Submitted:

30 May 2023

Posted:

01 June 2023

You are already at the latest version

Abstract

Keywords:

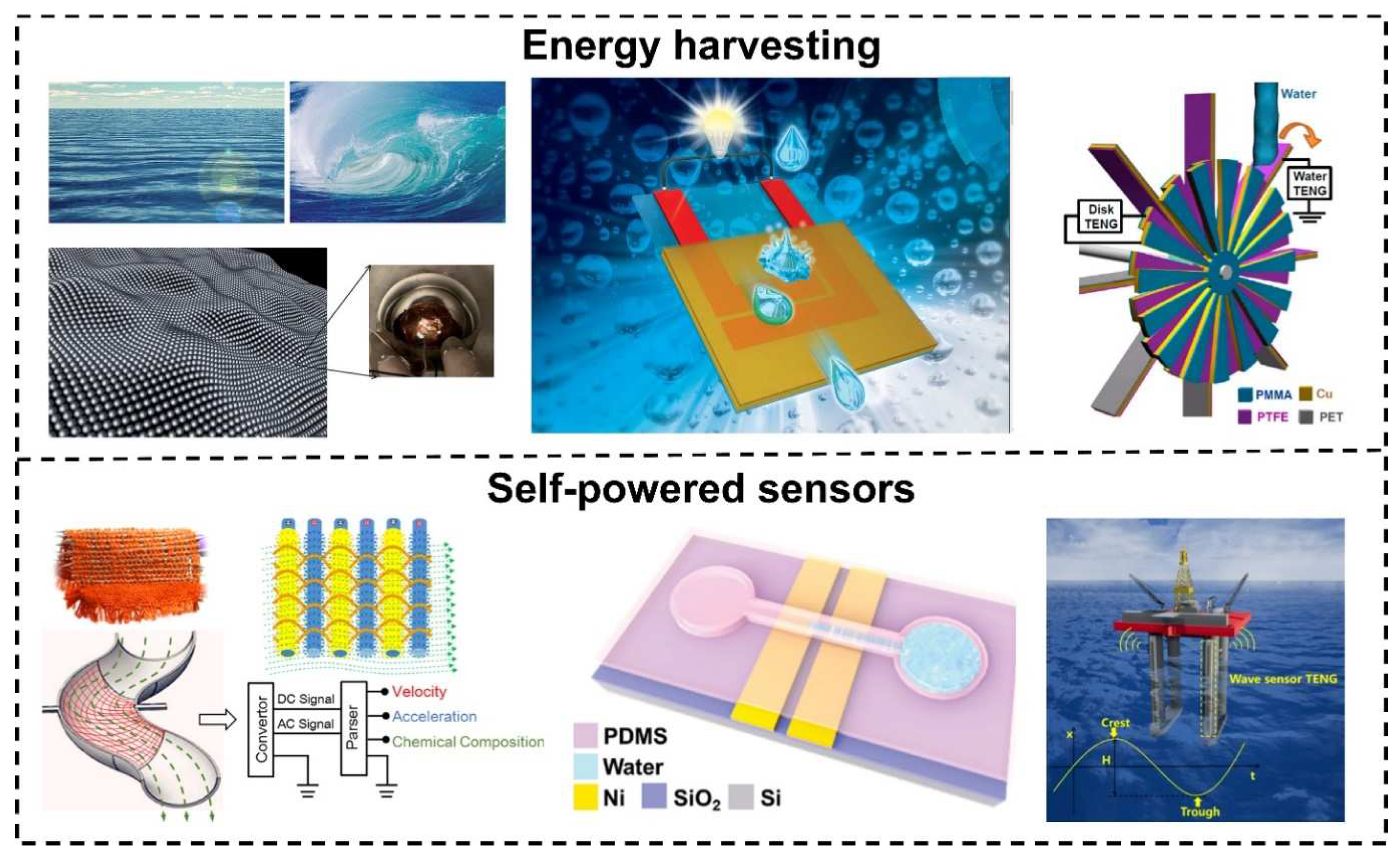

