1. Introduction

The SO

x and NO

x emissions limits from ocean-going vessels (OGVs) are laid down by the International Maritime Organization (IMO) in the MARPOL Protocol of 1997 (MARPOL PROT 1997, as amended), described in MARPOL Annex VI. Reference to Annex VI in this article will be to the Revised MARPOL Annex VI in 2008 and not to the 2021 Revised MARPOL Annex VI because airborne emission measurements took place before the entry into force of the 2021 revision [

1]. In MARPOL Annex VI designated emission control areas (ECAs) were defined with more stringent standards for SO

x and NO

x.

MARPOL Annex VI Regulation 14 defines the SO

x emission limits. As of 2008, the Baltic Sea and the North Sea were designated as a sulfur emission control area (SECA) (

Figure S1, upper). The maximum fuel s sulfur content (FSC) of the marine fuels used by OGVs in SECAs was reduced in successive steps until it reached the current limit of 0.1% FSC. Instead of using compliant fuels, OGVs can also use natural gas or an exhaust gas cleaning system (EGCS) to achieve the same emission level as the low-sulfur fuels (

Table S1) [

2,

3,

4,

5]. The sulfur limit outside the SECAs, initially set in 2005 to 3.5% [

1,

4,

6] was reduced in 2020 to 0.5% by the so-called 'Global Sulfur Cap' [

7] (

Figure S1, middle). On March 1, 2020, the so-called “Carriage Ban” came into force, prohibiting the carriage of non-compliant fuels in the bunker tanks, unless the OGV is equipped with an EGCS [

8].

Moreover, at European level, SO

x emissions from OGVs are regulated by the EU Sulphur Directive ((EU) 2016/802) and the Commission Implementing Decision ((EU) 2015/253), which lay down the rules regarding sampling and reporting of the sulfur content of marine fuels [

9,

10,

11,

12]. The latter stipulated that Member States must carry out documentary inspections on at least 10% of the total number of individual OGVs calling at Member State’ ports (Art 3.1, Implementing Decision). In addition, 40% of the inspected ships will be checked using approved (laboratory) fuel sampling methods for Member States that fully border the SECA area (Art 3.2(a)). However, the number of fuel samplings can be reduced by up to 50%, by subtracting the number of OGVs that have been checked for compliance using remote sensing or the rapid scan analysis (Art 3.3(a)) [

11]. At the national level, Belgium further implemented MARPOL Annex VI and the Sulfur Directive (EU) 2016/802) in 2020 [

13].

MARPOL Annex VI Regulation 13 introduced NO

x emission limits for OGVs and described dedicated NO

x emission control areas (NECAs) where stricter limits apply for recently built OGVs (Tier III, see further in this section) [

5]. Five years after the enactment of the North American and US Caribbean NECA on January 1, 2016 [

14], the SECA in the Baltic Sea and the North Sea was expanded in 2021 with a NECA and renamed emission control area (ECA) [

15,

16]. To reduce NO

x emissions in the OGV exhaust gases, engine manufacturers have the option to either tackle the combustion processes in the engine or to install NO

x abatement systems like a selective catalytic reduction (SCR) and/or exhaust gas recirculation (EGR) [

17].

MARPOL Annex VI divides the merchant fleet into four categories, from tier I to tier III, and before tier I (tier 0), according to the construction of the ship based on the keel-laying date (KLD) or a similar stage of construction (Reg. 2.19). The emission limits per tier follow a decreasing curve in function of the engine rated speed (ERS or n), expressed in rotations per minute (RPM) (

Figure S1, lower). In order to obtain the required Engine International Air Pollution Prevention (EIAPP) Certificate, a verification test is executed before the installation of the engines onboard the OGV, in accordance with the NO

x Technical Code, MEPC.1/Circ.679 [

18,

19]. After the installation of the engines onboard an International Air Pollution Prevention (IAPP) Certificate is issued by a classification society. In addition, the NO

x Technical Code stipulates that all interchangeable parts that exert an influence on the NO

x emissions, described as “engine components” (1.3.3, NOx Technical Code), must be listed in the NO

x technical file and all modifications must be recorded and stored on-board together with the EIAPP Certificate and the IAPP Certificate [

18,

20]. Substantial modifications mean all modifications to the engine components that may cause NO

x emissions to exceed the limit, in which case a new verification test is required (6.4.16.1, NO

x Technical Code). Alternatively, the replacement of engine components that do not alter the NOx emissions are not considered as a substantial modification (1.3.2 NO

x Technical Code). The verification tests are based on five different engine test cycles with four to five engine loads and corresponding weighting factors (WF) (

Table S2). It is crucial to highlight that only for Tier III a “not to exceed” (NTE) limit is defined, which states that the NO

x emission may not exceed the limit by more than 50% at any of the individual engine loads [

18]. Another critical aspect of the Technical Code to highlight is that currently, no restrictions are described under the 25% main engine loading point for any of the tiers.

In contrast with the sulfur regulations, NO

x emissions from ships are currently not regulated by an EU directive. However, discussions are ongoing to evaluate if MARPOL and its Annexes, thus including NO

x emissions, can be included under a future revision of the Ship Source Pollution Directive (2005/35/EC) [

21]. More importantly, on 18 December 2022, the European Commission, the European Parliament, and the Council of the EU finalized a Provisional Agreement on a broad set of policy proposals of the "Fit for 55" climate package, including a landmark reform of the EU Emissions Trading System (ETS) and the milestone introduction of the Carbon Border Adjustment Mechanism (CBAM), which still requires formal approval from the Parliament and the Council before entering into force. Particularly, once formally adopted, the new ETS system will, for the first time, integrate emissions from the maritime sector into its scope, with the obligation to surrender allowances rising from 40% of verified emissions in 2024 to 100% in 2026. Moreover, besides the gradual implementation of CO

2 emission retributions, OGVs will also have to pay for their non-CO

2 emissions like N

2O and CH

4 from 2027 [

22,

23,

24]. At the end of 2024, it will be decided if other greenhouse gasses like NO

x and certain particles like Black Carbon (BC) will be included in the ETS [

25,

26,

27].

In order to create an adequate compliance level to MARPOL Annex VI Regulation 13 and 14, an effective enforcement strategy is required that incorporates a reasonable non-compliance detection rate. In addition, a discouraging legal sanctioning scheme is essential that stands in proportion to the economic benefits obtained from non-compliance. Such an effective enforcement strategy will not only contribute to environmental protection, human health and economic benefits, but will also contribute to a level playing field for the maritime transport sector. Therefore, ensuring that all market actors follow the same set of rules and conditions is considered as one of the backbones of international trade [

28,

29,

30,

31].

Airborne measurements have been shown to provide an efficient solution to monitor the compliance of OGVs with regard to the emission regulations [

32,

33,

34,

35,

36,

37,

38,

39]. Even so, the use of airborne measurement data has not yet been recognized as an independent legal evidence for observed possible non-compliant OGVs, and is thus far, merely used for risk-based targeting of inspections in ports. However, the effect of the provision of airborne alerts on the effective results of port inspections of OGVs is not yet examined until now.

To increase the enforcing effect of airborne monitoring, the airborne measurements would need to obtain a legal evidence status, not only to serve as an alerting mechanism but also to become a direct enforcement action. An essential part of the process of receiving the status of legal recognition of airborne measurements is the validation of the airborne measurement reliability in real world conditions. So far, only limited studies have been executed comparing on-board measurements with remote measurements [

32,

33,

40].

