Submitted:

28 April 2023

Posted:

29 April 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Animals management and diets

2.2. Dry-cured Bísaro loin and Cachaço manufacture

2.3. Volatile compounds

2.4. Sensorial Analysis

2.5. Statistical Analysis

3. Results and Discussion

3.1. Volatile compounds of dry-cured loin and dry-cured “cachaço”

| COMPOUNDS INFORMATION | DRY-CURED LOIN | DRY-CURED “CACHAÇO” | SEM | Sig. Product | Sig. Treat. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | LRI | m/z | T1 | T2 | T3 | T4 | T5 | T1 | T2 | T3 | T4 | T5 | |||

| Glycidol | 512 | 43 | 6.64 | 9.40 | 9.97 | 11.40 | 8.60 | 5.91 | 6.94 | 6.45 | 6.76 | 6.49 | 0.586 | 0.025 | 0.648 |

| 2-Butanol, (R)- | 610 | 59 | 0.56 | 0.36 | 0.93 | 0.52 | 12.99 | 0.25 | 1.01 | 0.17 | 0.36 | 0.83 | 1.203 | 0.292 | 0.343 |

| 1-Butanol | 706 | 56 | 0.33 | 0.45 | 0.34 | 0.34 | 0.49 | 0.77 | 0.92 | 0.76 | 0.88 | 0.97 | 0.032 | <0.001 | 0.308 |

| 2-Pentanol | 749 | 45 | 2.59 | 2.13 | 1.58 | 1.99 | 2.24 | 1.20 | 0.73 | 1.00 | 0.94 | 1.01 | 0.136 | <0.001 | 0.690 |

| 1-Butanol, 3-methyl- | 805 | 55 | 12.36 | 16.23 | 13.67 | 14,78 | 10.69 | 3.12 | 3.11 | 2.68 | 4.79 | 2.65 | 1.133 | <0.001 | 0.884 |

| 1-Pentanol | 842 | 55 | 6.43 | 9.25 | 6.60 | 6.45 | 12.58 | 23.77 | 26.02 | 21.78 | 29.04 | 27.49 | 1.069 | <0.001 | 0.429 |

| 2,3-Butanediol | 911 | 45 | 41.95 | 20.62 | 30.50 | 38.45 | 19.30 | 37.27 | 51.67 | 41.90 | 47.41 | 20.78 | 3.934 | 0.211 | 0.392 |

| 1-Hexanol | 947 | 56 | 12.66 | 25.09 | 17.64 | 18.68 | 29.29 | 8.16 | 11.00 | 9,35 | 9.18 | 10.70 | 1.489 | <0.001 | 0.257 |

| 1-Octen-3-ol | 1040 | 57 | 19.39 | 18.36 | 14.90 | 13.29 | 22.92 | 45.80 | 43.51 | 33.14 | 52.12 | 52.98 | 1.962 | <0.001 | 0.273 |

| Benzyl alcohol | 1111 | 108 | 11.28 | 11.94 | 10.18 | 9.62 | 10.02 | 7.47 | 8.98 | 10.84 | 8.85 | 8.17 | 0.514 | 0.094 | 0.834 |

| Terpinen-4-ol | 1191 | 111 | 0.68 | 0.56 | 0.43 | 0.54 | 0.50 | 0.16 | 0.13 | 0.14 | 0.15 | 0.13 | 0.017 | <0.001 | 0.140 |

| Thymol | 1290 | 150 | 0.09 | 0.09 | 0.07 | 0.12 | 0.08 | 0.02 | 0.02 | 0.01 | 0.01 | 0.02 | 0.004 | <0.001 | 0.164 |

| TOTAL ALCOHOLS | 114.96 | 114.48 | 106.81 | 116.18 | 129.70 | 133.90 | 154.04 | 128.22 | 160.49 | 132.22 | |||||

| Propanal | 536 | 58 | 2.68 | 2.17 | 1.79 | 1.66 | 3.16 | 15.45 | 14.05 | 14.73 | 16.93 | 14.40 | 0.648 | <0.001 | 0.960 |

| Propanal, 2-methyl- | 565 | 72 | 0.87 | 0.94 | 1.00 | 1.24 | 0.79 | 0.57 | 1.05 | 0.81 | 0.83 | 0.74 | 0.061 | 0.213 | 0.341 |

| Butanal, 3-methyl- | 660 | 58 | 7.75 | 8.84 | 11.65 | 12.75 | 7.37 | 2.65 | 5.05 | 4.69 | 4.71 | 3.45 | 0.875 | 0.003 | 0.595 |

| Pentanal | 727 | 58 | 9.01 | 8.21 | 6.10 | 6.46 | 11.51 | 24.34 | 25.60 | 21.57 | 27.44 | 26.35 | 0.881 | <0.001 | 0.484 |

| 2-Butenal, 2-methyl- | 798 | 84 | 1.04 | 1.16 | 1.22 | 1.87 | 1.26 | 0.51 | 1.29 | 0.90 | 0.92 | 1.16 | 0.153 | 0.275 | 0.737 |

| Hexanal | 842 | 55 | 162.54 | 153.55 | 140.13 | 130.40 | 183 | 291.52 | 320.50 | 287.24 | 325.08 | 302.33 | 9.878 | <0.001 | 0.904 |

