Submitted:

02 March 2023

Posted:

03 March 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

- sterile, single-use surgical-type masks were used by the medical profession;

- commercial, single-use surgical-type masks were used by the beauty industry (nail salons);

- disposable KN95/P2 type masks, with and without valves, were used in the construction industry to filter-out low levels of dust and paint fumes; and

2. Methodology

3. Results

3.1. Single-Use Polypropylene Three-Ply Masks

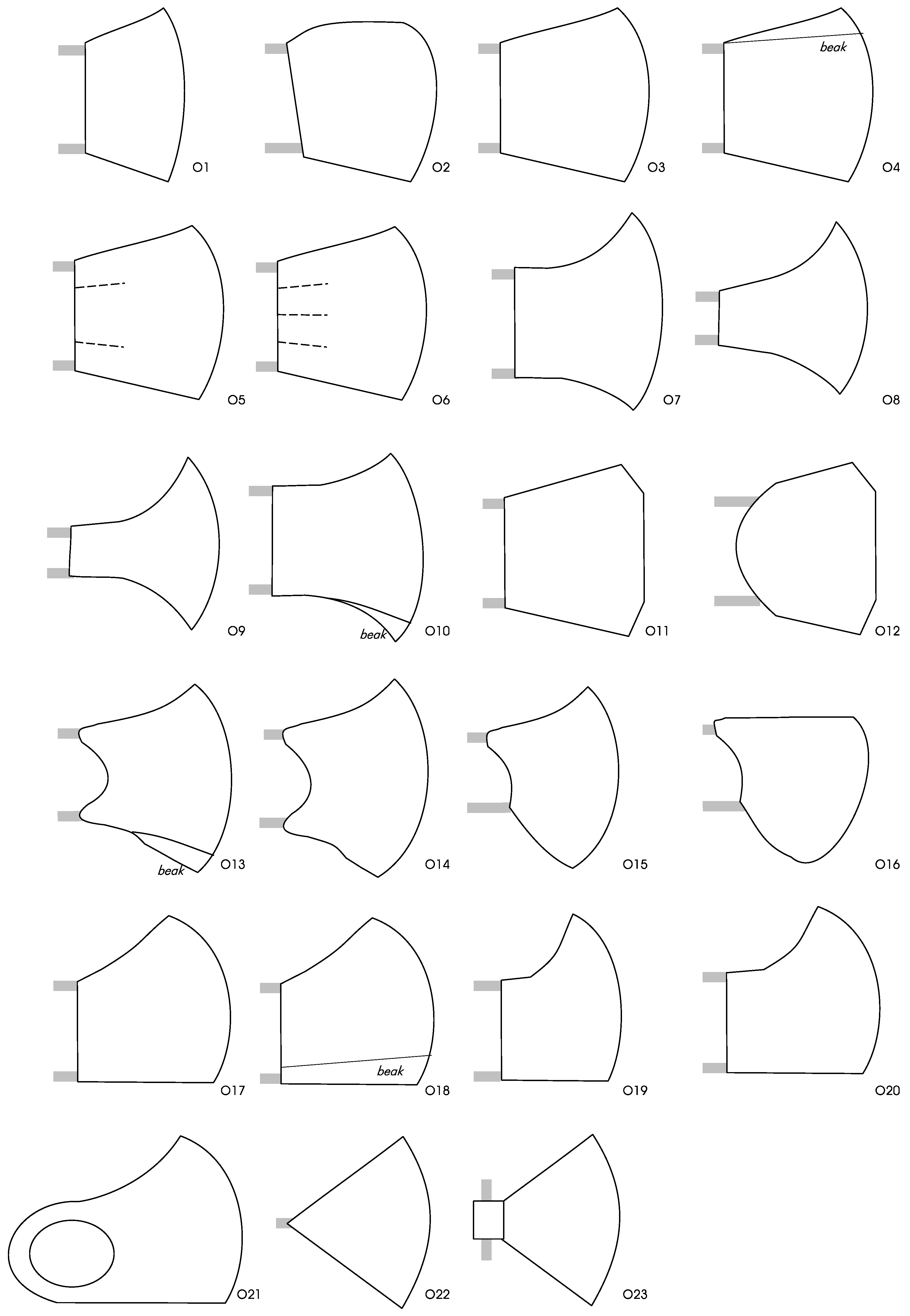

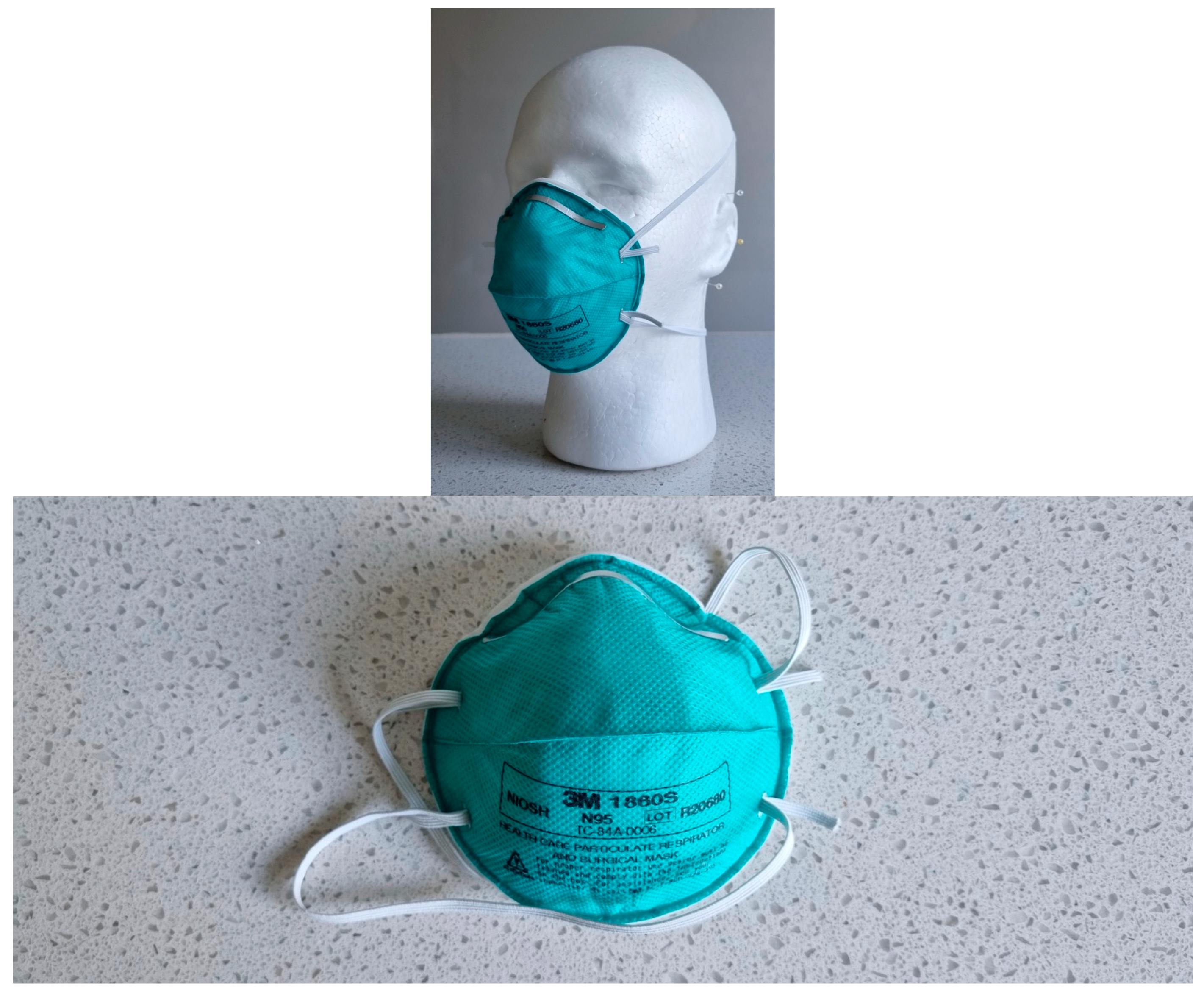

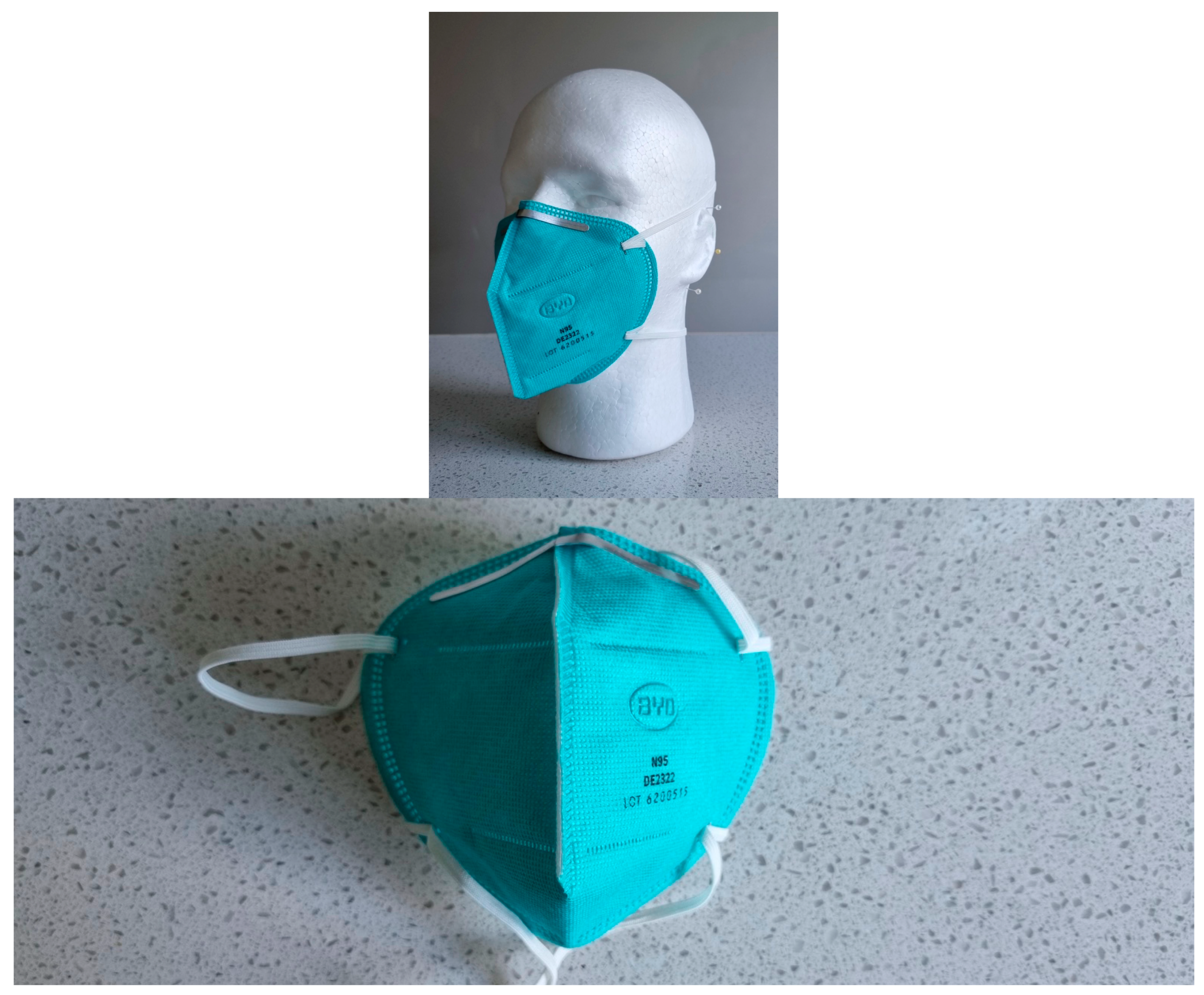

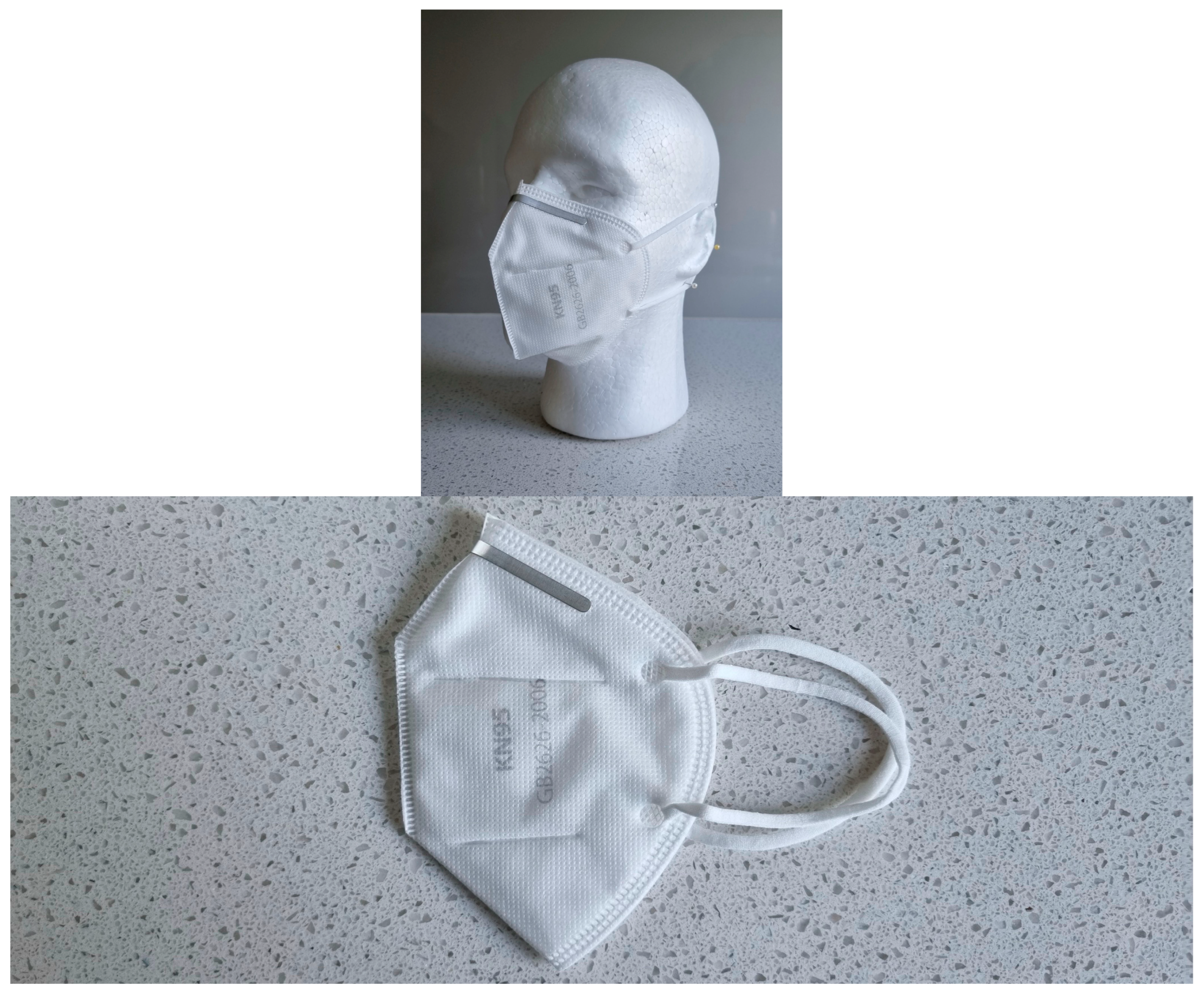

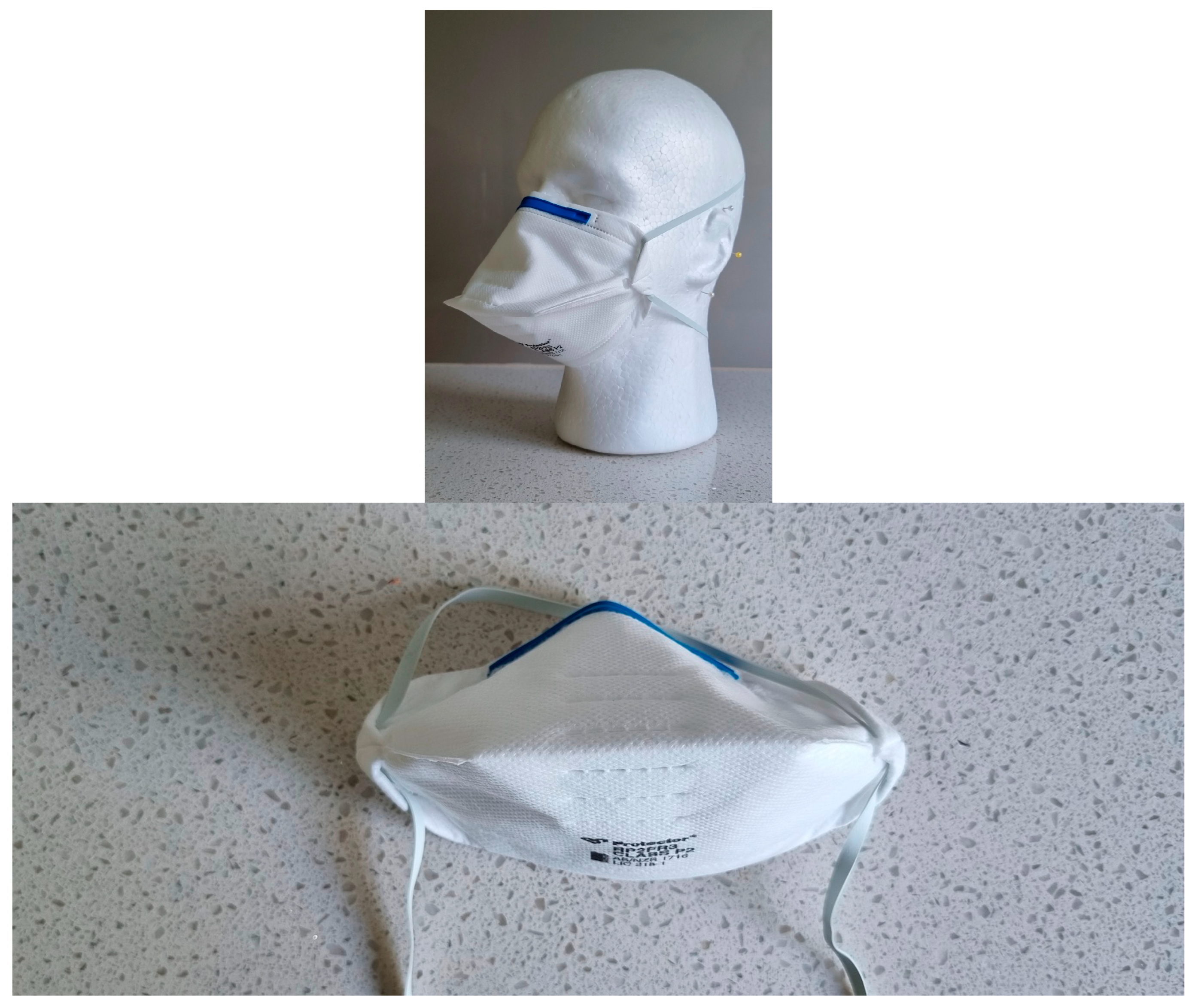

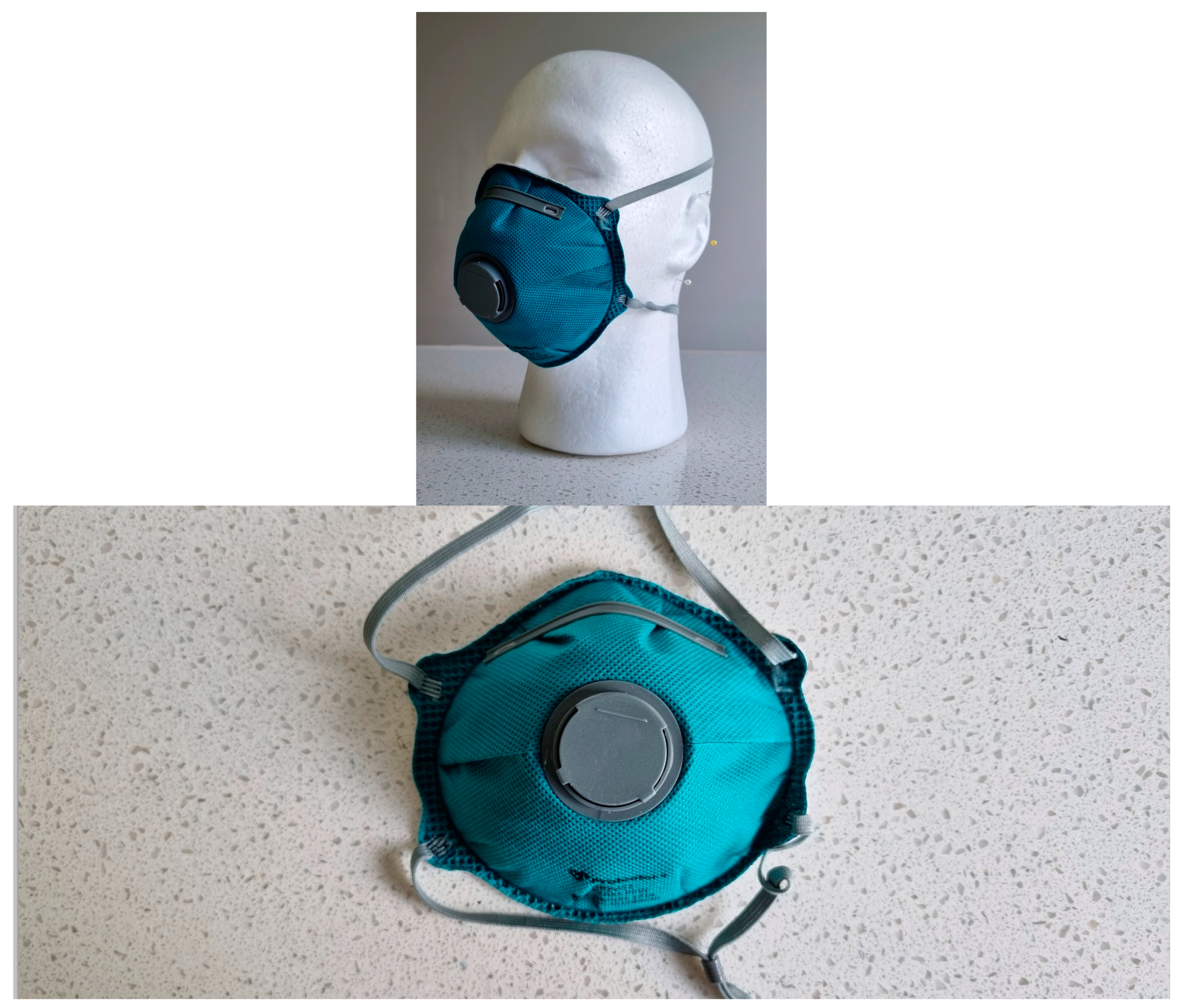

3.2. Single-Use KN95/P2 Polypropylene Masks

3.3. Fabric Masks, Commercial Production

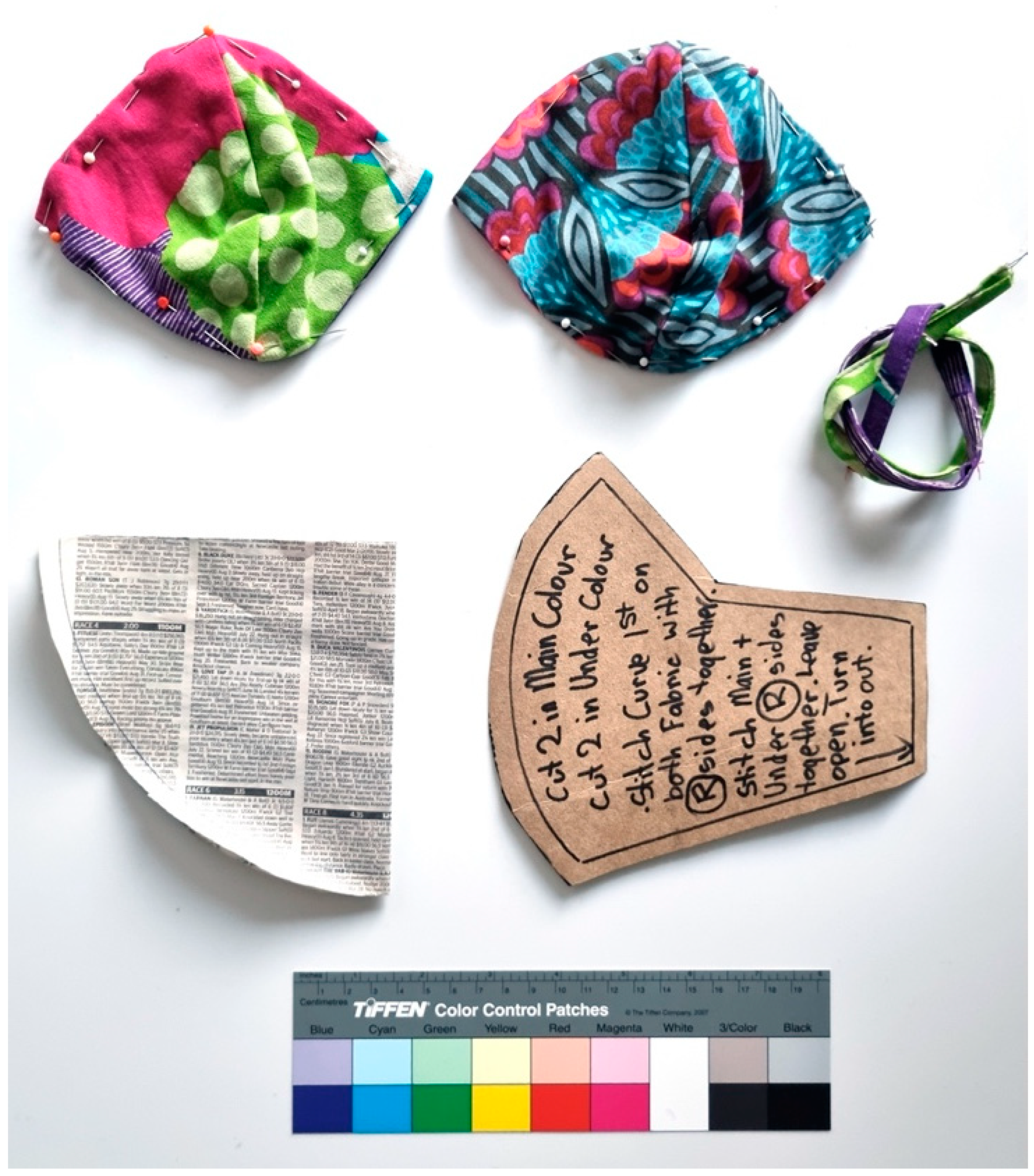

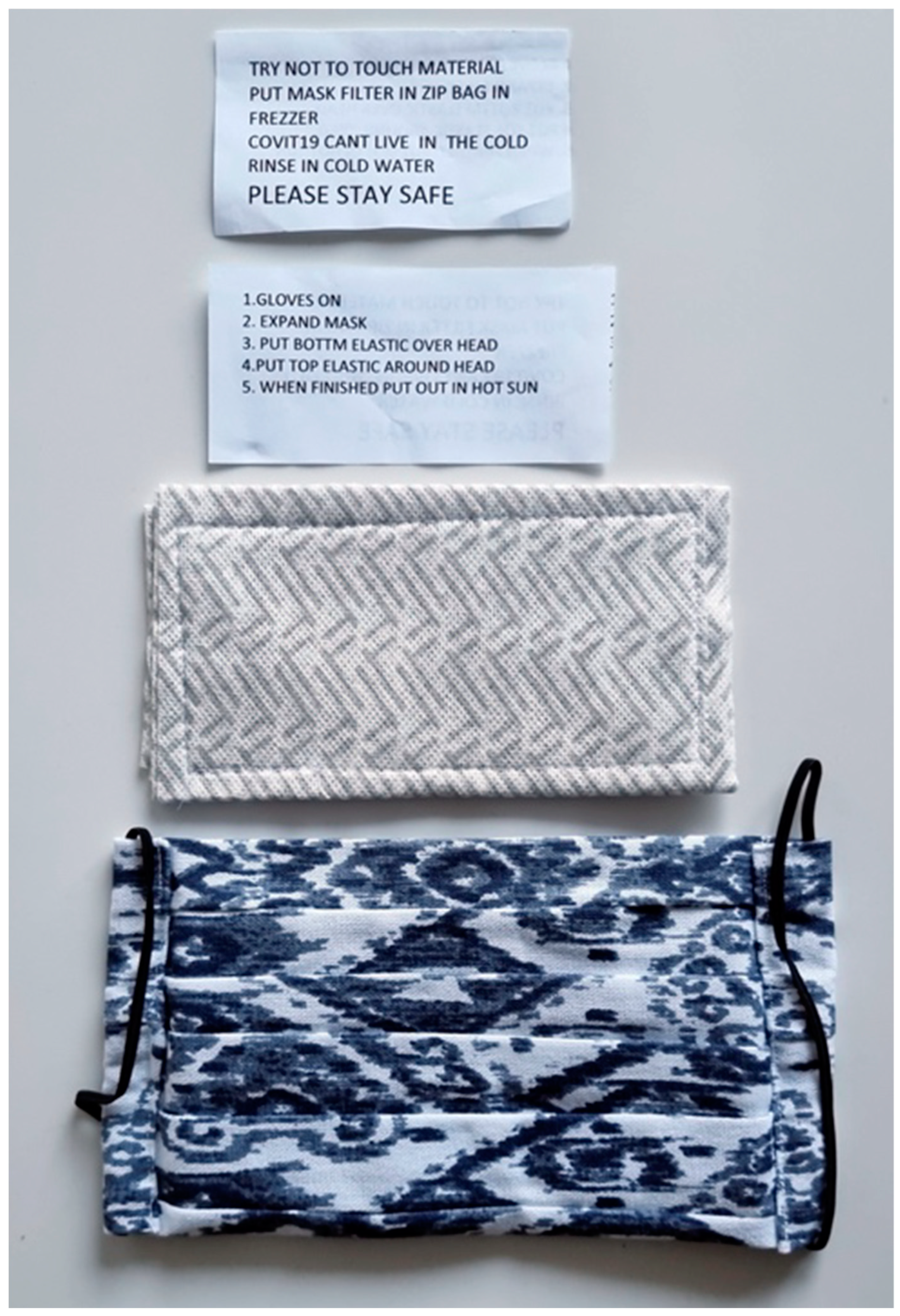

3.4. Fabric Masks, Artisanal Production

4. Discussion and Conclusions

Funding

Conflicts of Interest

Nota bene

References

- WHO. Naming the coronavirus disease (COVID-19) and the virus that causes it. Available online: https://www.who.int/emergencies/diseases/novel-coronavirus-2019/technical-guidance/naming-the-coronavirus-disease-(covid-2019)-and-the-virus-that-causes-it (accessed on Aug 10, 2020).

- Stadnytskyi, V.; Anfinrud, P.; Bax, A. Breathing, speaking, coughing or sneezing: What drives transmission of SARS-CoV-2? Journal of Internal Medicine 2021. [Google Scholar] [CrossRef]

