1. Introduction

The direct bandgap of InGaN alloys has been attracting tremendous research attentions due to their excellent emission properties for light-emitting diodes and laser diodes [

1,

2]. However, several critical issues related to epitaxial growth remain unsolved [

3]. This is mainly due to large lattice mismatch of up to ~11% between GaN and InN, which results in compositional instability in InGaN [

4]. Therefore, solving the lattice mismatch has become an important prerequisite for the high-quality InGaN epilayer growth, and it is urgently needed to achieve high efficiency and high luminescence in green light emitting devices [

3]. During the heteroepitaxial growth of InGaN thin films on GaN buffers, large lattice mismatches lead to huge strains, resulting in plastic relaxation of misfit strain. This has been evidenced as occurrence of parallel networks of straight misfit dislocations aligned along with <10-10> orientations in compressively strained InGaN/GaN [

5,

6,

7,

8,

9] as well as in tensile strained AlGaN/GaN [

10] heterostructures. III-nitride epilayers grown on (0001) substrates suffer from the absence of primary gliding planes due to the lack of resolved shear stress, and possible plastic strain relaxation needs the activation of secondary glide planes. The origin of the misfit dislocations is ascribed to internal and external factors, for example, growth surface steps [

11,

12], use of ELOG GaN substrates [

5], from pre-existing threading dislocations in the substrate as reported by Mathews [

13,

14,

15,

16]. Different theoretical models based on force-equilibrium [

17] or energy-balance equations [

18] including that of Matthews-Blakeslee and Fischer [

13,

19] are used to account for the generation of misfit dislocations via glide process. Formation of misfit dislocations is first attributed to its nucleation at the surface, followed by its glide to the heterointerface on {11-22} pyramidal planes [

5]. In this study, we have found that in the strain relaxation process only a part of the heterostructure is fully strained, while the other parts are partially relaxed. In this paper, we have investigated transition from screw type to edge type misfit dislocations in the In

xGa

1-xN/GaN heterostructures grown on (0001) sapphire substrates with indium composition in the range of 0 to 20%.

3. Results and Discussions

Without indium composition, no defects were found in plan-view samples (not shown here).

