2.1. Problems and requirements

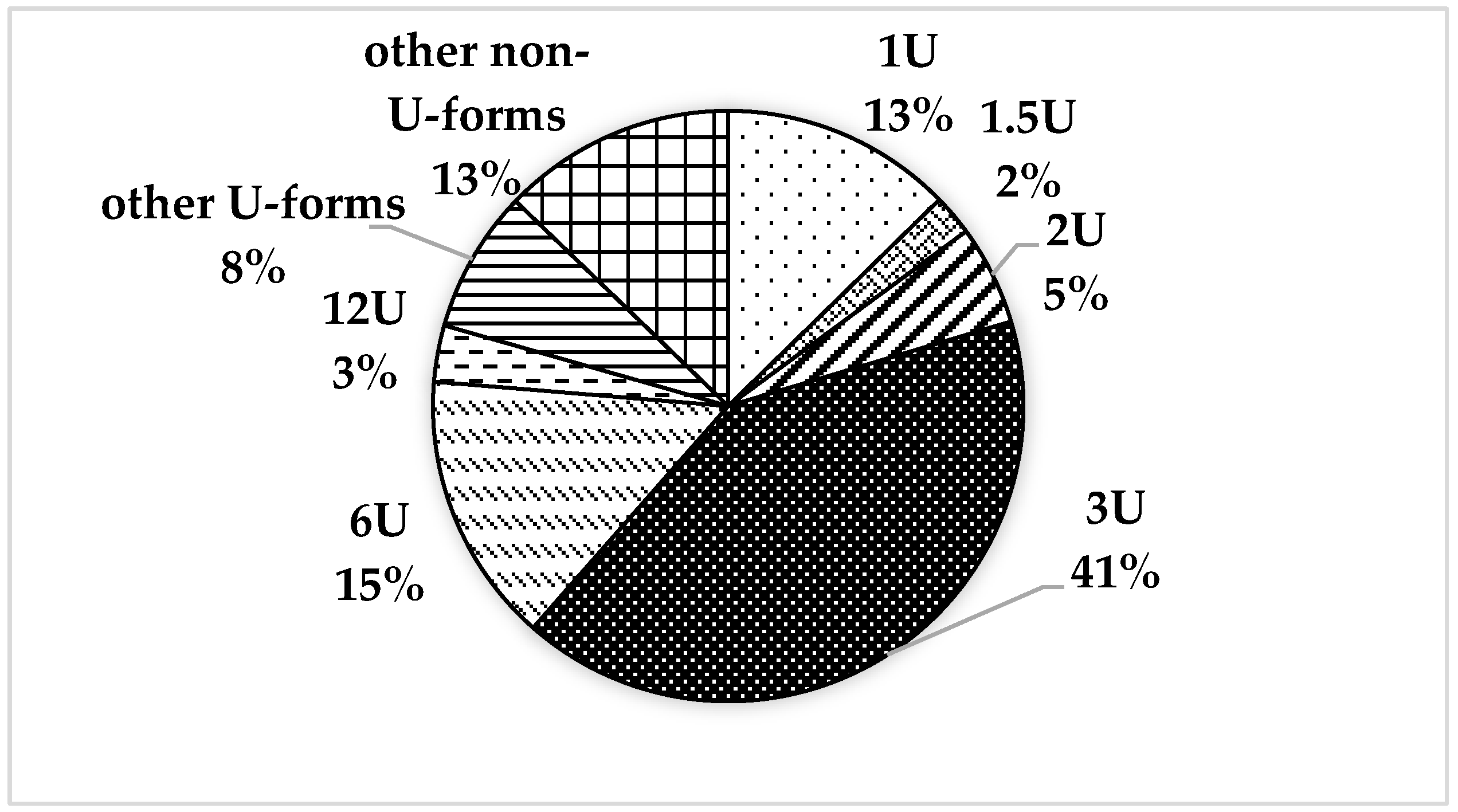

According to the Nanosatellite and CubeSat database [

18], 3,163 out of 3,627 nanosatellites are CubeSats of the U form factor, and 41% of these satellites are designed in 3U size.

Figure 1.

A chart of CubeSat dustribution by types [

18].

Figure 1.

A chart of CubeSat dustribution by types [

18].

The problems for a gripper design and operation in berthing tasks can be summarized in the following aspects:

geometry-based grasping of CubeSats

keeping the CubeSat after grasping

minimization of mass, inertial characteristics of the gripper

lightweight and low-cost solution for terrestrial testing

In previous works [

21,

22], geometry-based grasping is planned along CubeSats’ diagonal ribs by using L-shaped fingertips. In general, CubeSats are not designed with docking or berthing ports, but their shape and dimensions are standardized. A gripper design can be based on its geometry so that a standard grasping can be planned for these types of satellites.

After grasping, a CubeSat should be firmly kept by the gripper and not to slip out from its fingertips while being transferred to the berthing port. Grasping force in this case should be large to keep the CubeSat and to avoid its slip, but small enough to not damage it. The berthing operation from [

21,

22] also considers keeping multiple satellites on the base station and using only one manipulator only. Therefore, berthing ports based on CubeSats’ geometry, are required to be on the base station. Around a half of CubeSats use foldable structures such as solar panels or antennas. Unfolded elements of CubeSat can prevent it to be grasped or entering in the berthing port.

CubeSats’ body dimensions do not exceed 36 centimeters in size and 24 kg in mass [

18]. For such small satellites, both the manipulator and the gripper can be designed with suitable mass and dimensions and make the base station for maintaining CubeSats cost-efficient. Manipulators like Canadarm2 [

4] with Dextre or ERA [

6] with their size, mass, and complexity, are overengineered for this task. Focusing on the berthing can help minimize the mass and inertia characteristic of the gripper. A folding gripper structure is one of the ways to reduce volume in the launcher spacecraft. To reduce development costs, a prototype for preliminary testing of grasping mechanics can be designed using low-cost materials and manufacturing technics, such as 3D-printing.

