1. Introduction

Management of industry infrastructure assets and products involves various processes that require and generate large amounts of data. There is a constant need to collect and analyze this data to support decision-making. Over the past decade, computing capabilities have advanced tremendously. This situation has fostered the emergence of Industry 4.0, emerging as a new industrial revolution [

1]. Progress has brought new tools and approaches (such as Internet of Things = IoT and cloud computing) aimed at increasing the efficiency of industrial processes. One of the tools of Industry 4.0 is the Digital Twin (DT) approach. It has become very popular in recent years, and is receiving a lot of attention from specific industries as well as the scientific community [

2,

3,

4,

5,

6].

The article deals with the processes of digitalization of shipbuilding processes for the establishment of a digital twin system (DTS). In order to properly and effectively address the topic, an analysis of the state of the knowledge was carried out both from the DT basics and more detailed solutions dedicated to the shipbuilding industry.

The concept of the digital twin is not new and dates back to 2002 when Prof. Michael Grieves presented it as a product life cycle model [

6,

7]. This model had three elements that make up DT: real space, virtual space and data flow space. Since then, many researchers have tried to develop the concept. The first formal definition of DT was introduced by the National Aeronautics and Space Administration (NASA) in a study indicating strategic development technologies [

8]. In simple terms, it defined DT as an integrated, multi-physics, multi-scale, probabilistic simulation of a post-built state, or as a system that uses the best available physical models, sensor updates, history, etc., to reflect the life of its corresponding real-world twin. DT continuously forecasts the state of its sibling to increase both the lifespan and probability of its successful operation.

The assumptions and initial definitions of DT converge in the literature, and most researchers refer to them. Analyzing the progression of ongoing DT research, it can be observed that currently their interpretation is becoming increasingly differentiated. In a review of the literature, the authors [

9] note that more and more diverse DT concepts are being developed. The main divergences concern the dilemma of whether DT is just a digital representation of a physical object or something more. One can also encounter the approach that DT is a sort of technology [

10,

11]. The study [

9] identified several leading approaches while showing their shortcomings. The need to unify nomenclature was shown as a basic conclusion. Attention was also drawn to the increasing misuse of the name DT both among researchers and on the part of technology and software vendors and suppliers, who use this very popular term to describe their products and technologies [

9,

12]. Analyzing the available literature, one can see an increase in the popularity of the classification proposed in [

13], where the authors defined three levels of digitalization of processes and objects: "digital model", "digital shadow" and "digital twin". This classification seems justified because it accurately distinguishes the degree of digitalization of actual processes and tries to organize the nomenclature. On the other hand, some researchers treat these classes as synonyms for DT, which causes unnecessary complications in naming. The scale of the problem in naming and defining DTs is described in detail in [

9,

14], among others. Analyzing the available studies, one must agree with [

15] that studies of the "true digital twin" are rare. It can also be said that the concept of DT is a victim of its success, it is fashionable, which causes its frequent misuse as a slogan that does not reflect its true meaning [

2,

6].

DT work is being carried out in virtually all industries [

16]. The degree of advancement in each sector varies. This is mainly due to the predisposition and characteristics of a particular industry and its degree of digitalization. It can be noted that the degree to which the cadre of specialists in a given industry is prepared for the digital revolution also has a major impact on the progress of the works. It seems natural that the electronics industry, for example, will be more advanced in terms of the broadly defined Industry 4.0 than the tradition-bound shipbuilding industry. It can be observed that researchers and entrepreneurs in areas less advanced in the digital revolution have perceived great opportunities and are intensifying work in this area. They are identifying and solving more and more tasks in order to apply DT widely and effectively. Intensive work is also being carried out in the maritime sector. Their results are described, among others, by the authors of papers [

17,

18,

19,

20,

21,

22,

23,

24,

25,

26,

27,

28,

29,

30]. Analyzing the cited studies from the field of shipbuilding, as in other industries, one can notice discrepancies in the unambiguous definition of DT as well as the idea of its use. These problems have been identified and described by researchers, and work has been undertaken to systematize DT issues also in the field of shipbuilding [

16,

17].

As a result of the analysis of the literature and the authors' experience in the field of the shipbuilding industry, for the purposes of this study, DT was defined as a digital model of a physical production system with work items flowing through it, which receives continuous updates and processes data throughout the production process from product conception, through the design, planning, manufacturing and quality control phases, until the product is commissioned.

It is assumed that bidirectional data transfer connects the digital twin with its physical counterpart in the real world. The model distinguishes functional components between which information is also exchanged, in effect we say that the digital twin constitutes a system with well-defined tasks, boundaries and structure.

The performed review of the state of the art in the field of DT, both in purely theoretical and practical terms, shows a varying degree of progress in different industries. At the same time, considerable diversity of approaches can be noted, the spectrum of issues with which DT is associated is wide, there are a lot of definitions of DT associated with individual industries.

Taking into account the complexity of the issue and the individual parameters of individual industries, in order to fully exploit the possibilities of DT, it is necessary for researchers and specialists in both theoretical and practical issues to work together.

2. Shipbuilding Industry - Specifics and Readiness for the Digital Revolution

Maritime transport handles about 90% of world trade in goods, and is one of the basic elements of globalization. Maritime transport is highly competitive against other global shipping methods which, paradoxically, does not support its development. Although the process of improving the technology and efficiency of vessels is constantly carried out, it is not as intensive as in other industries. The aspect of competitiveness in the development of this industry is active mainly between individual manufacturers and shipowners. Development activities, unfortunately, are often not coordinated. Manufacturers (shipyards) and shipowners mostly act independently of each other. Often, the interests and goals of the individual participants in the marine transportation market and manufacturers of marine transportation equipment are not consistent. This results in a rather disjointed development work. The topic is complex, in addition to purely technical and organizational problems, important aspects limiting the development processes of the shipping industry are:

- High costs of implementing modern technologies;

- Lack of systemic investment initiatives;

- Lack of awareness of the benefits of digitalization of facilities and processes among specialized personnel of the shipbuilding industry. This awareness is necessary for effective action in the pursuit of shipbuilding development especially in the direction of Industry 4.0.

At the same time, there is another aspect placing a strong global emphasis on the comprehensive development of maritime transportation, and that is the environmental aspect. Maritime transportation is one of the largest sources of both air and water pollution. The broader shipping industry accounts for 2.4% of global greenhouse gas emissions [

31]. Political and social pressure on environmental aspects is strong and growing intensely. The aspirations for increasing globalization with simultaneous efforts to minimize the negative impact on the environment are pushing the shipbuilding industry comprehensively towards the most recent industry optimization solutions such as the transformation towards Industry 4.0.

When analyzing the state of the shipbuilding industry and its readiness for the revolution in question, it is important to note the huge variation in the technological sophistication of manufacturers (shipyards). Unfortunately, most of the world's shipyards are definitely technologically behind the few shipyards that are highly invested and technologically advanced. This is a very serious aspect of shipbuilding development that cannot be bypassed. These conditions should be recognized by global institutions. A systemic approach to solving this issue is necessary.

Some shipyards and most marine transportation systems are becoming increasingly complex and advanced. Development leads to highly integrated safety and performance management systems. These systems are already common mainly in the area of ship operations. Maintaining and effectively managing these systems as a whole is difficult and, when combined with systems related to ship production, it is currently unheard of.

It can be concluded that practically the only chance to integrate these areas, in order to effectively manage and improve them, is to fully digitalize them and lead them in the direction of Industry 4.0. The comprehensive application of the idea of DT as part of Industry 4.0 seems purposeful. This conclusion is confirmed by basically all researchers conducting work in this area.

As a result of the analysis of the state of knowledge in the field of DTs and their applications in the shipbuilding industry (shipbuilding), one can see great progress especially in the general view of DTs. A number of studies relating to the general, theoretical approach to the subject have been produced and the detailing mainly concerns the issues of operation and the design stage. The design stage seems to be the most advanced towards digitalization. Taking into account the capabilities of current specialized design software, it can be stated that the stage of DT creation in the design stage of the ship is being realized. It makes the development of the project in digital form possible, not only in terms of technical drawings and general documentation, but also in the form of full virtual models covering the structure, installations, ship systems, equipment and designed technology and production information. In addition to the design stage, DT issues of the operation area are well represented in the literature. This applies to the sphere of transport systems and individual vessels. These studies are mostly at the preliminary stage, referring to specific cases without the necessary generalized concepts and definitions [

32]. At the same time, it can be said that there are practically no studies related to the detailed analysis of the production stage. It can be concluded that a gap has been created in the studies in the field of DT of the manufacturing process of ships. This space should be filled and combined with the others. It is necessary to integrate works in the direction of general conceptualization of DT for the entire lifespan of a ship supported by specific solutions for its individual stages. This direction is indicated, among others, by the authors [

18].

The production process of hull construction is divided into a number of stages, each stage consists of a huge number of operations using different technologies and materials. There are interactions between these elements, and they are dependent on each other. The amount of data involved in each stage is enormous. The challenges of digitization of this process within the DT system are great.

This paper proposes a comprehensive approach to creating a DT system of the ship manufacturing process. It includes the digitalization of technological processes, logistics and transportation processes, production planning processes, quality control, and the flow streams of materials and prefabricated products through the shipyard. In the proposed approach, the DT system is a hybrid whole consisting of the DT of the production process and the DT of the first stage of the vessel-product life cycle. The production process, its parameters are dependent on where it is implemented, i.e., the shipyard itself and its parameters. That is, in order to digitalize the production process, it is necessary to digitalize the shipyard.

An extremely important aspect is the already mentioned degree of technical sophistication of a given shipyard. Discrepancies in this regard are often very large. This fact makes it necessary to determine the readiness of a given shipyard for the digital revolution. For some of them it will be an evolution and for some a revolution. In the assumption, the proposed DT system will help improve not only the product but also the place and methods of its construction.