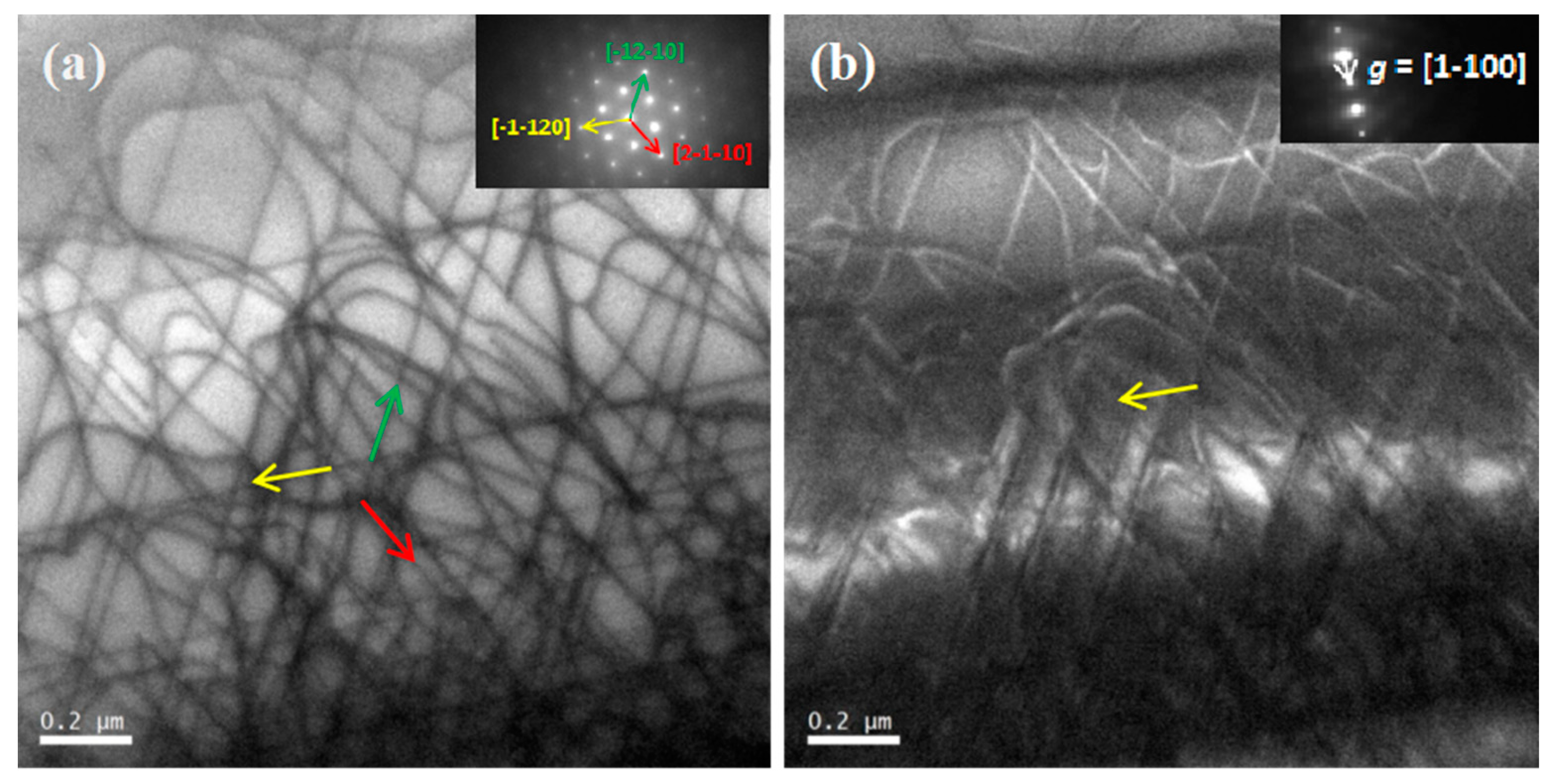

Figure 1a,b exhibit [0001] zone axis and [1–100] dark field plan-view TEM images of In

0.09Ga

0.91N/GaN heterostructure, respectively. A network of straight dislocation lines and dislocation half loops at the interface can be observed in

Figure 1a. These dislocation lines extend over several micrometers in the entire observable area with an average inter-line spacing of 100 nm. The three sets of dislocation lines are aligned along with the <11-20> directions, which can be assessed from the selected area diffraction pattern for zone axis [0001] in the inset of

Figure 1a. The Burgers vectors of these dislocations can be identified by TEM diffraction contrast analysis [

20]. As shown in the dark field image (see

Figure 1b) taken under

g = [1–100] diffraction condition from the same area, we observe that only those set of dislocation lines along [–1–120] direction (yellow arrow) disappears, indicating that these dislocations satisfy the invisibility criterion

g . b = 0. Therefore, the Burgers vector

b of this set of dislocations is

a = 1/3[-1-120], which is parallel to the dislocation line orientation, and are identified as screw ones. The other two sets of dislocations are also verified as screw ones according to the same method. Thus, all the interface dislocations in In

0.09Ga

0.91N/GaN heterostructures are identified as pure screw dislocations with

b =

a. The occurrence of screw dislocations is unusual as it well known that the screw dislocations cannot relax the strain of the film.

