Submitted:

31 May 2023

Posted:

31 May 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Experimental methods

2.1. Geological background of the study area

2.2. Experimental scheme

2.3. Experimental conditions and steps

3. Experimental results and analysis

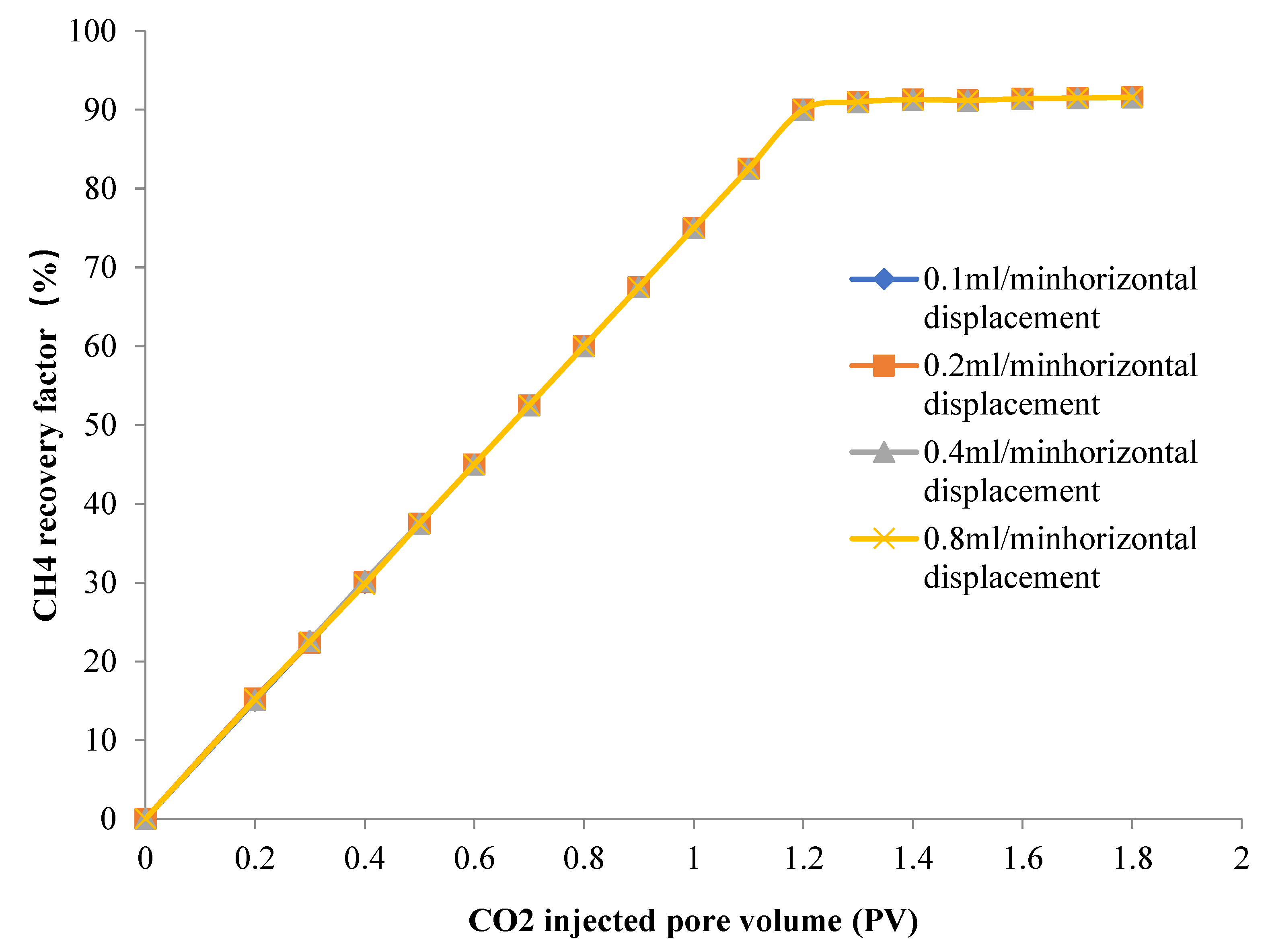

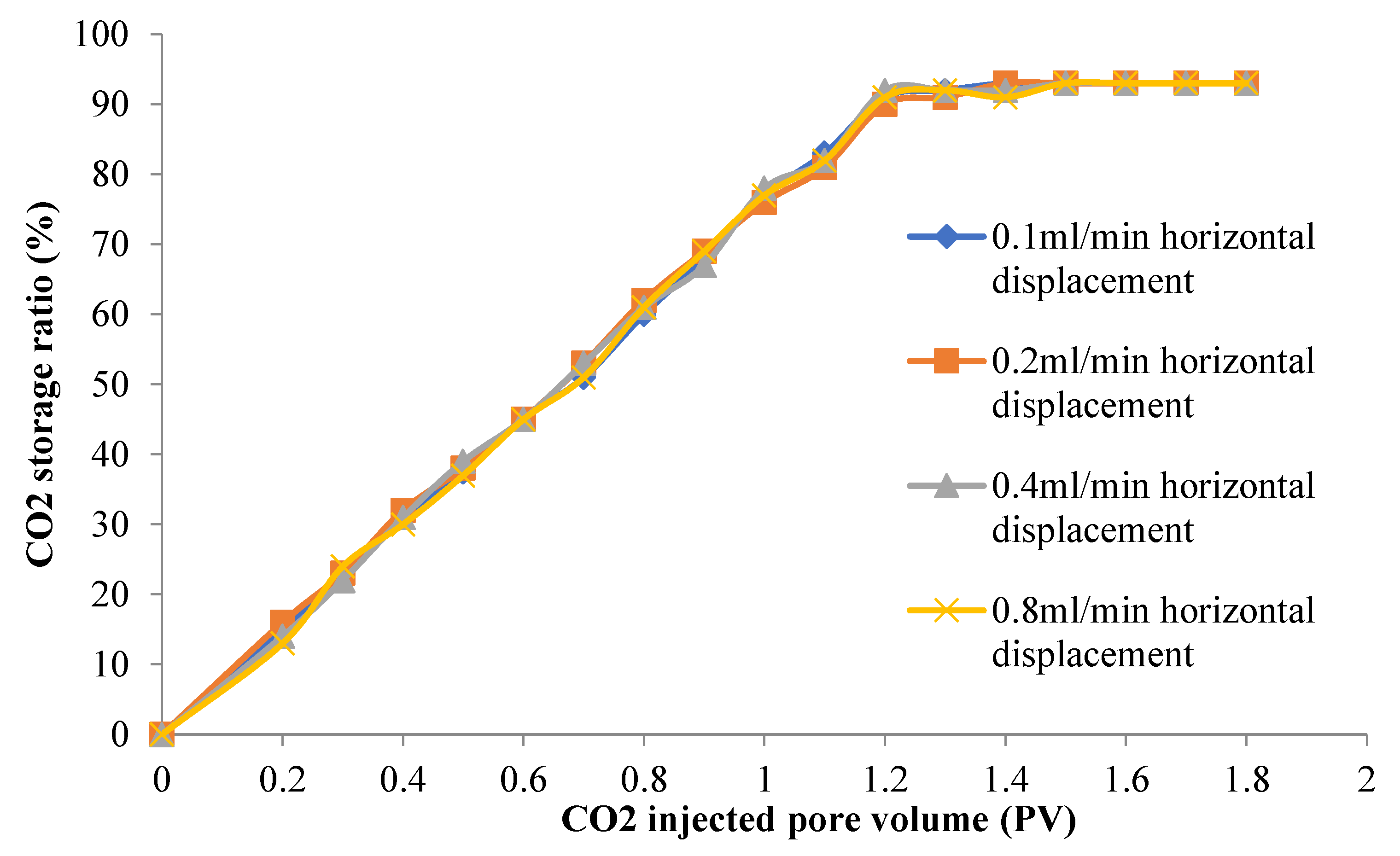