3. Results and discussion

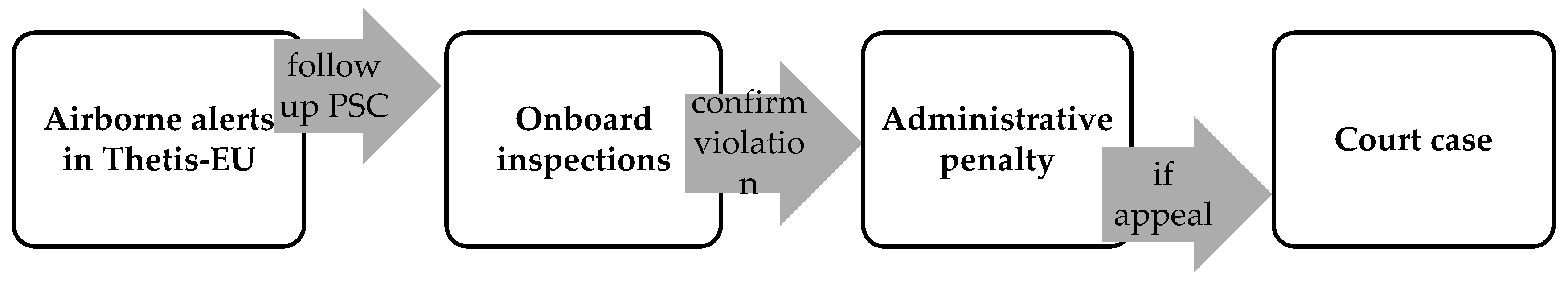

3.1. Follow-up airborne FSC alerts by port inspection authorities

3.1.1. Results on-board inspections and airborne monitoring

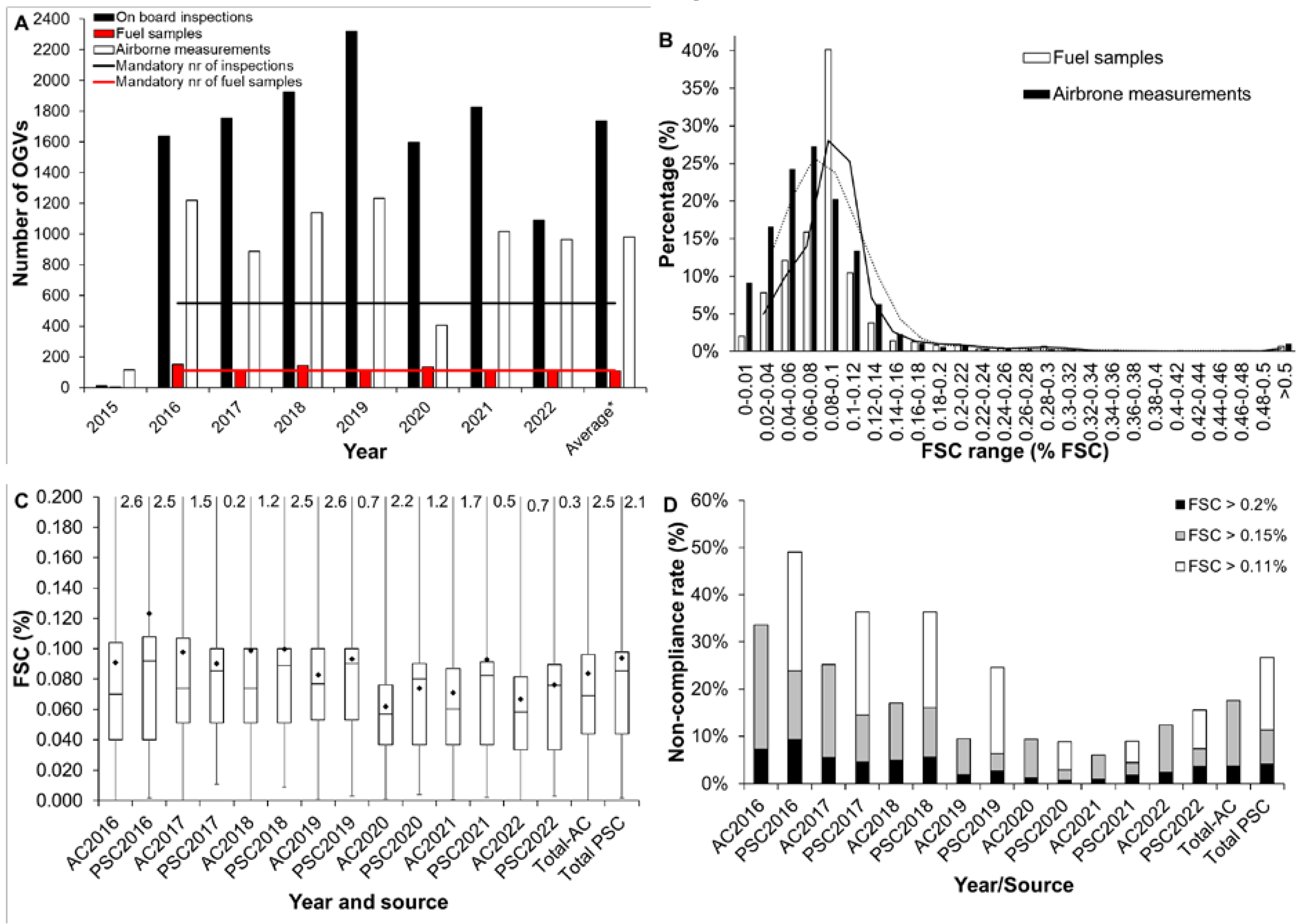

For Belgium, it was defined, in accordance with the EMSA, that

ca. 55000 OGVs are calling Belgian ports every year. According to the Commission Implementing Decision ((EU) 2015/253), inspections must be carried out on 10% of these port calls (Art 3.1), which amounts to 550 inspections per year. Belgian inspection authorities started with sulfur inspections in 2015, but as they only carried out 5 inspections in that year, 2016 is used as the starting point. In total, 12148 on-board inspections have been completed between 2016 and 2022 (

Figure 2A). With an average of 1735 inspections per year, it is substantially higher than the 550 mandatory inspections. The Commission’s Implementation Decision further indicates a 40% fuel sampling effort for MS bordering a SECA (Art 3.2.), representing 220 fuel samples. However, a reduction up to 50% may be applied when remote monitoring is used (Art 3.3), which comes down to 110 mandatory fuel samples per year [

11]. In total, 871 fuel samples were taken between 2016 and 2022, or 124 fuel samples per year on average, therefore amply fulfilling the required number of fuel samples.

During the global Covid-19 pandemic, the number of port calls in Belgian ports decreased by 8% in 2020 and by 5% in 2021 compared to 2019 [

52]. Despite this, Belgium still managed to meet the pre-Covid set number of inspections and fuel samples, which contrasts with the impact of the pandemic within the Paris MoU, for which a 27% reduction in the number of PSC inspections was reported [

53].

When in port the overall FSC non-compliance is assessed based on the document inspections, the compliance rate is very high; 99.5% of the OGVs had an FSC under 0.15%. When looking at the compliance rate based on fuel samples alone, compliance is substantially lower, with 92.2% of the OGVs under 0.15% FSC. The average FSC from the collected fuel samples was 0.096% FSC.

Regarding airborne monitoring, between 2016 and 2022, 6961 OGVs were checked for FSC, with an average of 978 OGVs per year. A total of 626.5 flight hours were spent on MARPOL Annex VI surveillance or an average of 89.5 flight hours per year Of the measured OGVs, 93.6% were considered compliant, and the mean observed FSC was 0.084% FSC.

3.1.2. Comparison of port inspection and airborne results

The significant difference in the number of fuel inspections between port inspections and airborne inspections immediately demonstrates the scale advantage of airborne monitoring. It takes 275 man hours per year to carry out 110 fuel samples in the port(only including the time of the inspection), while for 110 measurements, 10 flight hours would suffice, with a crew of 4 on board or 40 man hours, so almost 7 times more time efficiency.