| 2-Hexenal, (E)- | 931 | 83 | 0.19 | 0.20 | 0.17 | 0.15 | 0.26 | 1.34 | 0.97 | 0.96 | 1.30 | 1.37 | 0.050 | <0.001 | 0.440 |

| Heptanal | 965 | 70 | 10.33 | 10.11 | 8.90 | 9.45 | 11.12 | 14.12 | 17.39 | 14.33 | 16.26 | 15.13 | 0.702 | <0.001 | 0.887 |

| Methional | 990 | 104 | 0.37 | 0.40 | 0.50 | 0.52 | 0.38 | 0.05 | 0.17 | 0.14 | 0.08 | 0.10 | 0.021 | <0.001 | 0.481 |

| Furfural | 993 | 96 | 0.02 | 0.02 | 0.02 | 0.01 | 0.05 | 0.18 | 0.15 | 0.16 | 0.21 | 0.17 | 0.008 | <0.001 | 0.814 |

| Benzaldehyde | 1034 | 106 | 5.39 | 5.45 | 8.06 | 4.13 | 9.97 | 4.08 | 13.23 | 4.83 | 8.47 | 11.16 | 1.060 | 0.382 | 0.410 |

| Octanal | 1054 | 56 | 5.03 | 4.68 | 3.57 | 4.23 | 3.92 | 5.13 | 5.57 | 4.69 | 5.20 | 5.40 | 0.234 | 0.075 | 0.651 |

| 2,4-Heptadienal, (E,E)- | 1067 | 81 | 0.05 | 0.03 | 0.03 | 0.03 | 0.06 | 1.67 | 1.23 | 1.33 | 2.07 | 1.77 | 0.088 | <0.001 | 0.638 |

| Benzeneacetaldehyde | 1106 | 91 | 18.11 | 30.04 | 69.21 | 28.55 | 77.19 | 2.96 | 21.59 | 9.30 | 11.67 | 13.77 | 7.735 | 0.0391 | 0.615 |

| 2-Octenal, (E)- | 1109 | 55 | 0.40 | 0.35 | 0.31 | 0.27 | 0.53 | 4.37 | 3.93 | 3.04 | 5.39 | 5.07 | 0.231 | <0.001 | 0.548 |

| Nonanal | 1133 | 57 | 5.24 | 5.21 | 4.06 | 4.05 | 5.02 | 7.27 | 8.74 | 7.20 | 8.32 | 8.06 | 0.281 | <0.001 | 0.653 |

| 2-Nonenal, (E)- | 1184 | 70 | 0.47 | 0.35 | 0.29 | 0.35 | 0.38 | 0.72 | 0.76 | 0.68 | 0.82 | 0.66 | 0.035 | <0.001 | 0.883 |

| 2-Decenal, (E )- | 1253 | 70 | 0.20 | 0.21 | 0.15 | 0.17 | 0.18 | 0.30 | 0.29 | 0.25 | 0.30 | 0.27 | 0.014 | <0.001 | 0.719 |

| TOTAL ALDEHYDES | 229.69 | 231.92 | 257.16 | 206.29 | 316.15 | 377.23 | 441.56 | 376.85 | 436.00 | 411.36 | |||||

| Acetic acid | 689 | 60 | 0.30 | 0.19 | 0.17 | 0.23 | 0.20 | 0.49 | 0.31 | 0.40 | 0.34 | 0.23 | 0.018 | <0.001 | 0.248 |

| Butanoic acid | 910 | 60 | 2.60 | 2.06 | 3.33 | 3.86 | 3.51 | 21.59 | 15.85 | 22.42 | 19.87 | 13.90 | 0.834 | <0.001 | 0.358 |

| Butanoic acid, 3-methyl- | 959 | 60 | 5.65 | 1.97 | 2.93 | 6.68 | 1.93 | 5.56 | 4.03 | 1.49 | 5.50 | 1.51 | 0.828 | 0.899 | 0.337 |

| Hexanoic acid | 1071 | 60 | 0.95 | 0.88 | 0.60 | 0.92 | 1.46 | 15.45 | 7.79 | 7.81 | 14.73 | 16.75 | 1.224 | <0.001 | 0.617 |

| TOTAL ACIDS | 9.50 | 5.10 | 7.03 | 11.69 | 7.10 | 43.09 | 27.98 | 32.12 | 40.44 | 32.39 | |||||

| COMPOUND INFORMATION | DRY-CURED LOIN | DRY-CURED “CACHAÇO” | SEM | Sig. Product | Sig. Treat. | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| NAME | LRI | m/z | T1 | T2 | T3 | T4 | T5 | T1 | T2 | T3 | T4 | T5 | |||

| Pentane | 527 | 57 | 0.66 | 1.37 | 0.67 | 0.79 | 1.48 | 3.15 | 2.25 | 2.49 | 2.31 | 2.14 | 0.152 | <0.001 | 0.874 |

| 1,4-Pentadiene | 539 | 67 | 1.05 | 2.28 | 1.04 | 2.05 | 2.37 | 1.87 | 1.21 | 1.77 | 2.57 | 1.16 | 0.242 | 0.981 | 0.734 |

| Cyclopentane, 1,2-dimethyl | 665 | 56 | 0.29 | 0.31 | 0.16 | 0.20 | 0.26 | 0.28 | 0.26 | 0.25 | 0.26 | 0.24 | 0.020 | 0.649 | 0.666 |

