Submitted:

11 May 2023

Posted:

12 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Description of Organic Rankine Cycles

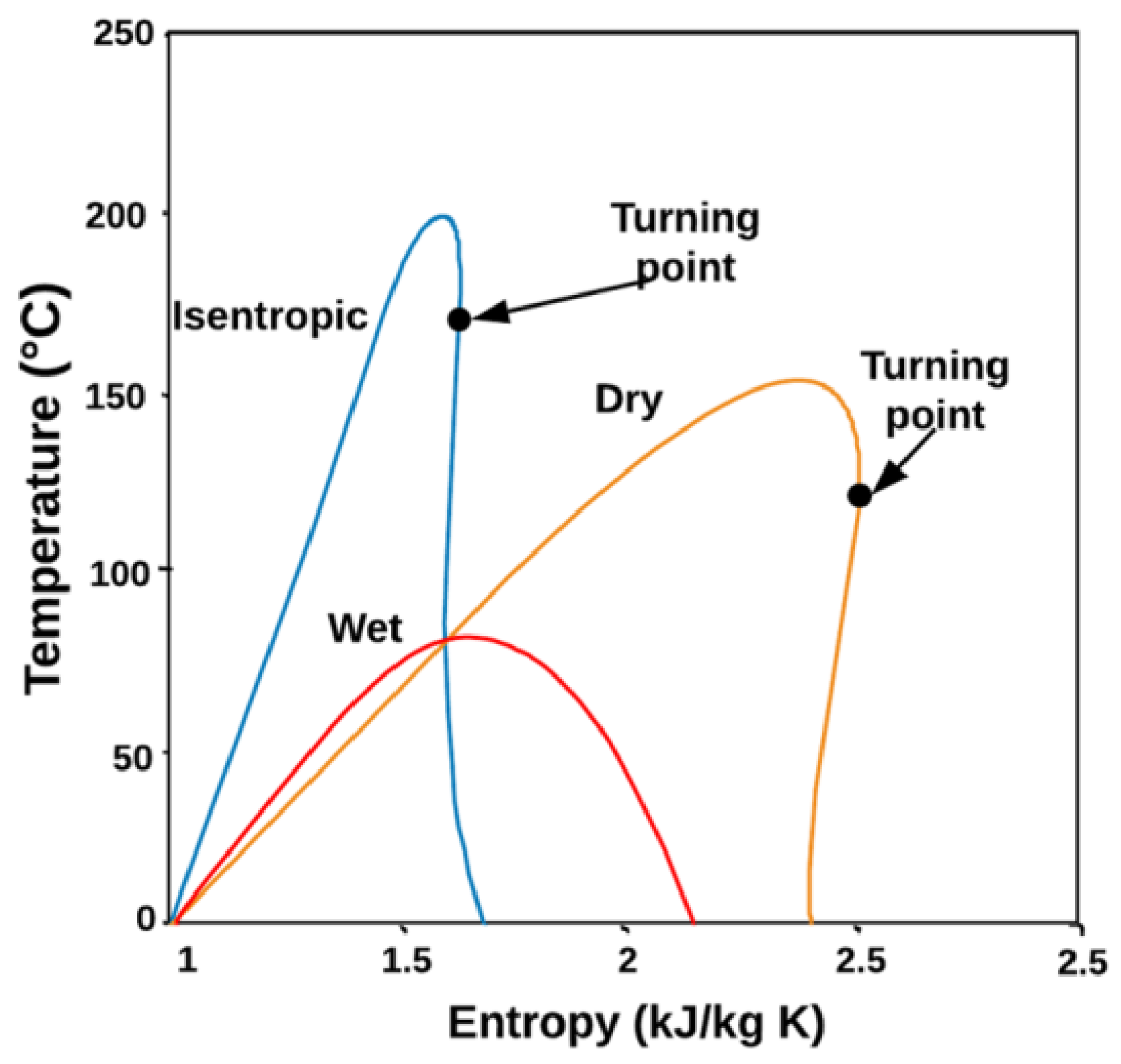

2.1. Working Fluids for ORC

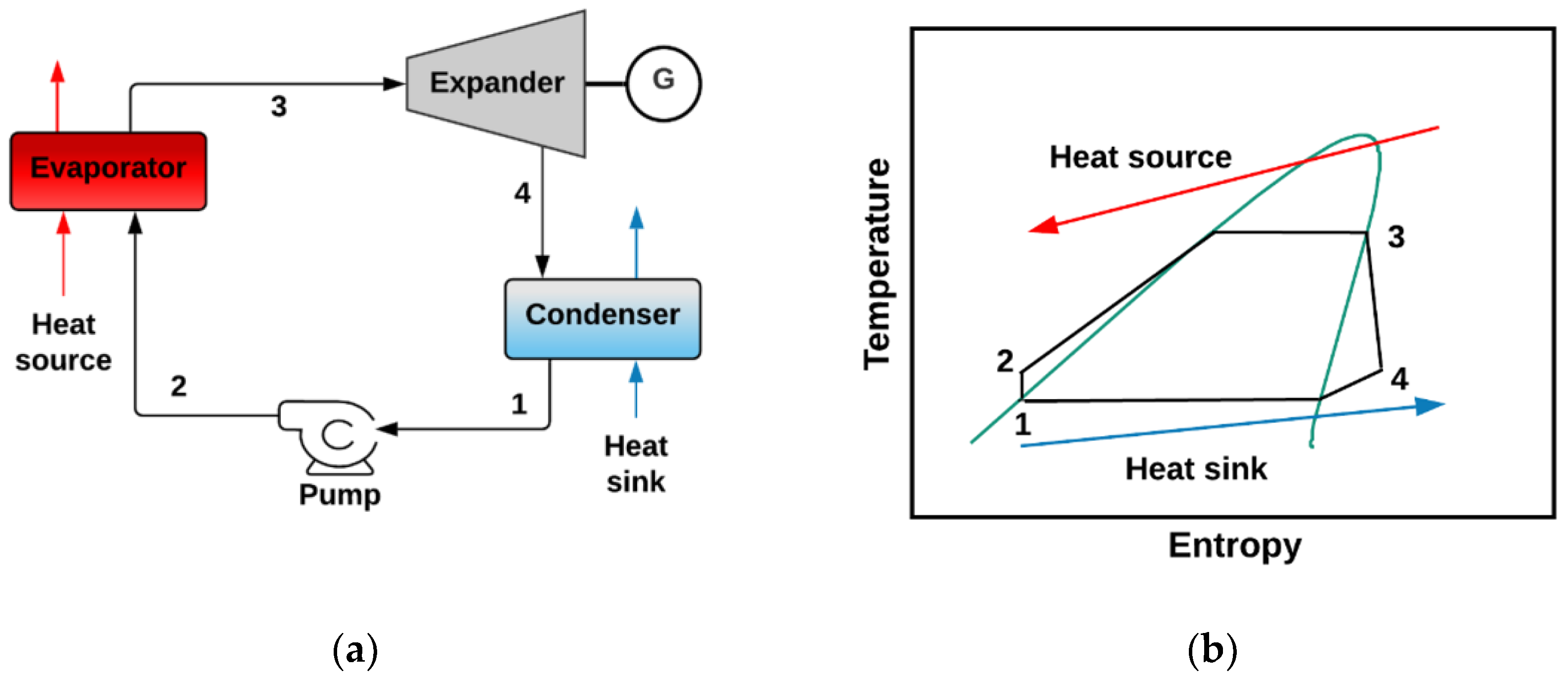

3. Single-Stage ORC

3.1. Thermoeconomic and Life Cycle Analysis of ORC

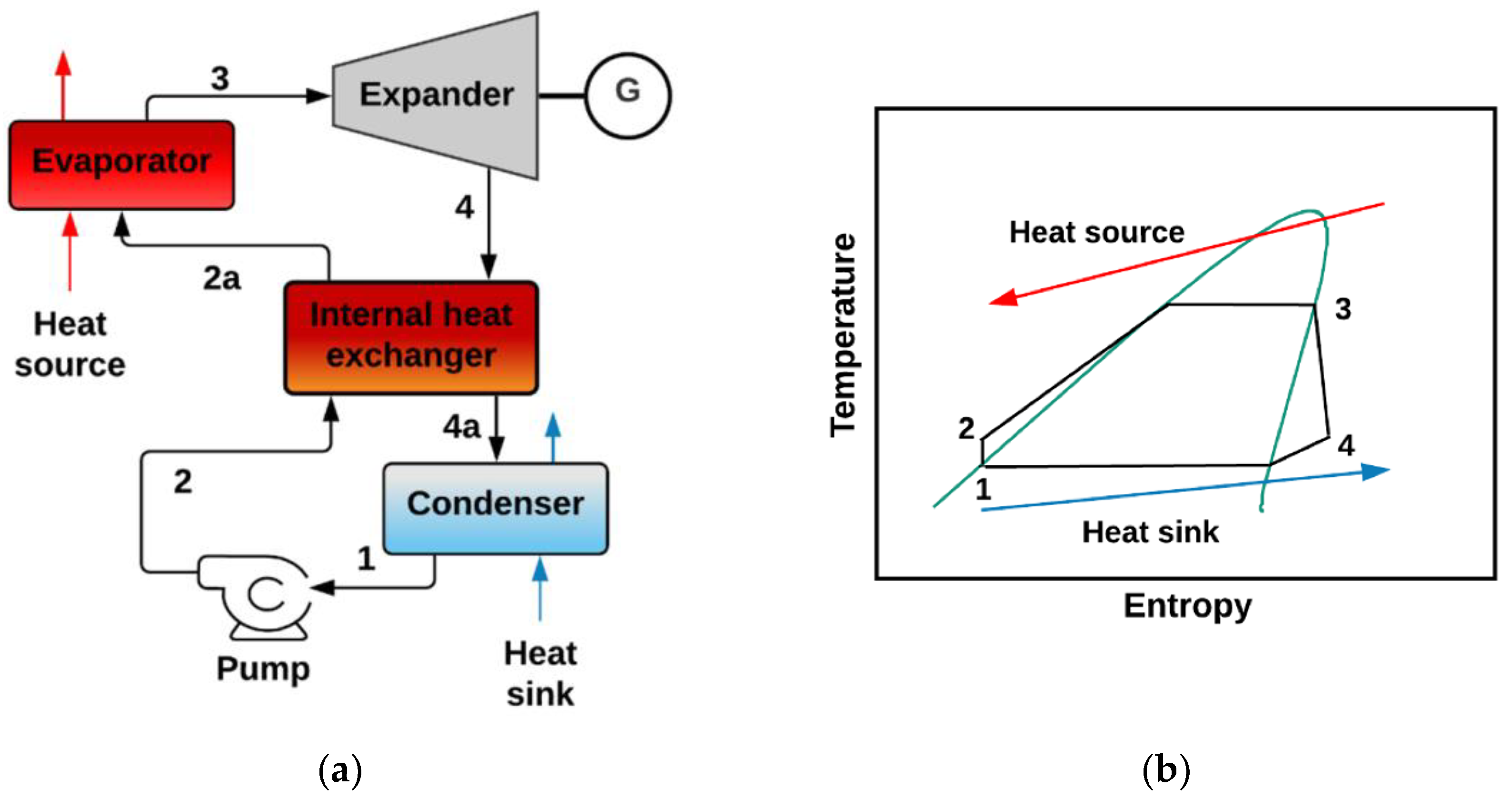

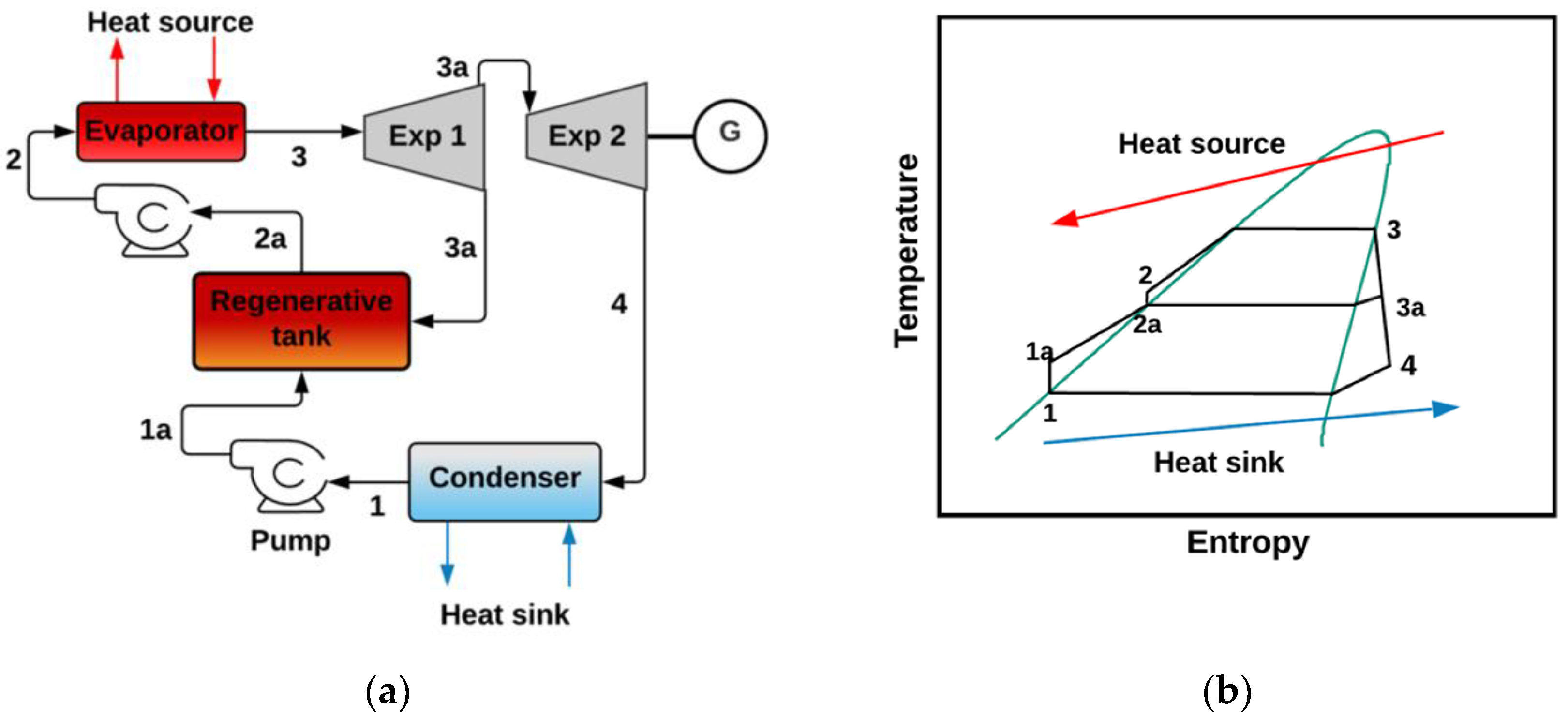

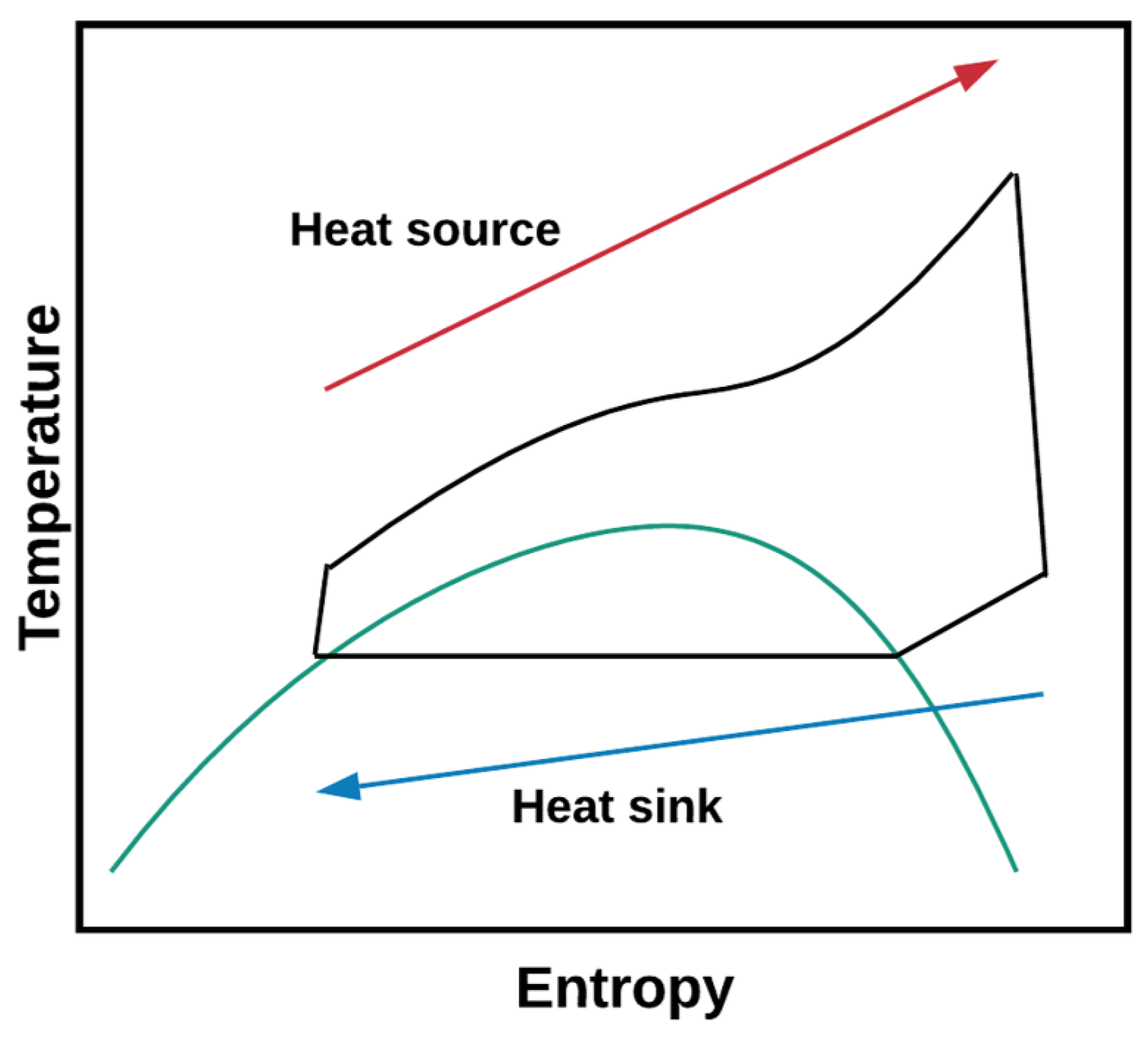

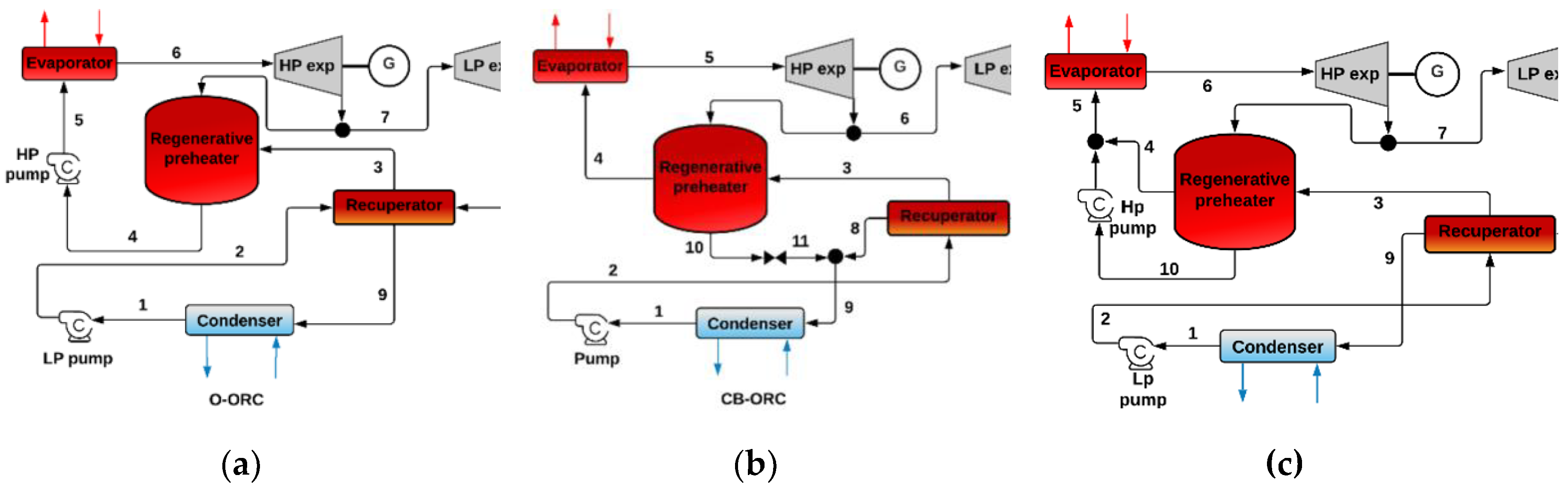

4. Recuperative, Regenerative, Reheated, and Supercritical ORCs

4.1. Comparison between Recuperative, Regenerative, and Reheated ORCs

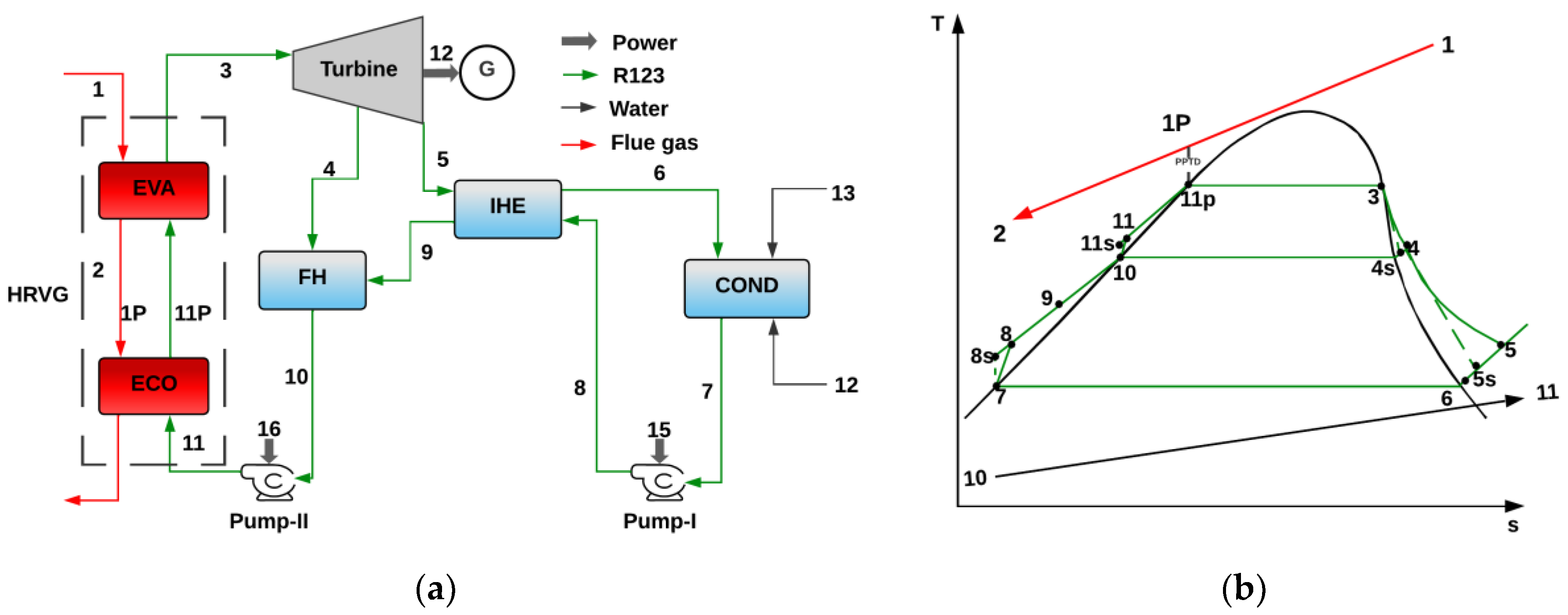

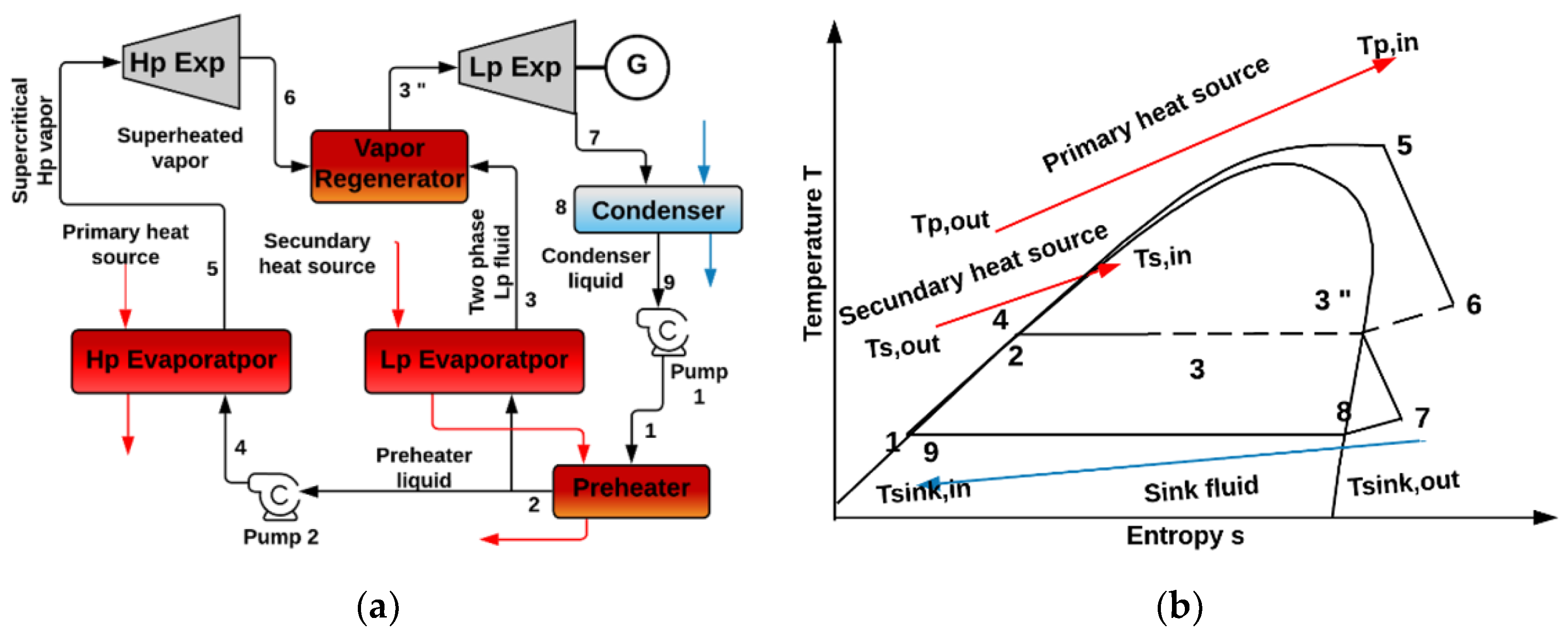

4.2. Supercritical ORC

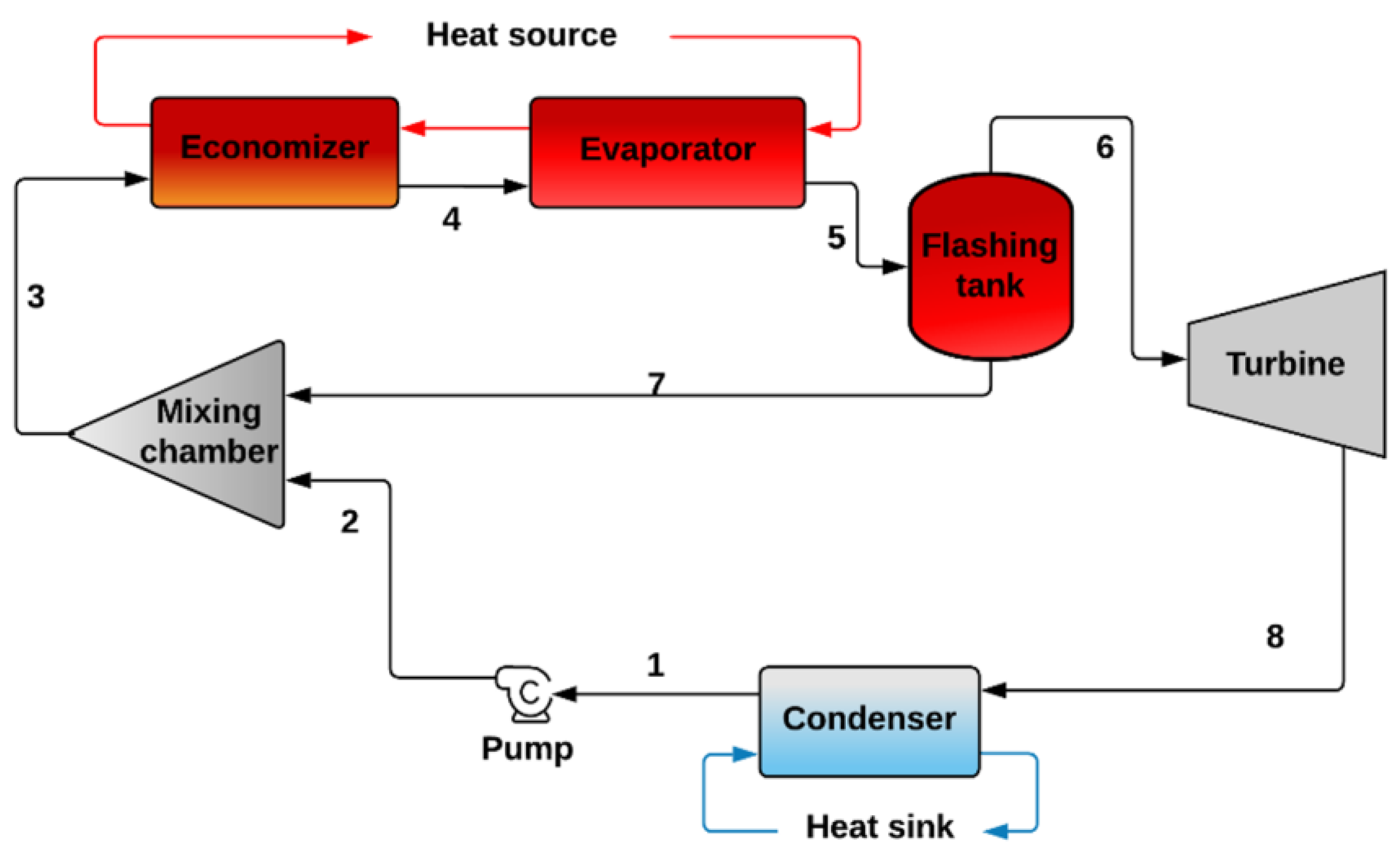

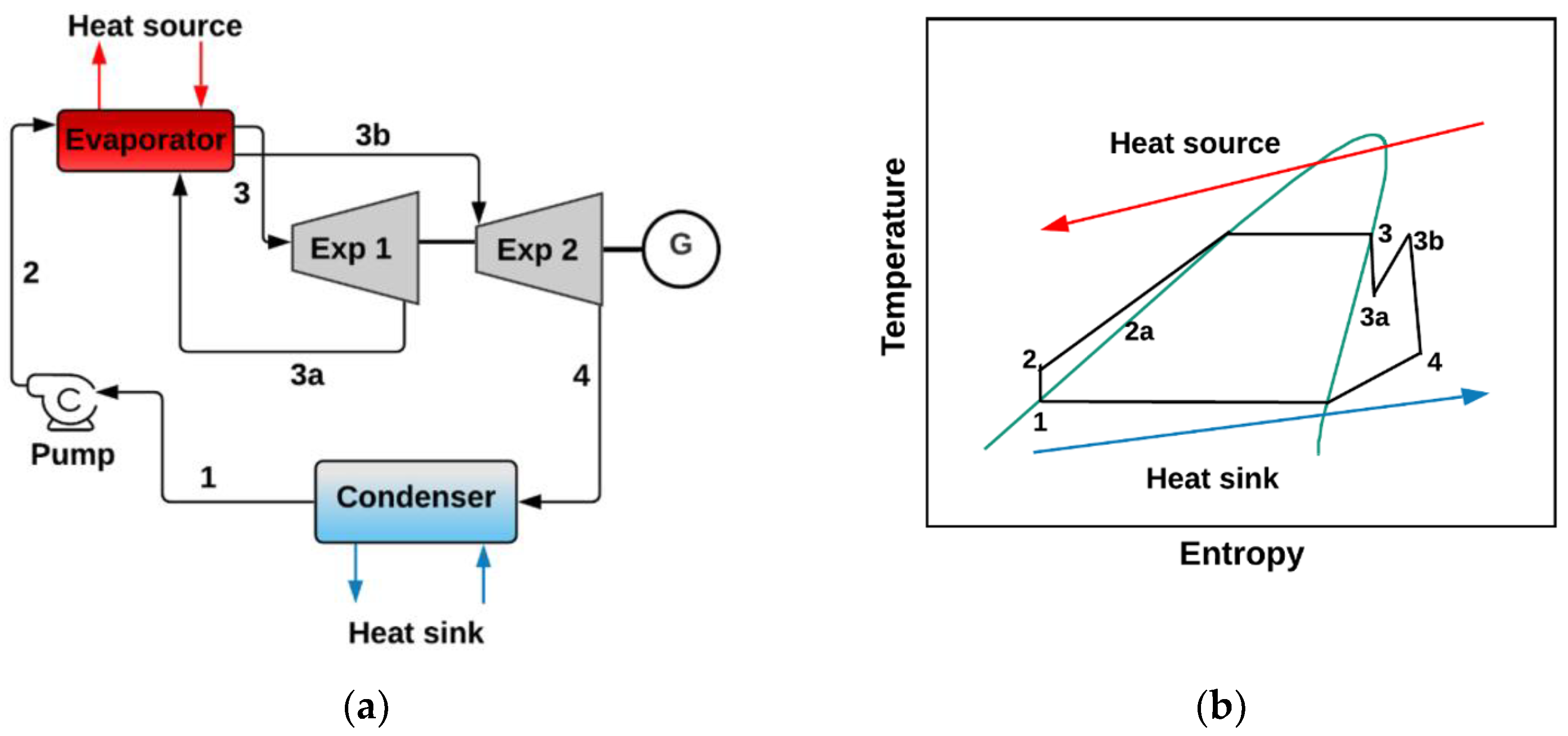

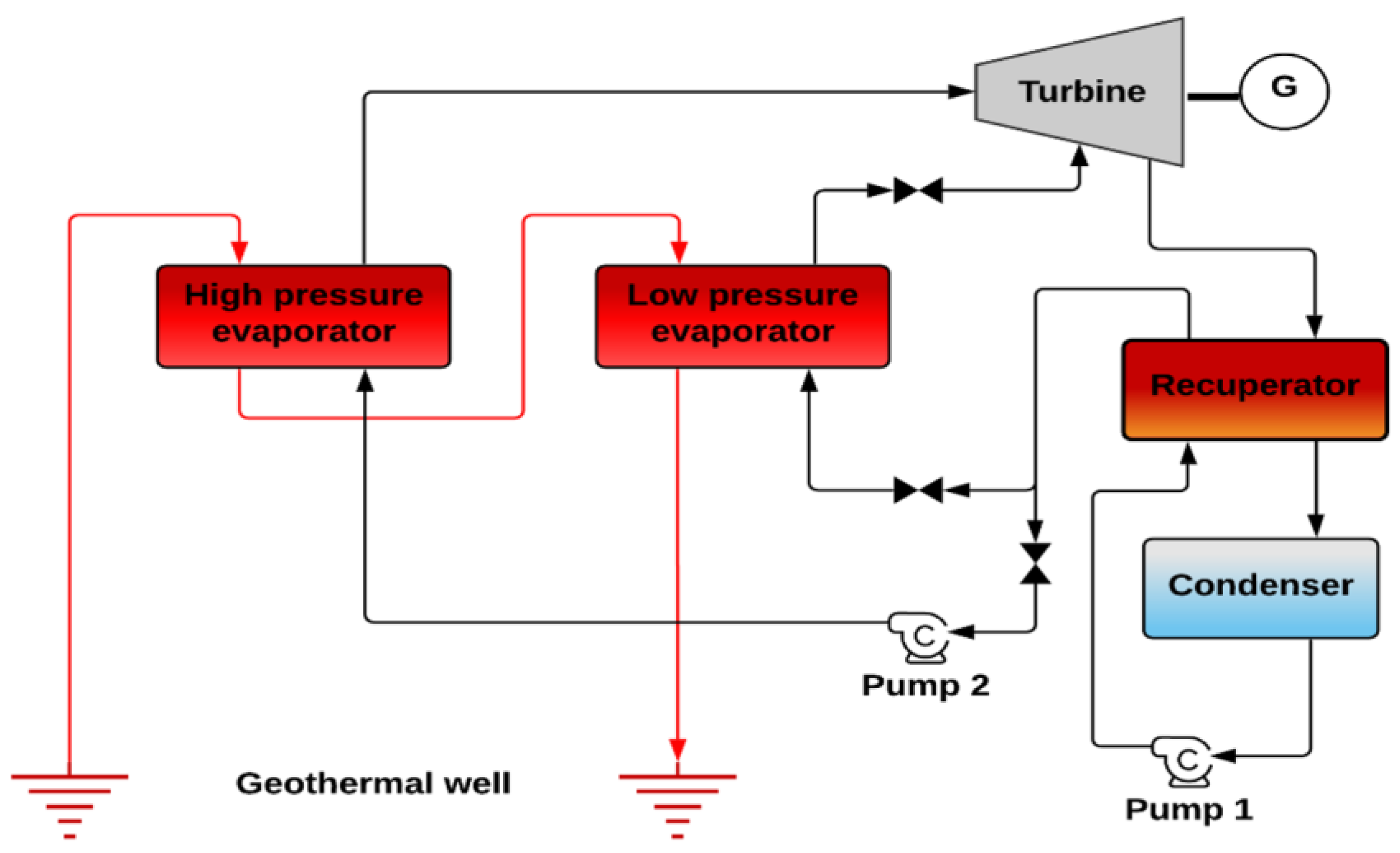

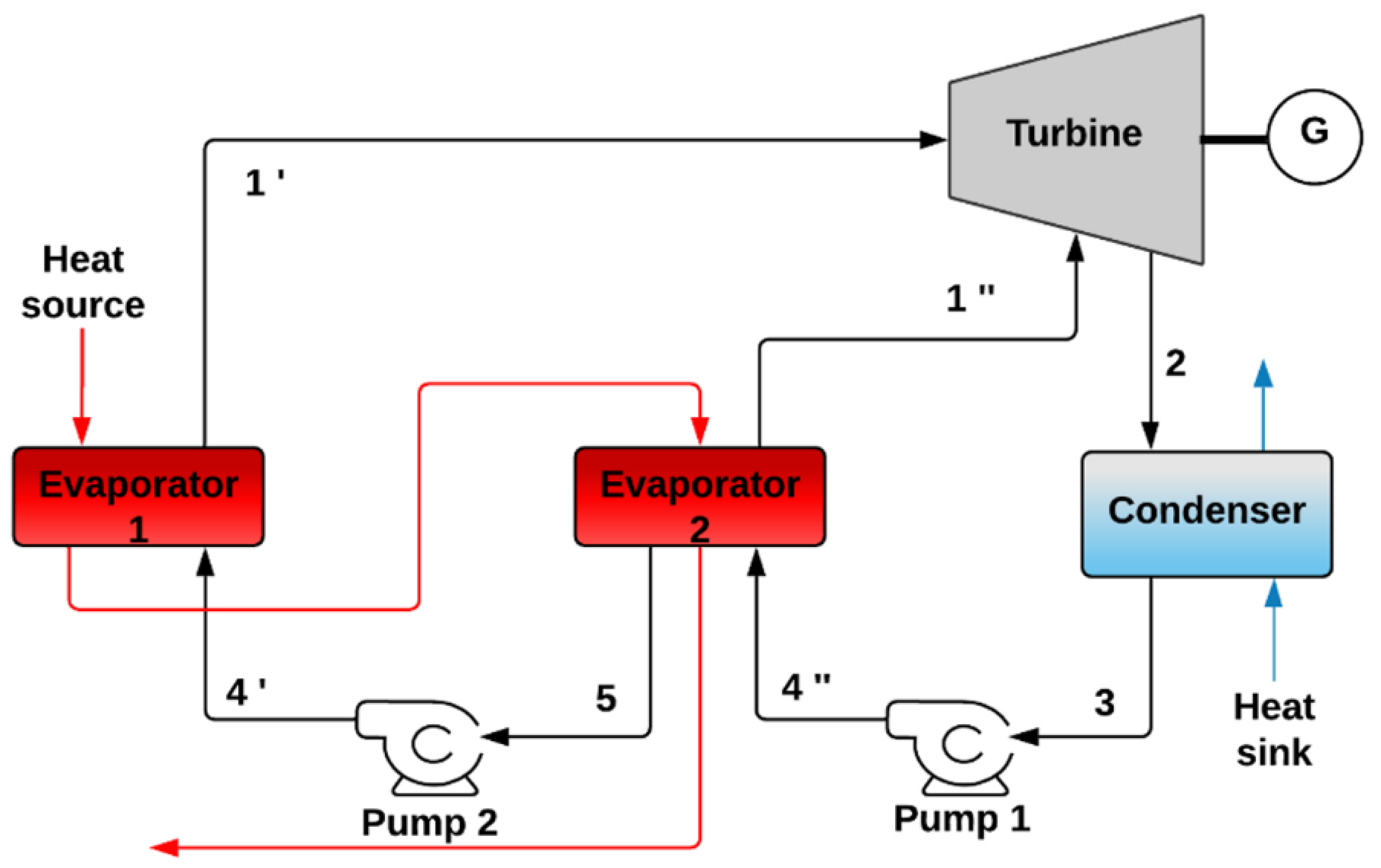

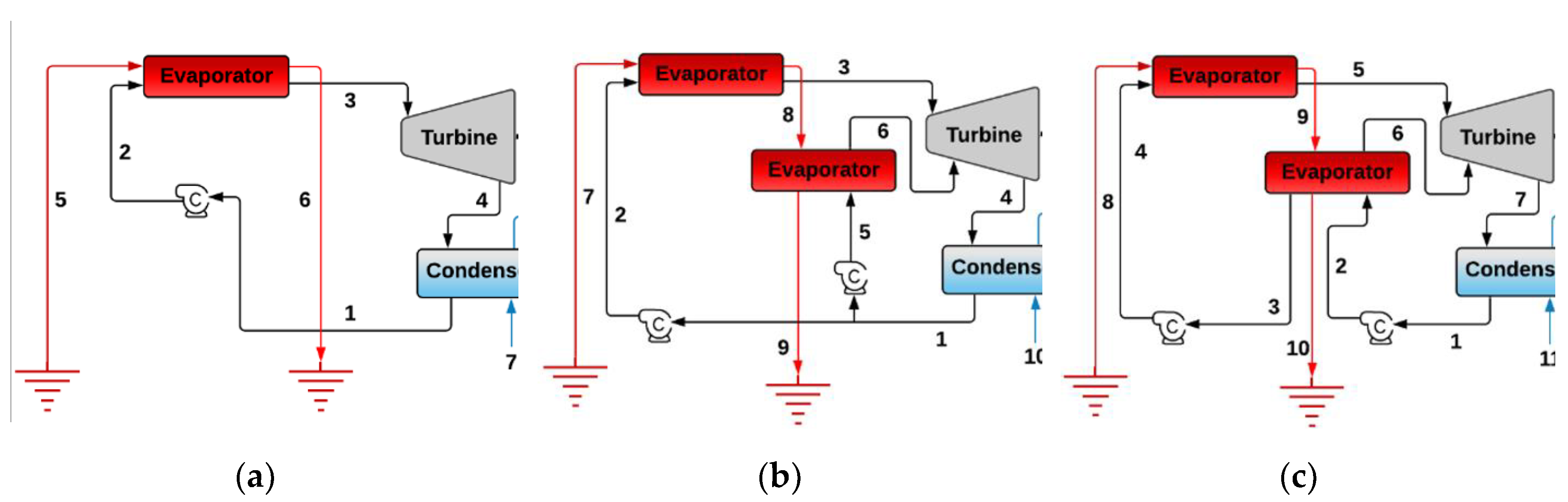

5. Two-Stage ORC

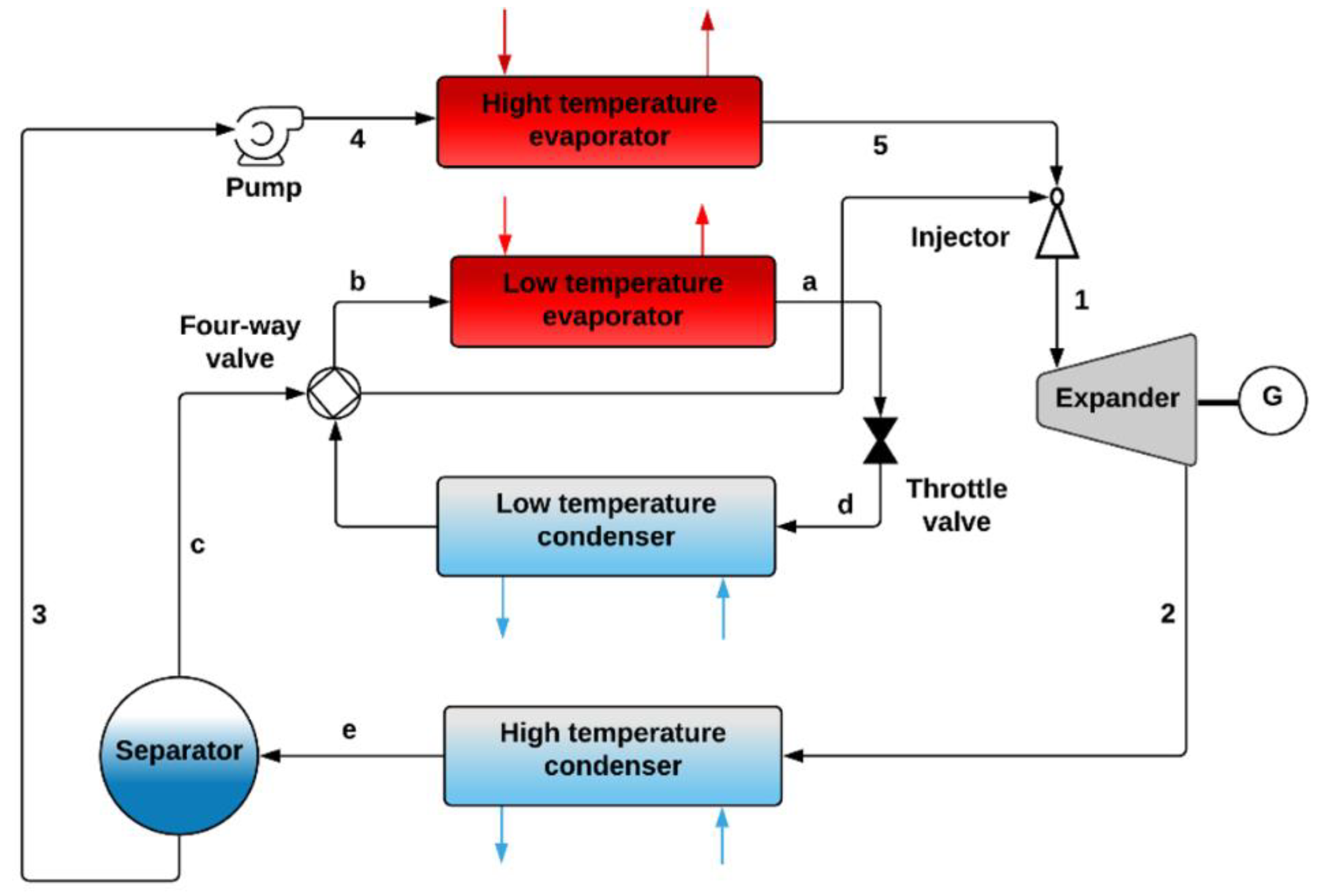

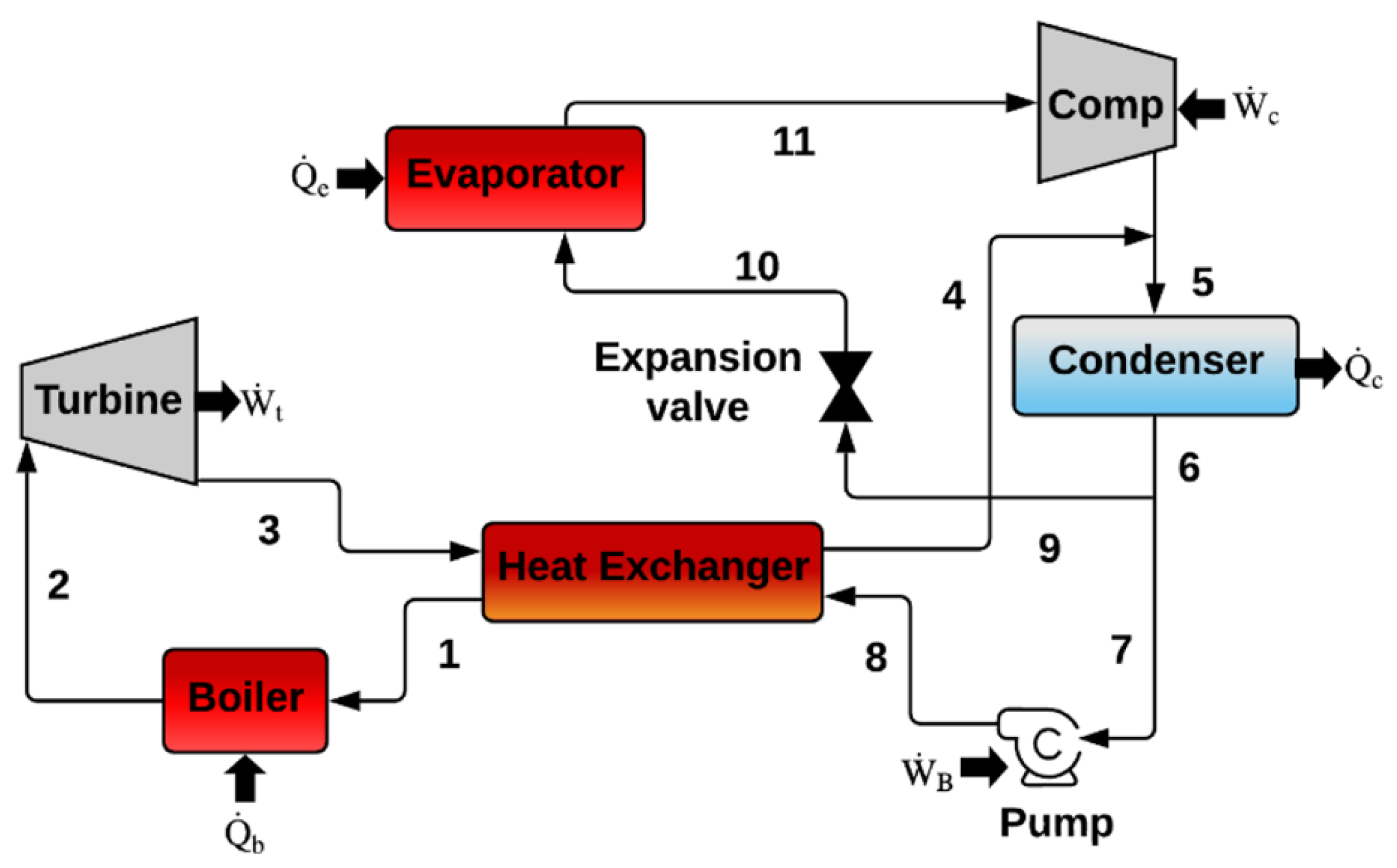

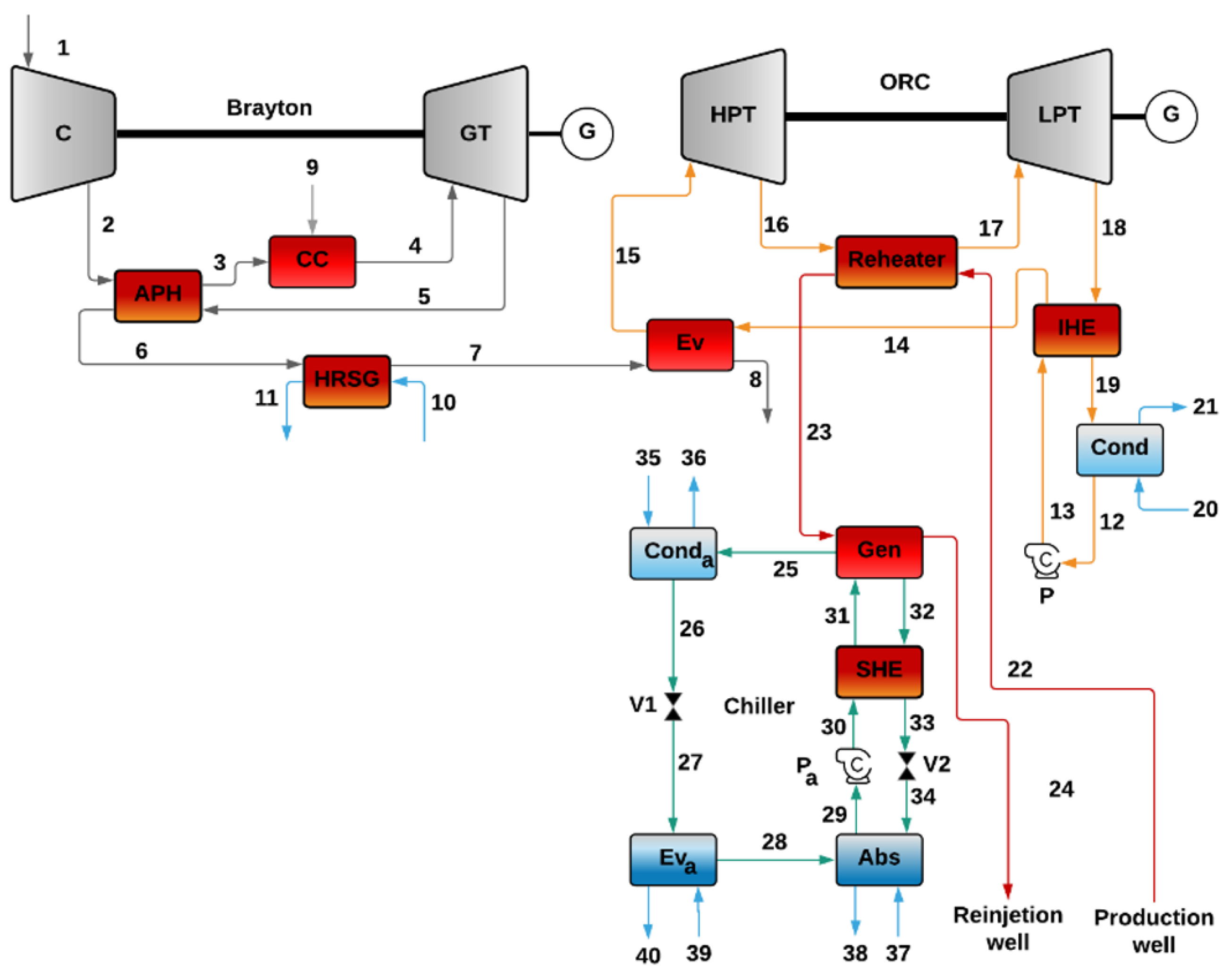

6. Hybrid ORC

7. Discussion

7.1. Basic ORC

7.2. Recuperative, Regenerative, Reheated, and Supercritical Cycles

| Reference | Cycle more efficient | Conditions | Working fluid | Output | Efficiency (%) | Component with the highest irreversibilities | LCOE | |

|---|---|---|---|---|---|---|---|---|

| Thermal | Exergy | |||||||

| Algieri and Šebo [54] | Recuperative | THS = 139 °C | Isobutane, isopentane and R245ca* | 4.0 kW | 14.0 | - | - | - |

| Canbolat et al. [55] | Recuperative | THS = 127 °C | R142b, R227ea, R245fa*, R600 and R600a | - | 16.7 | 60.0 | Evaporator | - |

| Zhang et al. [56] | Superheated recuperative | THS = 100 °C | R245fa, R1234ze(Z), isopentane e isobutane* | 24.0 kW | 26.38 | 34.0 | - | - |

| Uusitalo et al. [58] | Recuperative | THS = 300 °C | hydrocarbons, siloxanes and fluorocarbons | 31.1 kW | 25.2 | - | - | - |

