1. Introduction

Conventional, rigid-bodied robots are extensively used in manufacturing and can be specifically programmed to perform a single task efficiently, but often with limited adaptability. Because they are built of rigid links and joints, they are unsafe for interaction with humans [

1]. Soft robots are mostly processed with soft materials. Compared with rigid robots, the degrees of freedom are highly redundant, the motion is more flexible, and it can change its form actively or passively according to the surrounding environment. This greatly compensates for the shortcomings of rigid robots and pushes the design, modeling, control, and application of robots to a higher platform [

2]. In recent years, soft robotics has developed rapidly due to its inherent flexibility, versatile morphology, and wide range of use cases [

3,

4,

5,

6]. For example, the robotic gripper, as an end-effector, can easily cause deformation of the object's structure when faced with smooth surfaces or fragile or small objects, as the size of the rigid gripper's gripping force is difficult to control precisely. The flexible gripper is highly flexible due to its soft material, making it more precise and safer when gripping objects [

7,

8,

9,

10,

11,

12].

In addition, soft robots have many advantages: (1) Soft robots are soft and easily deformable due to the soft materials they use. They can be deformed to varying degrees under different driving methods [

13,

14,

15,

16,

17,

18,

19]. (2) The soft material can increase the contact area with the object through its deformation, making it more adaptable to different industrial environments. (3) The soft robot can be controlled by software to connect the human to the object, and its softness makes it safe for interaction [

20,

21,

22,

23]. Flexible grippers are already in use in industry, but even within the same application, the requirements for performing functions vary and change. The traditional concept of a rigid mechanical gripper is to design a fully functional mechanical gripper directly to meet the requirements. This is a simpler design concept, but it has the disadvantage that when the target object is changed in size or the twist angle needs to be changed, a new rigid gripper is required to meet the requirements. Suppose the soft twist gripper is broken down into different single-functional modules. In that case, the soft gripper, by combining different functional modules, will completely avoid the disadvantages of the traditional design model. The speed of replacement and customization flexibility will be greatly enhanced in the real world of industrial production.

Calisti et al. designed a pull-wire-driven soft gripper imitating an octopus tentacle that is capable of grasping pencils and screws by winding them [

24]. Ilievski et al. developed a pneumatic multi-cavity soft starfish gripper with high adaptivity that can effectively envelop and grip objects, but the contact force between the gripper and the object is small and the stability when gripping the object is not enough [

25]. Manti et al. designed a soft-body manipulator with good adaptability and capable of non-destructive grasping. It is capable of grasping fragile objects without damage but is unable to perform the twisting function at the same time [

26]. Chen et al. at Michigan State University produced a wire-driven three-finger soft gripper, which is made of silicone material with a friction generator attached to the surface to achieve self-sensing, and the gripper is capable of grasping different objects by pulling the wire drive during the grasping process [

27].

Different from articulated objects constructed by rigid parts linked with discrete joints, soft pneumatic objects are composed of soft materials and embedded chambers [

28]. One practical application of soft robots is to pick up and place objects in unknown environments [

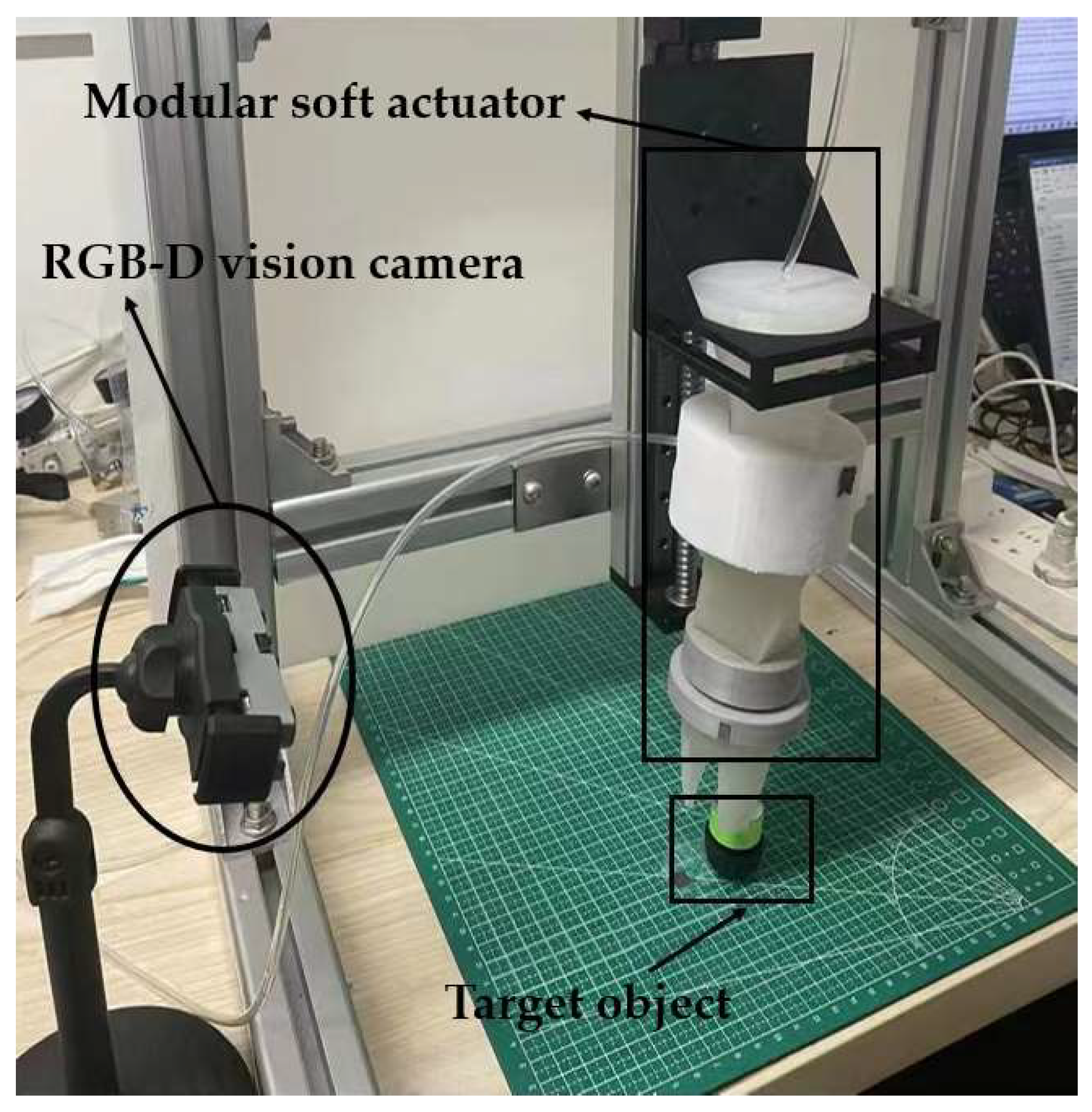

29]. This article presents the design of a modular soft twist gripper that can be quickly assembled and disassembled. The grippers in this paper can be twisted as a whole, and the angle of twisting can be precisely controlled by using different modules. As shown in

Figure 1. The twisting and gripping functions are implemented in the diagram through a twisting actuator and a gripping actuator, respectively. Torsional actuators can be divided into positive quadrilateral and positive pentagonal torsional actuators. The gripping actuators are three-finger gripping actuators. All soft actuator modules are assembled quickly via a dedicated assembly interface. When faced with different torsion angles and gripping requirements, the soft actuator modules can be quickly disassembled and adapted to the actual requirements.

The modular design of the flexible torsion gripper is divided into two modules: the torsion module and the gripping module. The torsion module has two torsion actuators: positive quadrilateral and positive pentagonal. The two actuators' angles and torsion forces are different and can be used for different applications.

The torsional actuator can perform superimposed movements of linear and torsional motion, which allows it to be seen as a modular unit. When two modular units are combined, several different forms of motion can be formed by the difference between the initial and end states of two modular units. Connecting the bottom and top surfaces together is possible to achieve similar functions. Combining torsional actuators to form different forms of motion makes it possible to use the modular soft gripper in various combinations of modular configurations, preparing it for use in different industrial environments.