| Heptane | 673 | 71 | 10.90 | 17.59 | 11.79 | 13.99 | 13.58 | 10.19 | 9.17 | 10.51 | 6.98 | 8.02 | 0.757 | 0.003 | 0.697 |

| Octane | 817 | 85 | 36.06 | 49.53 | 35.05 | 42.34 | 43.57 | 29.16 | 28.19 | 28.87 | 21.62 | 23.48 | 1.932 | <0.001 | 0.735 |

| 2-Octene, (E)- | 828 | 55 | 0.17 | 0.20 | 0.15 | 0.16 | 0.29 | 0.18 | 0.17 | 0.18 | 0.19 | 0.22 | 0.010 | 0.934 | 0.051 |

| Nonane | 927 | 57 | 0.88 | 0.89 | 0.64 | 0.79 | 0.58 | 0.61 | 0.46 | 0.55 | 0.43 | 0.72 | 0.039 | 0.010 | 0.758 |

| α-Phellandrene | 961 | 93 | 4.90 | 4.16 | 3.36 | 5.39 | 3.58 | 1.78 | 1.26 | 1.45 | 1.72 | 1.29 | 0.202 | <0.001 | 0.219 |

| Hexane, 3,3-dimethyl | 927 | 85 | 0.48 | 0.46 | 0.35 | 0.44 | 0.35 | 0.32 | 0.25 | 0.28 | 0.24 | 0.37 | 0.020 | 0.003 | 0.696 |

| Butane, 2,2,3-trimethyl- | 994 | 57 | 0.39 | 0.35 | 0.21 | 0.32 | 0.21 | 0.16 | 0.15 | 0.15 | 0.14 | 0.16 | 0.016 | <0.001 | 0.306 |

| Nonane, 5-methylene- | 999 | 56 | 0.48 | 0.47 | 0.28 | 0.37 | 0.23 | 0.18 | 0.17 | 0.18 | 0.16 | 0.18 | 0.022 | <0.001 | 0.332 |

| Decane | 1018 | 57 | 2.13 | 3.68 | 1.89 | 2.03 | 1.52 | 1.02 | 0.69 | 0.51 | 0.80 | 0.97 | 0.153 | <0.001 | 0.248 |

| β-Myrcene | 1021 | 93 | 1.16 | 1.09 | 0.73 | 1.30 | 0.73 | 0.35 | 0.24 | 0.26 | 0.38 | 0.27 | 0.054 | <0.001 | 0.166 |

| (Z)-4-Methyl-2-hexene | 1043 | 98 | 0.83 | 0.75 | 0.54 | 0.68 | 0.44 | 0.26 | 0.30 | 0.28 | 0.27 | 0.29 | 0.036 | <0.001 | 0.488 |

| 2,2,4,4-Tetramethyloctane | 1048 | 57 | 33.59 | 31.00 | 23.97 | 30.09 | 19.66 | 14.07 | 15.60 | 15.46 | 13.73 | 14.59 | 1.376 | <0.001 | 0.526 |

| γ-Terpinene | 1078 | 93 | 3.55 | 2.66 | 2.41 | 3.91 | 2.33 | 0.89 | 0.69 | 0.80 | 1.00 | 0.77 | 0.142 | <0.001 | 0.153 |

| Undecane | 1098 | 85 | 0.51 | 0.49 | 0.39 | 0.47 | 0.34 | 0.28 | 0.26 | 0.25 | 0.24 | 0.29 | 0.019 | <0.001 | 0.613 |

| Dodecane, 2,6,10-trimethyl- | 1171 | 57 | 0.61 | 0.57 | 0.47 | 0.58 | 0.48 | 0.32 | 0.34 | 0.30 | 0.30 | 0.38 | 0.027 | 0.001 | 0.914 |

| Dodecane | 1171 | 71 | 0.46 | 0.45 | 0.34 | 0.42 | 0.35 | 0.25 | 0.25 | 0.20 | 0.24 | 0.26 | 0.019 | <0.001 | 0.594 |

| 2-Heptene, 3-methyl | 1184 | 83 | 0.34 | 0.30 | 0.24 | 0.27 | 0.30 | 0.58 | 0.55 | 0.51 | 0.72 | 0.60 | 0.031 | <0.001 | 0.886 |

| Cyclododecane | 1206 | 83 | 0.57 | 0.53 | 0.42 | 0.53 | 0.43 | 0.29 | 0.32 | 0.25 | 0.29 | 0.32 | 0.023 | <0.001 | 0.668 |

| TOTAL HYDROCARBONS | 100.01 | 119.13 | 85.10 | 107.12 | 93.08 | 66.19 | 62.78 | 65.50 | 54.59 | 56.72 | |||||

| 2,3-Butanedione | 594 | 86 | 0.76 | 0.25 | 0.32 | 0.61 | 0.30 | 0.92 | 1.39 | 1.15 | 0.90 | 0.54 | 0.082 | 0.002 | 0.470 |

| 2-Butanone | 599 | 72 | 1.48 | 2.04 | 2.92 | 2.84 | 18.00 | 1.66 | 4.43 | 3.35 | 2.57 | 2.79 | 1.536 | 0.413 | 0.379 |

| 1-Penten-3-one | 715 | 55 | 0.06 | 0.04 | 0.04 | 0.04 | 0.08 | 0.89 | 0.61 | 0.62 | 0.80 | 0.97 | 0.037 | <0.001 | 0.334 |

