1. Introduction

The current awareness of the importance of environmental issues, linked to the scarcity of the planet’s resources, and the negative consequences of greenhouse gas emissions, has imposed the need to adopt alternative approaches to construction. Today, in fact, the building industry is oriented to a greater attention to the choice of materials and to every phase of the life cycle of buildings. This new way of designing has the parameters of the so-called circular economy, an alternative model to the traditional linear type, in which waste is no longer something to be disposed of in landfills, but a resource to be reused and recycled. To pursue sustainable development, the European Commission, with the 2030 Climate Target Plan [

1], proposes to increase the EU’s ambition to reduce greenhouse gas emissions to at least 55% below 1990 levels by 2030, and achieving climate neutrality by 2050. The new proposal maintains the commitment made in the Communication on the European Green Deal and is in line with the Paris Agreement [

2], which aims to keep the global temperature rise well below 2 ºC [

3]. Global efforts are currently focused on achieving the UN Sustainable Development Goals of the 2030 Agenda for Sustainable Development [

4], signed in 2015 by 193 countries, which provides an integrated vision of the three dimensions of sustainable development: economic, social, and environmental sustainability. The seventeen Objectives set by the Agenda, to be achieved by 2030, are interconnected and embrace the most important issues for sustainability, such as the fight against poverty, the elimination of hunger in the world, the reduction of inequalities and the fight against the climate change.

Environmental policies contributed to a decline in greenhouse gas emissions for construction operations between 2019 (9.6 Gt) and 2020 (8.7 Gt). Despite the slight reduction, however, the global account of CO

2e emissions (direct and indirect related to heating, cooling, lighting, etc.) from the construction sector, compared to the total, remains high and stands at 37% [

5].

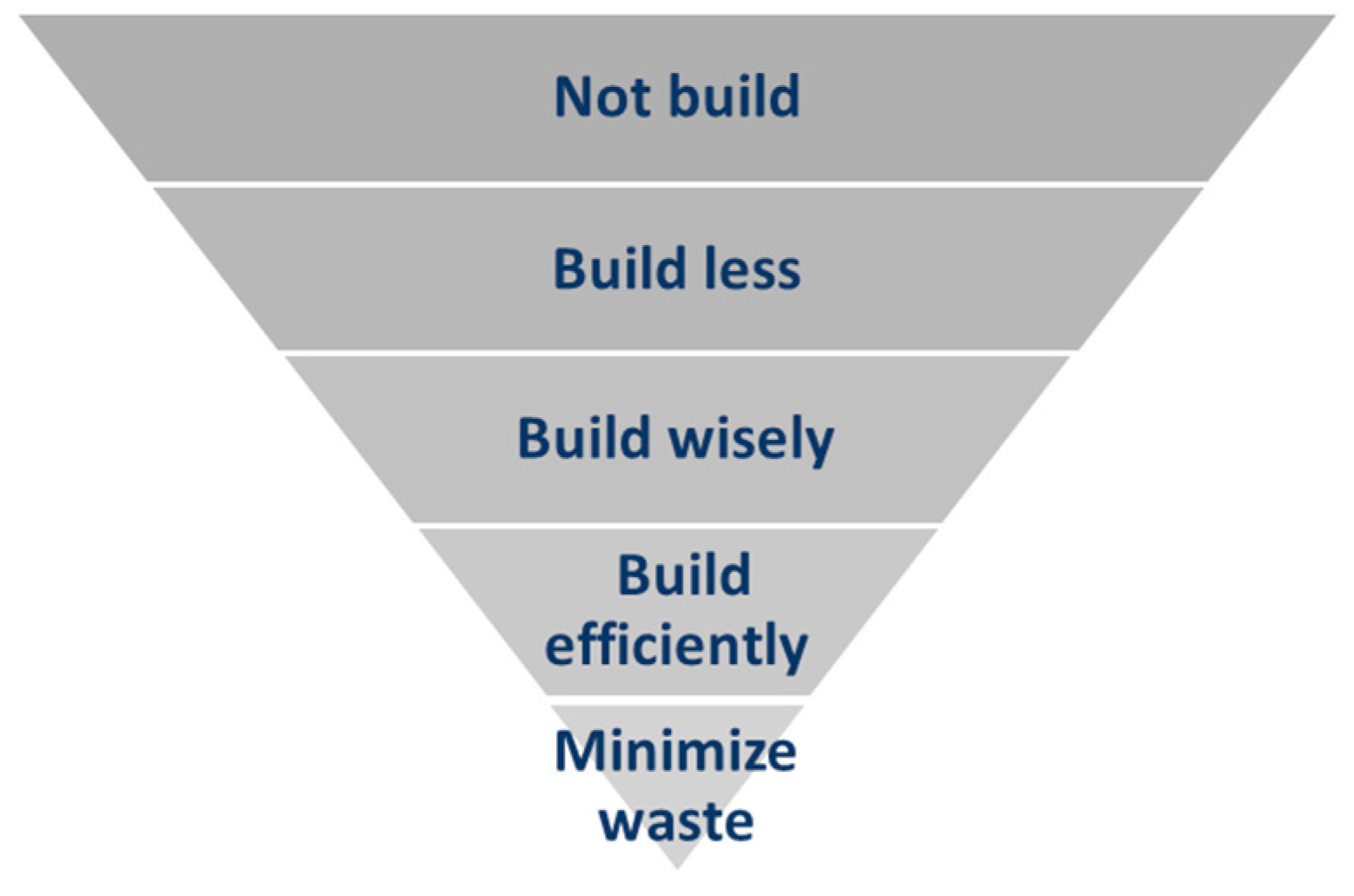

The construction industry requires the extraction of large quantities of raw materials, with the consequent consumption of energy resources and release of pollutant emissions into the atmosphere. It is possible to draw a graph that defines the trajectory to follow to minimize the emissions of CO

2e of the construction sector. (

Figure 2). In the perspective of complete decarbonization, the best approach would be not to build at all, an unattainable goal, which however orients us towards a construction model based on flexible design and removable and reusable structures. when not building cannot be an option we should at least build less, maximizing the use of buildings. Build wisely means reusing waste materials and using low-carbon products. With an additional effort it is possible to reach an efficient design, optimizing structural solutions. The final step is a construction design that minimizes waste, based on the strategies prefabrication, reuse and recycling.

Figure 1.

Approaches to decarbonization-oriented design.

Figure 1.

Approaches to decarbonization-oriented design.

2. State-of-the-Art

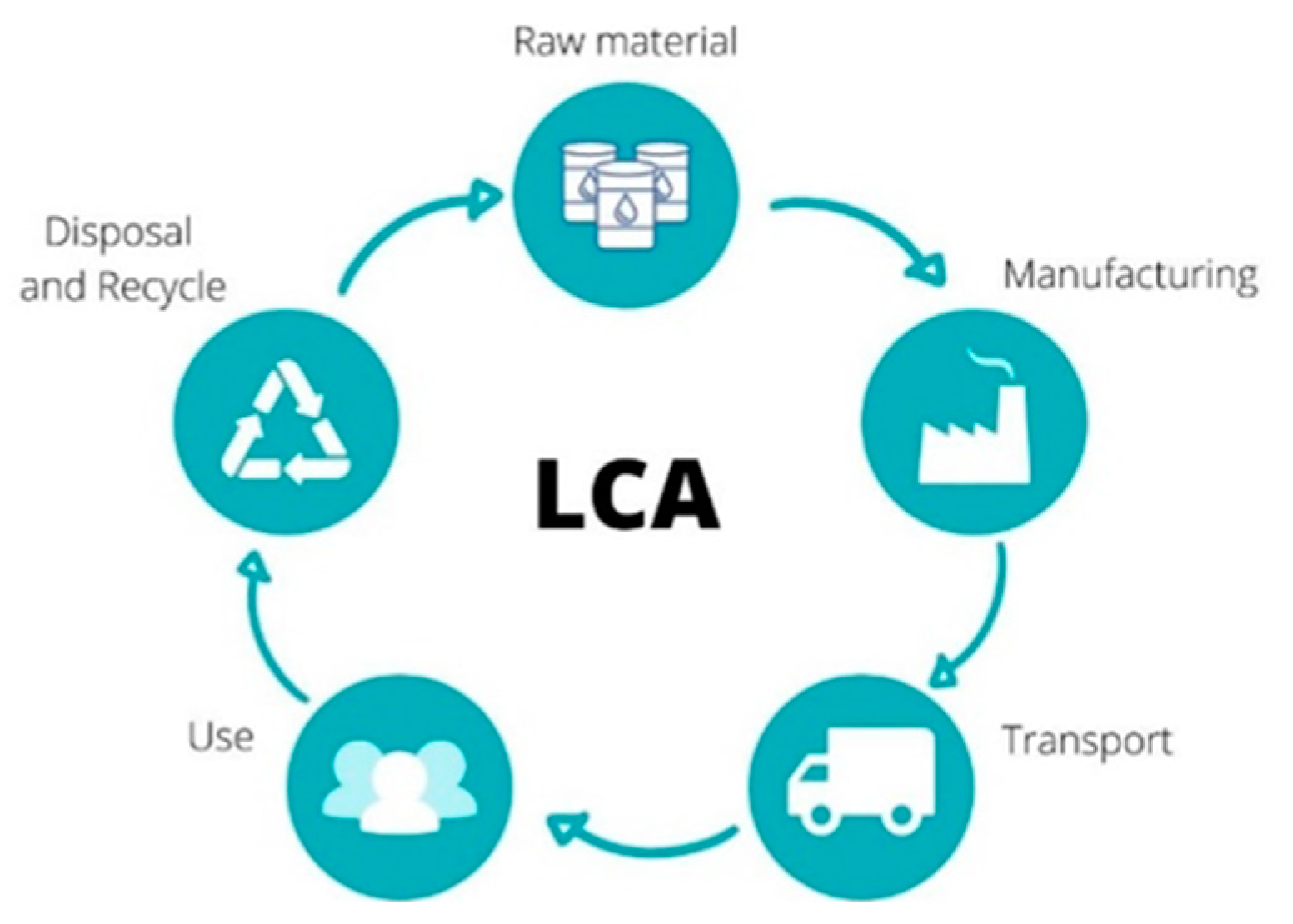

Life Cycle Assessment (LCA) is an objective procedure that allows to assess the environmental impact associated with a product or activity, and to orient the design choices to improve the environmental quality. Studying the ecological footprint through an LCA analysis means identifying and quantifying different factors (materials used, energy requirements, solid waste, and emissions) considering all the phases of the life cycle of a product, from the acquisition of raw materials until its recycling process (

Figure 3).

In this research two objective and quantitative environmental indicators were used to analyze the impact of each phase of a building’s life cycle: Operational Energy (OE) and Embodied Energy (EE). The embodied energy is the one that materials need throughout their life cycle, so products with higher EE have more impact on the environment. Operational energy, on the other hand, is the amount of energy required to operate the building during its use. The embodied and operational energy rates correspond to consequent CO2e emission factors: Embodied Carbon (EC) and Operational Carbon (OC).

In the recent publication by Bontempi (2021) [

6] he emphasized the importance of reliable and open-access databases that contain information on embodied carbon (EC) and embodied energy (EE) for various raw materials. These databases have significantly contributed to the development of sustainability analysis tools based on energy use and emissions. By utilizing general parameters such as EC and EE, these tools can be applied to all sectors and can be considered as pre-screening methods, which can be used as a preliminary assessment before conducting a complete life cycle assessment (LCA).

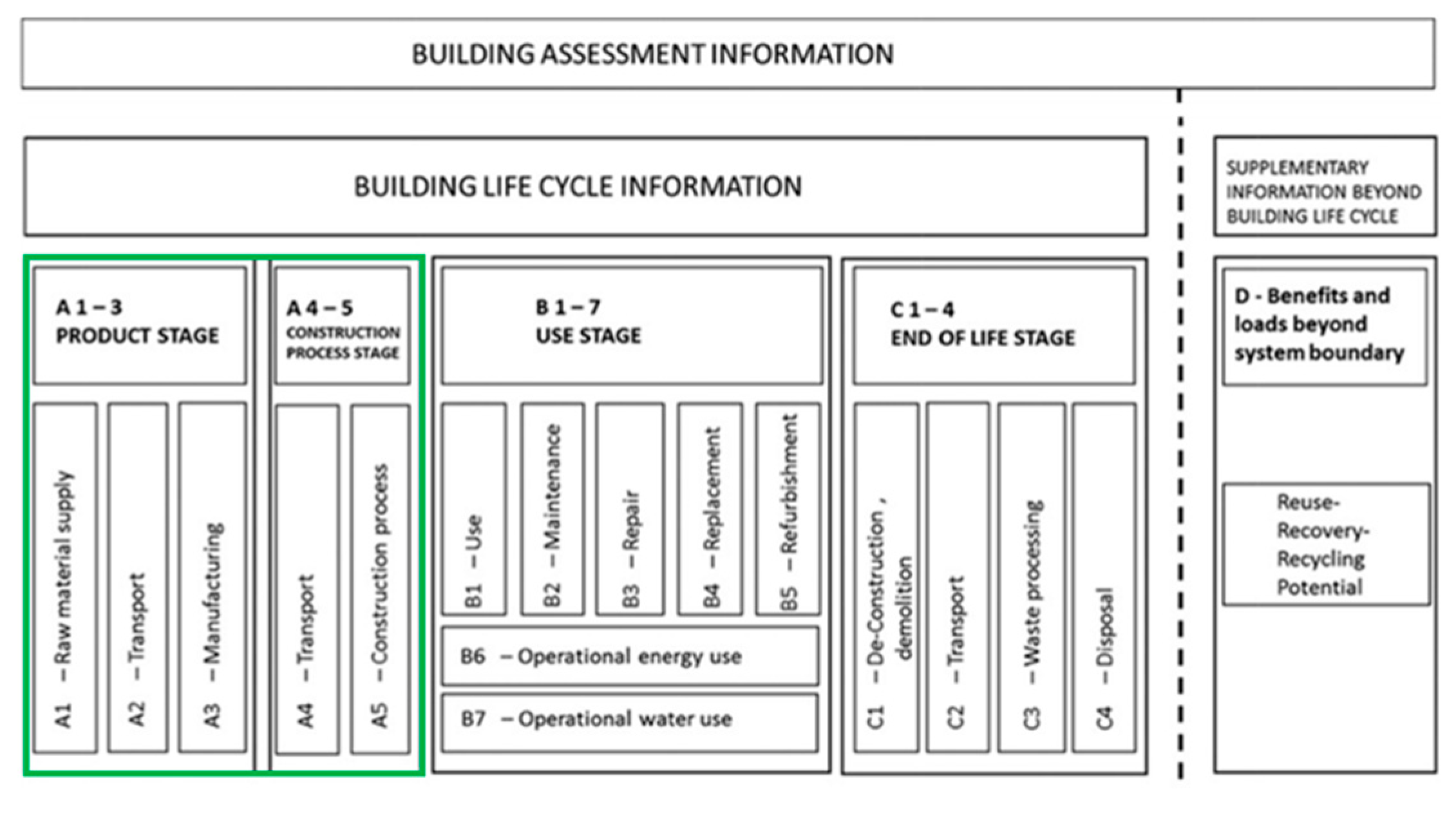

The LCA approach is recommended by various European policies, including the Integrated Product Policy [