| Ali et al. [59] | Basic, Recuperative | THS = 165 °C | Butane, Isobutane, Isopentane*, etc. | 89.61 kW | 19.83 | - | Evaporator | - |

| Pezzuolo et al. [60] | Basic, Recuperative | THS = 170 °C | benzene*, toluene, cyclopentane, etc. | 4.0 MW | 25.7 | 37.60 | - | 0.118 USD/kWh |

| Agromayor and Nord [61] | Simple, Recuperative | THS = 600 °C | Alkylbenzenes, alkanes and siloxanes | 550 kW | - | 30.0 | - | - |

| Lu et al. [68] | Basic, Recuperative | THS = 140 °C | zeotropic mixtures R601a/R600 and R245fa/R600a | 36.4 kW | 11.11 | - | - | - |

| Imran et al. [71] | Basic, Recuperative, Regenerative | THS = 160 °C | R600, R600a, R601, R601a, R245fa* and SES36 | 68.4 kW | 14.02 | 55.93 | - | - |

| Reference | Cycle more efficient | Conditions | Working fluid | Output | Efficiency (%) | Component with the highest irreversibilities | LCOE | |

|---|---|---|---|---|---|---|---|---|

| Thermal | Exergy | |||||||

| Wang et al. [72] | Basic, Recuperative, Regenerative | THS = 150 °C | Fourteen working fluids R245fa* | - | 12.0 | 48.0 | - | - |

| Li [73] and Li [74] | Basic, Regenerative, Recuperative, Reheated | THS = 130 °C | Fourteen working fluids, R245fa* | - | 13.2–13.8 | - | 0.26 USD/kWh | |

| Yang and Yeh [75] | Reheated | THS = 94 °C | R600*, R600a, R1233zd, R1234yf, R1234ze | 332.7 kW | 8.29 | - | - | 0.3 USD/kWh |

| Liu et al. [79] | Basic Supercritical | THS = 130 °C | R125, R218, R143a, R32, R290, R134a, R227ea, R1234ze(E), and R152a* | 599.1 kW | 11.18 | - | - | - |

| Manente et al. [80] | Supercritical | THS = 150 °C | R1234yf*, R134a, R1234ze(E), R1234ze(Z), R245fa, R600a | 900.8 kW | 10.64 | - | - | - |

| Moloney et al. [82] | Binary, Single flash | THS = 240 °C | Twenty different working fluids | 150 kW | 19.0 | 50.0 | Turbine | - |

| Lukawski et al. [84] | Basic, Recuperative supercritical | THS = 220 °C | Thirteen working fluids. R134a* | 120 kW | 19.0 | - | - | - |

