Submitted:

24 May 2023

Posted:

25 May 2023

You are already at the latest version

Abstract

Keywords:

Introduction

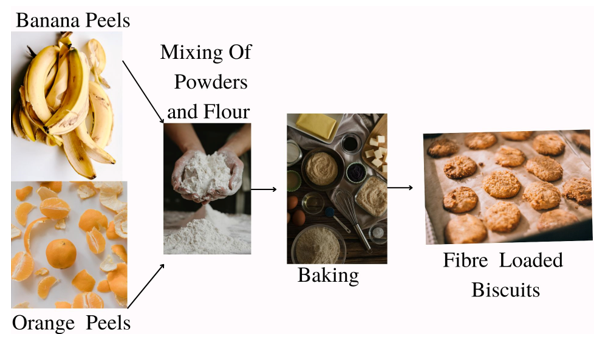

MATERIAL AND METHODS

| Treatment | Wheat flour (g) | Orange peel powder (g) | Banana peel powder (g) | Sugar (g) | Shortening (g) | Egg (g) | Milk powder (g) | Salt (g) | Baking powder (g) | Vanilla essence (drops) |

|---|---|---|---|---|---|---|---|---|---|---|

| T0 | 100 | 0 | 0 | 60 | 20 | 40 | 5 | 1 | .5 | 2 |

| T1 | 95 | 2.5 | 2.5 | 60 | 20 | 40 | 5 | 1 | .5 | 2 |

| T2 | 90 | 5 | 5 | 60 | 20 | 40 | 5 | 1 | .5 | 2 |

| T3 | 85 | 7.5 | 7.5 | 60 | 20 | 40 | 5 | 1 | .5 | 2 |

| T4 | 80 | 10 | 10 | 60 | 20 | 40 | 5 | 1 | .5 | 2 |

| components | Wheat flour (%) | Orange peel powder (%) | Banana peel powder (%) |

