; Chen, C.; Tian, Z.-N.; Chen, Q.-D.; Yu, Y.-S.; Sun, H.-B. Parallel-Integrated Sapphire Fiber Bragg Gratings Probe Sensor for High Temperature Sensing. IEEE Sensors J. 2022, 22, 5703–5708. [CrossRef]

- Xu, B.; He, J.; Du, B.; Xiao, X.; Xu, X.; Fu, C.; He, J.; Liao, C.; Wang, Y. Femtosecond laser point-by-point inscription of an ultra-weak fiber Bragg grating array for distributed high-temperature sensing. Opt. Express 2021, 29, 32615–32626. [CrossRef]

- Sun, X.; Chang, Z.; Zeng, L.; Zhang, L.; Hu, Y.; Duan, J. Simultaneous vector bending and temperature sensing based on eccentric multi-mode fiber Bragg gratings. Sensors Actuators A: Phys. 2021, 331, 112903. [CrossRef]

- Hsu, C.-Y.; Chiang, C.-C.; Hsieh, T.-S.; Hsu, H.-C.; Tsai, L.; Hou, C.-H. Study of fiber Bragg gratings with TiN-coated for cryogenic temperature measurement. Opt. Laser Technol. 2020, 136, 106768. [CrossRef]

- Ayupova, T.; Shaimerdenova, M.; Tosi, D. Shallow-Tapered Chirped Fiber Bragg Grating Sensors for Dual Refractive Index and Temperature Sensing. Sensors 2021, 21, 3635. [CrossRef]

- Wang, Y.; Tao, J.; Yuan, W.; Lian, Z.; Ling, Q.; Chen, D.; Yu, Z.; Lu, C. Hollow Core Bragg Fiber Integrated With Regenerate Fiber Bragg Grating for Simultaneous High Temperature and gas Pressure Sensing. J. Light. Technol. 2021, 39, 5643–5649. [CrossRef]

- Wang, H.; Gao, S.; Yue, X.; Cheng, X.; Liu, Q.; Min, R.; Qu, H.; Hu, X. Humidity-Sensitive PMMA Fiber Bragg Grating Sensor Probe for Soil Temperature and Moisture Measurement Based on Its Intrinsic Water Affinity. Sensors 2021, 21, 6946. [CrossRef]

- Zhu, F.; Hao, X.; Zhang, Y.; Jia, P.; Su, J.; Wang, L.; Liu, L.; Li, X.; An, G. D-shaped optic fiber temperature and refractive index sensor assisted by tilted fiber bragg grating and PDMS film. Sensors Actuators A: Phys. 2022, 346, 113870. [CrossRef]

- Li, M.; Gong, Y.; Yin, J.; Li, W.; Shao, Y.; Cong, A.; Huang, G. Highly-sensitive and wide-range temperature sensor based on polymer-filled micro-cavity in fibre Bragg grating by temperature segmentation. Optik (Stuttg) 2021, 245, 167707. [CrossRef]

| Fiber structure | Material | Temp. range | Sensitivity | Refs. |

|---|---|---|---|---|

| SMF-MMF | N/A | 0-900°C | 13.4pm/°C | [99] |

| SMF-NCF-SMF | N/A | N/A | – 260 pm/°C | [100] |

| arc-shaped misaligned MZI on SMF | N/A | N/A | -0.953nm/°C | [101] |

| MMF-SMF-MMF | PDMS on graphene Au-Au@Ag NPs | N/A | 1.02 nm/°C | [102] |

| SMF-HCF-SMF | PDMS | 25°C–80°C | −384 pm/°C | [103] |

| SMF-NCF-SMF | PDMS | 28°C–50°C | 580.6 pm/°C | [104] |

| SMF-MMF-SMF | N/A | 27°C–31°C | -2060 pm/°C | [107] |

| core-offset SMF | N/A | 30°C–270°C | 0.0449 nm/°C | [108] |

| S-tapered fiber | N/A | -- | -1.403 nm/°C | [110] |

| FPI in SMF | N/A | 1000°C | 17.7 pm/°C | [111] |

| SMF-SCPSF-SMF | N/A | 200°C - 1000°C | 106.64 pm/°C | [113] |

| multimode POF | N/A | 25°C - 110°C | 1.04×10–3°C-1 | [114] |

| FBGs embedded in PLA | N/A | 20°C - 70°C | 139 pm/°C | [115] |

| Fiber structure | Material | Temp. range | Sensitivity | Refs. |

|---|---|---|---|---|

| FBG | N/A | 5-50 °C | 28.9 pm/ °C | [126] |

| FBG | N/A | 27–427 °C | 14.42 pm/°C | [127] |

| FBG | N/A | -5 – 35 °C | 35 mV/°C | [128] |

| Sapphire-FBG | N/A | 0-1800 °C | 41.2 pm/°C | [129] |

| Sapphire-FBG | N/A | 0-1200 °C | 30.19 pm/°C | [130] |

| FBG | N/A | 0-1000 °C | 18.2 pm/°C | [131] |

| FBG | N/A | 40-260 °C | 13 pm/°C | [132] |

| FBG | Titanium nitride | 25 to −195 °C | 10.713 pm/ °C | [133] |

| Tapered FBG | Gold | 0-50 °C | 9.893 pm/°C | [134] |

| Hollow core Bragg fiber | N/A | 600 °C | 25.925 pm/°C | [135] |

| FBG | poly (methyl methacrylate) | 15-35 °C | −0.080 nm/°C | [136] |

| FBG | polydimethylsiloxane | 20, 30, 40 and 50 °C | 4.88, 5.15, 4.53 and 4.38 nm/°C | [137] |

| FBG | Polymer | 80 °C | 9.33 nm/°C | [138] |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).