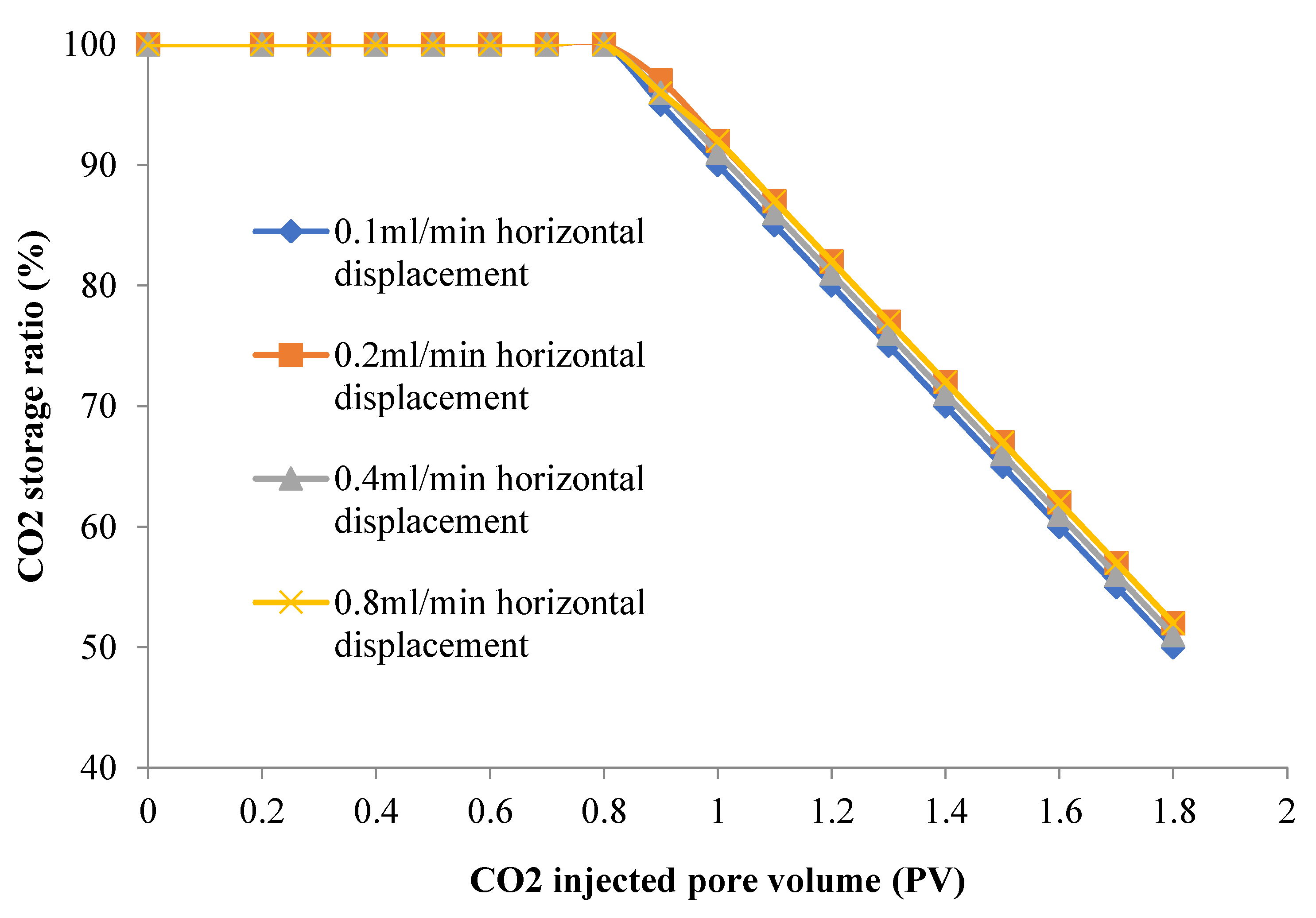

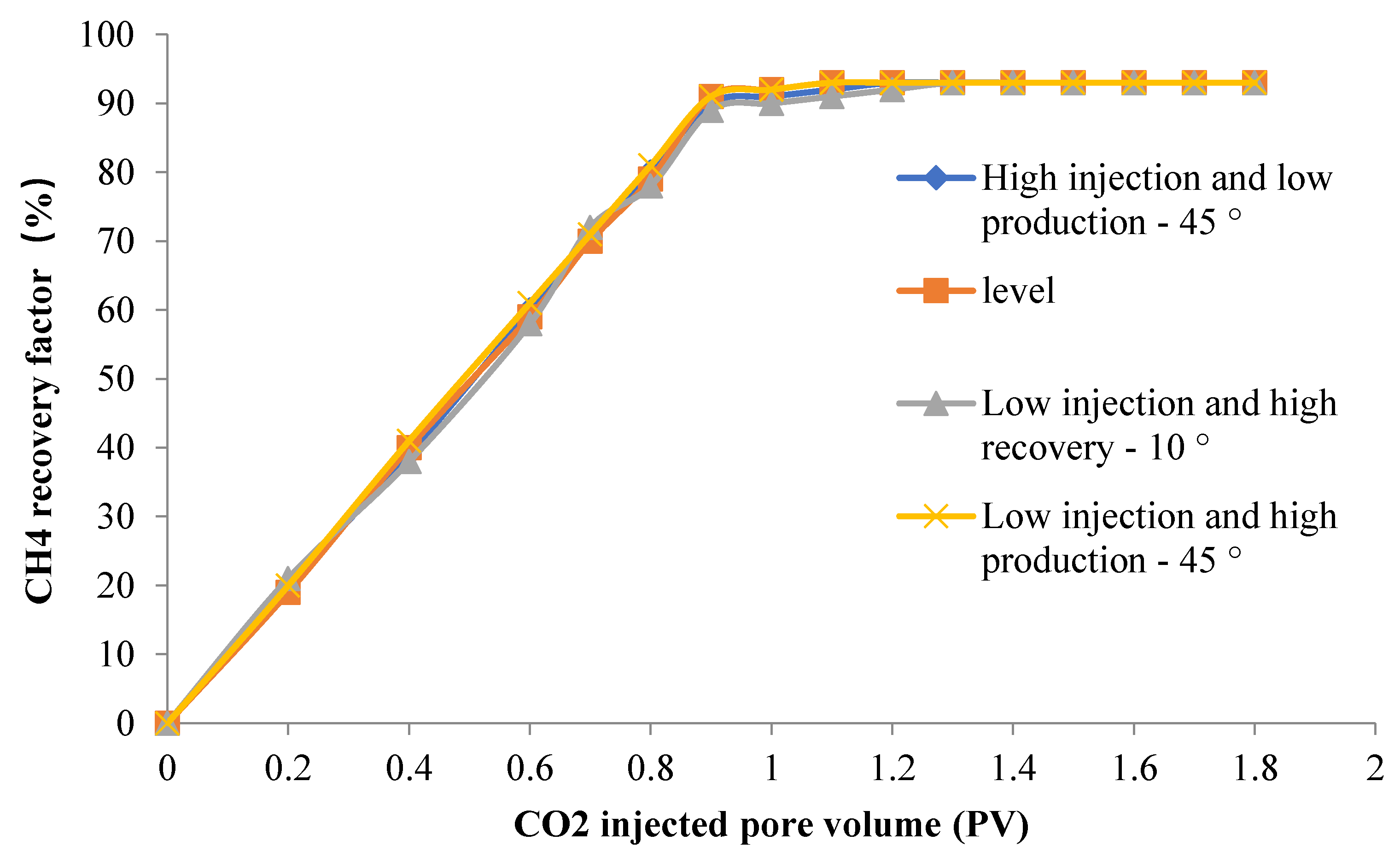

3.1. Test results

4. Conclusion

Conflicts of interest:

