1. Introduction

Materials known as neodymium-doped yttrium aluminum garnet (Nd:YAG) are crystalline materials of the cubic system made from neodymium-doped yttrium aluminum garnet, which has excellent physical, chemical, thermal, mechanical, and optical properties [

1,

2,

3,

4,

5,

6,

7]. One of the applications of this type of material is its widespread use in white light emitters manufacturing. However, the development of lasers has always been conditioned by the availability of suitable materials for their use. In 1995, Ikesue et al. demonstrated that transparent Nd:YAG ceramics could be produced using ceramic fabrication techniques such as dry pressing and sintering [

2]. Therefore, sintering of active media by ceramic methods has become an alternative for solid-state laser active media manufacturing. Ceramic processing allows functional dopant gradients to aid thermal management, increase pumping efficiency and add functional elements such as Q-switches to the active medium [

3].

There are different synthesis routes for Nd:YAG among which the solid-state reaction, the solvo-thermal synthesis and the sol-gel route stand out [

4,

5]. Liquid-phase sintered materials are generally deteriorated by prolongation of the final stage. In addition, the use of additives used in the sintering of transparent ceramics while contributing to the process, have at the same time been identified as the cause of optical defects [

6]; so the synthesis of YAG by means of solid-state reactions is therefore of interest, in addition to the simplicity and low cost of this process.

In optical applications, such as lasers, it is suggested that the materials to be worked with must have a series of characteristics such as being homogeneous, i.e., without the presence of second phases with different refractive index and isotropic; the main limitation of ceramic materials is related to the scattering of light due to residual porosity [

8]. Chemical structures, compositions, and crystalline contents influence the transparency of ceramic materials. It has been shown that the transparency and therefore the laser efficiency are rapidly reduced and with the presence of pores [

9]. This is the reason that has prompted the development of transparent optical materials focusing on materials with cubic structure.

Technological advances in the synthesis, shaping, and sintering of ceramic powders have made it possible to adapt the microstructural, mechanical, and optical property relationships in the case of this type of materials [

10]. Emphasizing the optical properties, the general condition sought in improving them is their homogeneity with respect to their dielectric properties through solid-state sintering. In order to optimize the reactive solid-state sintering process, Vorona et al. studied the phase composition, microstructure and optical properties of YAG ceramics doped with 0 ÷ 0.15% by weight of MgO; after analyzing the characteristics of Mg

2+ ions, they concluded that the optimal concentration range of MgO sintering contributes to achieving transparent YAG ceramics [

11]. Along the same line of research, Wentao Jia studied the quantitative relationship between microstructure and mechanical and optical properties in transparent Nd:YAG ceramics. In his study, W. Jia applied stereology and fractals to identify the quantitative relationship between them and mechanical properties of transparent Nd:YAG ceramics sintered at 1750ºC for 8-50 h [

12]. The improvement of laser performance in transparent Nd:YAG ceramics has been investigated by Yuelong Fu et al. with preparations of 2% Nd:YAG ceramics using a solid-state reactive sintering method [

13]. The sintered samples were annealed at different temperatures for different times, obtaining ceramics with high density and homogeneous structure with an average grain size of 15 μm. They concluded that, at 1450 °C and 5 hours of retention, the concentration of color centers in the sample is relatively low and the efficiency of the laser slope is the highest.

In addition to the study of the different types of properties and the way they are linked to each other and how they end up affecting the performance of lasers due to their optical properties, there are authors who in their studies pay special attention to the behavior and nature of carbon contaminations, dispersed in the matrix of yttrium aluminum garnet. Kosyanov et al., showed that an increase in applied pressure from 30 to 70 MPa changed the color of the ceramic; the samples darkened and became dark brown, affecting the optical properties of the material [

13,

14]. To the best of our knowledge, there is no genuine interest in developing improvements in the optical properties by starting from the solid-state sintering of powders and emphasizing the economic and methodological advantages that this type of treatment presents, so the work to be done is promising in this area. In addition, the grinding parameters are usually not as long as those previously mentioned, so that the grinding time represents another advantage for its realization.

2. Materials and Methods

For the present study, the Y

3Al

5O

12 perovskite was synthesized. For this purpose, a mixture in stoichiometric amounts according to the reaction 1 was prepared.

Powders of Y

2O

3 and Al

2O

3 (Sigma-Aldrich, 99.9 % purity and 1 m size) were ground in a planetary mill (Retsch PM 100, Germany) during 3 hours at a rotation speed of 300 rpm. Also, a stainless-steel container with zirconia grinding elements of 0.3 cm diameter was utilized, as well as, a powder weight/ball weight ratio of 1:12. After milling, the particle size distribution and specific surface area were determined using a Mastersizer 2000 equipment of English origin. The powders’ mixtures resulting from the milling step were subjected to a thermal treatment at 900, 1,100, 1,300, and 1,500 °C, in order to follow the advance of reaction 1. The thermal treatment was carried out in an electric resistance furnace (Carbolite RHF17/3E, England) for 1 hour, as well as the heating sped was 25 °C/min. The advance of the chemical reaction was followed by X-ray diffraction analysis (Siemens, D-5000, Germany). Once the formation temperature of the compound Y

3Al

5O

12 was determined (reaction 1 complete), mixtures were prepared with the two initial components with additions of neodymium (0, 0.25, 0.5 and 1 atomic %). These mixtures were carried out in the planetary mill; the powders were mixed under the same conditions mentioned at the beginning of this methodology. With the powders resulting from the second grinding stage, cylindrical tablets 1 cm in diameter by 0.3 cm thick were obtained by uniaxial compaction at 250MPa using a press (Porter-30T, Mexico), which were then subjected to sintering treatments for 2h at 1500°C in an electric furnace. The density of the sintered samples was evaluated through the Archimedean principle, using standards established in the ASTM C20-00 standard [