- Gorbunov, B. Aerosol particles generated by coughing and sneezing of a SARS-CoV-2 (COVID-19) host travel over 30 m distance. Aerosol and Air Quality Research 2021, 21. [Google Scholar] [CrossRef]

- Karaivanov, A.; Lu, S.E.; Shigeoka, H.; Chen, C.; Pamplona, S. Face masks, public policies and slowing the spread of COVID-19: evidence from Canada. Journal of Health Economics 2021, 102475. [Google Scholar] [CrossRef] [PubMed]

- Cherry, T.L.; James, A.G.; Murphy, J. The impact of public health messaging and personal experience on the acceptance of mask wearing during the COVID-19 pandemic. Journal of economic behavior & organization 2021, 187, 415–430. [Google Scholar]

- Guy Jr, G.P.; Lee, F.C.; Sunshine, G.; McCord, R.; Howard-Williams, M.; Kompaniyets, L.; Dunphy, C.; Gakh, M.; Weber, R.; Sauber-Schatz, E. Association of state-issued mask mandates and allowing on-premises restaurant dining with county-level COVID-19 case and death growth rates—United States, March 1–December 31, 2020. Morbidity and Mortality Weekly Report 2021, 70, 350. [Google Scholar] [PubMed]

- MacIntyre, C.R.; Nguyen, P.-Y.; Chughtai, A.A.; Trent, M.; Gerber, B.; Steinhofel, K.; Seale, H. Mask use, risk-mitigation behaviours and pandemic fatigue during the COVID-19 pandemic in five cities in Australia, the UK and USA: A cross-sectional survey. International Journal of Infectious Diseases 2021, 106, 199–207. [Google Scholar] [CrossRef] [PubMed]

