IEEE-30 Bus System

The system data are presented in [

1,

51,

52]. According to the given scenario, 19 control variables are considered. These control variables are as follows:

6 variables of generator bus voltages

4 variables of transformer tap settings

9 variables of reactive power of the VAR compensators

As seen in

Table 2, the voltages are bounded by a minimum of 0.90 and a maximum of 1.10 per unit (p.u.), with 1.10 being the upper threshold and 0.90 being the lower threshold. Similarly, the transformer taps are restricted within a range of 0.9 to 1.1, where 1.1 signifies the upper limit and 0.9 signifies the lower limit. The VAR compensators are constrained with a lower limit of 0 MVARs and an upper limit of 7 MVARs, respectively.

As seen in

Table 3, the proposed GWO algorithm demonstrated a significant percentage improvement in both total loss and voltage deviation compared to PSO, GA, and ABC methods. Specifically, the GWO method achieved a percentage improvement of 11.55%, 21.99%, and 10.14% in total loss compared to PSO, GA, and ABC, respectively. Similarly, the GWO method achieved a percentage improvement of 210.54%, 1.62%, and 57.09% in voltage deviation compared to PSO, GA, and ABC, respectively.

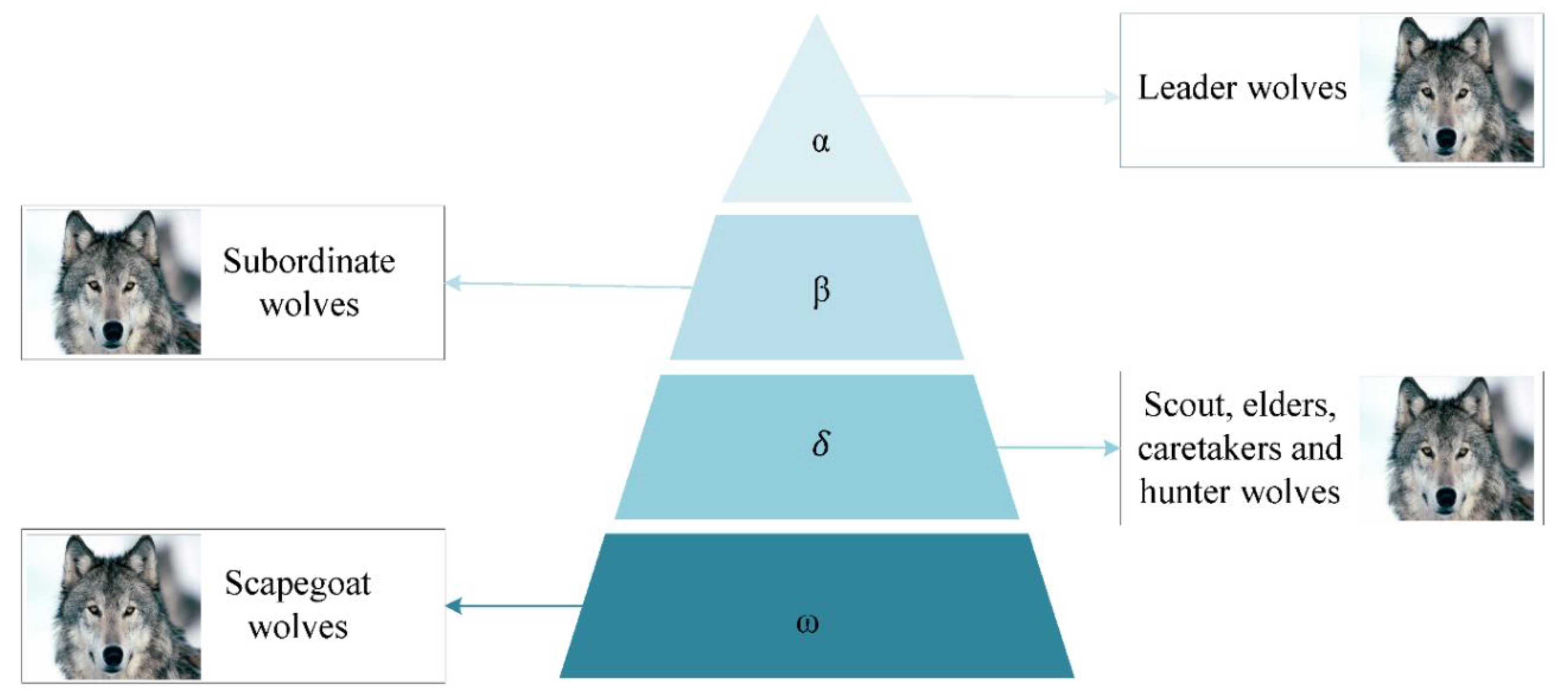

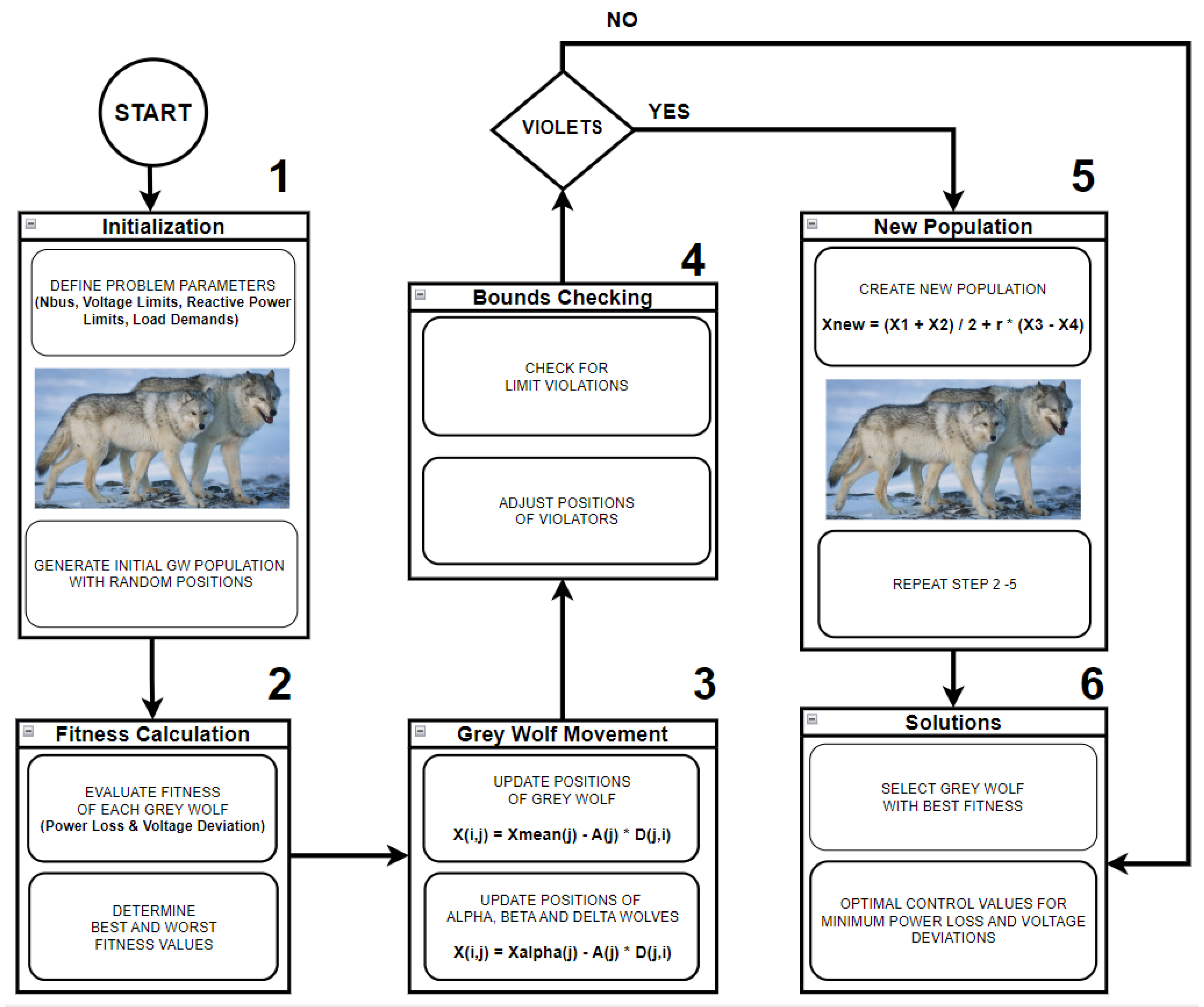

In the proposed GWO algorithm, the number of agents is an important parameter that affects the optimization performance. Increasing the number of agents can help to improve the exploration ability of the algorithm and increase the probability of finding the global optimal solution. However, increasing the number of agents also increases the computational complexity of the algorithm.