Acknowledgments

References

- Wu, S.; Zou, C.; Ma, D.; Zhai, X.; Yu, H.; Yu, Z. Reservoir property changes during CO2–brine flow-through experiments in tight sandstone: Implications for CO2 enhanced oil recovery in the Triassic Chang 7 Member tight sandstone, Ordos Basin, China. J. Asian Earth Sci. 2019, 179, 200–210. [Google Scholar] [CrossRef]

- Jin, L.; Hawthorne, S.; Sorensen, J.; Pekot, L.; Kurz, B.; Smith, S.; Heebink, L.; Herdegen, V.; Bosshart, N.; Torres, J.; et al. Advancing CO2 enhanced oil recovery and storage in unconventional oil play—Experimental studies on Bakken shales. Appl. Energy 2017, 208, 171–183. [Google Scholar] [CrossRef]

- Zhou, X.; Wang, Y.; Zhang, L.; Zhang, K.; Jiang, Q.; Pu, H.; Wang, L.; Yuan, Q. Evaluation of enhanced oil recovery potential using gas/water flooding in a tight oil reservoir. Fuel 2020, 272, 117706. [Google Scholar] [CrossRef]

- Li, D. , Saraji, S., Jiao, Z., and Zhang, Y. (2021). CO2 injection strategies for enhanced oil recovery and geological storage in a tight reservoir: An experimental study. Fuel, 284, 119013.

- Burrows, L.C.; Haeri, F.; Cvetic, P.; Sanguinito, S.; Shi, F.; Tapriyal, D.; Goodman, A.L.; Enick, R.M. A Literature Review of CO2, Natural Gas, and Water-Based Fluids for Enhanced Oil Recovery in Unconventional Reservoirs. Energy Fuels 2020, 34, 5331–5380. [Google Scholar] [CrossRef]

- Wang, L.; Tian, Y.; Yu, X.; Wang, C.; Yao, B.; Wang, S.; Winterfeld, P.H.; Wang, X.; Yang, Z.; Wang, Y.; et al. Advances in improved/enhanced oil recovery technologies for tight and shale reservoirs. Fuel 2017, 210, 425–445. [Google Scholar] [CrossRef]

- Zhu, C.-F.; Guo, W.; Wang, Y.-P.; Li, Y.-J.; Gong, H.-J.; Xu, L.; Dong, M.-Z. Experimental study of enhanced oil recovery by CO2 huff-n-puff in shales and tight sandstones with fractures. Pet. Sci. 2020, 18, 852–869. [Google Scholar] [CrossRef]

- AlRassas, A.M. , Vo Thanh, H., Ren, S., Sun, R., Al-Areeq, N.M., Kolawole, O., and Hakimi, M.H. (2022). CO2 Storage and Enhanced Oil Recovery via the Water Alternating Gas Scheme in a Mixed Transgressive Sandstone-Carbonate Reservoir: Case Study of a Large Middle East Oilfield. Energy and Fuels, 36(17), 10299-10314.

- Chaturvedi, K.R.; Sharma, T. In-situ formulation of pickering CO2 foam for enhanced oil recovery and improved carbon storage in sandstone formation. Chem. Eng. Sci. 2021, 235, 116484. [Google Scholar] [CrossRef]

- Wang, Y.; Shang, Q.; Zhou, L.; Jiao, Z. Utilizing macroscopic areal permeability heterogeneity to enhance the effect of CO2 flooding in tight sandstone reservoirs in the Ordos Basin. J. Pet. Sci. Eng. 2020, 196, 107633. [Google Scholar] [CrossRef]

- He, Y.; Qiao, Y.; Qin, J.; Tang, Y.; Wang, Y.; Chai, Z. A Novel Method to Enhance Oil Recovery by Inter-Fracture Injection and Production Through the Same Multi-Fractured Horizontal Well. J. Energy Resour. Technol. 2021, 144. [Google Scholar] [CrossRef]

- Zhang, K.; Li, S.; Liu, L. Optimized foam-assisted CO2 enhanced oil recovery technology in tight oil reservoirs. Fuel 2020, 267, 117099. [Google Scholar] [CrossRef]

- Sun, L. , Bai, B., Wei, B., Pu, W., Wei, P., Li, D., and Zhang, C. (2019). Recent advances of surfactant-stabilized N2/ CO2 foams in enhanced oil recovery. Fuel, 241, 83-93.