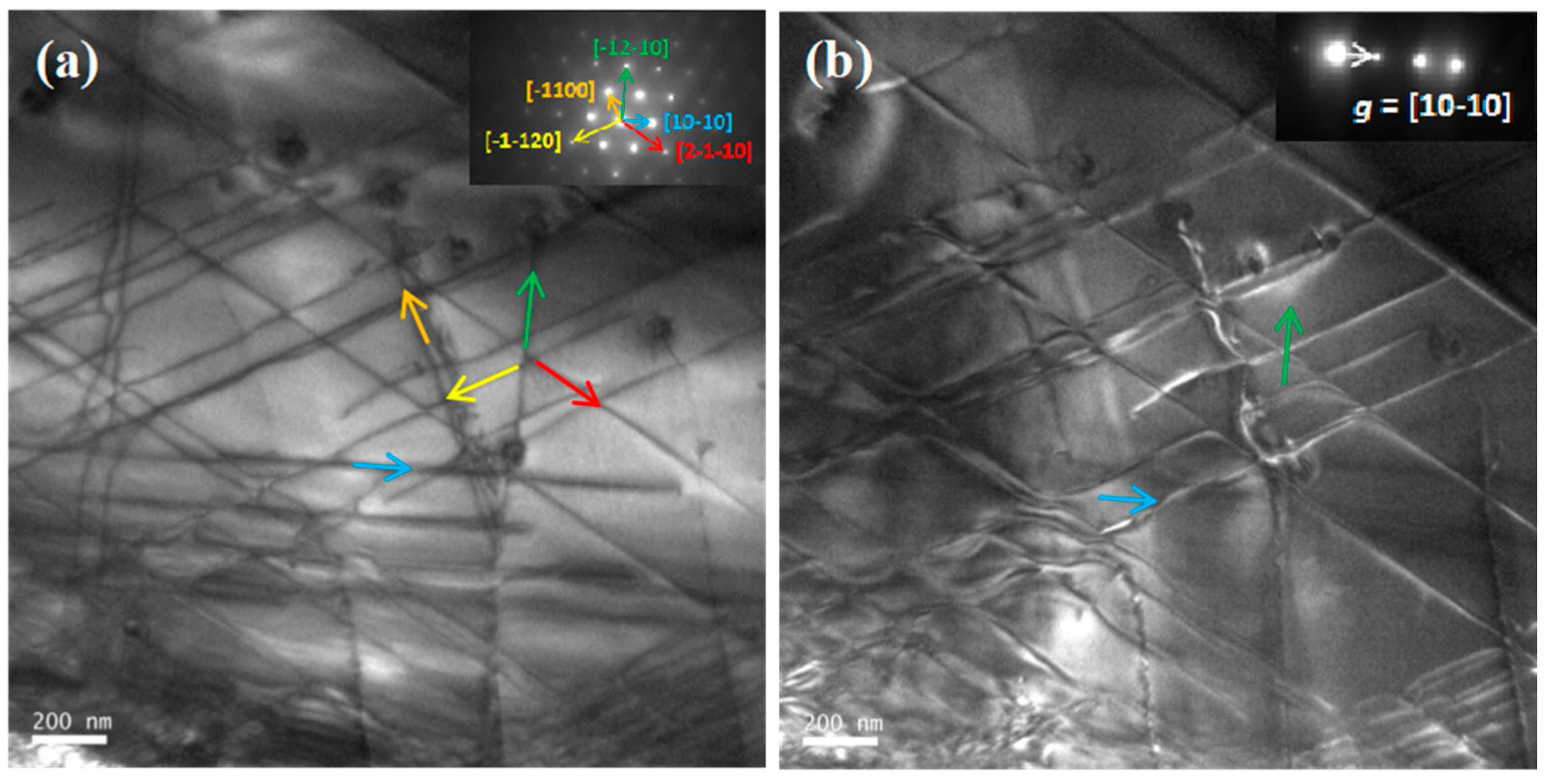

Also for higher In-content of 17%, a network of dislocation lines with an average interline spacing of 200 nm can be seen in the dark-field images obtained at

g = [10-10] (see

Figure 2a). The three sets of dislocation lines are aligned along with the <11-20> directions and two sets of dislocation lines are along with the <10-10> directions. The dark field image for

g = [10-10] of the same area (

Figure 2b) shows that one set of dislocation lines along [-12-10] direction (green arrow) disappears. Hence,

b =

a = 1/3[-12-10] for these dislocations in the direction parallel to the dislocation line. These dislocations are again identified as screw ones. Similarly, the other two sets of dislocations (yellow and red arrows) along the equivalent <11-20> directions are also verified as screw-type ones. We also found that one set of dislocation lines that are along [10-10] direction (blue arrow) also become invisible under this beam condition, which means its

b =

a = 1/3[-12-10], i.e. perpendicular to the dislocation line direction. Hence, this set of dislocations are identified as edge-type dislocations, i.e., misfit dislocations (MDs). The other set of dislocation (orange arrow) along equivalent <10-10> direction is also verified as MDs. Thus, for In = 17%, all the observed dislocations have Burgers vector of

a, with most of them are screw dislocations along <11-20> and the remaining are MDs along <10-10> directions.