When comparing the FSC measurement distribution between the aircraft and fuel inspections, they broadly show the same patterns. The aircraft measurements have the highest proportion in the 0.06-0.08% FSC interval (median = 0.086% FSC), and the fuel samples have a higher proportion in the 0.08-0.1% FSC interval (median = 0.069% FSC) (

Figure 2B). This difference is also observed in the average FSC values, which indicates that the average FSC of the airborne measurements is 0.084% FSC, significantly lower than the average measured FSC in the port of 0.094% FSC (

P < 0.001). (see

Figure 2C). To exclude the effect of the airborne alerts, the average FSC was calculated for the fuel samples excluding the samples carried out after airborne alerts, which was 0.087% FSC. Although the difference was already much smaller, it still appeared to deviate significantly from the average FSC from airborne measurements (

P < 0.001) (Figure S

2, upper), which indicates the presence of a slight negative measurement bias for the airborne measurements. This average FSC of the fuel inspections without alerts was furthermore compared with the average FSC of the fuel inspections that followed up on an alert, which was with 0.21% FSC significantly higher (

P < 0.001) and even exceeding the 0.1% FSC legal limit substantially (Figure S

2, lower), therefore demonstrating the added value of the airborne surveillance.

It is not easy to draw conclusions about the compliance rates between the airborne results and the results of either the on-board inspections or the fuel samples (

Figure 2D). On-board inspections may miss non-compliance if no suspicious aspects in the documents are observed (Type II errors). Fuel samples, on the other hand, may be biased as they are not taken randomly, but are taken after suspicious aspects in the documents, after an alert from airborne monitoring, or due to previous deficiencies. When the overall compliance based on the document inspections is compared to the airborne compliance rate, the airborne compliance rate is significantly lower (

P = 0.000). When the compliance rate based on the fuel samples is compared to the airborne results, the airborne compliance is significantly higher (

P = 0.0281).

However, to compare the compliance rate of the airborne measurements with the unbiased fuel sampling, the number of fuel samples greater than 0.15% FSC, excluding the fuel samples initiated after the airborne alert was calculated, was 94.1%. The number of airborne measurements, exceeding 0.15% FSC was 94.2% highly comparable. In general, the difference was not found to be significant (P = 0.8691).

3.1.3. Follow-up alerts based on Thetis-EU

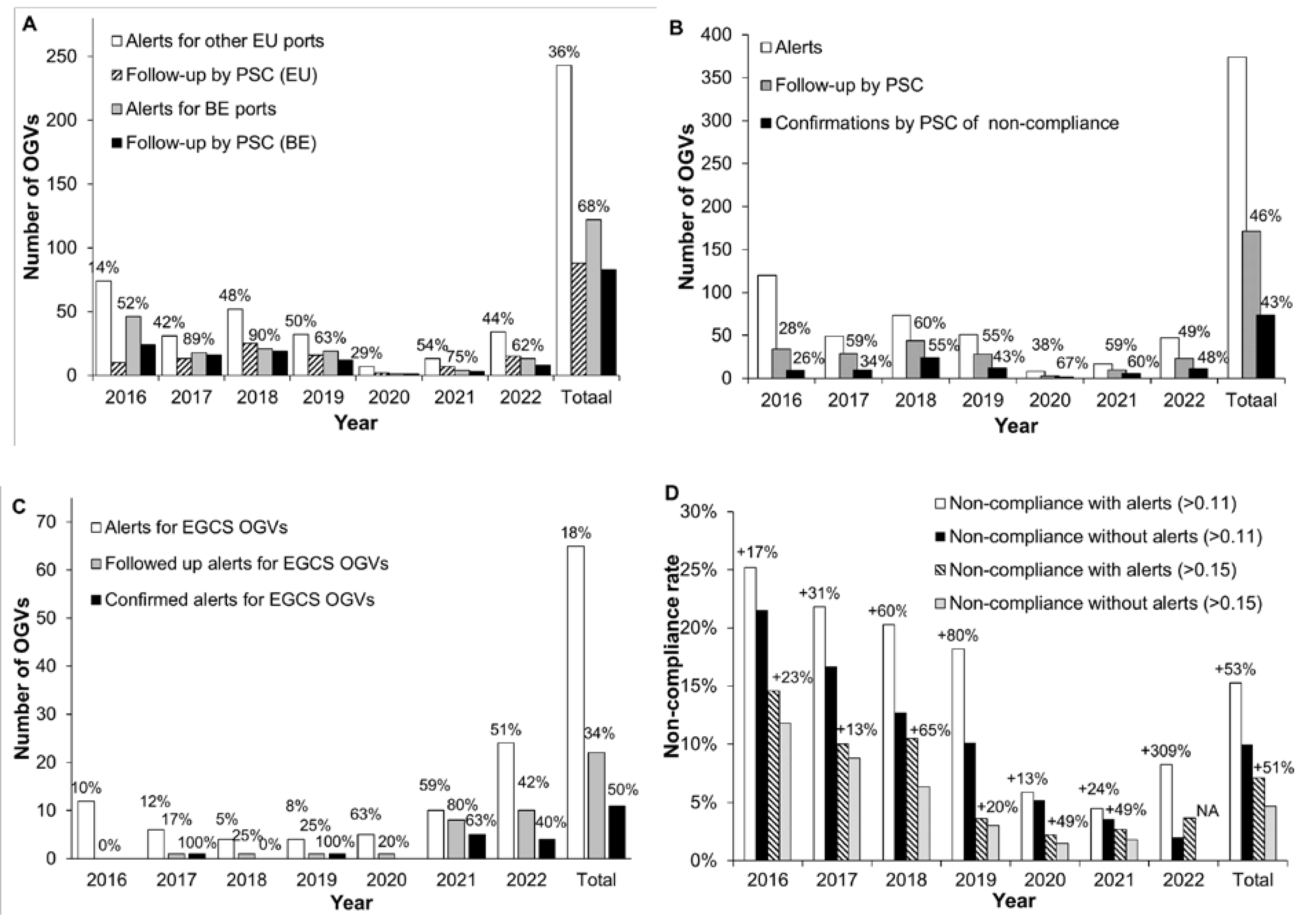

All possible non-compliant OGVs observed by the coastguard aircraft were reported to the Belgian port inspection authorities by email. Only about 1/3 of the observed potentially non-compliant OGVs went to a Belgian port. In case the non-compliant OGVs were sailing to a Belgian port, inspectors of FPS Mobility prioritized these OGVs for inspection and carried out an inspection on board whenever it was operationally feasible. In case the non-compliant OGV was not sailing to a Belgian port, an alert was made in Thetis-EU. Initially this was done manually by FPS Mobility, but from 2019 the results were automatically uploaded to Thetis-EU after each flight. Once an OGV was inspected in a Belgian or another EU port, inspectors reported this in Thetis-EU. For all airborne alerts, a manual check was carried out to see whether actions had been taken, as Thetis-EU does not (yet) contain a tool that can generates those exports. For the evaluation of the follow-up, a qualitative approach was used to see if the OGV was followed up within a reasonable time. For OGVs operating only in the ECA, a limit of 14 days was used; for OGVs operating on international routes, it was checked if the OGV was inspected upon their return to the ECA (within a maximum 3 months).