| 2-Pentanone | 719 | 86 | 5.51 | 5.17 | 3.41 | 5.00 | 4.07 | 4.94 | 6.67 | 4.98 | 3.61 | 3.31 | 0.629 | 0.918 | 0.810 |

| 2,3-Pentanedione | 735 | 57 | 4.42 | 3.04 | 3.37 | 14.81 | 9.85 | 5.97 | 6.41 | 7.58 | 6.25 | 6.25 | 1.412 | 0.848 | 0.651 |

| Acetoin | 786 | 45 | 19.38 | 8.32 | 10.23 | 24.94 | 8.93 | 17.72 | 27.18 | 22.85 | 14.72 | 6.06 | 2.058 | 0.424 | 0.345 |

| 2-Hexanone | 854 | 58 | 1.60 | 1.94 | 1.16 | 1.51 | 1.15 | 1.02 | 1.17 | 0.91 | 0.73 | 0.79 | 0.136 | 0.052 | 0.658 |

| 2-Heptanone | 959 | 58 | 14.02 | 18.12 | 12.61 | 14.78 | 13.59 | 17.53 | 17.70 | 9.86 | 15.38 | 16.08 | 1.335 | 0.784 | 0.620 |

| 4-Hexen-3-one, 5-methyl- | 1031 | 83 | 0.28 | 0.38 | 0.30 | 0.36 | 0.35 | 0.30 | 0.30 | 0.27 | 0.30 | 0.41 | 0.024 | 0.513 | 0.675 |

| Butyrolactone | 1034 | 86 | 0.77 | 0.64 | 0.81 | 1.07 | 0.71 | 1.89 | 1.76 | 1.72 | 1.96 | 1.67 | 0.048 | <0.001 | 0.334 |

| 3,5-Octadien-2-one | 1121 | 95 | 0.72 | 0.41 | 0.46 | 0.46 | 0.83 | 2.05 | 1.73 | 1.78 | 2.62 | 2.37 | 0.141 | <0.001 | 0.662 |

| 2-Nonanone | 1126 | 58 | 2.07 | 2.29 | 2.00 | 2.23 | 1.69 | 2.66 | 2.98 | 0.87 | 2.60 | 2.46 | 0.284 | 0.654 | 0.710 |

| TOTAL KETONES | 51.07 | 42.64 | 37.63 | 68.65 | 59.55 | 57.55 | 72.33 | 55.94 | 52.44 | 43.70 | |||||

| Acetic acid, methyl ester | 547 | 74 | 0.30 | 0.19 | 0.17 | 0.23 | 0.20 | 0.49 | 0.31 | 0.40 | 0.34 | 0.23 | 0.025 | 0.008 | 0.188 |

| Ethyl Acetate | 603 | 61 | 10.70 | 9.71 | 8.21 | 9.11 | 10.78 | 5.10 | 3.91 | 2.26 | 4.00 | 4.53 | 0.578 | <0.001 | 0.605 |

| Propanoic acid, ethyl ester | 735 | 102 | 0.52 | 0.28 | 0.30 | 2.81 | 1.63 | 0.23 | 0.15 | 0.11 | 0.27 | 0.22 | 0.291 | 0.123 | 0.555 |

| n-Propyl acetate | 742 | 61 | 0.15 | 0.18 | 0.17 | 0.25 | 0.62 | 0.08 | 0.13 | 0.06 | 0.09 | 0.09 | 0.042 | 0.029 | 0.317 |

| Propanoic acid, 2-methyl-, ethyl ester | 798 | 71 | 3.36 | 2.65 | 1.92 | 2.55 | 1.91 | 0.90 | 0.60 | 0.41 | 0.93 | 0.61 | 0.236 | <0.001 | 0.698 |

| Butanoic acid, ethyl ester | 850 | 71 | 10.68 | 11.53 | 9.61 | 11.64 | 11.15 | 14.04 | 8.08 | 8.05 | 12.13 | 12.72 | 1.017 | 0.956 | 0.753 |

| Butanoic acid, 2-methyl-, ethyl ester | 902 | 102 | 7.83 | 5.11 | 3.49 | 5.09 | 3.41 | 1.72 | 1.57 | 0.94 | 2.00 | 1.33 | 0.578 | 0.004 | 0.632 |

| Butanoic acid, 3-methyl-, ethyl ester | 906 | 88 | 15.81 | 9.00 | 7.01 | 9.89 | 6.78 | 3.08 | 3.53 | 1.93 | 3.49 | 2.31 | 1.147 | 0.004 | 0.642 |

| 1-Butanol, 3-methyl-, acetate | 932 | 70 | 0.63 | 0.43 | 0.41 | 0.41 | 0.93 | 0.65 | 0.50 | 0.43 | 0.70 | 0.59 | 0.049 | 0.938 | 0.191 |

| 1-Butanol, 2-methyl-, acetate | 935 | 70 | 0.25 | 0.08 | 0.09 | 0.11 | 0.21 | 0.03 | 0.06 | 0.07 | 0.03 | 0.02 | 0.014 | <0.001 | 0.508 |

| Hexanoic acid, ethyl ester | 1039 | 88 | 8.15 | 11.98 | 7.60 | 10.20 | 12.60 | 8.57 | 7.47 | 6.38 | 9.59 | 12.74 | 0.848 | 0.372 | 0.294 |