15]. To determine the functional groups, present in the compound formed, FTIR analysis was performed (Rayleight WQF-510A, China). The pump source used to obtain the emission spectra, was a laser diode that operates at 806 nm with an optical power of 80 mW; the laser light was collimated by a microscope objective of 10X. The absorption spectra of the pills were measured using a Cary 5000 UV-Vis-NIR spectrophotometer, in which the sample was placed so that the waveguides were perpendicular to the incident light beam and a range of 300-900 nm so that it could cover the main absorption bands of the material. Finally, observations of microstructure of sintered samples were performed by optical microscopy (Nikon Eclipse Ma200, Japan).

3. Results

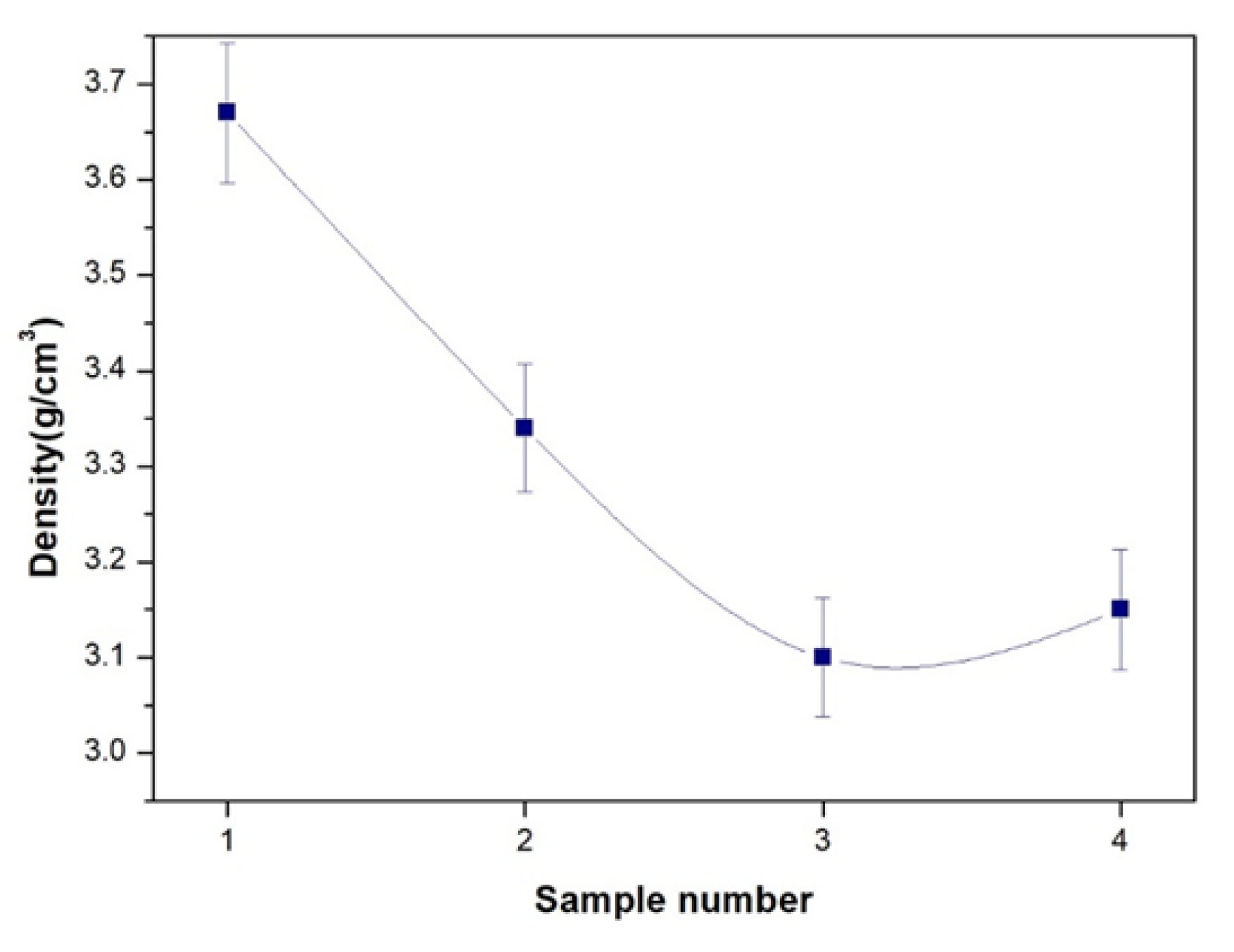

3.1. Density

Figure 1 shows the apparent density achieved by the sintered samples as a function of the Nd content. What is observed in this figure is that as the Nd content increases, the density of the samples tends to decrease, this is probably because the melting point of Nd is 1,024°C. If the samples were sintered at 1,500°C, the Nd at that temperature must have been in liquid phase and, due to its low wettability, could not move within the mixture to occupy the porosity of the mixture which caused the porosity was not closed during sintering.