In terms of analyzing the follow-up of airborne alerts by port inspection authorities, a distinction was made between Belgian and other EU ports of destination (

Figure 3 A). In 2015, only five inspections were carried out in Belgium. Moreover, the airborne measurement was taken in a test period without the results put in Thetis-EU, so that 2015 is omitted in the analysis. In 2016, only 34 of 120 alerts were followed up (28%). This low follow-up was mainly due to the limited follow-up of alerts in Thetis-EU, as 24 alerts out of 46 alerts for Belgian ports were followed up, and only 10 out of 74 alerts for other EU ports were followed up. In 2017 the overall follow-up improved to 59%, with 16 out of 18 alerts followed-up in Belgian ports and 13 out of 31 alerts in other EU ports. In 2018 the overall follow-up increased further to 60%. Again, the follow-up in Belgium was very high with 19 out of 21 alerts. Also, the follow-up in other EU ports increased with 25 out 52 alerts followed-up. In 2019 there were fewer alerts reported, resulting in a limited decrease of the follow-up to 55%, with 12 out of 19 alerts in Belgium, and 16 out of 32 alerts in other EU ports. In 2020, due to the global Covid-19 pandemic, the global follow-up fell substantially back to 38%: one alert was delivered to Belgian ports, which was followed up and two out of seven alerts were followed up by other EU ports. In 2021, the overall follow-up increased again to 59%, three out of four alerts in Belgian ports were followed up, and in other EU ports 7 out of 13 alerts were followed up. In 2022 more alerts were generated, whereas the follow-up fell back to 49%, with 8 out of 13 alerts followed up in Belgian ports and 15 out of 34 in other EU ports. During 2016-2022, 83 out of 122 reported FSC alerts to a Belgian port have been followed up (68%), and 88 out of 243 alerts had been followed up in other EU ports (36%) (

Figure 3A). The overall follow-up of airborne alerts for OGVs with all ports of destinations combined is 46%, which can still be considered relatively high, as 20% of the observed OGVs had a port of destination outside the SECA.

3.1.4. Confirmation rate of airborne alerts in ports

The confirmation of the airborne alerts was analyzed based on the results of the fuel sampling, entered in Thetis-EU after an alert was followed up by port inspection authorities. An alert was considered to be confirmed as soon as the measurement of the fuel sampling was above 0.11%.FSC. In Belgium, a public statement and financial penalty are only applied above 0.15% FSC, and this limit was investigated separately.

In the period 2016-2022, port inspection authorities in Belgium and in other EU countries were able to confirm the alert in 43% of the cases, after an inspection had been carried out on board of the OGV (

Figure 3B). Noteworthy is that the confirmation rate is lower for Belgian ports (39%) compared to other ports (48%), which is likely due to the fact that most alerts for OGVs with a Belgian port of destination went to Antwerp (22% of the observed OGVs), while OGVs with another country as a destination went to Rotterdam (17% of the observed OGVs) (

Figure S3). OGVs going to Antwerp must sail on the river Scheldt, which takes 5-6 hours, adding therefore several hours to the time lap between the measurement and the fuel sampling, hence decreasing the chance of confirming the non-compliance.

The reason why the port inspection authorities did not always confirm the initial alerts may be due to several factors. One of the factors is time: on average, the time between the alert and the on-board inspection was 49 days. In the meanwhile, the OGV might have completed the fuel changeover procedures or switched to compliant fuel. The median time to successfully confirm the non-compliance was 2 days. The high follow-up time was often a result of alerts for OGVs with a destination of a port outside the EU and the OGV could only be inspected after entering an EU port. In other cases, the OGV was only in port for a very short time or arrived in the evening (or the weekend) and the inspectors did not have sufficient time or staff to organize an on-board inspection. In some cases, lack of confirmation could be the result of a false positive alert (Type I error). One of the reasons for getting a false alert were high emissions of VOC’s, resulting in higher SO

2 readings. These false positives were eliminated from 2020 on by installing a customized hydrocarbon kicker [

35]. Very high NO

x non-compliances may also have impacted FSC measurements between 2016-2019. From 2020 on, this NO cross-sensitivity was also eliminated with the installation of the NO

x sensor [

35,

36]. Nevertheless, both NO and VOCs have most likely only impacted the yellow flags. In some cases, ship incinerators may also affect SO

2 readings. However, it is unlikely that this would result in multiple false readings as these are highly temporal events. By taking multiple measurements, these Type I errors are significantly reduced [

35]

3.1.5. Follow-up of EGCS OGV alerts

The amount of OGVs equipped with an EGCS or so-called scrubber, increased drastically over the years. At the end of 2021, 30% of the global fleet was equipped with an EGCS system [

54]. As OGVs equipped with an EGCS are able to use Heavy Fuel Oil (HFO) with an FSC of up to 3.5% or more, they pose a significant risk for high SO

2 emissions in case of non-compliance. Non-compliance may occur intentionally, for instance, to lower fuel consumption or when no action was taken after technical failures or system-generated alarms. Non-compliance can also occur unintentionally if the on-board emission monitoring system is not functioning properly. If non-compliance occurs, this will result in SO

2 emissions that can be multiple times higher than emissions from non-compliant OGVs that are not equipped with an EGCS, but most likely operating on Very Low Sulfur Fuel Oil (VLSFO) of 0.5% FSC outside the ECA area. This means that, when observed as non-compliant, these non-EGCS OGVs are generally observed with FSC values between 0.13% FSC and 0.5% FSC.

A wide variety of shortcomings with EGCS OGVSs are also observed by other EU Member States, such as Germany and Netherlands. In order to draw awareness to these issues, the Netherlands submitted in 2022 an information document at MEPC 79 to address certain inspection issues of EGCS OGVs in ports [

55].

Since the start of the Global Cap in 2020, the number of EGCS OGVs observed has increased dramatically. This shift was also clearly observed in the number of alerts generated for EGCS OGVs (

Figure 3C). Before 2020, there were very few alerts for EGCS-OGVS, besides for some OGVs that were emitting higher levels of SO

2 in their commissioning phase in 2015 and 2016. However, of the 2363 monitored OGVs in the period 2020-2022, 21% were equipped with an EGCS. In the period 2020-2022, 44 non-compliant EGCS-OGVs have been observed, representing 59% of the total number of observed non-compliant OGVs, which indicates that the proportion of EGCS-OGV in the non-compliance observations is almost three times as high as the relative amount of observed EGCS OGVs. The overall rate of non-compliance observations for EGCS OGVs was 15% over the period 2020-2022, while the overall rate of non-compliant observations for non-EGCS OGVs was with 1.8%, significantly lower (

P = 0.000). When focusing on the higher observed FSC levels over the period 2020-2022, 12 of 12 observed OGVs with an FSC above 0.5%, were equipped with an EGCS. From a flag color perspective, 16 out of 21 red flags were EGCS OGVs and 12 out of 18 orange flag OGVs were equipped with an EGCS. For yellow flags, 16 out of 38 were equipped with an EGCS.

EGCS OGVs are not only observed more often to be non-compliant, they provide also more challenges for the on board inspections. In accordance with the IMO guidelines on EGCS, OGVs are required to keep data logs on regulated parameters, which are among others: SO

2/CO

2 ratios, PH values of water in- and outlets, concentration of Polycyclic Aromatic Hydrocarbons (PAHs) and suspended matter in the discharged water. OGVs are required to keep these logs for minimum 18 months on-board (7.4, 2015 EGCS Guidelines) [

2,

3,

4,

5,

46]. Nevertheless, checking these logs is very time consuming and has a low efficiency in detecting deficiencies. Even with the use of airborne alerts, the sanctioning of EGCS OGVs is not easy. In some cases, the logs showed compliant values, in some cases the non-compliant values lasted only for a short time and in one case the non-compliance was confirmed but the OGV owners provided information that showed due diligence.

From 2016-2022, a total of 55 alerts were generated from OGVs with EGCS. For 39% of these alerts an on-board inspection was initiated (with 40% in Belgian ports and 39% in other ports), which is 6% lower than for non-EGS, but with no significant difference (P = 0.6178). For 41% of the inspections following an alert, non-compliance was confirmed, which is 16% lower than for the non-EGCS OGVs, also not statistically different (P = 0.4154). This demonstrates that airborne monitoring provides an important added valued in the enforcement of the EGCS regulations.