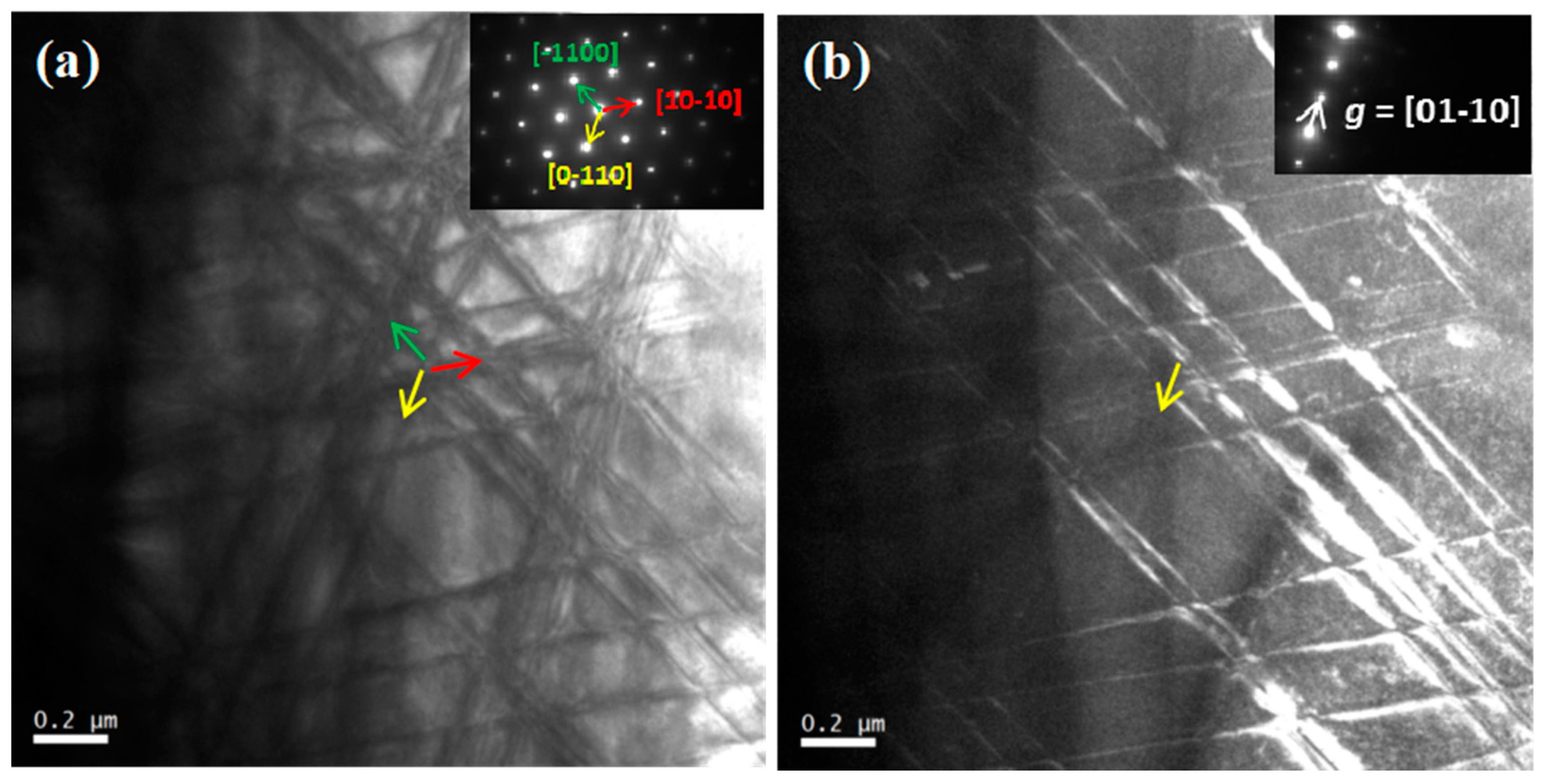

When we go further higher in In-content (In = 20%), unlike the previous two cases only one type of network of dislocation lines can be observed in bright filed TEM image (see

Figure 3a). The three sets of dislocation lines are aligned along the <10-10> directions with average interline spacing of ~200 nm. In

Figure 3b, we observe that one set of dislocation lines along [0-110] direction (yellow arrow) become invisible in the dark field image obtained

g = [01-10]. Thus,

b =

a = 1/3[2-1-10] for these dislocations, which is perpendicular to its line direction, again classifying them as MDs. The other two sets of dislocations (green and red arrows) are also verified as MDs. Thus, all the observed dislocations are pure MDs, which contributes toward relaxation of the lattice mismatch strain. Some of the dislocations were found to dissociate into two separate dislocations which meanders along the same <10-10> direction as shown in

Figure 3. Diffraction analysis displayed that the latter were also a-type dislocations. This dissociation indicates that the MDs in such heterostructures could exist with Burgers vector of both

a and 2

a as reported by Liu and Li et al. [

6,

8].