2.2. Grasping analysis

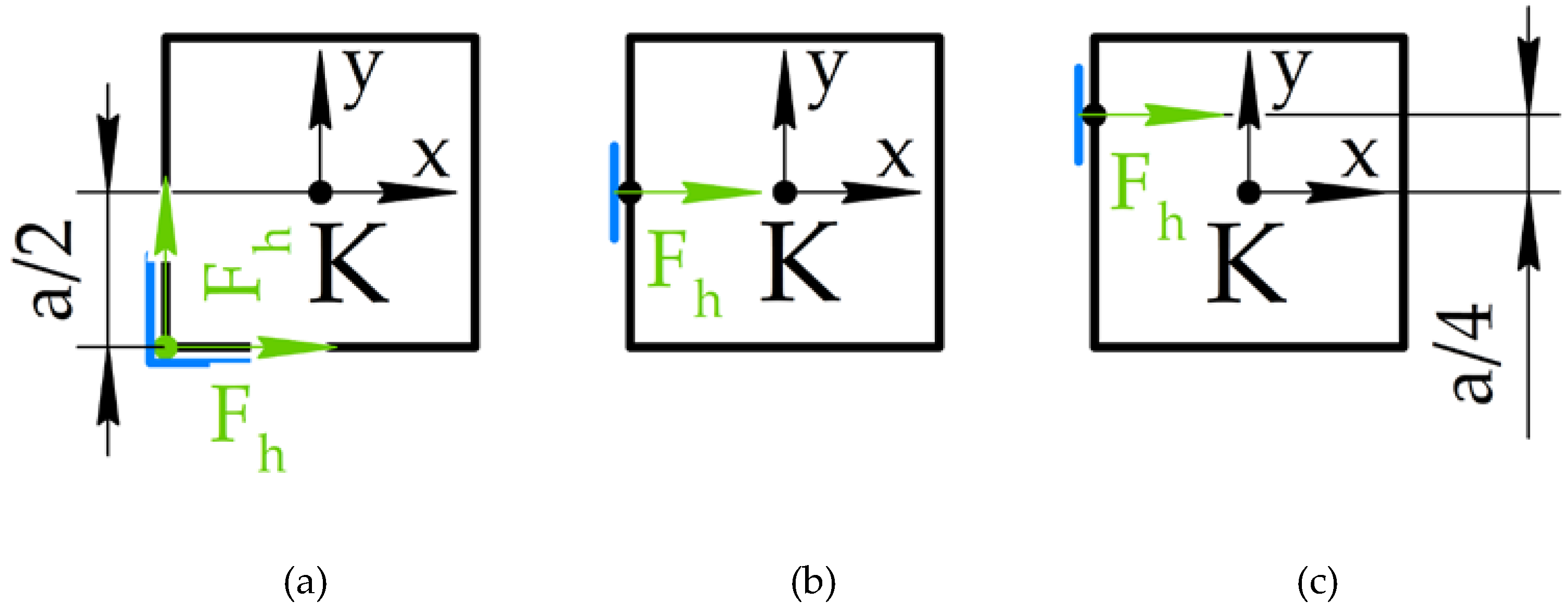

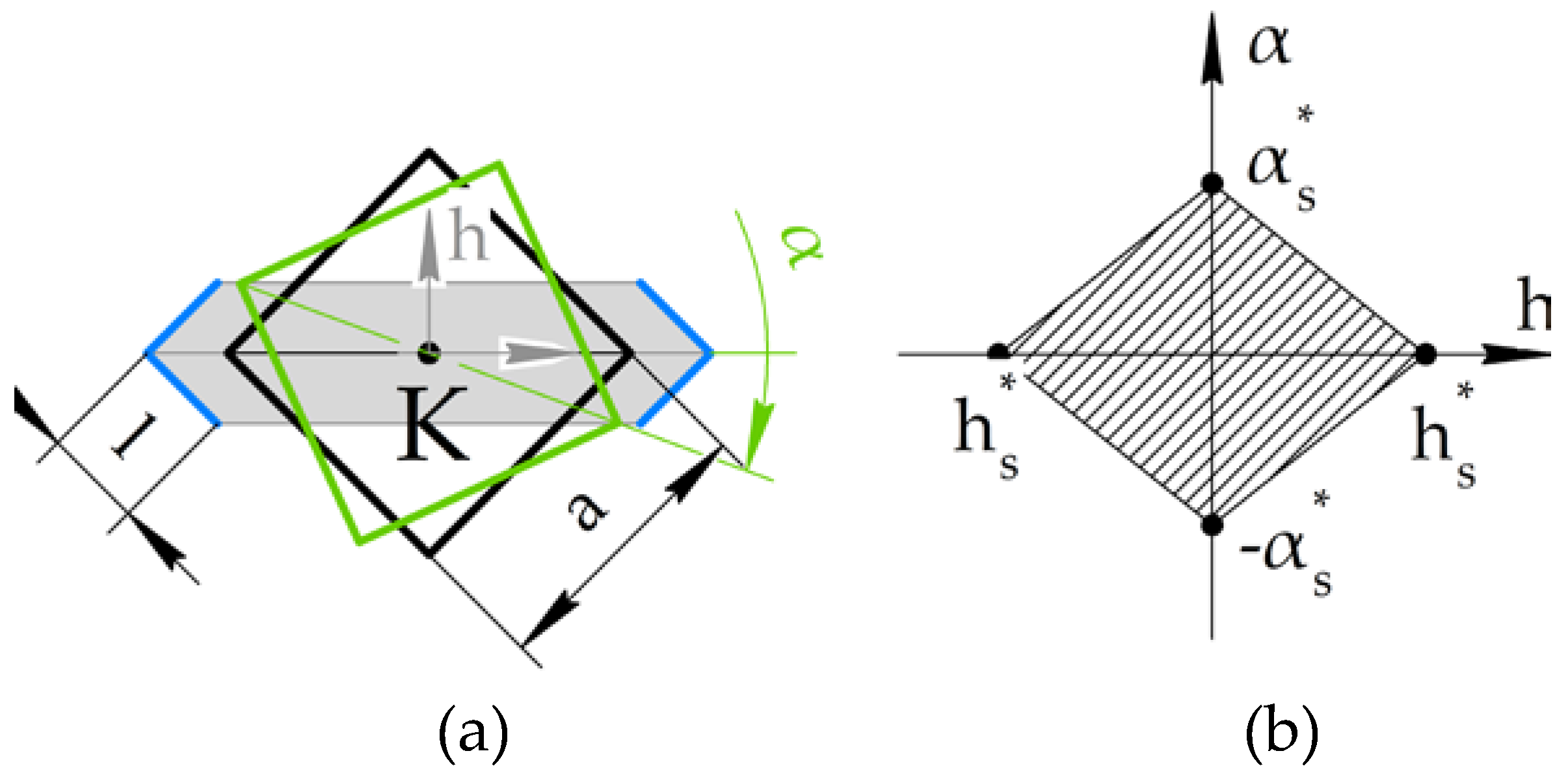

To find a suitable gripper configuration, a typical static planar task is presented in

Figure 2 in different ways of contact with the grasped body and the gripper fingertip. A square profile of CubeSat is considered as a grasped body in the presented task. The mass center K with the coordinate system Kxy is placed in the center of the square with the side equal to

a. It is assumed that a CubeSat is in contact with fingertips with forces F

h. Three types of contact are presented in this task. The first is a L-shaped fingertip presented in

Figure 2a. It contacts with the grasped body in its corner. The holding forces F

h act from the contact point along the sides of the grasped body. The planar fingertip grasping by the middle of the side of the body with the force F

h is presented in

Figure 2b. The planar fingertip contact by the edge of the side of the body with the force F

h is shown in

Figure 2c.

