Submitted:

14 April 2023

Posted:

14 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Materials

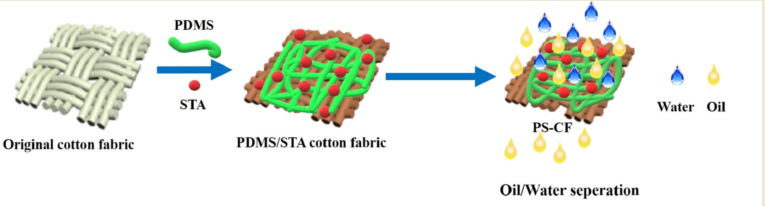

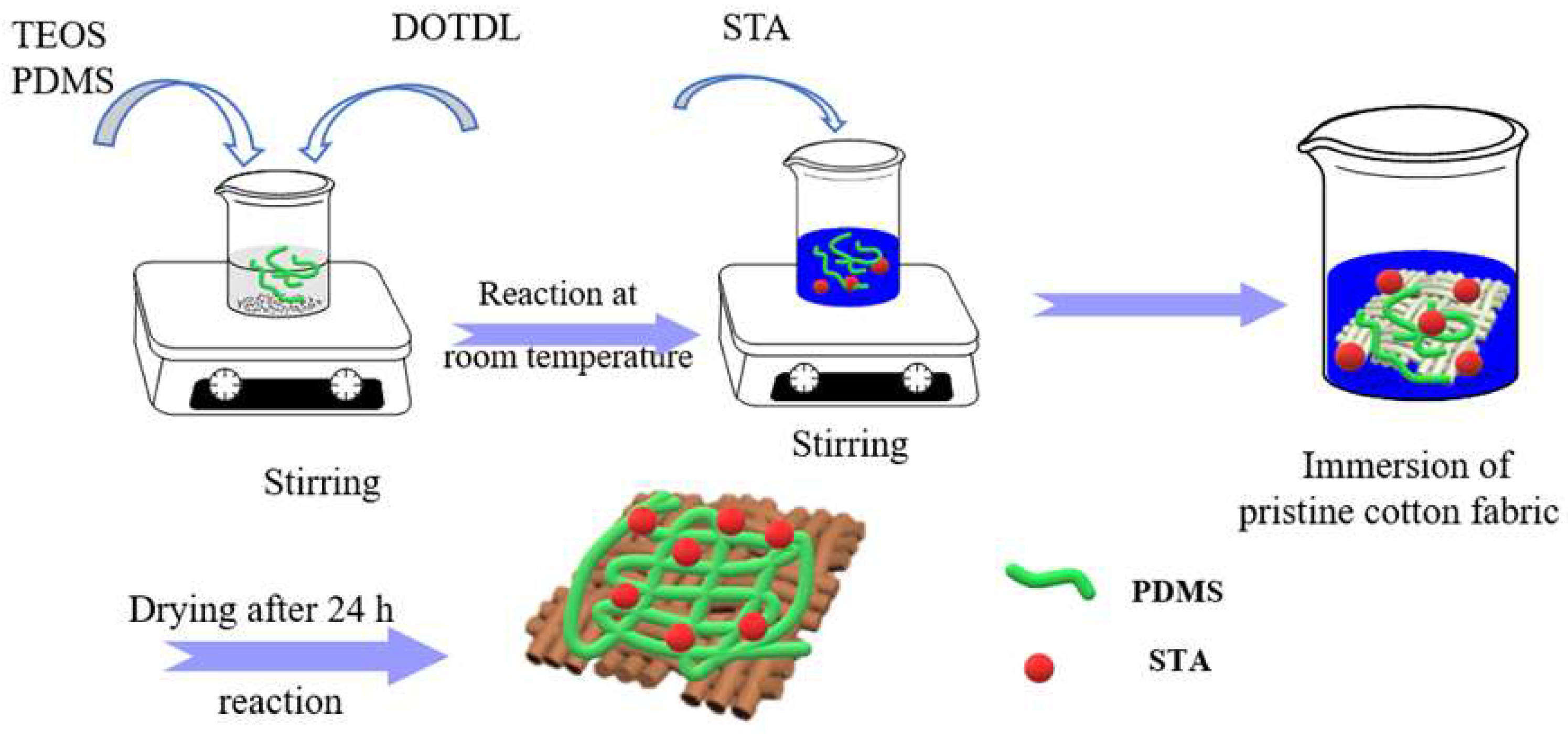

2.2. Fabrication of superhydrophobic cotton fabric

2.3. Characterizations

3. Results and discussion