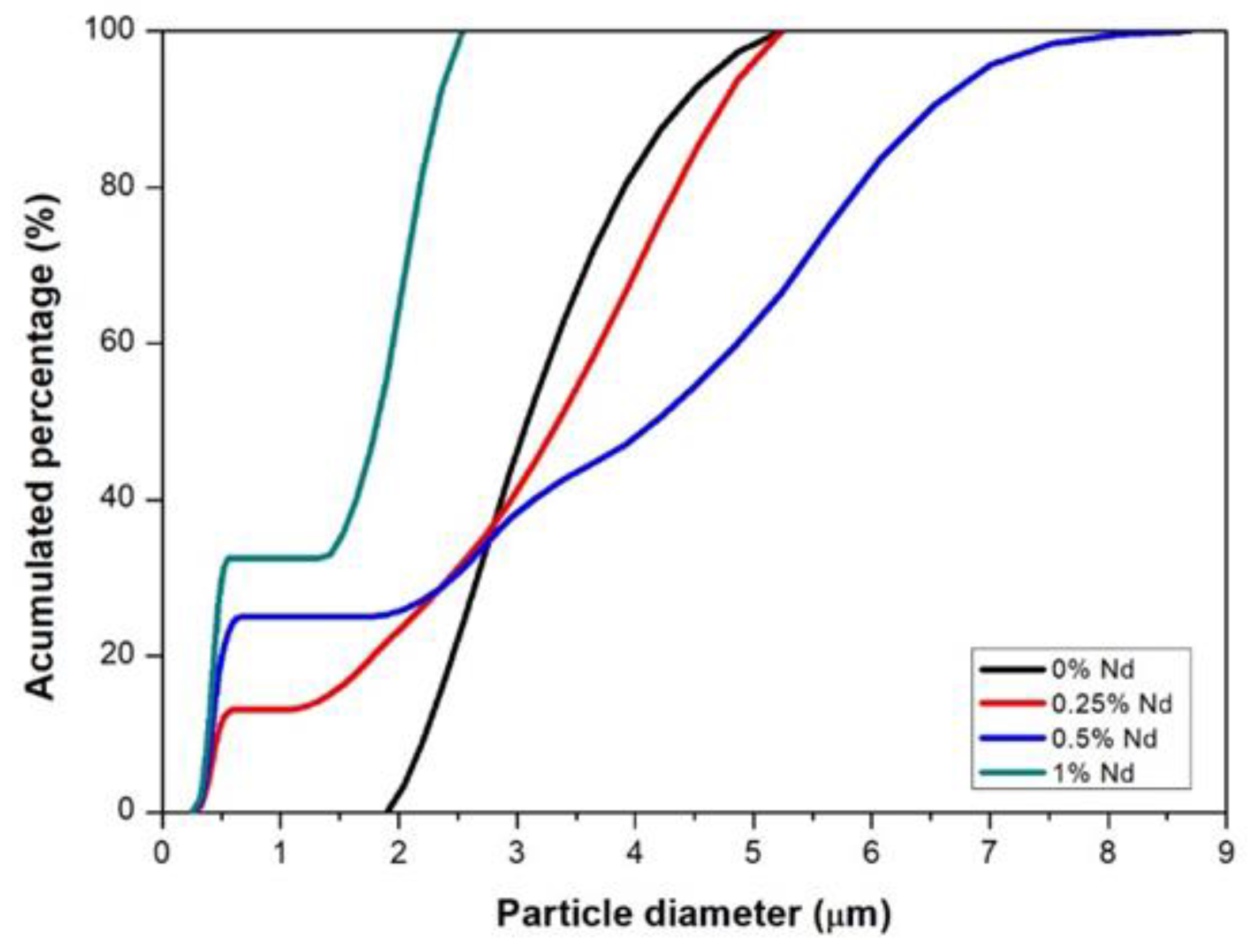

3.2. Particle size

Figure 2 shows the results of the particle size distribution analysis for each of the study samples. The figure shows that the particle sizes varied from less than 1 micron to several microns; the sample with 0.5 at. % Nd exhibited the largest size distribution, with sizes ranging from 0.2 microns to 9 microns. On the other hand, the sample with 1 at. %Nd is the one with the smallest size distribution, since the particle sizes range between 0.2 and 2.5 microns. The sample with 0.25 at. % Nd also shows sizes below 1 micron and maximum sizes of approximately 5 microns. In comparison, the sample without Nd addition presents sizes between 2 and 5 microns. The strong size variation, especially due to the large particle sizes in the sample with 0.5%Nd, is what causes the densification in this sample to be not so good since during the compaction of the powders in this sample there must have been empty spaces (pores) difficult to close with sintering. According to these results, the samples without Nd and with low Nd content (0.25 % Nd) are the ones that densified better. Therefore, the size distribution of these samples is the one that favors the porosity closure during sintering. As mentioned before, the presence of Nd hinders the sintering of the compounds, due to the liquid state in which it is present at the temperature (1,500°C) of formation of the compound (Y

3Al

5O

12), which corresponds to the sintering temperature.