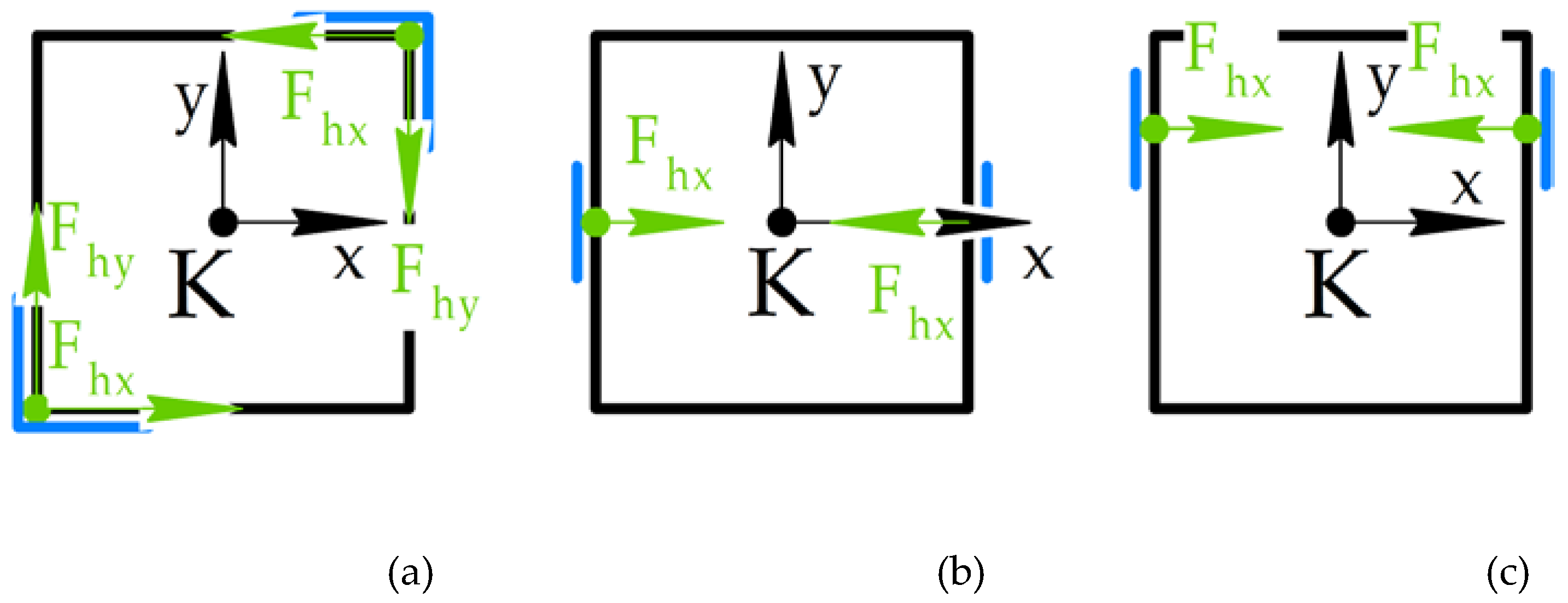

These types of contact can be used in different combinations of each other applied to the different corners and sides of the grasped body. According to [

23], static equilibrium can be ensured with two contact points. The sum of forces and moments acting on the body is equal to zero, which is a representation of the equilibrium condition.

To balance the forces, two similar fingertips should act to the counter sides of the grasped body. For example, two L-shaped fingertips from

Figure 2a should act on the counter corners of the grasped body, as shown in

Figure 3a. The same condition is applied for the fingertips in

Figure 2b and 2c, which is shown in

Figure 3b and 3c, respectively.

Other combinations give unbalanced forces or moments to the grasped body. The equilibrium conditions for three ways of contact for fingertips from

Figure 3a – 3c, named as FT3a, FT3b, FT3c, respectively, can be expreesed as:

In Equations 1 – 3, the holding forces Fhx and Fhy keep the grasped body on all its sides. This way is also because the ribs of the body are considered more rigid, and it is possible to apply larger Fh to ensure object keeping. In addition, force keeping in planar type fingertips is limited and not always possible because of sensors or solar panels installed on CubeSat’s surfaces.

The solution for planar grasping from previous work [

24] is based on concept of grasping by diagonals, as shown in

Figure 4a. The accuracy limitations of the proposed method are explained below. The grasping zone is limited by the borders of the fingertips. The central line connecting their corners is a bisector of an angle between the fingertips’ sides. For convenience, the coordinate system is set along one of the diagonals of the grasped body. The linear deviation h and the angular α are used to define the grasping area. The profile can be grasped if two of its counter diagonals are placed in the grasping zone. The linear deviation h is measured by the center of the difference between the gripper of the center and the grasped body along the h axis. The angle of deviation α is measured as the angle between two lines, one of which connects the corners of the fingertips, the other is a diagonal of a grasped body. Four points in

Figure 4b represent maximum deviations, two of them for linear deviation, and two others are for angular deviation. For square profile of a grasped body with its side equal to

a, the diagonal is equal to

. The width of a grasping zone with the fingertip corner side equal to

l, is equal to

, where

l <

a. The linear deviation h corresponds to half of this width in both directions, so the deviations h*

s and -h*

s are equal

and

, respectively. If to rotate the grasped body around the center in such a way that its counter-diagonals touch borders of the grasping zone, a right triangle can be drawn, where a hypotenuse is equal to a diagonal of the grasped body, and the shortest side of a triangle is equal to the width of the grasping zone. The ratio between the width of the grasping zone and the diagonal of the grasped body is equal to sine of an angular deviation, and, therefore, the maximal angular deviation α can be represented as arcsine of this ratio, as shown in Equation 10.

Likewise in Equation 10, .