7]. The main advantage of "life cycle thinking" is to prevent environmental loads from moving from one phase to another, or from one geographical area to another or from an environmental matrix (such as air quality) to another (for example water quality) [

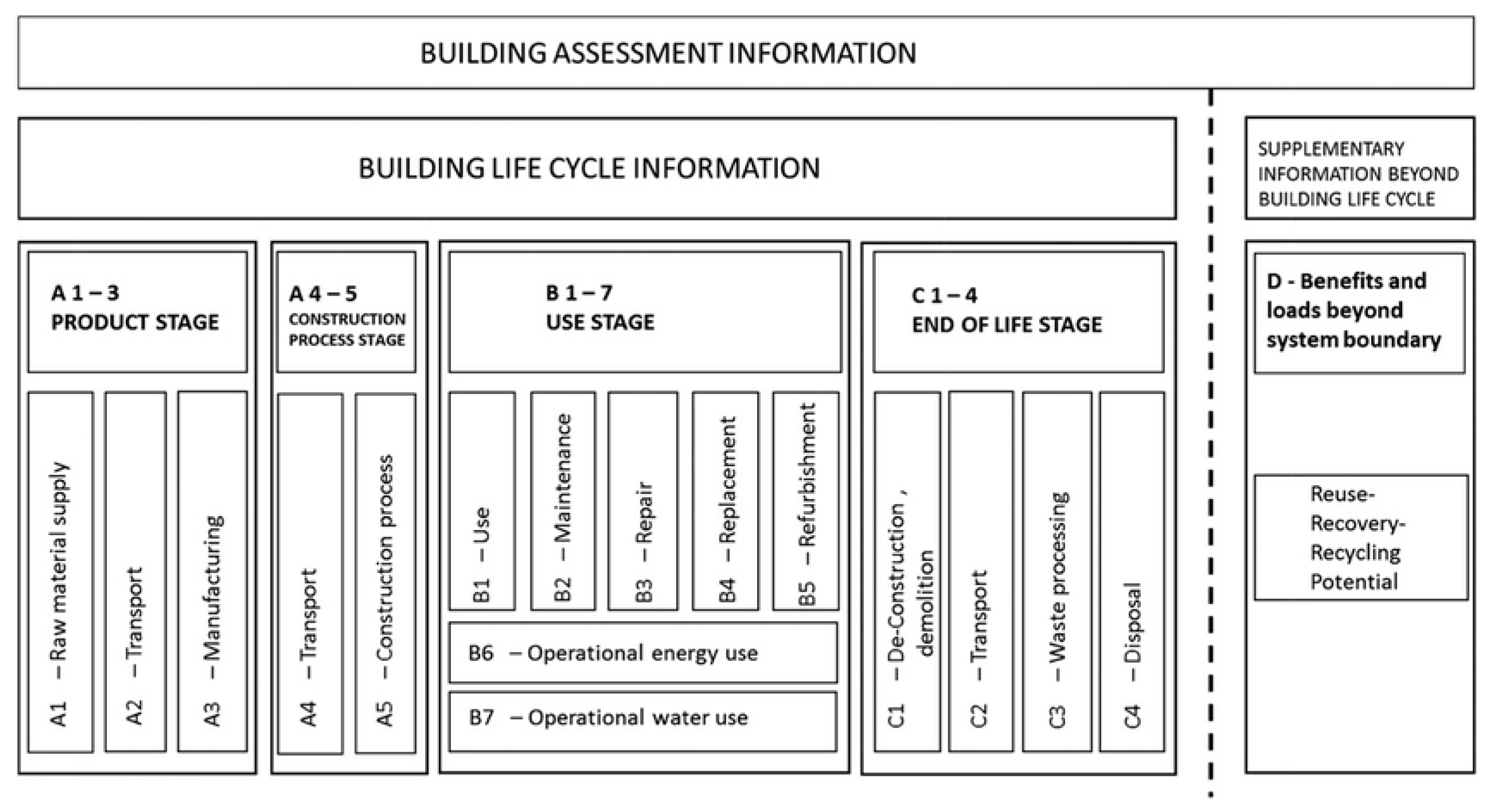

8]. European Standard BS EN 15978:2011 [

9], "Sustainability of construction works - Assessment of the environmental performance of buildings - Calculation method", specifies the methodology, based on life cycle analysis, to assess the environmental performance of a building. The life cycle of the building is outlined in five blocks: Production, Construction, Use, End of Life, Benefits and Loads (

Table 1).

The production phase includes the supply of raw materials (A1), the transport of these to the production sites (A2) and the processing (A3);

The Construction phase includes the transport of materials from the production site to the construction site (A4) and the construction of the building (A5);

The Use phase includes building use (B1), maintenance (B2), repair (B3), replacement of damaged parts (B4), renovation (B5), energy use (B6) and water use (B7);

The End-of-life phase includes deconstruction/demolition (C1), transportation of materials from construction site to landfill or treatment sites (C2), waste treatment (C3) and disposal (C4)

To allow the transformation of the life cycle from linear to circular it is necessary to focus on the phase Benefits and loads deriving from the activities of reuse, recovery, and potential recycling (D).

The study "Life-Cycle Assessment and the Environmental Impact of Buildings: A Review" by F.G. Banfill et al. [

10] aimed to provide an overview of the current state of life-cycle assessment (LCA) studies in the building sector, identify the challenges faced by researchers and practitioners, and suggest areas for further research. The authors highlighted the difficulties of conducting LCA for buildings, such as the complexity of the production process and the long lifespan of buildings, as well as the lack of standardization and data inventory within the building sector. They stressed the need for an internationally accepted framework and conversion tools to enable comparison between LCA studies. Despite the limitations and criticisms presented, the study concludes that LCA is a powerful tool for evaluating the environmental impact of buildings and has the potential to make a significant contribution to sustainable development.

Even for wood, which has gained popularity in construction due to its sustainability and low environmental impact compared to traditional building materials, it is important to conduct a thorough Life Cycle Assessment (LCA) that considers the entire life cycle of the material, from production to disposal, to ensure that it is truly a sustainable option.

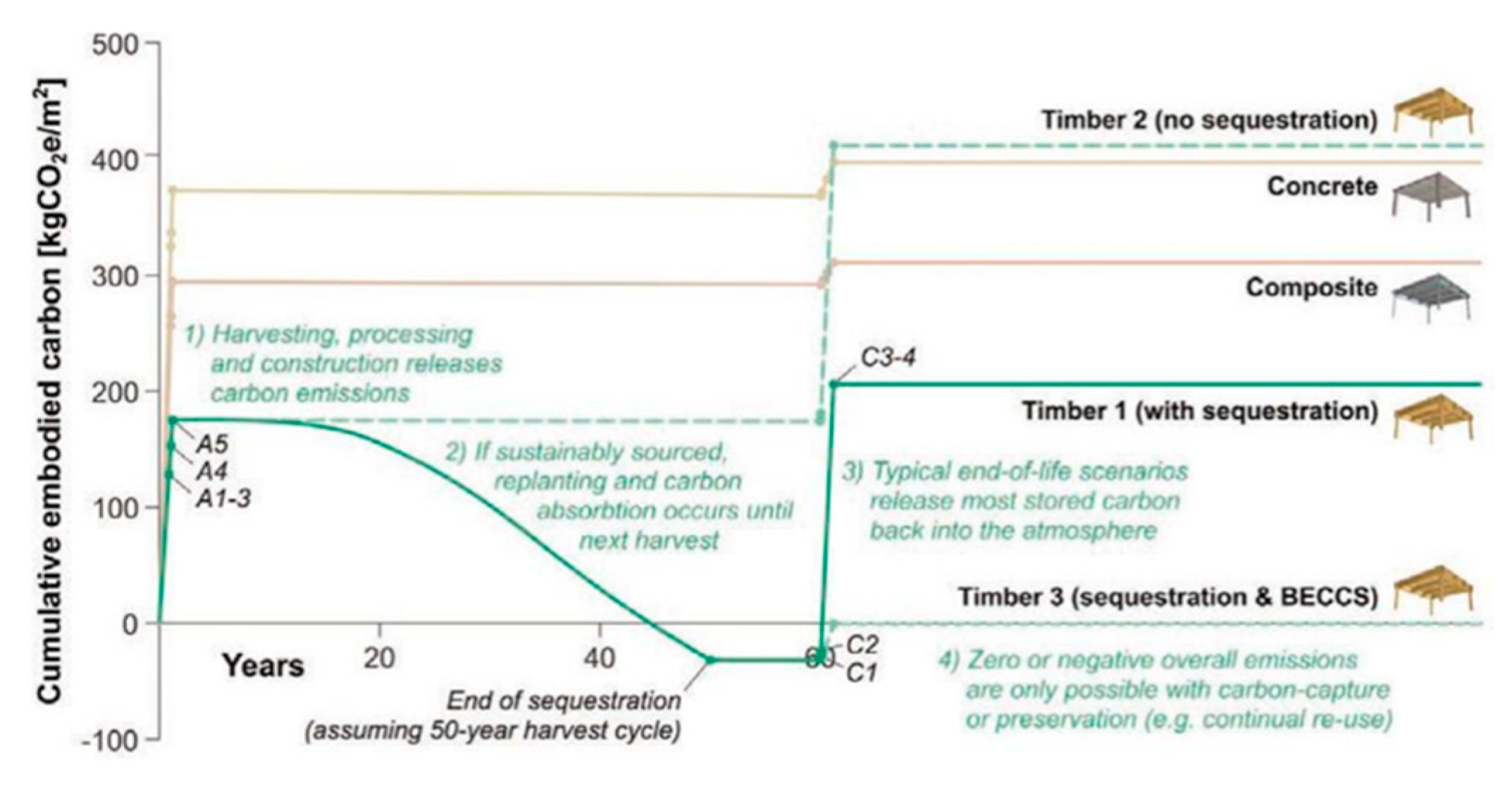

The publication "Timber and carbon sequestration" by Will Hawkins [

11] studies the profile of a multi-storey structure in relation to the amount of Embodied Carbon, assuming that it is made each time with a different material. The analysis is made in relation to the life-cycle phases marked by the European standard BS EN 15978:2011. The aim of the research is to highlight the environmental benefits of using wood in building construction. The report shows that the concrete structure solution is the most impacting on the environment, followed by steel and wood. Production emissions for timber products, from harvesting, drying and sawdust are significant and cannot be avoided, in fact it is better not to build at all than to build a timber building. In phase B (BS EN 15978:2011) it's possible to appreciate the advantage of the use of wood due to the carbon compensatory credit. Carbon storage is possible because the tree, during its growth, absorbs carbon dioxide, transforms it into carbon and releases oxygen into the environment. Carbon remains trapped in the tree until it rots or is incinerated, and then returns to the atmosphere. Timber building therefore means creating a real carbon warehouse, which would otherwise have ended up in the atmosphere once the life of the tree had ended. For the concrete and steel structures, analyzing the phases of use (B) and end of life (C) we notice very small changes in the amount of Embodied Carbon, while for the wood solution there is an important change. Despite the large emissions, total carbon is still lower for the timber building than for the concrete and steel ones.

In fact, wood, despite being among the first materials to be used in construction, is among the best solutions for the realization of biocompatible structures. This is why in recent years the research has been interested in these innovative systems, and in particular in the advantages of building dry rather than wet, in terms of Embodied Energy and Embodied Carbon. To confirm this thesis is also, among many, the article titled "Evaluation of envi-ronmental sustainability threshold of “humid” and “dry” building systems, for reduc-tion of embodied carbon (CO

2)" by Di Ruocco and Melella [

12], of particular interest for the purposes of this research. In fact, this article focuses on the evaluation of the environmental sus-tainability threshold of "humid" and "dry" building systems. The authors use a life cycle assessment (LCA) to quantify the embodied carbon dioxide (CO

2e) of different building systems and investigate the relationship between their environmental sustainability and moisture content. The comparison of building systems has revealed that the reinforced concrete construction system has the highest embodied carbon, while timber construction system is the most environmentally friendly option. Furthermore, the study has shown that appropriate design choices can lead to a significant reduction of 51% in Embodied Energy and 69% in Embodied Carbon. These findings are justified by the fact that dry construction systems offer higher disassemblability, thus promoting the reuse of building components with the same function. Conversely, wet construction systems allow the reintroduction of components into the production cycle with different functions, which often leads to lower performance and increased energy consumption.