- Prata, J.C.; Silva, A.L.P.; Duarte, A.C.; Rocha-Santos, T. Disposable over Reusable Face Masks: Public Safety or Environmental Disaster? Environments 2021, 8, 31. [Google Scholar] [CrossRef]

- Kournikakis, B.; Harding, R.K.; Tremblay, J.; Simpson, M. Comparison of protection factors for selected medical, industrial and military masks. Applied Biosafety 2000, 5, 12–18. [Google Scholar] [CrossRef]

- Cherrie, J.W.; Apsley, A.; Cowie, H.; Steinle, S.; Mueller, W.; Lin, C.; Horwell, C.J.; Sleeuwenhoek, A.; Loh, M. Effectiveness of face masks used to protect Beijing residents against particulate air pollution. Occupational and environmental medicine 2018, 75, 446–452. [Google Scholar] [CrossRef]

- Park, C.-Y.; Kim, K.; Roth, S. Global shortage of personal protective equipment amid COVID-19: supply chains, bottlenecks, and policy implications; Asian Development Bank: 2020.

- Sayers, E. Facing COVID: Engaging participants during lockdown. International Journal on Disability and Human Development 2022, 21, 353–358. [Google Scholar]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. Face Masks Donated to Charity. A cross-section of masks donated to charitable organisations by a regional Australian community; SAEVS, Charles Sturt University: Albury, NSW, 2022. [Google Scholar]

- Spennemann, D.H.R. Patterns of a Pandemic. A documentation of COVID-19 masks sold, lost and discarded in a regional Australian city; 164; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, 2021. [Google Scholar]