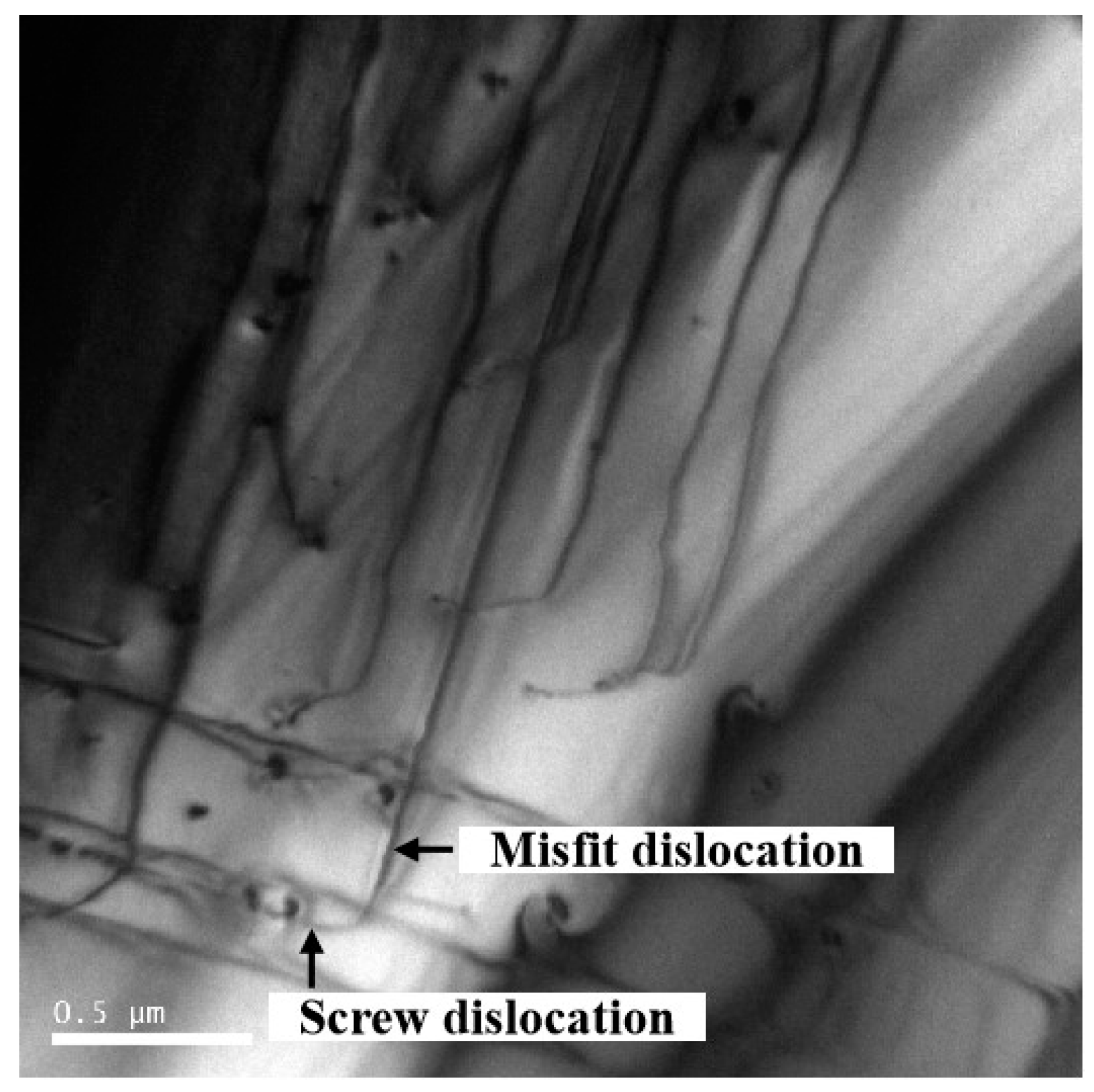

One can realize a particular trend in the occurrence of dislocations from

Figure 1,

Figure 2 and

Figure 3, as the lattice mismatch increases with indium composition from 9% to 20%, the interface dislocations transform from entirely screw dislocations into entirely misfit dislocations. In sample In