3. Digital Twin System

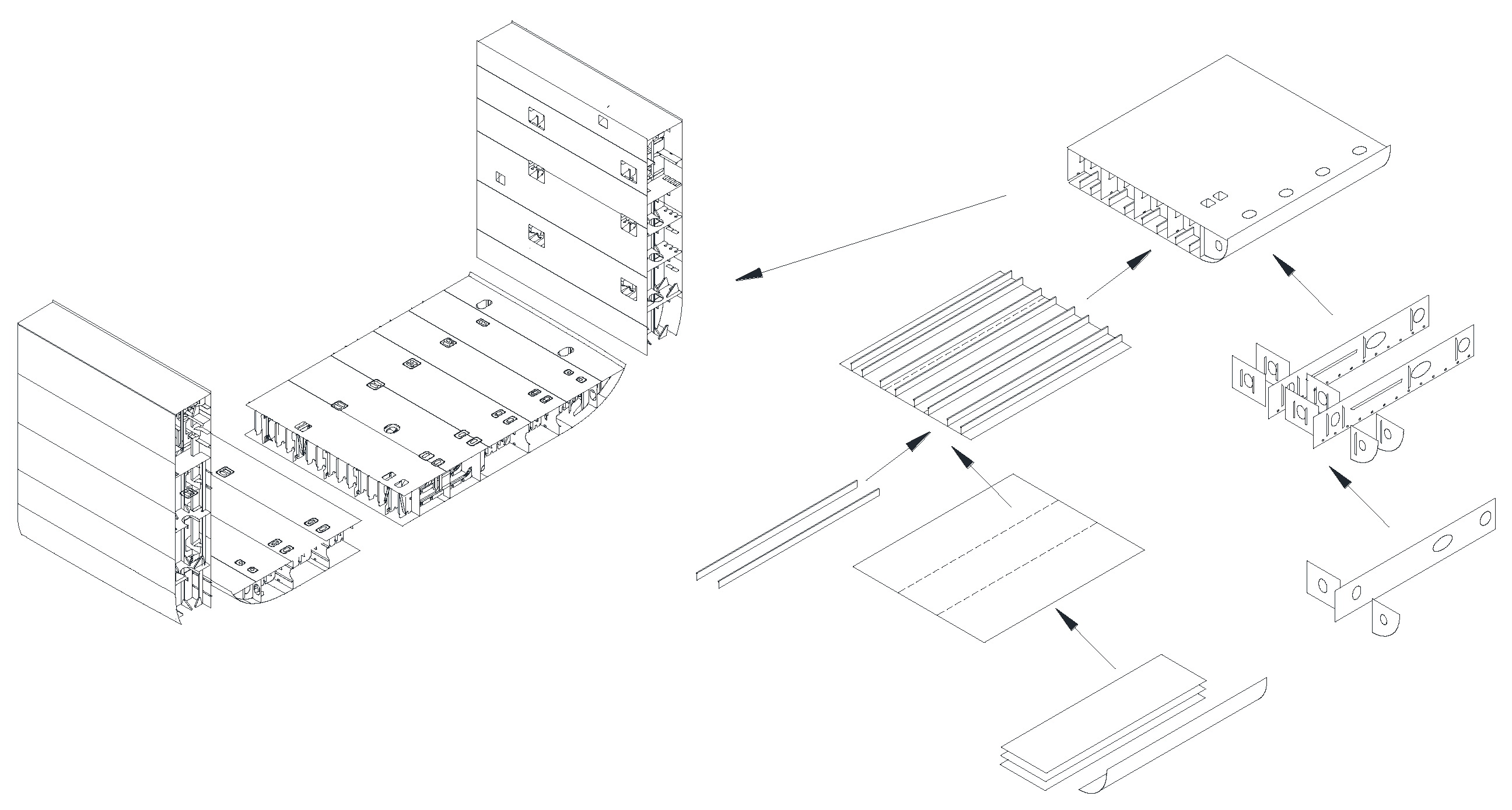

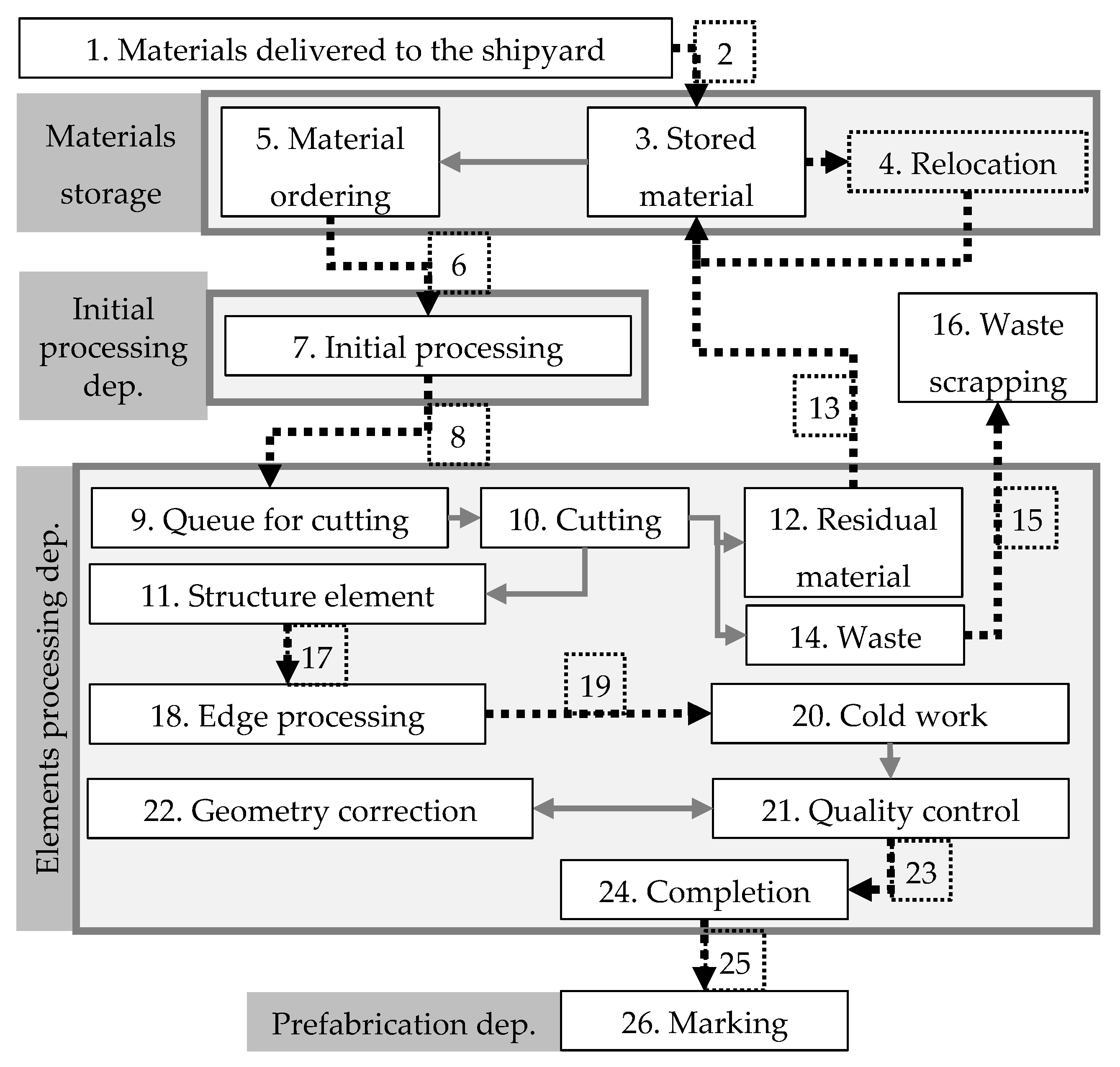

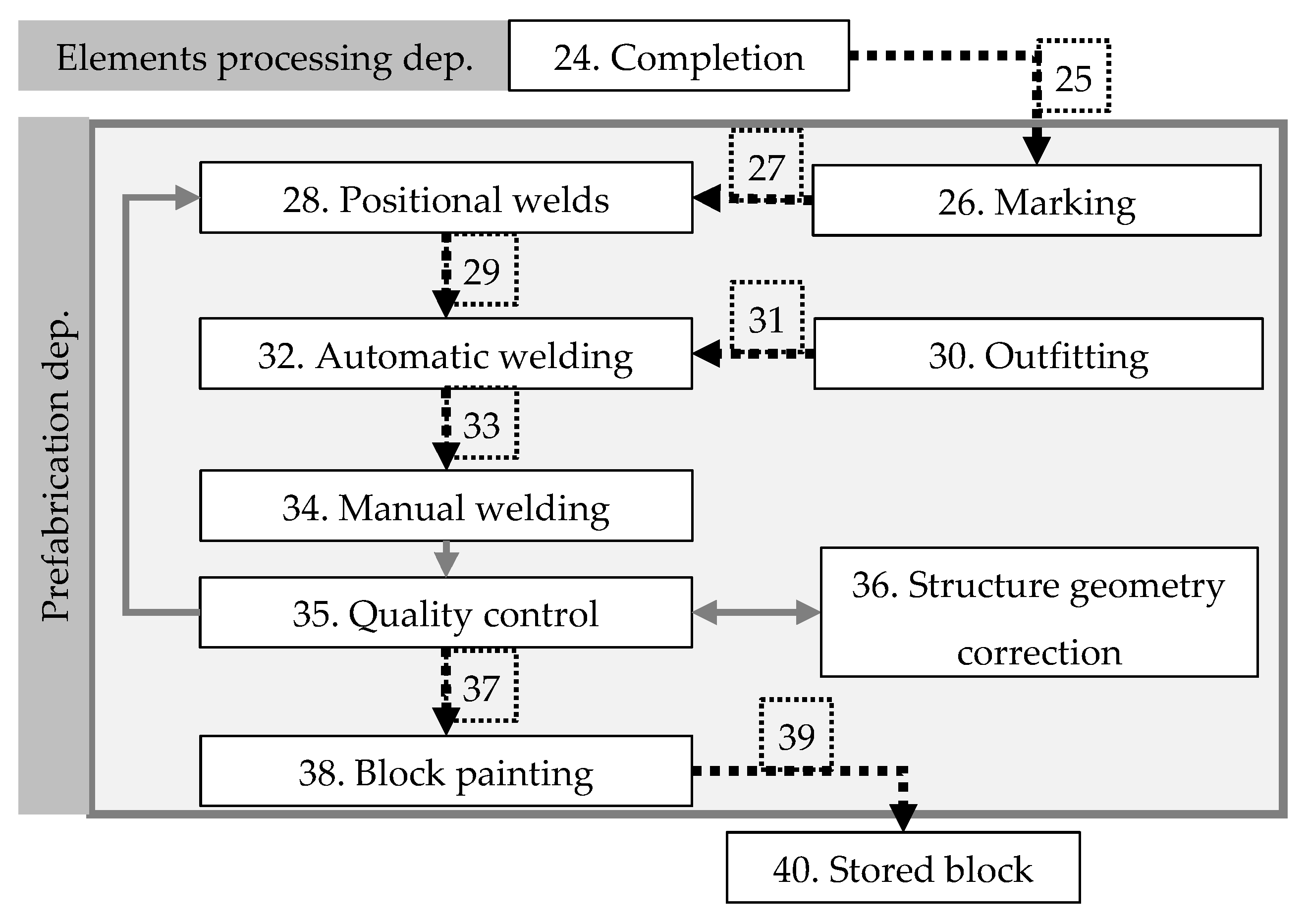

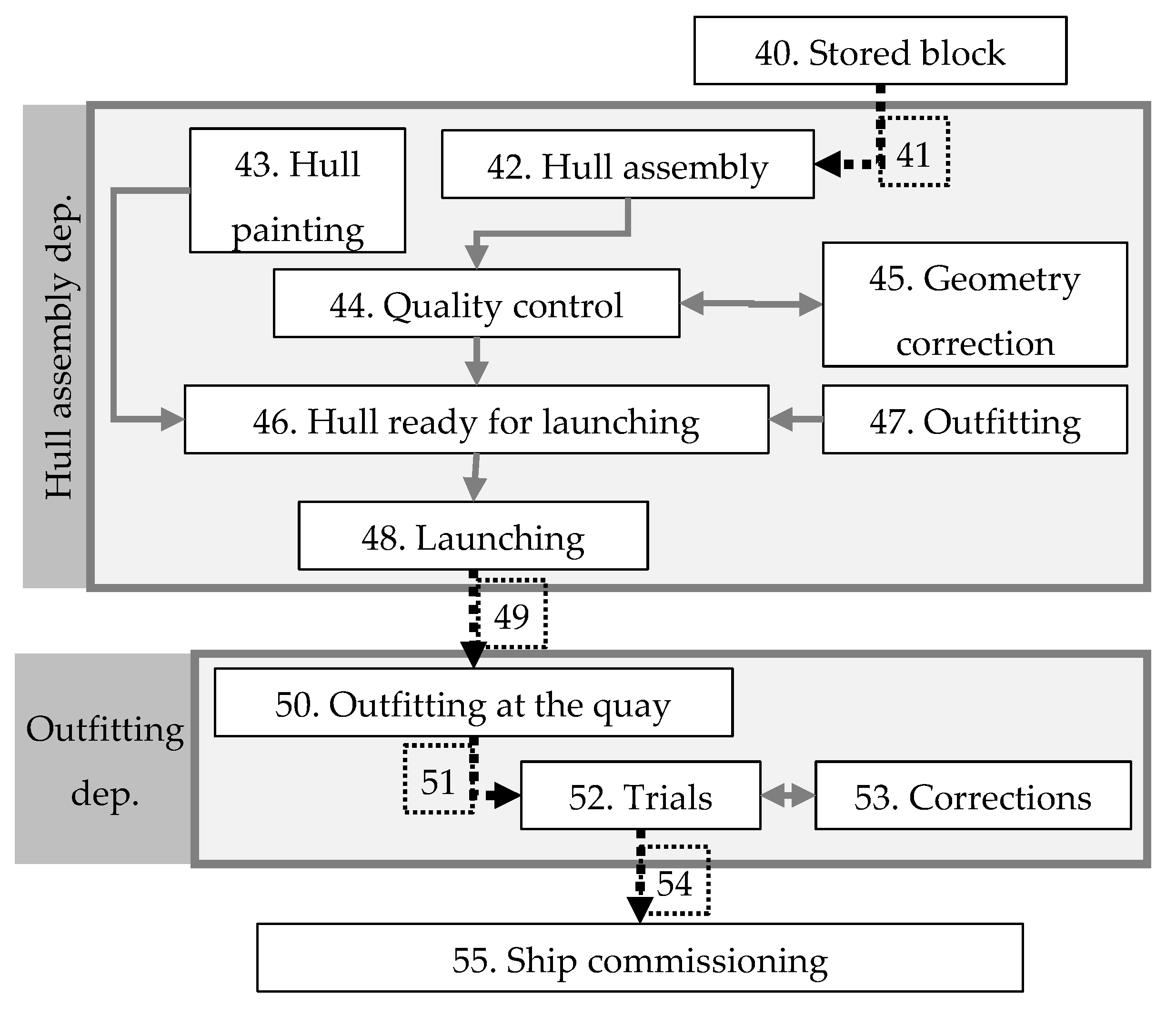

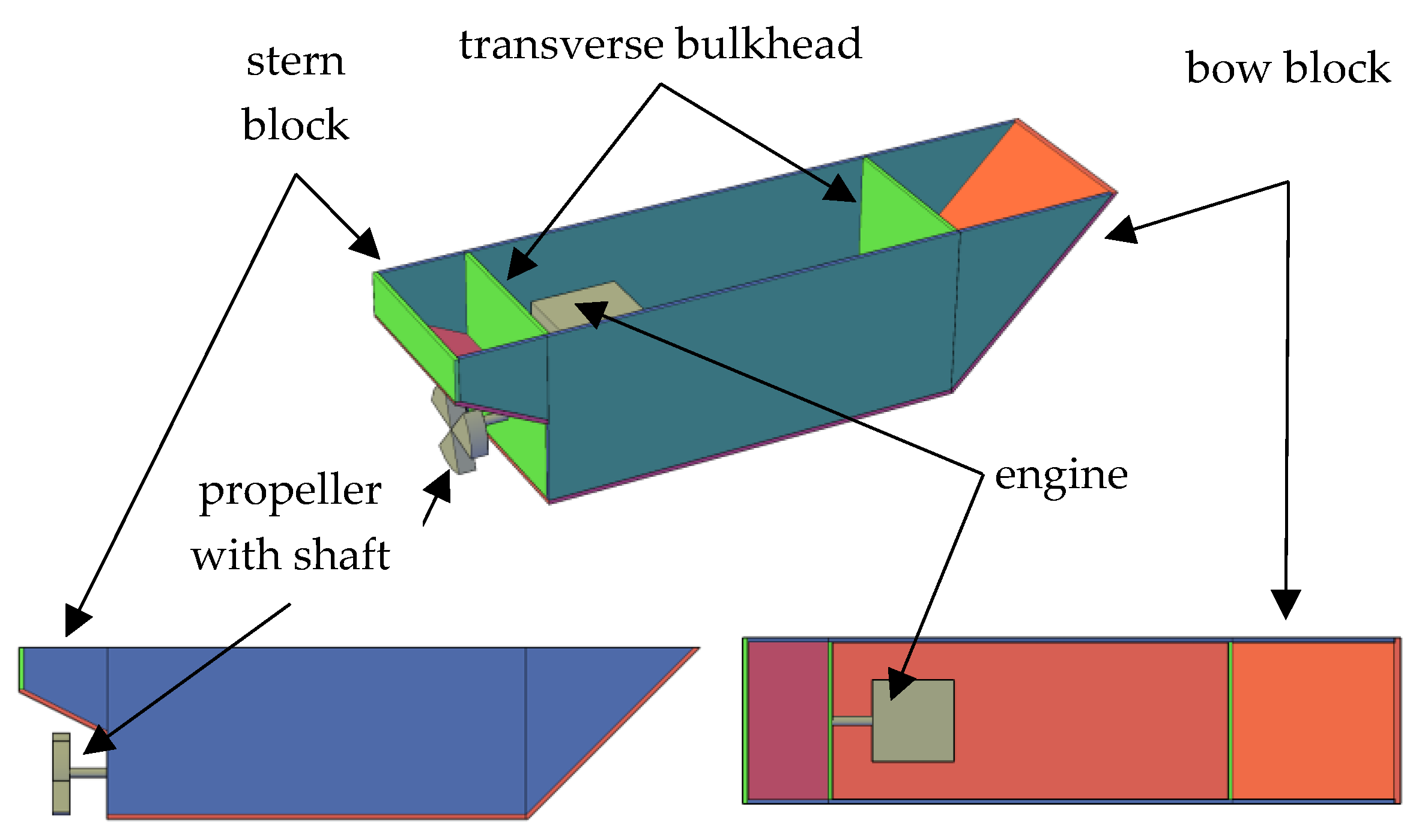

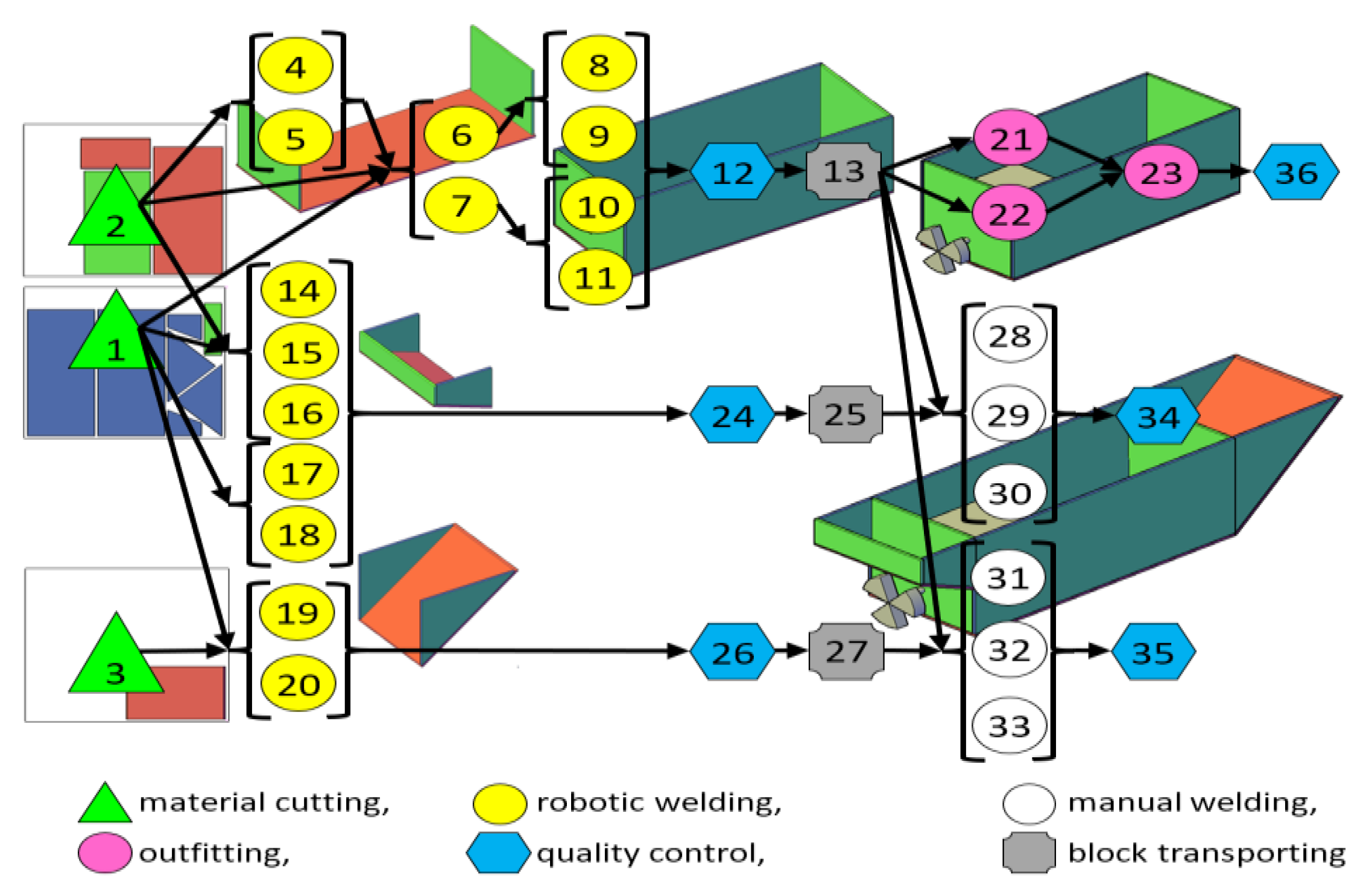

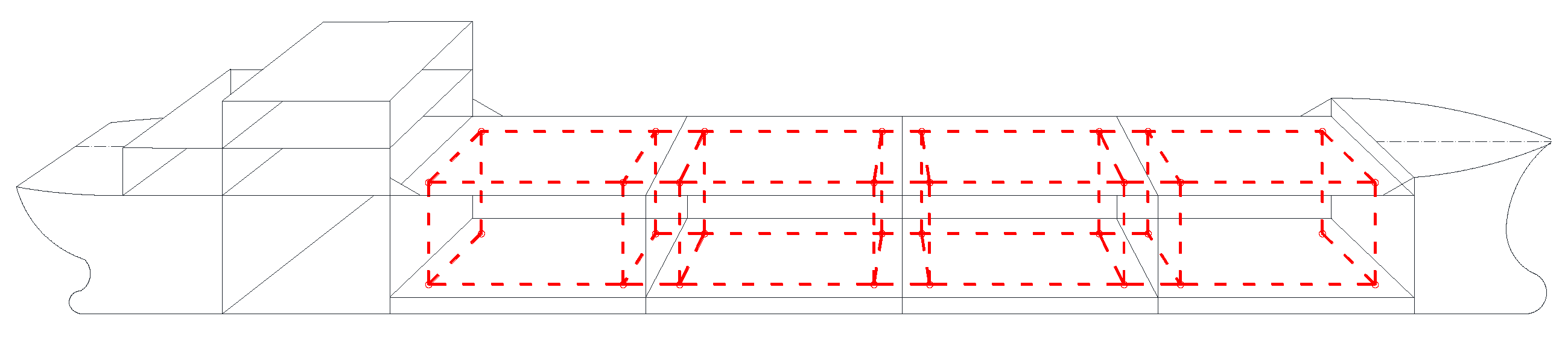

We consider a typical situation in which a ship is assembled from structural blocks and fittings. The large size of the blocks and the large number of details included in their composition (

Figure 1) makes it necessary to separate the prefabrication process into processes of preliminary-prefabrication. Simultaneous implementation of prefabrication at multiple stations reduces production time, and therefore is a source of financial savings. Thus, it is assumed that each block is built from assemblies and subassemblies. To further reduce the ship's production time, outfitting can be added as early as the section assembly stage.

Joining of structural elements and equipment is carried out by welding (mostly) or bolted connections (some outfitting elements). The order in which connections are made is an important technological matter and affects, among other things, the thermal deformation of the structure. Structural elements are made by the shipyard in the processes of cutting and forming metal sheets and hot-rolled profiles. Outfitting components are partly made in the shipyard (pipes, ladders, hatch covers, etc.) and partly delivered to the shipyard as ready-to-assemble (engines, generators, electronics, pumps, lifting gear, furniture, etc.).

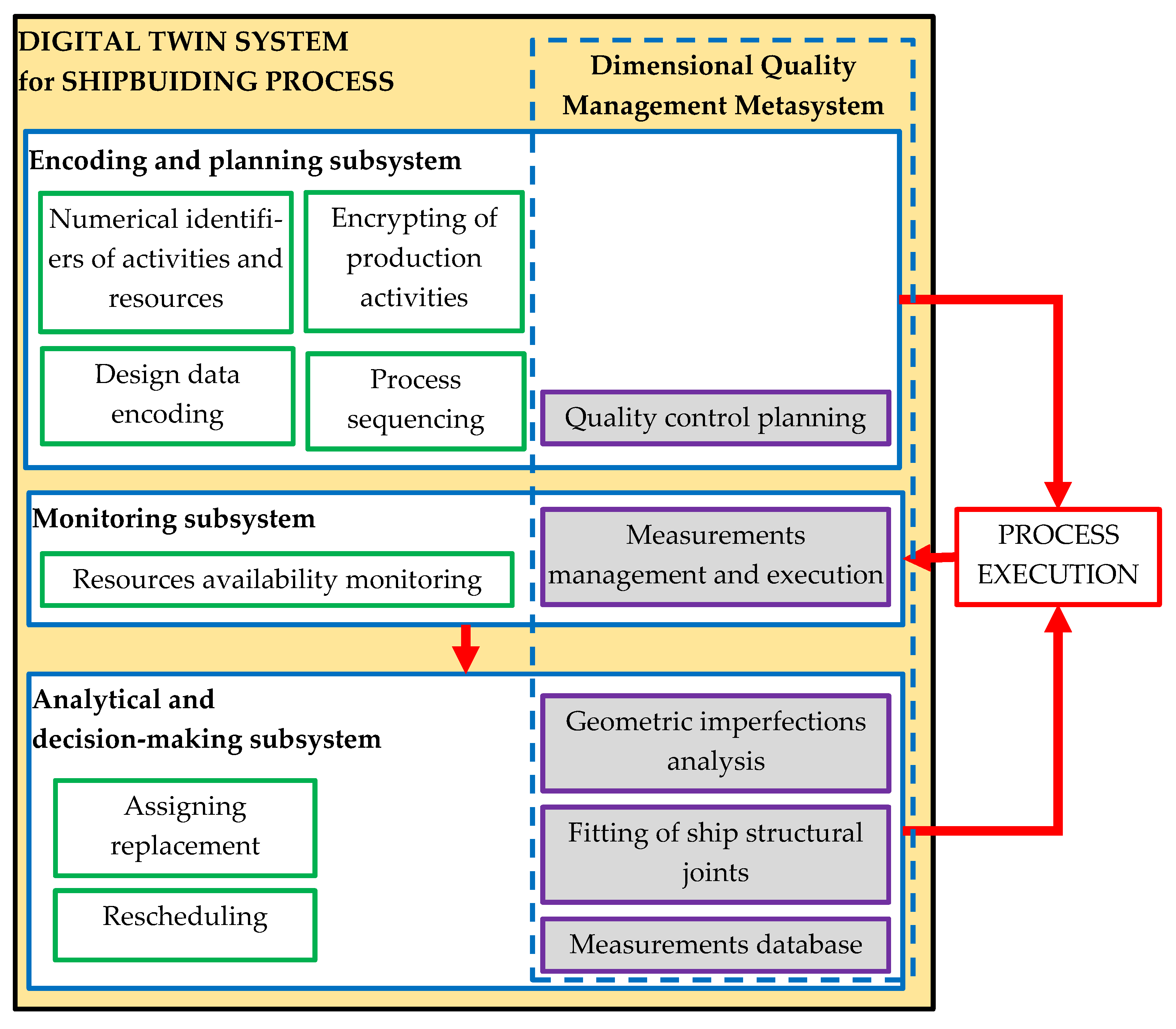

The concept of a digital twin of the ship production process must take into account both the specifics of the hull, as well as the extensive structure of the shipyard. In addition, the digital twin must take into account systematic monitoring of implemented processes and quality control of completed structures. The proposed digital twin, in practice, is a comprehensive system for planning and control of shipyard processes. It is based on the following component subsystems (

Figure 3):

Encoding and Planning Subsystem, which connects yard resources to individual production activities. In addition, this plan records the correlation of each operation with the timeline. This results in a design-technology pattern, the implementation of which is a production task.

Monitoring Subsystem based mainly on measuring activities and monitoring the availability of workers, equipment and materials.

Analytical and Decision-making Subsystem, which:

-

based on the identified dimensional imperfections of the structure, plans the scope of repair work and considers the necessary modifications to the plan,

-

examines the possibility of the remaining shipyard resources taking over duties in the event of the incapacity of an employee or device,

-

reorganizes work in case of other difficulties, such as blockage of transportation routes, or problems with the supply of materials and energy.

Dimensional quality management has a special function in the shipbuilding process due to its geometric complexity and large size, as well as the variety of technological and transport operations carried out in the shipyard. The exothermic nature of many technological processes causes difficulties in controlling deformation phenomena. Large masses of processed structures result in deformations in transport operations. Existing theoretical methods of deformation prediction prove to be insufficient with such a complex structure as a hull. As a result, the planning of measurements, their implementation and the analysis of measurement data must be integrated with each other and given special priority in the process of organization and implementation of the DT system in the shipyard.