| Cakici et al. [87] | Recuperative supercritical | THS = 160 °C | R134a*, R124, R142b, R227ea, and isobutane | 5800 kW | 12.0 | 45.0 | Parabolic trough solar collectors | - |

7.3. Two-Stage ORC

7.4. Hybrid Systems

8. Conclusions

9. Future Directions

- Simulation of dynamic systems: some recent studies on energy systems, including ORCs, have proposed dynamic models that consider the transient behavior of the main operating parameters. Thus, the theoretical performance predicted by such numerical models is more realistic than that corresponding to steady-state models. In the case of hybrid cycles, as mentioned previously, a large number of studies are related to the use of solar energy without thermal energy storage, which implies that the temperature of the energy source is highly dependent on time. This is an example where dynamic numerical simulation models should be used. Similar to the heat supply temperature, many other parameters of a variant nature should be analyzed from the dynamic perspective.

- Validation of proposed models: to date, the vast majority of studies on organic cycles found in the literature have not been validated experimentally. This implies that there is a huge number of cycles with extremely attractive performance parameters; however, in the case of advanced cycles with multiple components, there is no certainty of their operational viability, neither for technical issues in real environments, nor economic ones. A major experimental research effort on such systems should be carried out in the short and medium term.

- Characterization of working fluids: a large number of theoretical studies consider the use of new working fluids, particularly of zeotropic mixtures, whose properties in many cases are defined, either in the different specialized software or through semi-empirical correlations. However, it is sometimes difficult to find the thermophysical properties of such substances in the ranges required for organic cycles. For these reasons, it is considered necessary that shortly, there will be more research on the properties of new working fluids in the operating ranges of interest.