0.13Ga

0.87N/GaN heterostructure, this transformation process is well captured.

Figure 4 shows a bright field plan-view TEM image, which exhibits clearly this transformation process of the dislocations from screw type to edge type, detailed analysis is shown in a schematic diagram below. This implies plastic relaxation of the layers gradually replaces elastic relaxation process.

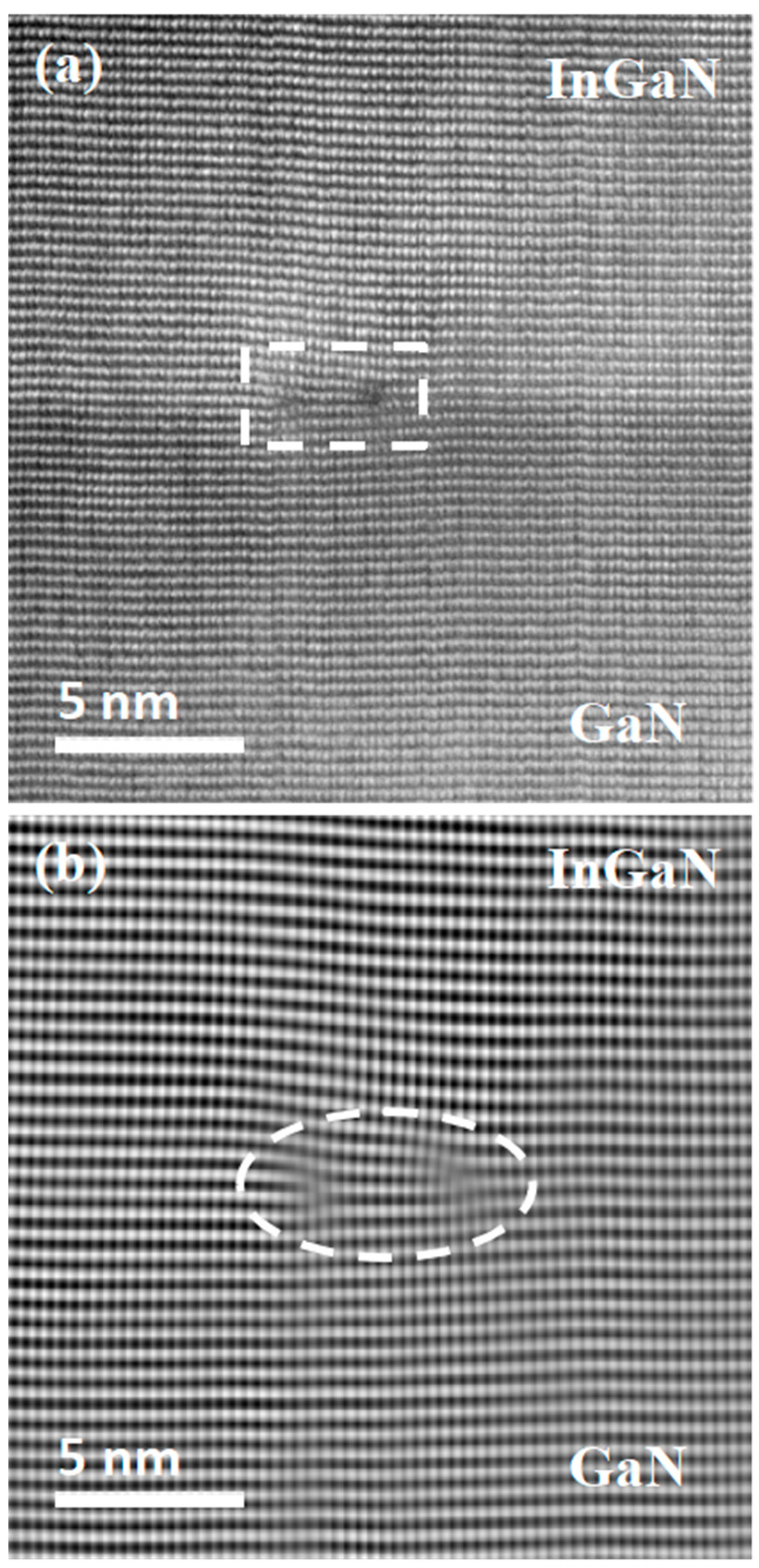

To determine the dislocations in the plan-view TEM images are interfacial dislocations, a high resolution TEM (HRTEM) image of InGaN/GaN heterostructure was taken under [1010] zone axis, as shown in

Figure 5a. It can be seen that the plan-view dislocations exist at the heterointerface (marked with the dashed line). Due to the large misfit strain and the presence of indium, the atomic arrangement in the heterostructure cannot be observed clearly in the HRTEM image. In order to facilitate the observa tion of {1120} lattice fringes, we acquired the Fourier filter ing image using in-plane Fourier spots.

Figure 5b is a Fou rier filtering image of

Figure 5a. We clearly observed in

Figure 5b that extra half plane of atoms lie at the interface, therefore these interfacial dislocations are MDs (see the dashed line).