- Spennemann, D.H.R. COVID-19 Face Masks as a Long-Term Source of Microplastics in Recycled Urban Green Waste. Sustainability 2022, 14, 207. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Impact of Vehicular Traffic on Single Use Surgical Face Masks as a source of Environmental Micro-fiber Pollution. Pollution 2023, 9, [accepted]. [Google Scholar] [CrossRef]

- MedicalXpress. China exported more than 220 billion masks in 2020: government. Available online: https://medicalxpress.com/news/2021-01-china-exported-billion-masks.html.

- Spennemann, D.H.R. Collecting COVID-19 Ephemera: a photographic documentation of examples from regional Australia; Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, 2021. [Google Scholar]

- Spennemann, D.H.R. COVID-19 on the ground: heritage sites of a pandemic. Heritage 2021, 3, 2140–2162. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. “No Entry into New South Wales”: COVID-19 and the Historic and Contemporary Trajectories of the Effects of Border Closures on an Australian Cross-Border Community. Land 2021, 10, 610. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Curating the Contemporary: a case for national and local COVID-19 collections. Curator 2022, 65, 27–42. [Google Scholar] [CrossRef] [PubMed]

- Spennemann, D.H.R. The Material Culture of the COVID-19 Pandemic. A Descriptive Catalogue of SARS-Cov-2 Rapid Antigen Tests collected for the Albury LibraryMuseum; SAEVS, Charles Sturt University: Albury, NSW, 2023. [Google Scholar]