- Cogeneration systems: the results of the analyses of hybrid systems described in this review, in general, predict a better performance of the systems in which the ORCs are integrated. For this reason, future proposals for systems simultaneously producing several useful energy effects, particularly those of an experimental nature, should be encouraged.

- Multi-objective optimization: Some recent research has conducted optimization studies on systems with several objective functions, which typically are energy and/or economic parameters; however, the vast majority of analyses leave aside environmental aspects, such as those related to life cycle analyses or direct and indirect emissions to the environment. It is expected that, soon, the studies on the proposed new power cycles can be complemented with analyses from an environmental approach.

- Supercritical ORC: Regarding supercritical cycles, the number of studies addressing them is currently limited. Some studies (as Moloney et al. [82]), indicate that supercritical cycles can be more efficient than subcritical ones when the ORC takes advantage of a low-temperature heat source. Thus, today there is a large number of studies in the literature about the huge potential for the exploitation of this type of thermal source, i.e., some of geothermal nature. For this reason, it is desirable to intensify the research on supercritical organic systems.

- Cleaner production: in recent decades, the trend towards the design and implementation of systems that efficiently take advantage of the various sources of clean energy, has been one of the priorities of research and development of energy technology. In this sense, organic Rankine systems have not been the exception. It is expected that a growing integration of ORCs will be maintained for the use of energy sources such as geothermal, solar, or even waste heat from industrial processes or from any other process suitable to be used by an organic power system.