The study "Mitigation Strategies for Reduction of Embodied Energy and Carbon, in the Construction Systems of Contemporary Quality Architecture" by Di Ruocco et al. [

13] searches the construction system with the lowest values of EE and EC, comparing three architectures, one made of reinforced concrete, one in steel and one in wood. The results show that the timber construction system is the one with the lowest value of EE and EC, therefore the best from the environmental point of view.

Although the advantages of timber construction have been well-investigated in the literature, the following considerations emerged from the state-of-the-art study:

The C2C circular approach (from Cradle-To-Cradle) was only partially investigated.

No study has quantified, with the C2C approach, the potential of wood systems for carbon storage.

A standardized calculation methodology for measuring the amount of embodied carbon at the production and construction stages has not been defined.

With reference to the criticalities found in the state of the art, the purpose of this study is to develop a calculation methodology for the construction systems that allows to evaluate the embodied energy and carbon during the production and construction phases of timber buildings. In this way the research also aims to highlight how Wood is the most valid solution to pursue sustainable development. The new calculation methodology developed was applied to a frame construction system and an X-lam panel system.

3. Tools and Methods

The proposed methodology is articulated in the following phases:

Phase I: Definition of the scope of investigation;

Phase II: Technological characterization of the building;

Phase III: Estimation of CO2e emissions;

3.1. Phase I: Definition of the Scope of Investigation

In the first phase, the study boundaries were defined in accordance with the European standard BS EN 15978:2011[

8]. Specifically, the scope of this research is the analysis of phase A, consisting of five modules. Modules A1 to A3 of the building life cycle are about the environmental impact of the production phase, and include raw material procurement, transportation to factories and production. Modules A4 and A5, on the other hand, are about the impact of the construction phase, which includes transport to construction site and construction activities. The boundary of the system that has been considered is called ‘from Cradle-To-Handover’.

3.2. Phase II: Technological Characterization of the Building

The technological characterization of the building was based on the UNI 8290-1981 [

14] standard, with the detailed breakdown into classes of technological units (1st level), technological units (2nd level), and technical elements (3rd level). The classes of technological units of supply and service facilities, safety installations, internal and external equipment have not been counted for the purposes of research, as they are considered invariant. The next step was the analysis of two timber construction technologies: framed one and the one with X-LAM panels. The study of the construction systems, the materials of the technical elements and the connections is fundamental to define the processes necessary for the construction. This was done using technical data sheets and catalogues provided by companies operating in the sector, as well as the UNI 11277:2008 [

15] standard, which combines each construction system with a laying technology.

Table 2.

Building assessment information – from Cradle-To-Handover phases (Source: BS EN 15978).

Table 2.

Building assessment information – from Cradle-To-Handover phases (Source: BS EN 15978).

3.3. Phase III: Estimation of CO2e Emissions

In the third step, the CO2e emissions generated during the phases of production and construction of a building, obtained as the sum of 3 rates, were calculated:

Rate of CO2e, A1-A3 emissions due to the production activity.

Rate of CO2e, A4 emissions due to the transport from production site to construction site.

Rate of CO2e, A5 emissions due to the construction activities.

The methodology combines modules A1 to A3 because the emission estimation refers to coefficients (derived from the ICE database) that consider together the extraction of raw materials, transport to factories and production.

3.3.1. Rate of CO2e, A1-A3 Emissions due to the Production Activity

The objective of the production phase analysis (A1-A3) is to highlight the variation in CO2e emissions according to the choices that the designer can make. These choices may concern the use of virgin materials or secondary raw materials, technological solutions, or even the evaluation of the chemical characteristics of the elements.

The total embodied carbon relative to the production phase has been calculated, through an approach LCI (Life Cycle Inventory), multiplying the weight of each material for the relative "Coefficient of Embodied Carbon Primary" contained in the "Inventory of carbon and energy" (ICE database V.3.0) [

16] drawn up by the University of Bath. For wood elements this inventory gives two EC values, one negative and one positive; Between the two values, the negative one was chosen to take into account the carbon storage property of the material.

The total emissions for modules A1-A3 are obtained by adding the emissions for each material:

3.3.2. Rate of CO2e, A4 emissions due to the transport from production site to construction site.

The rate of CO

2e related to module A4 (construction phase) is the sum of the emissions generated by the production of the percentage of loss due to handling and those generated by the means of transport.

It is therefore necessary to consider, in addition to the weight of the material that arrives intact at the construction site, a percentage of loss due to transport problems (damage due to movement). The total quantity to be transported is then calculated as:

The emissions generated by the additional quantity in phase A1-A3 are calculated using the ICE database again:

Moreover must be evaluated the stops to be reached by means of transport of the elements and the number of travels from the production site to the construction site.This is strongly influenced by the chosen articulated truck model, specifically the size of the vehicle, the maximum transportable volume and the maximum transportable weight. It is possible to estimate the CO

2e emission rate due to the means of transport as follows:

Where:

D(i): Distance to be covered to transport the single material

Fequip(i): Emission factor for the specific means of transport

All the vehicles chosen have a diesel engine and the emission factor has been calculated on the basis of the maximum transportable flow from them. These values were taken from a research by the Politecnico di Milano on average GHG emissions from means of transport [

17].

3.3.3. Rate of CO2e, A5 Emissions Due to the Construction Activities

The emissions related to the construction phase are divided into two rates:

The emissions from waste management for each material are calculated as follows:

Where:

CO2e A5w(i): Embodied carbon factor from construction waste [kgCO2e];

WF

(i): Single material waste factor, given by the equation:

WR(i): scrap rate. It can be estimated using the WRAP Net Waste Tool data [

18] or obtained from guides for construction companies;

CO2e A1-3(i): Emissions from the material in stages A1 to A3, including carbon sequestration for all wood elements;

CO2e A4(i): Emissions from the transport of material from the production site to the construction site;

CO2e C2(i): Emissions related to the transport of material from the construction site to the landfill site;

CO2e C3/C4(i): In the case of landfill disposal, stage C4 is considered. When waste is reusable, reference is made to the C3 stage, that is about the treatment for recovery or recycling;

Recycling will be considered as the only possible option in this research, since waste will certainly be of such a size that it cannot be reused, and landfill and incineration will not be considered for environmental protection.

The first step is the classification of waste materials based on the European Waste Catalogue [

19] which assigns to each category of materials a European Waste Code (EWC). This allows the identification of the nearest authorized transforming center. Once transport distances, number of journeys and means of transport have been established, emissions are calculated as well as for transport phase A4:

Where:

D(i): Distance from construction site to component recycling center

Fequip(i): Emission factor for the specific means of transport

The carbon incidence due to processing for recycling of materials is calculated considering the type of treatment, the machinery used, the hourly power of the machinery, the number of kilograms treated in one hour, the total treatment time, energy consumed and carbon emission coefficient (depending on the type of machinery).

Where:

E(i): Energy consumed for the processing

Fmachine(i): Emission factor for the specific machinery

t(i): Time required for processing

P(i): Power of the machinery

Information relating to the specific type of machinery is derived from the datasheets and the carbon emission coefficient varies according to the type of engine as specified in

Table 3. These are data derived from Appendix "A" of the UKETS Manual (01)05 "Guidelines for the measurement and reporting of emission in the UK Emission Trading Scheme" [

20], coherent with the National Plan for Atmospheric Emissions (National Air Emission Inventory) [

21].

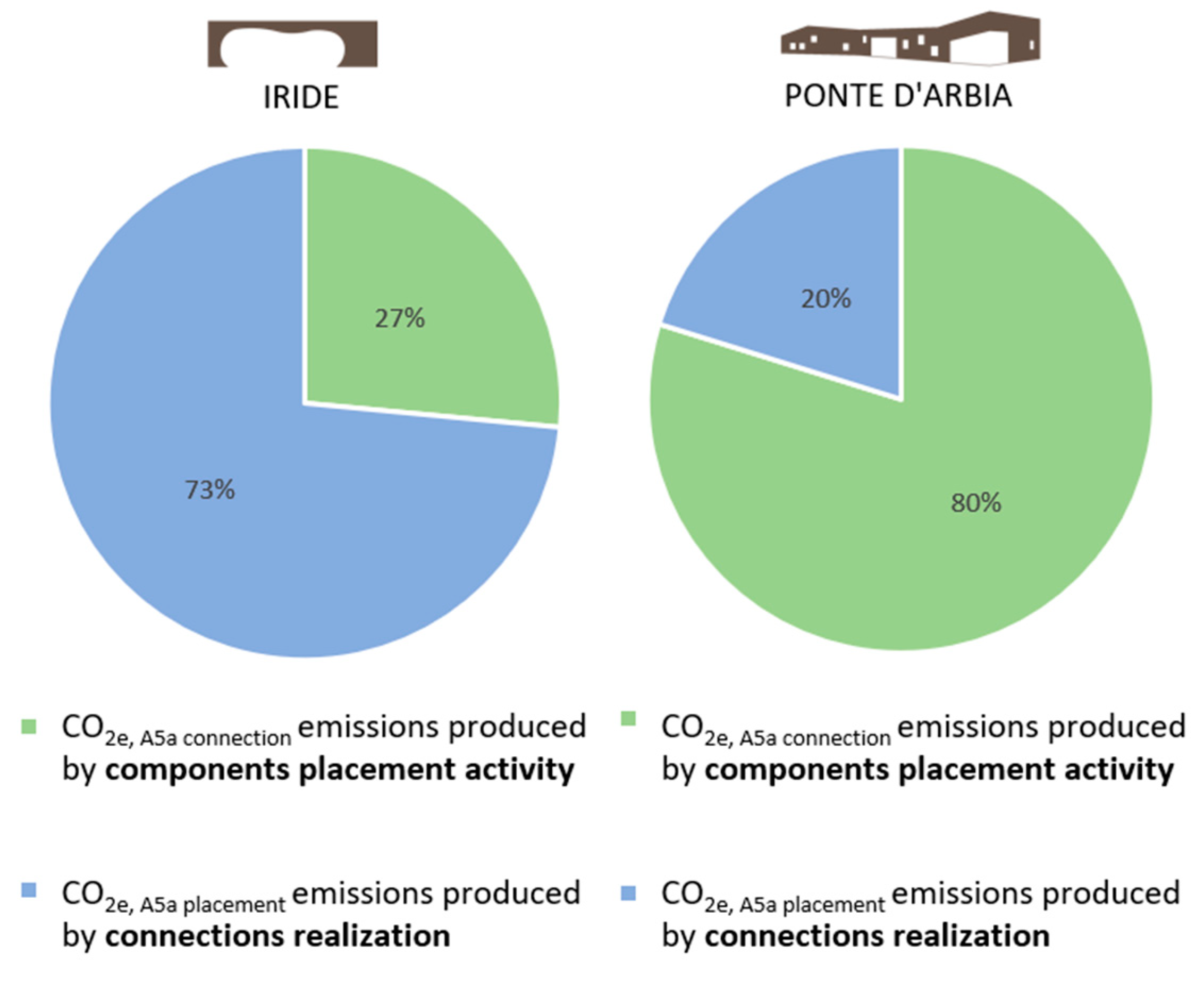

The A5a rate is given by the sum of the emissions generated by two types of operations: components placement (CO

2e, A5a placement) and connections realization (

CO2e, A5a connection). Depending on the construction system and assembly technology, the mode of transport and the instrument and/or the machinery used for installation have been defined. The total emissions related to construction activities are therefore calculated as follows:

2.1 RATE OF CO

2e EMISSIONS FROM COMPONENT PLACEMENT (

CO2e, A5a placement)

Where:

t = Time of use of the machine necessary to place each element, also considering the return journey.

P(i)= Machine power

Fmachinery (i) = Emission factor of the specific handling machinery

To define the transport methods of the elements to be connected it is necessary to consider that:

- -

The maximum weight that can be lifted by an operator under optimal conditions is 25 kg (UNI ISO 11228-1) [

22];

- -

The maximum load capacity of a Liebeherr crane 32TT [

23] is 2500 kg;

- -

The maximum capacity of a Liebeherr telescopic crane, LTM 1040-2.1 [

24] is 40000 kg.

It is therefore established which of the elements of the buildings required transport by machinery and which, instead, could have been transported manually. The seconds required for the positioning operations were evaluated based on the technical data sheets of the machines and the videos available on the web and divided into three steps: T

0 (seconds required to connect the element to the crane hook), T

1 (seconds required to reach the position), T

1' (seconds required to return to the starting point) (

Table 4).

The connecting crane is a current-powered machine; the emission factor for the production and consumption of electricity has been provided by Ispra [

25] and considers electricity produced from renewable and non-renewable sources.

2.1 RATE OF CO

2e EMISSIONS FROM THE CONNECTIONS (

CO2e, A5a connection)

Where:

t = Time of use of the connection tool

P(i)= Tool power

Ftool (i) = Emission factor of the specific tool

The installation technology of the elements and the precise models of the tools used have been identified (

Table 5).