Figure 3 distinguishes the functions of the system, which are proposed to be collectively regarded as the Dimensional Quality Management Metasystem (DQMM) within the DT system.

The main purpose of the DQMM is to collect and process geometric data. This data is used on an ongoing basis for the control of the production process and for subsequent process analysis and optimization. This is a very complex and multifaceted issue. It involves a number of aspects of shipbuilding processes, both in terms of technological and equipment resources and in terms of measurement processes and data analysis. Geometric quality issues can be divided into the following thematic groups:

design and implementation tolerances,

hardware resources and measurement systems,

measuring operations,

analysis of the results and their use.

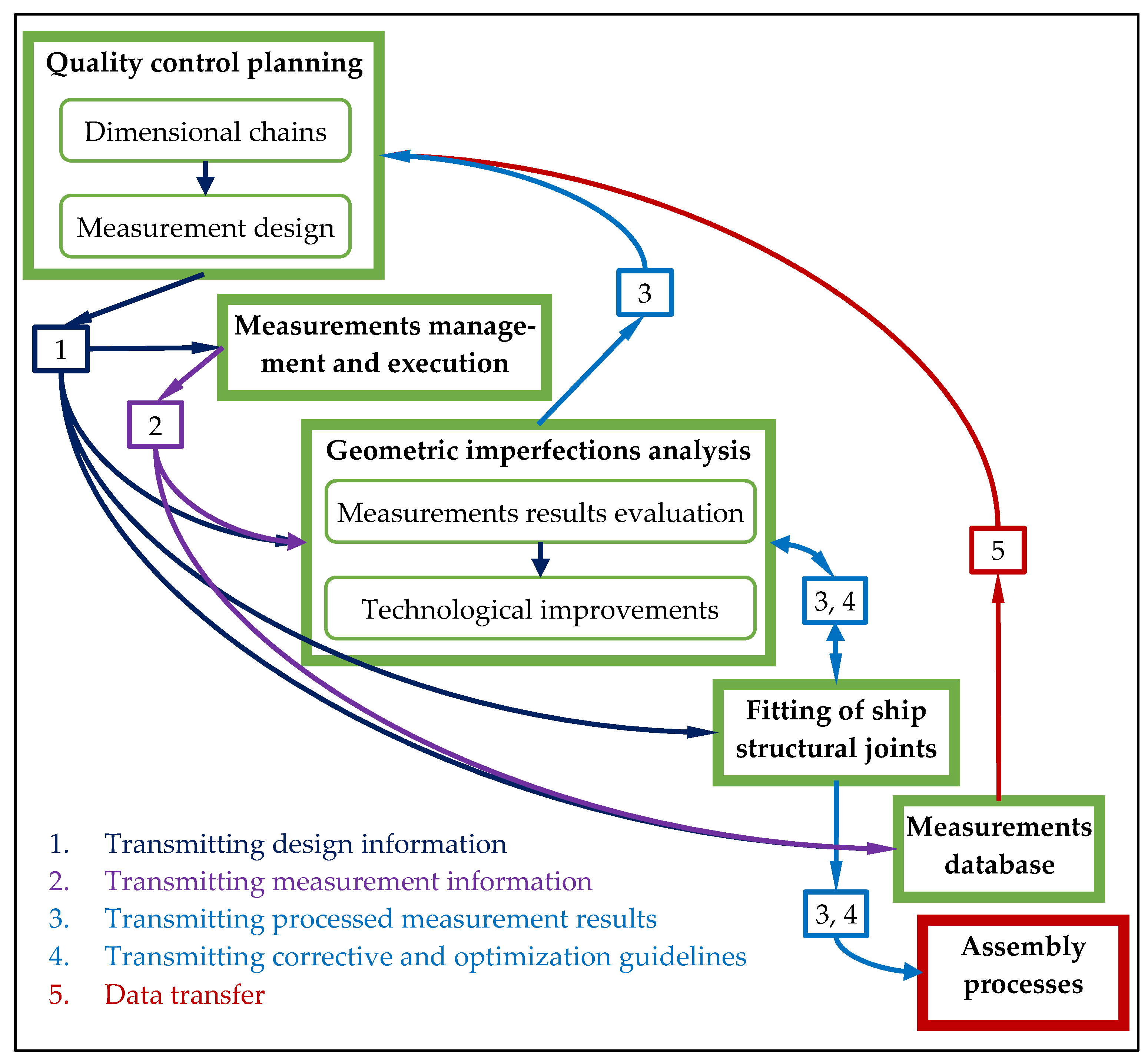

For effective data collection, universal, systematized procedures for coding processes of quality monitoring are necessary. From observation of functioning shipyard procedures, their strengths and weaknesses were identified. The most common deficiencies were noted mainly in the area of data analysis and feedback between the various elements of the functioning systems. These observations, together with an analysis of the idea of ship DTs, allowed the development of the concept of data exchange within the DQMM, shown in

Figure 4.

Adapting existing systems and developing new ones based on the proposed scheme will enable effective and systematic digitalization of dimensional quality monitoring processes. The proposed scheme forms the basis for the creation of DTs in the area of shipbuilding improvement and quality control.

The following subsections describe each subsystem of the DT system and its basic functions. Special attention is given to the practical implementation of each task and the way it is numerically encrypted.

3.1. Encoding and Planning Subsytem

Numerical Identifiers od Activities

Efficient information management in a highly branched production flow, with such a large number of simultaneously processed work items, as is the case in shipbuilding, it requires the introduction of numerical identifiers. They will allow to clearly describe the types of operations performed during the process. Identification of production operations is part of the production planning and encoding subsystem in the proposed DT system.

Figure 5,

Figure 6 and

Figure 7 shows the sequence of typical operations carried out in a shipyard. They perform production, transportation, storage and control functions. The grouping of types of operations within the shipyard's departments is conventional. In practice, the structure of departments can be much more extended. It is important to note that assembly in the prefabrication department is carried out in a loop, symbolizing successive assembly steps.

Each operation is given a sequential number, which will be used in coding the production plan. The proposed system for identifying operations is a compromise between complexity and simplicity. In practice, it is possible to expand or reduce the number of distinguishable operations. The purpose of analyzing the production process may be looking at only selected elements of it and, consequently, a selective approach to building a digital twin.

Transportation operations (2, 6, 8, 13, 15, 17, 19, 23 and 25) have been singled out because they can be carried out by different means and via different routes. It is also important to control the duration of these operations and their timely completion. Material ordering (5) is an operation that involves processing design data, analyzing available workstations and materials in stock, and then preparing cutting templates.