Conflicts of Interest

Nomenclature

| ACS | absorption cooling system |

| CCS | compression cooling system |

| DS | dehumidification system |

| ECS | ejector cooling system |

| ExD | exergy destruction |

| Exp | expander |

| COP | coefficient of performance |

| G | generator |

| HPE | high-pressure evaporator |

| HPT | high-pressure turbine |

| HS | heat source |

| LPE | low-pressure evaporator |

| LPT | low-pressure turbine |

| LCOE | levelized cost of energy |

| ORC | organic Rankine cycle |

| PBP | payback period |

| SP | single-pressure |

| TP | two-pressure |

References

- IEA. Global Energy Review: CO2 Emissions in 2021. IEA: Paris, 2022. [Google Scholar]

- BCS, Inc. Waste Heat Recovery: Technology and Opportunities in U. S. Industry. 2008. [Google Scholar]

- Thekdi, A.; Nimbalkar, S.U. Industrial waste heat recovery-potential applications, available technologies and crosscutting R&D opportunities. 2015. [Google Scholar]

- Park, B.-S.; Usman, M.; Imran, M.; Pesyridis, A. Review of Organic Rankine Cycle experimental data trends. Energy Convers Manag 2018, 173, 679–691. [Google Scholar] [CrossRef]

- Tartière, T.; Astolfi, M. A world overview of the organic Rankine cycle market. Energy Procedia 2017, 129, 2–9. [Google Scholar] [CrossRef]

- Pethurajan, V.; Sivan, S.; Joy, G.C. Issues, comparisons, turbine selections and applications—An overview in organic Rankine cycle. Energy Convers Manag 2018, 166, 474–488. [Google Scholar] [CrossRef]

- Ahmadi, A.; Assad, M.E.H.; Jamali, D.H.; Kumar, R.; Li, Z.X.; Salameh, T.; et al. Applications of geothermal organic Rankine Cycle for electricity production. J Clean Prod 2020, 274, 122950. [Google Scholar] [CrossRef]