3. Results and Discussion

3.1. Control Performance Analysis Experiment of Soft Actuator

3.1.1. Torque Measurement Experiment

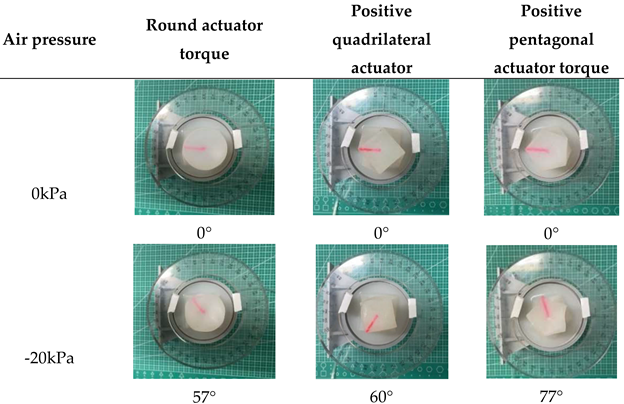

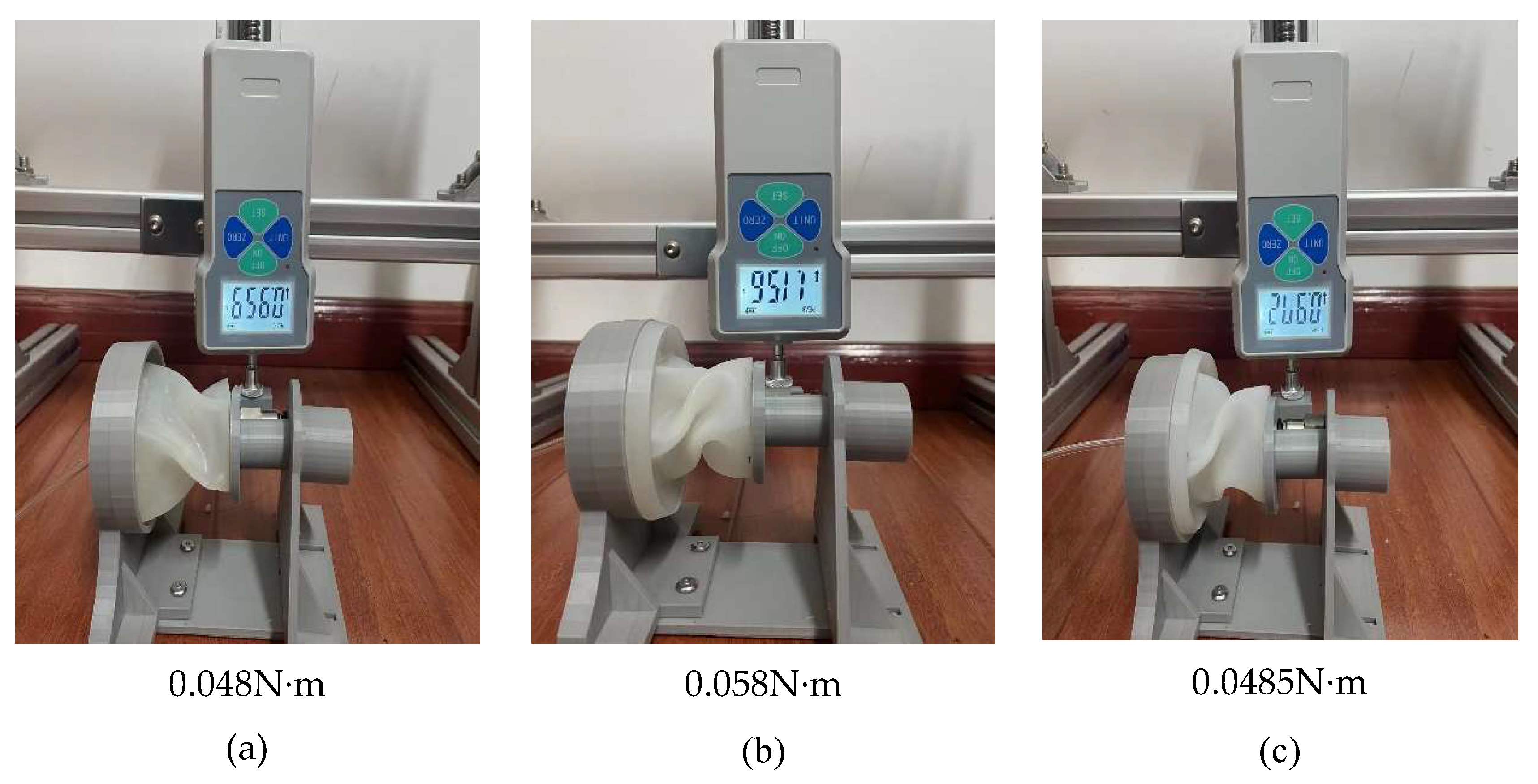

When measuring the torque characteristics, the initial angle of the torsion module was preset at a torsion angle of 0° and the negative pressure was gradually increased. Through multiple measurements for the average, the experimental data results are shown in

Table 4.

Torsional actuator with different base shapes - 70 kPa torque measurement as shown in

Figure 15.

3.1.2. Torsional Angle Measurement Experiment

After placing the flexible torsion module in the middle of the measuring platform, the air pressure input to the actuator is controlled by turning the regulator valve. The initial angle of the torsion actuator was preset at 0º and the negative pressure was gradually increased to measure the angle of the torsion actuator at 10kPa intervals. The data was averaged over several measurements and measured for each of the three different bottom surfaces of the torsion actuator. The table shows that the torsional angle of the torsional actuator differs for the three different shapes of the bottom surface when the same negative pressure is applied. The maximum torsion angle for the quadrilateral base actuator is 78°, the maximum torsion angle for the pentagonal base actuator is 90° and the maximum torsion angle for the circular base actuator is 73°. The three actuators have a large variation in torsional angle from 0 to -10 kPa, a gentle variation in torsional angle from -10 kPa to -50 kPa and a maximum torsional angle at the same time at -50 kPa.

Table 5.

Torsional angle-pressure diagram for torsional actuators with different base shapes.

Table 5.

Torsional angle-pressure diagram for torsional actuators with different base shapes.

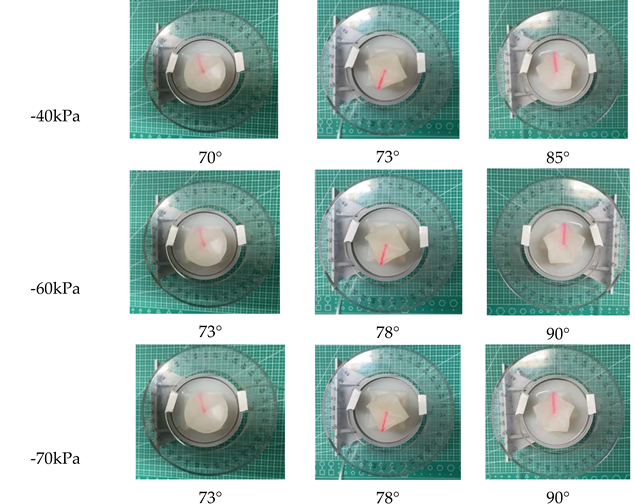

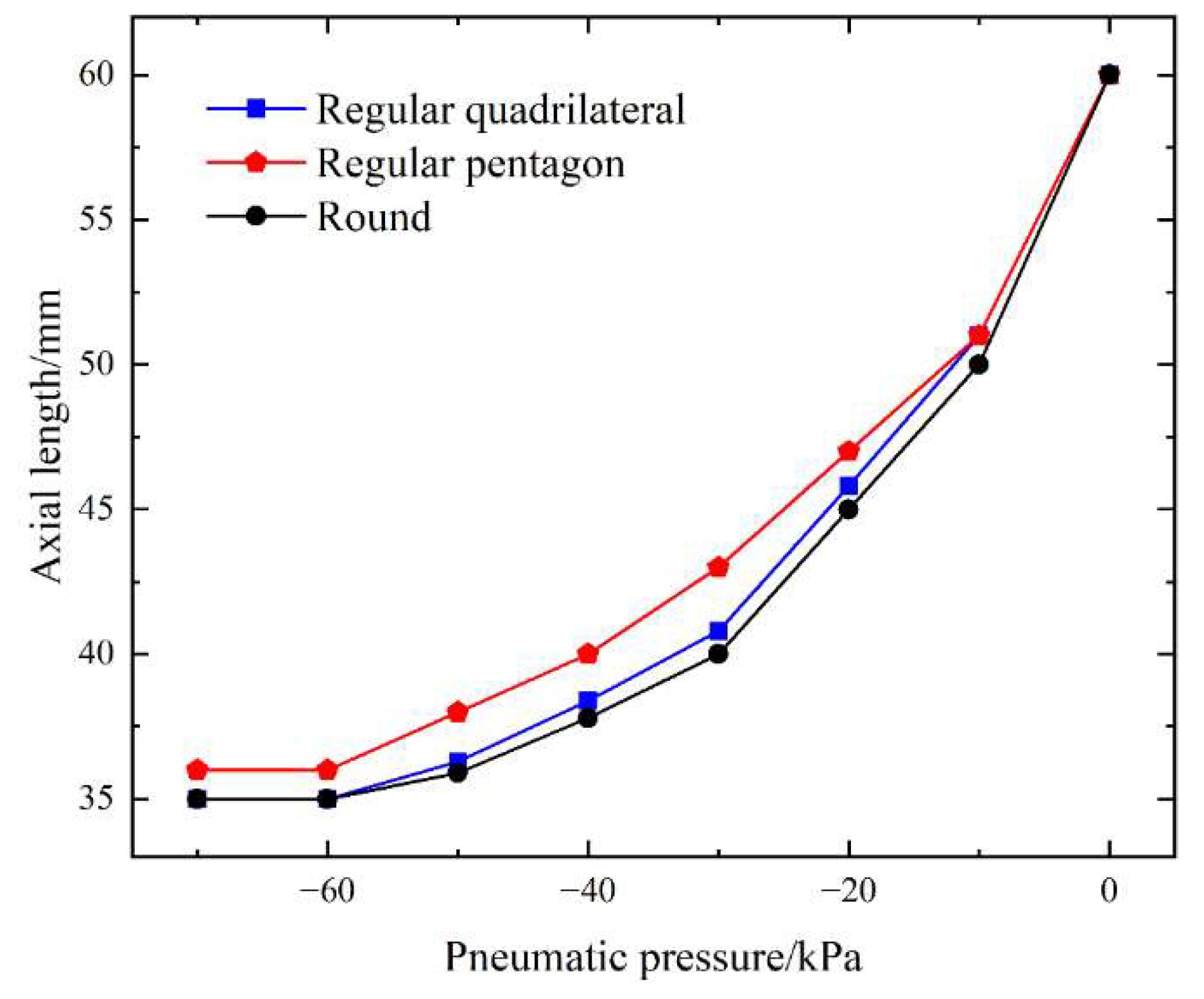

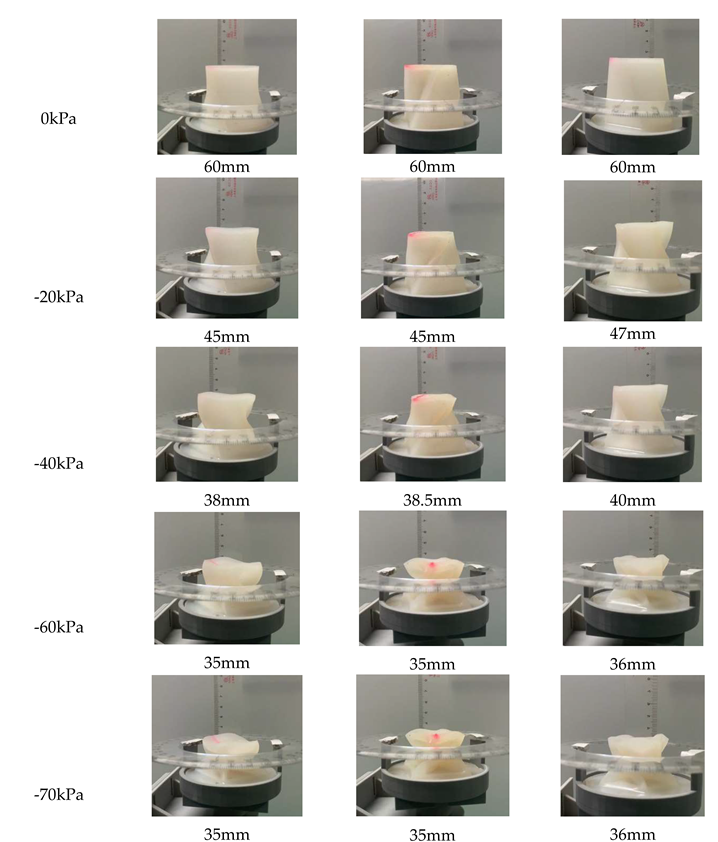

3.1.3. Experimental Measurement of Axial Length Variation of Flexible Torsional Actuators

In the process of torsional actuator contraction torsion, the inclined plane of the actuator tilts and collapses inward, resulting in the axial contraction of the actuator. Therefore, the torsional actuator will perform two kinds of motion, linear motion and torsional motion, under the drive of negative pressure. This measurement experiment will measure the axial length change of the actuator with different shapes in the torsional process, and calculate the average value through multiple measurements. The data of three torsional actuators with different bottom surfaces were measured respectively to obtain

Table 6 and

Figure 16.