Prefabrication is carried out in multiple stages, which is why the return arrow from operation 35 to operation 28 is marked in

Figure 6. This means that the prefabrication of an assembly is followed by joining it with other assemblies. After quality control, welding is carried out again, etc. until the hull blocks are obtained, which are transported to the painting chambers.

The operations listed above are classes of activities that we can perform in the production process. Within a given class, multiple operations are most often performed. For example, during the construction of the hull, we repeatedly cut steel plates, and we label each such activity as the implementation of operation No. 10.

Some operations have the same names, but are carried out at different stages of the ship production process, so it is important to mark each activity with an operation number. This applies to quality control, for example. Some of the inspection activities will be assigned operation number 21, some 35, and others 44. With this designation, we can clearly identify what the quality control concerns and where it is carried out.

Numerical Identifiers of Resources

Implementation of the production process requires resources supply. The proposed DT system within the production planning and coding subsystem takes into account the human resources, materials, energy, equipment and production and transportation space, i.e., workstations, warehouses and communication routes, among others.

Employees whose involvement in the process we want to include in the DT are given numbers. Each employee is assigned a unique identifier and a description in the database. The information stored about a worker must relate at least to the occupation he or she is engaged in and the current state of his or her working capabilities.

Materials consumed in the construction of the hull mainly include steel plates and hot-rolled profiles. Each assortment group includes a sheet of a specified thickness, or a profile of a specified cross section. The assortment groups are assigned numbers. In addition, detailed information about the geometry of each material group must be stored in the database. These are usually the dimensions of a rectangular sheet, the length of a profile, or a technical drawing of an irregularly shaped sheet. A more detailed description relates to so-called residual materials, which are created in cutting processes and stored for reuse. Such materials can be standardized, or completely arbitrary in terms of geometry. It is very important to update the database with information on the quantity of each assortment group in the shipyard's warehouses.

The energy carriers in the shipyard can be electricity, technical gases and fuels. Each form of energy consumed in the shipyard is given a consecutive number. Additional information assigned to the consecutive numbers should be: unit of measurement and level of shipyard resources.

Devices, like employees, are individually numbered and each is assigned in the database to a selected class of device. This way, equipment that can be used interchangeably, such as welding machines, can be grouped together.

The last part of the description of the shipyard's resources in the digital twin is the area on which production, storage and transportation takes place. In order to mark the place where activities are carried out, the yard area is divided into regions. Each region is given an individual number, map and description in the database.

Design Data Encoding

Data on the structure of the hull, the detailed geometry of its elements, the arrangement of outfitting and how all the elements are connected, come from the CAD system that the design office uses. The design process of a ship is a multi-stage process and is structured as a design spiral. A 3D model of the ship can be included as part of a digital twin, but the system concept discussed here assumes that only production-relevant information concerning the set of elements and the connections between them is extracted from the design data.

Elements can be classified as part of a steel construction or outfitting assortment items. Two such elements are assumed to be uniquely identified for each connection. A given pair of elements may be assigned only one connection. This approach may seem unnatural. In the case of double-sided welds, the two sides together are treated as one connection. Similarly, intermittent welds between two elements are identified as one connection. A joint consisting of multiple bolts attaching a piece of outfitting to a structural component, or to another piece of outfitting, is also treated as one joint.

Encoding the design data means numbering the elements and connections. In addition, each element is assigned the corresponding drawing documentation and technical description in the database. Also, each connection, in addition to the number, has design data stored, such as weld thickness, required edge preparation, remelting, etc.

Process Sequencing

The activity is a part of the production process that uses yard resources and is related to a specific work object. Planning the production sequence means introducing a binary relation on the set of all scheduled production activities. This relation can be represented as a directed acyclic graph, whose arcs indicate the temporal succession of activities.

Engineers responsible for welding technologies play an important role in sequencing the process. They must take into account the geometry of the structure and the anticipated problems of thermal deformation and component fit-up during assembly. It is also important to plan welding in such a way as to make the best use of automatic welding stations.

In outfitting planning, it is necessary to take into account the accessibility of the structure so that components such as the engine, generators, pumps, etc. can be installed.

Process sequencing includes dimensional quality control activities at successive stages of assembly. The extent of inspection of each assembly, section, block and entire hull is subject to separate analysis and must take into account the quality requirements as well as the measurement methods used.

The sequence is crucial in analyzing the effects of production disruptions. Based on that, we can conclude that an activity is critical or some delay is possible.

Quality Control Planning

As part of the dimensional analysis, measurement work is designed and tolerances and dimensional chains are analyzed. Tolerances and dimensional chains are determined at the design stage. Their design is based on the parameters of the manufacturing process, the requirements of shipowner supervision and regulations including those of classification societies. Effective cooperation and data exchange in this regard is essential. To guide changes, modifications and improvements in cooperation, it is necessary to perform an analysis of the environment in which the planning and implementation of measurement work takes place. The development and coding of the organizational structure must place special emphasis on full digitalization of the forms of cooperation between the various services.

Measurement systems can be described by mathematical models that allow to determine their basic parameters depending on the measurement task and the measurement equipment used. The basic parameter that can be determined from the models is their measurement uncertainty. Procedures for mathematical modeling of measurement systems are presented in the study [

33]. For coding dimensional chains and tolerances, their generally known mathematical descriptions should be used. In the coding, mathematical models that describe tolerances for a given manufacturing process are created. Their forms and values are related to the characteristics of the product (vessel), shipyard technology and applicable regulations. Due to the high individuality of each shipyard, these analyses must be carried out for each case separately.

Measurement processes are different at each stage of production. The way they are conducted depends on the range of geometric data that must be taken. Each measurement process will have its own identification code. The designations should include, among other things, their duration, the number of employees, the number of similar jobs that can be carried out simultaneously. In addition, equipment resources and measurement systems should be coded. Depending on their characteristics, they will receive unique identifiers containing their technical parameters. Measurement processes, like measurement systems, will be described individually. These models will enable their measurement uncertainty to be determined dynamically depending on the situation arising. A system for dynamic modeling of measurement processes will be created.

Identification of individual elements and their suitability for digitalization will indicate necessary and justified investments in equipment and technological facilities. For example, in measurement equipment to speed up measurement work and increase the accuracy and quantity of data and their automatic digitalization.

In general, the planning process will take into account information including:

the scope and timing of the measurement works,

measuring methods and equipment,

measurement procedures,

measurement service,

form and purpose of measurement results.

Encoding of Production Activities

Based on the sequence of the process, it is possible to tie each activity to a timeline and define planned start and end dates.

If we distinguish

P activities in the production process, then each activity

p = 1, 2, ...,

P is described by the following code:

where:

wop ∈ ({0,1},I×1) – a binary vector of engaged employees, woi = 1, when The i-th employee performs a given activity, I - the number of employees,

map ∈ (,J×1) – vector of repetition of assortment groups of materials, maj – the number of units of material from group j used during the activity, J – the number of material assortment groups,

enp∈ (,K×1) – energy consumption vector, enk – the amount of k-type energy consumed during the activity, K - the number of forms of energy,

eqp ∈ ({0,1},L×1) – binary vector of devices used, eql = 1 when the l-th device is used during a given activity, L - number of devices,

plp ∈ – localisation number,

elp ∈ ({0,1},M×1) – binary vector of added elements, elm = 1, when m-th component is processed, or assembled during an activity, M – the number of elements constituting the vessel,

cop ∈ ({0,1},N×1) – binary vector of connections made, copn= 1, when the n-th connection is made during the activity, N - the number of connections in the vessel,

opp ∈ – The identifier of the operation to which the activity is assigned (see Figures 3, 4, 5),

tp ∈ (,2×1) – subprocess start and end date range.

A collection of coded activities forms a production plan. Each activity has a specific time segment. The plan must meet a number of constraints. Technical constraints arise from the sequence. In addition, an important problem is controlling the locations of the activities. Each location has a certain capacity. A limited number of activities can be carried out simultaneously in prefabrication halls, a limited number of blocks can be stored in the yard, transport routes often allow one block at a time. The number of available workers and equipment is a limitation. This is most often the cause of increased production time and the formation of task queues in production buffers. In the long term, the phenomenon of excessive buffers can be solved through development investments, creation of new positions and implementation of technological innovations.

We assume that the plan has been optimized in terms of thoughtful criteria. Balancing production capacity is an important planning objective. We strive for an even distribution of workforce and equipment and a reduction in idle time. The material supply plan, which is linked to the production plan, must also be taken into account.

3.2. Monitoring Subsystem

Resources Availability Monitoring

With the plan created, it is possible to check in each unit of time which activity is about to start and determine which workers should be on standby, which equipment is needed, which quantities of materials and which pieces of construction or equipment should be delivered.

Executing production according to plan requires regular monitoring of the readiness of resources needed by a certain date. Monitoring resource availability requires collecting information on:

the status of material stocks, including items of equipment,

energy resources, signed contracts with suppliers, disruptions in continuity of supplies, potential alternative sources,

material and equipment delivery schedule, occurring delays,

health and safety risks, accidents and breakdowns,

planned employee vacations, sick leave, training plans, new employee hires, layoffs,

space availability for production execution, transportation and storage.

Resource monitoring in the DT system is global across the enterprise. Its important function is to handle multiple processes simultaneously and share information between processes. The coordination of the entire enterprise is thereby made possible. This is crucial for resource sharing.

Measurements Management and Execution

In the construction process, each shipyard has a team for managing and executing measurement work. Measurement processes involve measurement teams (who perform measurement work) and employees directly related to the production process. These employees are mainly technologists who coordinate prefabrication and assembly work. For DT, it is necessary to fully digitalize the cooperation between measurement teams and technologists.

Measurement processes for each unit under construction are strictly defined and designed, these are the so-called basic measurements. During the construction process, additional measurement work is necessary as a result of disruptions. This work disrupts the entire construction process by absorbing production stations, measurement teams, equipment and technologists. In order to effectively manage these resources within the DT, a digital description of them is necessary. Such a description must include:

measuring devices,

measurement systems,

measurement tasks with their duration,

necessary human resources for handling of measurement works,

analysis and description of results (measurement data processing time),

circulation of information.

Having a full digital description of the various elements of measurement management and up-to-date descriptions of ongoing production processes (vessels under construction), it will be possible to dynamically design and manage measurement work taking into account current disruptions in production processes.

For DT, it is essential to eliminate analog devices from measurement processes in favor of digital devices. Analog optical devices are still widely used in ship metrology. They have a lot of advantages, however, for the needs of DT it is necessary to strive for full digitalization of measurement processes. Commonly used electronic total stations should be supported by 3D scanners. This will allow to create hybrid measurement systems eliminating disadvantages of individual devices. Combining the versatility and speed of total station measurements with the huge amount of data obtained by scanning processes will allow to develop a measurement system ideally suited to the needs of creating DT ships. Digitalization of measurement systems and measurement tasks means developing their mathematical models and programming them. It is also necessary to code the number and competence of employees necessary for measurement and technological operation. For the smooth functioning of the whole, it is necessary to code the procedures for analyzing the results, taking into account the necessary time to carry them out and the circulation/exchange of information. For the entirety of the discussed issues, the ideal solution seems to be the use of a data cloud which will be updated by individual participants in the discussed processes.

3.3. Analytical and Decision-Making Subsystem

DT must ensure that data describing all processes is collected in real time and made available through high-fidelity simulations. In order to systematize the different elements of the DT, it is necessary to properly distinguish the different stages of its development throughout the production cycle. The response system must provide feedback within the individual elements as well as between them. Reacting should be considered as current use to control the ongoing production process, as well as late use applicable to the optimization of design, production and operational systems.

Given that the process of coding and analysis of individual DT elements itself, due to the diversity of production stages, will use a number of different digitalization and data processing tools, it is necessary to develop a methodology for coupling this data. This stage must be developed last. For its detailed development, specific functional solutions of the previously discussed coding stages are necessary.

Geometric Imperfections Analysis

Coding analysis of measurement data and deviations will be based on their mathematical and geometric models. The coding process, due to its use, should be separated into the stage of the ongoing production process and the stage of long-term analysis of production process optimization.

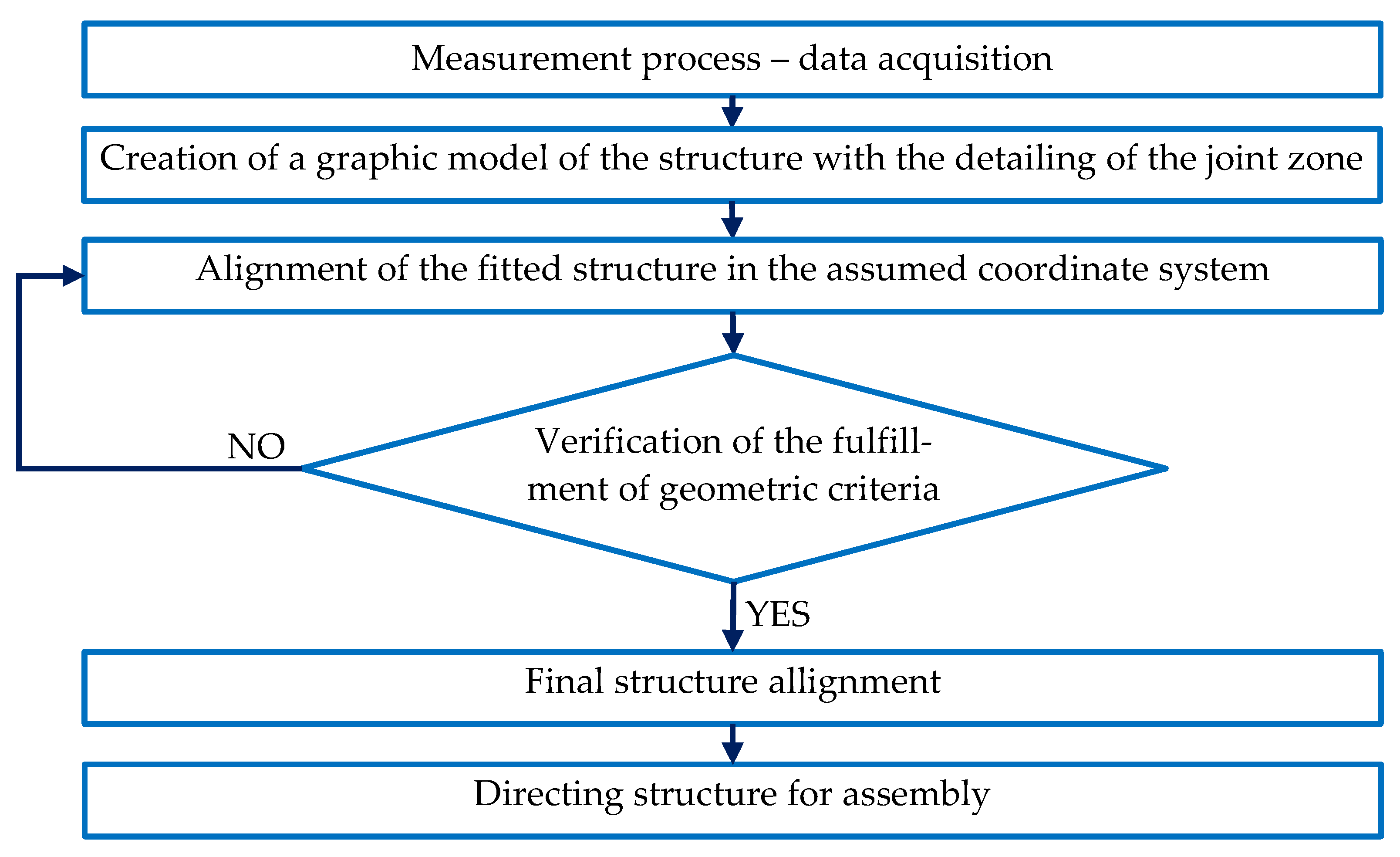

Fitting of Ship Structural Joints

Fitting of joints is a procedure rarely used in shipyards. Decisions to send a structural component for repair are usually made without first analyzing the fit of the actual joint geometries. Often it may turn out that failure to meet the assembly tolerances of individual sections does not eliminate their assembly suitability. Analysis of all assembled components together gives a complete picture about dimensional chains. In order to eliminate wrong decisions, it is postulated to abandon the criterion of repair based on tolerance evaluation in favor of evaluation according to assembly suitability. Of course, the fit process must take into account overriding tolerances related to the aspect of operational safety and regulatory requirements that must be met. The process of digitalization and introduction of DTs offers tremendous opportunities for such application. The general algorithm of the fitting of joints procedure is presented in

Figure 8.