|---|---|---|---|

| Moisture | 11.03a | 7.04a | 6.32d |

| Protein | 11.27b | 4.97d | 8.19c |

| Fat | 2.24c | 1.89e | 4.76e |

| Fibre | 0.46e | 13.97b | 10.03a |

| Ash | 0.81d | 5.50c | 9.63b |

| Treatment | Moisture (%) | Protein (%) | Ash (%) | Fat (%) | Fibre (%) |

|---|---|---|---|---|---|

| T0 | 3.38e | 9.15a | 0.84e | 27.85a | 0.54e |

| T1 | 4.42d | 8.93b | 1.01d | 27.63a | 2.24d |

| T2 | 5.84c | 8.46c | 1.97c | 27.28b | 3.87c |

| T3 | 6.21b | 7.74d | 2.24b | 26.93c | 4.27b |

| T4 | 6.98a | 6.91e | 2.73a | 26.47d | 4.93a |

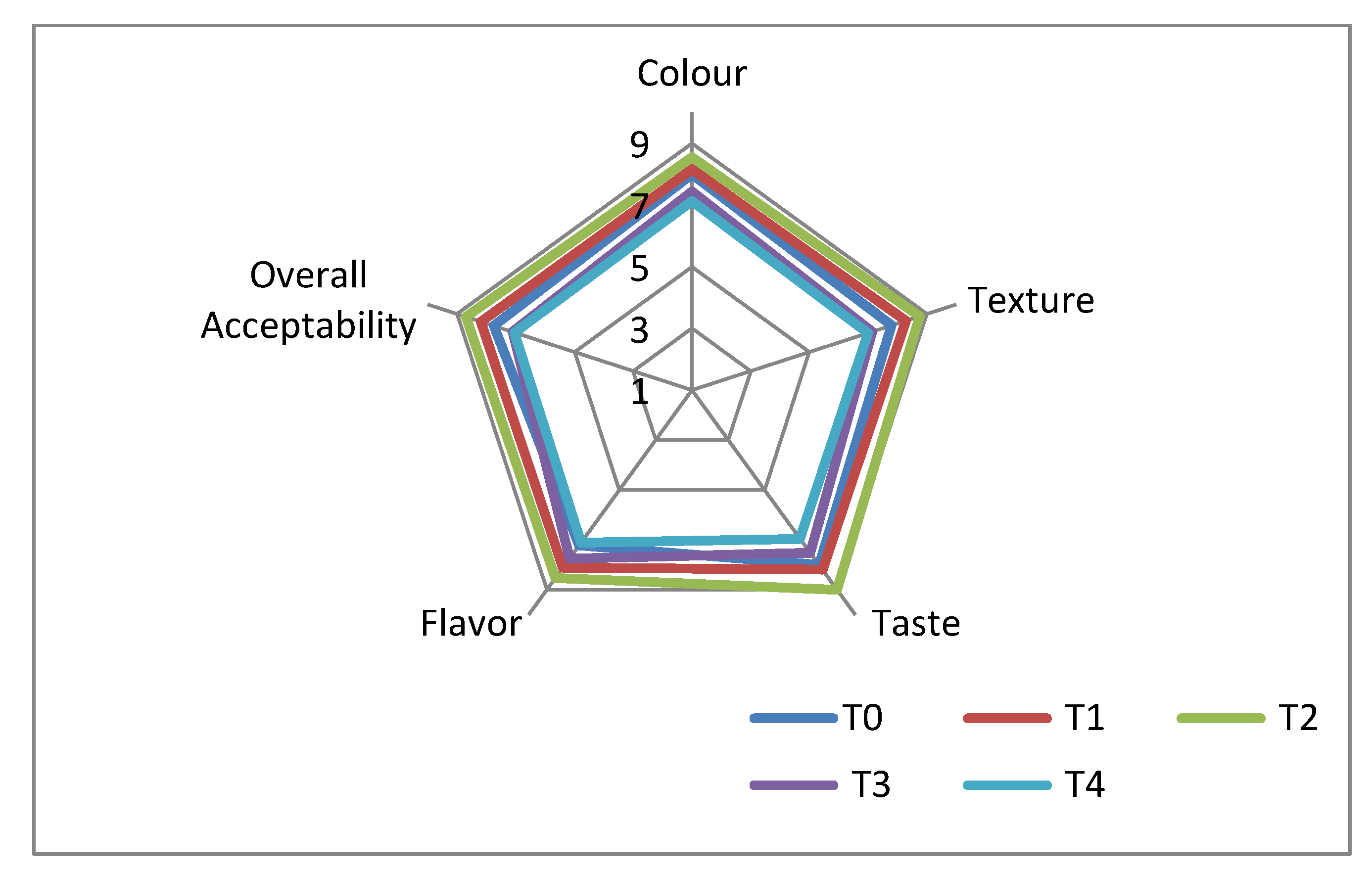

| Treatment | Colour | Texture | Taste | Flavour | Overall acceptability |

|---|---|---|---|---|---|

| T0 | 8 | 7.8 | 8 | 7.21 | 7.75 |

| T1 | 8.16 | 8.29 | 8.19 | 8.12 | 8.19 |

| T2 | 8.55 | 8.76 | 9 | 8.52 | 8.70 |

| T3 | 7.44 | 7.14 | 7.51 | 7.75 | 7.46 |

| T4 | 7.13 | 7 | 6.96 | 7.11 | 7.05 |

Conclusion

References

- Pazera, A. , Slezak, R., Krzystek, L., Ledakowicz, S., Bochmann, G., Gabauer, W. and Kara, J. Biogas in Europe: food and beverage (FAB) waste potential for biogas production. Energy & fuels. 2015, 29, 4011–4021. [Google Scholar]

- Kuyu, Chala. Review on Potential Use of Fruit and Vegetables By-Products as A Valuable Source of Natural Food Additives. IISTE-Food Science and Quality Management. 2015, 45, 47–61. [Google Scholar]

- Kohajdová, Z. , Karovičová, J., Magala, M. et al. Effect of apple pomace powder addition on farinographic properties of wheat dough and biscuits quality. Chem. Pap. 2014, 68, 1059–1065. [Google Scholar] [CrossRef]

- Obafaye, RO, Omoba, OS. Orange peel flour: A potential source of antioxidant and dietary fiber in pearl-millet biscuit. J Food Biochem; 2018. m. [CrossRef]