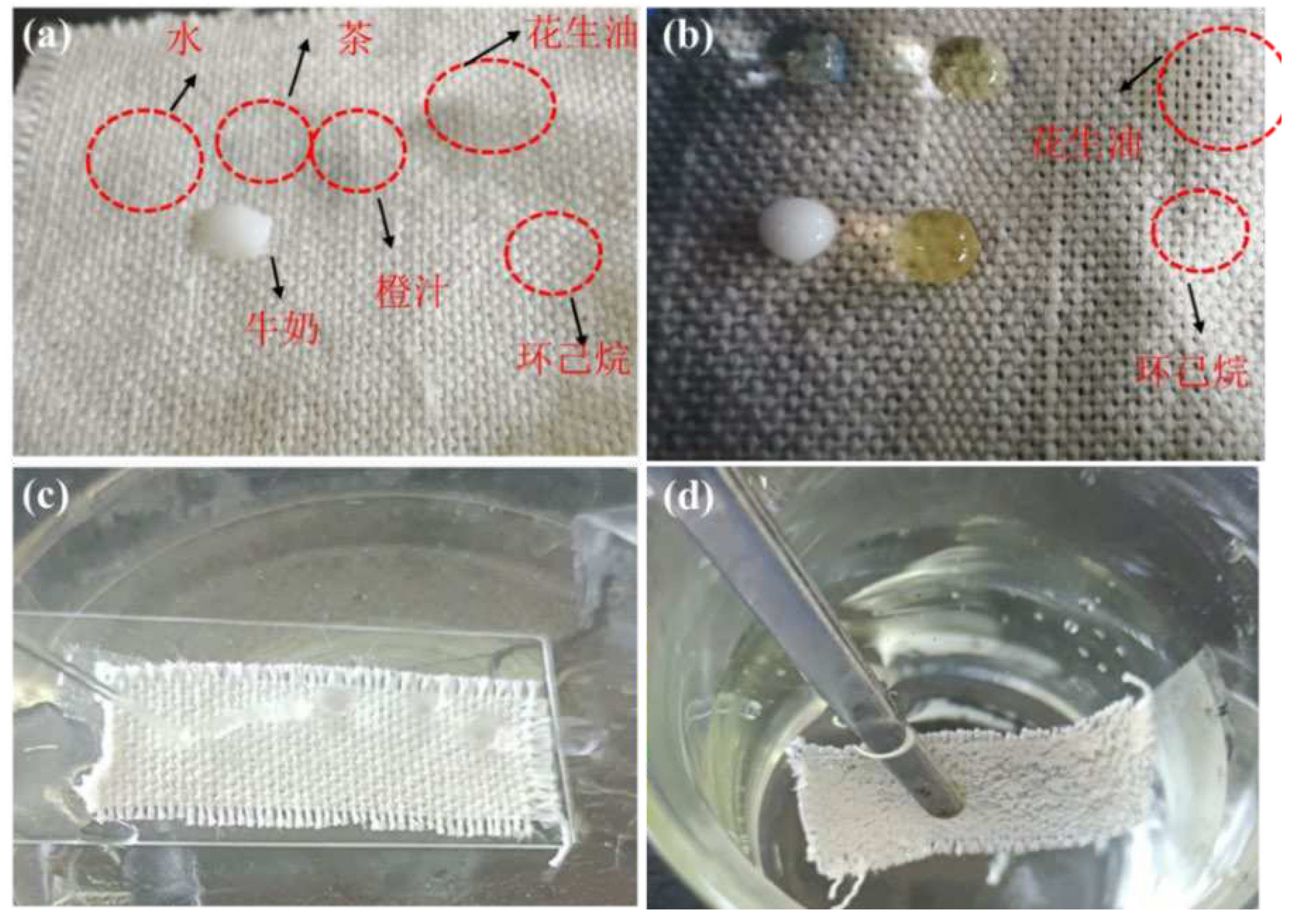

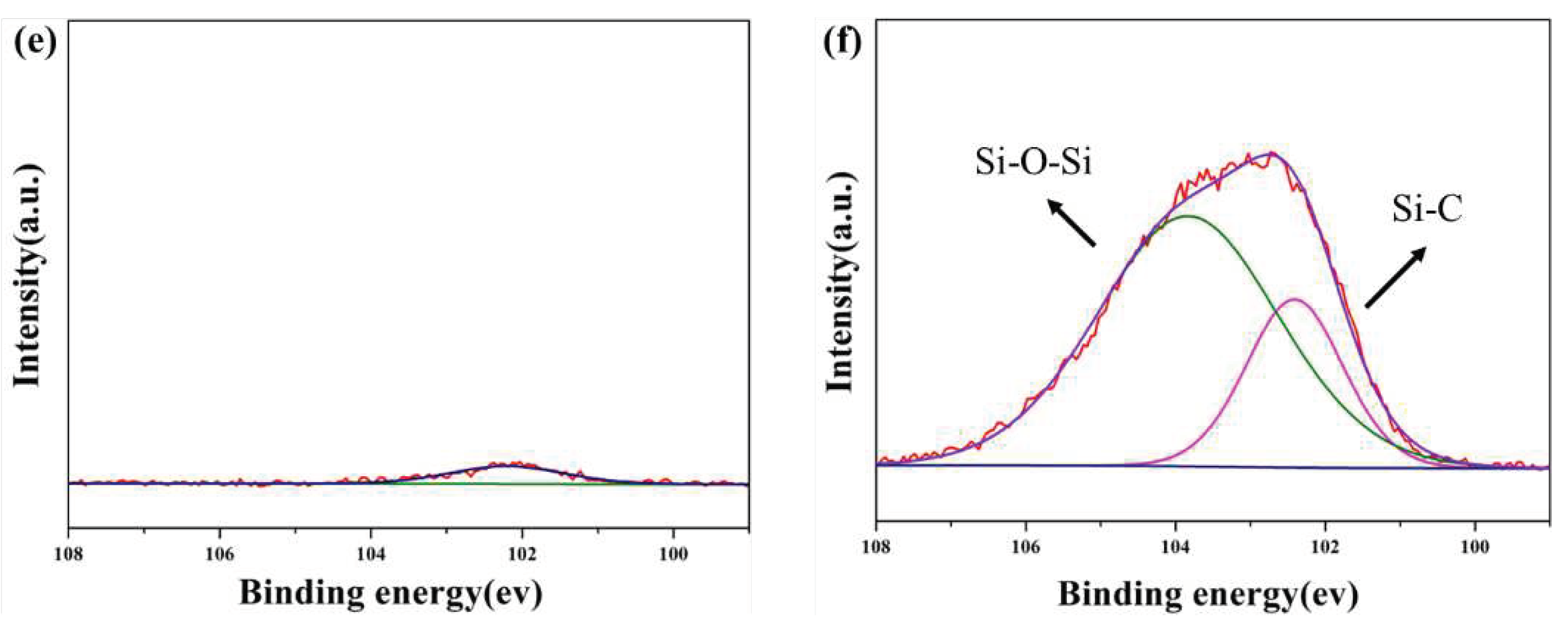

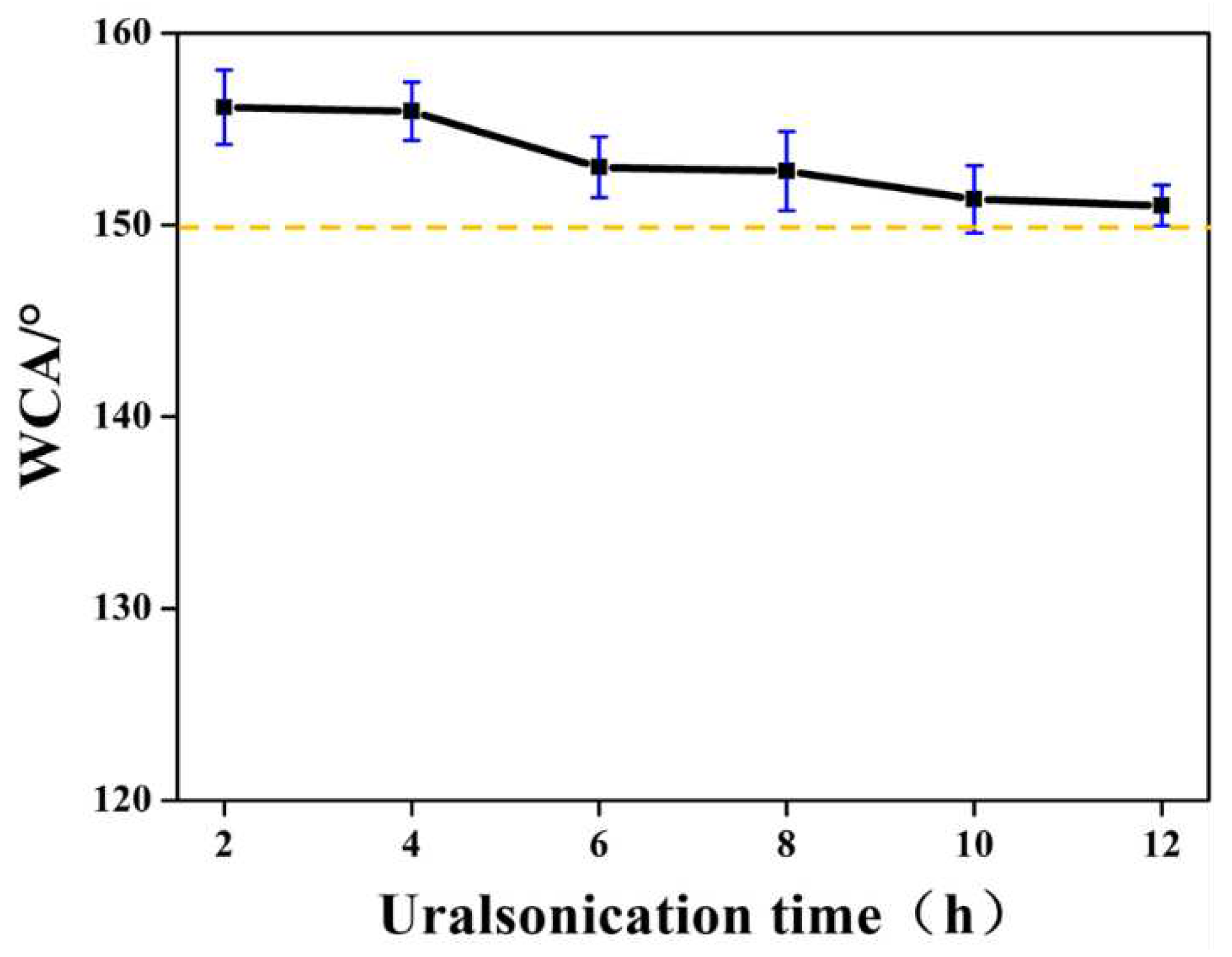

3.1. Wettability of superhydrophobic cotton fabric

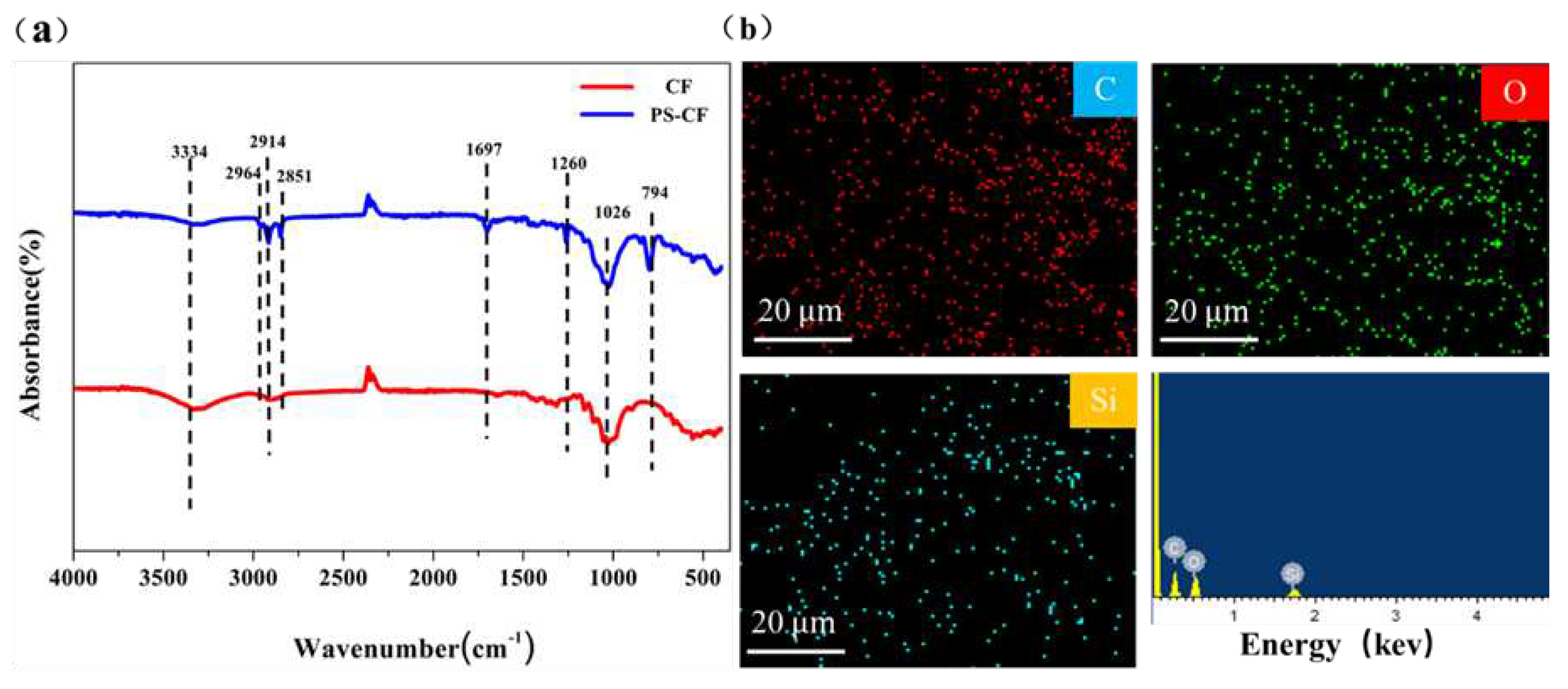

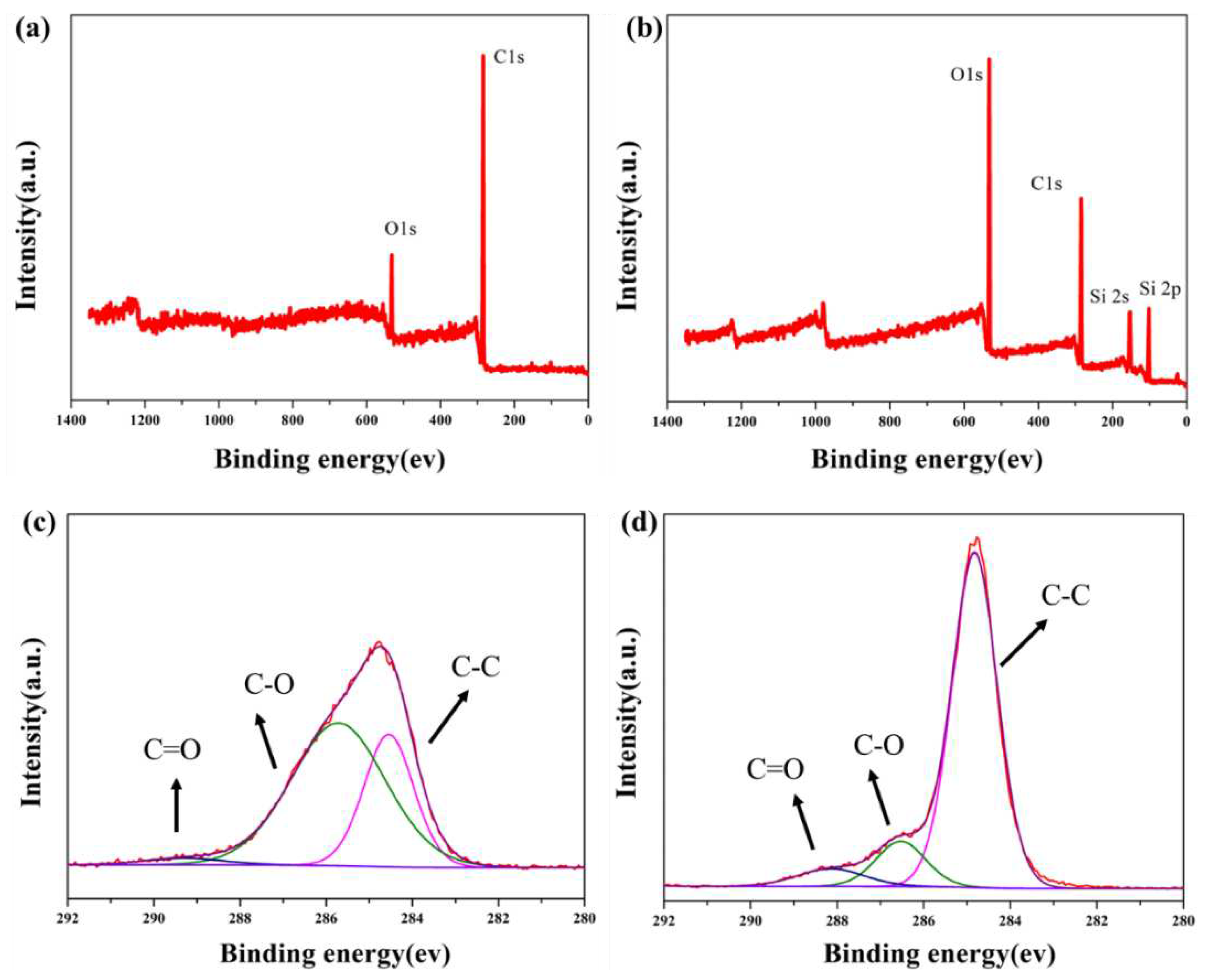

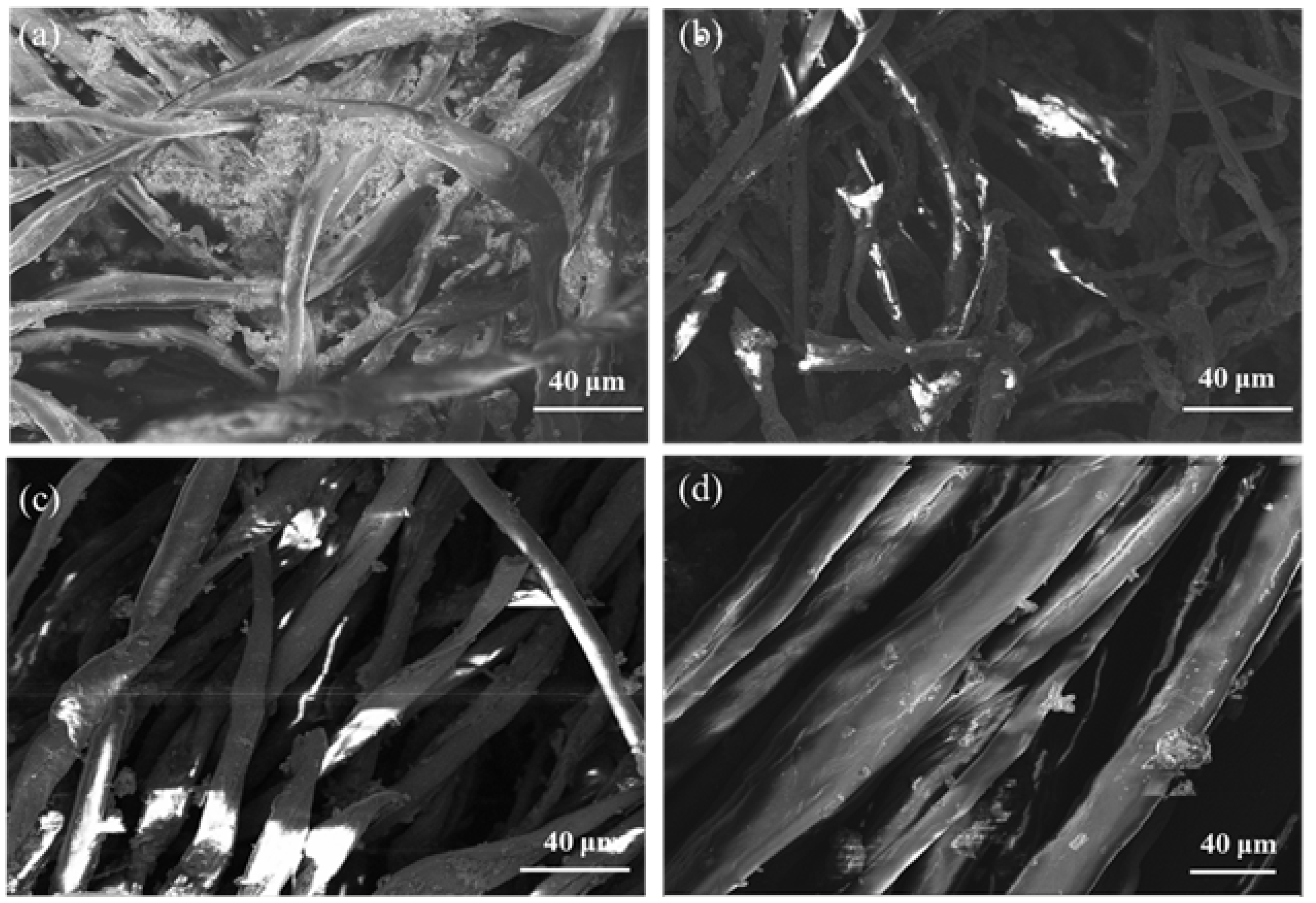