- Bai, M.; Zhang, Z.; Chen, Q.; Weifeng, S.; Du, S. Research on the Enhanced Oil Recovery Technique of Horizontal Well Volume Fracturing and CO2 Huff-n-Puff in Tight Oil Reservoirs. ACS Omega 2021, 6, 28485–28495. [Google Scholar] [CrossRef] [PubMed]

- Zuo, M.; Chen, H.; Qi, X.; Liu, X.; Xu, C.; Yu, H.; Brahim, M.S.; Wu, Y.; Liu, H. Effects of CO2 injection volume and formation of in-situ new phase on oil phase behavior during CO2 injection for enhanced oil recovery (EOR) in tight oil reservoirs. Chem. Eng. J. 2023, 452, 139454. [Google Scholar] [CrossRef]

- Cheng, H.; Ma, P.; Dong, G.; Zhang, S.; Wei, J.; Qin, Q. Characteristics of Carboniferous Volcanic Reservoirs in Beisantai Oilfield, Junggar Basin. Math. Probl. Eng. 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Rajkumar, P.; Pranesh, V.; Kesavakumar, R. Influence of CO2 retention mechanism storage in Alberta tight oil and gas reservoirs at Western Canadian Sedimentary Basin, Canada: hysteresis modeling and appraisal. J. Pet. Explor. Prod. Technol. 2021, 11, 327–345. [Google Scholar] [CrossRef]

- Baban, A.; Keshavarz, A.; Amin, R.; Iglauer, S. Residual Trapping of CO2 and Enhanced Oil Recovery in Oil-Wet Sandstone Core – A Three-Phase Pore-Scale Analysis Using NMR. Fuel 2023, 332. [Google Scholar] [CrossRef]

- Lake, L.W. , Lotfollahi, M., and Bryant, S.L. (2019). CO2 enhanced oil recovery experience and its messages for CO2 storage. In Science of Carbon Storage in Deep Saline Formations (pp. 15-31). Elsevier.

- Han, J., Cheng, H., Shi, Y., Wang, L., Song, Y., Zhnag, W. (2016) Connectivity analysis and application of fracture cave carbonate reservoir in Tazhong. Science Technology and Engineering 2016, 16, 147–152.

- Milad, M.; Junin, R.; Sidek, A.; Imqam, A.; Tarhuni, M. Huff-n-Puff Technology for Enhanced Oil Recovery in Shale/Tight Oil Reservoirs: Progress, Gaps, and Perspectives. Energy Fuels 2021, 35, 17279–17333. [Google Scholar] [CrossRef]

- Huang, X.; Li, A.; Li, X.; Liu, Y. Influence of Typical Core Minerals on Tight Oil Recovery during CO2 Flooding Using the Nuclear Magnetic Resonance Technique. Energy Fuels 2019, 33, 7147–7154. [Google Scholar] [CrossRef]

- Hou, Z.-K.; Cheng, H.-L.; Sun, S.-W.; Chen, J.; Qi, D.-Q.; Liu, Z.-B. Crack propagation and hydraulic fracturing in different lithologies. Appl. Geophys. 2019, 16, 243–251. [Google Scholar] [CrossRef]

- Bai, J.; Liu, H.; Wang, J.; Qian, G.; Peng, Y.; Gao, Y.; Yan, L.; Chen, F. CO2, Water and N2 Injection for Enhanced Oil Recovery with Spatial Arrangement of Fractures in Tight-Oil Reservoirs Using Huff-‘n-puff. Energies 2019, 12, 823. [Google Scholar] [CrossRef]

- Alvarado, V.; Manrique, E. Enhanced Oil Recovery: An Update Review. Energies 2010, 3, 1529–1575. [Google Scholar] [CrossRef]