It can be seen from

Figure 16 that under negative pressure of 0kPa~-70kPa, torsional actuators with different bottom surfaces have little difference in their axial lengths, because torsional actuators with regular quadrilateral and circular bottom surfaces have the same number of supporting axes, which makes their axial length change curves almost the same with only slight differences. Compared with the regular quadrilateral and circular bottom surface, the regular pentagonal torsional actuator has an extra axis on the side, making its final axial length 2mm longer than the other two.

Table 6.

Axial length-pressure diagram of torsion actuator with different bottom shapes.

Table 6.

Axial length-pressure diagram of torsion actuator with different bottom shapes.

| Air pressure |

Circular actuator |

Regular quadrilateral actuator |

Regular pentagon actuator |

|

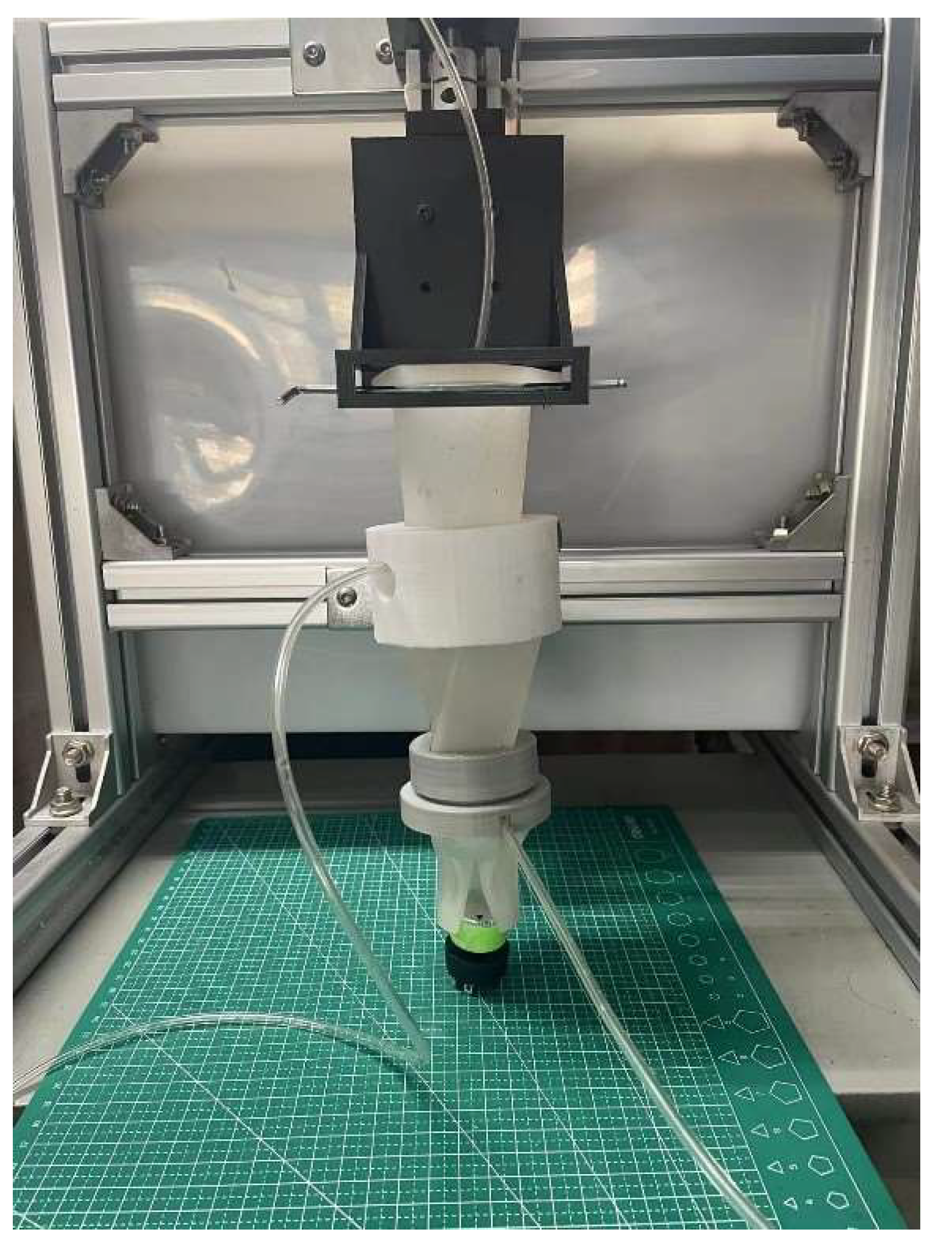

3.2. Software Torsion Gripper System Overall Experiment

(1) Grab actuator grab experiment

The gripper grasps the target as shown in

Figure 17. The conditions for success of its grasping action are as follows: no falling occurs in the process of effectively grasping objects. As shown in the following picture, the captured items are USB flash drive (9g), circular industrial switch (31g), L-shaped Allen wrench (13g), and quail egg (11g). The software gripper simulates grabbing objects, as shown in

Figure 18.

The measurement of the gripping efficiency of the soft gripping actuator is guided by the "Standard Test Method for Responsive Robots". The objective is to capture statistically significant functional data according to the standard test method. Through many experiments, it can be concluded that, first, the soft body is more stable when grasping cylindrical objects. The reason is that when the three knuckles are bent, the surface is in an arc state, forming an enveloping structure for the objects, which can grasp the target objects more stably. When the soft grasp actuator grabs fragile objects on the surface, such as quail eggs, because the silicone rubber material is soft, the finger cavity of the soft grasp can adaptively change the current state according to the shape of the object when grasping the object, so that it is completely fitted to the surface of the target object, so it is suitable for grasping fragile and fragile objects on the surface. At the same time, due to the structure of the front end of the finger cavity, it is found in the experiment that the soft body is easy to fall when grasping small objects such as L-shaped wrench.

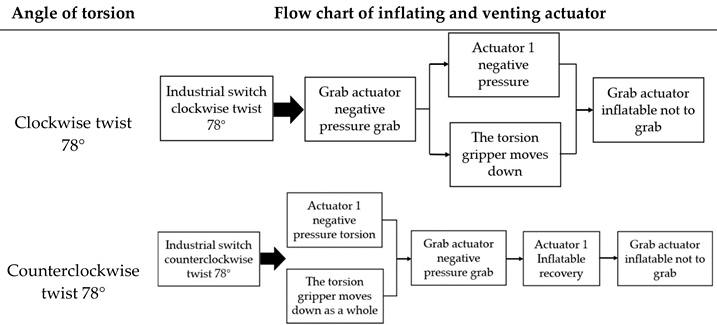

(2) Torsional grab experiment

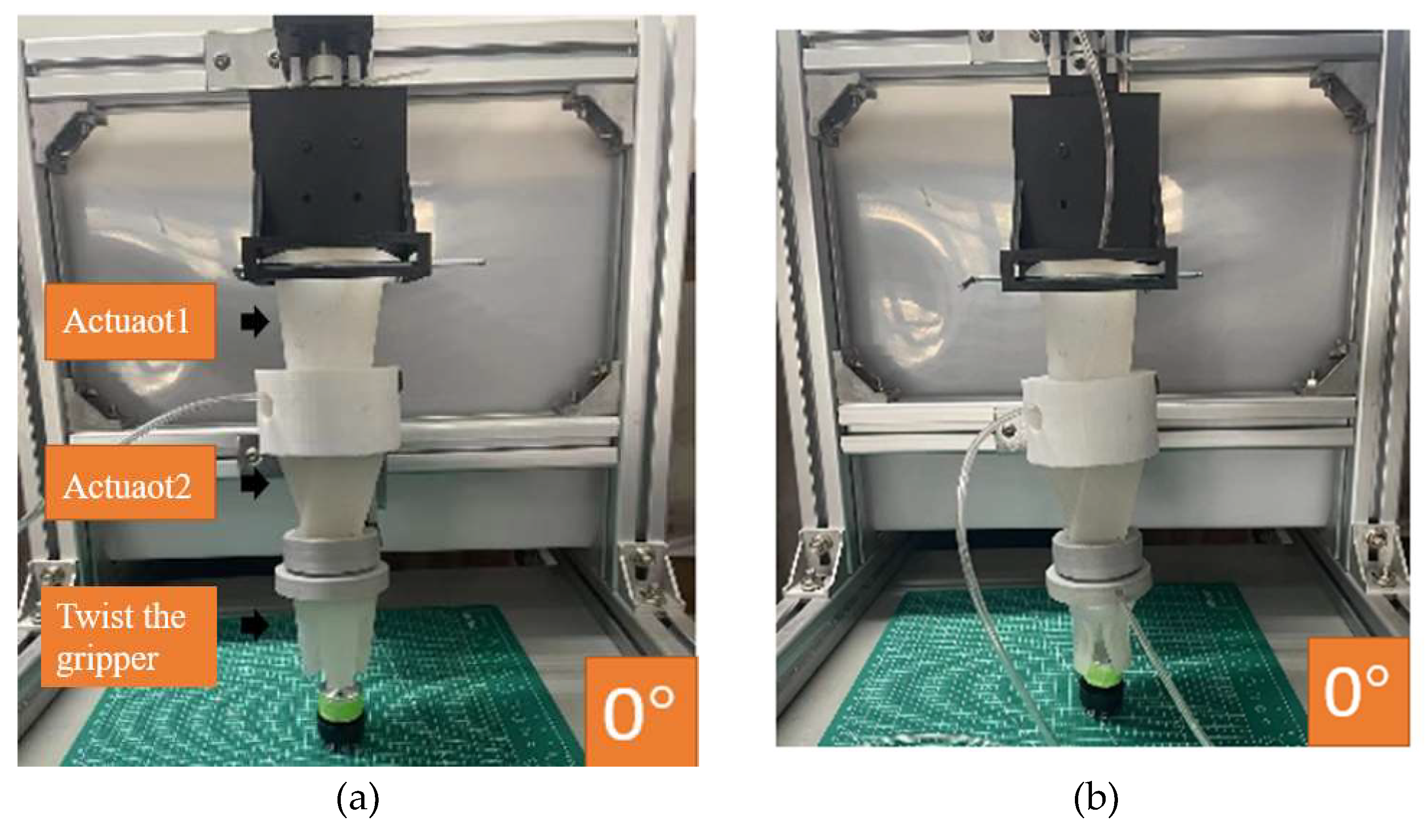

In this experiment, the platform will be built in the form of the second modular combination, to control the torsional actuator 1, torsional actuator 2, grab the actuator suction and ventilation, to achieve the industrial switch torsion -78°~78°. The experimental diagram of this experiment is shown in

Figure 19.