The conducted study investigated the effect of the number of agents on the convergence behavior of the GWO algorithm, and convergence curves were plotted using different numbers of agents. The results showed that increasing the number of agents led to faster convergence and improved optimization performance. However, this also resulted in increased computational time, which could limit the practical application of the algorithm. Selecting an appropriate number of agents is crucial in balancing the trade-off between computational complexity and performance in the GWO algorithm for optimization.

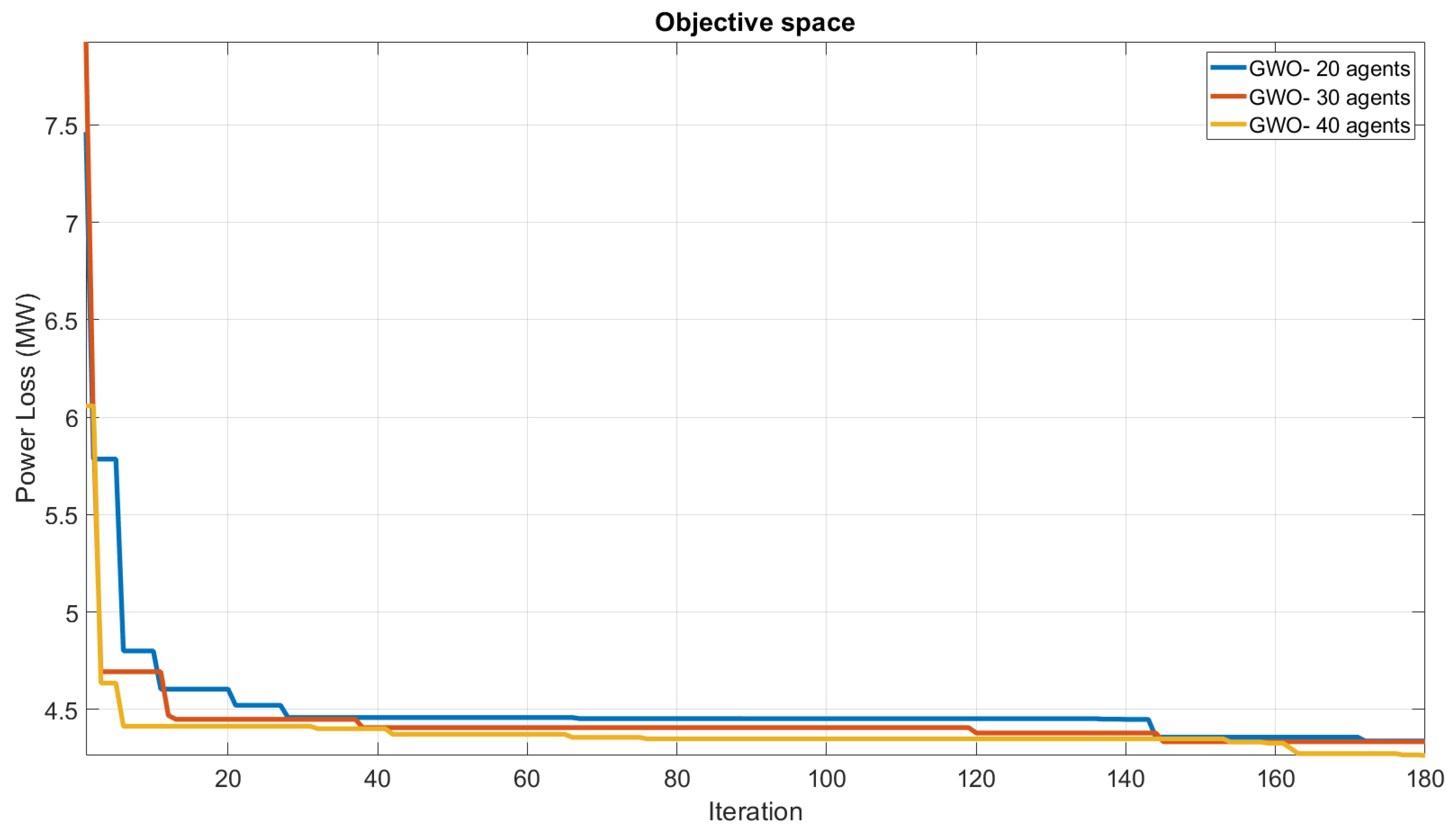

As shown in

Figure 3 of the study, the proposed GWO algorithm demonstrated excellent convergence performance for Scenario 1 of the IEEE-30 test system, with agent numbers of 20, 30, and 40. These results suggest that the GWO algorithm efficiently converges, and holds promising potential in solving optimization problems for various test systems. The obtained convergence curves in the study can provide insights into selecting the optimal number of agents for the GWO algorithm in various optimization problems.

The system data are presented in [

51,

56]. According to the given scenario, 25 control variables are considered. These control variables are as follows:

6 variables of generated power

6 variables of generator bus voltages

4 variables of transformer tap settings

9 variables of reactive power of the VAR compensators

As seen in

Table 4, the lower and upper limits of the generated power value range from 0.05 p.u. to 1.00 p.u. The voltages are bounded by a minimum of 1.00 and a maximum of 1.10 p.u. with 1.10 being the upper threshold and 1.00 being the lower threshold. Similarly, the transformer taps are restricted within a range of 0.9 to 1.1, where 1.1 signifies the upper limit and 0.9 signifies the lower limit. The VAR compensators are constrained with a lower limit of 0 MVARs and an upper limit of 5 MVARs, respectively.