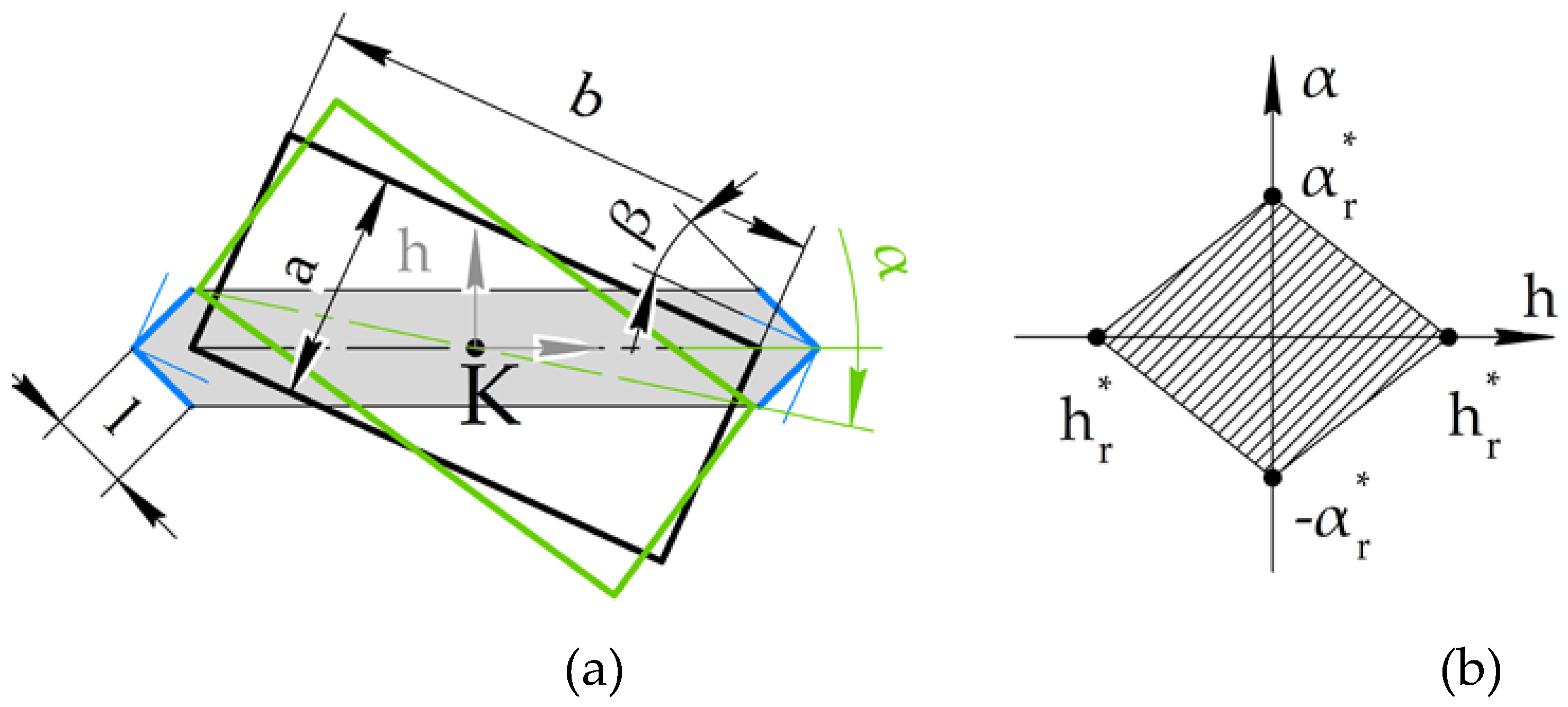

The same way can be used to explain the linear and angular deviations for the rectangular grasped body with sides equal to a and b in

Figure 5a. The h-axis is placed perpendicularly to one of the diagonals of the grasped body. The diagonal

d for the grasped body can be found by Pythagorean theorem, as

. Maximal linear deviation for the rectangular grasped body h*

r in

Figure 5b remains the same as in the previous task for a square body, or

. Angular deviation α*

r can be presented as a ratio between the grasping zone width and the grasped body diagonal, as

For square grasped body, its diagonals are orthogonal to each other and at 45 degrees to both corresponding sides. Both fingertips are parallel to the sides of the grasped body, and the central line of the grasping zone is coplanar to the diagonal

d of the grasped body. But for the rectangular body, the diagonal divides the right angle between its sides into two nonequal angles. To comply with this diagonal, the fingertips should be able to rotate at angle β. As mentioned above, the angle between a central line and each side of a fingertip is equal to 45 degrees. The angle γ between the diagonal of the rectangular grasped body and their sides a and b can be presented as the arctangent function between its sides, or

. The angle β is a difference between 45 degrees and this function, as

CubeSats 1U-3U and 12U correspond to this task. For grasping rectangular profiled CubeSats 6U, the fingertips should be adaptive and rotate by angle β. Using Equations 10-12, the calculated numerical results for linear h and angular α deviations are listed in

Table 1 for the L-shaped fingertips with a side equal to 25 mm.