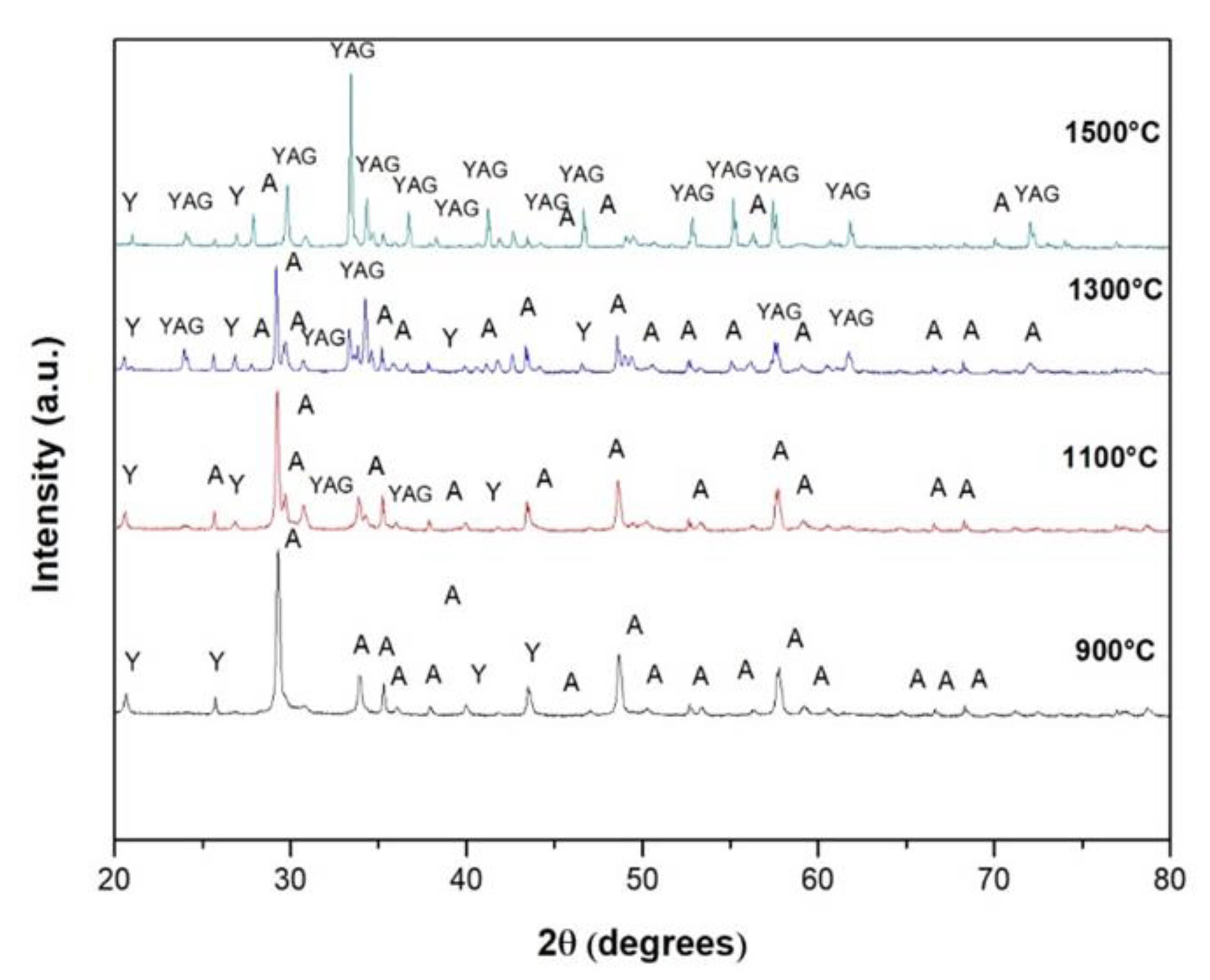

3.3. Crystalline structure

Figure 3 shows the diffraction patterns of the Y

2O

3 + Al

2O

3 powder mixture that was subjected to interrupted tests at different temperatures to observe the progress of reaction 1 and to determine the formation of the Y

3Al

5O

12 compound. In this figure, it can be seen that at 900°C reaction 1 has not started. This can be affirmed because the crystalline phases present here correspond to the 2 original components of the sample Y

2O

3 + Al

2O

3. At 1,100°C, the first traces of the desired garnet formation begin to appear, becoming more abundant at 1,300°C. At 1,500°C the predominant crystalline phase in the sample corresponds to that of yttrium aluminum garnet (Y

3Al

5O

12), although some traces of the alumina phase are still observed in the corresponding spectrum. The minimal width of the peaks and their intensity indicate the strong crystallinity of the compound formed. From these spectra, it can be summarized that reaction 1 starts to occur at approximately 1,100°C and is completed at 1,500°C, the latter being the formation temperature of Y

3Al

5O

12.

Diffractions in resulting spectrum at 1,500 °C correspond to Nd-YAG in agreements with JCPDS 79-1892. The unit cell of Nd-YAG was calculated by the least square method using all reflections of Nd-YAG in spectrum at 1,500 °C of

Figure 3. The calculated result reveals that the crystals have body-centered cubic crystalline structure with space group Ia3d. The lattice parameter for YAG with different addition of Nd are presented in

Table 1.

The lattice parameter values increase with increasing neodymium in the Y

3Al

5O

12 compound due to the slightly larger atomic radius of neodymium (1.82 Å) with respect to yttrium (1.80 Å). However, these values are similar to those reported in literature [

7,

16,

17].