For each of the instruments the operating time has been determined through videos provided by the manufacturers, videos corresponding to real cases and data sheets (

Table 6).

A processing capacity of 6 m3/h is declared on the data sheets of the concrete screed machinery [[31], on the basis of which the operating time of the machine is then calculated.

4. Application to the Case Studies

The selection of case studies considered the following requirements:

Buildings made with predominantly dry technology system;

No.1 building made with a wood framed construction system;

No.1 building made with a XLAM panel construction system;

The selected buildings must present the characteristics of contemporary architectural works, in terms of the quantity of publications, citations, and web presence.

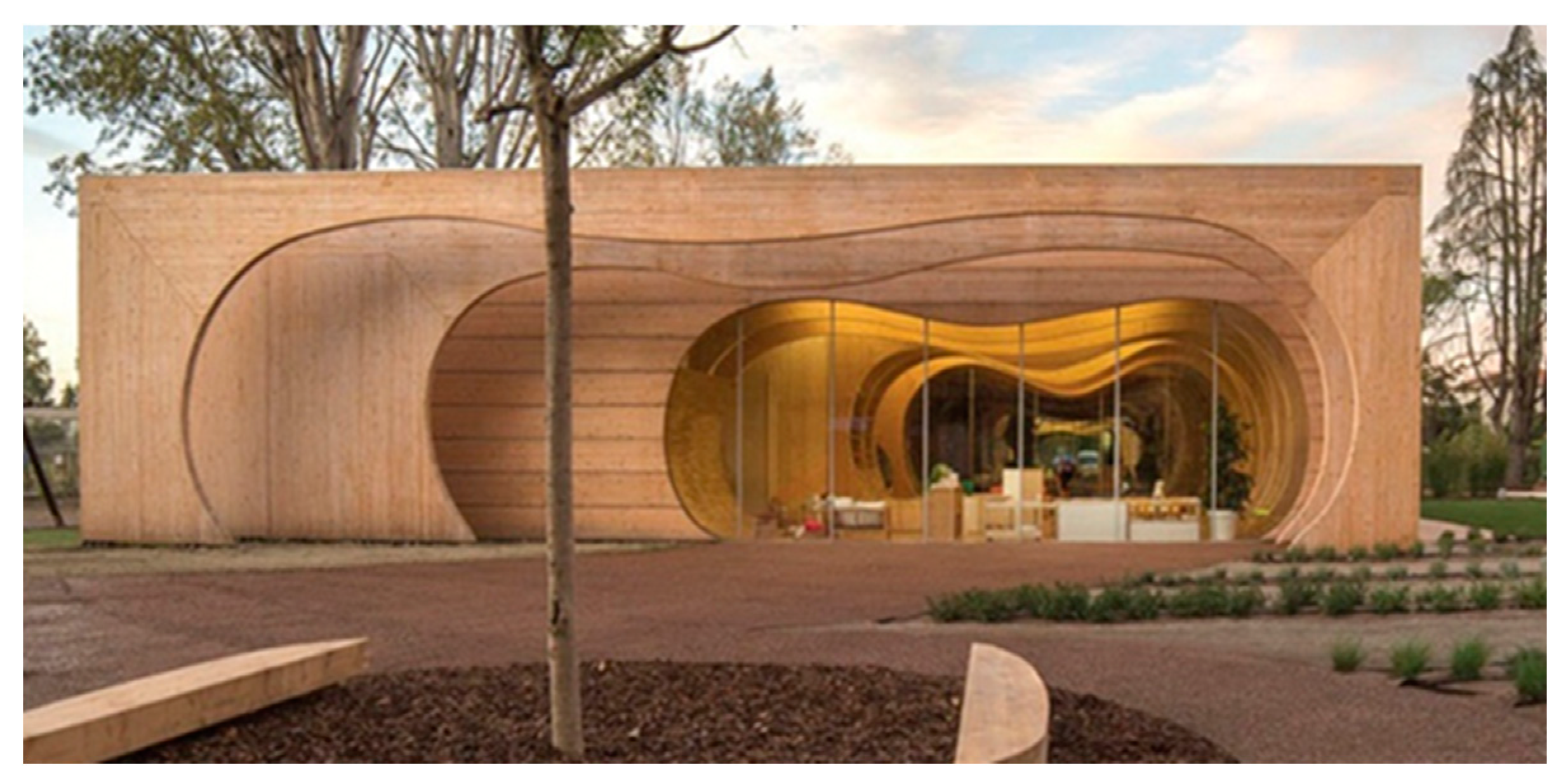

The first selected building is ‘IRIDE’ kindergarten (

Figure 4), in Guastalla, Italy, designed by Mario Cucinella and realized in 2015 with a timber framed structure.

The second building studied for the purpose of this research is the kindergarten of Ponte d’Arbia, Italy, designed in 2016 by Studio Settanta7, in timber X-LAM panels (

Figure 5).