1. Introduction

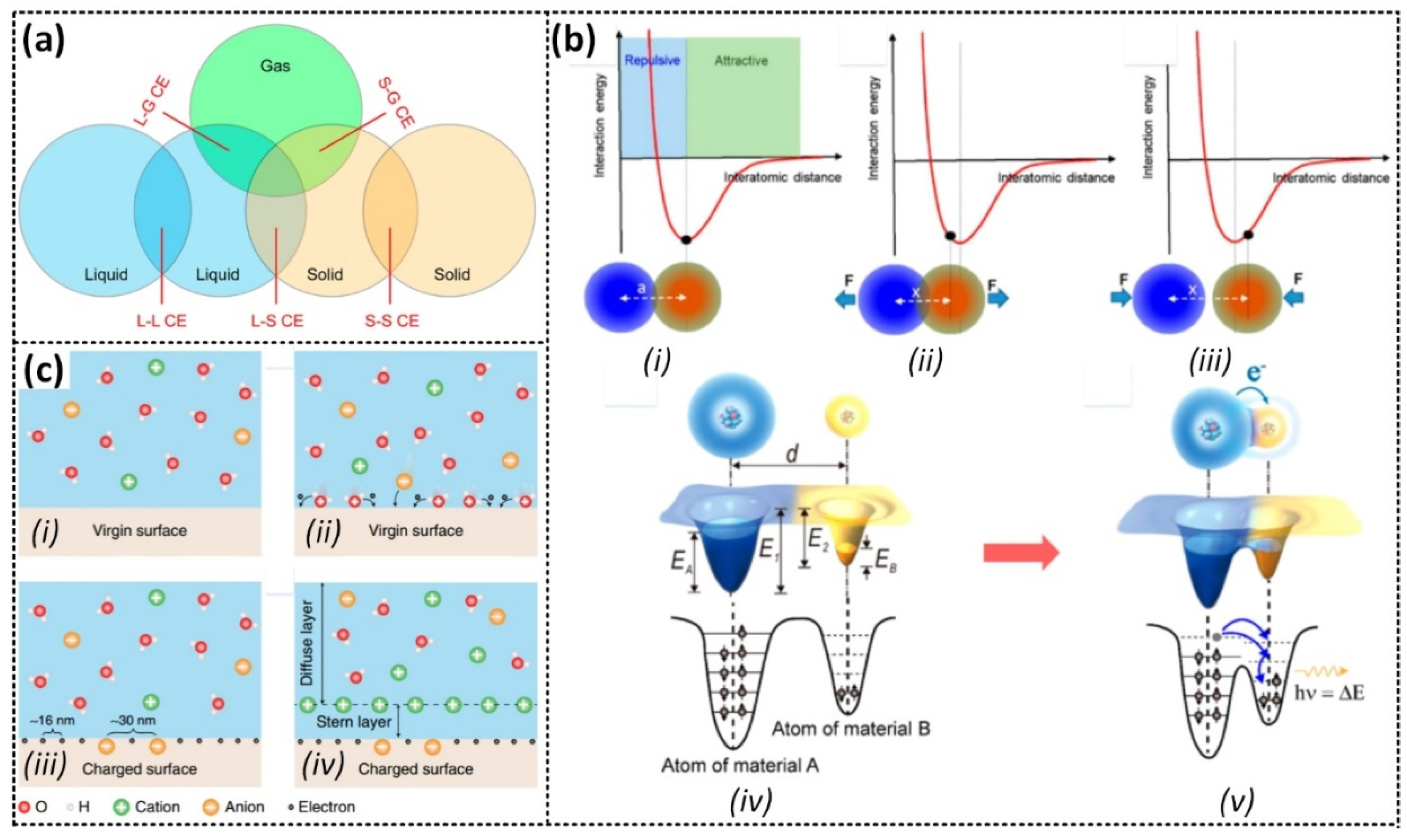

2. Liquid-Solid Contact Triboelectric Nanogenerator

2.1. Mechanism of Liquid-Solid Contact Electrification