According to the results provided, the GWO (proposed) algorithm outperforms the ABC algorithm in terms of both total loss and voltage deviation. The total loss for GWO (proposed) is significantly reduced by 46.96% compared to ABC, while the voltage deviation is improved by 5.99%. These findings suggest that the GWO (proposed) algorithm offers superior performance in minimizing total loss and voltage deviation, indicating its effectiveness for power system optimization. The percentage improvements in both total loss and voltage deviation highlight the potential of the GWO (proposed) algorithm as a promising optimization technique for power system applications, potentially leading to more efficient and reliable power system operations.

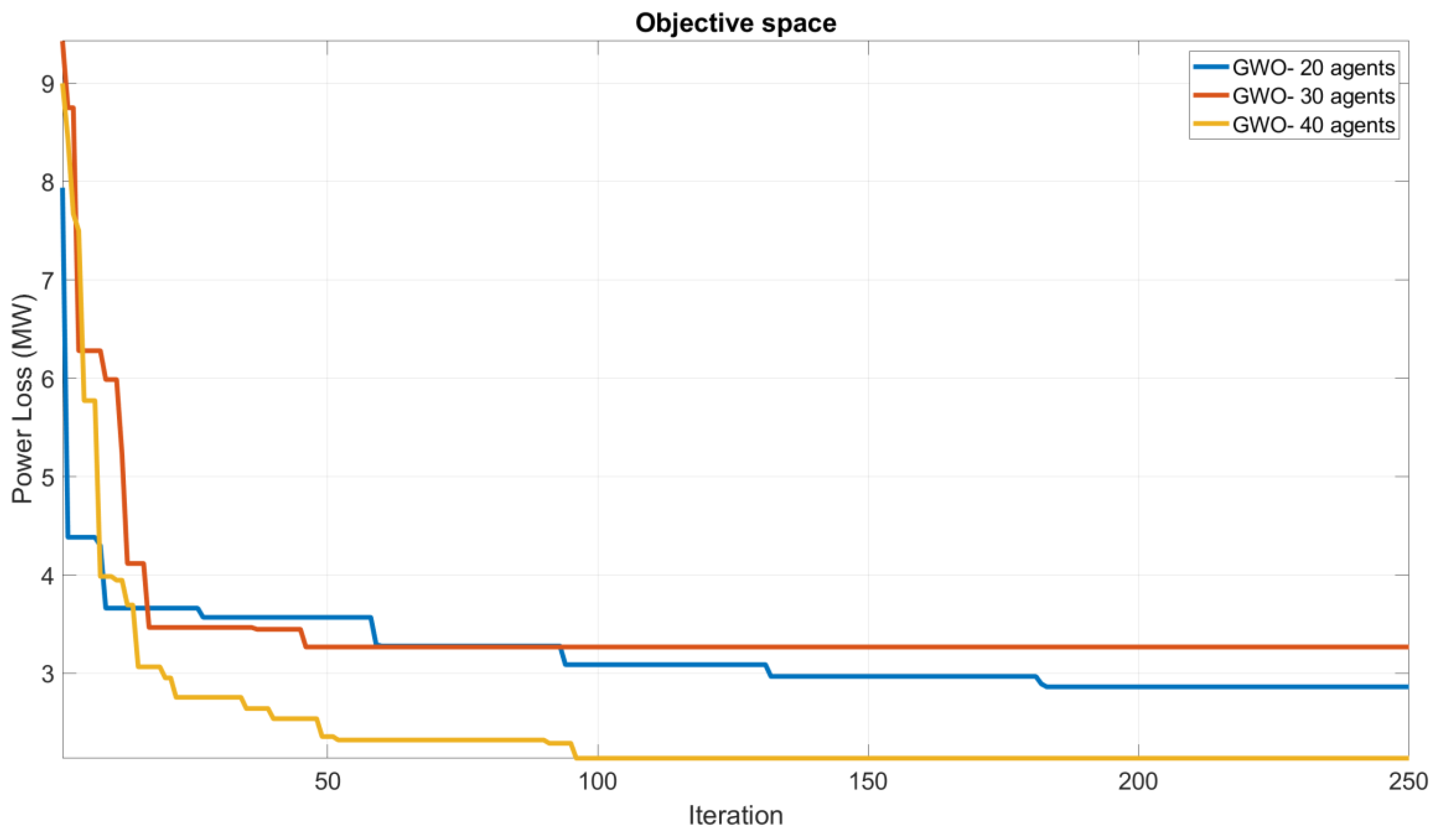

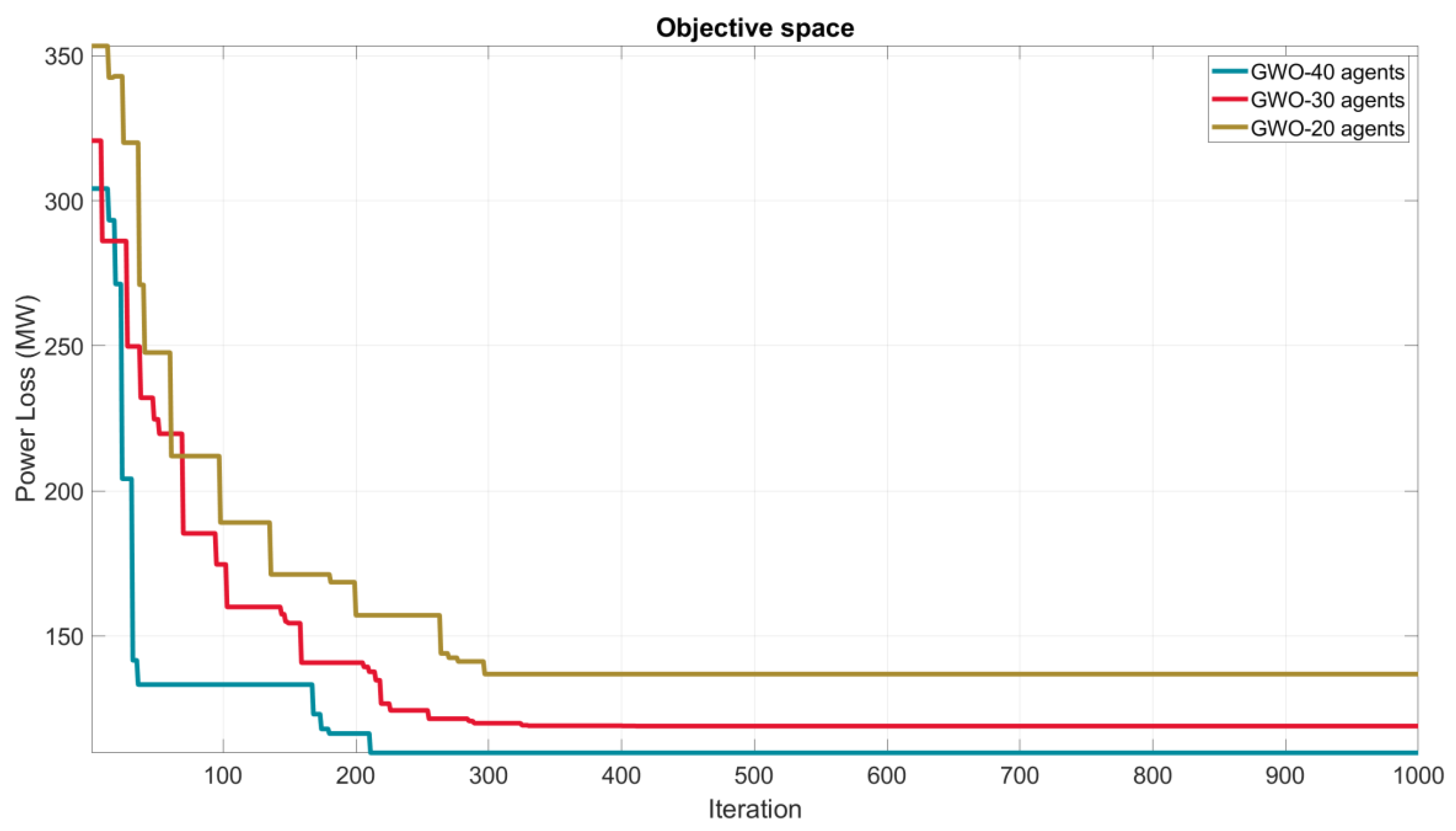

The power loss convergence analysis of the GWO (proposed) algorithm, as depicted in

Figure 4, reveals its remarkable performance in achieving convergence for Scenario 2 of the IEEE-30 test system, employing varying agent numbers such as 20, 30, and 40.