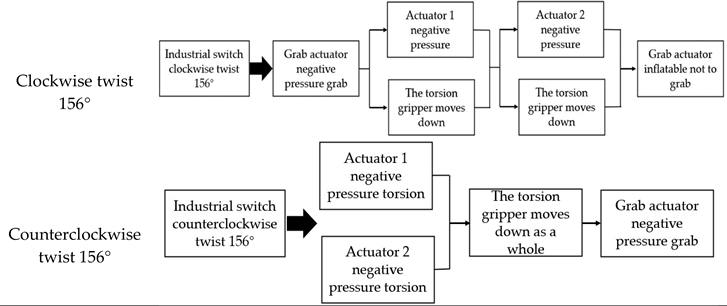

In this experiment, the industrial switch will be twisted through the aspiration and inflation of torsional actuator 1 and torsional actuator 2. The flow chart of the control system is shown in

Table 7.

It can be seen from above that the torsional Angle of the regular quadrilateral torsional actuator is 78° and its axial length is 35mm under the pressure of -70kPa. Therefore, in the process of torsion, a single torsion actuator will be accompanied by a 25mm height expansion. Therefore, in the process of torsion of the actuator, the grip should be moved down a certain distance as a whole.

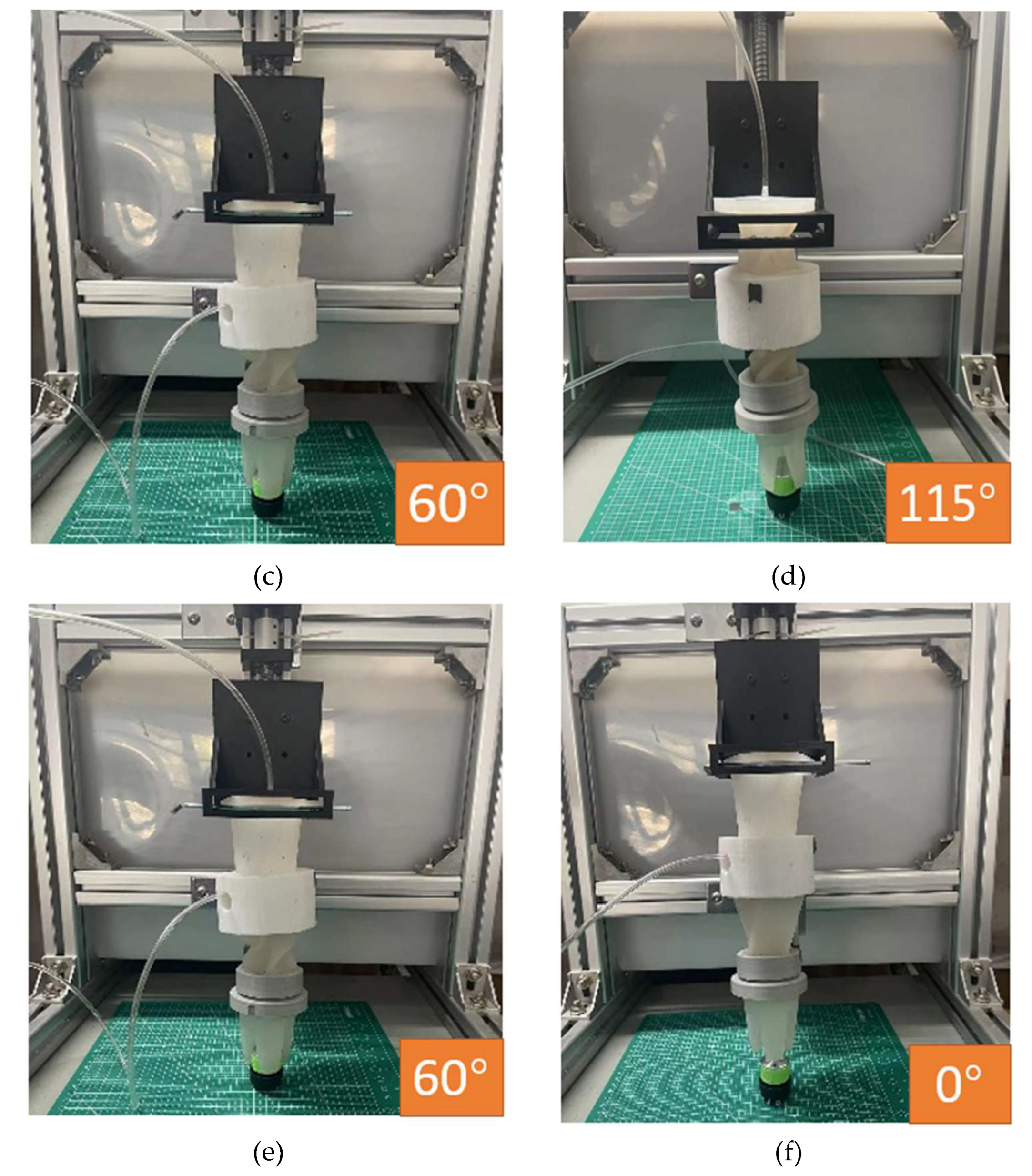

(3) Industrial switch torsion experiment

After analyzing the inflating and venting sequence of each module, the industrial switch will be tested for clockwise and counterclockwise torsion. This experiment will measure the maximum torsion Angle of the soft gripper to the industrial switch in practice, and analyze whether there is any error between the actual torsion Angle and the theoretical torsion Angle, and analyze and optimize the error. The experimental process is shown in

Figure 20.

The measured torsion Angle of the actual industrial switch is 60° when driving actuator 1, and 115° when driving actuator 1 and actuator 2. The reasons why the theoretical torsion Angle is smaller than the torsion Angle of the actuator are as follows: ① There is relative sliding between the grasping actuator and the industrial switch in the torsion process; ② Due to the weight of the actuator quick assembly interface, the actual torsion Angle of the actuator is less than 78°; ③ There are errors in the positioning process of soft actuator. The reason why the torsion Angle of actuator 2 is smaller than that of actuator 1 is that the gravity of actuator 2 is greater than that of actuator 1, so the torsion Angle is smaller than that of actuator 1.

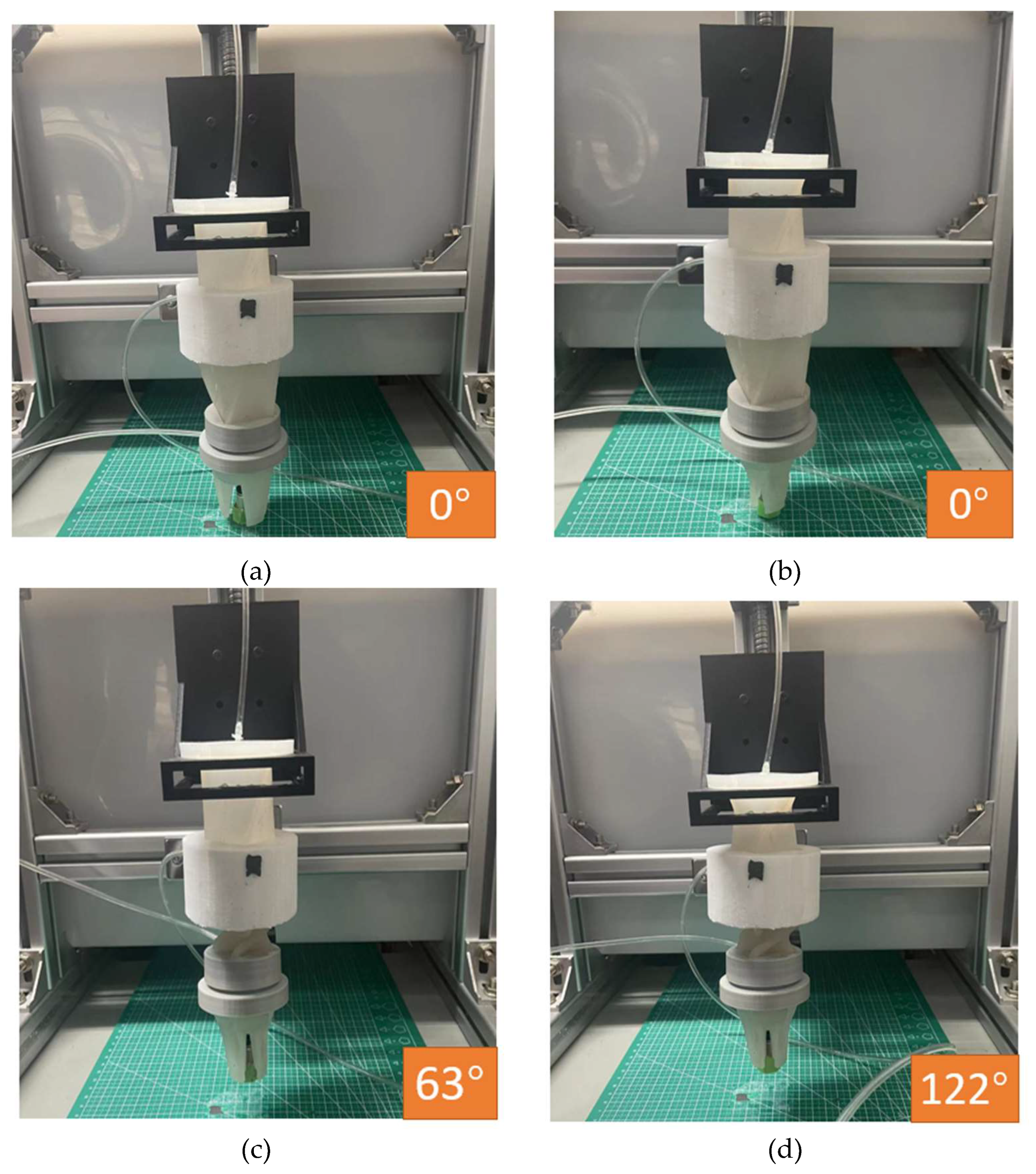

(4) The experiment of torsional objects stuck in space

This experiment will simulate the Angle adjustment of the workpiece in assembly line production, and the process of Angle adjustment of the workpiece is shown in

Figure 21.