3.1.6. Improvement of port inspections

As mentioned in section 3.1.1, the compliance rate of neither the fuel sample results nor the on-board documentary inspections reflected the actual random non-compliance rate of OGV at the port. It was therefore not easy to determine the direct benefits of aerial monitoring for port inspections. In section 3.1.1., it was already demonstrated that the average FSC of all on-board fuel samples, including the fuel samples initiated after an airborne alert, was higher than the average FSC of the fuel samples that were executed without an alert. In addition, fuel sample compliance rates, including those taken after an airborne alert, were significantly higher than the airborne non-compliance rate. Furthermore, no difference was observed in compliance rate between the fuel samples and the airborne measurements after omitting the fuel samples that were taken after an airborne alert. In section 3.1.2, it was furthermore demonstrated that 43% of the airborne alerts were confirmed.

To demonstrate that airborne measurements have a positive effect on the efficiency of the inspections in ports, different approaches are used to support this link. In a first approach, the relative increase in the observed compliance percentage during port inspections, with or without the use of airborne alerts, is examined. Experience with the EU funded CompMon project [

39] shows that random non-compliance in the port is around 3%. With a confirmation rate of 43%, this would mean an improvement with factor 13 in case port inspection authorities would rely only on airborne monitoring alerts. With the relative low number of alerts, Belgian port inspection authorities cannot rely solemnly on alerts from the aircraft to initiate an investigation (as shown in section 3.1.2 only ca. 1/3 of the fuel samples are taken after an airborne alert). To examine the actual realized benefits of the airborne alerts for the Belgian port inspection authorities, the non-compliance rate from all port inspections, including the inspections initiated after an alert, i are compared with the non-compliance rate of the port inspections excluding those initiated after an alert. This analysis shows an overall significant increase of the observed non-compliance in port inspections of ca 53% (

P = 0.0035) above 0.11% FSC, and a significant increase of 51% above 0.15% FSC (

P = 0.044) (

Figure 3D). If we look at the increase in violations above 0.2% FSC, the increase is still 48%, while the difference is not significant (

P = 0.1342), which is purely a result of the lower number of high non-compliances.

In a second approach, the level of non-compliance was examined by comparing three compliance levels (0.11% FSC, 0.15% FSC and 0.20% FSC). The non-compliance level of OGVs above 0.11% FSC in port inspections initiated without airborne alert was 10.0%, whereas the non-compliance of inspections resulting from an alert was 84%. The non-compliance level above 0.15% FSC in the port inspections taken without airborne alert was 6%, while the inspections initiated after an airborne alert was 38%. The observed non-compliance level above 0.2% FSC in port inspections without airborne alert was 4% and the non-compliance of the inspections after airborne alerts was 22%. The improvement of non-compliance rate by port inspections after an alert is significant for all levels (P = 0.000). This analysis shows that airborne monitoring can address both high and low FSC levels and can therefore be applied to identify large and small emitters where other warning mechanisms may be less successful.

For inspections of EGCS-OGVs, the added value of airborne monitoring in the enforcement chain is even more relevant. In total, 974 EGCS-OGVs have been inspected, representing 4% of the total number of inspections. Of all these inspections, six were executed after an alert generated by airborne monitoring. All port inspections lead to three confirmed violations of EGCS-OGVs, of which two were a result of an alert and only one was found without the help of airborne alerts, therefore increasing the efficiency of port inspections of EGCS-OGVs by factor three.

3.1.7. Administrative fines imposed in Belgian ports

Exhaustive information was collected from public statements (which is a statement of a criminal fact and a ticket for a fine issued by a law enforcement officer) and administrative fines issued for OGVs after an inspection in Belgian ports. The public statements and administrative fines imposed by Belgian port inspection authorities in 2016-2022 are shown in

Table 2. It is crucial to highlight that not all public statements were subject to a fine. In 2016, the regime of administrative fines for violations of shipping laws was not yet in force in Belgium [

44]. More importantly, it must be noted that not all confirmed non compliances resulted in a public statement. No public statement was made if the FSC was between 0.1% FSC and 0.15% FSC and as a consequence no fine followed. For one confirmed case, the reference sample was contaminated and could not be re-analyzed, which was therefore dismissed. One case for an EGCS OGV was confirmed as non-compliant, but due diligence was proven and the case was dismissed. In total, 32 public statements have been made for violations of MARPOL Annex VI, for a total amount of 1,425,200€. Among these, 12 violations (41%) resulted from an alert made by the Belgian Coastguard aircraft and one from an alert from the German Federal Maritime and Hydrographic Agency (BSH), resulting in an amount of 482,800€ (34%)

1. In the period 2016-2022, no perpetrators appealed against the fines, so no cases have come to court. Of the 32 public statements, three involved an EGCS-OGV, totaling fines of 216,000€;two of these OGVs were reported by the aircraft and represented a total fines of 200,000€.

In comparison : the total operational cost for the implementation of the sniffer program in 2016-2022 was 981,848€ (

Table S3). The fines generated with the help of remote measurements account for approx. 50% of government expenditure on airborne monitoring.

3.2. Follow-up airborne NOx alerts by port inspection authorities

The IMO regulations regarding NOx emission are complex and do not include compliance checks in ports. Therefore it is currently practically not possible for port inspection authorities to check effective compliance in ports. In contrast to Sulfur emissions from ships, there are no EU implementation regulations for NOx emissions from OGVs and no common European mandatory number of inspections have been defined. There is also no system for exchanging information on NOx inspection results and remote measurements.

There is no exhaustive information about compliance or non-compliance with the MARPOL NOx standards based on NOx inspections of OGVs in Belgian ports. The results of NOx inspections remain fragmentary and incomplete because these inspections by the Belgian PSC department and the Environmental Safeguarding and Dangerous Goods department are limited to an evaluation of the EIAPP and the IAPP certification documents issued by classification societies on behalf of the flag state authority (Recognized Organizations). This means that the only assessment of NOx compliance is based on remote measurements.

In the period 2020-2022, the Belgian Coastguard aircraft monitored NOx emissions of 2375 vessels of which 97.3% were found to be compliant. In 2020-2022, 35 alerts for possible non-compliance were send to port inspection authorities. More specifically, nine of these concerned OGVs with a Belgian port of destination, one Tier 0 OGV, one Tier I OGV and seven Tier II OGVs.

Port inspection authorities in Belgium followed up on two of these alerts and carried out a documentary inspection. However, none of these inspections could confirm if the OGV was non-compliant or not. As Thetis EU does not yet include the possibility to share NOx alerts, no detailed follow-up statistics of NOx alerts by other countries could be obtained. No fines have been imposed for NOx emission violations to date.

In other ECA countries, for instance in the United States, a more rigorous inspection regime is already in place although the inspections are merely based on a profound documentary analysis by technical NOx experts from the US Coastguard. Possible non-compliant NOx alerts for OGVs with the US as destination have been forwarded to the US Coastguard and resulted in two inspections. However, these inspections did not lead to any legal follow-up as the documents did not reveal any suspicious findings.

The very low follow-up of the alerts generated and the lack of any confirmation of non-compliance is due to the regulations themselves. In case the regulations would have included mandatory CEMS systems, port inspection authorities would have considerably more possibilities to check for effective NOx compliance during on-board inspections. On top of this, the use of a NTE limit for Tier I and Tier II would provide even more potential for effective on-board inspections. Unfortunately, based on these results, it can be concluded that the NOx regulations are not enforceable by port inspection authorities within the existing international and European legal frameworks.