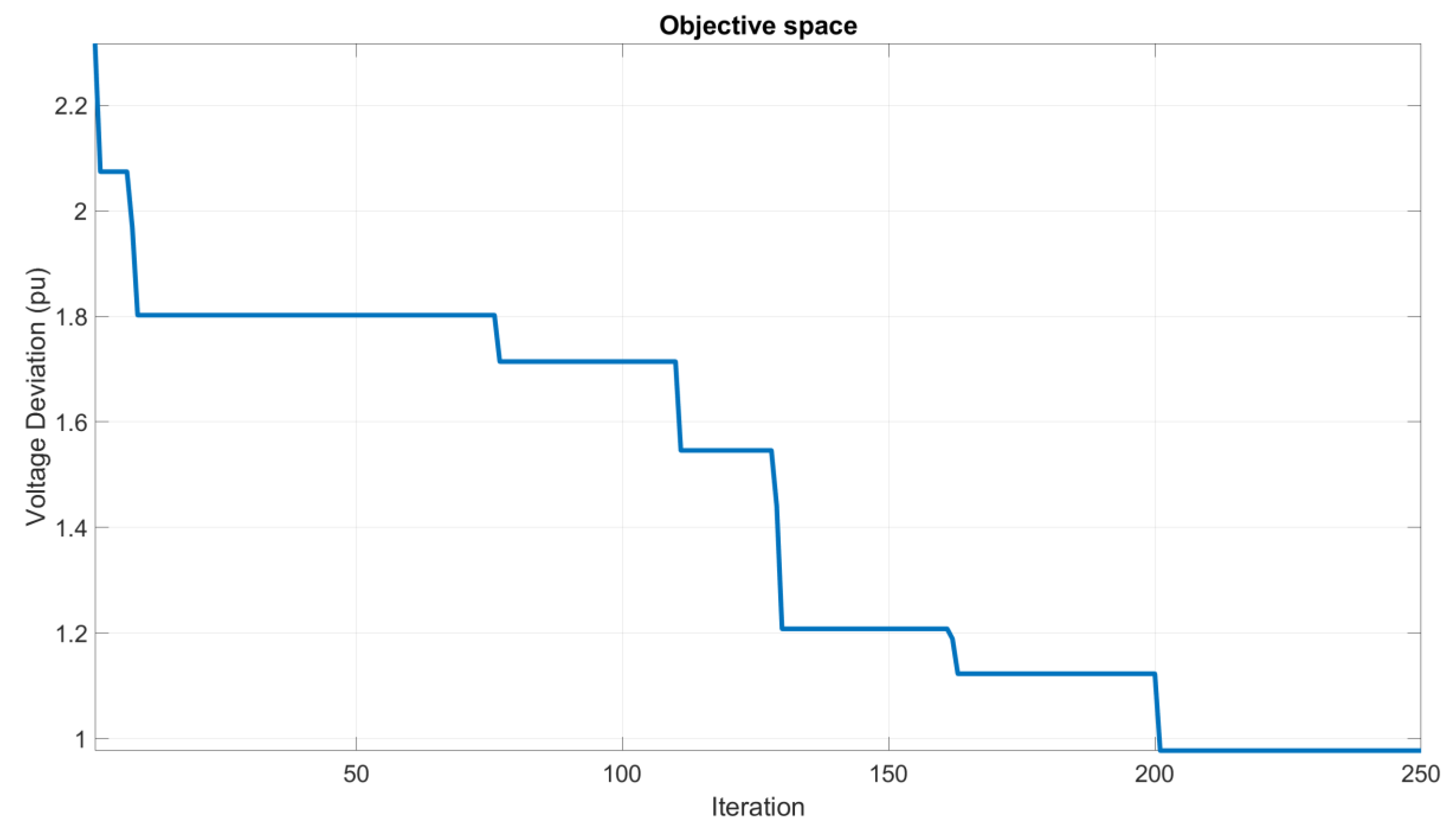

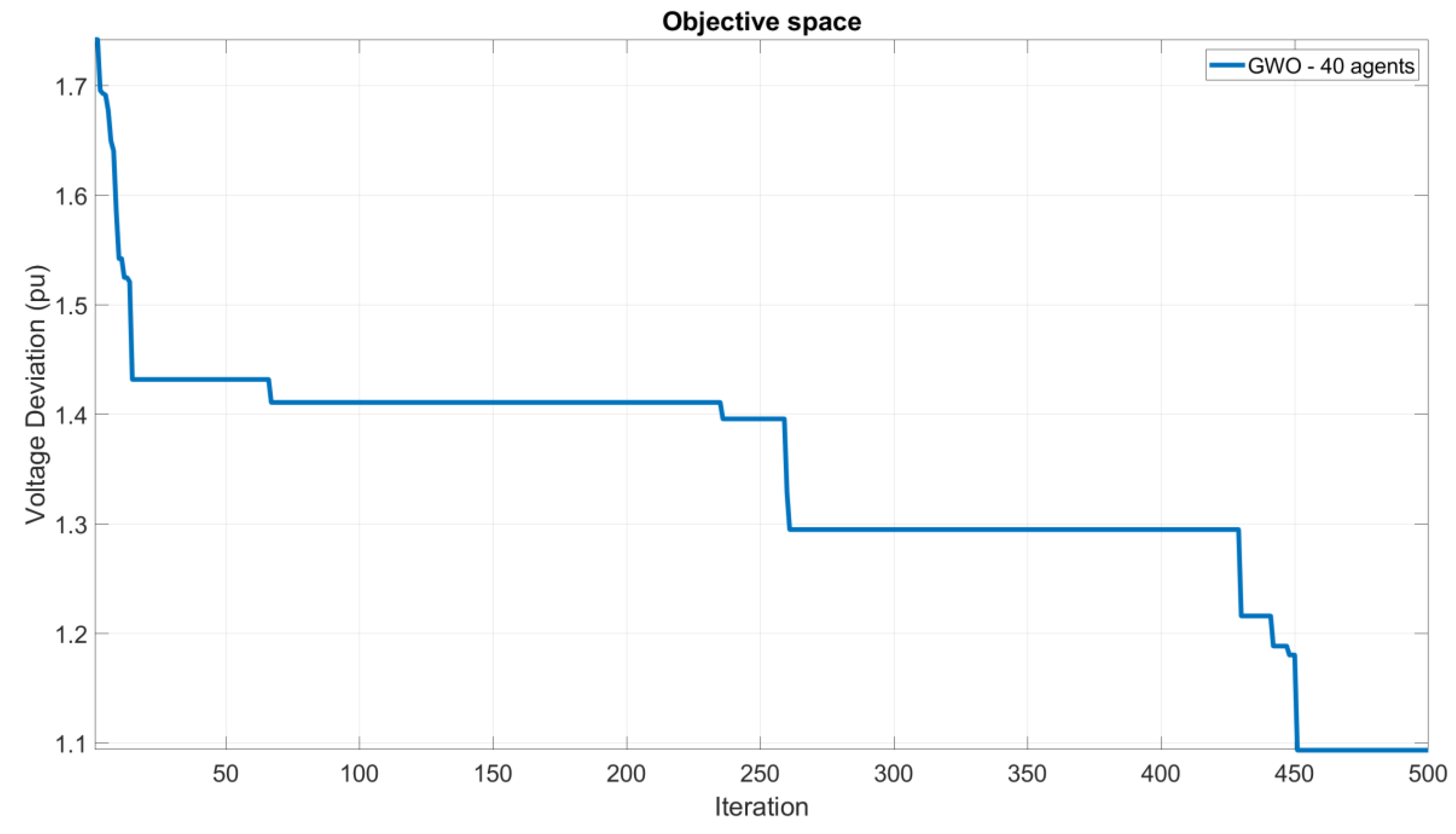

The voltage deviation convergence analysis of the GWO (proposed) algorithm, as depicted in

Figure 5, reveals its remarkable performance in achieving convergence for Scenario 2 of the IEEE-30 test system, employing under 40 agents. The results indicate that the GWO algorithm not only achieves low total power loss (2.0679 MW) but also exhibits minimal voltage deviation (0.9769 pu), underscoring its effectiveness in optimizing both power loss and voltage deviation simultaneously.

The IEEE-30 bus system with 27 control variables is an extended version of IEEE-30 bus system that incorporates two additional DGU control variables. These variables are the generator voltage magnitude control and the generator power control. According to the given scenario, 27 control variables are considered. These control variables are as follows:

7 variables of generated power with wind power

7 variables of generator bus voltages with wind bus

4 variables of transformer tap settings

9 variables of reactive power of the VAR compensators

The

Table 6 provides the lower and upper limits for variables such as wind power, generated power, voltages, tap settings, and compensation devices. These limits define the constrained ranges for each variable during the optimization process, guiding the optimization to achieve optimal results within these limits for improved system performance.

The

Table 7 provides an analysis of the performance of the GWO (proposed) algorithm on the control variables for the IEEE-30 test system scenario, including voltage deviation and total loss of power. The table presents the lower and upper limits for each control variable, as well as the results obtained by the GWO algorithm within these limits.

The GWO (proposed) algorithm effectively operates within the specified limits for all control variables, including Pwind and Vwind.

The inclusion of a DGU unit (0-10 MW) with wind power and wind bus voltage control parameters in the GWO (proposed) algorithm for optimizing IEEE 30 scenario 2 without modifying generator power values resulted in wind power control at 9.8 MW and wind bus voltage at 1.0604 pu among 27 optimized control variables. This suggests effective incorporation of DGU unit and control parameters by GWO, leading to satisfactory results in the IEEE 30 test system scenario. Total power loss is 1.8010 MW, and voltage deviation is 1.0154 pu, indicating successful optimization of control variables for the IEEE-30 test system.