It is measured that the actual torsion Angle of the workpiece is 63° when only actuator 1 is driven. When actuator 1 and actuator 2 are driven, the actual torsion Angle is 122°. After analysis, the actual torsion Angle is smaller than the theoretical Angle for the following reasons: (1) The weight of the workpiece and the interface offset a part of the torsion Angle; (2) There are errors in the positioning of the actuator.

To solve the above problems, if the actuator can be accurately moved to the industrial switch center, the torsion Angle will be increased. After that, the RGB-D visual algorithm is used to identify and determine the position of the industrial switch, and the positioning accuracy of the industrial switch is optimized through continuous comparison practice, so that the software gripper can move to the top of the target industrial switch center more precisely, and the deviation of the torsion Angle caused by inaccurate positioning is eliminated. After continuous grasping practice, the positioning error of the soft actuator in the left and right direction of the industrial switch was reduced to 1mm, and the torsion Angle of the industrial switch was also increased from 60° to 70°.

4. Conclusions

A modular software torsion grasping system is designed that can assemble actuators by modular assembly and make up for the shortcomings of traditional software grippers in torsion function. The actuating principle of the two actuators is explained, and the relevant parameters that may affect the actuating performance of the actuators are analyzed by using ABAQUS as the simulation platform. Combined with the results of the simulation experiment, the optimal structural design parameters of the torsional actuator and grasping actuator were optimized to improve the performance of the actuator.

In the actual torsion process, due to the sliding between the grasping actuator and the industrial switch and the weight of the quick assembly interface of the actuator, the actual torsion angle of the actuator is less than 78°, and the actual torsion angle is 60°. Then use the RGB-D visual algorithm to continuously compare and practice to optimize the gripper positioning so that the twist angle can be increased to 70°, which can meet the angle requirements of twisting the target item.

This paper introduces and uses the RGB-D algorithm to optimize the grasping process of the soft torsion gripper and the grasping accuracy of the soft torsion gripper when facing the target object by combining it with continuous contrast training. The actuating performance of the manufactured soft actuator samples with different bottom surfaces was tested on the test platform. A modular torsional grasping experimental test platform was built to test the torsional angle of the modular torsional gripper in the actual grasping process, and the grasping accuracy was optimized by the RGB-D algorithm, achieving a torsional angle of 70° for the single torsional actuator.

Figure 1.

Schematic diagram of the modular design of the flexible torsion gripper.

Figure 1.

Schematic diagram of the modular design of the flexible torsion gripper.

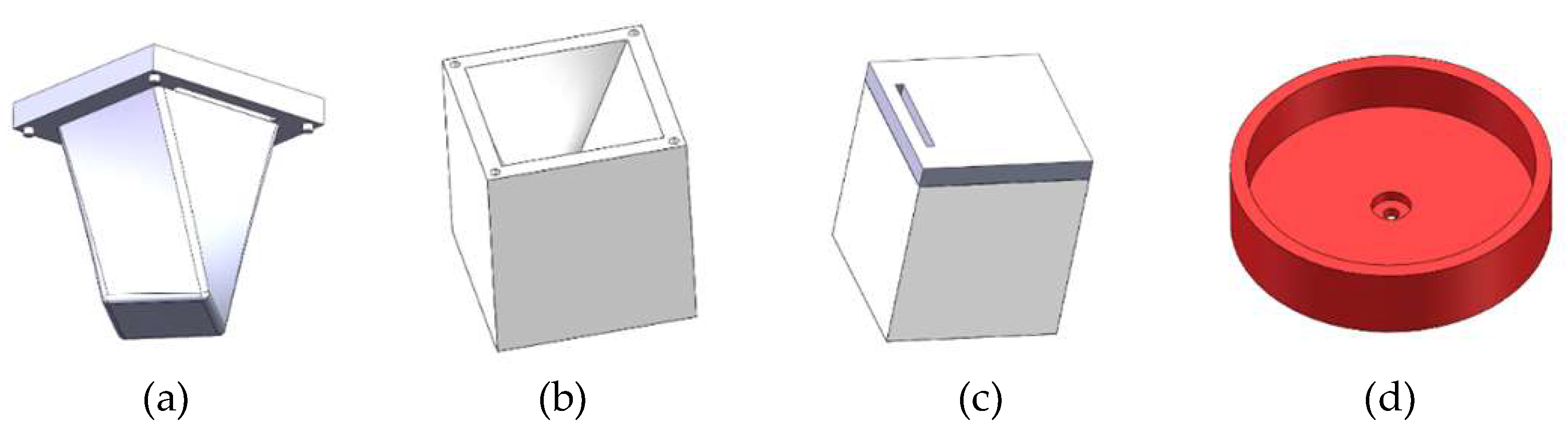

Figure 2.

Positive quadrilateral soft torsion actuator mould. (a) Upper mould A, (b) Lower mould B, (c) Integral mould, (d) Pouring mould.

Figure 2.

Positive quadrilateral soft torsion actuator mould. (a) Upper mould A, (b) Lower mould B, (c) Integral mould, (d) Pouring mould.

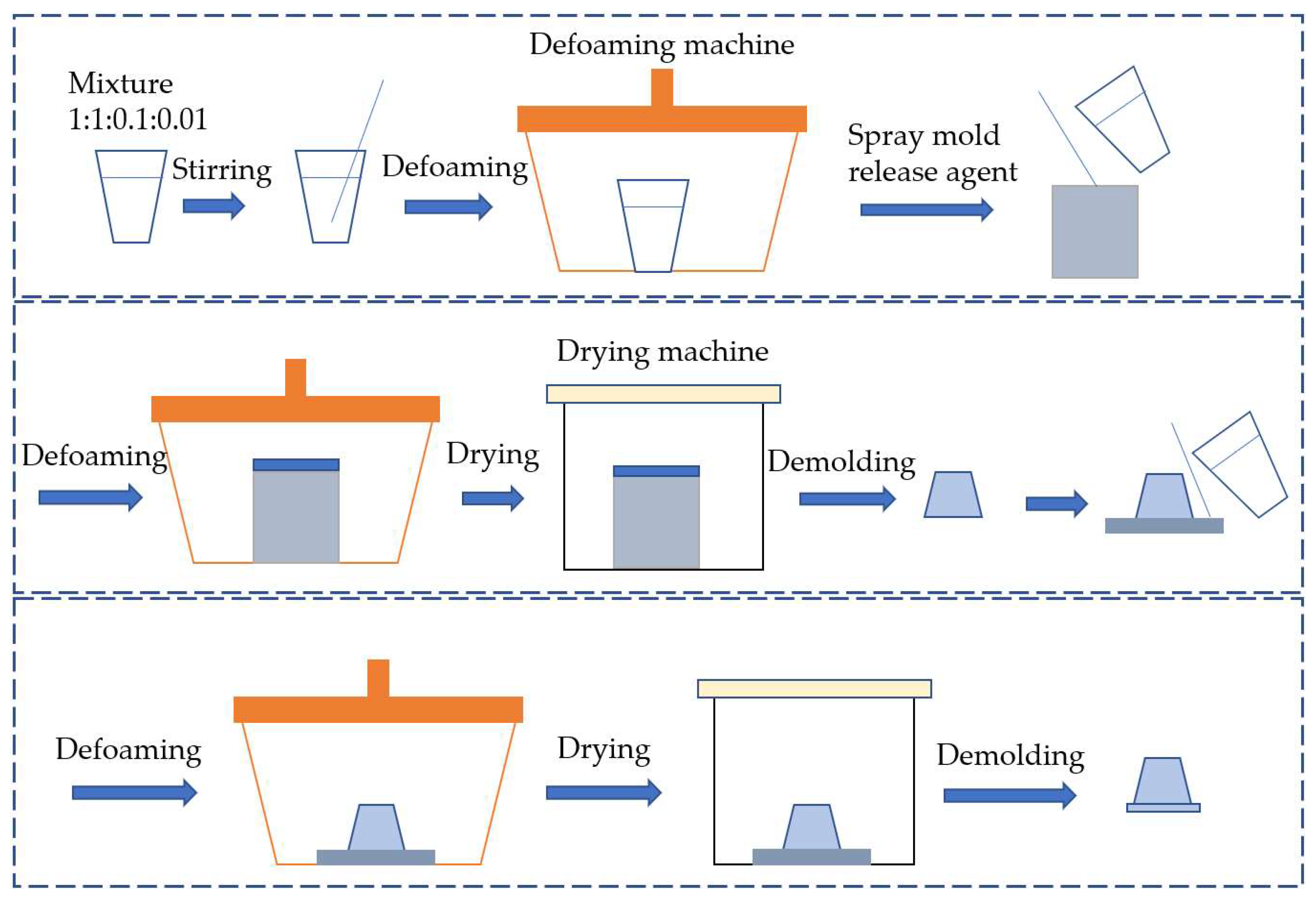

Figure 3.

Manufacturing process of torsional actuator.

Figure 3.

Manufacturing process of torsional actuator.