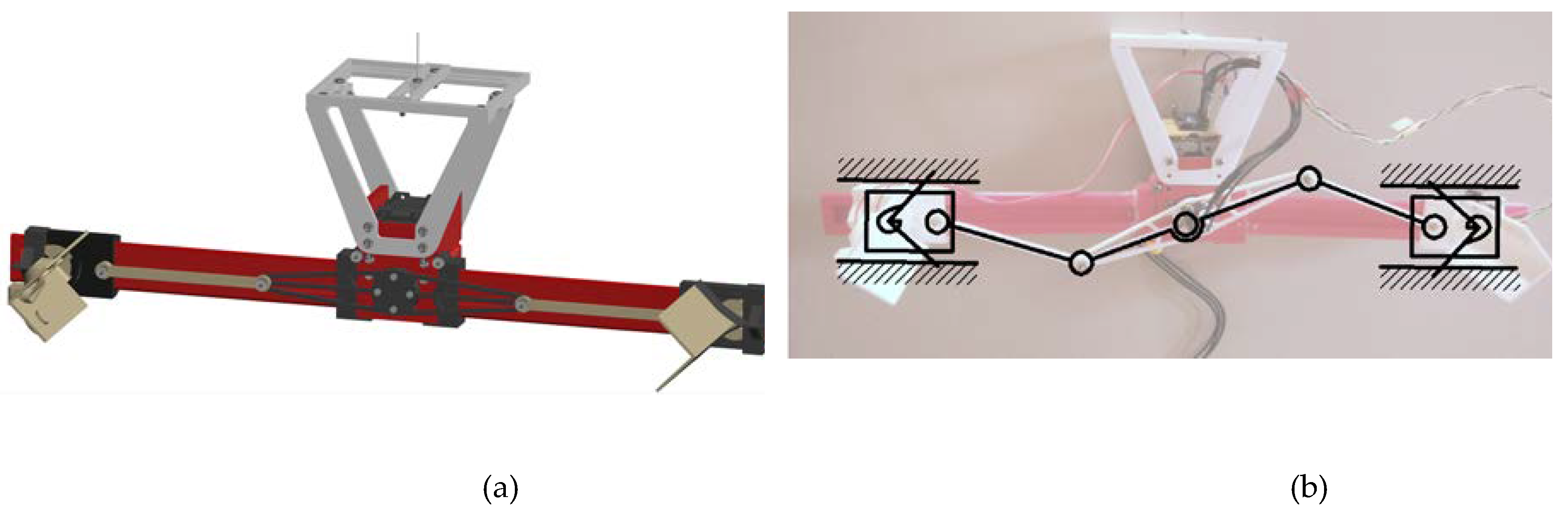

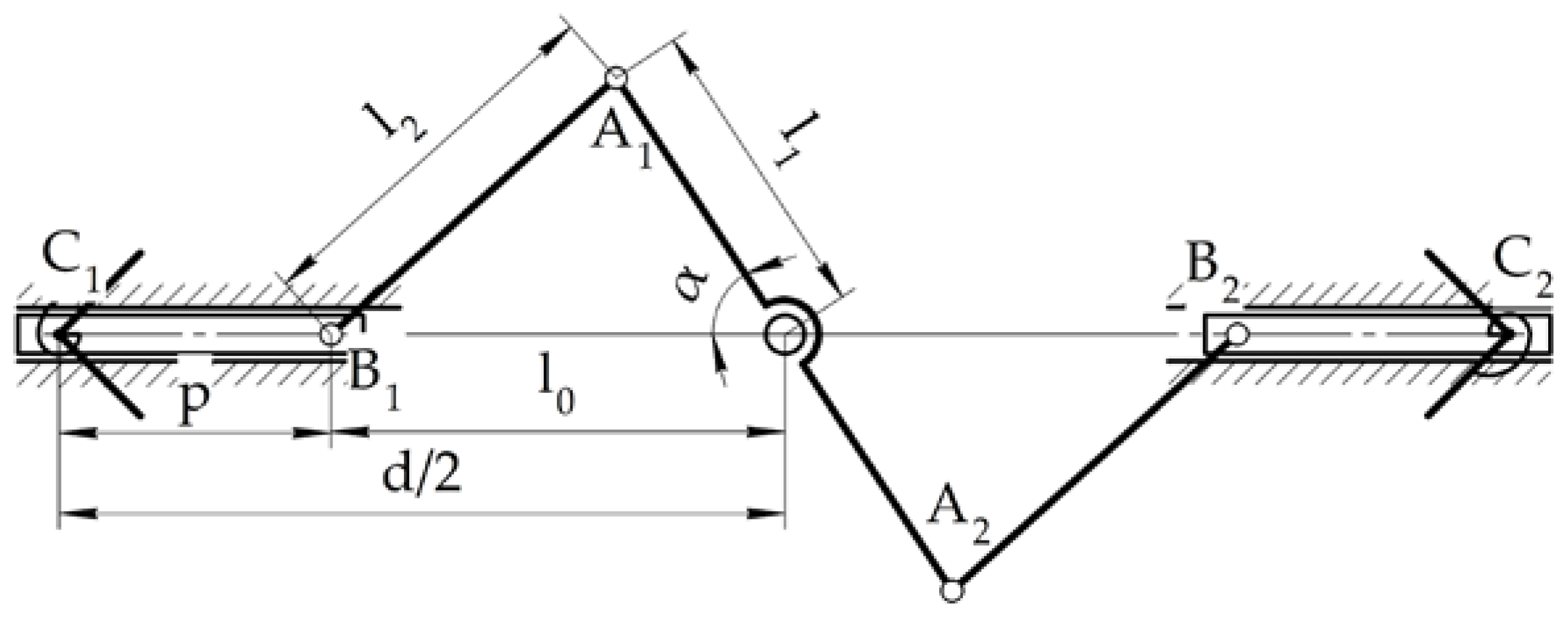

2.3. Gripper kinematic scheme

For the grasping task in

Figure 4 and

Figure 5, a novel gripper design is proposed to grasp different types of CubeSat from 1U to 12U. In previous works [

22,

24], the conceptual design has been presented as a double slider-crank mechanism, as shown in

Figure 6. It has two positions: opened and closed. In the opened position, the distance between fingertips corners

dmax is set to be 5% larger than the diagonal of the largest CubeSat 12U for a compact design, or 336.0 mm. For the closed position, the distance

dmin is set 1% lower than the diagonal of the smallest CubeSat 1U, or 140.0 mm, to ensure grasping. In

Figure 6, the general configuration of a mechanism is presented and distances

dmax and

dmin are replaced by the distance

d/2 from the center of the mechanism to the one of the fingertips. For the gripper design, a distance

p equal to 25 mm is set between the fingertip corner C

1 or C

2 and the crank end B

1 and B

2, respectively. The distance

d/2 in

Figure 6 is from the center of the gripper to the corner of the fingertip. In the opened configuration, the distance l

0 is the lengths sum of two cranks OA

1 and A

1B

1 for the first finger or OA

2 and A

2B

2 for the second finger. In the closed position, the mechanism becomes the right triangle, where the crank A

1B

1 with the length

l2 is the hypotenuse, and the crank OA

1 is one of the cathetes. The distance

l0 becomes another cathetus of the right triangle in the closed position. Length

l0 is equal to

d/2 minus h, and it is known in opened and closed positions of the gripper. Then lengths

l1 and

l2 of cranks can be found by solving an Equation 13.

The length l1 of Equation 5 is equal to 64.4 mm, and the length l2 is equal to 78.6 mm. These lengths are used as crank lengths in the CAD model design.

2.4. Gripper CAD design

The CAD design of a prototype is presented in

Figure 7a. A simplified gripper model from [

24] has been redesigned for being 3D printed and tested as a lab prototype from

Figure 7b, so all the components except ball bearings are designed in PLA. For the input actuation, Dynamixel AX-12A [

25] has been chosen. The model of this motor is covered by two parts, which protect the motor from external conditions and are used as basis for other parts. Two rails 180 mm long and 20 mm maximal width are used for translational movement of the fingers. The rails have a trapezoidal profile and a place for ball bearings to keep the fingers. They are inserted into the pockets that are adjusted to the enclosures of the motor. The pockets are designed to fold the gripper rails and keep them unfolded when the gripper is in use. The fingers consist of three parts, such as the car, the fingertip, and the cap with flexible elements. The car is 40 mm long, its profile repeats the profile of the rail with the gap 0.2 mm, and it has sockets for six ball bearings from each side. It has a hole for the crank, and a socket for the fingertip. This socket is designed with the restrictor that limits the free rotation of the fingertip by 21.16 degrees clockwise and counterclockwise. The L-shaped fingertips are designed on a cylindrical platform with diameter of 20 mm. The 25 mm wide and 70 mm long sides of the fingertip are placed 90 degrees related to each other. The central crank is double of the length

l1, or 128.8 mm, and the lengths of two other cranks are equal to

l2, or 78.6 mm.

For laboratory testing, an adjustable support has been designed. When sensors are installed on fingertips, the center of the mass can slightly move from the initial position. The platform allows to hang and manually center the gripper along two axes in 70×43 mm range.