- Haghighi, A.; Pakatchian, M.R.; Assad, M.E.H.; Duy, V.N.; Alhuyi Nazari, M. A review on geothermal Organic Rankine cycles: modeling and optimization. J Therm Anal Calorim 2021, 144, 1799–1814. [Google Scholar] [CrossRef]

- Wieland, C.; Schifflechner, C.; Dawo, F.; Astolfi, M. The organic Rankine cycle power systems market: Recent developments and future perspectives. Appl Therm Eng 2023, 224, 119980. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, C.; He, M.; Wang, J. Selection and evaluation of dry and isentropic organic working fluids used in organic Rankine cycle based on the turning point on their saturated vapor curves. Journal of Thermal Science 2019, 28, 643–658. [Google Scholar] [CrossRef]

- Györke, G.; Groniewsky, A.; Imre, A.R. A simple method of finding new dry and isentropic working fluids for organic rankine cycle. Energies 2019, 12, 480. [Google Scholar] [CrossRef]

- Imre, A.R.; Kustán, R.; Groniewsky, A. Thermodynamic selection of the optimal working fluid for organic Rankine cycles. Energies 2019, 12, 2028. [Google Scholar] [CrossRef]

- Györke, G.; Deiters, U.K.; Groniewsky, A.; Lassu, I.; Imre, A.R. Novel classification of pure working fluids for Organic Rankine Cycle. Energy 2018, 145, 288–300. [Google Scholar] [CrossRef]

- Wang, E.; Zhang, M.; Meng, F.; Zhang, H. Zeotropic working fluid selection for an organic Rankine cycle bottoming with a marine engine. Energy 2022, 243, 123097. [Google Scholar] [CrossRef]

- Blondel, Q.; Tauveron, N.; Lhermet, G.; Caney, N. Zeotropic mixtures study in plate heat exchangers and ORC systems. Appl Therm Eng 2023, 219, 119418. [Google Scholar] [CrossRef]

- Yang, L.; Gong, M.; Guo, H.; Dong, X.; Shen, J.; Wu, J. Effects of critical and boiling temperatures on system performance and fluid selection indicator for low temperature organic Rankine cycles. Energy 2016, 109, 830–844. [Google Scholar] [CrossRef]

- Li, J.; Alvi, J.Z.; Pei, G.; Su, Y.; Li, P.; Gao, G.; et al. Modelling of organic Rankine cycle efficiency with respect to the equivalent hot side temperature. Energy 2016, 115, 668–683. [Google Scholar] [CrossRef]

- Dai, B.; Zhu, K.; Wang, Y.; Sun, Z.; Liu, Z. Evaluation of organic Rankine cycle by using hydrocarbons as working fluids: Advanced exergy and advanced exergoeconomic analyses. Energy Convers Manag 2019, 197, 111876. [Google Scholar] [CrossRef]

- Luo, X.; Wang, Y.; Liang, J.; Qi, J.; Su, W.; Yang, Z.; et al. Improved correlations for working fluid properties prediction and their application in performance evaluation of sub-critical Organic Rankine Cycle. Energy 2019, 174, 122–137. [Google Scholar] [CrossRef]

- Fan, W.; Han, Z.; Li, P.; Jia, Y. Analysis of the thermodynamic performance of the organic Rankine cycle (ORC) based on the characteristic parameters of the working fluid and criterion for working fluid selection. Energy Convers Manag 2020, 211, 112746. [Google Scholar] [CrossRef]

- Zhang, X.; Li, Y. An examination of super dry working fluids used in regenerative organic Rankine cycles. Energy 2023, 263, 125931. [Google Scholar] [CrossRef]

- Bianchi, M.; Branchini, L.; De Pascale, A.; Melino, F.; Ottaviano, S.; Peretto, A.; et al. Performance and total warming impact assessment of pure fluids and mixtures replacing HFCs in micro-ORC energy systems. Appl Therm Eng 2022, 203, 117888. [Google Scholar] [CrossRef]

- Bahrami, M.; Pourfayaz, F.; Kasaeian, A. Low global warming potential (GWP) working fluids (WFs) for Organic Rankine Cycle (ORC) applications. Energy Reports 2022, 8, 2976–2988. [Google Scholar] [CrossRef]

- Nurhilal, O.; Mulyana, C.; Suhendi, N.; Sapdiana, D. The simulation of organic rankine cycle power plant with n-pentane working fluid. 2016, 040003. [Google Scholar] [CrossRef]

- Herath, H.M.D.P.; Wijewardane, M.A.; Ranasinghe, R.A.C.P.; Jayasekera, J.G.A.S. Working fluid selection of Organic Rankine Cycles. Energy Reports 2020, 6, 680–686. [Google Scholar] [CrossRef]

- Yadav, K.; Sircar, A. Selection of working fluid for low enthalpy heat source Organic Rankine Cycle in Dholera, Gujarat, India. Case Studies in Thermal Engineering 2019, 16, 100553. [Google Scholar] [CrossRef]

- Wang, H.; Li, H.; Wang, L.; Bu, X. Thermodynamic Analysis of Organic Rankine Cycle with Hydrofluoroethers as Working Fluids. Energy Procedia 2017, 105, 1889–1894. [Google Scholar] [CrossRef]

- Sakhrieha, A.; Shreimb, W.; Fakhruldeenb, H.; Hasanb, H.; Al-Salaymeh, A. Combined Solar-Geothermal Power Generation using Organic Rankine Cycle. Jordan Journal of Mechanical and Industrial Engineerineering 2016, 10, 1–9. [Google Scholar]

- Senturk Acar, M.; Arslan, O. Energy and exergy analysis of solar energy-integrated, geothermal energy-powered Organic Rankine Cycle. J Therm Anal Calorim 2019, 137, 659–666. [Google Scholar] [CrossRef]

- BADEMLİOGLU, A.H. EXERGY ANALYSIS OF THE ORGANIC RANKINE CYCLE BASED ON THE PINCH POINT TEMPERATURE DIFFERENCE. Journal of Thermal Engineering 2019, 5, 157–165. [Google Scholar] [CrossRef]

- Yamankaradeniz, N.; Bademlioglu, A.H.; Kaynakli, O. Performance Assessments of Organic Rankine Cycle With Internal Heat Exchanger Based on Exergetic Approach. J Energy Resour Technol 2018, 140. [Google Scholar] [CrossRef]

- Calise, F.; Macaluso, A.; Pelella, P.; Vanoli, L. A comparison of heat transfer correlations applied to an Organic Rankine Cycle. Engineering Science and Technology, an International Journal 2018, 21, 1164–1180. [Google Scholar] [CrossRef]

- Read, M.; Smith, I.; Stosic, N.; Kovacevic, A. Comparison of Organic Rankine Cycle Systems under Varying Conditions Using Turbine and Twin-Screw Expanders. Energies 2016, 9, 614. [Google Scholar] [CrossRef]

- Invernizzi, C.; Binotti, M.; Bombarda, P.; Di Marcoberardino, G.; Iora, P.; Manzolini, G. Water Mixtures as Working Fluids in Organic Rankine Cycles. Energies 2019, 12, 2629. [Google Scholar] [CrossRef]

- Sun, Z.; Huang, Y.; Tian, N.; Lin, K. Performance improvement of ORC by breaking the barrier of ambient pressure. Energy 2023, 262, 125408. [Google Scholar] [CrossRef]

- Serafino, A.; Obert, B.; Vergé, L.; Cinnella, P. Robust optimization of an organic Rankine cycle for geothermal application. Renew Energy 2020, 161, 1120–1129. [Google Scholar] [CrossRef]

- Huster, W.R.; Schweidtmann, A.M.; Mitsos, A. Impact of Accurate Working Fluid Properties on the Globally Optimal Design of an Organic Rankine Cycle. 2019, 427–432. [Google Scholar] [CrossRef]

- Khosravi, A.; Syri, S.; Zhao, X.; Assad, M.E.H. An artificial intelligence approach for thermodynamic modeling of geothermal based-organic Rankine cycle equipped with solar system. Geothermics 2019, 80, 138–154. [Google Scholar] [CrossRef]

- de Oliveira Neto, R.; Sotomonte, C.A.R.; Coronado, C.J. Off-design model of an ORC system for waste heat recovery of an internal combustion engine. Appl Therm Eng 2021, 195, 117188. [Google Scholar] [CrossRef]

- Ping, X.; Yang, F.; Zhang, H.; Xing, C.; Yu, M.; Wang, Y. Investigation and multi-objective optimization of vehicle engine-organic Rankine cycle (ORC) combined system in different driving conditions. Energy 2023, 263, 125672. [Google Scholar] [CrossRef]

- Sun, J.; Liu, Q.; Duan, Y. Effects of evaporator pinch point temperature difference on thermo-economic performance of geothermal organic Rankine cycle systems. Geothermics 2018, 75, 249–258. [Google Scholar] [CrossRef]

- Mustapic, N.; Brkic, V.; Kerin, M. Subcritical organic ranking cycle based geothermal power plant thermodynamic and economic analysis. Thermal Science 2018, 22, 2137–2150. [Google Scholar] [CrossRef]

- Kyriakarakos, G.; Ntavou, E.; Manolakos, D. Investigation of the Use of Low Temperature Geothermal Organic Rankine Cycle Engine in an Autonomous Polygeneration Microgrid. Sustainability 2020, 12, 10475. [Google Scholar] [CrossRef]

- Usman, M.; Imran, M.; Yang, Y.; Lee, D.H.; Park, B.-S. Thermo-economic comparison of air-cooled and cooling tower based Organic Rankine Cycle (ORC) with R245fa and R1233zde as candidate working fluids for different geographical climate conditions. Energy 2017, 123, 353–366. [Google Scholar] [CrossRef]

- Oyewunmi, O.; Markides, C. Thermo-Economic and Heat Transfer Optimization of Working-Fluid Mixtures in a Low-Temperature Organic Rankine Cycle System. Energies 2016, 9, 448. [Google Scholar] [CrossRef]

- Yaïci, W.; Entchev, E.; Talebizadehsardari, P.; Longo, M. Thermodynamic, Economic and Sustainability Analysis of Solar Organic Rankine Cycle System with Zeotropic Working Fluid Mixtures for Micro-Cogeneration in Buildings. Applied Sciences 2020, 10, 7925. [Google Scholar] [CrossRef]

- Baral, S. Experimental and Techno-Economic Analysis of Solar-Geothermal Organic Rankine Cycle Technology for Power Generation in Nepal. International Journal of Photoenergy 2019, 2019, 1–15. [Google Scholar] [CrossRef]

- Ergun, A.; Ozkaymak, M.; Aksoy Koc, G.; Ozkan, S.; Kaya, D. Exergoeconomic analysis of a geothermal organic Rankine cycle power plant using the SPECO method. Environ Prog Sustain Energy 2017, 36, 936–942. [Google Scholar] [CrossRef]

- Oyekale, J.; Petrollese, M.; Heberle, F.; Brüggemann, D.; Cau, G. Exergetic and integrated exergoeconomic assessments of a hybrid solar-biomass organic Rankine cycle cogeneration plant. Energy Convers Manag 2020, 215, 112905. [Google Scholar] [CrossRef]

- Wang, S.; Liu, C.; Zhang, S.; Li, Q.; Huo, E. Multi-objective optimization and fluid selection of organic Rankine cycle (ORC) system based on economic-environmental-sustainable analysis. Energy Convers Manag 2022, 254, 115238. [Google Scholar] [CrossRef]

- Zhang, H.; Guan, X.; Ding, Y.; Liu, C. Emergy analysis of Organic Rankine Cycle (ORC) for waste heat power generation. J Clean Prod 2018, 183, 1207–1215. [Google Scholar] [CrossRef]

- Li, G. Organic Rankine cycle environmental impact investigation under various working fluids and heat domains concerning refrigerant leakage rates. International Journal of Environmental Science and Technology 2019, 16, 431–450. [Google Scholar] [CrossRef]

- Yi, Z.; Luo, X.; Yang, Z.; Wang, C.; Chen, J.; Chen, Y.; et al. Thermo-economic-environmental optimization of a liquid separation condensation-based organic Rankine cycle driven by waste heat. J Clean Prod 2018, 184, 198–210. [Google Scholar] [CrossRef]

- Algieri, A.; Šebo, J. Energetic investigation of organic rankine cycles (ORCs) for the exploitation of low-temperature geothermal sources—a possible application in Slovakia. Procedia Computer Science 2017, 109, 833–840. [Google Scholar] [CrossRef]

- Canbolat, A.S.; Bademlioglu, A.H.; Kaynakli, O. A modeling of electricity generation by using geothermal assisted organic Rankine cycle with internal heat recovery. Energy Sources, Part A: Recovery, Utilization and Environmental Effects 2023, 45, 212–228. [Google Scholar] [CrossRef]

- Zhang, C.; Fu, J.; Yuan, P.; Liu, J. Guidelines for optimal selection of subcritical low-temperature geothermal organic Rankine cycle configuration considering reinjection temperature limits. Energies 2018, 11, 2878. [Google Scholar] [CrossRef]

- Proctor, M.; Yu, W.; Kirkpatrick, R.; Young, B. Dynamic modelling and validation of a commercial scale geothermal organic rankine cycle power plant. Energies 2016. [Google Scholar] [CrossRef]