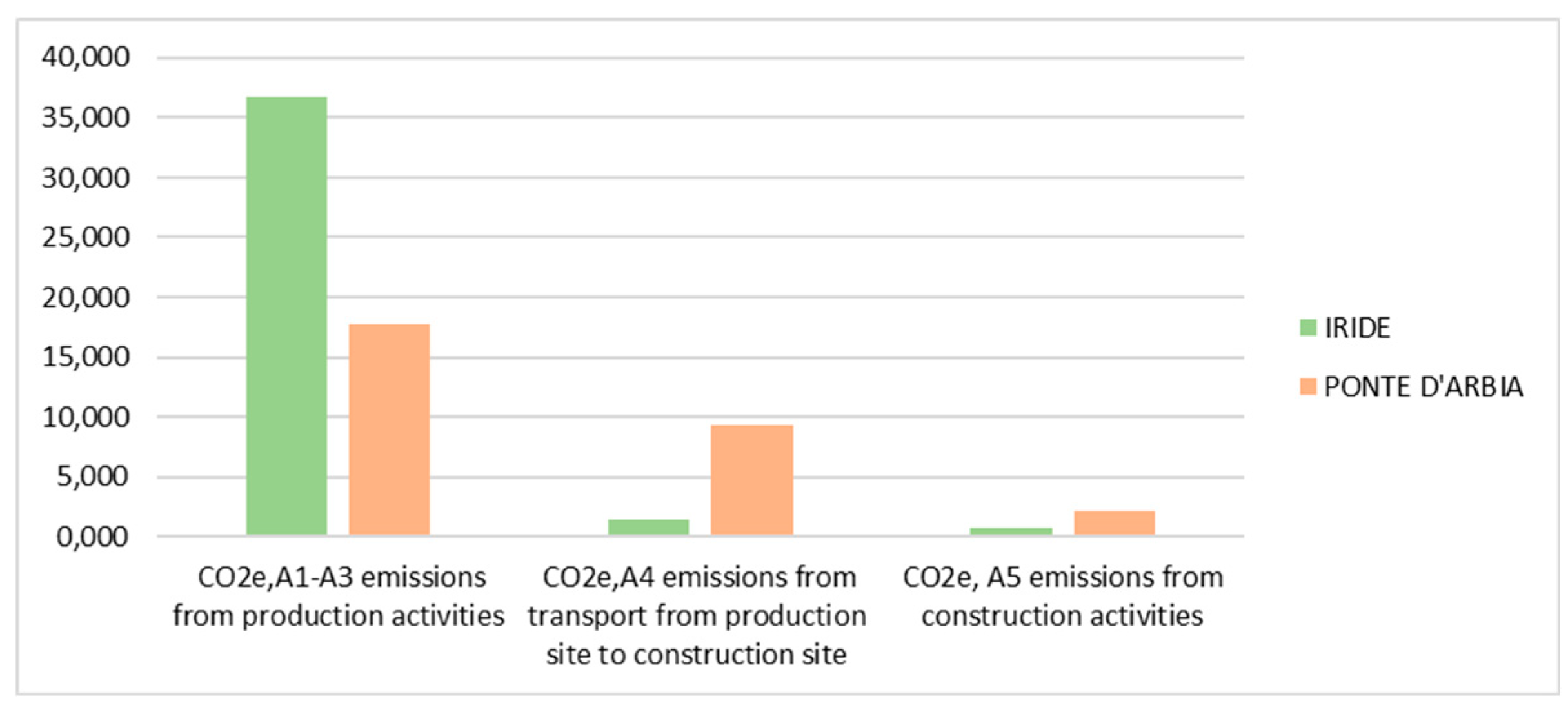

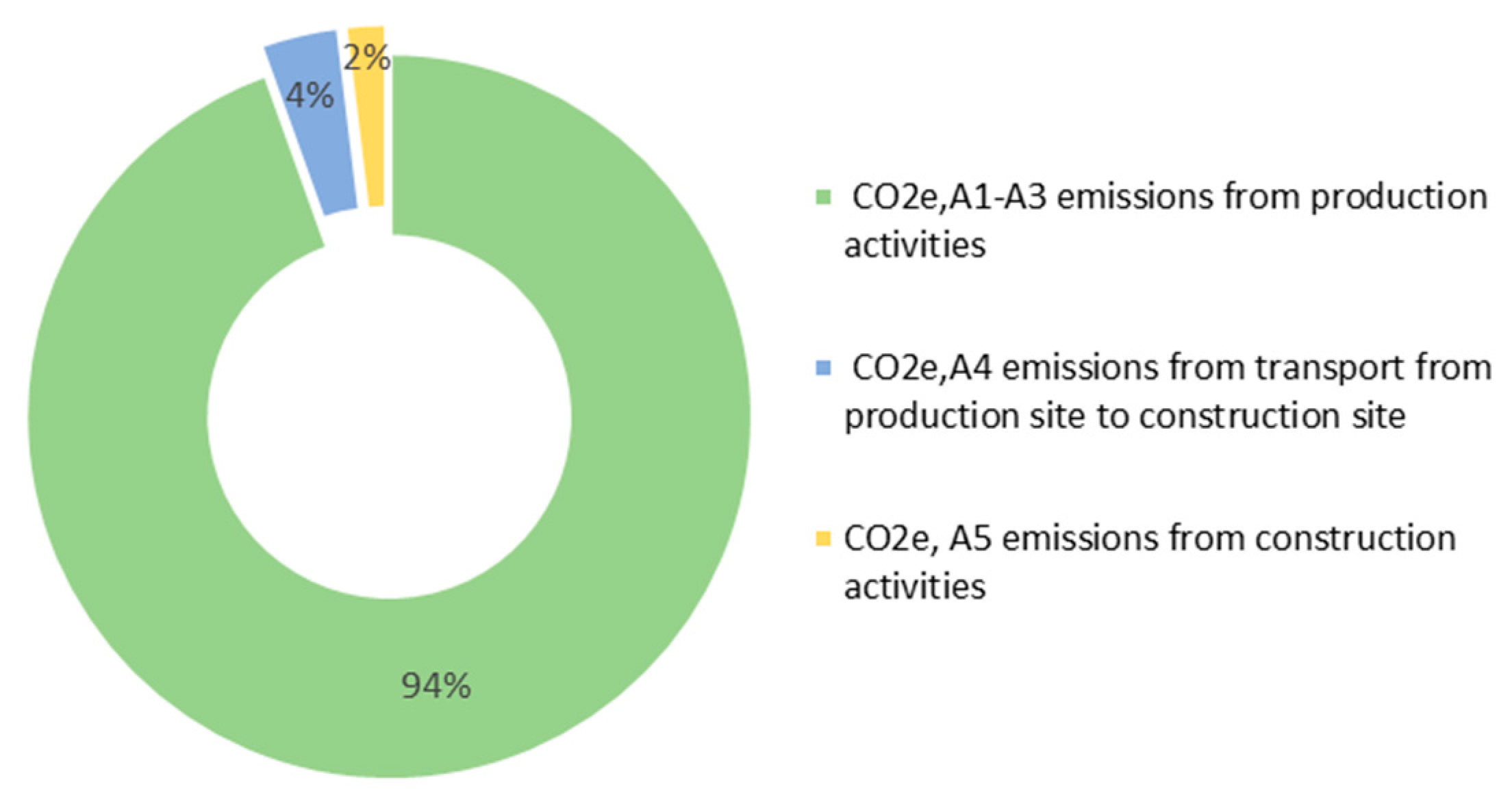

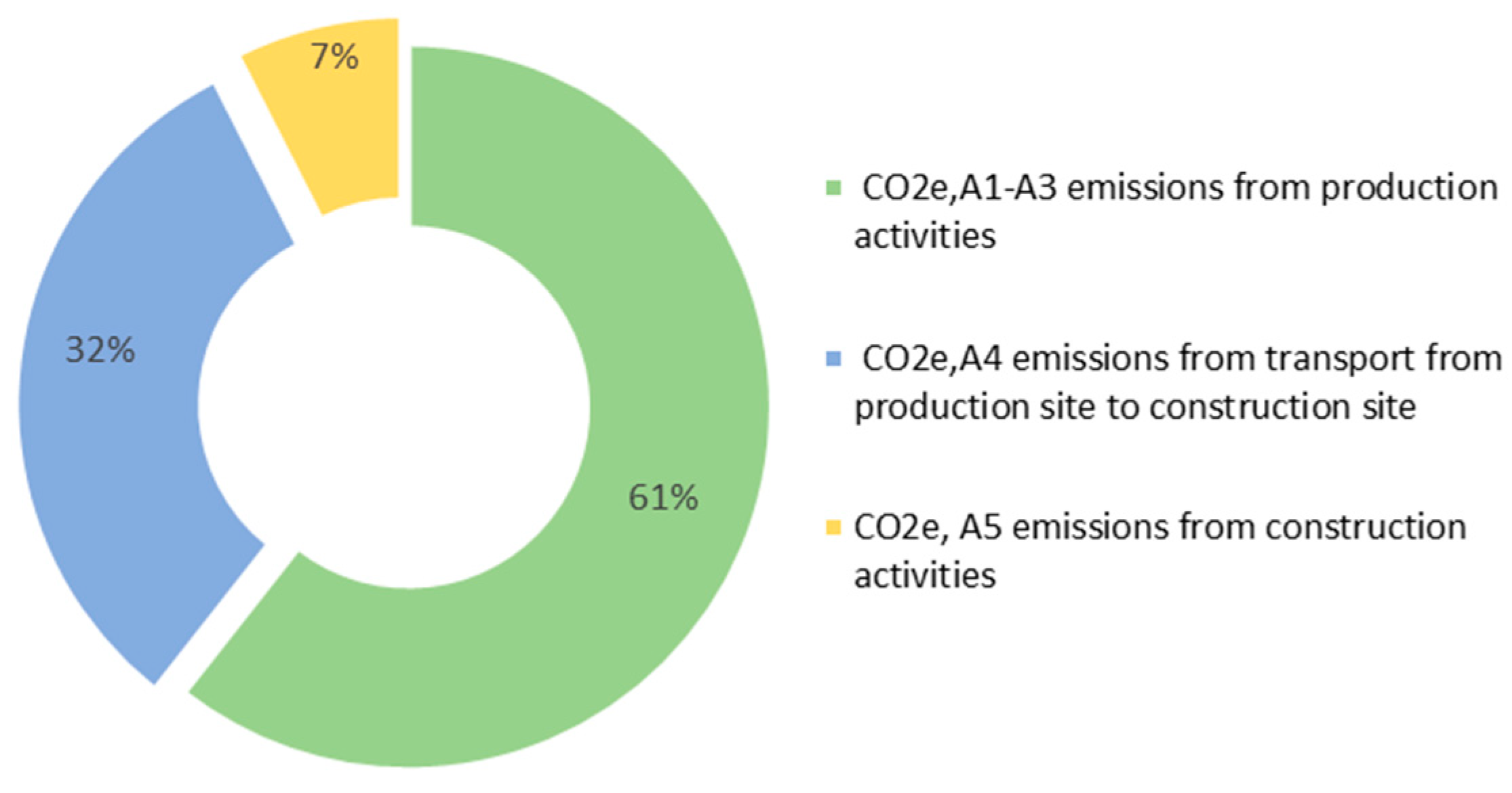

4.1. Estimation of CO2e Emissions

Once the technological units and the installation methods of the building components have been determined, the CO

2e emissions generated during the production and construction phases of the two selected cases have been estimated. The results obtained for each rate in terms of kg of CO

2e, and the incidence of each of the three rates on the total CO

2e emissions generated by the production and construction process are reported below (

Table 7 and

Table 8,

Figure 6 and

Figure 7).

In both cases, the greatest incidence in terms of emissions is caused by the production of the building elements, in green in the ring graphs. The lower rate, however, is, for both buildings, that of emissions related to construction activity, in yellow (

Figure 6 and

Figure 7).

5. Results

To compare the results obtained, the emissions for 1 m3 of built volume were evaluated by dividing the values obtained (in kg CO2e) by the volume of the two schools.

Table 9.

Comparison table of emissions from each school.

Table 9.

Comparison table of emissions from each school.

| Emissions rate |

IRIDE |

PONTE D’ARBIA |

| CO2e,A1-A3 emissions from production activities |

36,676 kg CO2e/m3

|

17,741 kg CO2e/m3

|

| CO2e,A4 emissions from transport from production site to construction site |

1,386 kg CO2e/m3

|

9,337 kg CO2e/m3

|

| CO2e, A5 emissions from construction activities |

0,742 kg CO2e/m3

|

2,194 kg CO2e/m3

|

| CO2e,A1-A5 |

38,80 kg CO2e/m3 |

29,272 kg CO2e/m3 |

Figure 8.

Comparison graph of emissions from each school.

Figure 8.

Comparison graph of emissions from each school.

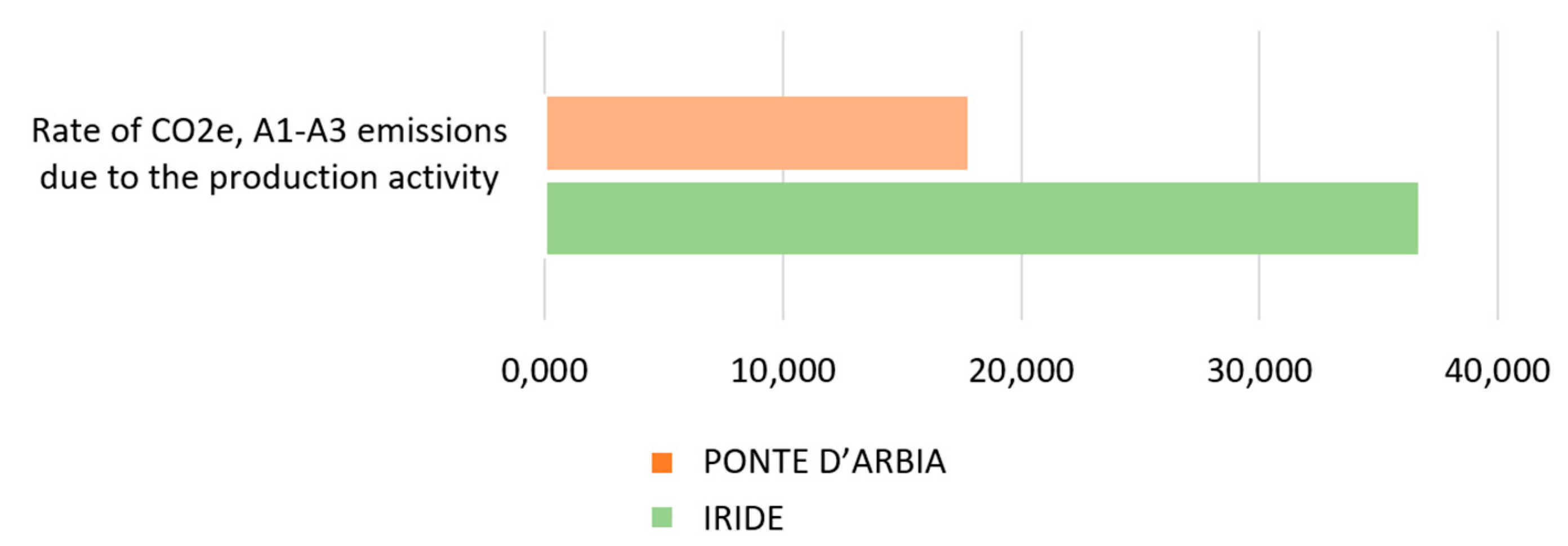

5.1. Rate of CO2e, A1-A3 Emissions Due to the Production Activity

As regards the rate of emissions at the production stage, there is a significant discrepancy between the results for the two case studies, with 36.68 kg CO

2e/m

3 for the Guastalla building and 17.74 kg CO

2e/m

3 for the Ponte d'Arbia building (

Figure 9).

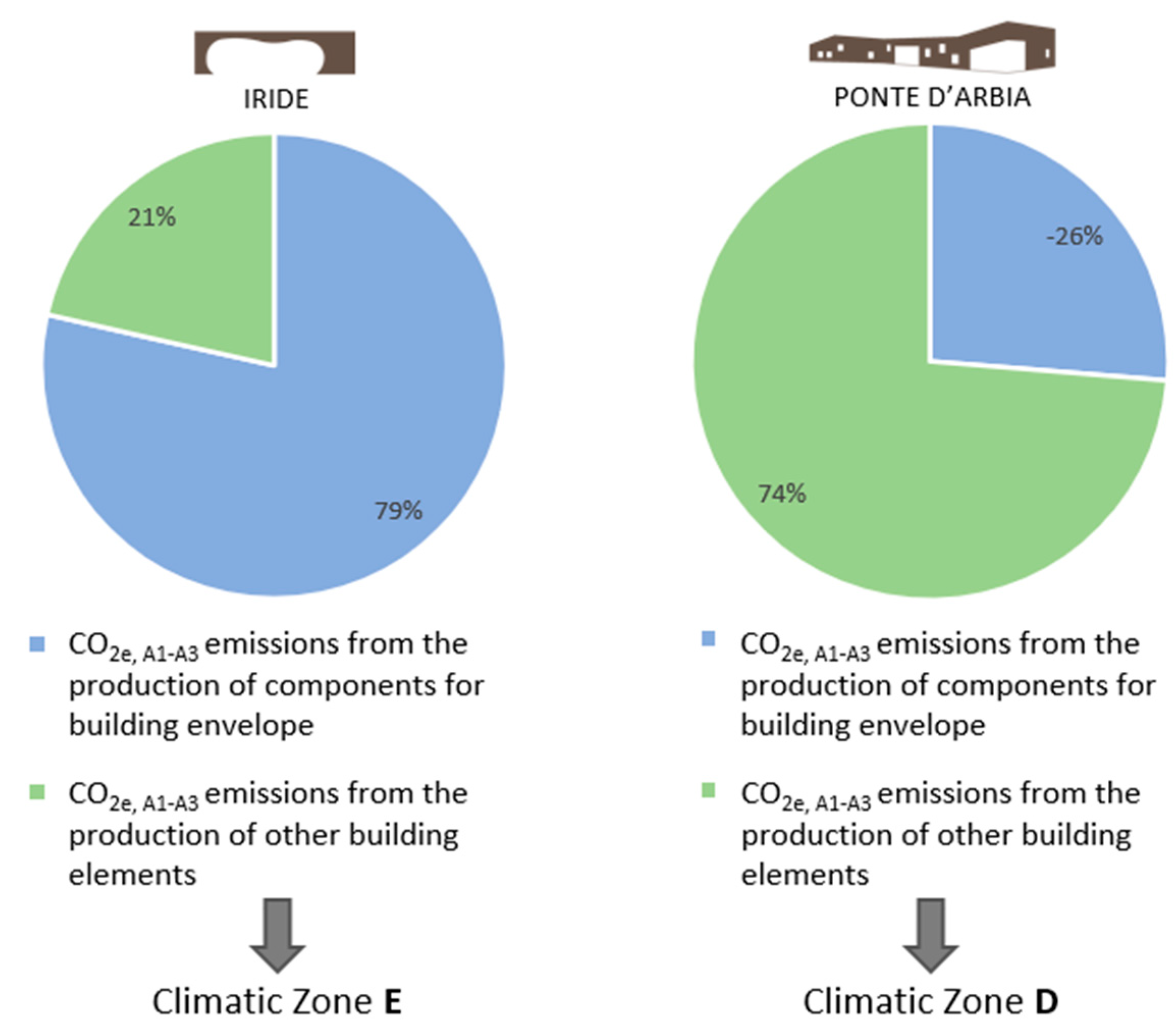

To investigate the reasons for the difference in CO2e, A1-A3 emissions between the two buildings, those due to the production of elements for the envelope and those generated by the production of other building components were separately compared.

By extrapolating the data on production emissions related to the building envelope, a significant difference can be observed between the two schools. For the Guastalla kindergarten (Climatic zone E), they amount to 28.80 Kg CO

2e/m

3 (79%), while for the Ponte d'Arbia kindergarten (Climatic zone D) they even have a negative value of -9.83 Kg CO

2e/m

3 (-26%) (

Figure 10). To produce the other building elements, on the other hand, the emissions generated are respectively 7.88 Kg CO

2e/m

3 and 27.57 Kg CO

2e/m

3.