| Octanoic acid, ethyl ester | 1187 | 88 | 3.38 | 4.79 | 3.08 | 3.53 | 5.54 | 3.39 | 3.19 | 1.95 | 3.93 | 4.41 | 0.348 | 0.294 | 0.262 |

| Decanoic acid, ethyl ester | 1314 | 88 | 2.16 | 3.04 | 1.87 | 1.98 | 3.12 | 2.14 | 1.75 | 0.84 | 2.31 | 2.20 | 0.231 | 0.197 | 0.465 |

| TOTAL ESTERS | 63.92 | 58.97 | 43.93 | 57.80 | 58.88 | 40.42 | 31.25 | 23.83 | 39.81 | 42 | |||||

| Furan, 2-ethyl | 702 | 81 | 0.86 | 0.80 | 0.33 | 0.70 | 0.82 | 1.50 | 1.34 | 1.28 | 1.60 | 1.22 | 0.082 | <0.001 | 0.640 |

| 2-n-Butyl furan | 935 | 81 | 0.85 | 0.74 | 0.53 | 0.66 | 0.80 | 1.70 | 1.33 | 1.05 | 1.78 | 1.40 | 0.086 | <0.001 | 0.411 |

| Furan, 2-pentyl | 1026 | 81 | 8.27 | 7.25 | 5.11 | 7.48 | 7..92 | 10.00 | 9.30 | 6.80 | 10.64 | 9.49 | 0.781 | 0.207 | 0.696 |

| Furan, 2-propyl | 1078 | 81 | 0.17 | 0.15 | 0.14 | 0.14 | 0.26 | 1.83 | 1.72 | 1.62 | 2.46 | 2.49 | 0.098 | <0.001 | 0.410 |

| TOTAL FURAN | 10.15 | 8.94 | 6.11 | 8.98 | 9.80 | 15.03 | 13.69 | 10.75 | 16.48 | 14.60 | |||||

| Sulfide, allyl methyl | 699 | 88 | 8.03 | 4.91 | 7.04 | 11.53 | 3.39 | 6.27 | 4.52 | 5.40 | 3.38 | 3.70 | 0.967 | 0.253 | 0.644 |

| 1H-Pyrrole, 3-methyl | 792 | 81 | 0.13 | 0.14 | 0.09 | 0.13 | 0.12 | 0.17 | 0.16 | 0.21 | 0.13 | 0.10 | 0.009 | 0.089 | 0.555 |

| 1,3-Benzenediol, monobenzoate | 829 | 105 | 0.85 | 1.18 | 0.96 | 1.03 | 1.06 | 0.48 | 0.34 | 0.29 | 0.53 | 0.58 | 0.055 | <0.001 | 0.780 |

| Pyrazine, 2,6-dimethyl- | 969 | 108 | 2.64 | 2.51 | 2.23 | 2.64 | 1.80 | 2.66 | 1.65 | 2.37 | 2.02 | 1.42 | 0.227 | 0.486 | 0.664 |