- Uusitalo, A.; Honkatukia, J.; Turunen-Saaresti, T.; Grönman, A. Thermodynamic evaluation on the effect of working fluid type and fluids critical properties on design and performance of Organic Rankine Cycles. Journal of Cleaner 2018, 188, 253–263. [Google Scholar] [CrossRef]

- Ali, M.; Khan, T.; Hajri, E. A Computer program for working fluid selection of low temperature organic Rankine cycle. ASME Power 2015. [Google Scholar] [CrossRef]

- Pezzuolo, A.; Benato, A.; Stoppato, A.; Mirandola, A. The ORC-PD: A versatile tool for fluid selection and Organic Rankine Cycle unit design. Energy 2016, 102, 605–620. [Google Scholar] [CrossRef]

- Agromayor, R.; Nord, L.O. Fluid selection and thermodynamic optimization of organic Rankine cycles for waste heat recovery applications. Energy Procedia 2017, 129, 527–534. [Google Scholar] [CrossRef]

- Huster, W.R.; Bongartz, D.; Mitsos, A. Deterministic global optimization of the design of a geothermal organic rankine cycle. Energy Procedia 2017, 129, 50–57. [Google Scholar] [CrossRef]

- Preißinger, M.; Brüggemann, D. Thermoeconomic evaluation of modular organic Rankine cycles for waste heat recovery over a broad range of heat source temperatures and capacities. Energies 2017, 10, 269. [Google Scholar] [CrossRef]

- Heberle, F.; Hofer, M.; Brüggemann, D. A Retrofit for Geothermal Organic Rankine Cycles based on Concentrated Solar Thermal Systems. Energy Procedia 2017, 129, 692–699. [Google Scholar] [CrossRef]

- Heberle, F.; Hofer, M.; Ürlings, N.; Schröder, H.; Anderlohr, T.; Brüggemann, D. Techno-economic analysis of a solar thermal retrofit for an air-cooled geothermal Organic Rankine Cycle power plant. Renew Energy 2017, 113, 494–502. [Google Scholar] [CrossRef]

- Ahmadi, A.; El Haj Assad, M.; Jamali, D.H.; Kumar, R.; Li, Z.X.; Salameh, T.; et al. Applications of geothermal organic Rankine Cycle for electricity production. J Clean Prod 2020, 274, 122950. [Google Scholar] [CrossRef]

- Stoppato, A.; Benato, A. Life Cycle Assessment of a Commercially Available Organic Rankine Cycle Unit Coupled with a Biomass Boiler. Energies 2020, 13, 1835. [Google Scholar] [CrossRef]

- Lu, J.; Zhang, J.; Chen, S.; Pu, Y. Analysis of organic Rankine cycles using zeotropic mixtures as working fluids under different restrictive conditions. Energy Convers Manag 2016, 126, 704–716. [Google Scholar] [CrossRef]

- Tiwari, D.; Sherwani, A.F.; Asjad, M.; Arora, A. Grey relational analysis coupled with principal component analysis for optimization of the cyclic parameters of a solar-driven organic Rankine cycle. Grey Systems 2017, 7, 218–235. [Google Scholar] [CrossRef]

- Van Erdeweghe, S.; Van Bael, J.; Laenen, B.; D’haeseleer, W. Design and off-design optimization procedure for low-temperature geothermal organic Rankine cycles. Appl Energy 2019, 242, 716–731. [Google Scholar] [CrossRef]

- Imran, M.; Usman, M.; Park, B.S.; Yang, Y. Comparative assessment of Organic Rankine Cycle integration for low temperature geothermal heat source applications. Energy 2016, 102, 473–490. [Google Scholar] [CrossRef]

- Wang, Y.Z.; Zhao, J.; Wang, Y.; An, Q.S. Multi-objective optimization and grey relational analysis on configurations of organic Rankine cycle. Appl Therm Eng 2017, 114, 1355–1363. [Google Scholar] [CrossRef]

- Li, G. Organic Rankine cycle performance evaluation and thermoeconomic assessment with various applications part II: Economic assessment aspect. Renewable and Sustainable Energy Reviews 2016, 64, 490–505. [Google Scholar] [CrossRef]

- Li, G. Organic Rankine cycle performance evaluation and thermoeconomic assessment with various applications part I: Energy and exergy performance evaluation. Renewable and Sustainable Energy Reviews 2016, 53, 477–499. [Google Scholar] [CrossRef]

- Yang, M.H.; Yeh, R.H. Economic performances optimization of an organic Rankine cycle system with lower global warming potential working fluids in geothermal application. Renew Energy 2016, 85, 1201–1213. [Google Scholar] [CrossRef]

- Nondy, J.; Gogoi, T.K. Exergoeconomic investigation and multi-objective optimization of different ORC configurations for waste heat recovery: A comparative study. Energy Convers Manag 2021, 245, 114593. [Google Scholar] [CrossRef]

- Zhar, R.; Allouhi, A.; Jamil, A.; Lahrech, K. A comparative study and sensitivity analysis of different ORC configurations for waste heat recovery. Case Studies in Thermal Engineering 2021, 28, 101608. [Google Scholar] [CrossRef]

- Javed, S.; Tiwari, A.K. Performance assessment of different Organic Rankine Cycle (ORC) configurations driven by solar energy. Process Safety and Environmental Protection 2023, 171, 655–666. [Google Scholar] [CrossRef]

- Liu, C.; Gao, T.; Zhu, J.; Xu, J. Performance Optimization and Economic Analysis of Geothermal Power Generation by Subcritical and Supercritical Organic Rankine Cycles. Proceedings of the ASME Turbo Expo 2016, 3. [Google Scholar] [CrossRef]

- Manente, G.; Da Lio, L.; Lazzaretto, A. Influence of axial turbine efficiency maps on the performance of subcritical and supercritical Organic Rankine Cycle systems. Energy 2016, 107, 761–772. [Google Scholar] [CrossRef]

- Chagnon-Lessard, N.; Mathieu-Potvin, F.; Gosselin, L. Geothermal power plants with maximized specific power output: Optimal working fluid and operating conditions of subcritical and transcritical Organic Rankine Cycles. Geothermics 2016, 64, 111–124. [Google Scholar] [CrossRef]

- Moloney, F.; Almatrafi, E.; Goswami, D.Y. Working fluid parametric analysis for recuperative supercritical organic Rankine cycles for medium geothermal reservoir temperatures. Renew Energy 2020, 147, 2874–2881. [Google Scholar] [CrossRef]

- Erdogan, A.; Colpan, O. Performance assessment of shell and tube heat exchanger based subcritical and supercritical organic Rankine cycles. Thermal Science 2018, 22, 855–866. [Google Scholar] [CrossRef]

- Lukawski, M.Z.; Tester, J.W.; Dipippo, R. Impact of molecular structure of working fluids on performance of organic Rankine cycles (ORCs). Sustain Energy Fuels 2017, 1, 1098–1111. [Google Scholar] [CrossRef]

- Song, C.; Gu, M.; Miao, Z.; Liu, C.; Xu, J. Effect of fluid dryness and critical temperature on trans-critical organic Rankine cycle. Energy 2019, 174, 97–109. [Google Scholar] [CrossRef]

- Wang, X.; Levy, E.K.; Pan, C.; Romero, C.E.; Banerjee, A.; Rubio-Maya, C.; et al. Working fluid selection for organic Rankine cycle power generation using hot produced supercritical CO2 from a geothermal reservoir. Appl Therm Eng 2019, 149, 1287–1304. [Google Scholar] [CrossRef]

- Cakici, D.M.; Erdogan, A.; Colpan, C.O. Thermodynamic performance assessment of an integrated geothermal powered supercritical regenerative organic Rankine cycle and parabolic trough solar collectors. Energy 2017, 120, 306–319. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Cheng, Z.; Wang, J.; Zhao, P.; Dai, Y. Thermodynamic Optimization of a Double-pressure Organic Rankine Cycle Driven by Geothermal Heat Source. Energy Procedia 2017, 129, 591–598. [Google Scholar] [CrossRef]

- Sun, Q.; Wang, Y.; Cheng, Z.; Wang, J.; Zhao, P.; Dai, Y. Thermodynamic and economic optimization of a double-pressure organic Rankine cycle driven by low-temperature heat source. Renew Energy 2020, 147, 2822–2832. [Google Scholar] [CrossRef]

- Manente, G.; Lazzaretto, A.; Bonamico, E. Design guidelines for the choice between single and dual pressure layouts in organic Rankine cycle (ORC) systems. Energy 2017, 123, 413–431. [Google Scholar] [CrossRef]

- Wang, S.; Liu, C.; Zhang, C.; Xu, X.; Li, Q. Thermo-economic evaluations of dual pressure organic Rankine cycle (DPORC) driven by geothermal heat source. Journal of Renewable and Sustainable Energy 2018, 10, 063901. [Google Scholar] [CrossRef]

- Fontalvo, A.; Solano, J.; Pedraza, C.; Bula, A.; Quiroga, A.G.; Padilla, R.V. Energy, Exergy and Economic Evaluation Comparison of Small-Scale Single and Dual Pressure Organic Rankine Cycles Integrated with Low-Grade Heat Sources. Entropy 2017, 19, 476. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Energetic optimization of regenerative Organic Rankine Cycle (ORC) configurations. Energy Convers Manag 2018, 159, 353–370. [Google Scholar] [CrossRef]

- Braimakis, K.; Karellas, S. Exergetic optimization of double stage Organic Rankine Cycle (ORC). Energy 2018, 149, 296–313. [Google Scholar] [CrossRef]

- Liu, G.; Wang, Q.; Xu, J.; Miao, Z. Exergy Analysis of Two-Stage Organic Rankine Cycle Power Generation System. Entropy 2021, 23, 43. [Google Scholar] [CrossRef] [PubMed]

- Li, T.; Yuan, Z.; Li, W.; Yang, J.; Zhu, J. Strengthening mechanisms of two-stage evaporation strategy on system performance for organic Rankine cycle. Energy 2016, 101, 532–540. [Google Scholar] [CrossRef]

- Li, T.L.; Yuan, Z.H.; Xu, P.; Zhu, J.L. Entransy dissipation/loss-based optimization of two-stage organic Rankine cycle (TSORC) with R245fa for geothermal power generation. Sci China Technol Sci 2016, 59, 1524–1536. [Google Scholar] [CrossRef]

- Wang, J.; Xu, P.; Li, T.; Zhu, J. Performance enhancement of organic Rankine cycle with two-stage evaporation using energy and exergy analyses. Geothermics 2017, 65, 126–134. [Google Scholar] [CrossRef]

- Li, J.; Ge, Z.; Duan, Y.; Yang, Z.; Liu, Q. Parametric optimization and thermodynamic performance comparison of single-pressure and dual-pressure evaporation organic Rankine cycles. Appl Energy 2018, 217, 409–421. [Google Scholar] [CrossRef]

- Wang, M.; Chen, Y.; Liu, Q.; Yuanyuan, Z. Thermodynamic and thermo-economic analysis of dual-pressure and single pressure evaporation organic Rankine cycles. Energy Convers Manag 2018, 177, 718–736. [Google Scholar] [CrossRef]

- Kazemi, N.; Samadi, F. Thermodynamic, economic and thermo-economic optimization of a new proposed organic Rankine cycle for energy production from geothermal resources. Energy Convers Manag 2016, 121, 391–401. [Google Scholar] [CrossRef]

- Samadi, F.; Kazemi, N. Exergoeconomic analysis of zeotropic mixture on the new proposed organic Rankine cycle for energy production from geothermal resources. Renew Energy 2020, 152, 1250–1265. [Google Scholar] [CrossRef]

- Nami, H.; Nemati, A.; Jabbari Fard, F. Conventional and advanced exergy analyses of a geothermal driven dual fluid organic Rankine cycle (ORC). Appl Therm Eng 2017, 122, 59–70. [Google Scholar] [CrossRef]

- Luo, X.; Huang, R.; Yang, Z.; Chen, J.; Chen, Y. Performance investigation of a novel zeotropic organic Rankine cycle coupling liquid separation condensation and multi-pressure evaporation. Energy Convers Manag 2018, 161, 112–127. [Google Scholar] [CrossRef]

- Zhou, Y.; Li, S.; Sun, L.; Zhao, S.; Ashraf Talesh, S.S. Optimization and thermodynamic performance analysis of a power generation system based on geothermal flash and dual-pressure evaporation organic Rankine cycles using zeotropic mixtures. Energy 2020, 194, 116785. [Google Scholar] [CrossRef]

- Surendran, A.; Seshadri, S. Design and performance analysis of a novel Transcritical Regenerative Series Two stage Organic Rankine Cycle for dual source waste heat recovery. Energy 2020, 203, 117800. [Google Scholar] [CrossRef]

- Li, T.; Hu, X.; Wang, J.; Kong, X.; Liu, J.; Zhu, J. Performance improvement of two-stage serial organic Rankine cycle (TSORC) driven by dual-level heat sources of geothermal energy coupled with solar energy. Geothermics 2018, 76, 261–270. [Google Scholar] [CrossRef]