- Cheng, H.; Wei, J.; Cheng, Z. Study on Sedimentary Facies and Reservoir Characteristics of Paleogene Sandstone in Yingmaili Block, Tarim Basin. Geofluids 2022, 2022, 1–14. [Google Scholar] [CrossRef]

- Mahzari, P.; Jones, A.P.; Oelkers, E.H. Impact of in-situ gas liberation for enhanced oil recovery and CO2 storage in liquid-rich shale reservoirs. Energy Sources, Part A: Recover. Util. Environ. Eff. [CrossRef]

- Kashkooli, S.B. , Gandomkar, A., Riazi, M., and Tavallali, M. S. (2022). Coupled optimization of carbon dioxide storage and CO2 enhanced oil recovery. Journal of Petroleum Science and Engineering 2022, 208, 109257. [Google Scholar]

| Stratum name | Stratigraphic characteristics |

|---|---|

| Lower Shihezi Formation | It is widely distributed on the plane and basically distributed in the whole study area. It is composed of He1 Member, He2 Member and He3 Member longitudinally. The lithology is mainly sandstone, with a certain amount of mudstone mixed between them. The reservoir physical property of Xiahezi Formation sandstone is the best, and it is the most important reservoir in this area. |

| Upper Shihezi Formation | It is widely distributed on the plane. The lithology is sandstone and mudstone. The thickness of mudstone is relatively large, with a total thickness of more than 100 meters. It has good capping capacity, providing good capping conditions for natural gas accumulation. |

| Shiqianfeng Formation | The whole area is distributed on the plane, and the lithology is dominated by sandstone and mudstone. As a regional caprock, mudstone is thicker and has stronger sealing capacity. |

| Experiment order | Influencing factors | Experimental content |

|---|---|---|

| 1 | Displacement$Speed | 0.1ml /min horizontal displacement of medium-seepage dry core |

| 2 | 0.2ml /min horizontal displacement of dry cores with medium permeability | |

| 3 | 0.4ml /min horizontal displacement of dry cores with medium permeability | |