- Spennemann, D.H.R. The Digital Heritage of the battle to contain COVID-19 in Australia and its implications for Heritage Studies. Heritage subm., [under review]. [CrossRef]

- Spennemann, D.H.R. Facing COVID-19: quantifying the use of reusable vs disposable facemasks. Hygiene 2021, 1, 120–128. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. COVID face masks: policy shift results in increased littering. Sustainability 2021, 13, 9875. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Environmental Decay of Single Use Surgical Face Masks as an agent of plastic micro-fiber pollution. Environments 2022, 9, 94. [Google Scholar] [CrossRef]

- De-la-Torre, G.E.; Dioses-Salinas, D.C.; Dobaradaran, S.; Spitz, J.; Keshtkar, M.; Akhbarizadeh, R.; Abedi, D.; Tavakolian, A. Physical and chemical degradation of littered personal protective equipment (PPE) under simulated environmental conditions. Mar. Pollut. Bull. 2022, 178, 113587. [Google Scholar] [CrossRef]

- Chen, X.; Chen, X.; Liu, Q.; Zhao, Q.; Xiong, X.; Wu, C. Used disposable face masks are significant sources of microplastics to environment. Environmental Pollution 2022, 285, 117485. [Google Scholar] [CrossRef]

- Cornelio, A.; Zanoletti, A.; Federici, S.; Ciacci, L.; Depero, L.E.; Bontempi, E. Environmental Impact of Surgical Masks Consumption in Italy Due to COVID-19 Pandemic. Materials 2022, 15, 2046. [Google Scholar] [CrossRef]