3.2. Formation of superhydrophobic PDMS/STA-coated cotton fabric

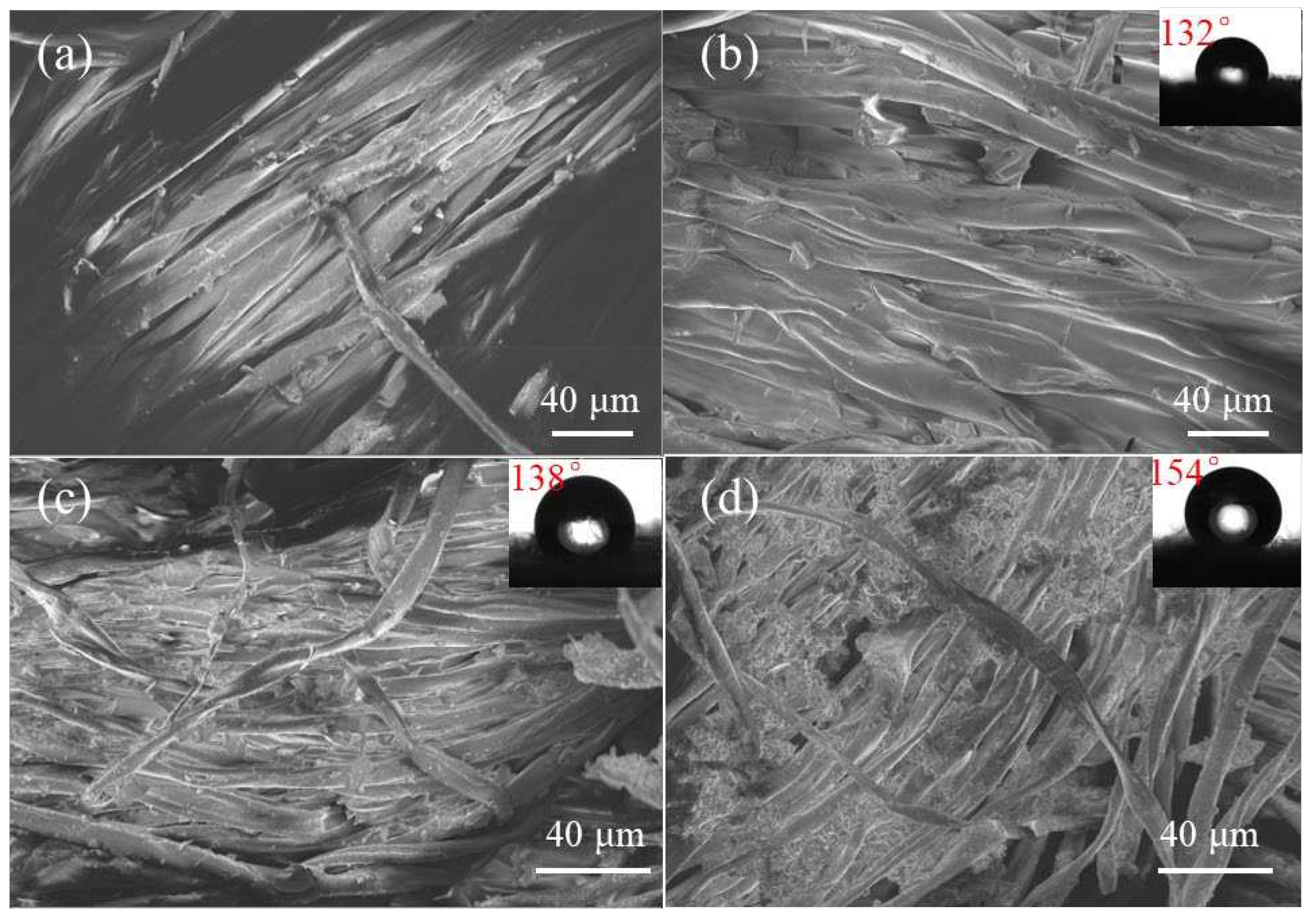

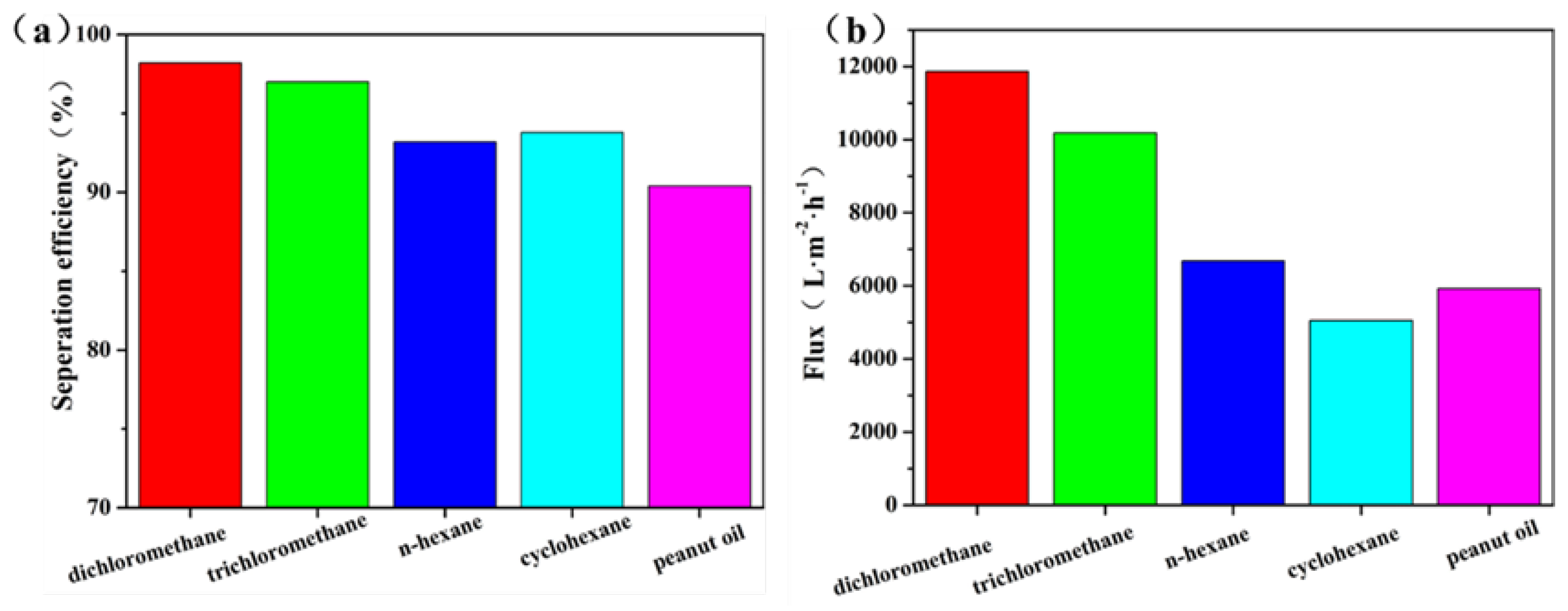

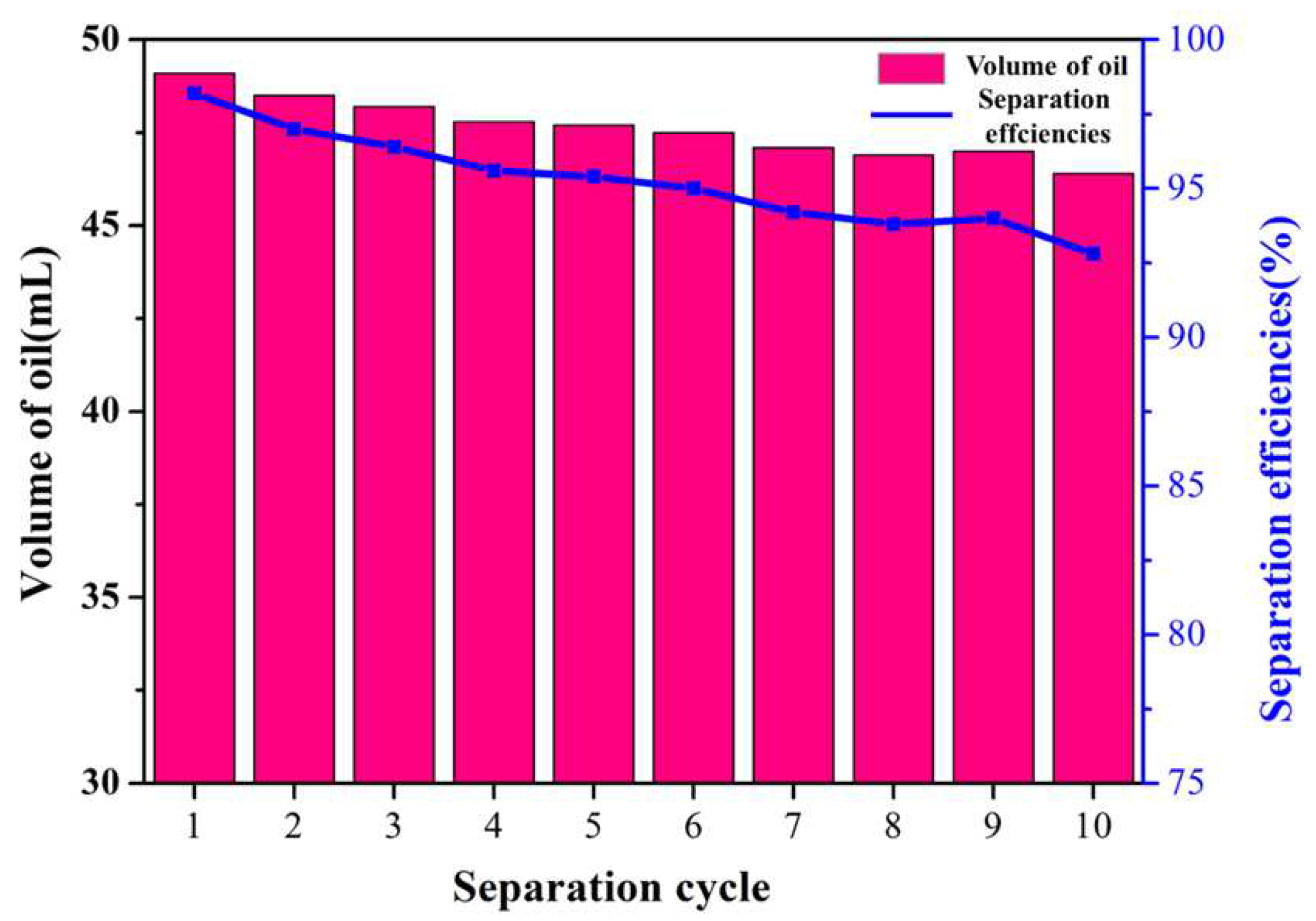

3.3. Oil-water separation

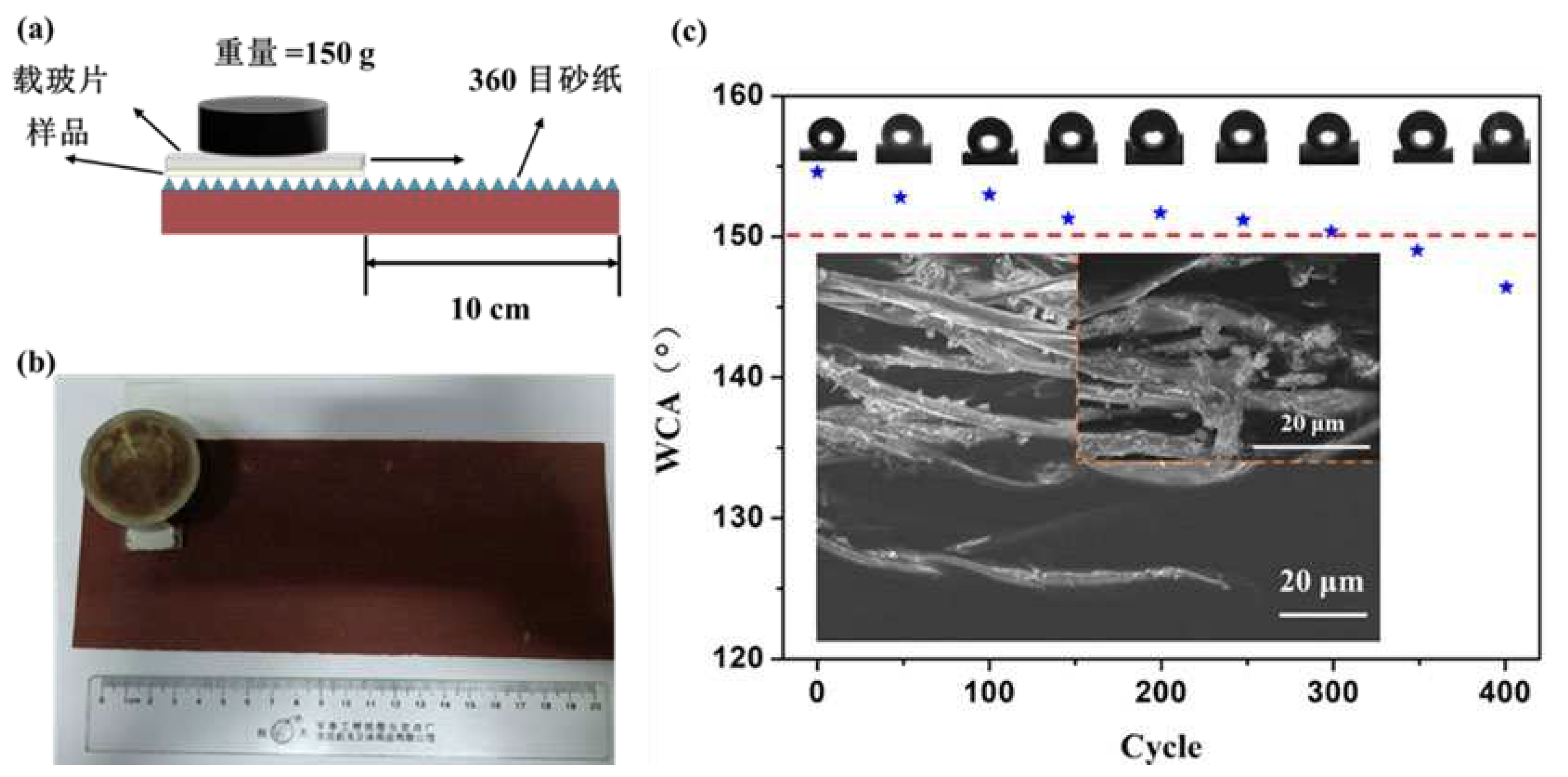

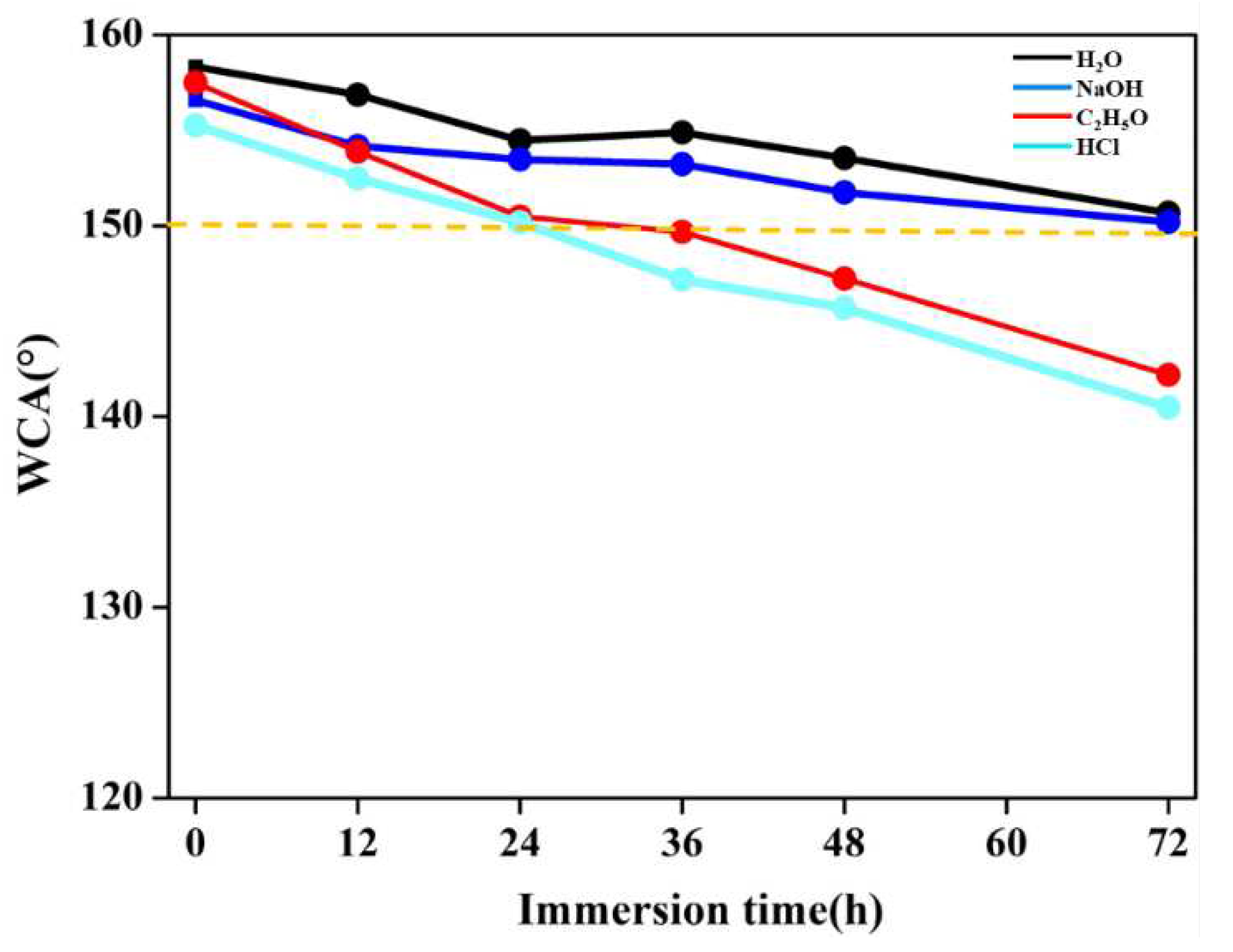

3.4. Durability and chemical stability of PS-CF

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- McClenachan, G.; Turner, R.E. Disturbance legacies and shifting trajectories: Marsh soil strength and shoreline erosion a decade after the Deepwater Horizon oil spill. Environmental Pollution 2023, 322, 121151. [Google Scholar] [CrossRef] [PubMed]

- Postel, S.L.; Daily, G.C.; Ehrlich, P.R. Human appropriation of renewable fresh water. Science 1996, 271, 785–788. [Google Scholar] [CrossRef]

- Ebenstein, A. The consequences of industrialization: Evidence from water pollution and digestive cancers in China. Review of Economics and Statistics 2012, 94, 186–201. [Google Scholar] [CrossRef]

- Alves, T.M.; Kokinou, E.; Zodiatis, G.; et al. Multidisciplinary oil spill modeling to protect coastal communities and the environment of the Eastern Mediterranean Sea. Scientific Reports 2016, 6, 1–9. [Google Scholar] [CrossRef] [PubMed]