Geometric and mathematical models of the assembled structures are required for fitting joints. These will be developed from measurement data using dimensional chain and tolerance models. In order to create an effective and functional fitting joints system, it is necessary to use measurement systems that provide data for analysis practically in real time or immediately after taking measurements. This must be digitalized data that enables simulation processes.

Measurements Database

The measurement database must contain all data acquired and used in the quality control system. An important element is the ability to expand the range of data to be collected. The database must be ready for optimizations and expansions of the systems it will support.

Assigning Replacement Resources and Rescheduling of Process

Information sent from the resource availability monitoring subsystem is analyzed on an ongoing basis. Unavailability of resources necessary to carry out activities planned in the process in the worst case results in waiting for workers or equipment to be restored to work, or for delivery of missing materials or prefabricated components. The extent of the impact depends on the sequence of the process. There is a so-called avalanche of events, that is, when a specific activity is delayed, all activities following it according to the sequence are delayed, and then all activities following each delayed activity also. This is a scenario we want to avoid, so we look for opportunities to replace missing resources and modify the schedule to minimize downtime.

Controlling the interchangeability of workers and equipment allows tasks to be shifted between workstations. Swapping the order in which activities are performed in many cases reduces the avalanche effect. In some situations it is necessary to delegate tasks to subcontractors on an emergency basis.

In most cases, modifying the plan involves additional costs, but the final decisions are based on the global balance of profits and losses.

4. An Example of Using the DT System

4.1. Hypothetical Production System

An example of the application of DT was developed not only to present its process of construction and implementation, but also to demonstrate its adaptability in cases where the analysis is to be fragmentary and intended to focus on selected elements of the process, or simply to allow a quick simplified analysis. For the purpose of presenting the proposed methodology, a highly simplified model was used, both in terms of the shipyard and the ship under construction. The example does not solve a specific real-world case, but is intended as a general presentation of the proposed solutions.

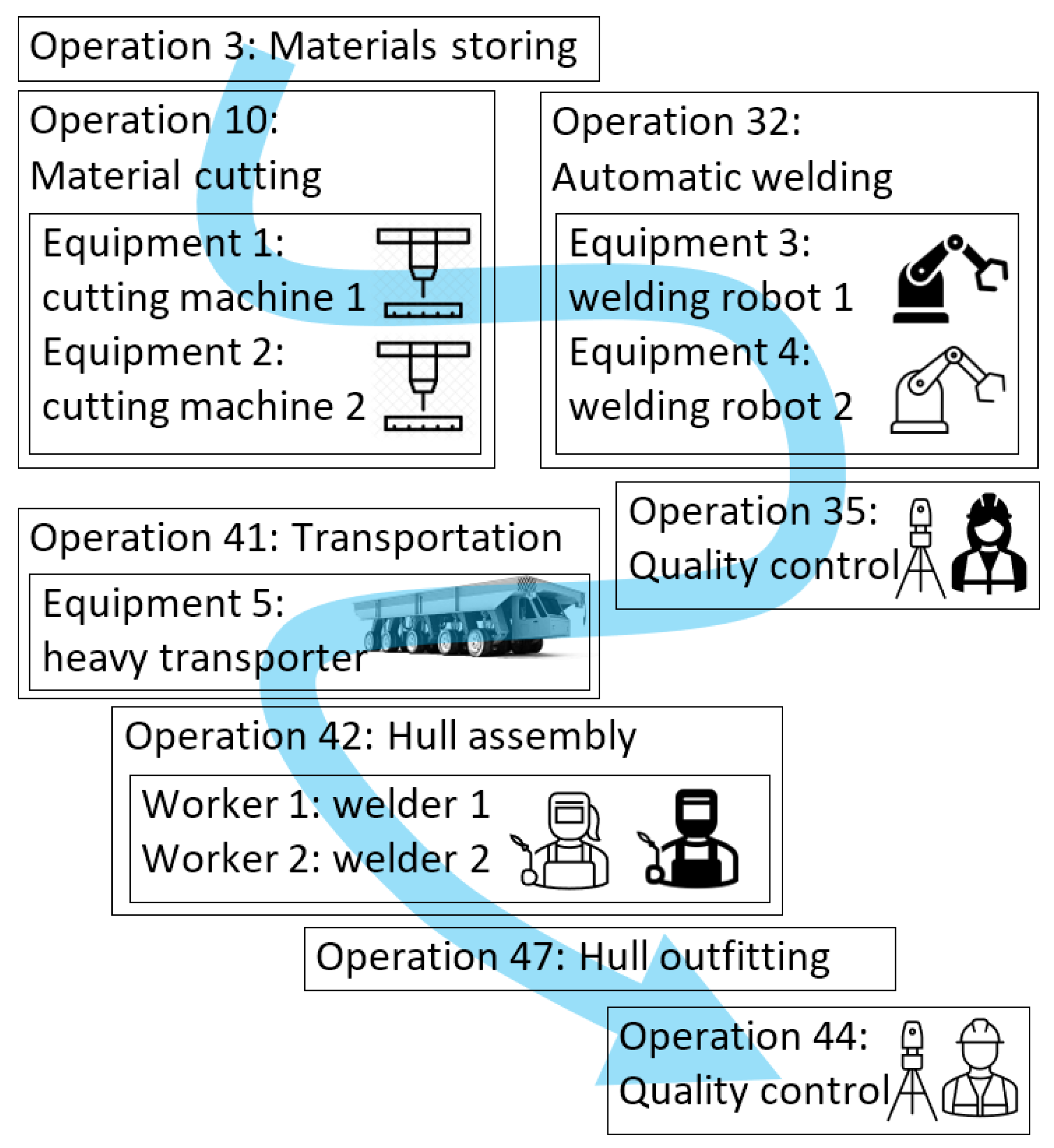

The process in the example shipyard has been described as a sequence of selected operations of storage, processing of elements, prefabrication of blocks and assembly of the hull -

Figure 9. These operations do not fully describe the production of the ship. The characteristics of some of the operations are limited to the indication of the equipment used, other operations may have employees assigned to them, still others only have a specific number to relate it to the scheme proposed in

Figure 5,

Figure 6 and

Figure 7.

In an example hypothetical shipyard, the transport of materials between the warehouse, cutting stations and welding robots is carried out continuously by a roller conveyor. Transport time in this case is not taken into account.

We assume that prefabrication of blocks is carried out using automatic welding at two stations. Each station can prefabricate one block at a time.

Joining the blocks together requires delivering them to the hull assembly station, where two welders work. The bottleneck of the process can be transportation between quality control of the prefabricated block and the hull assembly department. This route is served by one transporter, which can transport one block at a time. The block from the transporter is taken up by a lifting frame and transferred to manual welding. Equipment such as the propeller and main engine are assembled from the moment the midship block is delivered to the hull assembly station. The equipment assembly is carried out by a separate group of workers, which we do not include in the example.

4.2. Production Task

The ship's hull consists of 12 structural elements and two pieces of equipment. The hull is assembled from 3 blocks - bow, midship and stern (

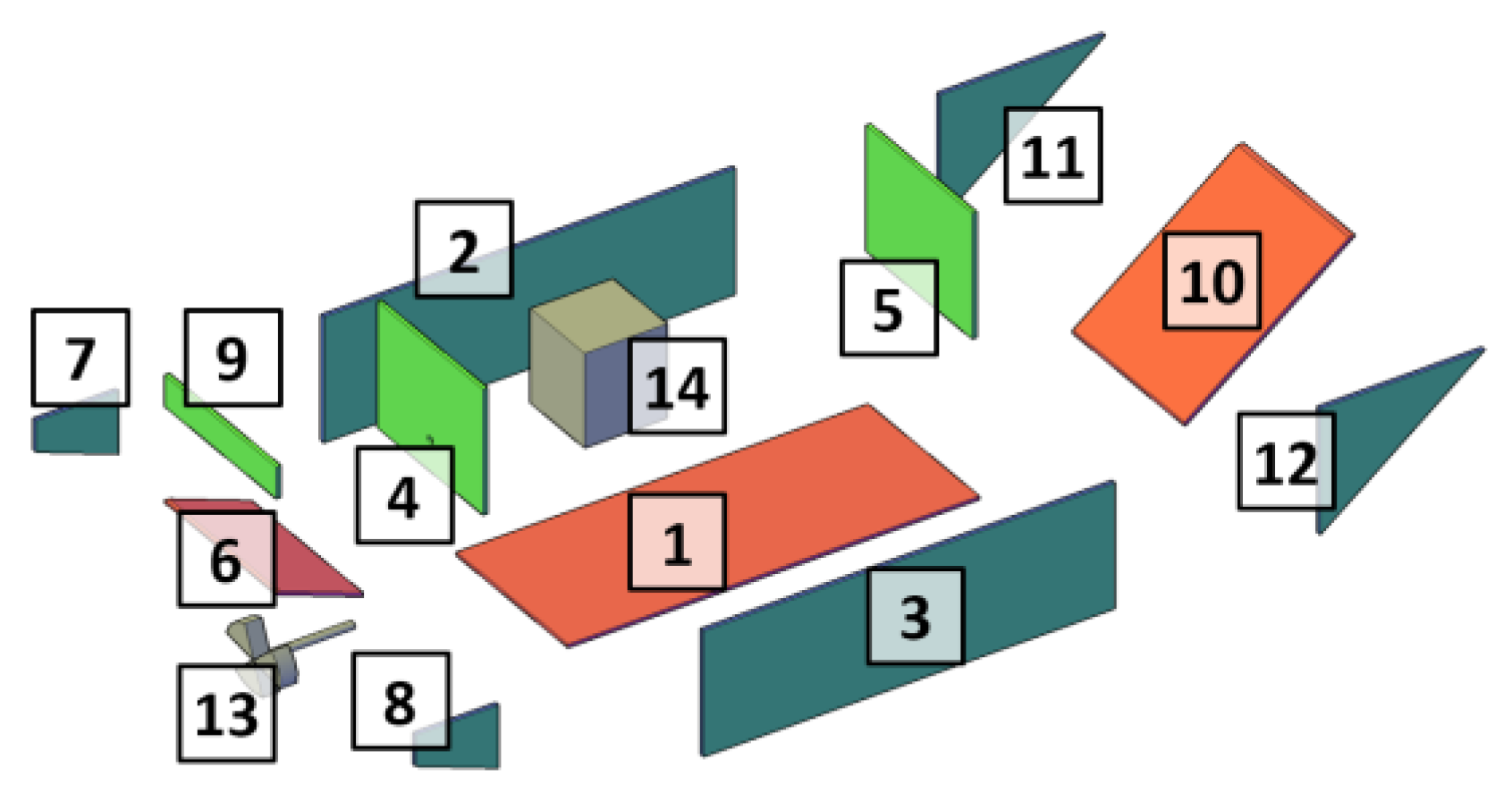

Figure 10).

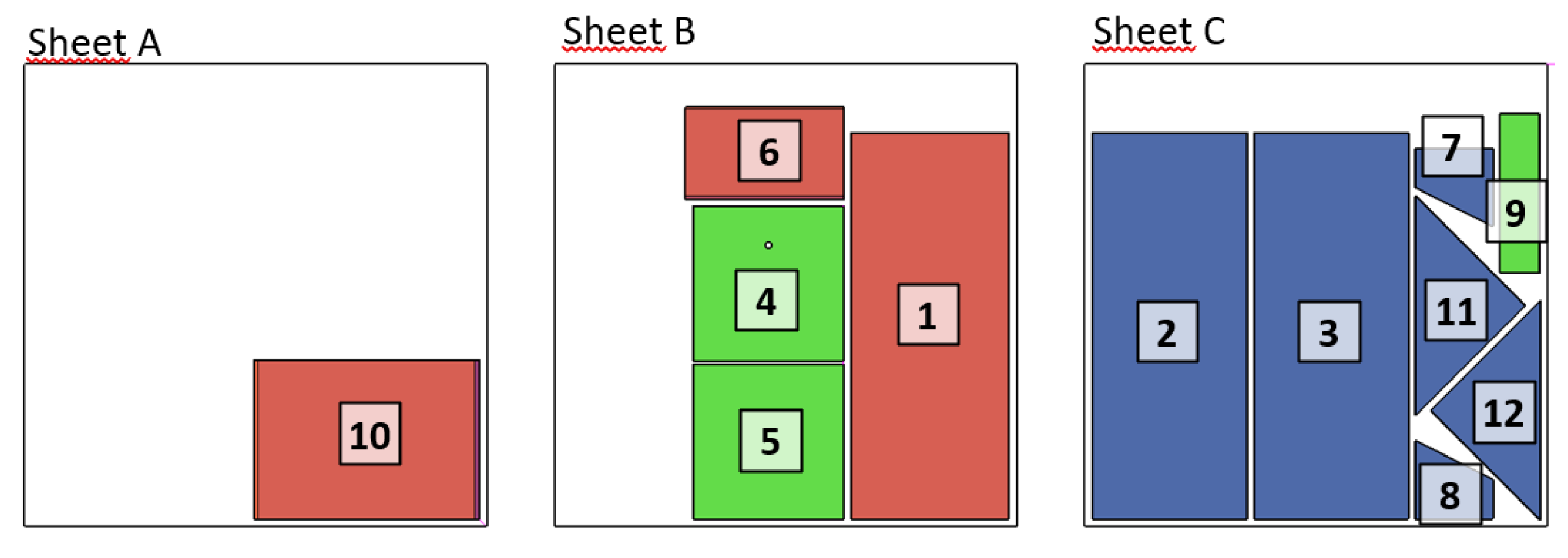

Based on the design of the structure, the material requirements are planned. For simplicity of the example, we assume that all structural components are cut from sheet metal of the same thickness. The elements belonging to the equipment are numbered 13 (propeller) and 14 (engine). The two pieces of equipment are separate assortment groups. Thus, we consider three material groups - steel sheets, propeller and engine. The numbering of the items is shown in

Figure 11.

Figure 12 shows the plans for metal sheet cutting.

Based on the design of the structure, the construction times of individual connections are estimated. For the example process, the times of activities in arbitrary units were adopted as dimensionless indicators. Welding and equipment assembly activities were numbered according to the connection numbers. The numbering of all activities and their assumed times are shown in

Table 1.

The process sequence was planned in such a way that as many activities as possible could be performed simultaneously. It was assumed that the installation of the bow and stern block in the hull could start simultaneously. The sequence, along with the designation of the types of activities, is shown in

Figure 13. Brackets were used to simplify the graph. An arrow drawn to a bracket refers to all the activities in the bracket.