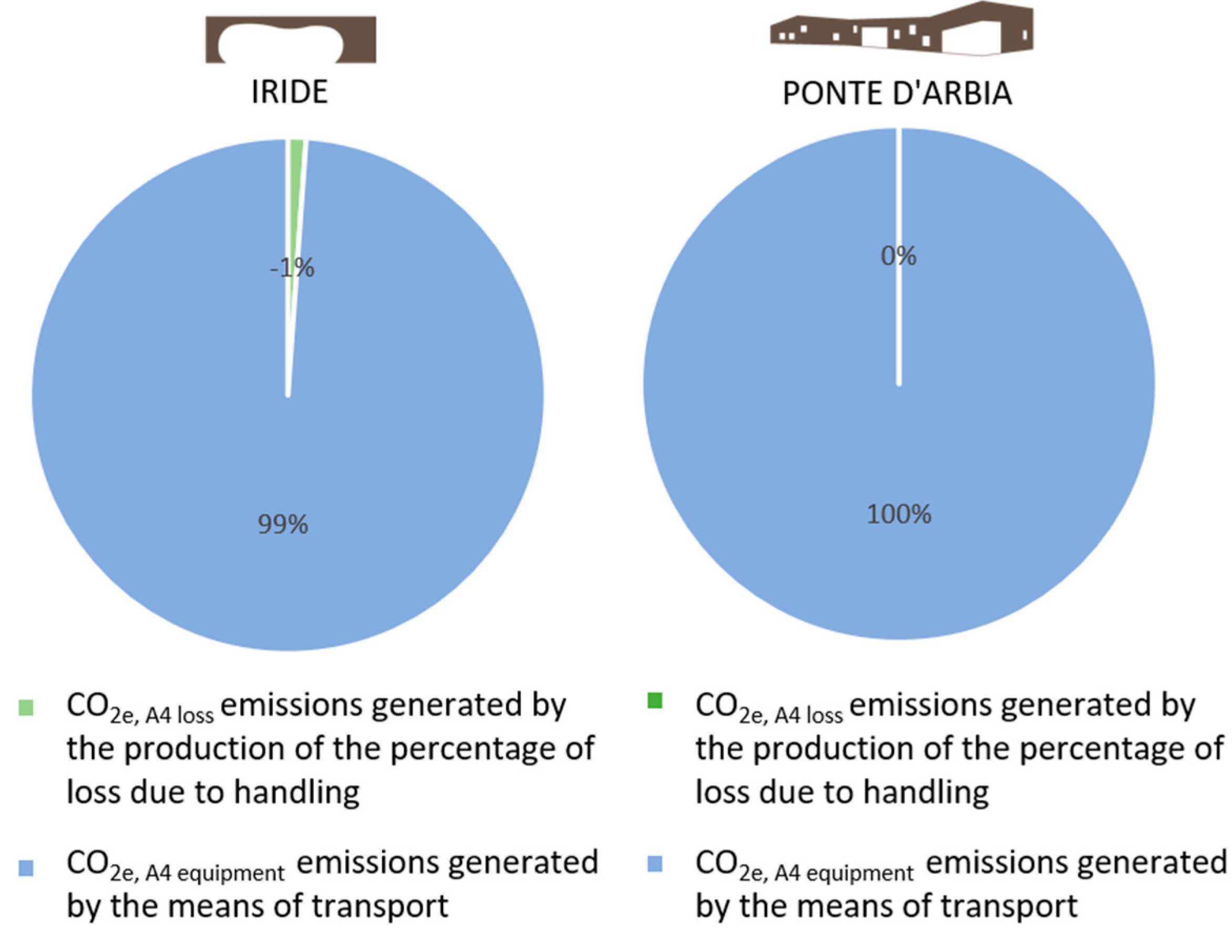

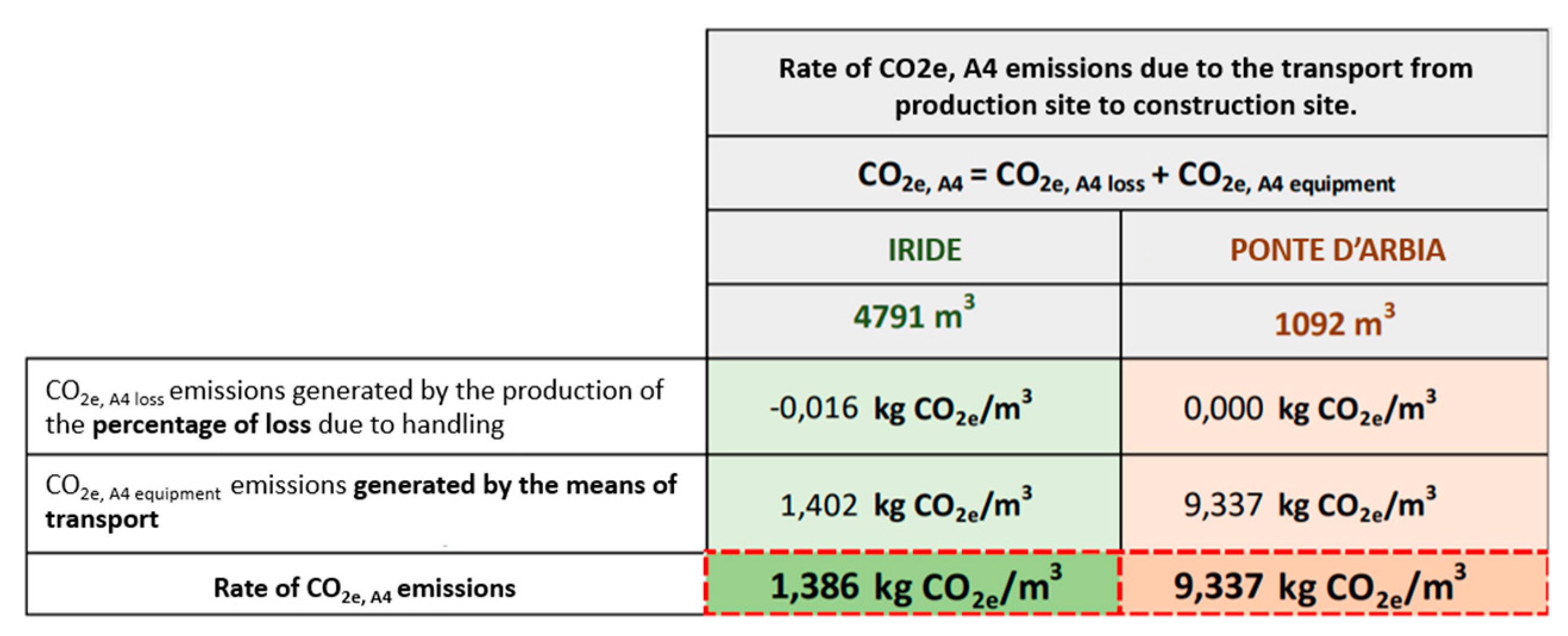

5.2. Rate of CO2e, A4 Emissions due to the Transport from Production Site to Construction Site

Regarding the emissions related to the transportation of the elements, it is important to note the negative value of those caused by handling losses at the Guastalla nursery (-0.016 kg CO

2e). In this school, among the elements considered vulnerable to transportation damages, there is the industrial parquet, which has an embodied carbon ICE coefficient of -0.81 kg CO

2e/kg, considering the carbon storage property of wood. For the Ponte d'Arbia nursery no element was considered vulnerable to handling damages; therefore, the emissions generated during production due to losses are zero (

Table 10).

The building situated in Siena generates notably higher CO2e emissions due to transportation compared to the one in Reggio Emilia. This discrepancy can be attributed to the elevated concentration of the construction industry in Northern Italy.

Specifically, in phase A4, the CO

2e production amounts to 1.402 kg CO

2e/m

3 for the Ponte d'Arbia kindergarten, while it reaches 9.337 kg CO

2e/m

3 for the Guastalla kindergarten (

Figure 11).

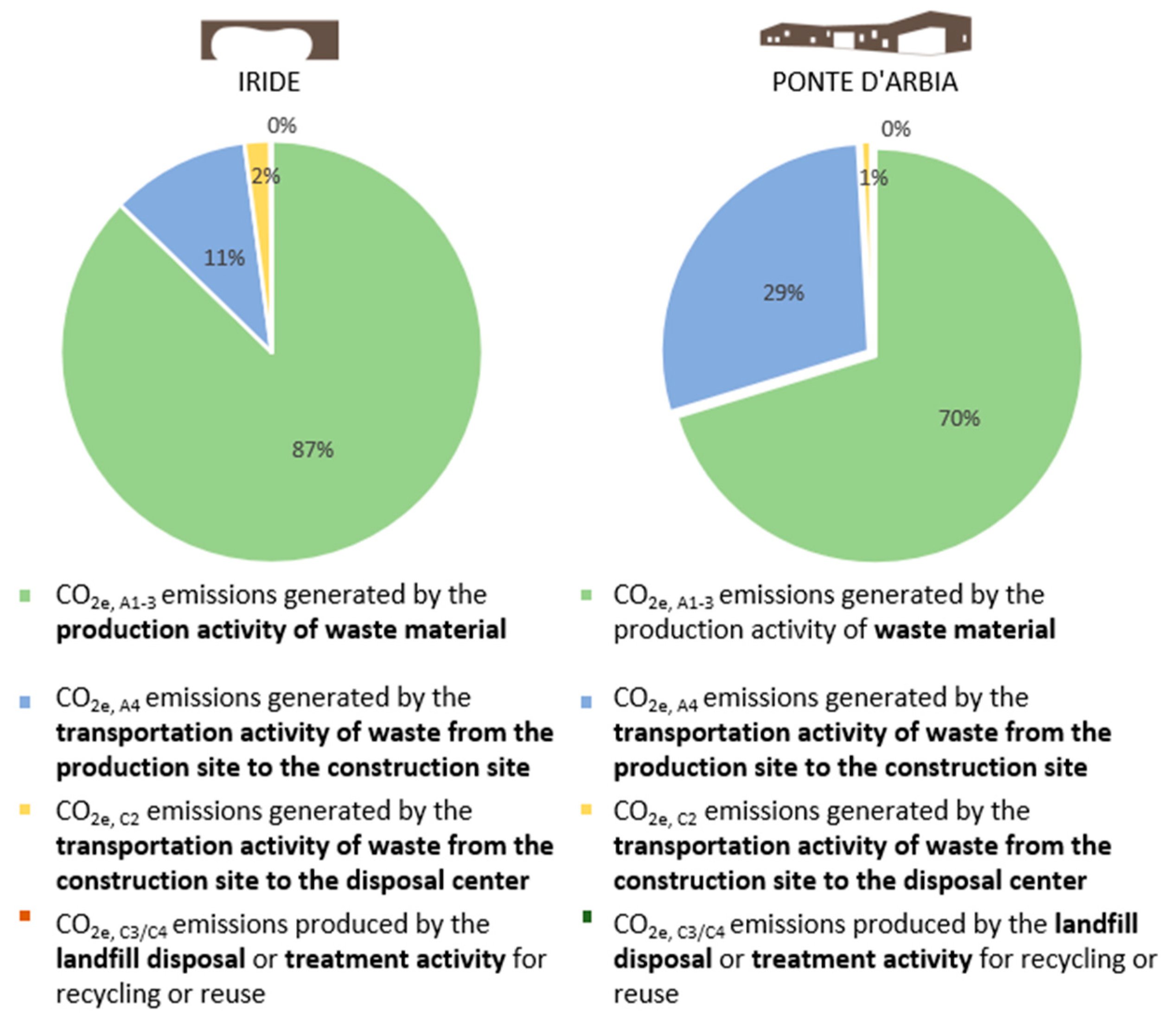

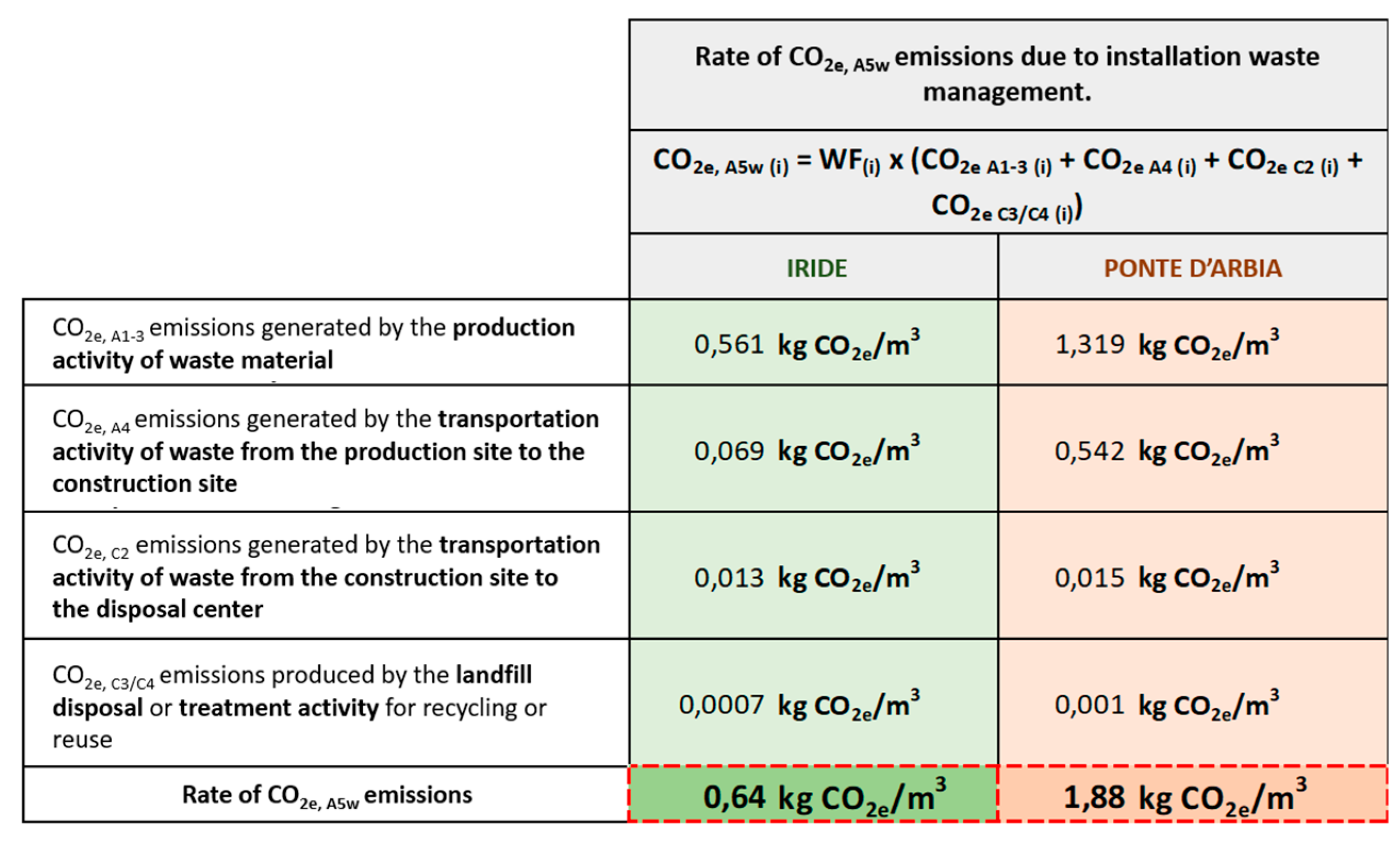

5.3. Rate of CO2e, A5w Emissions Due to Installation Waste Management

Comparing the results about CO

2e,A5w emissions obtained, after dividing them by the volume of the respective schools (

Table 11), a similarity can be observed between the two values related to the transportation of waste to the disposal site (0.013 kg CO

2e/m

3 for the Guastalla kindergarten and 0.015 kg CO

2e/m

3 for the Ponte d'Arbia kindergarten) and those related to the treatment for recycling (approximately 0.001 kg CO

2e/m

3 for both case studies).