- Sharma, J.; Dean, J.; Aljaberi, F.; et al. In-situ combustion in bellevue field in louisiana–history, current state and future strategies. Fuel 2021, 284, 118992. [Google Scholar] [CrossRef]

- Li, B.; Liu, X.; Zhang, X.; et al. Stainless steel mesh coated with silica for oil–water separation. European Polymer Journal 2015, 73, 374–379. [Google Scholar] [CrossRef]

- Zhan, M.; Yang, W.; Zhang, F.; et al. Experimental investigation on the separation performance for a new oil-water separator. Frontiers in Energy Research 2021, 8, 608586. [Google Scholar] [CrossRef]

- Khan, J.A.; Al-Kayiem, H.H.; Aleem, W.; et al. Influence of alkali-surfactant-polymer flooding on the coalescence and sedimentation of oil/water emulsion in gravity separation. Journal of Petroleum Science and Engineering 2019, 173, 640–649. [Google Scholar] [CrossRef]

- Xiang, B.; Sun, Q.; Zhong, Q.; et al. Current research situation and future prospect of superwetting smart oil/water separation materials. Journal of Materials Chemistry A 2022, 10, 20190–20217. [Google Scholar] [CrossRef]

- Baig, U.; Faizan, M.; Dastageer, M.A. Polyimide based super-wettable membranes/materials for high performance oil/water mixture and emulsion separation: A review. Advances in Colloid and Interface Science 2021, 297, 102525. [Google Scholar] [CrossRef]

- Yang, Y.; Guo, Z.; Liu, W. Special Superwetting Materials from Bioinspired to Intelligent Surface for On-Demand Oil/Water Separation: A Comprehensive Review. Small 2022, 18, 2204624. [Google Scholar] [CrossRef] [PubMed]

- Baig, U.; Faizan, M.; Dastageer, M.A. Polyimide based super-wettable membranes/materials for high performance oil/water mixture and emulsion separation: A review. Advances in Colloid and Interface Science 2021, 297, 102525. [Google Scholar] [CrossRef] [PubMed]

- He, Y.; Li, J.; Luo, K.; et al. Engineering reduced graphene oxide aerogel produced by effective γ-ray radiation-induced self-assembly and its application for continuous oil–water separation. Industrial & Engineering Chemistry Research 2016, 55, 3775–3781. [Google Scholar]

- Sim, I.; Park, S.; Shin, K.Y.; et al. Inkjet Printing of High Aspect Ratio Silver Lines via Laser-Induced Selective Surface Wetting Technique. Coatings 2023, 13, 683. [Google Scholar] [CrossRef]

- Jia, C.; Zhu, J.; Zhang, L. An Anti-Corrosion Superhydrophobic Copper Surface Fabricated by Milling and Chemical Deposition. Coatings 2022, 12, 442. [Google Scholar] [CrossRef]

- Li, A.; Jia, Y.; Zhang, F.; et al. The Effects of Zinc Oxide/Silicon Dioxide Composite Coating on Surface Wettability and the Mechanical Properties of Paper Mulching Film. Coatings 2022, 12, 555. [Google Scholar] [CrossRef]

- Barthlott, W.; Neinhuis, C. Purity of the sacred lotus, or escape from contamination in biological surfaces. Planta 1997, 202, 1–8. [Google Scholar] [CrossRef]

- Peng, J.; Yuan, S.; Geng, H.; et al. Robust and multifunctional superamphiphobic coating toward effective anti-adhesion. Chemical Engineering Journal 2022, 428, 131162. [Google Scholar] [CrossRef]

- Zhang, S.; Li, Y.; Yang, H.; et al. Multifunctional superhydrophobic composite coatings with remarkable passive heat dissipation and anticorrosion properties. Industrial and Engineering Chemistry Research 2021, 60, 11019–11029. [Google Scholar] [CrossRef]

- Al-Ahmed, Z.A.; Alzahrani, S.O.; AlJohani, A.K.B.; et al. An anticounterfeiting strategy based on photochromic nonwoven polyester fabric by plasma-assisting spray coating with ultraviolet-responsive silica@ strontium aluminate nanoparticles. Applied Organometallic Chemistry 2023, 37, e7035. [Google Scholar] [CrossRef]

- Sharma, J.; Dean, J.; Aljaberi, F.; et al. In-situ combustion in bellevue field in louisiana–history, current state and future strategies. Fuel 2021, 284, 118992. [Google Scholar] [CrossRef]

- Wang, W.; Dong, C.; Liu, S.; et al. Super-hydrophobic cotton aerogel with ultra-high flux and high oil retention capability for efficient oil/water separation. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 657, 130572. [Google Scholar] [CrossRef]

- Abu Jarad, N.; Imran, H.; Imani, S.M.; et al. Fabrication of superamphiphobic surfaces via spray coating: A review. Advanced Materials Technologies 2022, 7, 2101702. [Google Scholar] [CrossRef]

- Li, Y.; Shi, X.; Bai, W.; et al. Robust superhydrophobic materials with outstanding durability fabricated by epoxy adhesive-assisted facile spray method. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 664, 131109. [Google Scholar] [CrossRef]

- Yang, Z.; Chang, J.; He, X.; et al. Construction of robust slippery lubricant-infused epoxy-nanocomposite coatings for marine antifouling application. Progress in Organic Coatings 2023, 177, 107458. [Google Scholar] [CrossRef]

- Li, K.; Xiang, J.; Zhou, J.; et al. Self-healing and wear resistance stable superhydrophobic composite coating with electrothermal and photothermal effects for anti-icing. Progress in Organic Coatings 2023, 177, 107415. [Google Scholar] [CrossRef]

- Camalan, M.; Arol, A.İ. Preliminary assessment of spray coating, solution-immersion and dip coating to render minerals superhydrophobic. Minerals Engineering 2022, 176, 107357. [Google Scholar] [CrossRef]

- Xia, Y.; Fan, G.; Chen, K.; et al. Preparation and anti-corrosion performances of grass-like microstructured superhydrophobic surface on copper via solution-immersion. Materials Letters 2022, 323, 132482. [Google Scholar] [CrossRef]

- Liao, C.; Li, Y.; Gao, M.; et al. Bio-inspired construction of super-hydrophobic, eco-friendly multifunctional and bio-based cotton fabrics via impregnation method. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2022, 651, 129647. [Google Scholar] [CrossRef]

- Duan, Y.; Wu, J.; Qi, W.; et al. Eco-friendly marine antifouling coating consisting of cellulose nanocrystals with bioinspired micromorphology. Carbohydrate Polymers 2023, 304, 120504. [Google Scholar] [CrossRef] [PubMed]

- Ren, C.; Yu, Y. Superhydrophobic, heat-resistant alumina-methylsilsesquioxane hybrid aerogels with enhanced thermal insulating performance in high humidity. Ceramics International 2023, 49, 12625–12632. [Google Scholar] [CrossRef]

- Zhang, X.; Si, Y.; Mo, J.; et al. Robust micro-nanoscale flowerlike ZnO/epoxy resin superhydrophobic coating with rapid healing ability. Chemical Engineering Journal 2017, 313, 1152–1159. [Google Scholar] [CrossRef]

- Zhu, S.; Deng, W.; Su, Y. Recent advances in preparation of metallic superhydrophobic surface by chemical etching and its applications. Chinese Journal of Chemical Engineering 2023, in press. [CrossRef]

- Xue, Y.; Wang, Y.; Wang, Y.; et al. Functionalized superhydrophobic MWCNT/PEI nanocomposite film with anti-icing and photo-/electrothermal deicing properties. Materials Chemistry and Physics 2023, 297, 127385. [Google Scholar] [CrossRef]