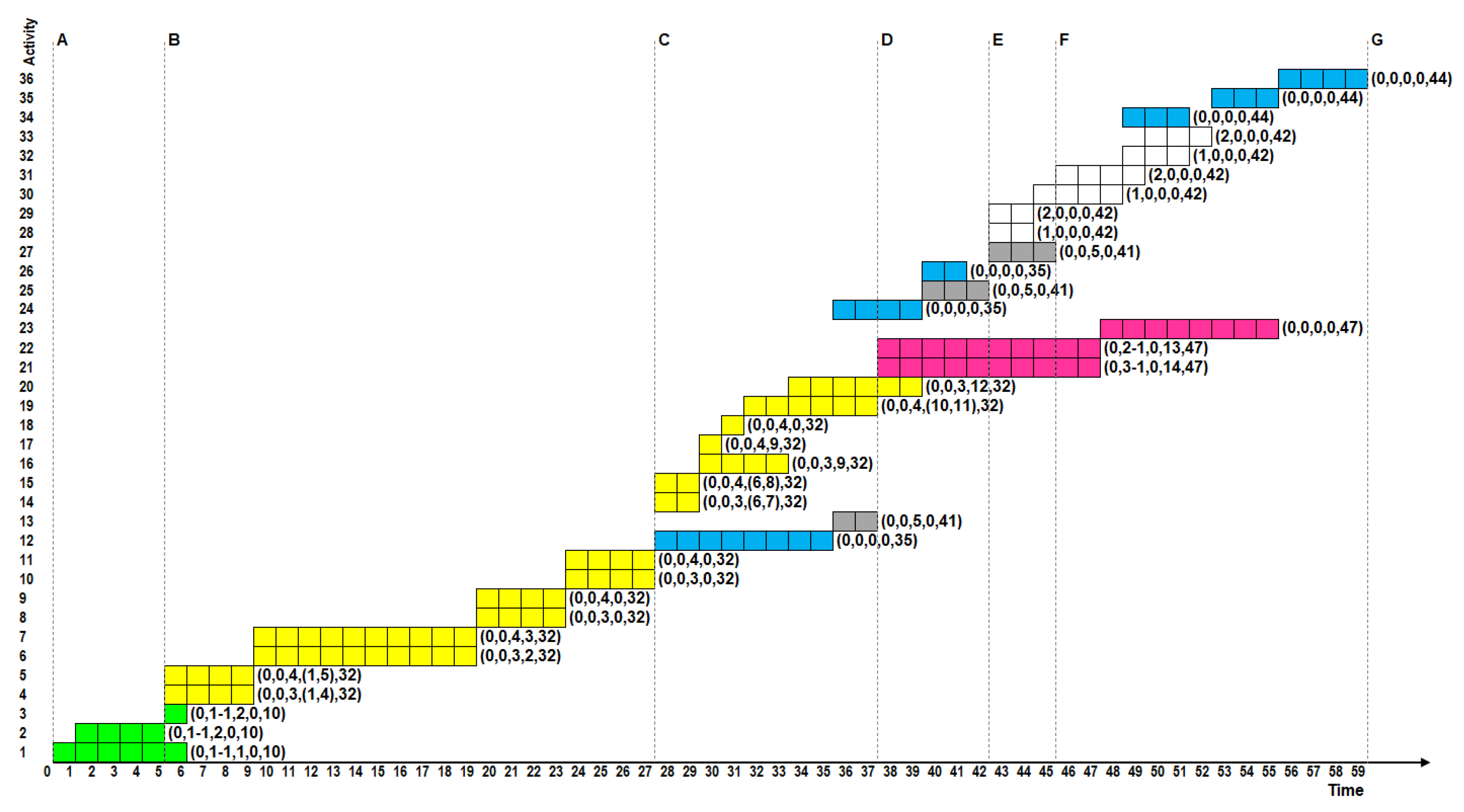

4.3. Encoded Production Plan

Having a given sequence, it is possible to develop a process schedule. This includes the duration of the activities and the available resources of the shipyard. In the example considered, the shipyard has two metal sheet cutting stations, two welding robots, two manual welders, one transporter and one quality control station each - after prefabrication and hull assembly.

The final production plan is recorded in the form of encoded activities.

Figure 14 shows the schedule for performing the activities. A simplified code is given next to each activity, containing in sequence: worker number, material number and quantity, device number, numbers of items to be added to the structure, operation identifier. If a code item does not apply to a specific activity, then it takes the value 0. The example discussed here does not take into account the two previously proposed parameters, that is, the types of energy consumed and the location of the activity.

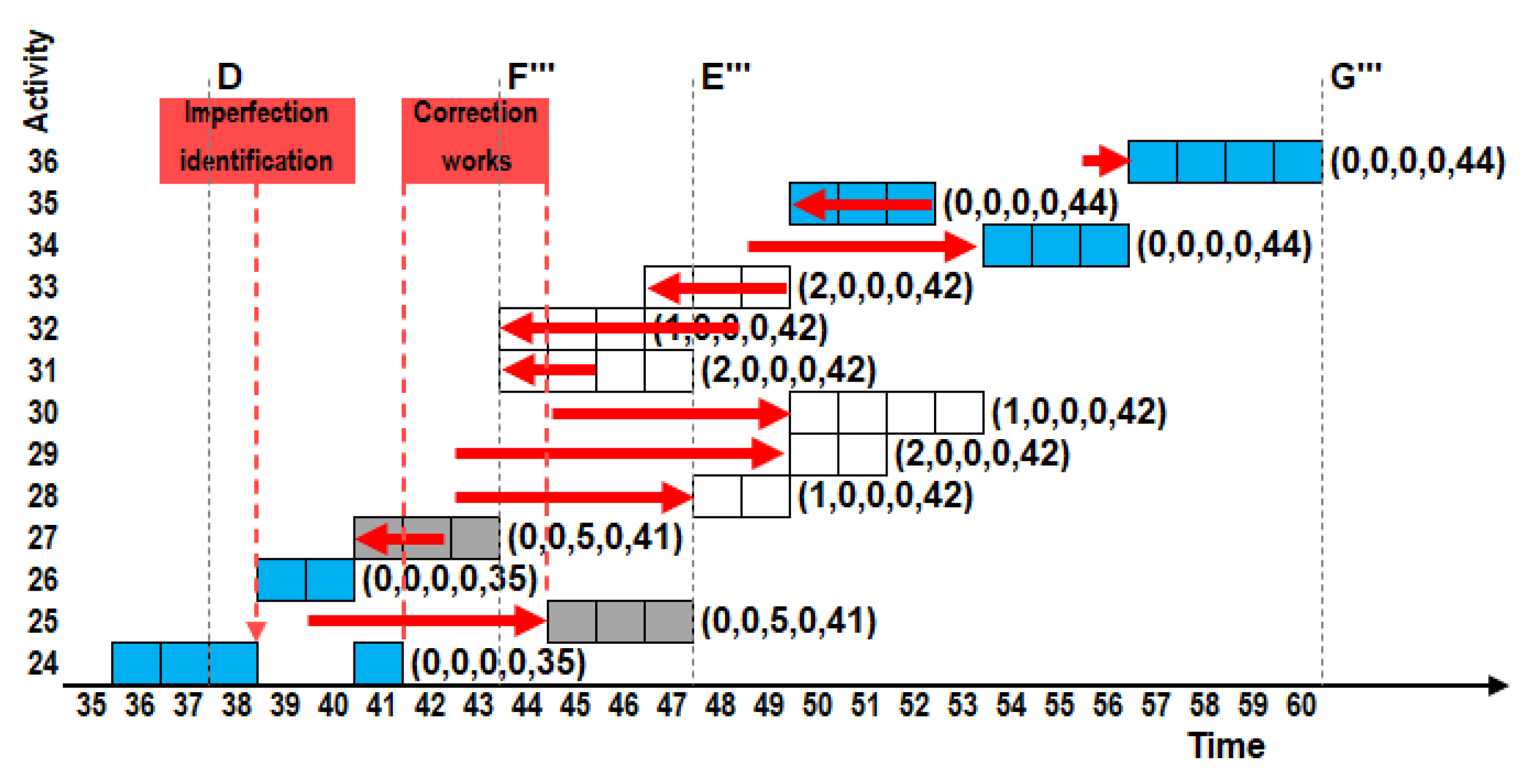

The process takes 59 time units. The Gantt chart marks selected characteristic dates: the start of the process (A), the start of prefabrication (B), the start of dimensional quality control after the completion of prefabrication of the midship block (C), the start of outfitting work after the midship block is delivered to the hull assembly station (D), the start of assembly of the stern block (E), the start of assembly of the bow block (F), and the end of the process (G).

4.4. Process Disruption Scenario and DT System Response

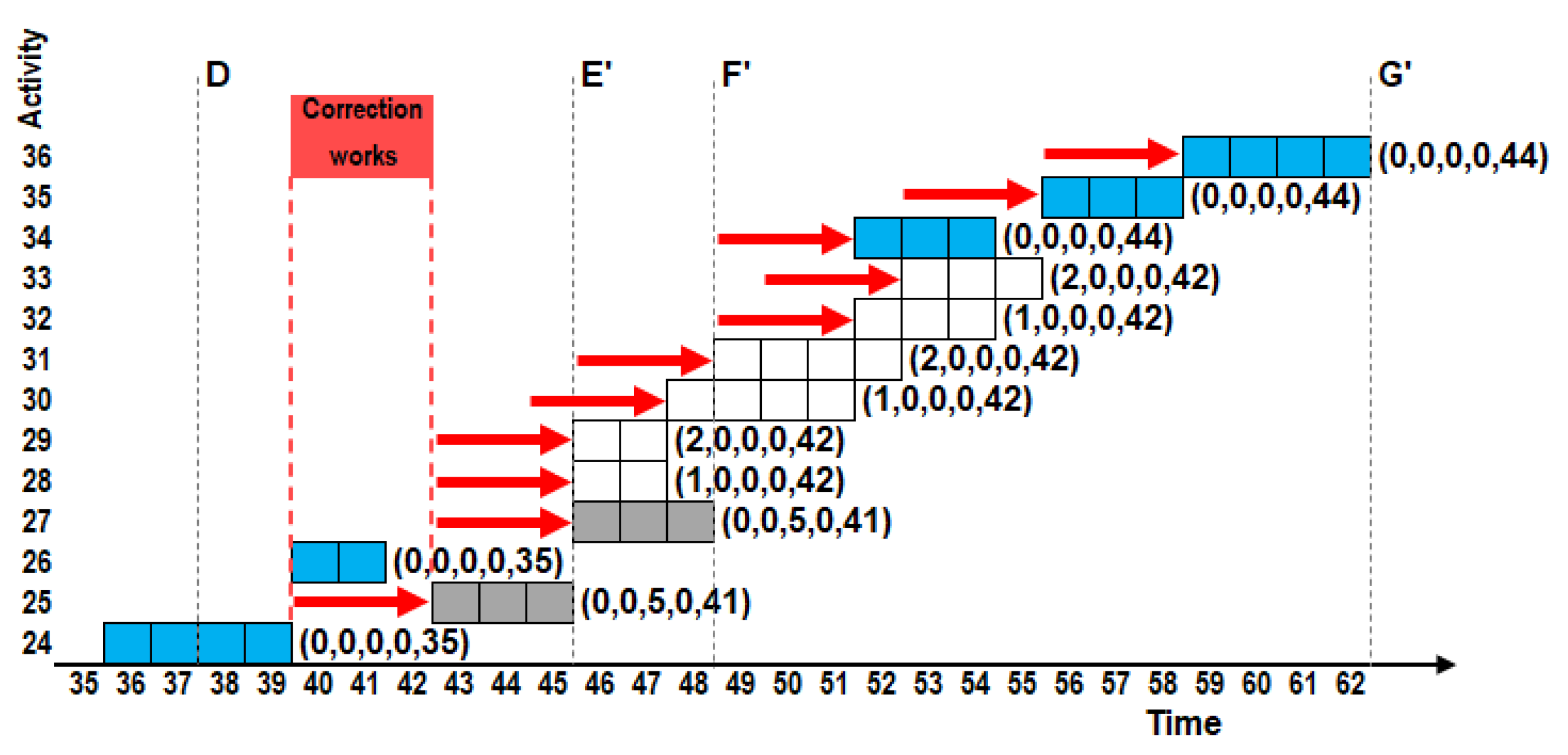

It is assumed that all system resources are in readiness at the time of production start-up. Possible disruptions in the example studied could result from equipment failures, work accidents, or failure to meet the quality requirements of prefabricated products. Ongoing monitoring of resource availability and integrated analysis of quality control results should lead to updating the plan when problems are detected.

Let's assume that during the measurement work of the stern block (activity No. 24), welding deformations beyond the accepted tolerances are detected. As a result, it is necessary to perform unforeseen corrective work, which will start at the beginning of the 40th time unit (after the measurement work is completed) and will last for 3 time units. Corrective work will cause transport activities 25 and 27 to be delayed, as a result, welding work 28 and 29 will be delayed. All manual welding work is performed by two welders, so their delays affect each other. Subsequently, quality checks at the hull assembly station will be delayed. This effect is shown in

Figure 15.

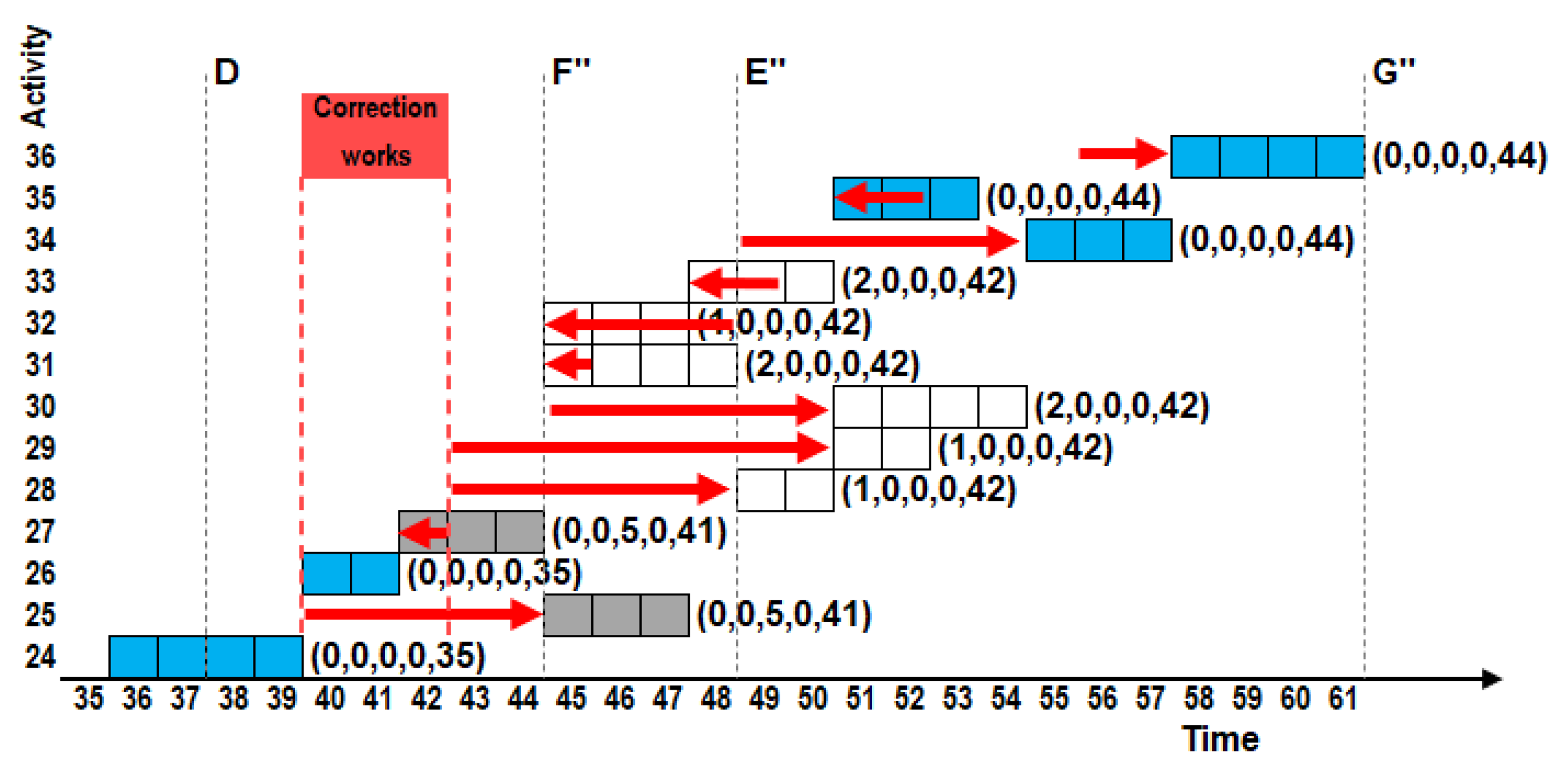

Integrated resource management in the proposed digital twin system enables the entire process to avoid such significant delays. The first decision that can be made is to change the order of block assembly. When the stern block quality problems are detected, the bow block is ready for assembly. The order of transportation of these two blocks is swapped. In addition, the order of making connections between the midship block and the bow block will be modified. Controlling the availability of workers and means of transportation makes it possible to reduce the delay from three to two time units -

Figure 16.