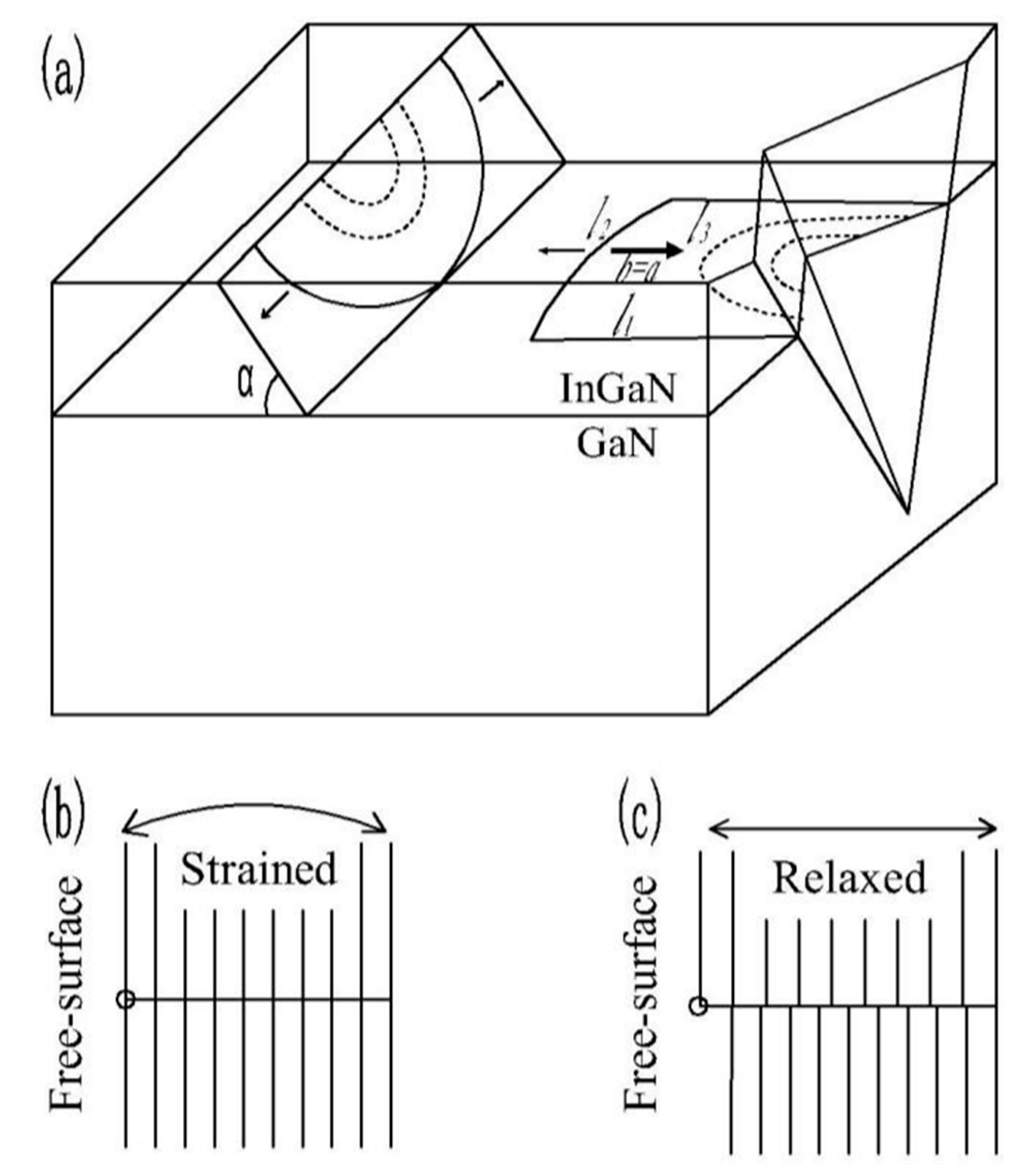

It is commonly understood that the strain occurring due to lattice mismatch between epitaxial layers and substrates is eased to an extent either by elastic relaxation or by plastic relaxation. The mechanisms for strain relaxation observed in the InGaN/GaN system have been reported by Liu et al. [

21], as shown in

Figure 6.

Figure 6a shows a schematic diagram illustrating the formation process of these dislocation half loops and misfit dislocation network. The dislocation half loop can be divided into three line segments:

l1,

l2 and

l3 (right portion of

Figure 6a). The Burgers vector (

b =

a) of the dislocation half loop is parallel to the propagation direction, thus,

l1 and

l3 are screw dislocations (elastic relaxation) and

l2 is an edge dislocation (plastic relaxation), namely, a misfit dislocation (ignoring the curvature of the segment). Nucleation and propagation of the dislocation half loop happens at the corner of the pit in the process that is driven by the misfit stress. This mechanism is illustrated by schematic diagrams as shown in

Figure 6b,c. At the intersection between the heterointerface and the free surface, the atomic bonding is rearranged because of the misfit shear stress, forming a ledge at the free surface, and an edge type misfit dislocation. Further relief of the misfit strain happens by continuous generation of misfit dislocations. The Burgers vector is in the slip plane, therefore propagation of the dislocation half loops occurs by glide on the basal plane.

Due to a lack of primary gliding planes in the absence of resolved shear stress in InGaN layers grown on GaN (0001), plastic strain relaxation requires activation of secondary glide planes, primary pyramidal ones. As explained by Srinivasan et al. [