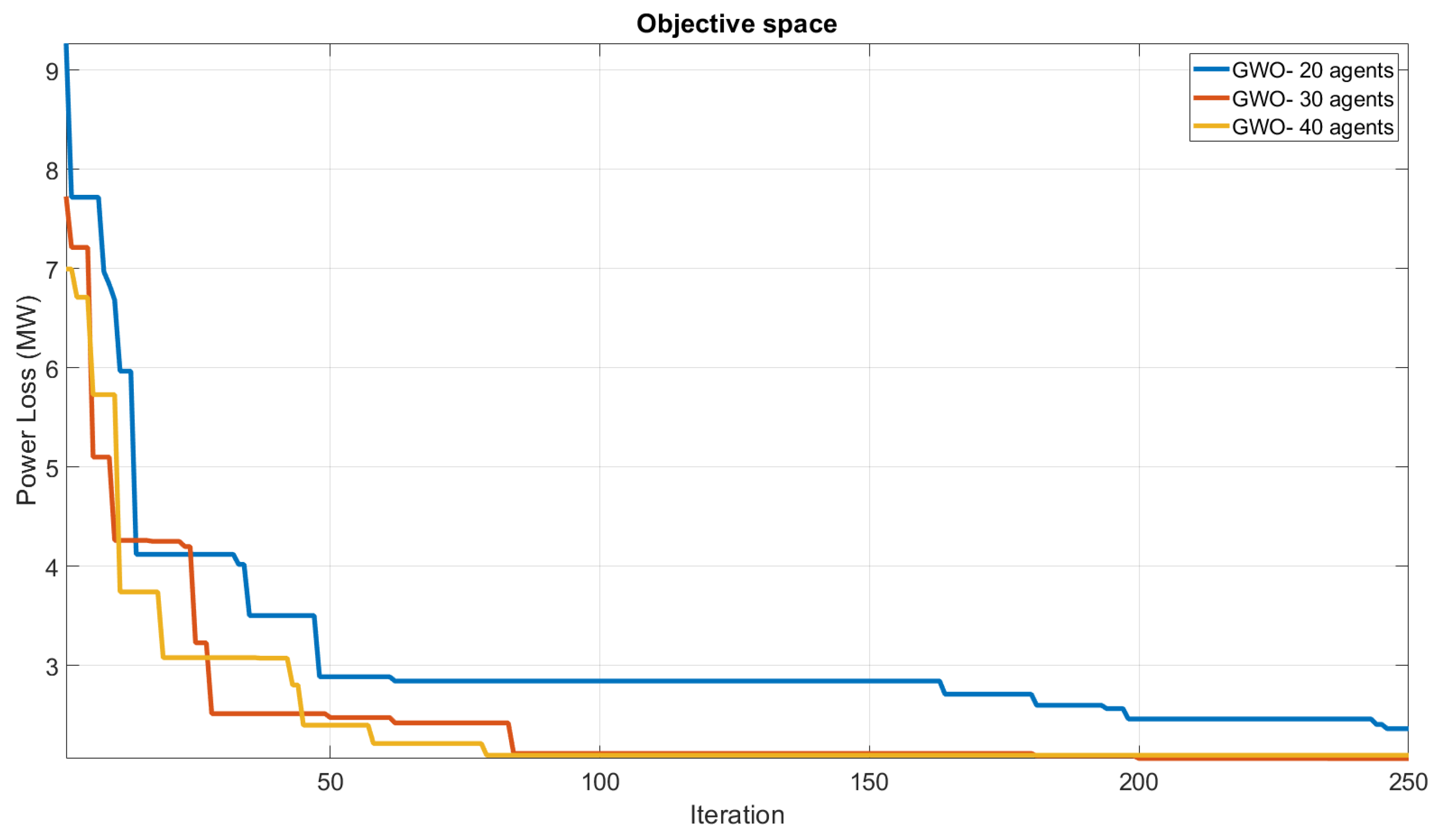

The power loss convergence analysis of the GWO (proposed) algorithm, as depicted in

Figure 6, reveals its remarkable performance in achieving convergence for Scenario 3 of the IEEE-30 test system, employing varying agent numbers such as 20, 30, and 40. The figure depicts the convergence values plotted up to 250 iterations for all agent numbers. Notably, it has been observed that the GWO (proposed) algorithm with 40 agents achieves the complete convergence value after only 100 iterations, showcasing the remarkable rapid convergence capability of the proposed algorithm.

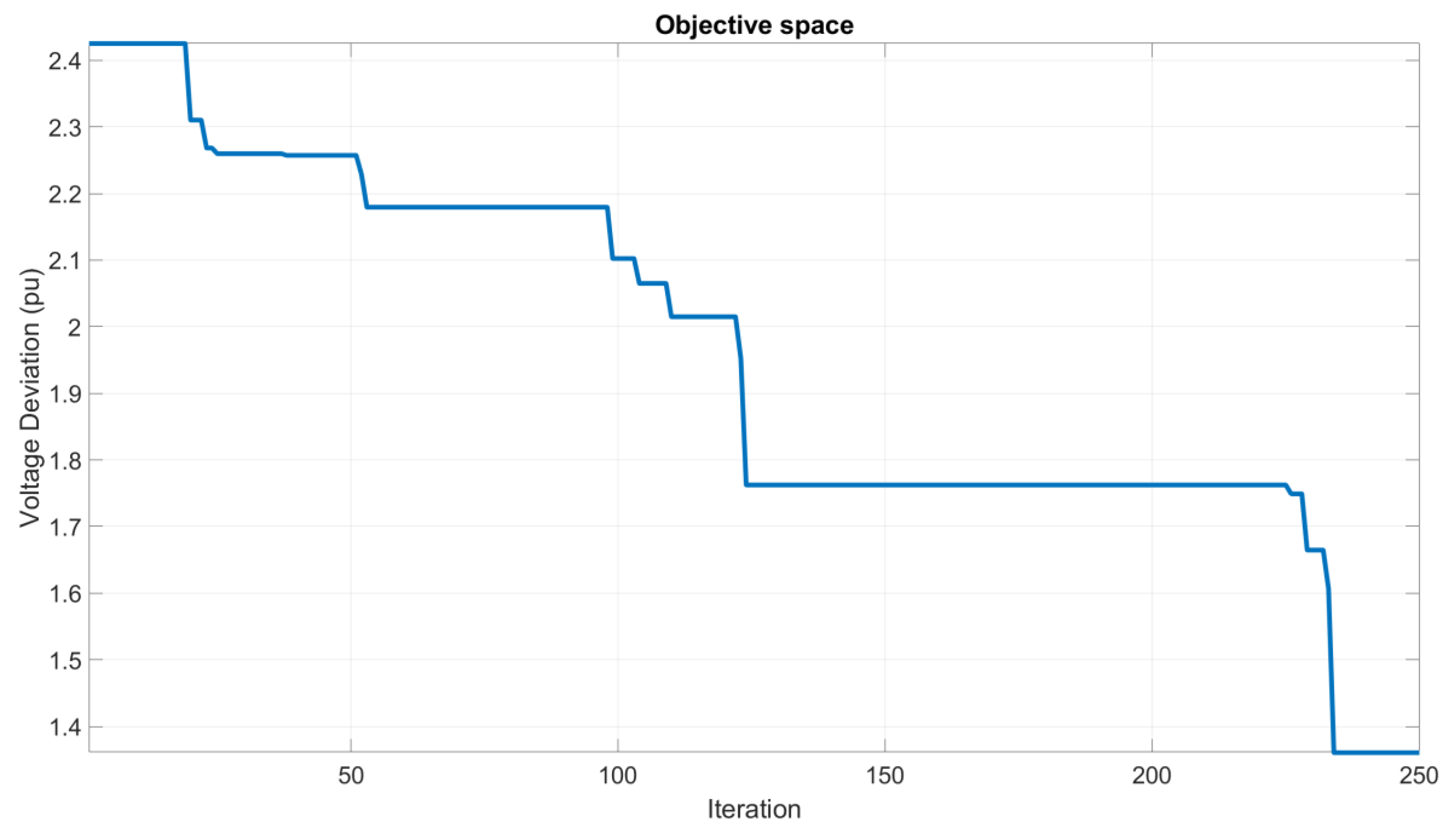

Similary, the voltage deviation convergence analysis of the GWO (proposed) algorithm, as depicted in

Figure 7, reveals its remarkable performance in achieving convergence for Scenario 3 of the IEEE-30 test system, employing for 40 agents.