- Du, H.; Huang, S.; Wang, J. Environmental risks of polymer materials from disposable face masks linked to the COVID-19 pandemic. Science of The Total Environment 2022, 152980. [Google Scholar] [CrossRef]

- Fadare, O.O.; Okoffo, E.D. Covid-19 face masks: A potential source of microplastic fibers in the environment. The Science of the total environment 2020, 737, 140279. [Google Scholar] [CrossRef]

- Kwak, J.I.; An, Y.J. Post COVID-19 pandemic: Biofragmentation and soil ecotoxicological effects of microplastics derived from face masks. J Hazard Mater 2021, 416, 126169. [Google Scholar] [CrossRef]

- Liang, H.; Ji, Y.; Ge, W.; Wu, J.; Song, N.; Yin, Z.; Chai, C. Release kinetics of microplastics from disposable face masks into the aqueous environment. Science of the Total Environment 2022, 816, 151650. [Google Scholar] [CrossRef]

- Saliu, F.; Veronelli, M.; Raguso, C.; Barana, D.; Galli, P.; Lasagni, M. The release process of microfibers: from surgical face masks into the marine environment. Environmental Advances 2021, 4, 100042. [Google Scholar] [CrossRef]

- Selvaranjan, K.; Navaratnam, S.; Rajeev, P.; Ravintherakumaran, N. Environmental challenges induced by extensive use of face masks during COVID-19: a review and potential solutions. Environmental Challenges 2021, 100039. [Google Scholar] [CrossRef]

- Shen, M.; Zeng, Z.; Song, B.; Yi, H.; Hu, T.; Zhang, Y.; Zeng, G.; Xiao, R. Neglected microplastics pollution in global COVID-19: disposable surgical masks. Science of the Total Environment 2021, 790, 148130. [Google Scholar] [CrossRef]

- Silva, A.L.P.; Prata, J.C.; Mouneyrac, C.; Barcelò, D.; Duarte, A.C.; Rocha-Santos, T. Risks of Covid-19 face masks to wildlife: Present and future research needs. Science of The Total Environment 2021, 148505. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.; An, C.; Chen, X.; Lee, K.; Zhang, B.; Feng, Q. Disposable masks release microplastics to the aqueous environment with exacerbation by natural weathering. Journal of Hazardous Materials 2021, 417, 126036. [Google Scholar] [CrossRef] [PubMed]

- Wu, P.; Li, J.; Lu, X.; Tang, Y.; Cai, Z. Release of tens of thousands of microfibers from discarded face masks under simulated environmental conditions. Science of the Total Environment 2022, 806, 150458. [Google Scholar] [CrossRef]

- Ma, J.; Chen, F.; Xu, H.; Jiang, H.; Liu, J.; Li, P.; Chen, C.C.; Pan, K. Face masks as a source of nanoplastics and microplastics in the environment: Quantification, characterization, and potential for bioaccumulation. Environmental Pollution 2021, 288, 117748. [Google Scholar] [CrossRef]

- Duong, M.C.; Nguyen, H.T.; Duong, B.T. A Cross-Sectional Study of Knowledge, Attitude, and Practice Towards Face Mask Use Amid the COVID-19 Pandemic Amongst University Students in Vietnam. Journal of Community Health 2021. [Google Scholar] [CrossRef]

- Dwivedi, K.; Sharma, E.; Fatima, N. An empirical analysis on consumer’s preferences of face mask during COVID-19 pandemic. International Journal of Home Science 2021, 7, 147–151. [Google Scholar]

- Green, D.N.; Kozen, F.H.; Blumenkamp, C.K. Facemasking Behaviors, Preferences, and Attitudes Among Emerging Adults in the United States During the COVID-19 Pandemic: An Exploratory Study. Clothing and Textiles Research Journal 2021, 0887302X211006775. [Google Scholar] [CrossRef]

- Lee, L.Y.-k.; Chan, I.C.-w.; Wong, O.P.-m.; Ng, Y.H.-y.; Ng, C.K.-y.; Chan, M.H.-w.; Ng, J.K.-c.; Koo, H.H.-t.; Lam, S.-t.; Chu, A.C.-w. Reuse of face masks among adults in Hong Kong during the COVID-19 pandemic. BMC Public Health 2021, 21, 1–11. [Google Scholar] [CrossRef]

- Matusiak, Ł.; Szepietowska, M.; Krajewski, P.K.; Białynicki-Birula, R.; Szepietowski, J.C. The use of face masks during the COVID-19 pandemic in Poland: A survey study of 2315 young adults. Dermatologic Therapy 2020, 33, e13909. [Google Scholar] [CrossRef]

- Angelo, D.; Britt, K.M.; Brown, M.L.; Camp, S.L. Spaces: Documenting COVID-19 Material Culture and Landscapes. Journal of Contemporary Archaeology 2021, 8, 154–184. [Google Scholar] [CrossRef]

- Magnani, M.; Magnani, N.; Venovcevs, A.; Farstadvoll, S. A contemporary archaeology of pandemic. Journal of Social Archaeology 2021, 14696053211043430. [Google Scholar] [CrossRef]

- Magnani, M.; Venovcevs, A.; Farstadvoll, S.; Magnani, N. How to record current events like an archaeologist. Advances in Archaeological Practice 2021, 9, 379–386. [Google Scholar] [CrossRef]

- Schofield, J.; Praet, E.; Townsend, K.A.; Vince, J. ‘COVID waste’and social media as method: an archaeology of personal protective equipment and its contribution to policy. Antiquity 2021, 95, 435–449. [Google Scholar] [CrossRef]

- Witcher, R. The materiality of COVID-19. Antiquity 2021, 95, 285–292. [Google Scholar]

- Davis, M.D.M. ‘Live with the Virus’ Narrative and Pandemic Amnesia in the Governance of COVID-19. Social Sciences 2022, 11, 340. [Google Scholar] [CrossRef]

- Tanne, J.H. Covid-19: Former advisers urge Biden to adopt new pandemic strategy and learn to live with virus. BMJ 2022, 376, 376:o356. [Google Scholar] [CrossRef]

- Department of Health and Aged Care. Coronavirus (COVID-19) case numbers and statistics. COVID-19 cases and 7 day rolling average, 01 Jan 2022 to 21 Feb 2023. Available online: https://www.health.gov.au/health-alerts/covid-19/case-numbers-and-statistics (accessed on Feb 27, 2023).

- Spennemann, D.H.R. Designing for COVID-2x: Reflecting on Future-Proofing Human Habitation for the Inevitable Next Pandemic. Buildings 2022, 12, 1–18. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Exercising under COVID-2x: conceptualizing future green spaces in Australia’s neighborhoods. Urban Design 2021, 5, 1–23. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Preparing for COVID-2x: urban planning needs to regard urological wastewater as an invaluable communal public health asset and not as a burden. Urban Design 2021, 5, 75. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. Residential Architecture in a post-pandemic world: implications of COVID-19 for new construction and for adapting heritage buildings. Journal of Green Building 2021, 16, 199–215. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. A Photographic Documentation of Sales Packaging of Single-use Surgical Face Masks; SAEVS, Charles Sturt University: Albury, NSW, 2022. [Google Scholar]

- Spennemann, D.H.R. The future archaeological signature of single-use surgical face masks, the most ubiquitous artefact of the COVID-19 pandemic: A Typological Study; SAEVS, Charles Sturt University: Albury, 2023. [Google Scholar]

- Spennemann, D.H.R. Photographic documentation of fibre patterns of spunbonded fabric used in single-use surgical face masks; SAEVS, Charles Sturt University: Albury, 2022. [Google Scholar]

- Spennemann, D.H.R. A rapid observational survey of face mask use in a major shopping centre in Melbourne (Victoria); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, 2021. [Google Scholar]

- Spennemann, D.H.R. A rapid observational survey of face mask use in a major shopping centre in Sydney (New South Wales); Institute for Land, Water and Society, Charles Sturt University: Albury, NSW, 2022. [Google Scholar]

- Safe Work Australia. Comparison of mask types for COVID-19. Available online: https://covid19.swa.gov.au/comparison-mask-types-covid-19 (accessed on Feb 20, 2023).