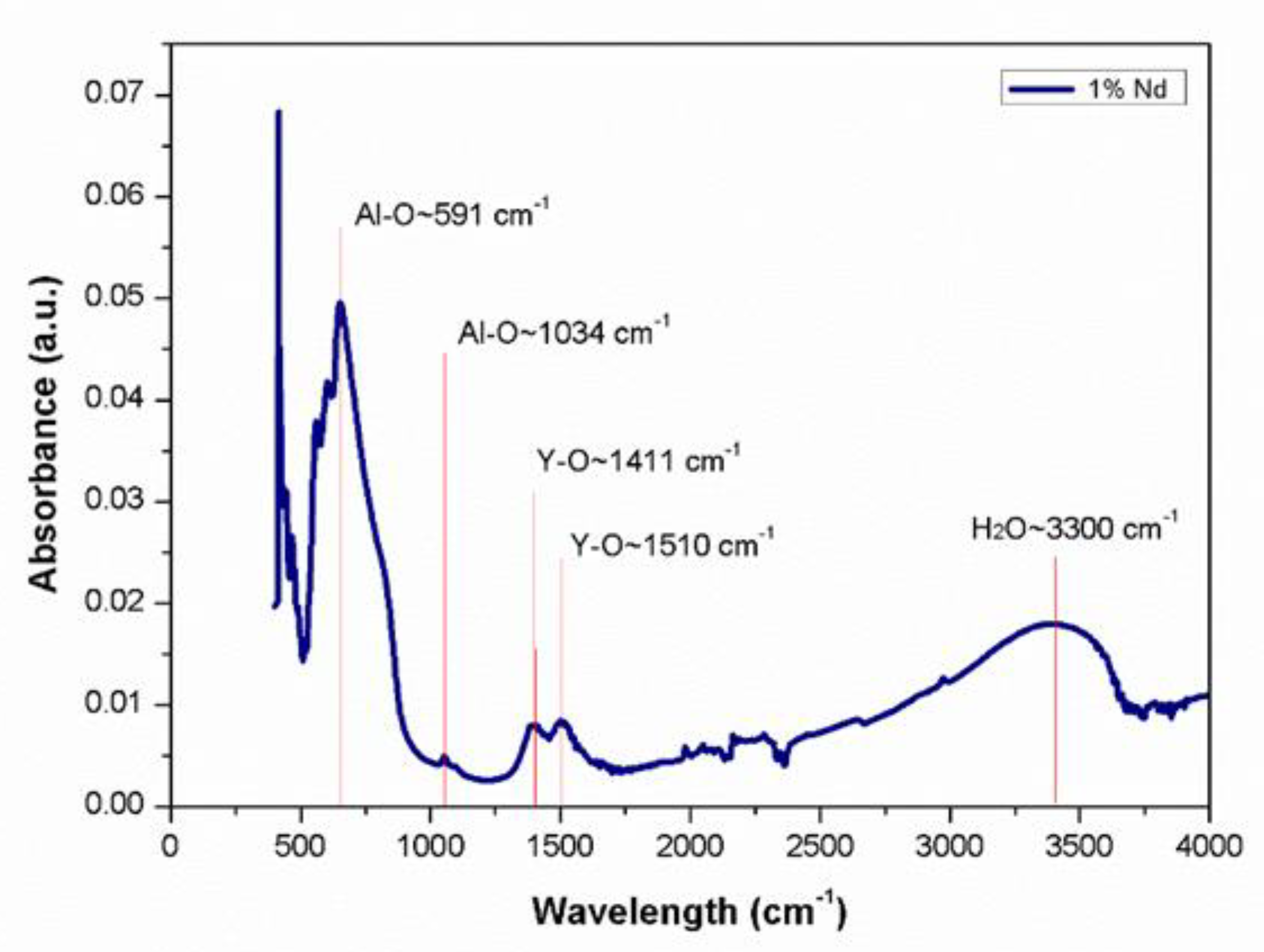

3.4. Fourier-transform infrared spectroscopy

Figure 4 shows the absorbance spectrum obtained by Fourier-transform infrared spectroscopy of the sample sintered at 1,500°C. This spectrum shows two peaks at 591 and 1034 cm

-1 which have been associated with the Al-O functional group of alumina. On the other hand, at wavenumbers of 1411 and 1510 cm

-1, two other peaks are observed, corresponding to the Y-O functional group matching the yttria. Finally, at 3300 cm

-1 one more peak was observed, which was associated with the H-O bond corresponding to water. The presence of this chemical bond is due to the absorption of water by the sample after it was sintered. From this spectrum, it can be confirmed that the functional groups composing the mixture are those corresponding to the elements of the compound Y

3Al

5O

12.