3.3. FSC validation

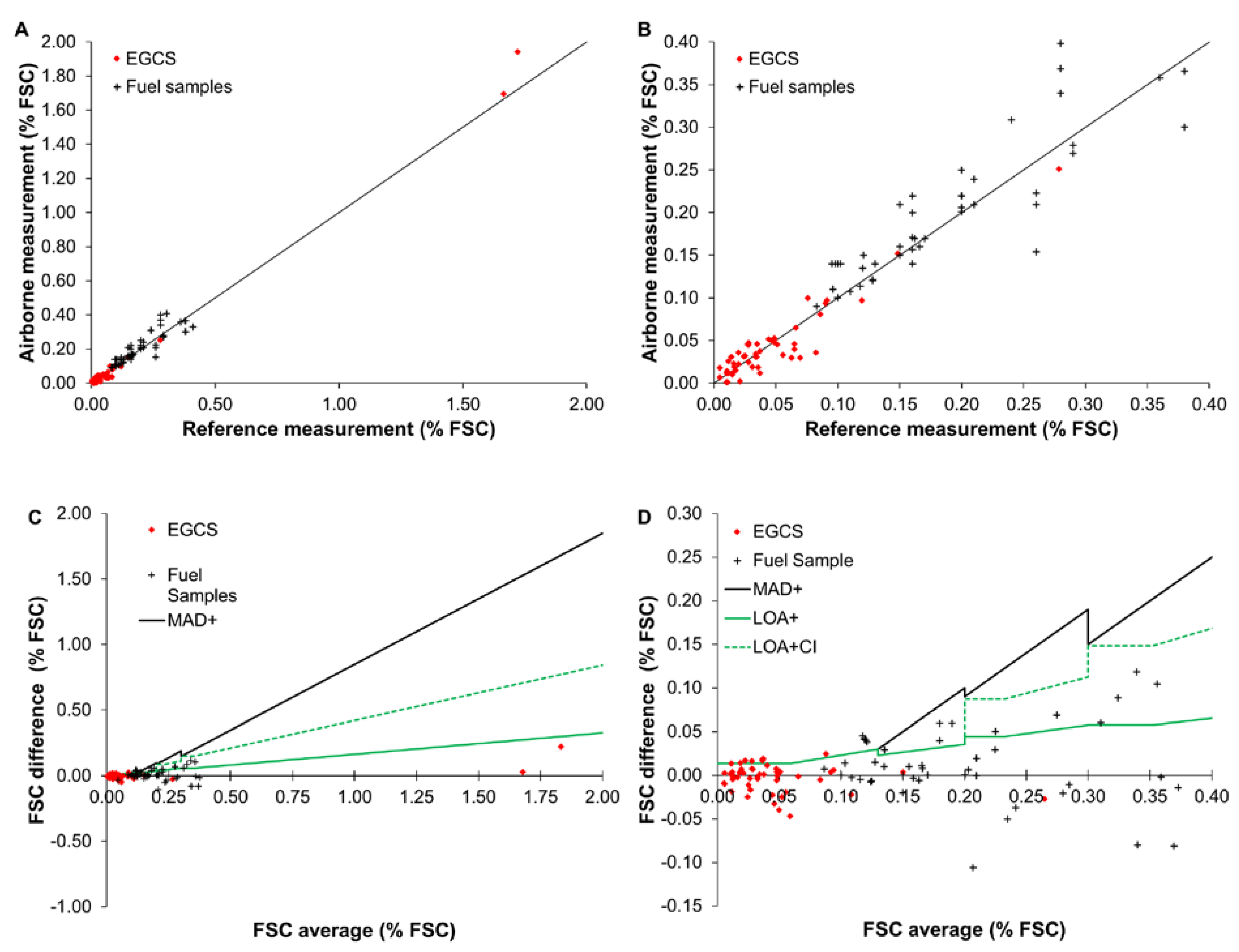

3.3.1. Fuel samples

During on-board inspections in Belgian ports, a fuel sample was taken for 145 airborne alerts. Unfortunately, not all fuel sampling data was useful, as in several cases the inspection was carried out several days to several months after the initial alert. In some cases the sampling data could not be applied because the OGV was still performing a fuel change procedure at the time of the measurement, so the FSC values were not comparable on arrival at port. However, a number of 51 fuel samples have been selected for comparison. Overall, the fuel sampling data relates very well with the airborne measurement data. With a low standard deviation of the difference between the reference data and the airborne measurements (

SDDiff = 0.006% FSC), the relative standard deviation is also very low (

RSD = 3%). The Pearson correlation coefficient (

r) between the fuel samples and the airborne measurement is very high (

r = 0.88) (

Table 3).

3.3.2. EGCS data

EGCS data was collected from 16 different OGVs for 71 airborne measurements, However, also for the EGCS data, a comparison was not always possible due to several reasons. For one OGV, the time reference in the EGCS logs was not reliable and GPS position was missing; for these airborne measurements, the exact reference measurement time could not be identified. For two OGVs, the EGCS logs contained only zero values, which could have been a result from either a problem with the gas analyzers of the CEMS or as a result of the technical characteristics, like detection limit or measurement resolution of the CEMS system. In total, reference data was found suitable for 56 measurements from 13 OGVs. Similarly, the EGCS reference data related very good with the airborne data. The standard deviation of the difference was slightly lower (

SDDiff = 0.004% FSC) compared to the fuel sampling data comparison, which was likely a result of the lower average FSC levels. The relative standard deviation, on the other hand, was marginally higher (

RSD = 4%), thus demonstrating the proportional bias. The Pearson correlation coefficient was even higher than the fuel sampling data comparison (

r = 0.997) (

Table 3).

3.3.3. Combined results

Both reference data sets (fuel samples and EGCS data) were combined to perform a comparison over the full measurement range. The combined dataset contained 107 measurements in total. A plot of the airborne measurement data against the combined reference data is provided in

Figure 4 (A and B), they visualizes the overall high correlation of both reference datasets with the airborne measurements. These plots also demonstrate that the fuel samples differed more from the perfect fit compared to the EGCS data, which is most likely a result from the longer time span between airborne measurement and the fuel sampling. Nevertheless, the fuel samples provided an important added value as they covered the higher section (non-compliant) of the FSC range for which only limited CEMS data was obtained.

The combined

SDDiff was similar as for the EGCS data (

SDDiff = 0.004% FSC). The combined

RSD was the same as for the fuel samples (

RSD = 3%). The combined Pearson correlation factor fell in between the individual correlation coefficients (

r = 0.991). To validate the uncertainty levels used in the different color flag thresholds, the data was divided according the FSC level of the color flags. For the green flag, a minimum of 0.02% FSC was used to avoid errors due to the detection limit of either the sniffer sensor or the CEMS. This indicated that the

SDdiff and

RSD were below the applied uncertainty levels for all non-compliant thresholds, which was defined by the operational threshold (

Tops) minus the sulfur limit (

S) (

Table 3).

A modified B&A graph is provided in

Figure 4 (C and D). For these graphs, the difference of the two measurement methods was plotted against the average value together with: 1) the Limits of agreement (+LOA); 2) the LOA added with the confidence interval (+LOA+CI); and 3) the maximum allowable difference (+MAD).

The standard B&A was modified by using the RSD where this was larger than the SD. In addition, the different σ values were used for the CIs as defined in the thresholds instead of the standard 1.96 (with σ = 1 and CI of 68% for yellow flags; σ = 1.96 and CI of 95% for orange flags; and σ = 2.576 and CI of 99% for red flags).

Finally, only the positive +LOA, +LOA+CI and +MAD were visualized as the object was to check for Type I errors, to evaluate the extent to which potential alerts haven been sent for compliant vessels. This analysis showed that the +LOA+CI was well below the +MAD for all color flags. Moreover, all measurements were below the +MAD. Based on this analysis, it can be concluded that the effective uncertainty of the sniffer sensor is well below the calculated uncertainty used for the alert thresholds. It also demonstrates the existence of a proportional bias (higher alerts differed more than lower alerts), whereas this error remained well within the MAD. The systematic bias that was found in previous studies was however sufficiently removed with the application of the FSC correction [

35].