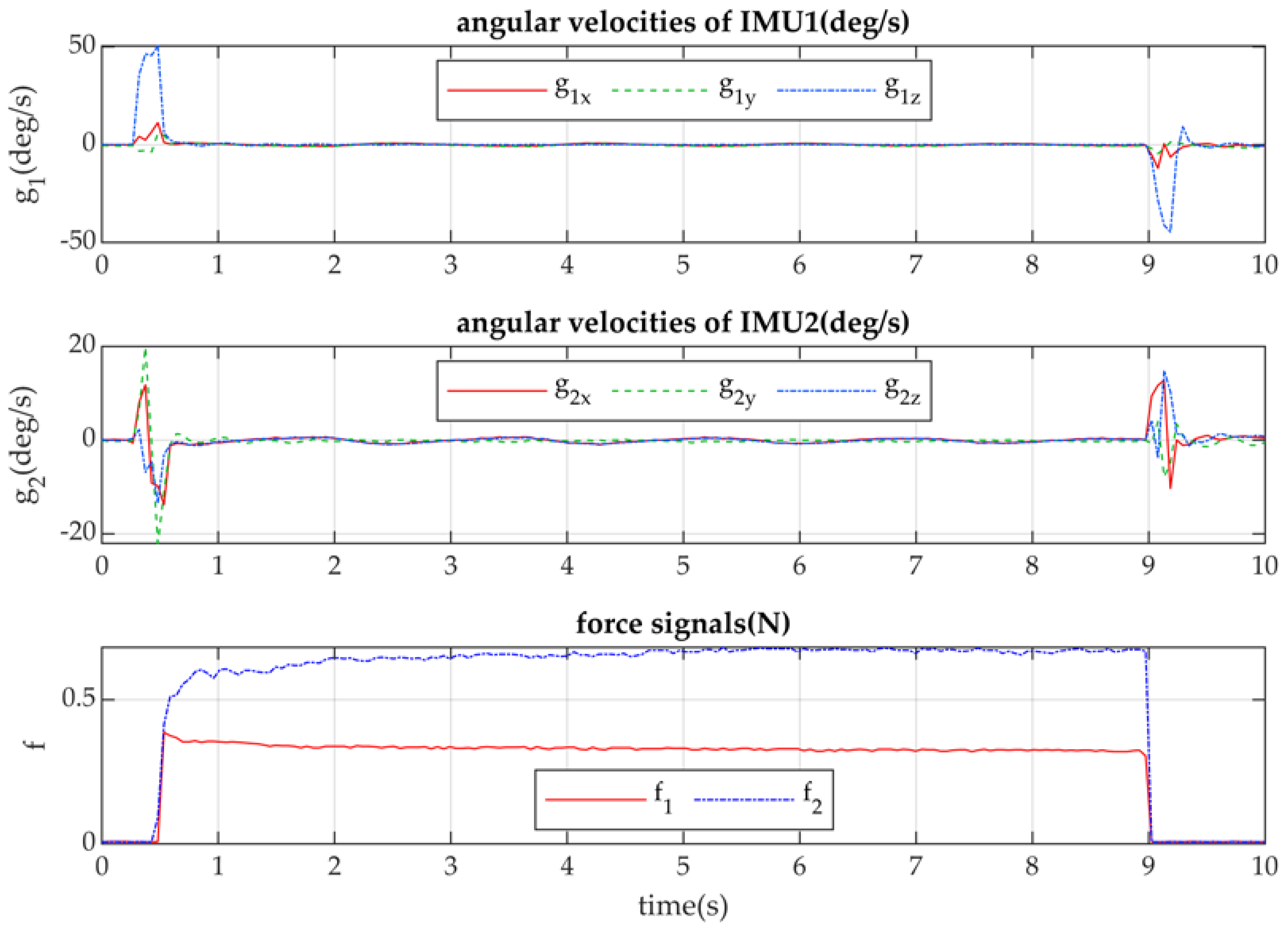

2.5. Testing design and modes

The lab prototype is made from CAD model from

Figure 7. The parts are printed in PLA material with 20% grid infill. The tolerances between the moving parts are 0.2 mm. Flexible elements are taken off to reduce resistance and friction for better adjustment of a fingertip during contact with the grasped body. The final mass of the printed prototype with the installed Arduino board is 215 gram.