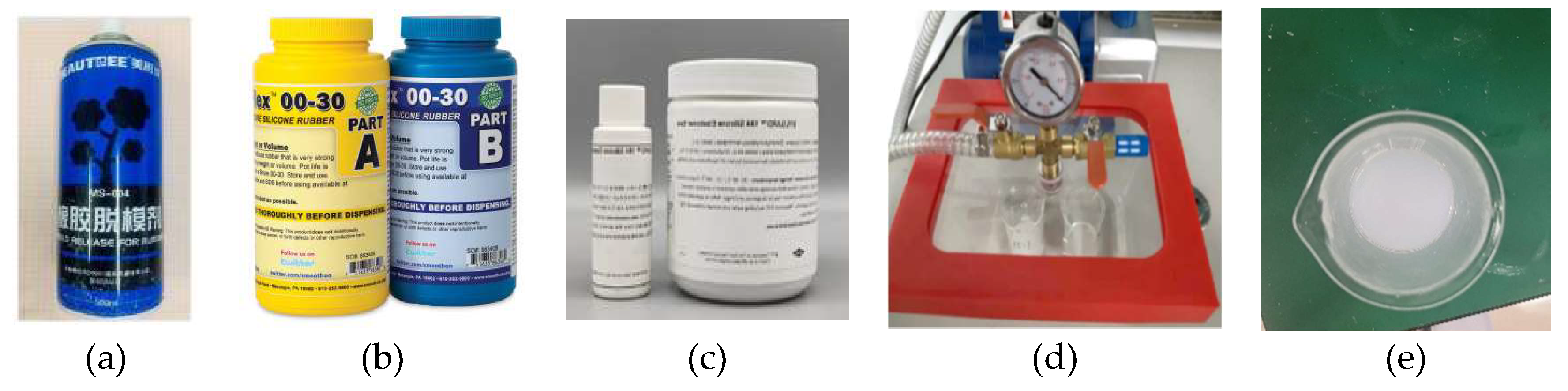

Figure 4.

Pre-preparation work for a flexible torsion actuator. (a) Rubber release agent, (b) Ecoflex 00-30 silicone rubber, (c) PDMS, (d) Vacuum defoamer, (e) Configured silicone rubber solution.

Figure 4.

Pre-preparation work for a flexible torsion actuator. (a) Rubber release agent, (b) Ecoflex 00-30 silicone rubber, (c) PDMS, (d) Vacuum defoamer, (e) Configured silicone rubber solution.

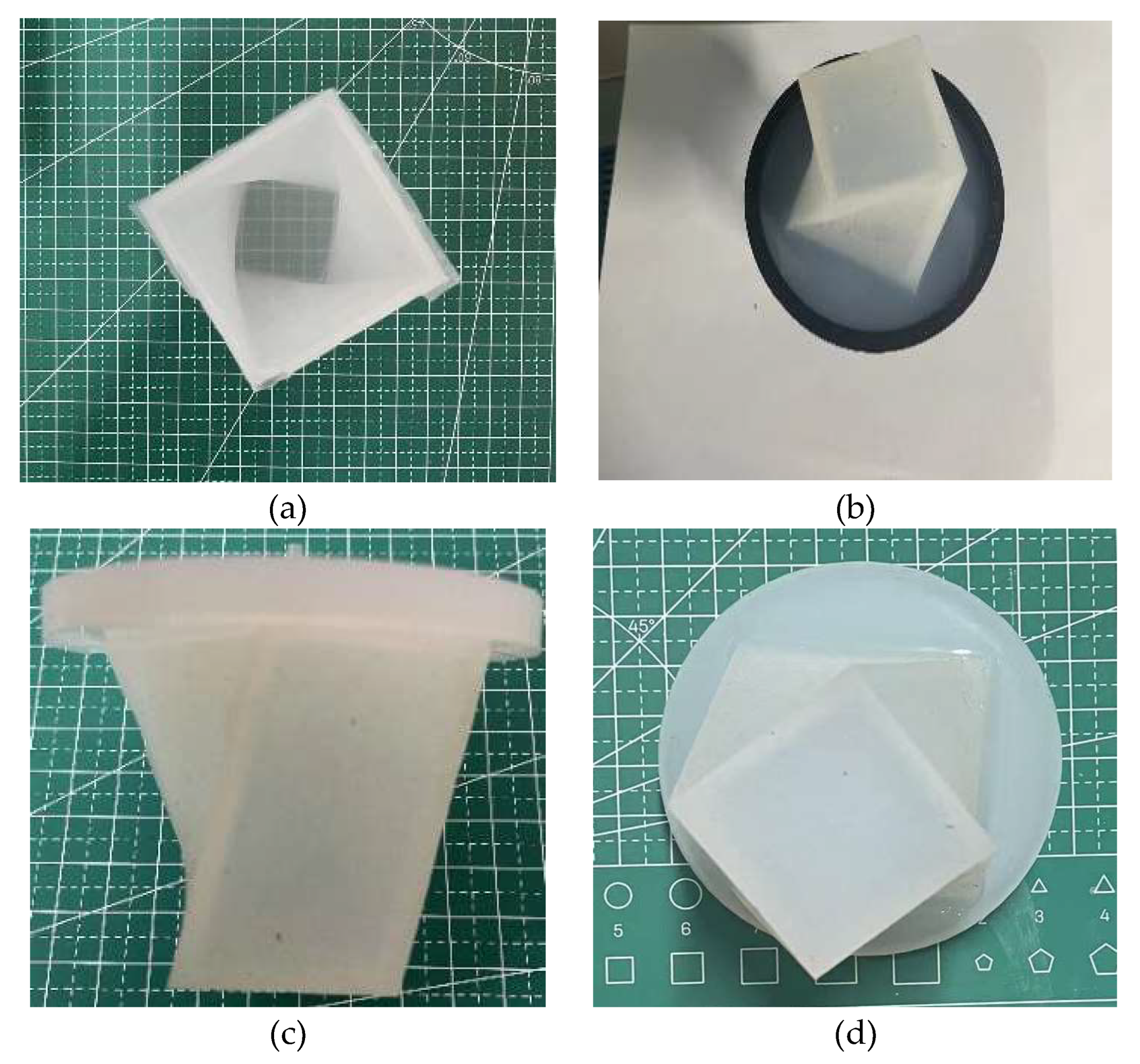

Figure 5.

Positive quadrilateral torsional actuator. (a) Upper part of the actuator, (b) Diagram of the casting process in the lower half of the mould, (c) Overall actuator, (d) Bottom surface of the actuator.

Figure 5.

Positive quadrilateral torsional actuator. (a) Upper part of the actuator, (b) Diagram of the casting process in the lower half of the mould, (c) Overall actuator, (d) Bottom surface of the actuator.

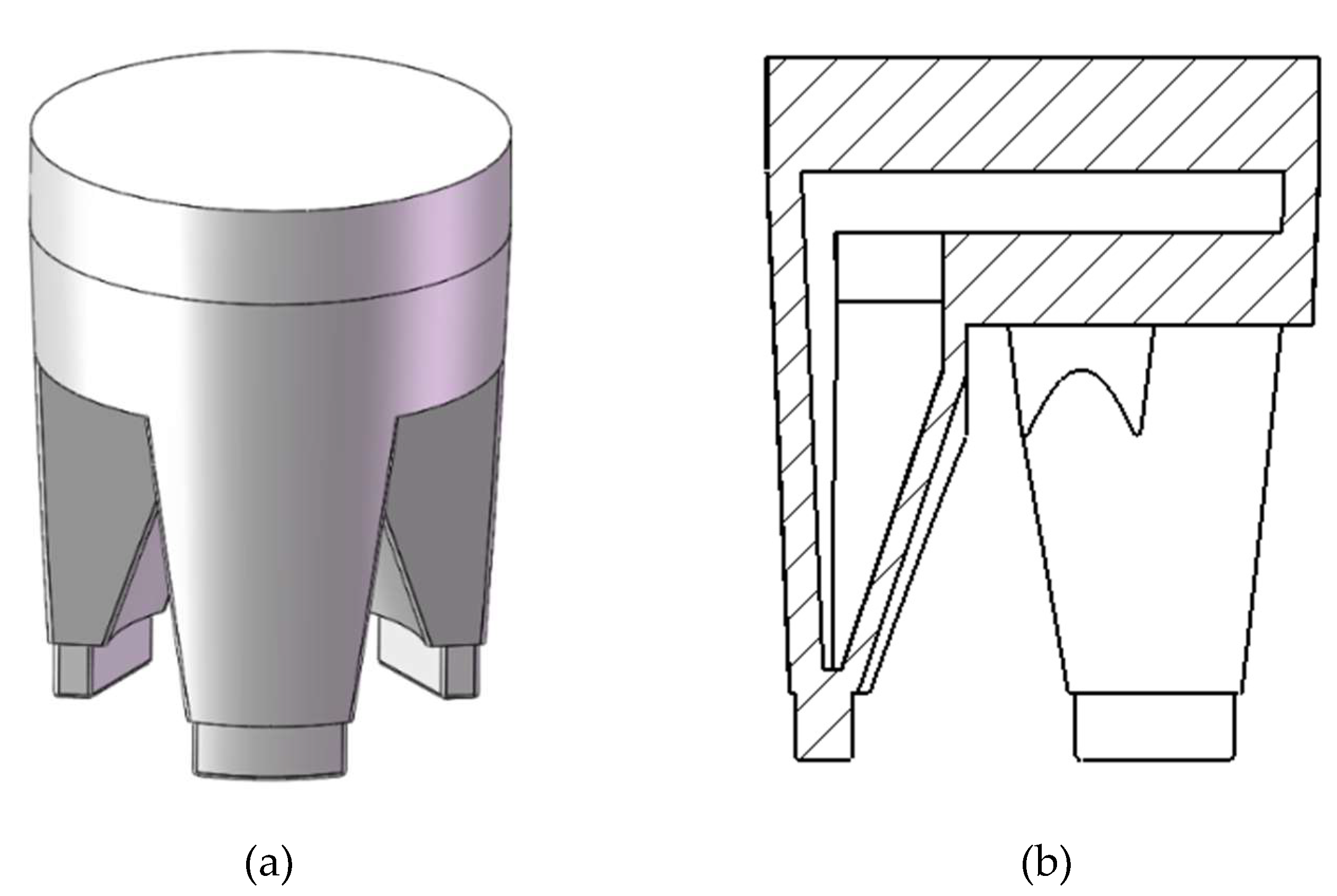

Figure 6.

Schematic diagram of the three-finger gripping actuator structure. (a) Isometric drawing, (b) Single finger section.

Figure 6.

Schematic diagram of the three-finger gripping actuator structure. (a) Isometric drawing, (b) Single finger section.