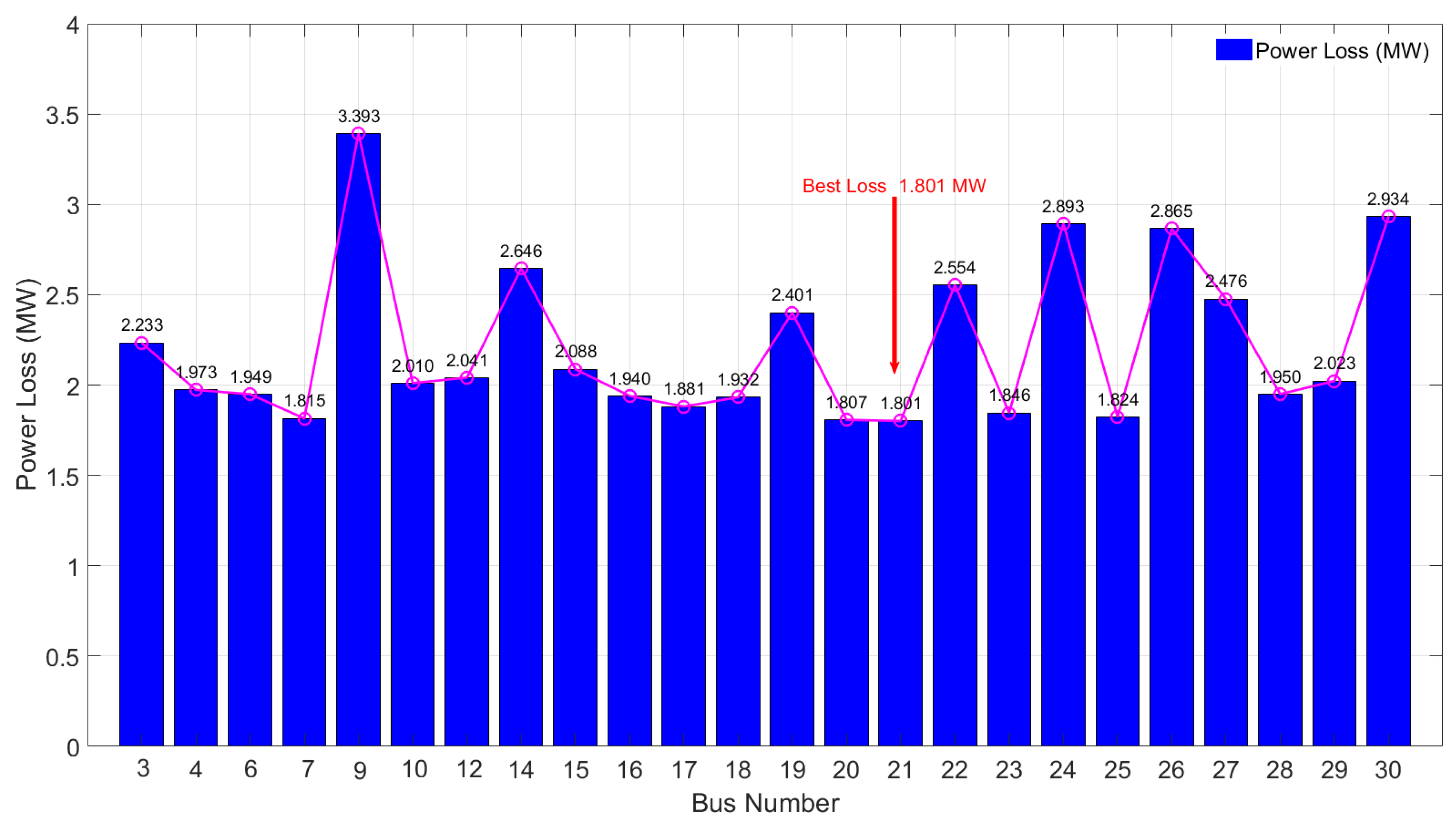

In the IEEE 30-bus test system, distributed generation units (DGUs) with wind power as a renewable energy source are connected to the buses, except for buses 1, 2, 5, 8, 11, and 13. Power loss values were observed for each bus. It was observed that the DGU connected to bus 21 caused the lowest power loss, with a value of 1.801 MW. The largest power loss was determined to occur with the DGU connected to bus 9, with a loss value of 3.393 MW. Therefore, the power loss difference between the DGU connected to bus 9 and the DGU connected to bus 21 is approximately 88.34% based on the observed values. Consequently, the implementation of the GWO method in the ORPD process yields favorable outcomes, including the simultaneous mitigation of power loss and voltage deviation, as well as the optimization of DGU placement, contributing to enhanced integration of renewable energy sources.

IEEE-118 Bus System

The system data are presented in [

53,

54,

55,

56]. According to the given scenario, 77 control variables are considered. These control variables are as follows:

54 variables of generator bus voltages

9 variables of transformer tap settings

14 variables of reactive power of the VAR compensators

Table 8 shows the limit settings for control variables in the IEEE-118 system. The lower limit for generator bus voltages is set at 0.95 p.u, while the upper limit is set at 1.10 p.u. Transformer tap settings are constrained within a lower limit of 0.90 p.u. and an upper limit of 1.10 p.u. Likewise, the compensation devices are bounded by -20 MVAR and 20 MVAR as the lower and upper limits, respectively. These threshold values serve as critical parameters in regulating the operation of the power system, ensuring stability and reliability.

According to the IEEE 118-bus test system, GWO (proposed) algorithm exhibits a significant improvement in power loss reduction compared to ABC, PSO, and GSA algorithms. GWO algorithm achieves the lowest power loss with a reduction of approximately 24.86% compared to ABC, 20.21% compared to PSO, and 16.40% compared to GSA, indicating its superiority in optimizing the power flow of the system. This suggests that GWO algorithm can be a promising choice for power system optimization, particularly in minimizing power losses and improving system efficiency. The results imply that GWO algorithm exhibits potential as an effective solution for power system optimization, with a notable capability in minimizing power losses and enhancing overall system efficiency.

The convergence analysis of the proposed GWO algorithm, as shown in

Figure 9, demonstrates its impressive performance in achieving convergence in Scenario 1 of the IEEE-118 test system with varying agent numbers (20, 30, and 40). The figure displays the convergence values plotted up to 1000 iterations for all agent numbers. Remarkably, the GWO (proposed) algorithm with 40 agents achieves the complete convergence value in just 229 iterations, highlighting the exceptional rapid convergence capability of the proposed algorithm.

Figure 10 presents the convergence analysis of voltage deviation for Scenario 1 of the IEEE-118 test system, utilizing the GWO (proposed) algorithm with 40 agents. The results highlight the outstanding performance of the algorithm in achieving convergence, with the voltage deviation value reaching a remarkable low of 1.09356 pu. This indicates the robustness and accuracy of the proposed algorithm in optimizing voltage levels and minimizing deviations, making it highly effective for power system optimization tasks.

The system data are presented in [

53,

54,

55,

56]. According to the given scenario, 131 control variables are considered. These control variables are as follows:

54 variables of generated power

54 variables of generator bus voltages

9 variables of transformer tap settings

14 variables of reactive power of the VAR compensators

Table 10.

Limit Setting for Control Variables for IEEE-118 System in Scenario 2.

Table 10.

Limit Setting for Control Variables for IEEE-118 System in Scenario 2.

| Variables |

Lower Limit |

Upper Limit |

| Generated Power |

0.05 pu |

3.60 pu |

| Voltages |

0.95 pu |

1.10 pu |

| Tap Settings |

0.90 pu |

1.10 pu |

| Compensation Devices |

-20 MVAR |

20 MVAR |

The table presents the variables and their corresponding lower and upper limits in the context of power system analysis. The lower and upper limits of generated power are set at 0.05 pu and 3.60 pu, respectively, indicating that the generated power must be within this range. Similarly, the voltages in the system must be maintained between 0.95 pu and 1.10 pu. The tap settings for voltage regulating devices are constrained within the range of 0.90 pu to 1.10 pu. Lastly, the compensation devices are limited to -20 MVAR to 20 MVAR, signifying the acceptable range for reactive power compensation. These limits play a crucial role in ensuring the stability and reliability of the power system operation by regulating the values of these variables within acceptable bounds.