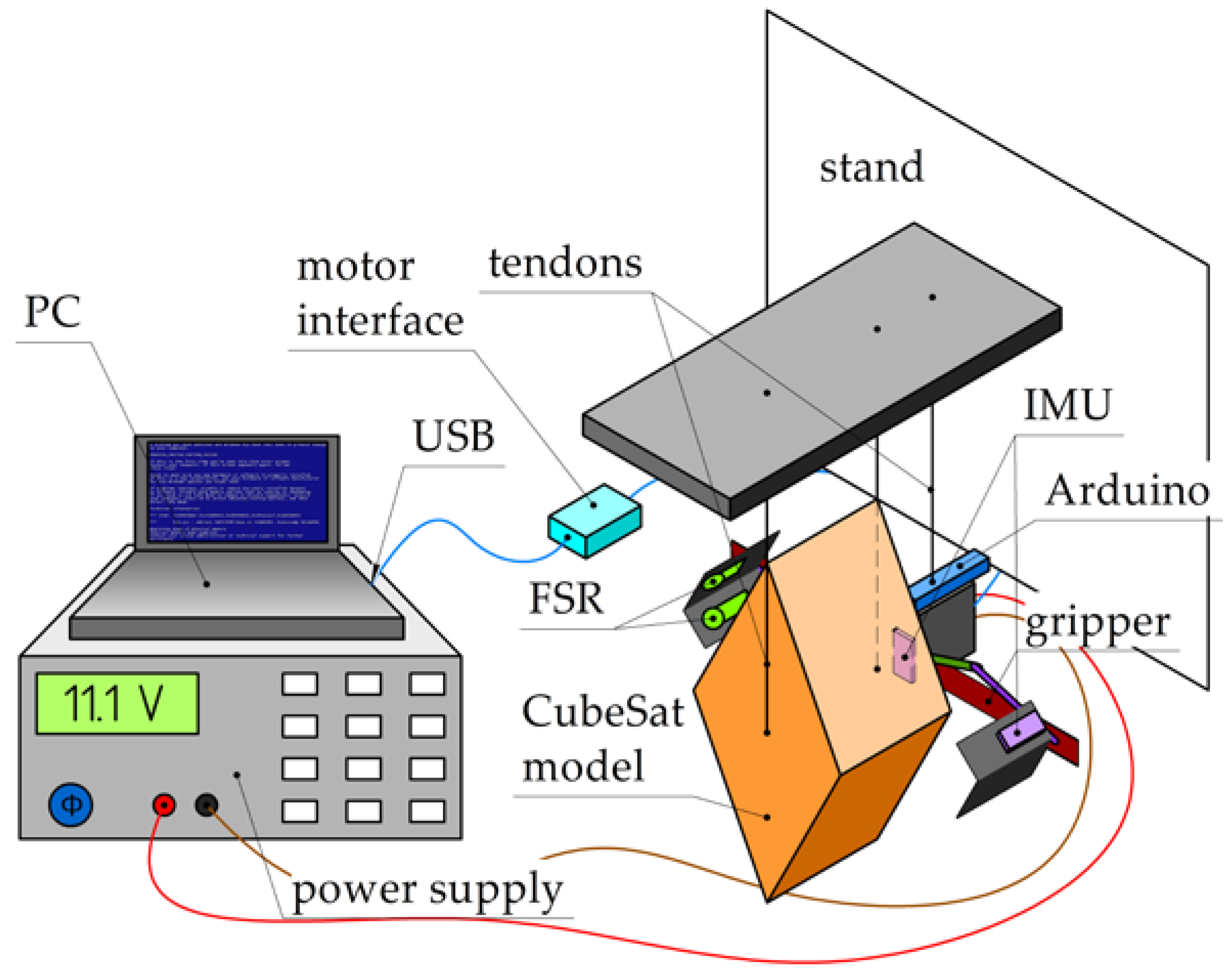

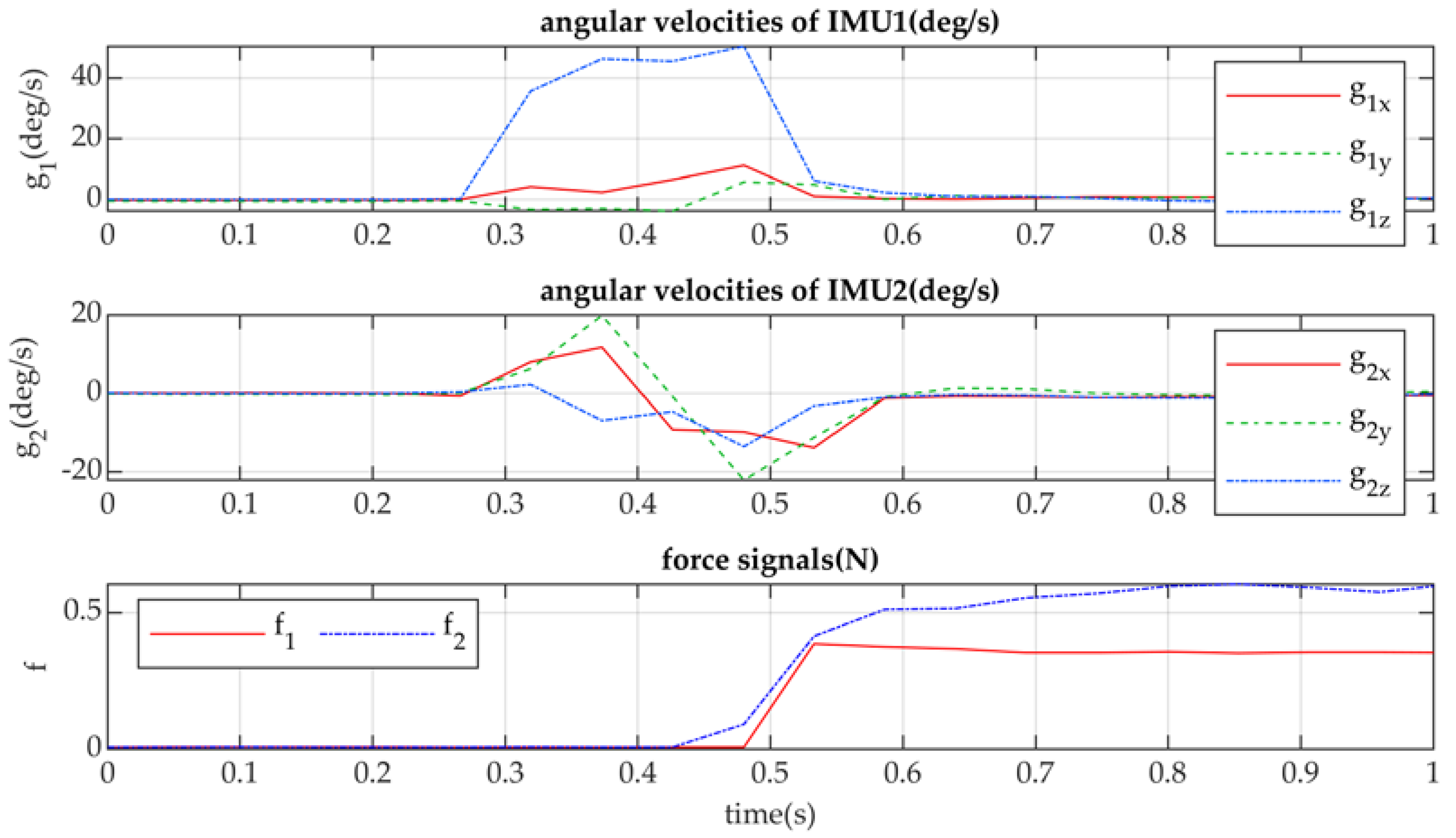

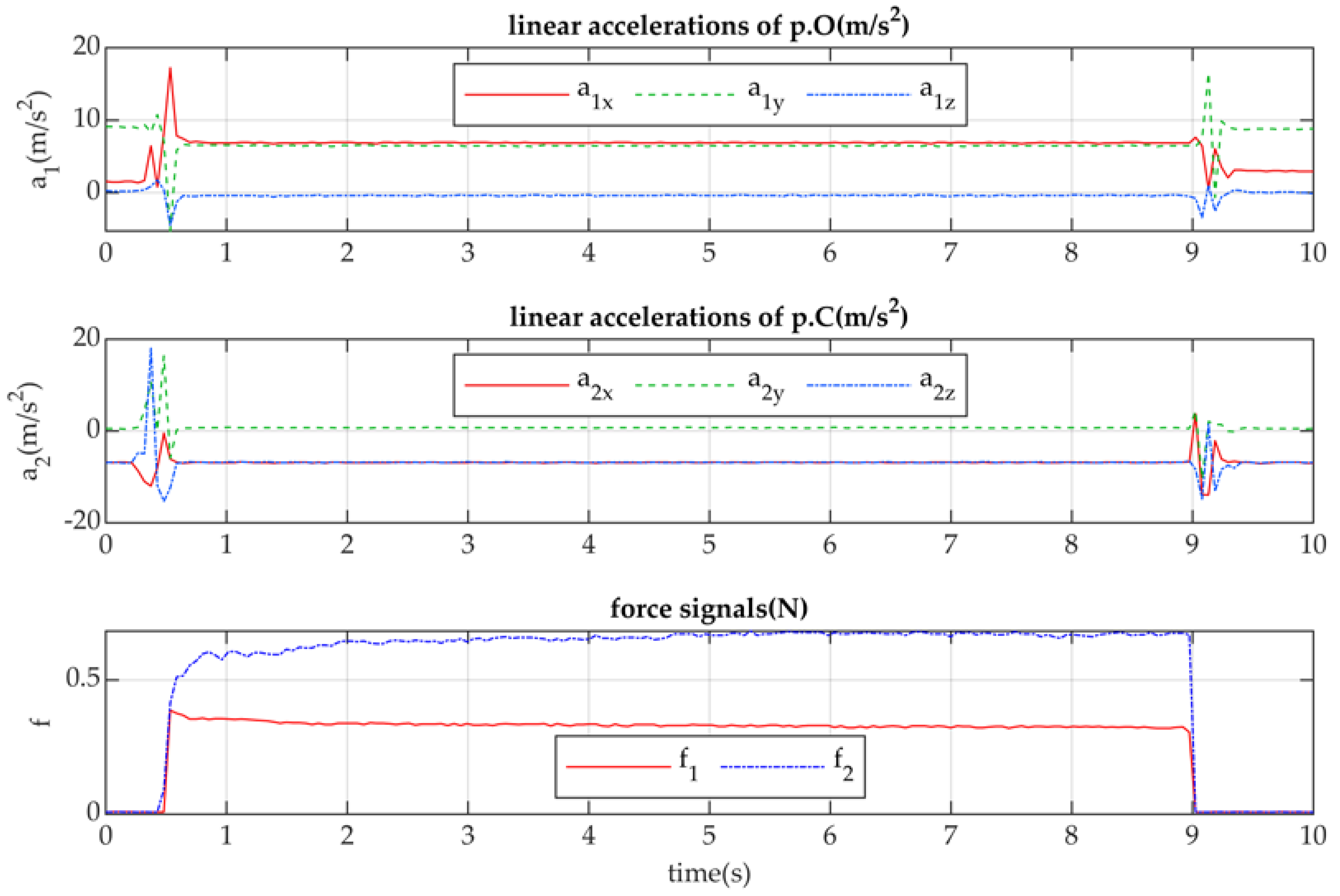

From

Figure 8, the grasped body is a cardboard box 210 × 210 × 50 mm, which is close to the dimensions of CubeSat 12U. The larger surface 210 × 210 mm is placed parallel to the gripper mechanism. The distance between the central gripper link and the surface of the gripped body is set 40 mm. The mass of the box is 160 gram.

The Dynamixel AX-12A motor of a gripper is powered by an external 11.1V power supply and controlled by the U2D2 computer interface. The motor is controlled by the software Dynamixel Wizard 2.0. It allows to control the speed, torque, limit rotation angles, and get real-time data, such as current usage and present position. Grasping is performed by movements of the motor, which are manually controlled by the Dynamixel Wizard 2.0 software.

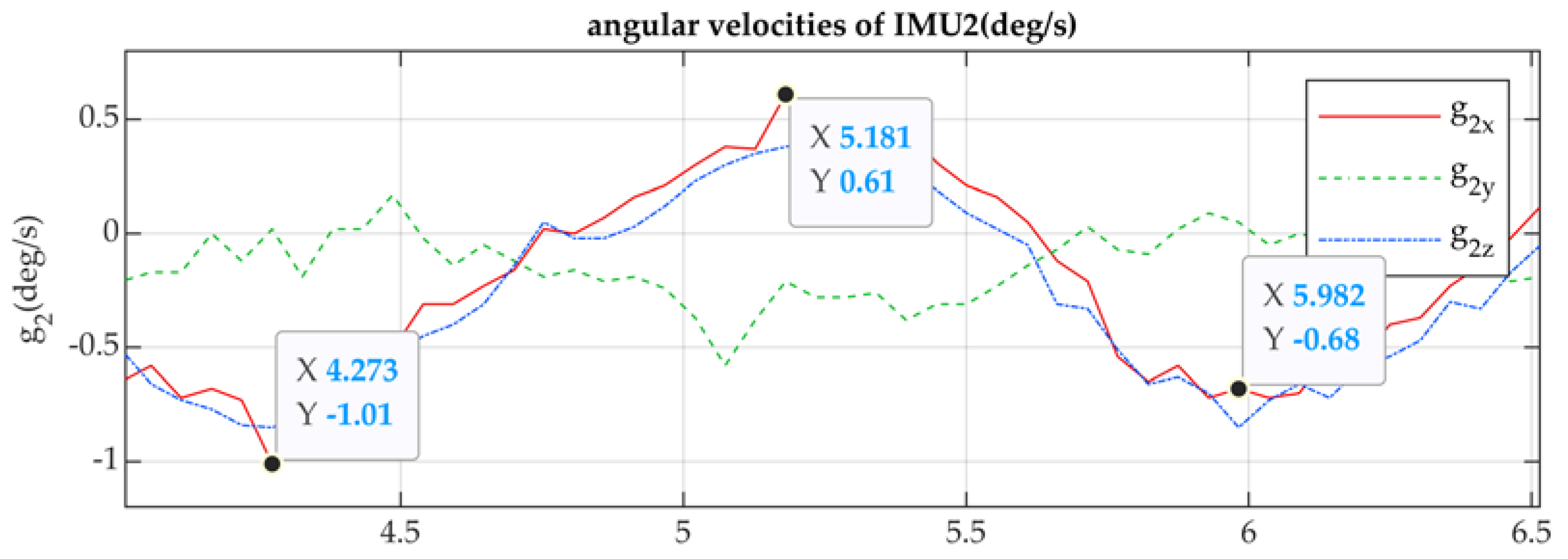

To measure impact during grasping operation, two inertial measurement unit (IMU) sensors BMI160 and two force sensor resistors FSR-400 are installed on the gripper. The first IMU is set in the gripper center on the central crank, and it is used to measure the gyroscope and acceleration data of the gripper center. The second is installed at the fingertip. It shows the data of the fingertip motions. Two force sensors are placed at the fingertip and measure the contact forces when grasping. One force sensor is set between the sides of the fingertip. The ribs of the carton box are with the 1 mm radius, and a small platform is designed to transmit contact forces from this rib to the sensor. Another fingertip is on one side of the fingertip, coordinates of its center are 20 mm from its top and 15 mm from the edge. If the grasping is successful, the surface of the box touches it, and a contact is registered. Another contact platform on the side of the fingertip is used to transmit distributed forces to the small surface of a force sensor.