3.5. Absorption Spectrum

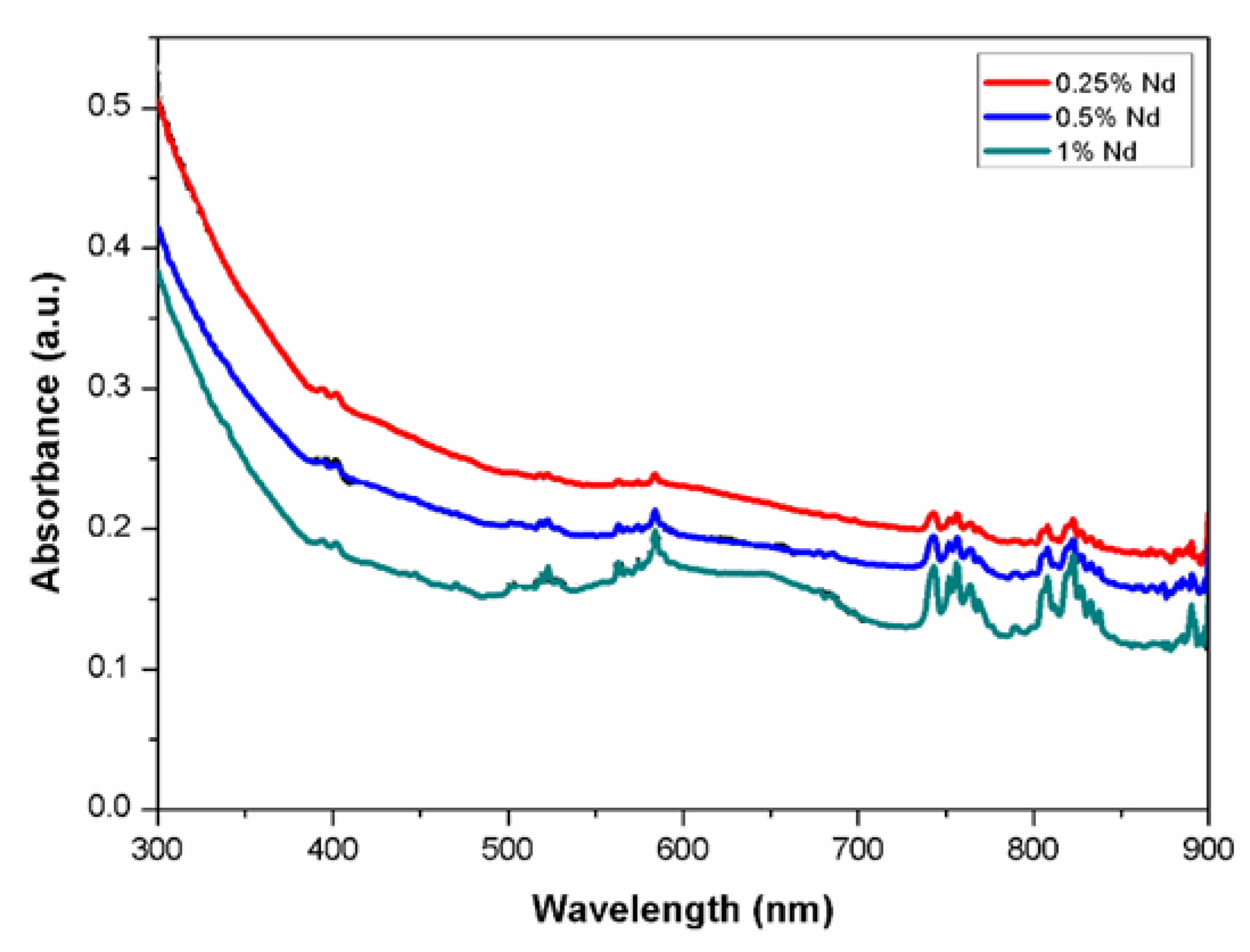

Absorption studies were performed for the samples with additions of Nd in atomic percentages from 0.25%, 0.5% and 1%.

Figure 5 shows the comparative absorption spectra for each of the samples. Predominant absorption bands can be better observed from the 1% Nd sample at around 750 and 810 nm, corresponding to transitions from the

4I

9/2 ground level to

4F

7/2:

4S

3/2 and

4F

5/2:

4H

9/2 levels, respectively. In addition, peaks at 520, 590 and 880 nm are also present. It can be seen that the bandwidth and the peak shape are the same for the samples with neodymium content, however, as the concentration increases, the peak absorbance is greater.

3.6. Emission Spectrum

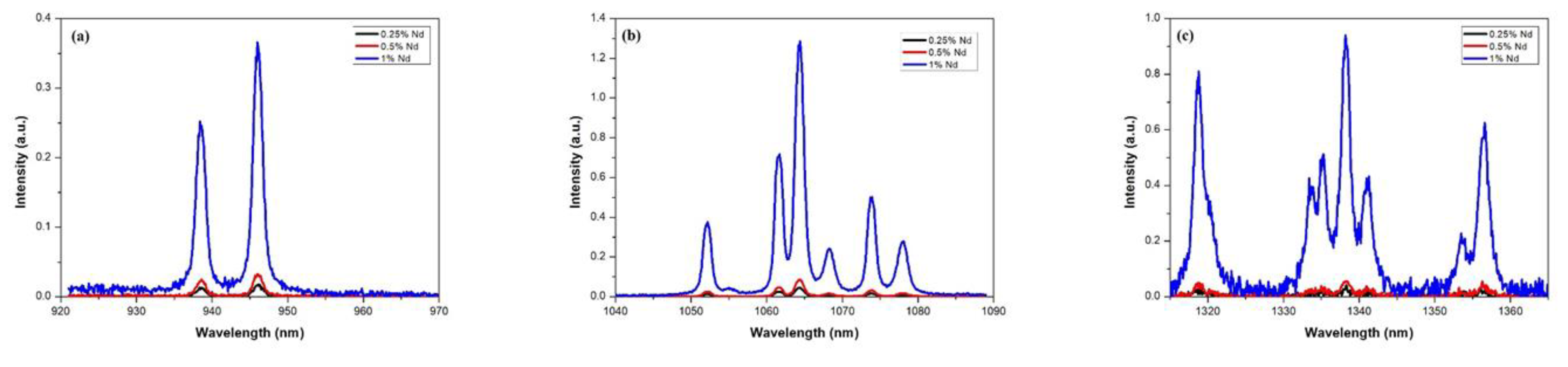

Emission studies were carried out at wavelengths from 930 to 1370 nm for the three samples doped with Nd.

Figure 6 shows the comparative emission spectra for each of the samples. As can be seen, the peak intensity increases as neodymium concentration increases. Still, the shape of the peaks and the bandwidth are maintained in all cases, which is important in laser emission applications. The emission spectra are presented in the three predominant regions due to radiative decay from the

4F

3/2 state to the

4I

9/2,

4I

11/2 and

4I

13/2 states that can be seen in the figure. The energy levels of Nd:YAG are determined by the neodymium (Nd) ions in the YAG, the predominant radiative transition at 1064 nm occurs between the upper stark level of the

4F

3/2 state and one of the

4I

11/2 states. The synthesized materials could have potential application in the development of a laser that emits in the near infrared region.