5], only three of the pyramidal plane systems allows for non-zero resolved shear stress: {1-102}<1-101>, {11-22}<11-23> and {1-101}<11-23>. As they glide within one of the slip systems, three main forces are exerted on them: the lattice misfit stress

Fm is the driving force, the line tension

Fl and the Peierls force

Fp are the resisting forces [

22,

23,

24]. The net driving force for dislocation half loop glide is given by

Fnet =

Fm -̶

Fl -̶

Fp. The first of the three pyramidal planes cannot contribute to dislocation glide due to high Peierls force, while the {11-22}<11-23> slip system is more favorable than {1-101}<11-23> because of large net driving force. It is reported that straight misfit dislocation lines can be generated at InGaN/GaN heterointerface, via slip or punch-out mechanism [

6,

8], as shown in left portion of

Figure 6a. Nucleation and injection of the misfit dislocation network take place in slip system of {11-22}<11-23> [

5,

6]. The driving force

Fd of the process is the resolved shear stress in the inclined {11-22} plane,

Fd =

Fm cos

α. Since the driving force for generating dislocation half loops is larger,

Fd =

Fm cos0 =

Fm. The resisting force for the formation and glide of dislocations on the basal plane is smaller than that for {11-22} planes, namely, the bond density between the basal planes is the lowest. Thus, plastic relaxation via dislocation half loops introduced at the heterointerface is easier than from the growth surface. Whereas interfacial dislocation half loops are restrained by the large dislocation line tension, because the ends of the half loops are pinned at the edge of the pit. The ends of the dislocation half loops are free to move on the growth surface, therefore the dislocation half loops can easily propagate along {11-22}<11-23> slip system and form misfit dislocation network at the interface.