There is a significant difference, however, in the production emissions rate: while it amounts to 0.561 kg CO2e/m3 for the construction in Guastalla, it reaches 1.319 kg CO2e/m3 for the construction in Ponte d'Arbia. This discrepancy is due to the presence of industrial parquet as construction waste in Guastalla, which, being made of wood, has a negative embodied carbon coefficient, thereby lowering the overall emissions value.

Regarding the results related to transportation from the production site to the construction site, the same considerations mentioned earlier for phase A4 apply.

From the observation of the pie charts (

Figure 12), it is evident that the emissions generated by the processes aimed at recycling construction waste have a very minimal impact on the total CO

2e, A5w. These emissions are present in such small quantities that they do not appear within the diagrams.

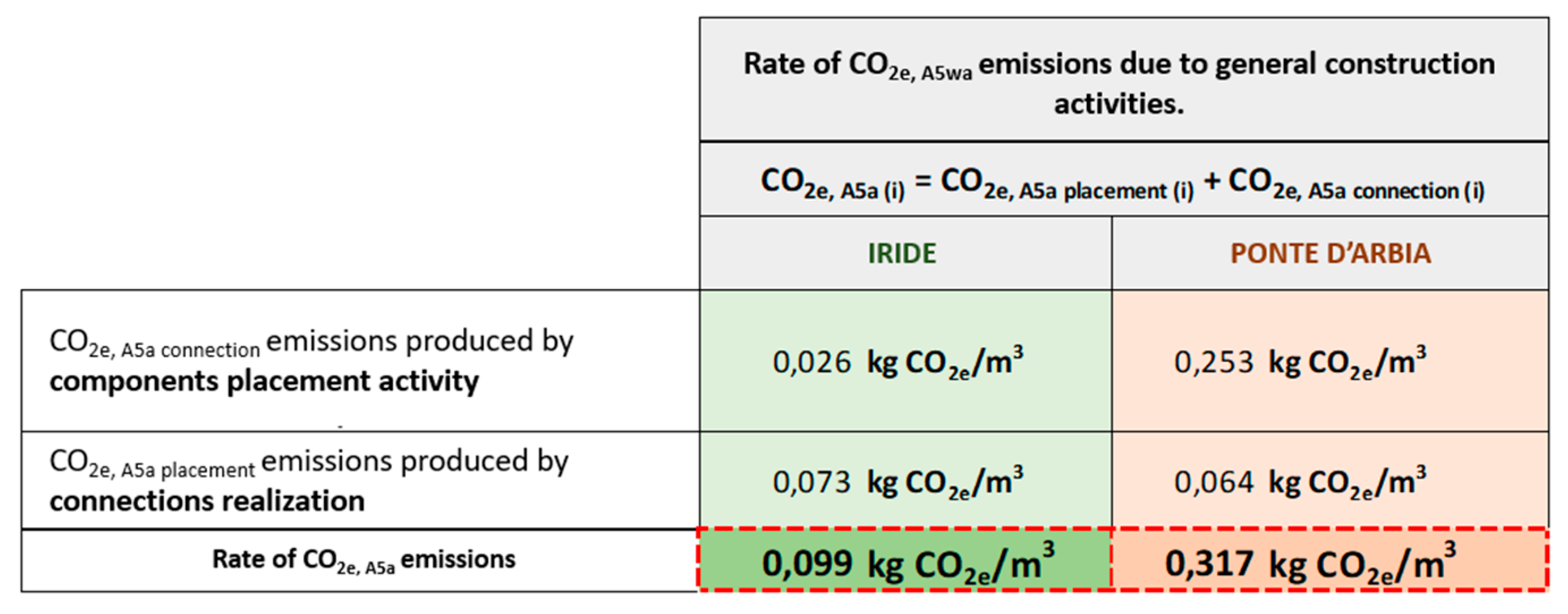

5.4. Rate of CO2e, A5a Emissions Due to the General Construction Activities

From the comparison of the results (

Table 12,

Figure 13), a significant difference in emissions produced by the transportation activity for the positioning of elements is evident between the two schools. This is justified by the fact that while a self-erecting crane powered by electricity, consuming 17.6 kW per hour, was used for the Guastalla kindergarten, a diesel-powered mobile crane with a consumption of 209 kW per hour was used for the Ponte d'Arbia kindergarten, resulting in approximately twelve times higher consumption. However, the two case studies show comparable values for emissions related to the installation of connections per cubic meter, with 0.073 kg CO

2e/m

3 for the Guastalla school and 0.064 kg CO

2e/m

3 for the Ponte d'Arbia school.

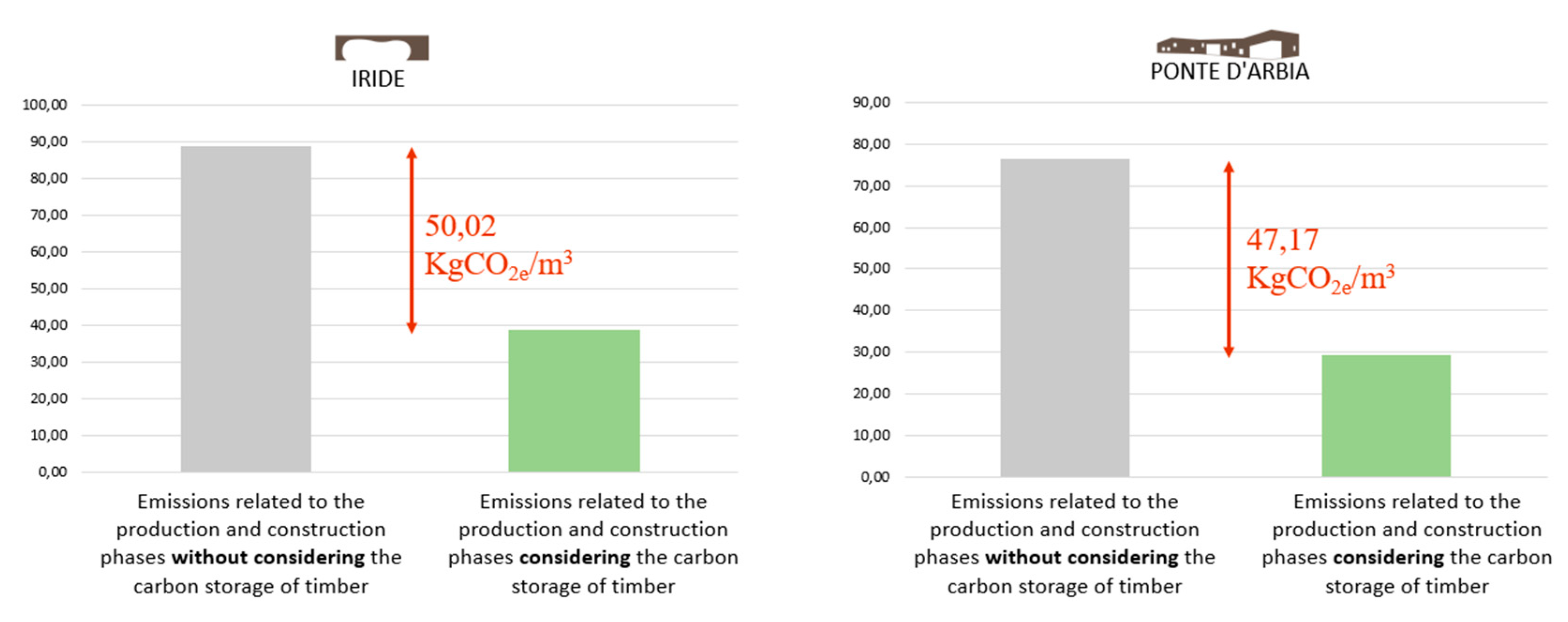

5.4. Comparison of the Results Obtained Considering and Not Considering the Compensatory Emission Credit for Carbon Storage in Timber

To assessing the benefits of timber utilization, emissions were evaluated without considering carbon storage. It has been found that the amount of stored CO

2e is approximately 50 kg CO

2e/m

3 for both schools (

Figure 14).

6. Discussion

Analyzing the obtained results leads to three important considerations:

With reference to emissions generated during A1-A3 phases, the results are closely dependent on the design choices, which are also influenced by the climatic zones in which the buildings are located. The Guastalla kindergarten, for instance, falls within climatic zone E, characterized by colder temperatures that require higher passive energy performance. On the other hand, the Ponte d'Arbia school (climatic zone D) has a very low, and even negative, emission rate also due to most of its elements being made of wood, which provides the advantage of a carbon offset credit.

The building in Siena exhibits considerably higher CO2e emissions resulting from transportation compared to the one in Reggio Emilia. This disparity can be attributed to the greater concentration of the construction industry in Northern Italy, which represents approximately 52% of all industries in Italy. This regional concentration significantly impacts the transportation distances required for goods, as they need to be transported from the production sites to the construction sites. To date, CO2e emissions resulting from transportation operations are mitigated using Low Emission Vehicles (LEV) as mandated by the Italian Ministerial Decree of October 11, 2017. In accordance with Criterion 2.5.3, the exclusive use of highly energy-efficient vehicles (EEV) is ensured. Additionally, the incentivizing Criterion 2.6.5 stipulates a maximum distance of 150 km for sourcing construction products. This requirement further reduces carbon emissions during transportation by promoting local suppliers and limiting the need for long-distance travel.

The results of phase A5 (construction) showed the importance of the use of electrical machinery and equipment to reduce greenhouse gas emissions and energy consumption. For the construction of the Guastalla kindergarten, an electric crane was used, with an energy consumption twelve times lower than the diesel-powered crane used for the kindergarten in Siena.

The implementation perspectives of this research can focus on two key aspects. Firstly, extending the field of investigation to encompass the other modules of the building life cycle, including phases B, C, and D. By examining the entire life cycle, a more holistic understanding of the environmental impact can be obtained. Secondly, defining an economic profile of the building's production and construction process is crucial. This entails evaluating the costs associated with design, material sourcing, labor, and other relevant factors during the construction process. By examining the economic aspects, it becomes possible to assess the efficiency and financial sustainability of various design and construction choices.

7. Conclusions

The choices regarding building materials have consequences that cannot be ignored, as highlighted in this article. Compared to cement and steel, it has been shown that the negative impact of wood on the environment is far less severe. Regardless of whether optimal end-of-life scenarios are planned or not, wood still has a lower carbon footprint compared to other important materials, as well as being sustainable and reusable. Environmental support policies are contributing to a push for greater adoption of wood, focusing on issues such as carbon pricing, life cycle assessment, and CO2 offsetting. The purpose of the research was to investigate and deepen the potential of circular economy processes and the use of wood in buildings. In particular, the study developed a methodology for assessing the environmental impact of the production phases of building materials and construction of buildings, which was then applied to two cases. The choice of the two buildings to analyze fell on the Asilo Iride by Mario Cucinella, located in Guastalla (Reggio Emilia), constructed with a timber frame construction system, and the Ponte d'Arbia nursery in Siena, built by the Settanta7 studio with X-Lam panels. What emerged from the results of this research is that, with reference to the production and construction phases, the frame construction technology has a higher environmental impact of about 30% compared to the X-Lam panel technology. However, both systems can store an amount of carbon equal to about 50 kgCO2e for every cubic meter of construction, empty or full. Finally, the benefit of carbon storage in wood translates into a saving of about 60% of CO2e emissions within the scope of the investigation. For this reason, it is possible to affirm that a predominantly timber construction system, thanks to its carbon storage property, confirms itself as the most virtuous solution in the perspective of climate neutrality by 2050.

It is important to underline how the use of wood in the design and construction of buildings does not necessarily have to replace other more established building materials; rather, it can offer a wide range of possibilities, being suitable for composite components and hybrid structures, in combination with concrete, steel, polymers, and even glass.

Timber construction is not a silver bullet solution to climate change, but it can provide a truly useful contribution. In addition to its ability to balance or reduce greenhouse gas (GHG) emissions, wood also supports better forest management and a brake on deforestation, both major issues related to global warming.

Author Contributions

Conceptualization, G.D.R.; Methodology, G.D.R.; Software, A.G.; Validation, G.D.R. and A.G.; Formal analysis, A.G.; Investigation, A.G; Resources, A.G.; Data Curation, A.G.; writing—original draft preparation, A.G.; Writing—review and editing, G.D.R.; Visualization, G.D.R.; Supervision, G.D.R. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Conflicts of Interest

The authors declare no conflicts of interest. The funders had no role in the study design, data collection, analysis, or interpretation, the writing of the manuscript, or the decision to publish the results.

References

- Communication from the Commission to The European Parliament, The Council, The European Economic and Social Committee and The Committee of The Regions ‘Fit for 55’: Delivering the EU’s 2030 Climate Target on the Way to Climate Neutrality COM (2021) 550 Final. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52021DC0550&from=EN (accessed on 25 March 2023).

- THE PARIS AGREEMENT. Available online: https://unfccc.int/sites/default/files/resource/parisagreement_publication.pdf (accessed on 7 March 2023).