3.7. Microstructure

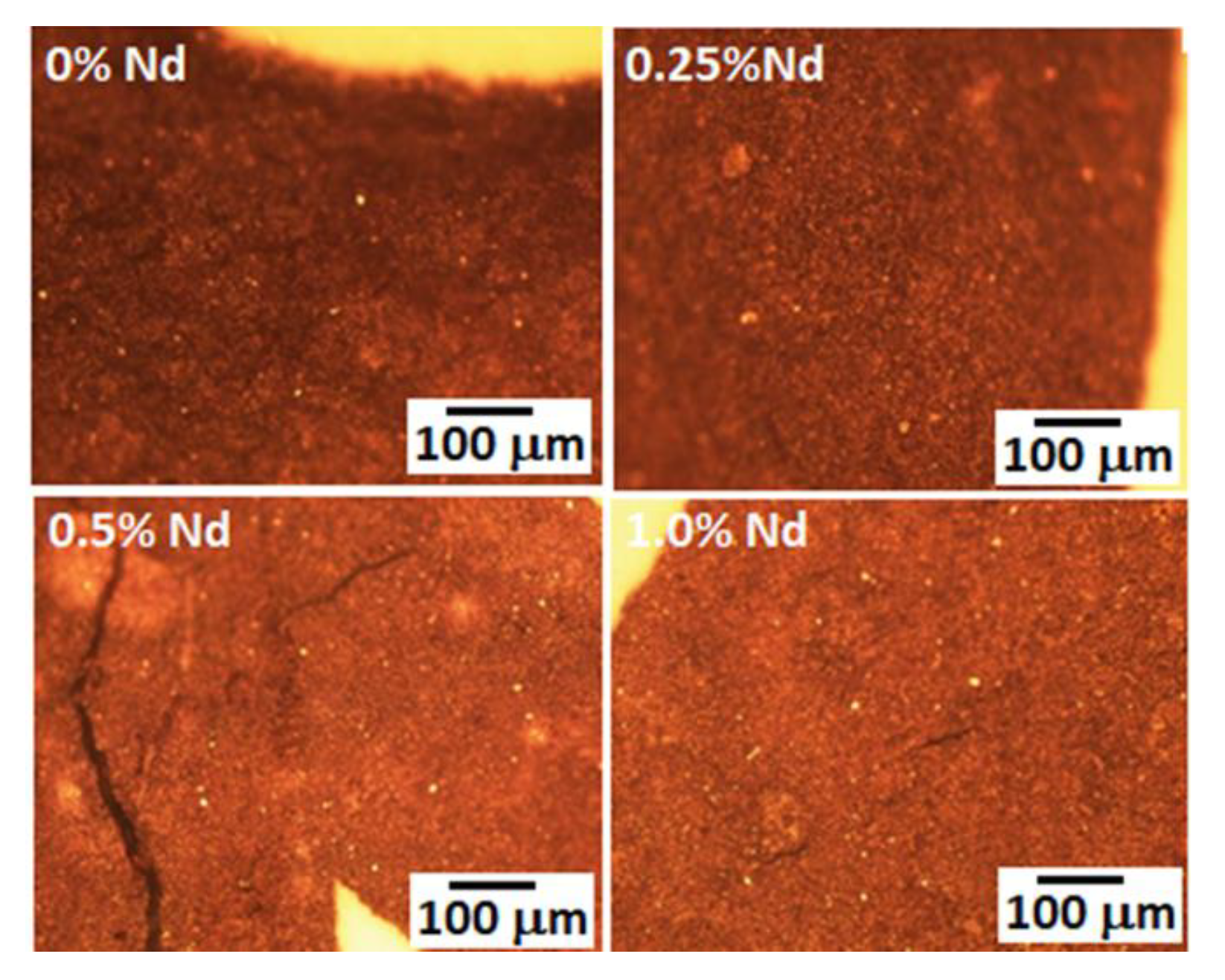

The microstructures of synthesized Nd:YAG, taken from the optical microscope are shown in

Figure 7. In general, the microstructure is very fine made up of irregular grains of different sizes and morphologies (angular, rounded, etc.). Due to the fine microstructure, the porosity of the samples cannot be distinguished. Apparently, finer particles are obtained for intermediate Nd contents (0.25 at. % and 0.5 at. %). However, the sample with 0.5 at. % Nd is cracked. According to density measurements, the higher the amount of Nd in the garnet, the lower the bulk density, a situation difficult to observe in these images. However, the very fine size present in these composites due to the type of processing carried out to manufacture them positively influences the optical properties of the composites, as already observed above. This suggests that if the processing conditions of these composites can be better controlled to obtain denser bodies, the optical properties will be further improved.

5. Conclusions

Through intense mixing of the ceramics Al2O3 and Y2O3 in a high energy mill and subsequent heat treatment at elevated temperature to induce solid state chemical reactions between the two initial components, the synthesis of the compound Y3Al5O12 doped with different percentages of neodymium was feasible. From the characterizations performed on the products obtained, the following results were obtained: X-ray diffraction patterns indicate that the formation of the Y3Al5O12 compound by solid-state reaction starts at approximately 1100°C and is completed at 1500°C; likewise, the newly formed compound has a cubic crystalline structure. The spectra obtained by Fourier transform infrared spectroscopy show the presence of the 2 functional groups (Al-O and Y-O) of the Y3Al5O12 compound. The analysis by optical absorption and emission spectroscopy indicates wavelength bands in agreement with the electronic structure of Nd ions in YAG. The microstructure of the manufactured composite is very fine, presenting equiaxial grains with sizes of less than 1 micron. This explains the good optical characteristics of the manufactured compound. The results are promising for the development of a light source based on a ceramic material obtained by the solid-state reaction method.