- Heberle, F.; Schifflechner, C.; Brüggemann, D. Life cycle assessment of Organic Rankine Cycles for geothermal power generation considering low-GWP working fluids. Geothermics 2016, 64, 392–400. [Google Scholar] [CrossRef]

- Sadeghi, M.; Nemati, A.; ghavimi, A.; Yari, M. Thermodynamic analysis and multi-objective optimization of various ORC (organic Rankine cycle) configurations using zeotropic mixtures. Energy 2016, 109, 791–802. [Google Scholar] [CrossRef]

- Chagnon-Lessard, N.; Mathieu-Potvin, F.; Gosselin, L. Optimal design of geothermal power plants: A comparison of single-pressure and dual-pressure organic Rankine cycles. Geothermics 2020, 86, 101787. [Google Scholar] [CrossRef]

- Wang, Q.; Wang, J.; Li, T.; Meng, N. Techno-economic performance of two-stage series evaporation organic Rankine cycle with dual-level heat sources. Appl Therm Eng 2020, 171, 115078. [Google Scholar] [CrossRef]

- Wang, Z.; Xia, X.; Pan, H.; Zuo, Q.; Zhou, N.; Xie, B. Fluid selection and advanced exergy analysis of dual-loop ORC using zeotropic mixture. Appl Therm Eng 2021, 185, 116423. [Google Scholar] [CrossRef]

- Najjar, Y.S.H.; Qatramez, A.E. Energy utilisation in a combined geothermal and organic Rankine power cycles. International Journal of Sustainable Energy 2019, 38, 831–848. [Google Scholar] [CrossRef]

- Matuszewska, D.; Olczak, P. Evaluation of Using Gas Turbine to Increase Efficiency of the Organic Rankine Cycle (ORC). Energies 2020, 13, 1499. [Google Scholar] [CrossRef]

- Yağlı, H.; Koç, Y.; Kalay, H. Optimisation and exergy analysis of an organic Rankine cycle (ORC) used as a bottoming cycle in a cogeneration system producing steam and power. Sustainable Energy Technologies and Assessments 2021, 44, 100985. [Google Scholar] [CrossRef]

- Hassani Mokarram, N.; Mosaffa, A.H. Investigation of the thermoeconomic improvement of integrating enhanced geothermal single flash with transcritical organic Rankine cycle. Energy Convers Manag 2020, 213, 112831. [Google Scholar] [CrossRef]

- Li, Z.; Li, W.; Xu, B. Optimization of mixed working fluids for a novel trigeneration system based on organic Rankine cycle installed with heat pumps. Appl Therm Eng 2016, 94, 754–762. [Google Scholar] [CrossRef]

- Sun, Y.; Lu, J.; Wang, J.; Li, T.; Li, Y.; Hou, Y.; et al. Performance improvement of two-stage serial organic Rankine cycle (TSORC) integrated with absorption refrigeration (AR) for geothermal power generation. Geothermics 2017, 69, 110–118. [Google Scholar] [CrossRef]

- Ehyaei, M.A.; Ahmadi, A.; El Haj Assad, M.; Rosen, M.A. Investigation of an integrated system combining an Organic Rankine Cycle and absorption chiller driven by geothermal energy: Energy, exergy, and economic analyses and optimization. J Clean Prod 2020, 258, 120780. [Google Scholar] [CrossRef]

- Leveni, M.; Cozzolino, R. Energy, exergy, and cost comparison of Goswami cycle and cascade organic Rankine cycle/absorption chiller system for geothermal application. Energy Convers Manag 2021, 227, 113598. [Google Scholar] [CrossRef]

- Wang, N.; Zhang, S.; Fei, Z.; Zhang, W.; Shao, L.; Sardari, F. Thermodynamic performance analysis a power and cooling generation system based on geothermal flash, organic Rankine cycles, and ejector refrigeration cycle; application of zeotropic mixtures. Sustainable Energy Technologies and Assessments 2020, 40, 100749. [Google Scholar] [CrossRef]

- Jafary, S.; Khalilarya, S.; Shawabkeh, A.; Wae-hayee, M.; Hashemian, M. A complete energetic and exergetic analysis of a solar powered trigeneration system with two novel organic Rankine cycle (ORC) configurations. J Clean Prod 2021, 281, 124552. [Google Scholar] [CrossRef]

- Jiménez-García, J.C.; Moreno-Cruz, I.; Rivera, W. Modeling of an Organic Rankine Cycle Integrated into a Double-Effect Absorption System for the Simultaneous Production of Power and Cooling. Processes 2023, 11, 667. [Google Scholar] [CrossRef]

- Lizarte, R.; Palacios-Lorenzo, M.E.; Marcos, J.D. Parametric study of a novel organic Rankine cycle combined with a cascade refrigeration cycle (ORC-CRS) using natural refrigerants. Appl Therm Eng 2017, 127, 378–389. [Google Scholar] [CrossRef]

- Li, W.; Lin, X.; Cao, C.; Gong, Z.; Gao, Y. Organic Rankine Cycle-assisted ground source heat pump combisystem for space heating in cold regions. Energy Convers Manag 2018, 165, 195–205. [Google Scholar] [CrossRef]

- Marty, F.; Serra, S.; Sochard, S.; Reneaume, J.M. Simultaneous optimization of the district heating network topology and the Organic Rankine Cycle sizing of a geothermal plant. Energy 2018, 159, 1060–1074. [Google Scholar] [CrossRef]

- Maali, R.; Khir, T. Thermodynamic analysis and optimization of an ORC hybrid geothermal–solar power plant. EuroMediterr J Environ Integr 2023. [Google Scholar] [CrossRef]

- Boukelia, T.E.; Arslan, O.; Djimli, S.; Kabar, Y. ORC fluids selection for a bottoming binary geothermal power plant integrated with a CSP plant. Energy 2023, 265, 126186. [Google Scholar] [CrossRef]

- Javanshir, N.; Mahmoudi, S.M.S.; Rosen, M.A. Thermodynamic and Exergoeconomic Analyses of a Novel Combined Cycle Comprised of Vapor-Compression Refrigeration and Organic Rankine Cycles. Sustainability 2019, 11, 3374. [Google Scholar] [CrossRef]

- Pashapour, M.; Jafarmadar, S.; Khalil Arya, S. Exergy Analysis of a Novel Combined System Consisting of a Gas Turbine, an Organic Rankine Cycle and an Absorption Chiller to Produce Power, Heat and Cold. International Journal of Engineering 2019, 32, 1320–1326. [Google Scholar] [CrossRef]

- Sharifishourabi, M.; Arab Chadegani, E. Performance assessment of a new organic Rankine cycle based multi-generation system integrated with a triple effect absorption system. Energy Convers Manag 2017, 150, 787–799. [Google Scholar] [CrossRef]

- Lee, H.; Ryu, B.; Anh, D.P.; Roh, G.; Lee, S.; Kang, H. Thermodynamic analysis and assessment of novel ORC- DEC integrated PEMFC system for liquid hydrogen fueled ship application. Int J Hydrogen Energy 2023, 48, 3135–3153. [Google Scholar] [CrossRef]

- Geng, D.; Du, Y.; Yang, R. Performance analysis of an organic Rankine cycle for a reverse osmosis desalination system using zeotropic mixtures. Desalination 2016, 381, 38–46. [Google Scholar] [CrossRef]

- Wang, E.; Yu, Z.; Collings, P. Dynamic control strategy of a distillation system for a composition-adjustable organic Rankine cycle. Energy 2017, 141, 1038–1051. [Google Scholar] [CrossRef]

- Gholamian, E.; Habibollahzade, A.; Zare, V. Development and multi-objective optimization of geothermal-based organic Rankine cycle integrated with thermoelectric generator and proton exchange membrane electrolyzer for power and hydrogen production. Energy Convers Manag 2018, 174, 112–125. [Google Scholar] [CrossRef]

- Azad, A.; Fakhari, I.; Ahmadi, P.; Javani, N. Analysis and optimization of a fuel cell integrated with series two-stage organic Rankine cycle with zeotropic mixtures. Int J Hydrogen Energy 2022, 47, 3449–3472. [Google Scholar] [CrossRef]

- Kaşka, Ö.; Yılmaz, C.; Bor, O.; Tokgöz, N. The performance assessment of a combined organic Rankine-vapor compression refrigeration cycle aided hydrogen liquefaction. Int J Hydrogen Energy 2018, 43, 20192–20202. [Google Scholar] [CrossRef]

- Ganjehsarabi, H. Mixed refrigerant as working fluid in Organic Rankine Cycle for hydrogen production driven by geothermal energy. Int J Hydrogen Energy 2019, 44, 18703–18711. [Google Scholar] [CrossRef]

- Han, J.; Wang, X.; Xu, J.; Yi, N.; Ashraf Talesh, S.S. Thermodynamic analysis and optimization of an innovative geothermal-based organic Rankine cycle using zeotropic mixtures for power and hydrogen production. Int J Hydrogen Energy 2020, 45, 8282–8299. [Google Scholar] [CrossRef]

- Cao, Y.; Haghghi, M.A.; Shamsaiee, M.; Athari, H.; Ghaemi, M.; Rosen, M.A. Evaluation and optimization of a novel geothermal-driven hydrogen production system using an electrolyser fed by a two-stage organic Rankine cycle with different working fluids. J Energy Storage 2020, 32, 101766. [Google Scholar] [CrossRef]

- Fallah, M.; Mohammadi, Z.; Mahmoudi, S.M.S. Advanced exergy analysis of the combined S–CO2/ORC system. Energy 2022, 241, 122870. [Google Scholar] [CrossRef]

- Wieland, C.; Schifflechner, C.; Braimakis, K.; Kaufmann, F.; Dawo, F.; Karellas, S.; et al. Innovations for organic Rankine cycle power systems: Current trends and future perspectives. Appl Therm Eng 2023, 225, 120201. [Google Scholar] [CrossRef]

| Reference | Cycle more efficient | Conditions | Working fluid | Output | Efficiency (%) | Cost (LCOE or PBP) | Component with the highest irreversibilities | |

|---|---|---|---|---|---|---|---|---|

| Thermal | Exergy | |||||||

| Sun et al. [88,89] | Basic, two-stage* | THS = 113 °C | R21, R114, and R245fa* | 818.6 kW | - | 5.85 | - | HPE |

| Manente et al. [90] | Basic, two-stage* | THS = 200 °C | R134a, R1234ze(Z), isobutane, isopentane, and cyclopentane | 8573 kW | 15.36 | - | - | - |

| Wang et al. [91] | Two-stage | THS = 113.8 °C | R1234zd | 614.27 kW | - | - | PBP = 3.99 | - |

| Fontalvo et al. [92] | Two-stage, basic, regenerative* | THS = 200 °C | R1234yf, R1234ze(E)*, and R1234ze(Z) | 33 kW | 18.1 | 60.0 | 0.3 USD/kWh PBP = 8 years |

- |

| Braimakis and Karellas [93,94] | Basic, two basic operating in cascade | THS = 100 °C | butane, pentane, cyclopentane*, cyclohexane, toluene, R134ze, and R134yf | - | 5.0 | 25.0 | - | - |

| Liu et al. [95] | Basic, two basic operating in cascade | THS = 140 °C | R600, R600a, R601a, and R245fa | - | - | 41.0 | - | - |

| Li et al. [96,97] | Two-stage | THS = 100 °C | R245fa | 9.0 kW | 9.2 | 42.0 | - | HPE |

| Li et al. [99] | Basic, two-stage | THS = 200 °C | R227ea, R236ea, R245fa*, R600, R600a, R601, R601a, R1234yf and R1234ze(E) | 100 kW | 13.5 | - | - | - |

| Wang et al. [100] | Basic, two-stage* | THS = 160 °C | Isobutane | 241.7 kW | 11.29 | - | 0.14 USD/kWh | - |

| Kazemi and Samadi [101] | Three-pressure levels | THS = 134.3 °C | Isobutane and R123* | - | 15.31 | 54.25 | - | Condenser |

| Samadi and Kazemi [102] | Three different pressures levels | THS = 124.5 °C | Isobutane, isopentane* | - | 13.78 | 53.02 | - | - |

| Luo et al. [104] | Basic, two basic operating in parallel* | THS = 195 °C | Isobutane-isopentane (0.9–0.1) | 407.62 kW | - | 31.77 | HPE | |

| Zhou et al. [105] | Two-stage | THS = 188 °C | 6 working mixtures, pentane/Cis-2-butane (0.539/0.461)* | 5983.19 kW | 18.43 | 62.96 | - | HPE |

| Surendran and Seshadri [106] | Transcritical regenerative two-stage | THS = 302 °C | Cyclopentane | 349 kW | 15.3 | 17.4 | - | HPE |

| Sadeghi et al. [109] | Basic, two-stage parallel, series two-stage* | THS = 100 °C | R407A | 940.3 kW | 8.53 | 55.63 | - | HPE |

| Wang et al. [111] | Two-stage series with dual-level HS | THS = 104 °C | R123 | 78 kW | 6.0 | 28.0 | 0.084 USD/kWh PBP = 1.71 years |

- |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).