Force sensor resistors, which are named as FSR in

Figure 8, are mostly used to register the existence of a contact, but not for the precise measurements. However, sensors calibration has been conducted using reference weights and Arduino board. The datasheet [

26] shows nonlinear resistance or conductance. The sensor was connected to analog pin of Arduino with 10K Ohm resistor, and the data were acquired as a signal from 0 to 1023. The function of the form y = k

1 / (x + k

2) + k

3 , where k

1 = -1000, k

2 = -1023, and k

3 = -0.97 are the empirical coefficients, was applied to the acquired data to convert them into Newtons.

Arduino Nano Every is used to acquire the data from the IMU and force sensors. It is installed on the gripper below the support platform. I2C connection is used to acquire the data from the IMU sensors; three components of angular velocities and three components of linear acceleration are taken from each sensor. Two components of force data are taken from the force sensor resistors. The frequency of acquiring data for 14 components in total is 15 Hz with the 115200 baudrate set on the Arduino board.

The test is planned as a grasping of a box, holding it, and releasing it. The box is fixed in the fingertips during the test. The commands of grasping and releasing are given by user in the Dynamixel Wizard 2.0 software. Grasping time is around 8.5 seconds, as the CubeSat can be held in the berthing operation, and this time is enough to observe the successful operation and behavior of the system, such as gripper oscillations together with the grasped body.

Figure 8.

A laboratory setup for gripper testing.

Figure 8.

A laboratory setup for gripper testing.