It should be noted that the swap of the order of assembly of blocks in the hull that has been made is acceptable from the point of view of the assumed sequence (see

Figure 13). In practice, it is possible to reduce the process delay by another time unit, which means maintaining the originally assumed lead time. This will be achieved, if dimensional imperfections of the aft block are found at an early stage of control measurements (activity 24). In such a situation, the decision on the need to change the order of block assembly may be made before the measurement activity is completed. The activity is aborted, the mobile measuring station is moved and the accelerated inspection of the bow block is immediately started (activity 26), which can save a unit of time. Inspection activity 24 is continued after the bow block inspection is completed. The correction work of the stern block is carried out while the bow block is installed in the hull.

Early detection of deformations beyond manufacturing tolerances allows quick response and saves time. Such opportunities are provided by the use of the SQMS quality monitoring system (see

Figure 6). The described reordering of work in the event of a disturbance related to dimensional quality allows to carry out a series of procedures included in the SMJ system at this time. Elements of the SAO deviation analysis system and then the SPS joint fitting system are activated. If positive readings are obtained, the section is directed to assembly. Otherwise, repair work on the section is necessary.

Efficient implementation of the above depends on the speed of data acquisition and analysis. The development of DT is practically the only solution to achieve the goal. However, in addition to the effective digitalization of all processes, it is necessary to develop measurement procedures that allow the acquisition of data of sufficient quantity, quality and in the shortest possible time. Hybrid measurement systems combining the advantages of different measuring devices and systems provide such opportunities. For example, scanners for large-scale engineering require a lot of time for the measurement procedure and data processing. In addition, they require the suspension of other technological work in the measurement zone. The use of faster and more accurate handheld scanners for measuring smaller areas of sections is suggested. For example, for scanning the geometry of section joints and the basic sizes will be measured with total stations. Measurement results obtained from individual measurement processes will be combined (combined) for analysis of, among other things, the fitting simulation process.

5. Implementation Conditions

The basic parameter that determines how to implement the DT system into the shipbuilding industry at the production stage is the variation in the technological sophistication of the shipyards. This is the so-called degree of readiness of the shipyard. Given the huge variation in the technological sophistication of individual shipyards as well as the specifics of digitalization of processes and products, implementation procedures will vary greatly. For example, the procedures for digitalizing production sequences will be similar regardless of technological sophistication, while the digitalization of DQMM may differ dramatically.

5.1. Implementation Procedures

DT system implementation procedures can be divided into two basic cases:

implementation in a newly built or comprehensively modernized shipyard,

implementation in an operating shipyard.

For the first case, implementation procedures will be carried out alongside the launch of production processes. The design process of the shipyard will include digitalization procedures and take into account their joint startup. Such a situation is ideal for implementation procedures because it eliminates all the problems associated with safely adapting existing processes for the DT system. Unfortunately, such cases will be sporadic because investments in new shipyards or thorough comprehensive modernization are rare.

In the case of operating shipyards, the technological readiness of individual processes and equipment for the development of the DT system should be determined. Due to the large differences in technological sophistication for each shipyard, this readiness must be determined individually. In addition, each process element must initially be considered separately and then in terms of cooperation with other processes. This will be followed by coding ("digitalization") of individual elements of the production process. In this stage, the necessary investments in the technology used will be identified.

5.2. An Example of a Preliminary Concept for Implementing the DT System's DQMM Functions

The implementation processes will cover a range of matters. Based on observations, it was noted that in operating shipyards, the implementation of DT systems will require the most work in the area of DQMM. Dimensional quality management affects most of the technological processes of shipbuilding. At the same time, it is often based on measurement methods using classical optical measuring devices. In terms of electronic devices, mainly electronic total stations are used. Advanced measurement systems based on scanning techniques are rare. In addition, digital circulation and analysis of measurement data is used only in technologically advanced shipyards. These conditions cause that the digitalization process of processes in most cases should be started from the areas within the DQMM. The concept of the initial stage of implementation of the DT system of the DQMM stage is presented below.

The process of implementing the DT system for DQMM should begin with:

inventory of the yard's dimensional control equipment (equipment, infrastructure, personnel, documentation, etc.),

identification of measurement procedures (including the measurement systems used) at the various stages of production,

identification of applied tolerances.

The next step is to determine the readiness of the resources held and the procedures used for their digitalization. The results achieved should be confronted with the proposed scheme of the DQMM (

Figure 4). This will allow identification of deficiencies and directions of work.

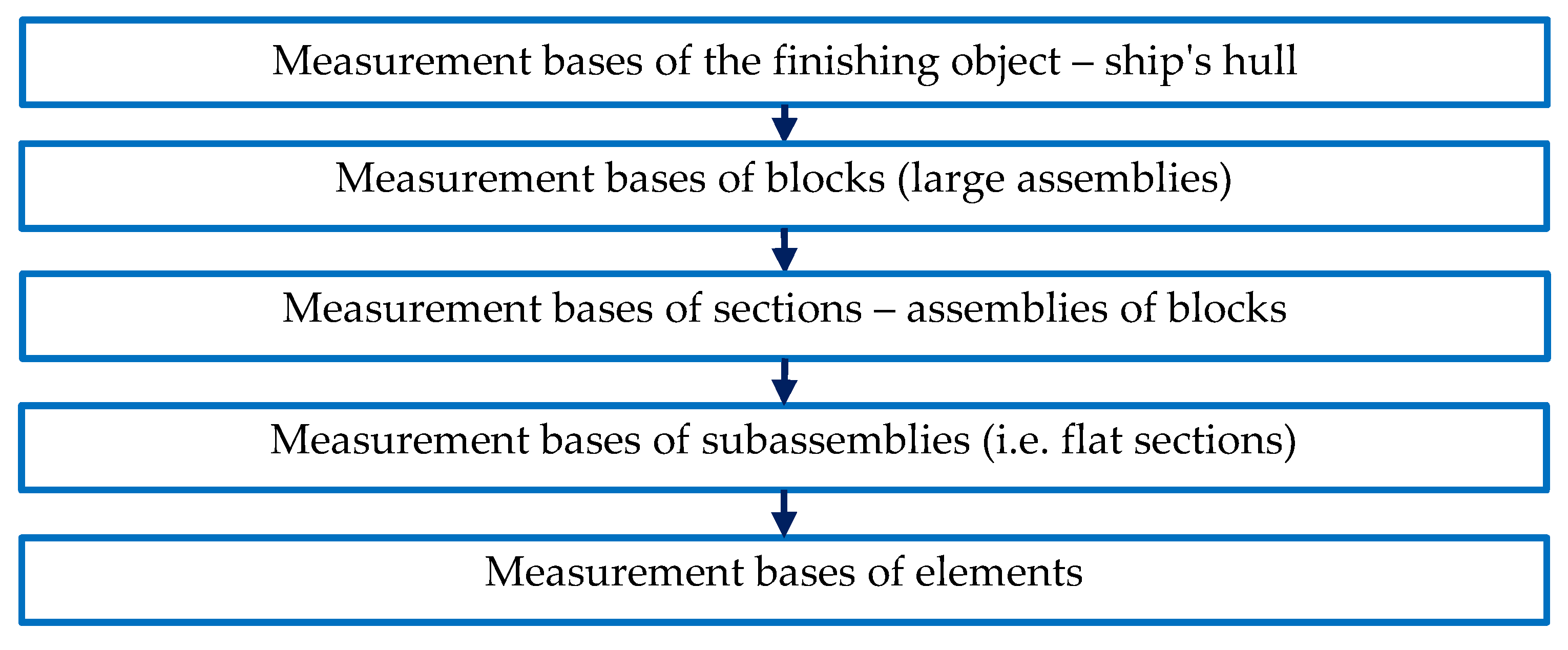

Regardless of the results obtained from the preliminary analysis, it is necessary in each case to develop procedures for digitalization of the geometry of the manufactured ship. It is necessary to develop the basic geometric schemes of the structure, for which the individual elements of the quality control system will refer. The so-called top-down method should be used to decomposition of the entire ship from the point of view of dimensional quality. It is necessary to start with the final product - its geometric parameters required to achieve. Geometric layouts of measurement bases should be built. A general scheme of hull measurement bases as a final product is presented in

Figure 18.

The compression of the measurement bases follows the scheme shown in

Figure 19. The individual components of the scheme refer to the division presented in

Figure 1.

Ultimately, we obtain a scheme of base points characterized by design coordinates. In deformation studies, the hull is represented by a set of observed points. They are placed on the surfaces of prefabricated and assembled structures according to the determined base points for comparison. The observed points are fixed with measurement marks, which are retained until the end of the production process. As a result of the control and measurement work, the actual parameters of the observed points are collected.

Observed points are interconnected with reference points (base points) by geometric elements: horizontal angles, vertical angles, line segments (straight lines on the sides of the elements) and height increments. Together they form a network of base and measurement (real) points. This network is defined as an expansive measurement matrix of the ship's hull. It is linked via reference points to the global OXYZ coordinate system of the ship's hull. The reference points have 'a priori' defined coordinates in this coordinate system. Throughout the production cycle, these points are fixed. The points of the observation network are acquired in successive stages of production. Their parameters in the production process are often updated repeatedly. The acquired points should be parameterized by the time of their determination. They will be the basis for the estimation of deformations occurring at time intervals. Finally, comparing the base points with the corresponding coordinates of the observed points, we will obtain the vectors of displacements relative to the design data. Whereas, by comparing the coordinates of the observed points at different time intervals, we will obtain the displacement vectors of the measurement points in the time space of the manufacturing process. Such an approach will allow analyzing the data both for the current production process, as well as conducting global analyses for optimizing production processes and creating complete DT systems. The resulting vectors should be linked to tolerances and dimensional chains. This linkage will form the basis for the implementation and operation of the various DQMM elements. Once the coding of the measurement base schemes has been developed, the digitalization of the remaining DQMM elements should proceed. Each of these elements represents a separate extensive research and development task.

All the described matters related to dimensional control are only an outline of the whole DQMM subject. They illustrate how extensive the process of creating a production stage DT system is.

6. Discussion

Ships are characterized by a long service life. At the same time, they are highly complex objects. One of the main ideas of DT creation is to support the digitalized object throughout its life cycle from the design stage through production, operation to the end of life and disposal. The process of creating their DTs is extensive and multidisciplinary. Based on the literature analysis performed, it was found that the work leading to a complete DT of a ship is at an early stage. It mainly includes the operation stage and the design stage. The literature analysis shows that the manufacturing process is practically ignored.

The sophistication of DT research in other industries in terms of manufacturing processes is often high. However, the characteristics of the shipbuilding industry make it impossible to transfer ready-made functioning solutions. It is reasonable to use the experience of other industries mainly in the field of data collection, transmission and analysis systems. However, it is necessary to adapt them to specific issues developed individually for the needs of the shipbuilding industry.

The methodology presented in the article for a comprehensive approach to the creation of a ship production DT system is at the same time a roadmap for the first stages of its implementation in practice. A system is proposed that digitally connects the shipyard, the production process and the product-ship. This hybrid can form the basis for digitizing further stages of the ship's life cycle – the operating period and disposal, i.e., creating a complete ship DT.

Researchers working on developing DTs of the various stages of the product life cycle (design, production and operation) should each time refer to the needs of the other stages. For example, when developing the DT of a manufacturing process, the needs of design data are often identified. In the same way, the needs of the operational stages should be addressed in the production and design stages. In general, a comprehensive approach is necessary when developing DTs.

The developed DT roadmap of the shipbuilding process is in the early stages of development. The next step will be to detail it in terms of individual components. Due to the complexity of the issue, the directions for further research will be multidisciplinary and extensive. The scope of work and research to be done parallels the steps of coding the individual components of the manufacturing process presented in Chapter 3 of this paper. The individual elements must work together – form a single DT. However, due to the level of complexity, it is impossible for one research team to develop them simultaneously. Some of these tasks are purely engineering and some require research work and scientific analysis. Different tasks require different workloads and realization times. It would be difficult to coordinate these works, however, modern possibilities of access to research results through their publication will effectively improve the idea of hybrid DT ship and its production process. The basic common assumption in conducting further research must be the ability to easily adapt the obtained results to cooperate (feedback) with other stages/elements of DT.

The authors will work successively on individual issues detailing them and developing tools for their application in the shipbuilding industry. Most of the DT elements can be applied separately in production processes. For some of them it is even advisable, as this will enable their testing and improvement. Dimensional quality control processes, for example, are constantly being conducted and developed in all shipyards. Their degree of digitalization, method and scope of use varies. By developing a universal way of coding and digitizing them, we will not limit the measurement systems already in operation. We are creating new opportunities for them to be used in functioning production processes and systems. Such an approach is deliberate for all stages of coding and digitizing production processes leading to the creation of a comprehensive DT system of ship production processes.

The application of DT in the shipbuilding industry will bring a number of benefits. It is necessary to ensure that all participants in the ship's life cycle notice and appreciate them. Such awareness will definitely accelerate the digital revolution in the shipbuilding industry.