- Infection Control Expert Group. Infection Control Expert Group. The Use of Face Masks and Respirators in the Context of COVID-19; Departmwent of Health: Canberra, ACT, 2020. [Google Scholar]

- CDC. Types of Masks and Respirators [Archive copy]. Available online: https://web.archive.org/web/20210210180932/https://www.cdc.gov/coronavirus/2019-ncov/prevent-getting-sick/types-of-masks.html (accessed on Feb 20, 2023).

- Bonds. Bonds Protective Comfy Face Mask Treated eith HEIQ Viroblock. Available online: https://www.bonds.com.au/bonds-face-mask-3-pack-zynr-blk.html (accessed on Feb 21, 2023).

- Factorie. Foundation Face Mask Adults. Available online: https://factorie.com.au/show-variation/?pid=9630228 (accessed on October 15, 2021).

- Supre. Foundation Face Mask Junior. Available online: https://supre.com.au/foundation-face-mask-junior/9630171-04.html (accessed on Feb 20, 2023).

- Ghanda. Face Mask. Available online: https://ghanda.com/product/face-mask_natural_642 (accessed on Feb 21, 2023).

- Cotton On. Foundation Face Mask Adults. Available online: https://cottonon.com/UK/foundation-face-mask-adults/9357067451063.html (accessed on October 15, 2021).

- Cotton On. Foundation Face Mask Junior. Available online: https://cottonon.com/SG/foundation-face-mask-adults/9630228-05.html?bvstate=pg:9/ct:r (accessed on Jan 18, 2022).

- Sexy Socks. Our Fabric Face Masks + Active Snood. Available online: https://buysexysocks.com/all-about-our-fabric-face-masks-active-snood/ (accessed on Feb 21, 2023).

- Carbon Collective. Reticulated Polyurethane Foam Mask. Available online: https://www.carboncollective.com/product/reticulated-polyurethane-foam-mask/ (accessed on Feb 21, 2023).

- FaceTubes. Pink Face Masks Face Mask Washable Neoprene Reusable Covid. Available online: https://www.facetubes.com.au/products/pink-face-masks-face-mask-washable-neoprene-reusable-covid (accessed on Feb 21, 2023).

- CHUU. CHUU Fashion Washable Soft Neoprene Face Cover Mask. Available online: https://www.amazon.com.au/CHUU-Fashion-Washable-Neoprene-Summer/dp/B0895JX6D3 (accessed on Feb 20, 2023).

- FaceTubes Australia. Black Face Masks Face Mask Washable Neoprene Reusable Covid. Available online: https://www.facetubes.com.au/products/black-face-masks-face-mask-washable-neoprene-reusable-covid?_pos=3&_sid=d7228c53f&_ss=r (accessed on Feb 20, 2023).

- ToBeGear. Reusable Washable Breathable Face Masks single layer. Available online: https://tobe.com.au/products/reusable-washable-breathable-face-masks-single-layer?variant=42930353078442 (accessed on Feb 20, 2023).

- Lovisa. 100% Silk Mask. Available online: www.lovisa.com.au/collections/100-silk-face-masks (accessed on Oct 12, 2022).

- Department of Health & Human Services. How to make a cloth mask. Instructions for making a cloth face mask. Available online: https://www.dhhs.vic.gov.au/sites/default/files/documents/202007/Design%20and%20preparation%20of%20cloth%20mask_0.pdf (accessed on Dec 10, 2020).

- Lincraft. Face Mask; Lincraft: Melbourne, 2020. [Google Scholar]

- Spotlight. Nose Wire Mask Project Sheet; Spotlight: South Melbourne, 2020. [Google Scholar]

- Baradaran-Binazir, M.; Heidari, F. The necessity of prohibiting the masks with exhalation valve during emerging infections Like COVID-19. Asia Pacific Journal of Public Health 2021, 33, 458–459. [Google Scholar] [CrossRef]

- Matuschek, C.; Moll, F.; Fangerau, H.; Fischer, J.C.; Zänker, K.; van Griensven, M.; Schneider, M.; Kindgen-Milles, D.; Knoefel, W.T.; Lichtenberg, A. Face masks: benefits and risks during the COVID-19 crisis. European journal of medical research 2020, 25, 1–8. [Google Scholar] [CrossRef]

- Chang, J.C.; Johnson, J.S.; Olmsted, R.N. Demystifying theoretical concerns involving respirators with exhalation valves during COVID-19 pandemic. American journal of infection control 2020, 48, 1564–1565. [Google Scholar] [CrossRef]

- Ippolito, M.; Iozzo, P.; Gregoretti, C.; Grasselli, G.; Cortegiani, A. Facepiece filtering respirators with exhalation valve should not be used in the community to limit SARS-CoV-2 diffusion. Infection Control & Hospital Epidemiology 2021, 42, 369–370. [Google Scholar]

- Kirubarajan, A.; Khan, S.; Got, T.; Yau, M.; Bryan, J.M.; Friedman, S.M. Mask shortage during epidemics and pandemics: a scoping review of interventions to overcome limited supply. BMJ open 2020, 10, e040547. [Google Scholar] [CrossRef]

- Shin, H.; Tunca, T.I. Do firms invest in forecasting efficiently? The effect of competition on demand forecast investments and supply chain coordination. Operations research 2010, 58, 1592–1610. [Google Scholar] [CrossRef]

- An, C.; Fromm, H. Supply chain management on demand: Strategies and technologies, applications; Springer Science & Business Media, 2005. [Google Scholar]

- Li, P. Supply chain management; BoD–Books on Demand, 2011. [Google Scholar]

- Francis, J.R. COVID-19: implications for supply chain management. Frontiers of health services management 2020, 37, 33–38. [Google Scholar] [CrossRef]

- Rowan, N.J.; Laffey, J.G. Challenges and solutions for addressing critical shortage of supply chain for personal and protective equipment (PPE) arising from Coronavirus disease (COVID19) pandemic–Case study from the Republic of Ireland. Science of the Total Environment 2020, 725, 138532. [Google Scholar] [CrossRef]

- Miller, F.A.; Young, S.B.; Dobrow, M.; Shojania, K.G. Vulnerability of the medical product supply chain: the wake-up call of COVID-19. BMJ quality & safety 2021, 30, 331–335. [Google Scholar]

- Armani, A.M.; Hurt, D.E.; Hwang, D.; McCarthy, M.C.; Scholtz, A. Low-tech solutions for the COVID-19 supply chain crisis. Nature Reviews Materials 2020, 5, 403–406. [Google Scholar] [CrossRef]

- Schwartz, A.; Stiegel, M.; Greeson, N.; Vogel, A.; Thomann, W.; Brown, M.; Sempowski, G.D.; Alderman, T.S.; Condreay, J.P.; Burch, J. Decontamination and reuse of N95 respirators with hydrogen peroxide vapor to address worldwide personal protective equipment shortages during the SARS-CoV-2 (COVID-19) pandemic. Applied Biosafety 2020, 25, 67–70. [Google Scholar] [CrossRef]