Author Contributions

Conceptualization, GVVG, ERR and CACA; methodology, OAER, JACR and JLH; validation, JACR, JLH and WJPR.; formal analysis, OAER, GVVG, ERR and CACA; investigation, OAER, JACR and JLH; resources, GVVG, JACR, JLH, CACA, WJPR and ERR; data curation, OAER, GVVG, JACR and JLH and JARG; writing—original draft preparation, OAER, GVVG, CACA and ERR; writing—review and editing, GVVG and CACA; visualization, GVVG, CACA and ERR; supervision, GVVG, CACA and ERR; project administration, ERR; All authors have read and agreed to the published version of the manuscript.

Funding

This research work did not receive any type of support for its realization.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

OAER thanks the national council of science and technology for the scholarship granted for the completion of her master's studies.

Conflicts of Interest

The authors declare no conflict of interest.

References

- S. Nakai, K. S. Nakai, K. Mima, Laser driven inertial fusion energy: present and prospective, Rep. Prog. Phys., 2004, 67 321-325. [CrossRef]

- Ikesue, Y. Lin Aung, T. Taira, T. Kamimura, K. Yoshida, G. L. Messing, Progress in Ceramic Lasers, Annu. Rev. Mater. Res., 2006, 36, 397–429. [Google Scholar] [CrossRef]

- Ikesue, Y. L. Aung, Ceramic laser materials, Nat. Photon, 2008, 2, 721–727. [CrossRef]

- L. Chang-qing, Z. Hong-bo, Z. Ming-fu, H. Jie-cai, M. Song-he, Fabrication of transparent YAG ceramics by traditional solid-state-reaction method, T. Nonferr. Metal. Soc. of China. 2007, 17, 148–153. [CrossRef]

- P. Jongnam, J. Joo, S. Gu Kwon, Y. Jang, T. Hyeon, Synthesis of Monodisperse Spherical Nanocrystals, Angewandte International Edition Chemie, 2007. [CrossRef]

- R. Boulesteix, A. Maître, J. F. Baumard, C. Sallé, Y. Rabinovitch, Mechanism of the liquid-phase sintering for Nd:YAG ceramics, Opt. Mater., 2009, 31, 711–715. [CrossRef]

- S. Kostić, Z. Ž. Lazarević, V. Radojević, A. Milutinović, M. Romčević, N. Ž. Romčević, A. Valčićb, Study of structural and optical properties of YAG and Nd:YAG single crystals, Mater. Res. Bull., 2015, 63, 80-87. [CrossRef]

- L. Chrétien, R. Boulesteix, A. Maître, C. Sallé, Y. Reignoux, Post-sintering treatment of neodymium-doped yttrium aluminum garnet (Nd:YAG) transparent ceramics, Opt. Mater. Express, 2014, 4, 2166–2173. [CrossRef]

- Y. Su, D. M. Xin, X. Chen, W. Xing, Effect of CAD-CAM ceramic materials on the color match of veneer restorations, J. Prosthet. Dent., 2021, 126, 255–e1. [CrossRef]

- M. Rubat du Merac, Transparent Ceramics: Materials, Processing, Properties and Applications, Editor: Michael Pomeroy, Encyclopedia of Materials: Technical Ceramics and Glasses, Elsevier, Ámsterdam, 2021.

- Vorona, A. Balabanov, M. Dobrotvorska, R. Yavetskiy, O. Kryzhanovska, L. Kravchenko, S. Parkhomenko, P. Mateychenko, V. Baumer, I. Matolínová, Effect of MgO doping on the structure and optical properties of YAG transparent ceramics, J. Eur. Ceram. Soc., 2020, 40, 861–866. [Google Scholar] [CrossRef]

- W. Jia, C. Su, H. Zhang, X. Zou, G. Ren, Q. Wei, M. Zhao, C. Ma., Quantitative relationship between microstructure and mechanical properties in Nd: YAG transparent ceramics, Ceram. Int., 2021, 47, 12144–12152. [CrossRef]

- N. Jiang, C. Ouynag, Y. Liu, W. Li, Y. Fu, T. Xie, Q. Liu, Y. Pan, J. Li, Effect of air annealing on the optical properties and laser performance of Yb:YAG transparent ceramics, Opt. Mater., 95, 2019. [CrossRef]

- D.Yu. Kosyanov, A. A. Vornovskikh, A. M. Zakharenko, E. A. Gridasova, R. P. Yavetskiy, M. V. Dobrotvorskaya, A. V. Tolmachev, O. O. Shichalin, E. K. Papynov, A. Y. Ustinov, V. G. Kuryavyi, A. A. Leonov, S. A. Tikhonov, Influence of sintering parameters on transparency of reactive SPSed Nd3+:YAG ceramics, Opt. Mater., 2021, 112. [CrossRef]

- ASTM C20-00, Standard test methods for apparent porosity, water absorption, apparent specific gravity, and bulk density of burned refractory brick and shapes by boiling water 2010.

- Golubovic, S. Nikolić, R. Gajić, S. Đurić, A. Valčić, The growth of Nd: YAG single crystals, J. Serb. Chem. Soc., 2002, 67, 291–300. [Google Scholar] [CrossRef]

- Golubovic, S. Nikolic, R. Gajić, Z. Dohčević-Mitrović, A. Valčić, Growth and IR Spectra of YAG and Nd:YAG Single Crystals, J. Metal., 2004, 10, 363–370. [Google Scholar]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).