| OTHERS COMPOUND | 11.65 | 8.74 | 10.32 | 15.33 | 6.37 | 9.58 | 6.67 | 8.27 | 6.06 | 5.80 | |||||

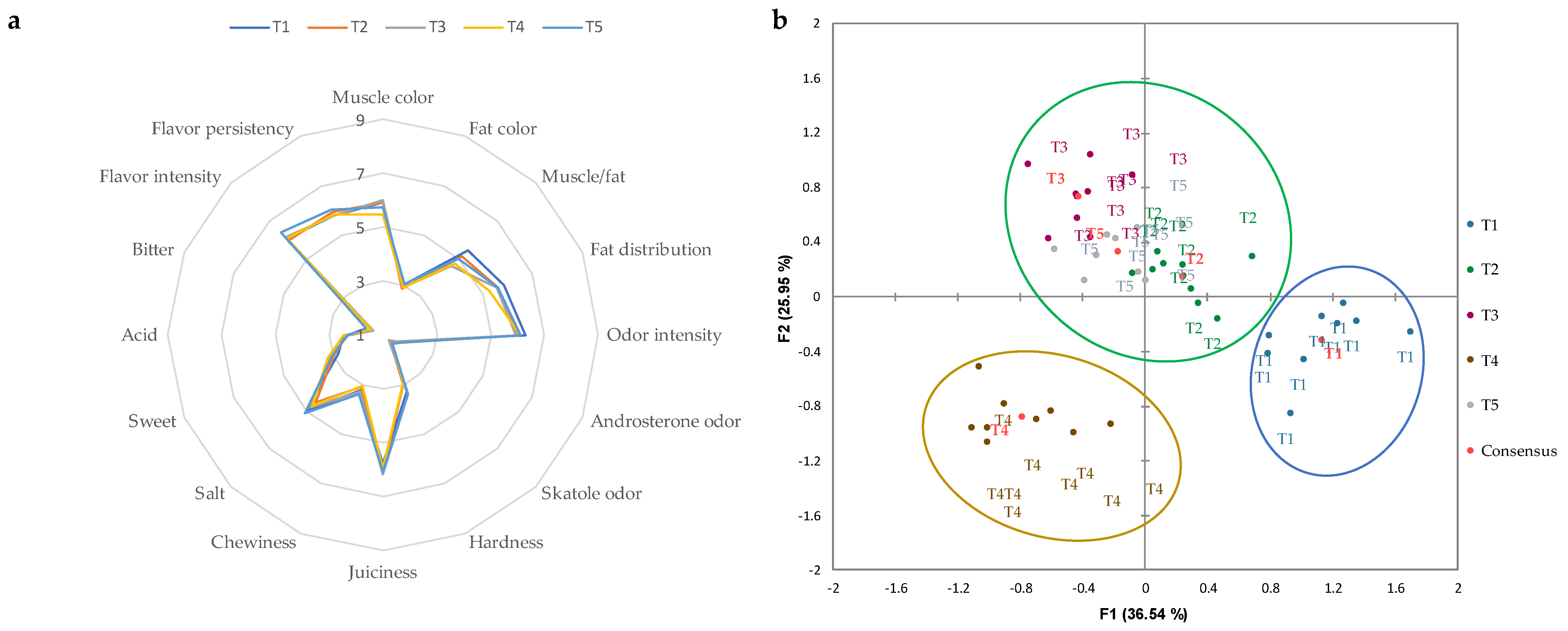

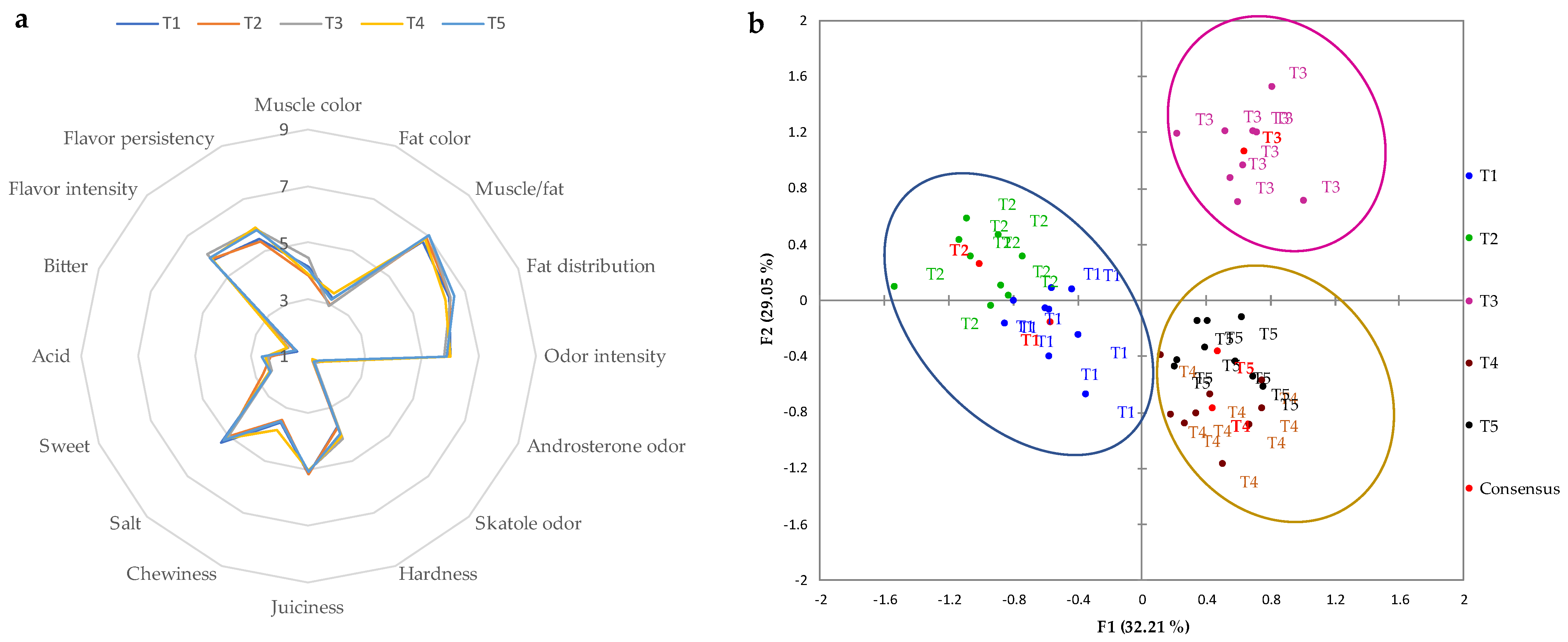

3.2. Sensory Characteristics

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Ramírez, R.; Cava, R. Volatile profiles of dry-cured meat products from three different Iberian X Duroc genotypes. J. Agric. Food Chem. 2007, 55, 1923–1931. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Purriños, L.; Pérez-Santaescolástica, C.; Pateiro, M.; Barba, J. F.; Tomasevic, I.; Bastianello-Campagnol, P. C.; Lorenzo, J. M. Caracterization of Volatile Compounds of dry-cured meat products using HS-SPME-GC/MS Techique. Food Analytical Methods. 2019, 12, 1263–1284. [Google Scholar] [CrossRef]

- Muriel, E.; Ruiz, J.; Martin, D.; Petron, M. J.; Antequera, T. Physico-chemical and sensory characteristics of dry-cured loin from different Iberian pig lines. Food Sci. Technol. Int. 2004, 10, 117–123. [Google Scholar] [CrossRef]