- Boškoski, I.; Gallo, C.; Wallace, M.B.; Costamagna, G. COVID-19 pandemic and personal protective equipment shortage: protective efficacy comparing masks and scientific methods for respirator reuse. Gastrointestinal endoscopy 2020, 92, 519–523. [Google Scholar] [CrossRef]

- Rubio-Romero, J.C.; del Carmen Pardo-Ferreira, M.; Torrecilla-García, J.A.; Calero-Castro, S. Disposable masks: Disinfection and sterilization for reuse, and non-certified manufacturing, in the face of shortages during the COVID-19 pandemic. Safety Sci. 2020, 129, 104830. [Google Scholar] [CrossRef]

- Gilbert, R.M.; Donzanti, M.J.; Minahan, D.J.; Shirazi, J.; Hatem, C.L.; Hayward-Piatkovskyi, B.; Dang, A.M.; Nelson, K.M.; Bothi, K.L.; Gleghorn, J.P. Mask reuse in the COVID-19 pandemic: creating an inexpensive and scalable ultraviolet system for filtering facepiece respirator decontamination. Global Health: Science and Practice 2020, 8, 582–595. [Google Scholar] [CrossRef]

- Gibson, C.; Carr, C.; Lyons, C.; Taksa, L.; Warren, A. COVID-19 and the shifting industrial landscape. Geographical Research 2021, 59, 196–205. [Google Scholar] [CrossRef]

- Nilasaroya, A.; Kop, A.M.; Collier, R.C.; Kennedy, B.; Kelsey, L.J.; Pollard, F.; Ha, J.F.; Morrison, D.A. Establishing local manufacture of PPE for healthcare workers in the time of a global pandemic. Heliyon 2023, 9, e13349. [Google Scholar] [CrossRef]

- Cameron, S.; Cheung, W.; Cronin, N.; Griffiths, K.; Hunt, R.; Innes, L.; Kol, M.; Lawrence, A.; Shah, A.; Skylas, K.; et al. Quantitative fit testing with limited supplies of respirator masks in hospital personnel during the COVID-19 pandemic. Australian Health Review 2020, 44, 542–543. [Google Scholar] [CrossRef]

- Spennemann, D.H.R. “COVID has been good to me”. The Artefact 2022, 44, 10–16. [Google Scholar]

- Washington Post Staff. How to sew your own fabric mask. Available online: https://www.washingtonpost.com/health/2020/04/05/how-sew-your-own-fabric-mask/ (accessed on Feb 20, 2023).

- Ammendolia, J.; Coalition, C.O.L.; Saturno, J.; Jacobs, S. Environmental concern emerges from COVID-19 pandemic: PPE waste by the public. Can. Sci. Policy Cent 2020. [Google Scholar]

- Wang, Z.; Guy, C.; Ng, K.T.W.; An, C. A new challenge for the management and disposal of personal protective equipment waste during the COVID-19 pandemic. 2021, 13, 7034.

- Islam, S.D.-U.; Safiq, M.B.; Bodrud-Doza, M.; Mamun, M.A. Perception and attitudes toward PPE-related waste disposal amid COVID-19 in Bangladesh: an exploratory study. Frontiers in Public Health 2020, 8, 592345. [Google Scholar] [CrossRef]

- Nowakowski, P.; Kuśnierz, S.; Sosna, P.; Mauer, J.; Maj, D. Disposal of personal protective equipment during the COVID-19 pandemic is a challenge for waste collection companies and society: a case study in Poland. Resources 2020, 9, 116. [Google Scholar] [CrossRef]

- Olatayo, K.I.; Mativenga, P.T.; Marnewick, A.L. COVID-19 PPE plastic material flows and waste management: Quantification and implications for South Africa. Science of the Total Environment 2021, 790, 148190. [Google Scholar] [CrossRef]

- Jiang, M.; Dodoo, N.A. Promoting Mask-Wearing in COVID-19 Brand Communications: Effects of Gain-Loss Frames, Self-or Other-Interest Appeals, and Perceived Risks. Journal of Advertising 2021, 50, 271–279. [Google Scholar] [CrossRef]

- Wang, Y.; Feng, D.; Ho, W.Y.J. Identity, lifestyle, and face-mask branding: A social semiotic multimodal discourse analysis. Multimodality & Society 2021, 1, 216–237. [Google Scholar]

- Faruque, Z. Know how to manage face-mask branding in the time of COVID-19. Campus Legal Advisor 2020, 21, 1–3. [Google Scholar] [CrossRef]

- Chughtai, A.A.; Seale, H.; Macintyre, C.R. Effectiveness of cloth masks for protection against severe acute respiratory syndrome coronavirus 2. Emerging infectious diseases 2020, 26. [Google Scholar] [CrossRef]

- Ataei, M.; Shirazi, F.M.; Nakhaee, S.; Abdollahi, M.; Mehrpour, O. Assessment of cloth masks ability to limit Covid-19 particles spread: a systematic review. Environmental Science and Pollution Research 2022, 1–32. [Google Scholar] [CrossRef]

- Narayan, Y.; Chatterjee, S.; Agrawal, A.; Bhardwaj, R. Assessing effectiveness and comfortability of a two-layer cloth mask with a high-efficiency particulate air (HEPA) insert to mitigate COVID-19 transmission. Physics of Fluids 2022, 34, 061703. [Google Scholar] [CrossRef]

- Tanisali, G.; Sozak, A.; Bulut, A.S.; Sander, T.Z.; Dogan, O.; Dağ, Ç.; Gönen, M.; Can, F.; DeMirci, H.; Ergonul, O. Effectiveness of different types of mask in aerosol dispersion in SARS-CoV-2 infection. Int. J. Infect. Dis. 2021, 109, 310–314. [Google Scholar] [CrossRef]

- Andrejko, K.L.; Pry, J.M.; Myers, J.F.; Fukui, N.; DeGuzman, J.L.; Openshaw, J.; Watt, J.P.; Lewnard, J.A.; Jain, S.; COVID, C. Effectiveness of face mask or respirator use in indoor public settings for prevention of SARS-CoV-2 infection—California, February–December 2021. Morb. Mortal. Wkly. Rep. 2022, 71, 212. [Google Scholar] [CrossRef]

- Duncan, S.; Bodurtha, P.; Naqvi, S. The protective performance of reusable cloth face masks, disposable procedure masks, KN95 masks and N95 respirators: Filtration and total inward leakage. PloS one 2021, 16, e0258191. [Google Scholar] [CrossRef]

- Pieris, A.; Lozanovska, M.; Dellios, A.; Miller-Yeaman, R.; Eklund, E.; Beynon, D.; Tuffin, R. Industrial sites and immigrant architectures. A case study approach. Fabrications 2019, 29, 257–272. [Google Scholar] [CrossRef]

- Mandavilli, A. The C.D.C. concedes that cloth masks do not protect against the virus as effectively as other masks [New York Times]. Available online: https://www.nytimes.com/2022/01/14/health/cloth-masks-covid-cdc.html (accessed on Feb 20, 2023).

- Morris, L.; Noack, R. Europe’s growing mask ask: Ditch the cloth ones for medical-grade coverings [The Washington Post]. Available online: https://www.washingtonpost.com/world/europe/europe-coronavirus-masks-regulations/2021/01/20/23463c08-5a74-11eb-a849-6f9423a75ffd_story.html (accessed on Feb 12, 2023).

- Nirappil, F. Time to double or upgrade masks as coronavirus variants emerge, experts say. Available online: https://www.washingtonpost.com/health/2021/01/27/double-mask-variants-guidance/ (accessed on Feb 12, 2023).

- Commissioner, H.C. Wearing a face mask in Healthcare settings. Available online: https://hcc.vic.gov.au/public/wearing-face-mask-healthcare-settings (accessed on Feb 20, 2023).

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).