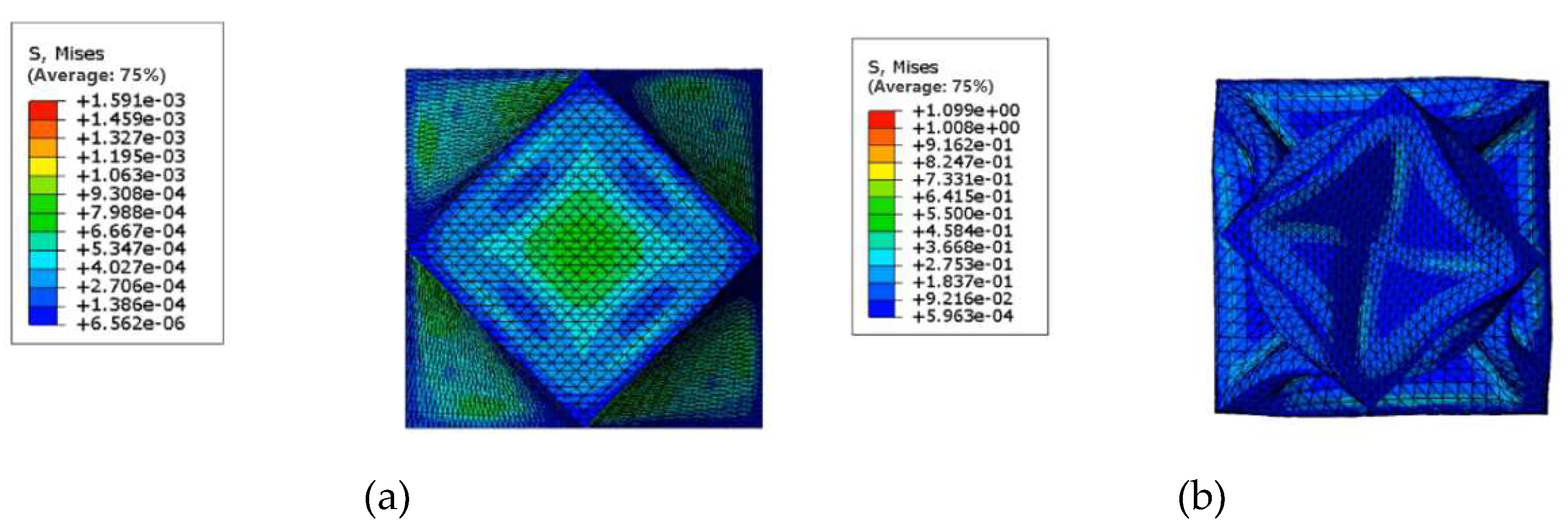

Figure 7.

Deformation results of the positive quadrilateral soft torsion actuator. (a) 0kPa, (b) -70kPa.

Figure 7.

Deformation results of the positive quadrilateral soft torsion actuator. (a) 0kPa, (b) -70kPa.

Figure 8.

Simulation results of torsional actuator with different side rib thickness at 70kPa. (a) Thickness of side ribs 2mm, (b) Thickness of side ribs 2.5mm, (c) Thickness of side ribs 3mm, (d) Thickness of side ribs 2mm.

Figure 8.

Simulation results of torsional actuator with different side rib thickness at 70kPa. (a) Thickness of side ribs 2mm, (b) Thickness of side ribs 2.5mm, (c) Thickness of side ribs 3mm, (d) Thickness of side ribs 2mm.

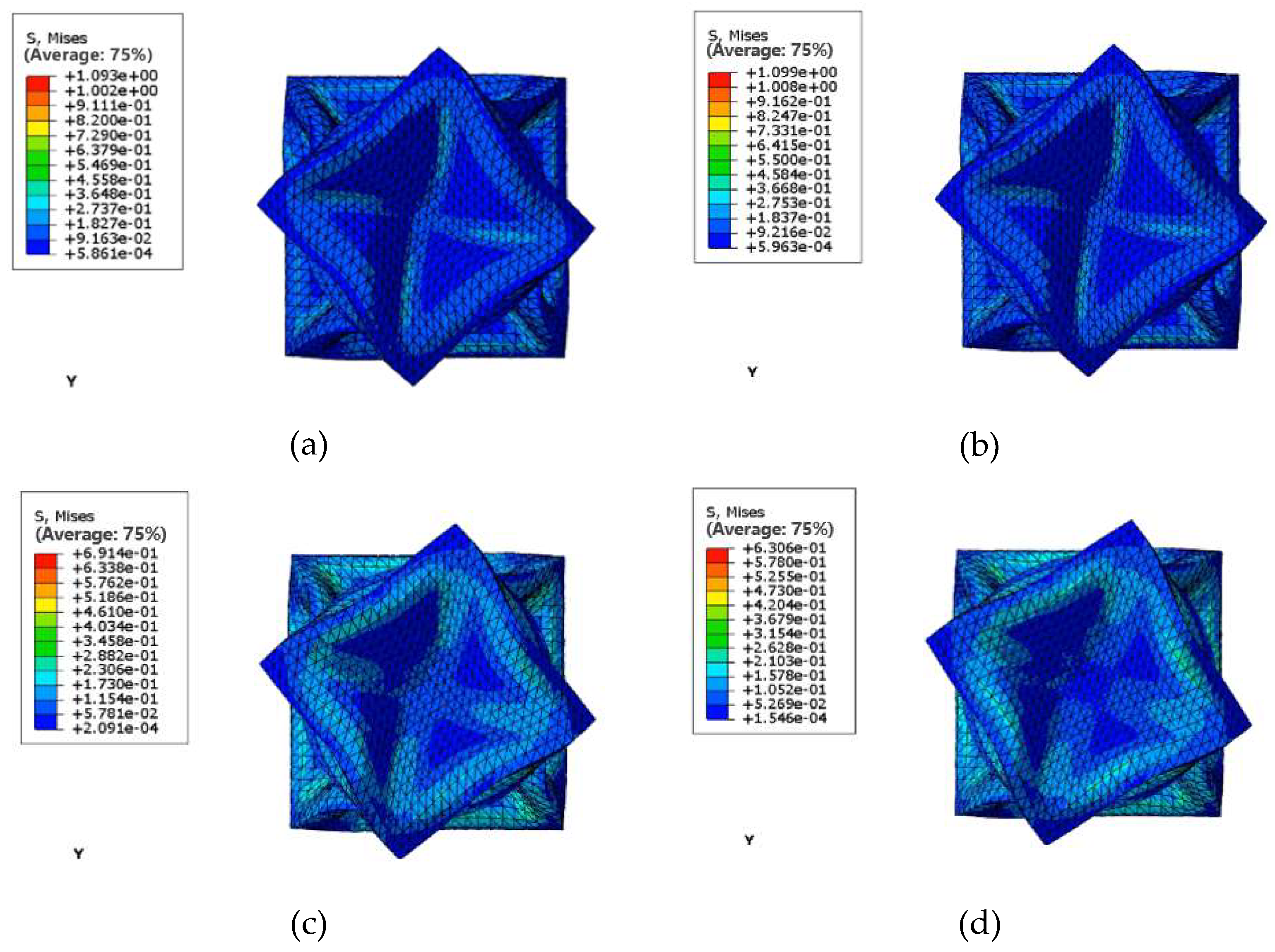

Figure 9.

Diagram of the results of the positive pressure finite element analysis. (a) 20 kPa front view, (b) 30 kPa front view, (c) 40 kPa front view, (d) 50 kPa front view, (e)(f) 50 kPa profile.

Figure 9.

Diagram of the results of the positive pressure finite element analysis. (a) 20 kPa front view, (b) 30 kPa front view, (c) 40 kPa front view, (d) 50 kPa front view, (e)(f) 50 kPa profile.