- Lorenzo, J. M. Influence of the type of fiber coating and extraction time on foal dry-cured loin volatile compounds extracted by solid-phase microextraction (SPME). Meat Science. 2014, 96, 179–186. [Google Scholar] [CrossRef] [PubMed]

- López-Salas, L.; Cea, I.; Borrás-Linares, I.; Emanuelli, T.; Robert, P.; Segura-Carretero, A.; Lozano-Sánchez, J. Preliminary investigation of different drying systems to preserve hydroxytyrosol and its derivatives in olive oil filter cake pressurized liquid extracts. Foods. 2021, 10, 1407. [Google Scholar] [CrossRef] [PubMed]

- Chraibi, H.; El Abbassi, F. E.; Sakami, S.; Kchikach, A. Investigation on the use of co-products from olive oil industry in earth bricks. Materials Today: proceedings. 2022, 58, 1044–1048. [Google Scholar] [CrossRef]

- Lorenzo, J.M.; Carballo, J.; Franco, D. Effect of the inclusion of chestnut in the finishing diet on volatile compounds of dry-cured ham from celta big breed. Journal of Integrative Agriculture. 2013, 12, 2002–2012. [Google Scholar] [CrossRef]

- Gravador, R. S.; Serra, A.; Luciano, G.; Pennisi, P.; Vasta, V.; Mele, M.; Pauselli, M.; Priolo, A. Volatiles in raw and cooked meat from lambs fed olive cake and linseed. Animal. 2015, 9, 715–722. [Google Scholar] [CrossRef]

- Leite, A.; Domínguez, R.; Vasconcelos, L.; Ferreira, I.; Pereira, E.; Pinheiro, V.; Outor-Monteiro, D.; Rodrigues, S.; Lorenzo, J.M. : Santos, E.M.; Andrés, S.C.; Campagnol, P, C, B.; Teixeira, A. Can the introduction of different olive cakes affect the carcass meat and fat quality of Bísaro pork? Foods, 2022, 11, 1165. [Google Scholar] [CrossRef]

- Álvarez-Rodriguez, J.; Teixeira, A. Slaughter weight rather than sex affects carcass cuts and tissue composition of Bísaro pigs. Meat Sci, 2019, 154, 54–60. [Google Scholar] [CrossRef]

- Council Regulation (EC) – Official Journal of the European Communities No 1099/2009 of 24 September 2009 on the protection of animals at the time of killing. 2009, 1–30.

- Leite, A.; Vasconcelos, L.; Ferreira, I.; Domínguez, R.; Pereira, E.; Rodrigues, S.; Lorenzo, J. M.; Teixeira, A. Effect of the inclusion of olive cake in the diet on the physicochemical characteristics of dry-cured loin and dry-cured “cachaço” of Bísaro pig. Applied Sci. 2023, 13, 1439. [Google Scholar] [CrossRef]

- NP EN ISO 8586:2014. Sensory Analysis—General Guidelines for the Selection, Training and Monitoring of Selected Assessors and Expert Sensory Assessors; Instituto Português da Qualidade, Ministério da Economia e Inovação: Caparica, Portugal, 2014. [Google Scholar]

- International Organization for Standardization UNE-EN ISO 8589:2010/A1:2014 Sensory analysis—General guidance for the design of test rooms.

- Soto, E.; Hoz, L.; Ordóñez, J.A.; Hierro, E.; Herranz, B.; López-Bote, C.; Cambero, M.I. Impact of feeding and rearing systems of Iberian pigs on volatile profile and sensory characteristics of dry-cured loin. Meat Sci. 2008, 79, 666–676. [Google Scholar] [CrossRef] [PubMed]

- Yu, A. N.; Sun, B.G.; Tian, D.T.; Qu, W.Y. Analysis of volatile compounds in traditional smoke-cured Bacon (CSCB) with different fiber coatings using SPME. Food Chemistry. 2008, 110, 233–238. [Google Scholar] [CrossRef] [PubMed]

- Domínguez, R.; Pateiro, M.; Gagaoua, M.; Barba, F.J.; Zhang, W.; Lorenzo, J. M. A comprehensive review on lipid oxidation in meat and meat products. Antioxidants. 2019, 8, 429. [Google Scholar] [CrossRef] [PubMed]

- Narváez-Rivas, M.; Gallardo, E.; León-Camacho, M. Analysis of volatile compounds from Iberian hams. Meat Sci. 2010, 85, 256–264. [Google Scholar]

- Górska, E.; Nowicka, K.; Jaworska, D.; Prybylski, W.; Tambor, K. Relationship between sensory attributes and volatile compounds of polish dry-cured loin. Asian-Australas J. Anim. Sci. 2017, 30, 720–727. [Google Scholar] [CrossRef]

- Vargas-Ramella, M.; Munekata, P. E. S.; Gagaoua, M.; Franco, D.; Campagnol, P.C.B.; Pateiro, M.; Barreto, A.C.S.; Domínguez, R.; Lorenzo, J.M. Inclusion of Healthy oils for improving the nutritional characteristics of dry-fermented deer sausage. Foods. 2020, 9, 1487. [Google Scholar] [CrossRef]

- Marušić, N.; Petrović, M.; Vidaček, S.; Petrak, T.; Medić, H. Characterization of traditional Istrian dry-cured ham by means of physical and chemical analyses and volatile compounds. Meat Sci. 2011, 88, 786–790. [Google Scholar] [CrossRef] [PubMed]