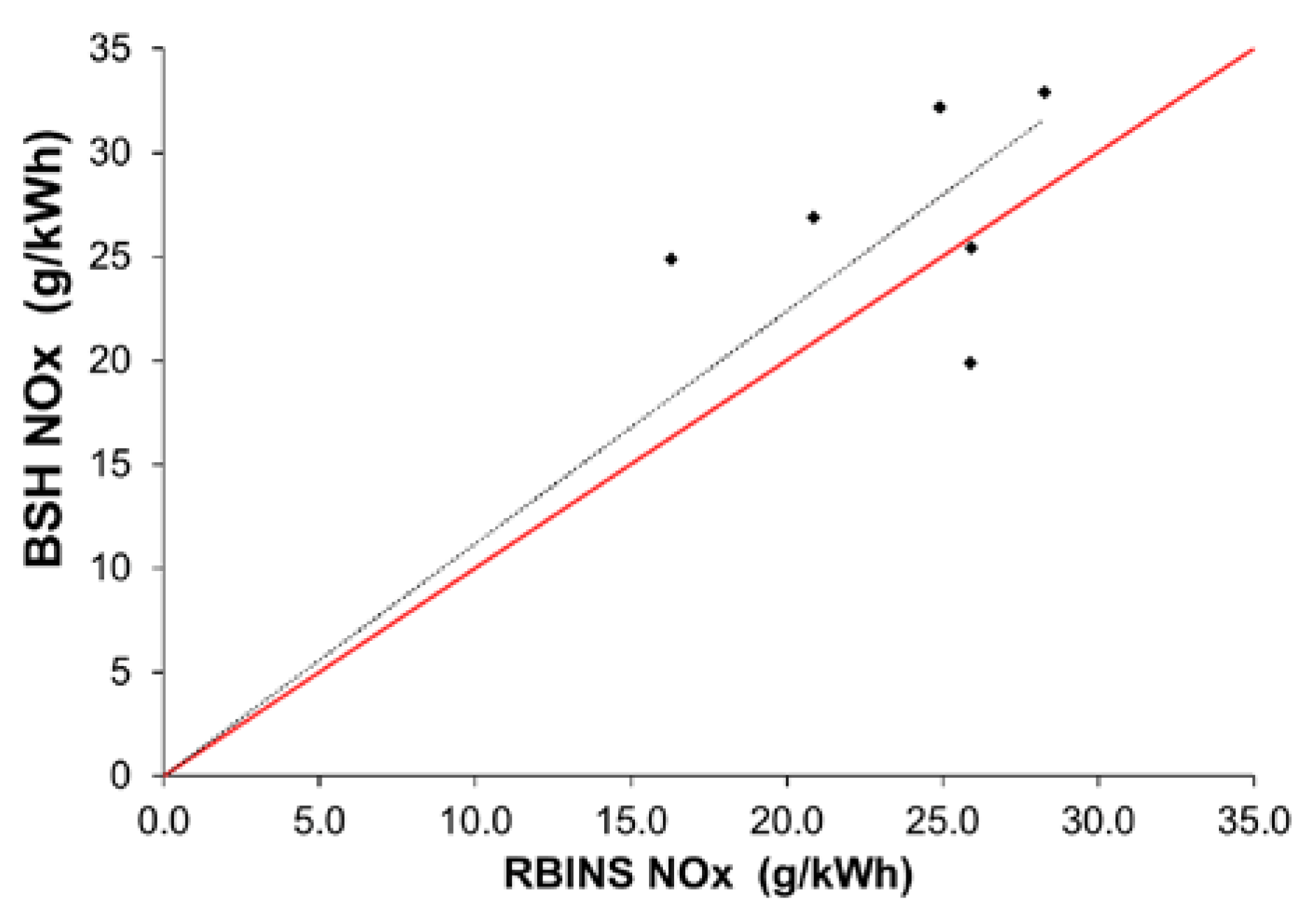

3.4. NOx validation

To validate NOx measurements, cooperation has been sought with the maritime industry. One Belgium engine manufacturer was found willing to provide measurement data from CEMS systems installed on their OGVs. Unfortunately these OGVs did not pass in the surveillance area of the Belgian coastguard aircraft during the airborne surveillance missions. NO

x alerts of ships with other destinations than Belgium have also been reported by email to other European monitoring agencies using fixed sniffers. These fixed sniffer sensors are currently also measuring NO

x, but are not generating alerts like the Belgian coastguard aircraft as they have no possibility to contact the OGV to request its Specific Fuel Consumption (SFC). Without this SFC information, the measurements have a large uncertainty. Moreover, the lack of EU regulations on NO

x makes this a low priority by the inspection authorities of EU member states. For instance, in Germany, the BSH did take the initiative to follow-up some alerts for OGVs that were inbound Germany. The comparison of these pairwise measurements is not as accurate as the comparison with EGCS or fuel samples as both sensors use the same measurement method. Nevertheless, for the concerned alerts a relatively good comparison was found with the measurements in Germany (

SDdiff = 5.55 g NO

x/kWh and

RSD = 22%), demonstrating that the NO

x measurements used by fixed stations and airborne stations are useful for alerting high NO

x non-compliant OGVs (

Figure 5).

3.5. Cost benefit analysis

3.5.1. Comparison of remote compliance monitoring with port inspections

An important aspect in the enforcement chain is the implementation cost. One of the incentives for the use of remote compliance monitoring is the improvement of the overall cost efficiency of the enforcement chain. The high labor effort is the most important coast factor in on-board inspections, followed by the cost of fuel sampling analysis by a certified laboratory (20-100€) [

39]. The total cost for the Belgian port inspection authorities amounted to approx. 540€ per FSC inspection in 2022. For NO

x, no practical real world emissions test is possible in port unless the OGV is equipped with a CEMS system with a data logger. For these vessels (generally Tier III OGVs), the inspection effort can be compared to an inspection of an EGCS OGV. For the OGVs that are not equipped with a CEMS, the use of remote emission measurements can be considered as the only practical way to control real world NO

x emissions, as engine emission verification tests are too l labor intensive to perform on a regular basis and these tests are beyond the scope and capacity of port inspections authorities.

To calculate the cost per airborne measurement, a distinction is made between: 1) the net cost or the effective supplementary cost for RBINS for the sniffer flights per flight hour, including fuel costs, breakdown of aircraft maintenance cost per flight hour, personal costs for the execution of the flights, amortization of sniffer hardware and software, gas calibrations and sensor maintenance (

Table S3); and 2) the full cost of the airborne operation program per hour, including overhead among which are: all costs, including personal costs related to the program management and administration, fixed platform costs (like insurance, aircraft stalling, avionics data subscriptions), crew trainings, office computer hard- and software and communication costs. The net cost can be regarded as the cost for RBINS to meet its national commitments, the full cost is the “commercial” cost used when executing sniffer flights contracted by other countries. The overall cost per airborne FSC measurement was estimated to be 122€ for the net costs and 188€ for the full cost. From 2020 onwards, both SO

2 and NO

x are measured, which resulted in a slightly lower number of inspections per hour. However, from that moment not one but two regulations were inspected for each OGV, decreasing therefore the cost per inspected regulation to 71€ for the net cost and 109€ for the gross cost (

Table 4).