References

- Saad, A.; Faddel, S.; Mohammed, O. IoT-Based Digital Twin for Energy Cyber-Physical Systems: Design and Implementation. Energies 2020, 13, 4762. [Google Scholar] [CrossRef]

- Saad, A.; Faddel, S.; Mohammed, O. IoT-Based Digital Twin for Energy Cyber-Physical Systems: Design and Implementation. Energies 2020, 13, 4762. [Google Scholar] [CrossRef]

- Jones, D.; Snider, C.; Nassehi, A.; Yon, J.; Hicks, B. Characterising the Digital Twin: A systematic literature review. CIRP J. Manuf. Sci. Technol. 2020, 29, 36–52. [Google Scholar] [CrossRef]

- Tao, F.; Zhang, H.; Liu, A.; Nee, A.Y.C. Digital Twin in Industry: State-of-the-Art. IEEE Trans. Ind. Inform. 2019, 15, 2405–2415. [Google Scholar] [CrossRef]

- Lim, K.Y.H.; Zheng, P.; Chen, C.-H. A state-of-the-art survey of Digital Twin: Techniques, engineering product lifecycle management and business innovation perspectives. J. Intell. Manuf. 2020, 31, 1313–1337. [Google Scholar] [CrossRef]

- Camposano, J.C.; Smolander, K.; Ruippo, T. Seven Metaphors to Understand Digital Twins of Built Assets. IEEE Access 2021, 9, 27167–27181. [Google Scholar] [CrossRef]

- Grieves, M.; Vickers, J. Digital Twin: Mitigating Unpredictable, Undesirable Emergent Behavior in Complex Systems. In Transdisciplinary Perspectives on Complex Systems, 1st ed.; Kahlen, F.-J., Flumerfelt, S., Alves, A., Eds.; Springer: Cham, Switzerland, 2017; pp. 85–113. [Google Scholar] [CrossRef]

- Shafto, M.; Conroy, M.; Doyle, R.; Glaessgen, E.; Kemp, C.; LeMoigne, J.; Wang, L. Technology Area 11: Modeling, Simulation, Information Technology and Processing Roadmap; NASA Office of Chief Technologist: Washington, DC, USA, 2010; Available online: https://www.nasa.gov/pdf/501321main_TA11-MSITP-DRAFT-Nov2010-A1.pdf (accessed on 30 September 2022).

- Vieira, J.; Poças Martins, J.; Marques de Almeida, N.; Patrício, H.; Gomes Morgado, J. Towards Resilient and Sustainable Rail and Road Networks: A Systematic Literature Review on Digital Twins. Sustainability 2022, 14, 7060. [Google Scholar] [CrossRef]

- Shim, C.; Dang, S.; Lon, S.; Jeon, C. Development of a bridge maintenance system for prestressed concrete bridges using 3D digital twin model. Struct. Infrastruct. Eng. 2019, 15, 1319–1332. [Google Scholar] [CrossRef]

- Marai, O.E.; Taleb, T.; Song, J. Roads Infrastructure Digital Twin: A Step Toward Smarter Cities Realization. IEEE Netw. 2021, 35, 136–143. [Google Scholar] [CrossRef]

- Lu, R.; Brilakis, I.K. Digital twinning of existing reinforced concrete bridges from labelled point clusters. Autom. Constr. 2019, 105, 102837. [Google Scholar] [CrossRef]

- Kritzinger, W.; Karner, M.; Traar, G.; Henjes, J.; Sihn, W. Digital Twin in manufacturing: A categorical literature review and classification. IFAC-PapersOnLine 2018, 51, 1016–1022. [Google Scholar] [CrossRef]

- Liu, M.; Fang, S.; Dong, H.; Xu, C. Review of digital twin about concepts, technologies, and industrial applications. J. Manuf. Syst. 2021, 58, 346–361. [Google Scholar] [CrossRef]

- Callcut, M.; Agliozzo, J.-P.C.; Varga, L.; McMillan, L. Digital Twins in Civil Infrastructure Systems. Sustainability 2021, 13, 11549. [Google Scholar] [CrossRef]

- da Silva Mendonça, R.; de Oliveira Lins, S.; de Bessa, I.V.; de Carvalho Ayres, F.A., Jr.; de Medeiros, R.L.P.; de Lucena, V.F., Jr. Digital Twin Applications: A Survey of Recent Advances and Challenges. Processes 2022, 10, 744. [Google Scholar] [CrossRef]

- Assani, N.; Matić, P.; Katalinić, M. Ship's Digital Twin-A Review of Modelling Challenges and Applications. Appl. Sci. 2022, 12, 6039. [Google Scholar] [CrossRef]

- Giering, Jan-Erik and Dyck, Alexander. Maritime Digital Twin architecture: A concept for holistic Digital Twin application for shipbuilding and shipping at - Automatisierungstechnik 2021, 69, 1081–1095. [CrossRef]

- Sthefano L. Andrade, Thiago Gabriel Monteiro, Henrique M. Gaspar (2015). Product Life-Cycle Management In Ship Design: From Concept To Decommission In A Virtual Environment, ECMS 2015 Proceedings edited by: Valeri M. Mladenov, Petia Georgieva, Grisha Spasov, Galidiya Petrova European Council for Modeling and Simulation. [CrossRef]

- Berre, A.-J. and R?dseth, ?.?J. (2018, Sep 27th-28th). From Digital Twin to Maritime Data Space: Transparent Ownership and Use of Ship Information. In: 13th ISIS-MTE. Search in Google Scholar.

- Fonseca, Í.A.; Gaspar, H.M. Challenges when Creating a Cohesive Digital Twin Ship: A Data Modelling Perspective. Ship Technology Research 2021, 68, 70–83. [Google Scholar] [CrossRef]

- Gausdal, A.H.; Czachorowski, K.V.; Solesvik, M.Z. Applying Blockchain Technology: Evidence from Norwegian Companies. Sustainability 2018, 10, 1985. [Google Scholar] [CrossRef]

- Hatledal, L.; Skulstad, R.; Li, G.; Styve, A.; Zhang, H. Co-Simulation as a Fundamental Technology for Twin Ships. MIC 2020, 41, 297–311. [Google Scholar] [CrossRef]

- Pang, T.Y.; Pelaez Restrepo, J.D.; Cheng, C.-T.; Yasin, A.; Lim, H.; Miletic, M. Developing a Digital Twin and Digital Thread Framework for an 'Industry 4.0' Shipyard. Appl. Sci. 2021, 11, 1097. [Google Scholar] [CrossRef]

- Perabo, F., Park, D., Zadeh, M. K., Smogeli, O. and Jamt, L. (2020, Jun 17th-19th). Digital Twin Modelling of Ship Power and Propulsion Systems: Application of the Open Simulation Platform (OSP). In: 29th ISIE, pp. 1265–1270. [CrossRef]

- Sánchez-Sotano, A., Cerezo-Narváez, A., Abad-Fraga, F., Pastor-Fernández, A. and Salguero-Gómez, J. (2020). Trends of Digital Transformation in the Shipbuilding Sector. In: L. R. Martínez, R. A. Osornio Rios and M. D. Prieto (Eds.), New Trends in the Use of Artificial Intelligence for the Industry 4.0, pp. 1–23. IntechOpen, London, UK. [CrossRef]

- Fonseca, Í.A.; Gaspar, H.M. Challenges When Creating a Cohesive Digital Twin Ship: A Data Modelling Perspective. Ship Technol. Res. 2021, 68, 70–83. [Google Scholar] [CrossRef]

- Anyfantis, K.N. An Abstract Approach toward the Structural Digital Twin of Ship Hulls: A Numerical Study Applied to a Box Girder Geometry. Proc. Inst. Mech. Eng. Part M J. Eng. Marit. Environ. 2021, 235, 718–736. [Google Scholar] [CrossRef]

- Arrichiello, V.; Gualeni, P. Systems Engineering and Digital Twin: A Vision for the Future of Cruise Ships Design, Production and Operations. Int. J. Interact. Des. Manuf. 2020, 14, 115–122. [Google Scholar] [CrossRef]

- Wen hao, W.; Guo bing, C.; Zi chun, Y. The Application and Challenge of Digital Twin Technology in Ship Equipment. J. Phys. Conf. Ser. 2021, 1939, 012068. [Google Scholar] [CrossRef]

- Hasanspahić, N.; Vujičić, S.; Čampara, L.; Piekarska, K. Sustainability and Environmental Challenges of Modern Shipping Industry. JAES 2021, 19, 369–374. [Google Scholar] [CrossRef]

- Låg, S. and Brathagen, S. W. (2017).Standardisation as an Enabler of Digitalisation in the Maritime Industry. Group Technology & Research, Position Paper, DNV GL AS, Høvik, Norway. Szukaj w Google Scholar.

- Rutkowski, R. Dynamical control of dimensional quality of large steel structures in production enterprises of low - level technological support, Polish Maritime Research, vol.17, no.1, 2010, pp.80-88. [CrossRef]

Figure 1.

Diagram of the prefabrication process workflow.

Figure 1.

Diagram of the prefabrication process workflow.

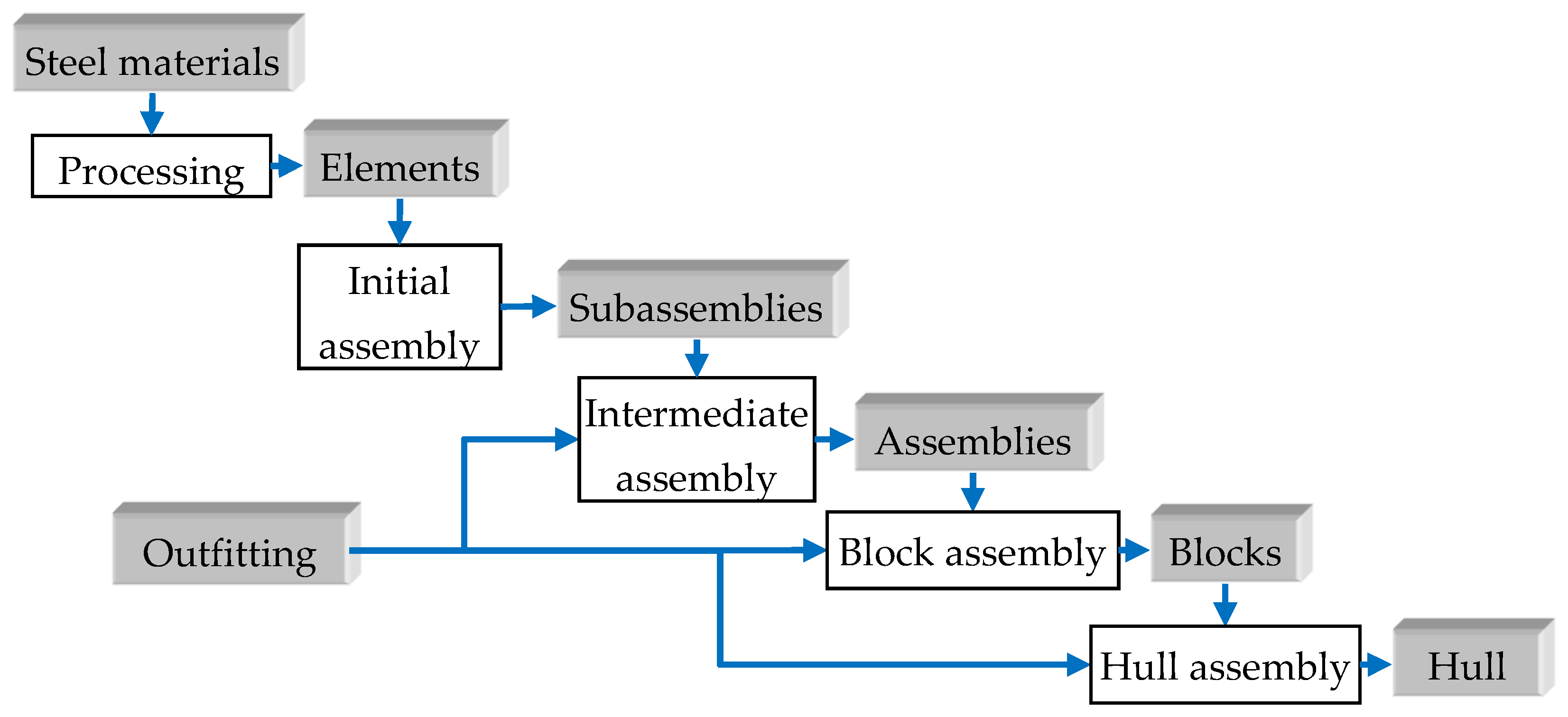

Figure 2.

Transformation of work objects in the course of ship production.

Figure 2.

Transformation of work objects in the course of ship production.

Figure 3.

General structure of proposed Digital Twin System.

Figure 3.

General structure of proposed Digital Twin System.

Figure 4.

Dimensional quality management metasystem.

Figure 4.

Dimensional quality management metasystem.

Figure 5.

Identifiers of storage and processing operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 5.

Identifiers of storage and processing operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 6.

Identifiers of prefabrication operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 6.

Identifiers of prefabrication operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 7.

Identifiers of hull assembly and outfitting operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 7.

Identifiers of hull assembly and outfitting operations; continuous arrows - change of state, dashed arrows - change of position (transport).

Figure 8.

Fitting of joints procedure scheme.

Figure 8.

Fitting of joints procedure scheme.

Figure 9.

Operations performed by the exemplary shipyard.

Figure 9.

Operations performed by the exemplary shipyard.

Figure 11.

Numbering of components.

Figure 11.

Numbering of components.

Figure 12.

Metal sheets cutting.

Figure 12.

Metal sheets cutting.

Figure 13.

Sequence of the exemplary process.

Figure 13.

Sequence of the exemplary process.

Figure 14.

Planned timeline for the process.

Figure 14.

Planned timeline for the process.

Figure 15.

Avalanche effect of adding stern block straightening activity - process time increased by two units.

Figure 15.

Avalanche effect of adding stern block straightening activity - process time increased by two units.

Figure 16.

Modification of the order of hull assembly - reducing the increase in process time by a unit.

Figure 16.

Modification of the order of hull assembly - reducing the increase in process time by a unit.

Figure 17.

Early detection of imperfections and stopping the measurements - complete avoidance of process delay.

Figure 17.

Early detection of imperfections and stopping the measurements - complete avoidance of process delay.

Figure 18.

A general scheme of hull measurement bases.

Figure 18.

A general scheme of hull measurement bases.

Figure 19.

General scheme of densification of measurement bases of the ship's hull.

Figure 19.

General scheme of densification of measurement bases of the ship's hull.

Table 1.

The numbering of all activities and their assumed times.

Table 1.

The numbering of all activities and their assumed times.

| Activity no. |

Time |

Description |

Activity no. |

Time |

Description |

| 1 |

6 |

cutting of sheet C |

19 |

6 |

welding of elements 10 + 11 |

| 2 |

4 |

cutting of sheet B |

20 |

6 |

welding of elements 10 + 12 |

| 3 |

1 |

cutting of sheet A |

21 |

10 |

joining of elements 1 + 14 (engine) |

| 4 |

4 |

welding of elements 1 + 4 |

22 |

10 |

joining of elements 4 + 13 (propeller) |

| 5 |

4 |

welding of elements 1 + 5 |

23 |

8 |

joining of elements 13 + 14 |

| 6 |

10 |

welding of elements 1 + 2 |

24 |

4 |

quality control of aft block |

| 7 |

10 |

welding of elements 1 + 3 |

25 |

3 |

transportation and positioning of aft block |

| 8 |

4 |

welding of elements 2 + 4 |

26 |

2 |

quality control of fore block |

| 9 |

4 |

welding of elements 2 + 5 |

27 |

3 |

transportation and positioning of fore block |

| 10 |

4 |

welding of elements 3 + 4 |

28 |

2 |

welding of elements 2 + 7 |

| 11 |

4 |

welding of elements 3 + 5 |

29 |

2 |

welding of elements 3 + 8 |

| 12 |

8 |

quality control of midship block |

30 |

4 |

welding of elements 4 + 6 |

| 13 |

2 |

transportation and positioning of midship block |

31 |

4 |

welding of elements 1 + 10 |

| 14 |

2 |

welding of elements 6 + 7 |

32 |

3 |

welding of elements 2 + 11 |

| 15 |

2 |

welding of elements 6 + 8 |

33 |

3 |

welding of elements 3 + 12 |

| 16 |

4 |

welding of elements 6 + 9 |

34 |

3 |

quality control after aft assembly in the hull |

| 17 |

1 |

welding of elements 7 + 9 |

35 |

3 |

quality control after fore assembly in the hull |

| 18 |

1 |

welding of elements 8 + 9 |

36 |

4 |

quality control after outfitting |

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).