- IPCC - Global warming of 1.5°C-Summary for Policymakers (2018). Available online: https://www.ipcc.ch/sr15 EN (accessed on 3 February 2022).

- United Nations General Assembly - Transforming Our World: the 2030 Agenda for Sustainable Development. Available online: https://www.un.org/en/development/desa/population/migration/generalassembly/docs/globalcompact/A_RES_70_1_E.pdf (accessed on 25 March 2023).

- United Nations Environment Programme. 2022 Global Status Report for Buildings and Construction. Available online: https://globalabc.org/sites/default/files/2022-11/FULL%20REPORT_2022%20Buildings-GSR_1.pdf (accessed on 25 March 2023).

- Bontempi, E. How to perform a material recovery sustainability evaluation preliminary to LCA? Resources, Environment and Sustainability 2022, 9, 100074. Available online: https://doi.org/10.1016/j.resenv.2022.100074 (accessed on February 2022). [CrossRef]

- Report From The Commission To The Council, The European Parliament, The European Economic And Social Committee And.

- The Committee Of The Regions - On the State of Implementation of Integrated Product Policy. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CELEX:52009DC0693&from=EN (accessed on 22 March 2023).

- UNEP, United Nations Environment Programme, 2004 Annual Evaluation Report, September 2005. Available online: https://wedocs.unep.org/bitstream/handle/20.500.11822/356/UNEP_Annual_Evaluation_Report_2 004.pdf?sequence=1&isAllowed=y (accessed on 3 February 2022).

-

BS EN 15978:2011; Sustainability of construction works - assessment of environmental performance of buildings - calculation method (incorporating corrigendum November 2011). British Standards Institution: London, 2011. Available online: https://www.greenbooklive.com/filelibrary/EN_15804/PN326-BRE-EN-15978-Methodology.pdf (accessed on 20 January 2020).

- Monkiz Khasreen, M.; Banfill, P.F.G.; Menzies, G.F. Life-Cycle Assessment and the Environmental Impact of Buildings: A Review. Sustainability. 2009. Available online: https://www.mdpi.com/2071-1050/1/3/674 (accessed on May 2023). [CrossRef]

- Hawkins, W. Timber and carbon sequestration. The Structural Engineer. 2021. Available online: https://www.istructe.org/journal/volumes/volume-99-(2021)/issue-1/timber-and-carbon-sequestration/ (accessed on 5 February 2022). [CrossRef]

- Di Ruocco, G.; Melella, R. Evaluation of envi-ronmental sustainability threshold of “humid” and “dry” building systems, for reduc-tion of embodied carbon (CO2). Vitruvio 2018, 3, 17–35. Available online: https://polipapers.upv.es/index.php/vitruvio/article/view/11020 (accessed on 16 April 2023). [CrossRef]

- Di Ruocco, G.; Melella, R.; Sicignano, E. Mitigation Strategies for Reduction of Embodied Energy and Carbon, in the Construction Systems of Contemporary Quality Architecture. Sustainability. 2019. Available online: https://www.mdpi.com/2071-1050/11/14/3806 (accessed on 16 April 2023). [CrossRef]

- Italian Standard UNI 8290/1-1981, - Edilizia residenziale. Sistema tecnologico. Classificazione e terminologia. Available online: https://store.uni.com/uni-8290-1-1981-a122-1983.

- Italian Standard UNI 11277:2008, Sostenibilità in edilizia - Esigenze e requisiti di ecocompatibilità dei progetti di edifici residenziali e assimilabili, uffici e assimilabili, di nuova edificazione e ristrutturazione. Available online: https://store.uni.com/uni-11277-2008-77843.html.

- Inventory of carbon and energy (ICE). Available online: https://circularecology.com/embodied-carbon-footprint-database.html.

- Politecnico di Milano. Convenzione tra il Ministero dell’Ambiente e della Tutela del Territorio e del Mare ed il Politecnico di Milano del 24 marzo 2014 per l’attuazione delle metodologie di calcolo dell’impronta di carbonio e di compensazione delle emissioni di CO2 di EXPO 2015. Available online: https://www.mase.gov.it/sites/default/files/archivio/allegati/impronta_ambientale/approfondimento_metodologico_viaggi.pdf (accessed on 11 May 2023).

- WRAP, Welcome to the Net Waste Tool. Available online: https://wrap.org.uk/wraps-builtenvironment-programme (accessed on 11 May 2023).

- European Waste Catalogue. 18 December 2014. Available online: https://eurlex.europa.eu/legal-content/IT/TXT/PDF/?uri=CELEX:32014D0955&from=IT (accessed on 11 May 2023).

- Department for Environment, Food and Rulal Affairs. Annex A: protocols for energy related CO2 emissions. UKETS (01)05rev2. Guidelines for the Measurement and Reporting of Emissions by Direct Participants in the UK Emission trading Scheme. 2003; 19–27. [Google Scholar]

- National Emissions Inventory. Available online: https://www.epa.gov/air-emissions-inventories/national-emissionsinventorynei#:~:text=The%20National%20Emissions%20Inventory%20(NEI,pollutants%20from%20air%20emissions%20sources (accessed on 11 May 2023).

- Italian Standard UNI ISO 11228-1 - Ergonomia - Movimentazione manuale - 1: Sollevamento e trasporto. Available online: http://store.uni.com/catalogo/uni-iso-11228-1-2009.

- Data Sheet for Liebeherr crane 32TT. Available online: https://cranemarket.com/specification1573 (accessed on 11 May 2023).

- Data Sheet for Liebeherr telescopic crane LTM 1040-2.1. Available online: https://www.liebherr.com/en/int/products/mobile-and-crawler-cranes/mobile-cranes/liebherrmobile-cranes/ltm-1040-2.1.html (accessed on 11 May 2023).

- ISPRA- Istituto Superiore per la Protezione e la Ricerca Ambientale, Report: Efficiency and decarbonisation indicators of the national energy system and the electricity sector. 2021. Available online: https://www.isprambiente.gov.it/files2021/pubblicazioni/rapporti/r343-2021.pdf (accessed on April 2022).

- Data Sheet for Nailer Hilti BX3-L. Available online: https://www.hilti.it/medias/sys_master/documents/hf9/h29/9559464935454/BX-3-Data-SheetTechnical-information-ASSET-DOC-8281172.pdf (accessed on 11 May 2023).

- Data Sheet for Drill screwdriver Hilti SF 4-A22. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_DRILL_DRIVERS_SCREW_DRIVERS__7124/CLS_CORDLESS_DRILL_DRIVERS_7124/r10563878 (accessed on 11 May 2023).

- Data Sheet for Powered rotary Hilti TE 30-A36. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_ROTARY_HAMMERS_SDSPLUS_7124/C LS_CORDLESS_ROTARY_HAMMERS_SDSPLUS_7124/r7492564 (accessed on 11 May 2023).

- Data Sheet for Impact wrench HILTI SIW 22T-A-1/2''. Available online: https://www.hilti.it/c/CLS_POWER_TOOLS_7124/CLS_IMPACT_DRIVERS_WRENCHES_7124/C LS_CORDLESS_IMPACT_WRENCHES_7124/r4265 (accessed on 11 May 2023).

- Data Sheet for Impact wrench HILTI SID 4-A22. Available online: https://www.hilti.it/c/CLS_CORDLESS_TOOLS_7123/CLS_CORDLESS_DRIVER_WRENCH_712 3/CLS_CORDLESS_IMPACT_DRIVER_7123/r3357052 (accessed on 11 May 2023).

- Data Sheet for OVERMAT 24.7 T R and OVERMAT: 13.4 T. Available online: https://www.overmat-screed.com/soluzioni/macchina-per-massetti-serie-t (accessed on 11 May 2023).

Figure 2.

Life Cycle Assessment Phases.

Figure 2.

Life Cycle Assessment Phases.

Figure 3.

Comparison of cumulative emissions of Embodied Carbon for different types of construction (Source: The Institution of Structural Engineers).

Figure 3.

Comparison of cumulative emissions of Embodied Carbon for different types of construction (Source: The Institution of Structural Engineers).

Figure 4.

IRIDE Kindergarten by Mario Cucinella, Guastalla.

Figure 4.

IRIDE Kindergarten by Mario Cucinella, Guastalla.

Figure 5.

Kindergarten of Ponte d’Arbia by Studio Settanta7, Ponte d’Arbia.

Figure 5.

Kindergarten of Ponte d’Arbia by Studio Settanta7, Ponte d’Arbia.

Figure 6.

Impact of the three CO2e emission rates - IRIDE kindergarten.

Figure 6.

Impact of the three CO2e emission rates - IRIDE kindergarten.

Figure 7.

Impact of the three CO2e emission rates - kindergarten of Ponte d’Arbia.

Figure 7.

Impact of the three CO2e emission rates - kindergarten of Ponte d’Arbia.

Figure 9.

Rate of CO2e, A1-A3 emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Figure 9.

Rate of CO2e, A1-A3 emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Figure 10.

Rate of CO2e, A1-A3 emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 10.

Rate of CO2e, A1-A3 emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 11.

Rate of CO2e, A4 emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 11.

Rate of CO2e, A4 emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 12.

Rate of CO2e, A5w emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 12.

Rate of CO2e, A5w emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 13.

Rate of CO2e, A5a emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 13.

Rate of CO2e, A5a emissions of the Iride kindergarten (left) and the Ponte D’Arbia kindergarten (right).

Figure 14.

Results for the Iride kindergarten (left) and the Ponte D’Arbia (right) obtained considering and not considering the compensatory emission credit for carbon storage in timber.

Figure 14.

Results for the Iride kindergarten (left) and the Ponte D’Arbia (right) obtained considering and not considering the compensatory emission credit for carbon storage in timber.

Table 1.

Building assessment information (Source: BS EN 15978).

Table 1.

Building assessment information (Source: BS EN 15978).

Table 3.

Carbon emission factors in relation to the engine of the machinery.

Table 3.

Carbon emission factors in relation to the engine of the machinery.

| Engine |

Carbon emission factor

[Kg C /kW h] |

Carbon emission factor

[Kg CO2 /kW h] |

| Coal |

0,0817 |

0,3 |

| Coke |

0,101 |

0,37 |

| Petroliferous Coke |

0,0927 |

0,34 |

| Gas/Diesel |

0,068 |

0,25 |

Table 4.

Seconds required for the positioning operations.

Table 4.

Seconds required for the positioning operations.

| Machine |

T0 [s] |

T1 [s] |

T1’ [s] |

| Telescopic crane |

18 |

45 |

45 |

| Self-propelled crane |

18 |

69 |

69 |

Table 5.

Tools.

| Installation technology |

Tool |

| Nailing |

Nailer Hilti: BX3-L [26] |

| Holes for dowels |

Drill screwdriver Hilti: SF 4-A22 [27] |

| Drillinf of the screed |

Powered rotary Hilti: TE 30-A36 [28] |

| Bolts |

Impact wrench Hilti: SIW 22T-A-1/2’’, Hilti: SID 4-A22 [29,30] |

| Screw connections |

Impact wrench Hilti: SID 4-A22[30] |

| In-situ concrete casting |

Automatic mixing and pumping machinery Overmat: 24.7 T R , Overmat 13.4 T [31] |

Table 6.

Operating time of the instruments.

Table 6.

Operating time of the instruments.

| Tool |

Seconds for nailing a nail |

Seconds for a hole |

Seconds for screwing a bolt |

Seconds for screwing a screw

(plasterboard systems) |

Seconds for screwing a screw

(wood) |

Nailer

HILTI : BX3-L |

2 |

- |

- |

- |

- |

Drill screwdriver

HILTI : SF 4-A22 |

- |

2,5 |

- |

- |

- |

Powered rotary

HILTI : TE 30-A36 |

- |

6 |

- |

- |

- |

Impact wrench

HILTI : SIW 22T-A-1/2’’ |

- |

- |

3 |

- |

- |

Impact wrench

HILTI : SID 4- A22 |

- |

- |

2 |

1 |

4,5 |

Table 7.

Case study: IRIDE kindergarten. Total emissions, in terms of tones, of each of the three rates.

Table 7.

Case study: IRIDE kindergarten. Total emissions, in terms of tones, of each of the three rates.

| CO2e emissions rate from production activities |

175,71 t CO2e

|

| CO2e emissions rate from transport from production site to construction site |

6,642 t CO2e

|

| CO2e emissions rate from construction activities |

3,553 t CO2e

|

| ∑CO2e emissions |

185,91 t CO2e

|

Table 8.

Case study: kindergarten of Ponte d’Arbia. Total emissions, in terms of tones, of each of the three rates.

Table 8.

Case study: kindergarten of Ponte d’Arbia. Total emissions, in terms of tones, of each of the three rates.

| CO2e emissions rate from production activities |

19,37 t CO2e

|

| CO2e emissions rate from transport from production site to construction site |

10,19 t CO2e

|

| CO2e emissions rate from construction activities |

2,40 t CO2e

|

| ∑CO2e emissions |

31,96 t CO2e

|

Table 10.

Rate of CO2e, A4 emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Table 10.

Rate of CO2e, A4 emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Table 11.

Rate of CO2e, A5w emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Table 11.

Rate of CO2e, A5w emissions of the Iride kindergarten and the Ponte D’Arbia kindergarten.

Table 12.

Rate of CO2e, A5a emissions of the Iride kindergarten and the Ponte D’Arbia.

Table 12.

Rate of CO2e, A5a emissions of the Iride kindergarten and the Ponte D’Arbia.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).