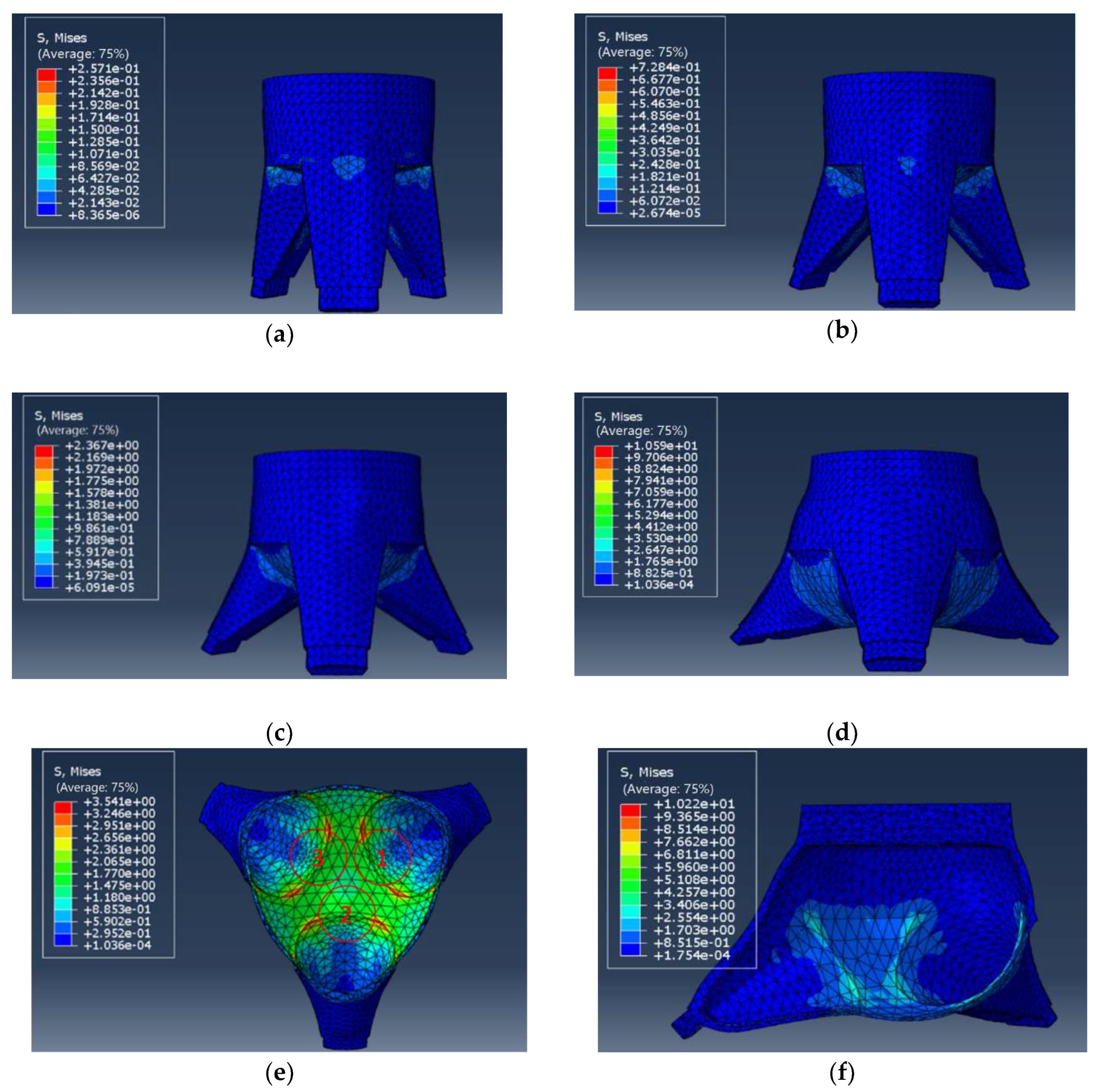

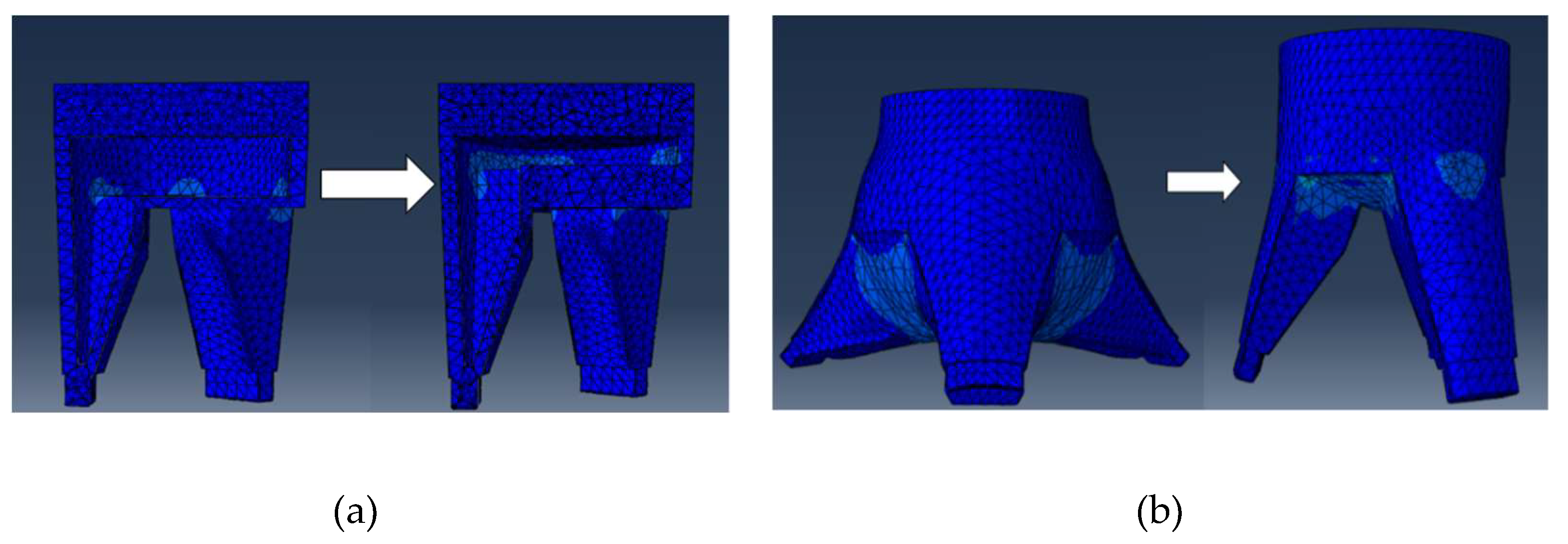

Figure 10.

Deformation of the bottom of the finger cavity of the gripping actuator after parameter changes. (a) Diagram showing the change in thickness of the base of the finger cavity, (b) Deformation diagram of the gripping actuator under positive pressure at 50kPa.

Figure 10.

Deformation of the bottom of the finger cavity of the gripping actuator after parameter changes. (a) Diagram showing the change in thickness of the base of the finger cavity, (b) Deformation diagram of the gripping actuator under positive pressure at 50kPa.

Figure 11.

Results of the negative pressure finite element analysis of the gripper actuator.

Figure 11.

Results of the negative pressure finite element analysis of the gripper actuator.

Figure 12.

Results of the negative pressure finite element analysis of the gripping actuator after changing the finger cavity thickness parameter.

Figure 12.

Results of the negative pressure finite element analysis of the gripping actuator after changing the finger cavity thickness parameter.

Figure 13.

Flow chart of algorithm model.

Figure 13.

Flow chart of algorithm model.

Figure 14.

Schematic diagram of the operation of the flexible actuator.

Figure 14.

Schematic diagram of the operation of the flexible actuator.

Figure 15.

Torsional actuator with different base shapes - 70 kPa torque measurement. (a) Positive quadrilateral bottom actuator, (b) Positive pentagonal bottom actuator, (c) Round bottom actuator.

Figure 15.

Torsional actuator with different base shapes - 70 kPa torque measurement. (a) Positive quadrilateral bottom actuator, (b) Positive pentagonal bottom actuator, (c) Round bottom actuator.

Figure 16.

Axial length characteristics of soft torsion actuator.

Figure 16.

Axial length characteristics of soft torsion actuator.

Figure 17.

Soft gripper gripping process diagram. (a) Initial state of the gripper, (b) The gripper moves to the vicinity of the target, (c) Gripper successfully grabs the target.

Figure 17.

Soft gripper gripping process diagram. (a) Initial state of the gripper, (b) The gripper moves to the vicinity of the target, (c) Gripper successfully grabs the target.

Figure 18.

Software gripper grasping test diagram. (a) USB flash drive, (b) circular industrial switch, (c) L-shaped Allen wrench, (d) quail egg.

Figure 18.

Software gripper grasping test diagram. (a) USB flash drive, (b) circular industrial switch, (c) L-shaped Allen wrench, (d) quail egg.

Figure 19.

The second modular combination experiment diagram.

Figure 19.

The second modular combination experiment diagram.

Figure 20.

Modular software gripper torsion process diagram. (a) Software gripper readiness, (b) Grab Actuator Negative Pressure Grab, (c) The negative pressure of actuator 1 is turned clockwise by 60°, (d) The negative pressure of actuator 2 is turned clockwise by 55°, (e) Actuator 2 deflates air and twists 55° counterclockwise, (f) The actuator deflates air and rotates 60° counterclockwise.

Figure 20.

Modular software gripper torsion process diagram. (a) Software gripper readiness, (b) Grab Actuator Negative Pressure Grab, (c) The negative pressure of actuator 1 is turned clockwise by 60°, (d) The negative pressure of actuator 2 is turned clockwise by 55°, (e) Actuator 2 deflates air and twists 55° counterclockwise, (f) The actuator deflates air and rotates 60° counterclockwise.

Figure 21.

Twisting grasp process diagram of modular software gripper. (a) Software gripper readiness, (b) Grab actuator negative pressure grab, (c) Actuator 1 is rotated clockwise, (d) Actuator 2 is rotated clockwise.

Figure 21.

Twisting grasp process diagram of modular software gripper. (a) Software gripper readiness, (b) Grab actuator negative pressure grab, (c) Actuator 1 is rotated clockwise, (d) Actuator 2 is rotated clockwise.

Table 1.

Specific material parameters for the Ecoflex series of silicone rubbers.

Table 1.

Specific material parameters for the Ecoflex series of silicone rubbers.

| Ecoflex series |

00-10 |

00-20 |

00-30 |

00-40 |

| Operable time |

40min |

30min |

45min |

18min |

| Curing time |

4h |

4h |

4h |

4h |

| Exercise elongation |

800% |

845% |

900% |

980% |

| Mixed viscosity |

14000 cps |

3000cps |

3000cps |

8000cps |

| Shore' s hardness |

00-10 |

00-20 |

00-30 |

00-40 |

| Tensile strength |

120psi |

160psi |

200psi |

315psi |

| Shrinkage ratio |

<0.001% |

<0.001% |

<0.001% |

<0.001% |

Table 2.

Lateral center thickness influence data sheet.

Table 2.

Lateral center thickness influence data sheet.

| Pressure |

Twist angle of 2.5mm side thickness |

Twist angle of 2mm side thickness |

Twist angle of 1.5mm side thickness |

| 0kPa |

0° |

0° |

0° |

| 10kPa |

29° |

31° |

32° |

| 20kPa |

54° |

56° |

57° |

| 30kPa |

62° |

66° |

70° |

| 40kPa |

65° |

70° |

74° |

| 50kPa |

67° |

73° |

76° |

| 60kPa |

69° |

75° |

78° |

| 70kPa |

70° |

75° |

78° |

Table 3.

Test data of torsional actuator deformation angle with different side edge thickness parameters.

Table 3.

Test data of torsional actuator deformation angle with different side edge thickness parameters.

| Pressure |

Twist angle of 3.5 mm thickness of side ribs |

Twist angle of 3 mm thickness of side ribs |

Twist angle of 2.5 mm thickness of side ribs |

Twist angle of 2 mm thickness of side ribs |

| 0kPa |

0° |

0° |

0° |

0° |

| 10kPa |

27° |

29° |

32° |

34° |

| 20kPa |

52° |

54° |

57° |

59° |

| 30kPa |

60° |

64° |

70° |

72° |

| 40kPa |

65° |

70° |

74° |

75° |

| 50kPa |

67° |

73° |

76° |

77° |

| 60kPa |

69° |

74° |

78° |

78° |

| 70kPa |

70° |

74° |

78° |

78° |

Table 4.

Experimental torque data for torsional actuators with different base shapes.

Table 4.

Experimental torque data for torsional actuators with different base shapes.

| Air pressure |

Positive quadrilateral actuator torque |

Positive pentagonal actuator torque |

Round actuator torque |

| 0kPa |

0N·m |

0N·m |

0N·m |

| -10kPa |

0.016N·m |

0.018N·m |

0.017N·m |

| -20kPa |

0.029N·m |

0.031N·m |

0.031N·m |

| -30kPa |

0.040N·m |

0.044N·m |

0.043N·m |

| -40kPa |

0.044N·m |

0.051N·m |

0.047N·m |

| -50kPa |

0.0477N·m |

0.055N·m |

0.0481N·m |

| -60kPa |

0.0479N·m |

0.057N·m |

0.0482N·m |

| -70kPa |

0.048N·m |

0.058N·m |

0.0485N·m |

Table 7.

Flow chart of the second modular combined control system.

Table 7.

Flow chart of the second modular combined control system.