| 4 | 0.8ml /min horizontal displacement of medium-seepage dry core | |

| 5 | Inclination | 0.2ml /min, inlet +45°displacement medium seepage dry core |

| 6 | 0.2ml /min, inlet -10°displacement medium seepage dry core | |

| 7 | 0.2ml /min, inlet -45°displacement medium seepage dry core | |

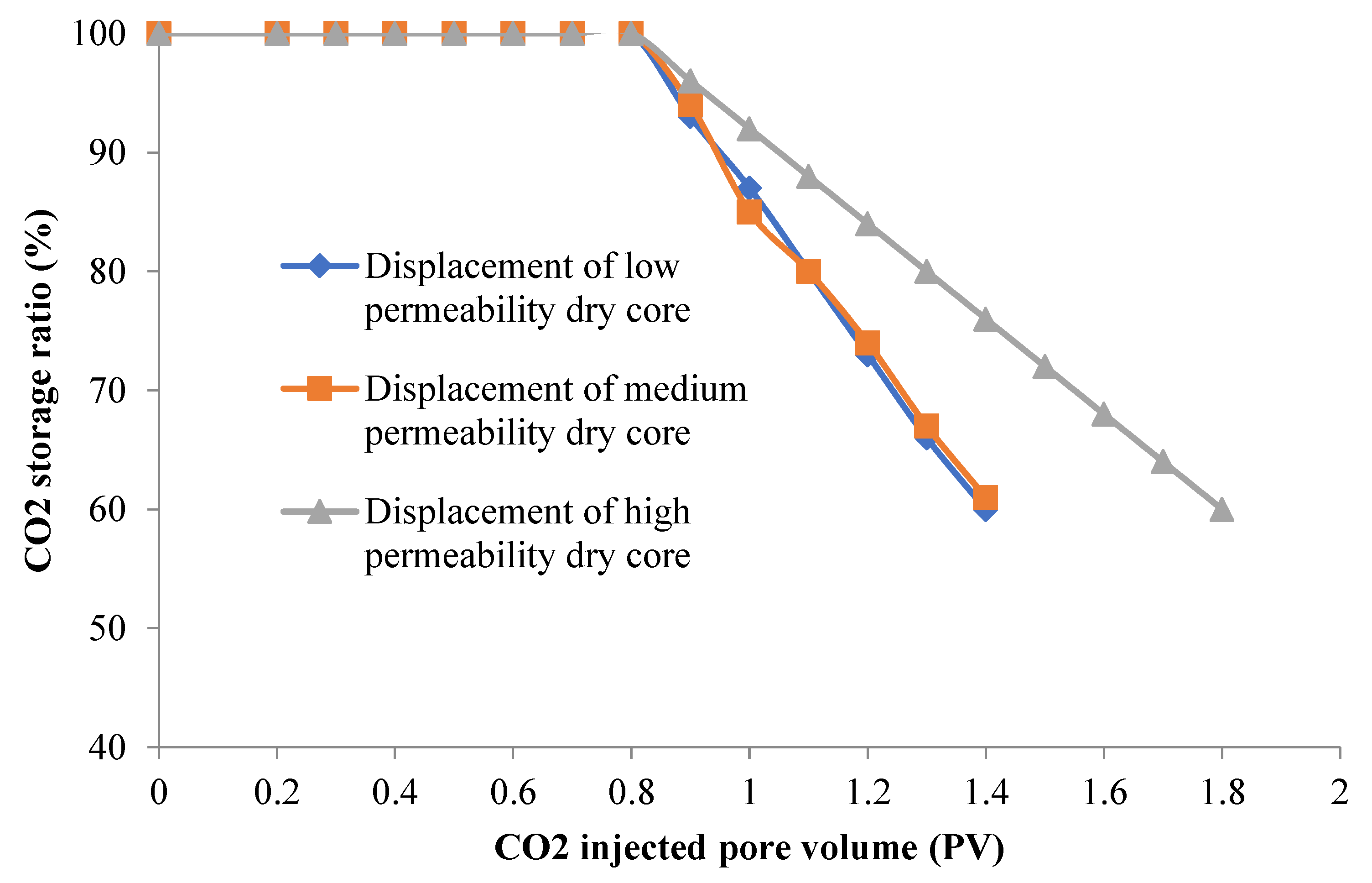

| 8 | Penetration | 0.2ml /min horizontal displacement of low seepage dry core |

| 9 | 0.2ml /min horizontal displacement of high seepage dry core | |

| 10 | Bound water | 0.2ml /min displacement of medium seepage cores with bound water |

| K++Na+ | Mg2+ | Ca2+ | Cl– | SO32– | HCO3– | CO32– | Total salinity (mg/l) |

|---|---|---|---|---|---|---|---|

| 12170 | 26 | 31 | 17380 | 270 | 2431 | 0 | 32308 |

| Core number | Core length (cm) | Core diameter (cm) | Pore volume (cm3) | Porosity (%) | Permeability (10-3μm2) |

|---|---|---|---|---|---|

| 1 | 4.31 | 2.51 | 2.35 | 11.2 | 1.8 |

| 2 | 4.84 | 2.56 | 2.73 | 11.0 | 1.8 |

| 3 | 5.11 | 2.49 | 2.85 | 11.3 | 2.3 |

| 4 | 5.23 | 2.51 | 2.91 | 11.4 | 2.4 |

| 5 | 5.32 | 2.49 | 2.83 | 11.0 | 2.3 |

| 6 | 4.53 | 2.53 | 2.51 | 11.4 | 1.9 |

| 7 | 4.64 | 2.48 | 2.83 | 11.2 | 1.9 |

| 8 | 5.01 | 2.56 | 2.75 | 11.4 | 2.6 |

| 9 | 5.32 | 2.56 | 2.82 | 11.1 | 2.1 |

| 10 | 5.21 | 2.53 | 2.84 | 11.3 | 2.0 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).