- Han, J.; Liu, E.; Zhou, Y.; et al. Robust superhydrophobic film on aluminum alloy prepared with TiO2/SiO2-silane composite film for efficient self-cleaning, anti-corrosion and anti-icing. Materials Today Communications 2023, 34, 105085. [Google Scholar] [CrossRef]

- Chu, Z.; Feng, Y.; Xu, T.; et al. Magnetic, self–heating and superhydrophobic sponge for solar–driven high–viscosity oil–water separation. Journal of Hazardous Materials 2023, 445, 130553. [Google Scholar] [CrossRef] [PubMed]

- Ouyang, Y.; Huang, Z.; Fang, R.; et al. Silica nanoparticles enhanced polysiloxane-modified nickel-based coatings on Mg alloy for robust superhydrophobicity and high corrosion resistance. Surface and Coatings Technology 2022, 450, 128995. [Google Scholar] [CrossRef]

- Jia, C.; Zhu, J.; Zhang, L. An Anti-Corrosion Superhydrophobic Copper Surface Fabricated by Milling and Chemical Deposition. Coatings 2022, 12, 442. [Google Scholar] [CrossRef]

- Wang, K.; Dong, Y.; Zhang, W.; et al. Preparation of stable superhydrophobic coatings on wood substrate surfaces via mussel-inspired polydopamine and electroless deposition methods. Polymers 2017, 9, 218. [Google Scholar] [CrossRef]

- Jeong, H.; Baek, S.; Han, S.; et al. Chemically Robust Superhydrophobic Poly (vinylidene fluoride) Films with Grafting Crosslinkable Fluorinated Silane. Macromolecular Research 2018, 26, 493–499. [Google Scholar] [CrossRef]

- Pathak, P.; Grewal, H.S. Solvent-free synthesis of superhydrophobic materials with self-regenerative and drag reduction properties. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 658, 130675. [Google Scholar] [CrossRef]

- Peng, Z.; Song, J.; Gao, Y.; et al. A fluorinated polymer sponge with superhydrophobicity for high-performance biomechanical energy harvesting. Nano Energy 2021, 85, 106021. [Google Scholar] [CrossRef]

- Lin, Y.; Zhang, H.; Zou, Y.; et al. Superhydrophobic photothermal coatings based on candle soot for prevention of biofilm formation. Journal of Materials Science & Technology 2023, 132, 18–26. [Google Scholar]

- Chen, Z.; Zuo, J.; Zhao, T.; et al. Superhydrophobic copper foam bed with extended permeation channels for water-in-oil emulsion separation with high efficiency and flux. Journal of Environmental Chemical Engineering 2023, 11, 109018. [Google Scholar] [CrossRef]

- Anitha, C.; Mayavan, S. Salvinia inspired fluroine free superhydrophobic coatings. Applied Surface Science 2018, 449, 250–260. [Google Scholar]

- Tagliaro, I.; Seccia, S.; Pellegrini, B.; et al. Chitosan-based coatings with tunable transparency and superhydrophobicity: A solvent-free and fluorine-free approach by stearoyl derivatization. Carbohydrate Polymers 2023, 302, 120424. [Google Scholar] [CrossRef] [PubMed]

- Ahmad, N.; Rasheed, S.; Ahmed, K.; et al. Facile two-step functionalization of multifunctional superhydrophobic cotton fabric for UV-blocking, self cleaning, antibacterial, and oil-water separation. Separation and Purification Technology 2023, 306, 122626. [Google Scholar] [CrossRef]

- Suryaprabha, T.; Sethuraman, M.G. Fabrication of a superhydrophobic and flame-retardant cotton fabric using a DNA-based coating. Journal of Materials Science 2020, 55, 11959–11969. [Google Scholar] [CrossRef]

- Li, S.; Yu, L.; Xiong, J.; et al. Facile Fabrication of Superhydrophobic and Flame-Retardant Coatings on Cotton Fabrics. Polymers 2022, 14, 5314. [Google Scholar] [CrossRef]

- Ejeta, D.D.; Wang, C.F.; Kuo, S.W.; et al. Preparation of superhydrophobic and superoleophilic cotton-based material for extremely high flux water-in-oil emulsion separation. Chemical Engineering Journal 2020, 402, 126289. [Google Scholar] [CrossRef]

- Li, L.; Li, B.; Sun, H.; et al. Compressible and conductive carbon aerogels from waste paper with exceptional performance for oil/water separation. Journal of Materials Chemistry A 2017, 5, 14858–14864. [Google Scholar] [CrossRef]

- Yin, Z.; Pan, Y.; Bao, M.; et al. Superhydrophobic magnetic cotton fabricated under low carbonization temperature for effective oil/water separation. Separation and Purification Technology 2021, 266, 118535. [Google Scholar] [CrossRef]

- Liu, M.; Tan, X.; Li, X.; et al. Transparent superhydrophobic EVA/SiO2/PTFE/KH-570 coating with good mechanical robustness, chemical stability, self-cleaning effect and anti-icing property fabricated by facile dipping method. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 658, 130624. [Google Scholar] [CrossRef]

- Yang, J.; He, T.; Li, X.; et al. Rapid dipping preparation of superhydrophobic TiO2 cotton fabric for multifunctional highly efficient oil-water separation and photocatalytic degradation. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 657, 130590. [Google Scholar] [CrossRef]

- Luo, M.; Sun, X.; Zheng, Y.; et al. Non-fluorinated superhydrophobic film with high transparency for photovoltaic glass covers. Applied Surface Science 2023, 609, 155299. [Google Scholar] [CrossRef]

- Yao, T.; Song, J.; Gan, Y.; et al. Preparation of cellulose-based chromatographic medium for biological separation: A review. Journal of Chromatography A 2022, 1677, 463297. [Google Scholar] [CrossRef] [PubMed]

- Wang, W.; Dong, C.; Liu, S.; et al. Super-hydrophobic cotton aerogel with ultra-high flux and high oil retention capability for efficient oil/water separation. Colloids and Surfaces A: Physicochemical and Engineering Aspects 2023, 657, 130572. [Google Scholar] [CrossRef]

- Wang, H.; Meng, J.; Li, F.; et al. Graphitic carbon nitride/metal-organic framework composite functionalized cotton for efficient oil-water separation and dye degradation. Journal of Cleaner Production 2023, 385, 135758. [Google Scholar] [CrossRef]

- Cassie, A.B.D.; Baxter, S. Wettability of porous surfaces. Transactions of the Faraday society 1944, 40, 546–551. [Google Scholar] [CrossRef]

- Qin, L.; Liu, Z.; Liu, T.; et al. A bioinspired, strong, all-natural, superhydrophobic cellulose-based straw. International Journal of Biological Macromolecules 2022, 220, 910–919. [Google Scholar] [CrossRef]

- Xu, Y.; Yu, Y.; Song, C.; et al. One-step preparation of efficient SiO2/PVDF membrane by sol-gel strategy for oil/water separation under harsh environments. Polymer 2022, 260, 125402. [Google Scholar] [CrossRef]

- Zhang, Y.; Zhang, Y.; Cao, Q.; et al. Novel porous oil-water separation material with super-hydrophobicity and super-oleophilicity prepared from beeswax, lignin, and cotton. Science of the Total Environment 2020, 706, 135807. [Google Scholar] [CrossRef] [PubMed]

- Wen, H.; Raza, S.; Wang, P.; et al. Robust super hydrophobic cotton fabrics functionalized with Ag and PDMS for effective antibacterial activity and efficient oil–water separation. Journal of Environmental Chemical Engineering 2021, 9, 106083. [Google Scholar] [CrossRef]

- Li, F.; Bhushan, B.; Pan, Y.; et al. Bioinspired superoleophobic/superhydrophilic functionalized cotton for efficient separation of immiscible oil-water mixtures and oil-water emulsions. Journal of colloid and interface science 2019, 548, 123–130. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).