- Imeneo, V. , Romeo, R., Gattuso, A., De Bruno, A., & Piscopo, A. Functionalized Biscuits with Bioactive Ingredients Obtained by Citrus Lemon Pomace. Foods. 2021, 10, 2460. [Google Scholar] [CrossRef] [PubMed]

- Weng, m. , li, y. , wu, l., zheng, h., lai, p., tang, b., & luo. Effects of passion fruit peel flour as a dietary fibre resource on biscuit quality. Food Science and Technology. 2021, 41, 65–73. [Google Scholar] [CrossRef]

- Khatun, M. , Ahmed, M. W., Hossain, M. M., Karmoker, P., & Iqbal, A. Utilization of Banana Peel Flour in Biscuit Making as Wheat Flour Substitute. European Journal of Agriculture and Food Sciences. 2021, 3, 32–35. [Google Scholar] [CrossRef]

- Parveen, H. , Bajpai, A., Bhatia, S., & Singh, S. Analysis of Biscuits Enriched With Fibre by Incorporating Carrot and Beetroot Pomace Powder. The Indian Journal of Nutrition and Dietetics. 2017, 54, 403. [Google Scholar] [CrossRef]

- Figuerola, F.M. L. Hurtado, A.M. Estevez, I. Chiffelle and F. Asenjo. Fiber concentrates from apple pomace and citrus peel as potential fiber sources for food enrichment. Food Chem. 2005, 91, 395–401. [Google Scholar] [CrossRef]

- Waddell, I. S. , & Orfila, C. Dietary fiber in the prevention of obesity and obesity-related chronic diseases: From epidemiological evidence to potential molecular mechanisms. Critical Reviews in Food Science and Nutrition, 2022. [Google Scholar] [CrossRef]

- Whitley, P.R. Biscuit Manufacture, Applied Science Publishers Ltd., London; 1970.

- AACC. Approved methods of the American Association of Cereal Chemists. 10th Edition. American association of Cereal Chemist, Inc. USA; 2000.

- Kulkarni & D, Desai & Ranveer, Dr. Rahul & Sahoo, A. Development of nutrient rich noodles by supplementation with malted ragi flour. International Food Research Journal. 2012, 19, 309–313.

- Gotmare, Sulekha & Gade, Jaya. Orange Peel: A Potential Source of Phytochemical Compounds. International Journal of ChemTech Research. 2018, 11, 240–243. [Google Scholar]

- Aboul-Enein, Ahmed & Salama, Dr.Zeinab & Gaafar, Alaa & Aly, Hanan & abou elella, Faten & Ahmed. HabibaIdentification of phenolic compounds from banana peel (Musa paradaisica L.) as antioxidant and antimicrobial agents.2016, 46-55.

- Hassan and Peh. Chemical Compositions of Banana Peels (Musa Sapientum) Fruits Cultivated in Malaysia Using Proximate Analysis. Research Journal of Chemistry and Environment; 2018.

- Hernawati, Aryani, A. , & Shintawati, R. Physical Characteristics, Chemical Composition, Organoleptic Test And The Number Of Microbes In The Biscuits With Addition Of Flour Banana Peels. Journal of Physics: Conference Series, 2017, 812, 012118. [CrossRef]

- Juarez-Garcia, E & Agama, Edith & Sayago-Ayerdi, Sonia & RODRÍGUEZ-AMBRIZ, S.L. & BELLO-PÉREZ, L.A. Composition, Digestibility and Application in Breadmaking of Banana Flour. Plant foods for human nutrition (Dordrecht, Netherlands); 2006.

- Aslam, H. K. W. , Ur Raheem, M. I., Ramzan, R., Shakeel, A., Shoaib, M., & Sakandar, H. Utilization of mango waste material (peel, kernel) to enhance dietary fiber content and antioxidant properties of biscuit. Journal of Global Innovations in Agricultural and Social Sciences, 2014, 2, 76–81. [Google Scholar] [CrossRef]

- Ajila, C.M., K. Leelavathi and U. J.S.P. RaoImprovement of dietary fiber content and antioxidant properties in soft dough biscuits with the incorporation of mango peel powder. J. Cereal Sci. 2008, 48, 319–326. [Google Scholar]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).