3.5.2. Comparison with other enforcement methods

The outcome of the EU funded SCIPPER (Shipping Contributions to Inland Pollution Push for the Enforcement of Regulations) and CompMon (Compliance Monitoring) projects showed that airborne monitoring using fixed wing platforms is significantly more cost-effective than inspections in port, but also compared to airborne operations using medium range drones (vertical take-off and landing) and helicopters [

39,

56,

57]. Based on the number of inspections and the costs of the operations in French waters, medium range drones are more expensive per inspection compared to on-board inspections. The reason why EU Member States prefer drones given their high cost per inspection lies in the EMSA RPAS (Remote Piloted Airborne Systems) program. The EU Member States are not charged for the deployment of the RPAS, but only have to provide the facilities and the legal authorizations. By centralizing the RPAS operations, the prices quoted by EMSA are lower than if a Member State would implement this type of operations individually. It should be noted that the EMSA RPAS program only started in 2019 and with the experiences gained the operational costs can reduce the coming years. The cost per inspection already showed a significant reduced price of 700-1000€ per OGV according to the SCIPPER project outcome [

56]. Fixed stations, on the other hand, are found to be the most cost effective, but have limited operational capabilities as they can only be used when shipping lanes pass close to the shore. The cost comparison made in the SCIPPER project demonstrated that this cost varied between 20€ and 770€ per OGV depending on the shipping density and the wind conditions on the location of the fixed station [

56]. The cost for fixed stations used in this comparison is based on the cost of the fixed station operated by TNO in the Netherlands on behalf of the Human Environment and Transport Inspectorate of the Ministry of Infrastructure and Water Management of the Netherlands (ILT) and the fixed station operated by Chalmers University in Denmark on behalf of the Danish Environmental Protection Agency (EPA). The operating cost and likewise the cost per inspection in the Netherlands in Rotterdam is substantially lower than the cost for the fixed station used in Denmark on the Great Belt Bridge due to the optimal wind orientation in Rotterdam, the higher maritime traffic density and the easily accessible location.

3.5.3. Cost per detected violation

The cost efficiency of the airborne operations can also be expressed in the cost price per confirmed violation, which clearly demonstrated the added value of airborne monitoring. The number of mandatory inspections according to the EU Directive is based on the number of port calls. For Belgium, the quota is 220 inspections with fuel sampling per year. However, as Belgium used remote monitoring, a reduction of 50% can be applied. For the non-compliance percentage of random fuel inspections, 2.7% was used. Therefore, 5.9 non-compliant OGVs would be identified. The total enforcement cost in this case would be 118,000€, thus resulting in a cost of 20,000€ per detected violation. In case port inspection authorities would rely solemnly on airborne alerts, the confirmation rate would increase to 43%. With a reduced quota of 110 inspection, this would provide 47 confirmed non-compliant OGVs. To be able to provide sufficient alerts, the aircraft would need to operate approx. 211.5 hours. The resulting cost per confirmed violation would be 8,304€, an improvement of almost 60%. However, the implementation of 211.5 flight hours would not be operationally and budgetary feasible. In addition, port inspection authorities also have to follow up other types of alerts and cannot fit their planning completely based on the aircraft operations. With an allocated 70 flight hours per year, the aircraft would be able to provide approx. 1/3 of the alerts, resulting in a combined number of detected violations of 18.4 OGVs, which is already a drastic improvement. When looking at the total price per confirmed violation, this would amount to 9,622€, which is an improvement of more than 50% compared to the base scenario without remote measurements. This would require all aircraft alerts to be followed up by an on-board inspection, which for operational reasons may not always be possible. However, even with a follow-up rate of 80%, an improvement of 42% can be realized.

4. Conclusion

Previous studies on airborne sniffer measurements, including recent sniffer improvements, have already demonstrated the reliability of airborne monitoring techniques for the enforcement of MARPOL Annex VI regulation 13 and 14. However, the effective improvement in enforcement of non-compliant OGVs remained unknown and only limited field validation studies have been performed. This study makes the first ink between airborne sniffer measurements and the results of port inspections, which shows that about46% of the alerts generated by the airborne monitoring are followed-up by an inspection of the OGC, and about 43% of the alerts followed-up are confirmed by port inspection authorities. This study furthermore demonstrates that by including airborne alerts in the enforcement chain, the number of non-compliant detections in Belgian ports increased with 53%. When examining the sanctions issued by the FPS Mobility and Transport, 41% of all MARPOL Annex VI sanctions appear to be the result airborne alerts, which corresponds to 34% of the total amount of fines.

Compliance and follow-up of EGCS OGVs was also examined in this study. Due to the introduction of the Global Cap, the number of EGCS OGVs increased drastically, which coincided with a steep increase in the number of non-compliant EGCS-OGVs. The number of non-compliant EGCS OGVs was even higher than the number of non-compliant non-EGCS OGVs for the period 2020 until 2022, while the frequency of observed EGCS OGVs in that period was only 30%. However, the inspection on-board of these OGVs poses major challenges for the port inspection authorities. The results clearly demonstrate that inspections of EGCS OGVs after airborne alerts improved the inspections drastically. Looking at sanctions, airborne alerts accounted for 2/3 of the sanctioned EGC-OGVs.

The results of this study also indicate that up to 80% of the observed potential non-compliant OGVs were not followed up or, if followed up, could not be confirmed with a fuel sample analysis. These results highlight the strong incentive to further explore the use of sniffer measurements as legal evidence for further tightening of the MARPOL Annex VI enforcement chain. Therefore, a field validation is performed, demonstrating the real world measurement reliability. For that field validation, FSC measurements in air are compared to FSC reference values from fuel samples and EGCS CEMS measurements. This analysis shows that the accuracy of the sensor is even better as expected.

For NOx, the situation is entirely different. Due to the lack of a mechanism for a practical compliance check by port inspection authorities in the IMO Regulations and the absence of EU regulations is this regard, only very limited NOx inspections are carried out in ports. Moreover, these inspections are only based on documentary checks and cannot asses the real world NOx emissions and compliance, as would be the case with the use of remote measurements. In order for the real NOx emissions to be assessed by port inspection authorities, CEMS should become mandatory in international or European regulations. Consequently, the non-compliances observed by the aircraft remain only indicative and cannot be compared with the results of port inspections. In addition, no large scale field validation could be conducted, but the comparison of high NOx alerts with other measurements in Germany have confirmed the Belgian NOx alerts and demonstrating the need for a more effective enforcement based on real world emission measurements.

This study also analyzed the cost effectiveness of airborne monitoring and compared it to the cost of on-board inspections. Airborne measurements have been proven to be significantly cheaper than on-board inspections. By using airborne monitoring, the cost per detected violation can potentially be reduced by 40-50%. Although airborne monitoring is less cost effective as fixed stations per inspection, airborne measurements provide more flexibility as they can operate over a full ECA area. Airborne monitoring also provide more opportunities to obtain legal evidence, as it is possible to collect multiple measurements, dramatically increasing the reliability of non-compliance alerts.

This study has also demonstrated that airborne measurements can play a first role in the enforcement chain as a scientifically proven sound legal evidence for further legal actions. The field validation performed in this study can be regarded as an initial assessment, while further large-scale field validation experiments for compliance with both SO2 and NOx emissions from a legal evidence perspective remain highly advisable. These large-scale field validation experiments require a substantial organization and are therefore best organized in the framework of a EU-funded project with participation of other EU Member States.

Author Contributions

Conceptualization, Ward Van Roy; Data curation, Ward Van Roy; Formal analysis, Ward Van Roy; Funding acquisition, Ward Van Roy, Kobe Scheldeman and Ronny Schallier; Investigation, Ward Van Roy, Jean-Baptiste Merveille, Annelore Van Nieuwenhove, Kobe Scheldeman and Benjamin Van Roozendael; Methodology, Ward Van Roy; Project administration, Ward Van Roy and Kobe Scheldeman; Resources, Ward Van Roy, Jean-Baptiste Merveille, Annelore Van Nieuwenhove, Kobe Scheldeman and Benjamin Van Roozendael; Software, Ward Van Roy; Validation, Ward Van Roy; Visualization, Ward Van Roy; Writing – original draft, Ward Van Roy; Writing – review & editing, Ward Van Roy, Jean-Baptiste Merveille, Annelore Van Nieuwenhove, Kobe Scheldeman, Benjamin Van Roozendael, Ronny Schallier and Frank Maes.