- Hierro, E.; De la Hoz, L.; Ordónez, A. Headspace volatile compounds from salted and occasionally smoked dried meats (cecinas) as affected by animal species. Food Chemistry. 2004, 85, 649–657. [Google Scholar] [CrossRef]

- Olivares, A. , Navarro, J.L.; Flores, M. Establishment of the contribution of volatile compounds to the aroma of fermented sausages at different stages of processing and storage. Food Chemistry. 2009, 115, 1464–1472. [Google Scholar] [CrossRef]

- Sánchez-Peña, C.M.; Luna, G.; García-González, D.L.; Aparicio, R. Characterization of French and Spanish dry-cured hams: influence of the volatiles from the muscles and the subcutaneous fat quantified by SPME-GC. Meat Sci. 2005, 69, 635–645. [Google Scholar] [CrossRef] [PubMed]

- Bis-Souza, C.V.; Pateiro, M.; Domínguez, R.; Lorenzo, J.M.; Penna, A.L.B.; da Silva Barreto, A.C. Volatile profile of fermented sausages with commercial probiotic strains and fructooligosaccharides. J. Food Sci. Technol. 2009, 56, 5465–5473. [Google Scholar] [CrossRef] [PubMed]

- Muriel, E.; Antequera, T.; Petrón, M.J.; Andrés, A.I.; Ruiz, J. Volatile compounds in Iberian dry-cured loin. Meat Sci. 2004, 68, 391–400. [Google Scholar] [CrossRef] [PubMed]

- Lorenzo, J.M.; Gómez, M.; Purriños, L.; Fonseca, S. Effect of commercial starter cultures on volatile compound profile and sensory characteristics of dry-cured foal sausage. J. Sci. Food Agric. 2016, 96, 1194–1201. [Google Scholar] [CrossRef]

- Andrade, M.J.; Córdoba, J.J.; Casado, E.M.; Córdoba, M.G.; Rodríguez, M. Effect of selected strains of Debaryomyces hansenii on the volatile compound production of dry fermented sausage “salchichón”. Meat Sci. 2010, 85, 256–264. [Google Scholar] [CrossRef]

- Nárváez-Rivas, M.; Vicario, I.M. , Alcade, M.J.; León-Camacho, M. Volatile hydrocarbon profile of Iberian dry-cured hams. A possible tool for authentication of hams according to the fattening diet. Talanta. 2010, 81, 1224–1228. [Google Scholar] [CrossRef]

- Martín, A.; Córdoba, J.J.; Aranda, E.; Córdoba, M.G.; Asensio, M.A. Contribution of a selected fungal population to the volatile compounds on dry-cured ham. Int J Food Microbiol. 2006, 110, 8–18. [Google Scholar] [CrossRef]

- Pérez-Santaescolástica, C.; Carballo, J.; Fulladosa, E.; Garcia-Perez, J.V.; Benedito, J.; Lorenzo, J.M. Effect of proteolysis index level on instrumental adhesiveness, free amino acids content and volatile compounds profile of dry-cured ham. Food Res Int. 2018, 107, 559–566. [Google Scholar] [CrossRef]

- Sidira, M.; Kandylis, P.; Kanellaki, M.; Kourkoutas, Y. Effect of immobilized Lactobacillus casei on volatile compounds of heat treated probiotic dry-fermented sausages. Food Chem. 2015, 178, 201–207. [Google Scholar] [CrossRef] [PubMed]

- García-González, D. L.; Tena, N.; Aparicio-Ruiz, R.; Morales, M.T. Relationship between sensory attributes and volatile compounds qualifying dry-cured hams. Meat Sci. 2008, 80, 315–325. [Google Scholar] [CrossRef] [PubMed]

- Petričević, S.; Radovčić, N.M.; Lukić, K.; Listeš, E.; Medić, H. Differentiation of dry-cured hams from different processing methods by means of volatile compounds, physico-chemical and sensory analysis. Meat Sci. 2018, 137, 217–227. [Google Scholar] [CrossRef] [PubMed]

- Marco, A.; Navarro, J.L.; Flores, M. The sensory quality of dry fermented sausages as affected by fermentation stage and curing agents. Eur. Food Res. Technol. 2008, 226, 449–458. [Google Scholar] [CrossRef]

- Akköse, A.; Ünal, N.; Yahnkrhç, B.; Kaban, g.; Kaya, M. Volatile compounds and some physico-chemical properties of pastirma produced with different nitrate levels. Asian-Austral. J. Anim. 2017, 30, 1168–1174. [Google Scholar] [CrossRef]

- Ruiz, J.; Ventanas, J.; Cava, R.; Andres, A.; Garcia, C. Volatile compounds of dry-cured Iberian ham as affected by the length of the curing process. Meat Sci. 1999, 52, 19–27. [Google Scholar] [CrossRef] [PubMed]

- Ansorena, D.; Gimeno, O.; Astiasaran, I.; Bello, J. Analysis of volatile compounds by GC–MS of a dry fermented sausage: chorizo de Pamplona. Food Res Int. 2001, 34, 67–75. [Google Scholar] [CrossRef]

- Fortin, A.; Robertson, W. M.; Tong, A.K.W. The eating quality of Canadian pork and its relationship with intramuscular fat. Meat Science. 2005, 69, 297–305. [Google Scholar] [CrossRef] [PubMed]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).