As seen in

Table 11 that using the GWO algorithm shows that keeping control variables within their specified limits resulted in a significantly lower power loss (68.1578 MW) compared to the IEEE-118 test system without power control parameters. After 213 iterations, the GWO algorithm was able to find the optimal values for the control variables, which remained optimal until the end of the simulation at 1000 iterations. This indicates that the GWO algorithm successfully optimized the system by finding optimal values for control variables while respecting their limits. The results suggest that the GWO algorithm has the potential to improve power system performance by minimizing power losses.

The IEEE-118 bus system has been expanded to include two new control variables that specifically target Distributed Generation Units (DGUs). These variables are the generator voltage magnitude control and the generator power control. With these additions, the system now boasts a total of 133 control variables, making it an extended version of the original IEEE-118 bus system. According to the given scenario, 133 control variables are considered. These control variables are as follows:

55 variables of generated power with wind power

55 variables of generator bus voltages with wind bus

9 variables of transformer tap settings

14 variables of reactive power of the VAR compensators

Table 12 shares the same values as

Table 11 for generated powers, generator bus voltages, transformer tap settings, and compensation values, while generated power values are constrained within a lower limit of 0.05 p.u. and an upper limit of 3.60 p.u. In Scenario 3, an additional distributed generation unit (DGU) powered by wind energy is introduced into the system, with a power output ranging from 0 to 0.5 per unit (50 MW).

According to the

Table 13 results, the GWO algorithm successfully minimized power losses with a value of 28.1372 MW, while keeping voltage deviation within acceptable limits with a value of 1.12945 pu. The ability of the GWO algorithm to optimize the control variables within their specified limits demonstrates its potential to enhance power system performance. By minimizing power losses and maintaining acceptable voltage levels, the GWO algorithm can improve the reliability and efficiency of power systems.

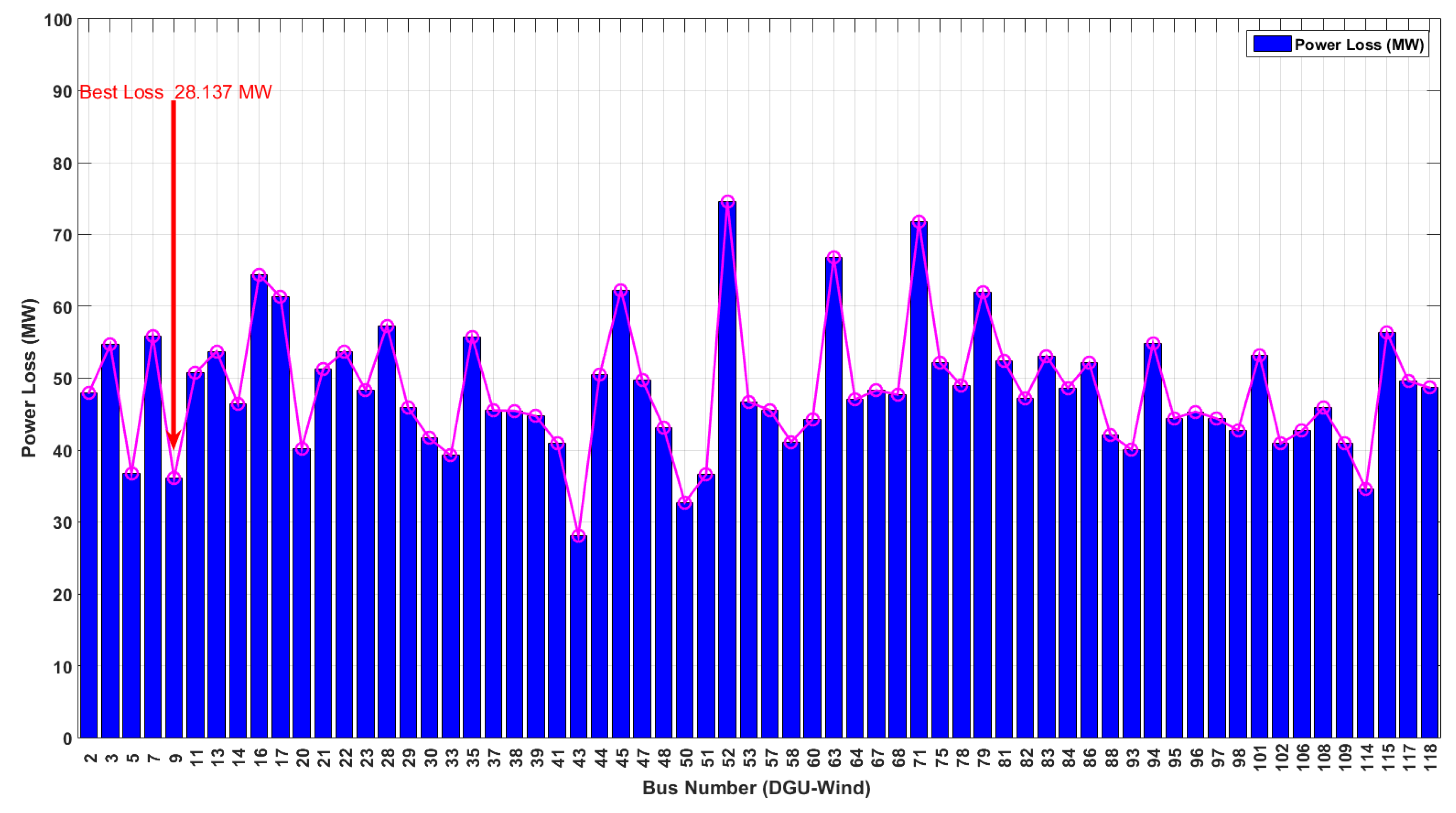

In the IEEE 118-bus system of Scenario 3, the integration of distributed generation units (DGUs) utilizing wind power has been investigated. These DGUs are connected to the buses, except for standard PV buses, highlighting the potential for renewable energy sources to be utilized in power systems. As seen in Figure 12, the results revealed that the placement of DGUs significantly affects the overall power loss of the system. Notably, the DGU connected to bus 9 resulted in the lowest power loss of 28.1372 MW, while the highest power loss of 74.59583 MW was observed with the DGU connected to bus 52, indicating a significant difference of approximately 165.4%. These findings highlight the importance of carefully selecting the location of DGUs in order to optimize system performance and maximize renewable energy utilization.

Figure 11.

Power loss convergence patterns for Scenario3 of the IEEE 118-bus system (wind integration).

Figure 11.

Power loss convergence patterns for Scenario3 of the IEEE 118-bus system (wind integration).

The use of the GWO algorithm in the optimization process has yielded promising results. Specifically, the GWO algorithm has facilitated the simultaneous mitigation of power loss and voltage deviation, while also optimizing DGU placement. This successful implementation of the GWO algorithm has contributed to the efficient integration of renewable energy sources into the power system, leading to enhanced system performance and increased utilization of renewable energy. Overall, these results demonstrate the potential of the GWO algorithm as a powerful tool for optimizing power system operation and promoting sustainable energy solutions. Further research is needed to investigate the applicability of the GWO algorithm to other power systems and to explore the potential for further improvements in renewable energy integration.