2.2. Basic Mode of Operation of Liquid-Solid Triboelectric Nanogenerator

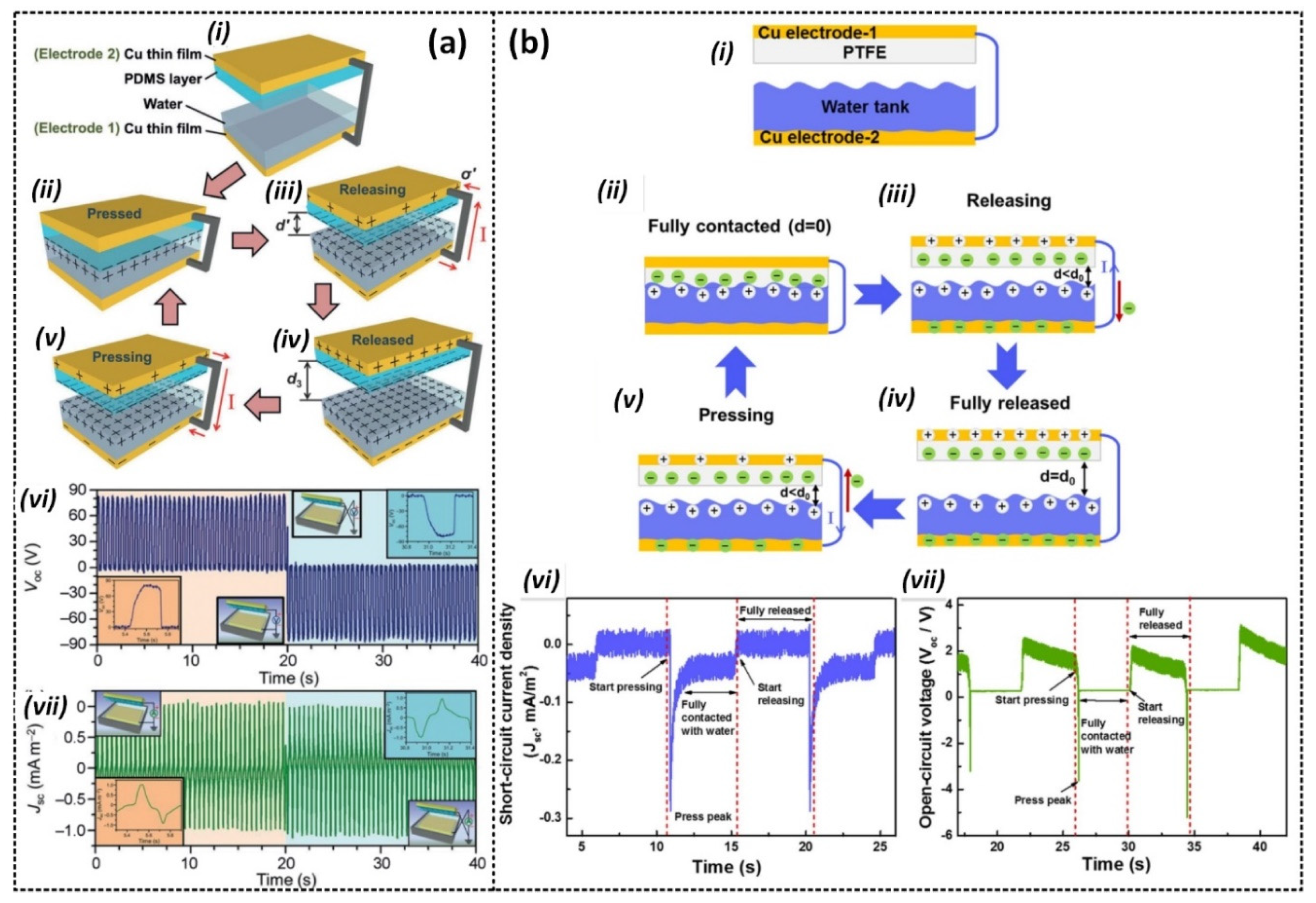

2.2.1. Contact-Separation Mode

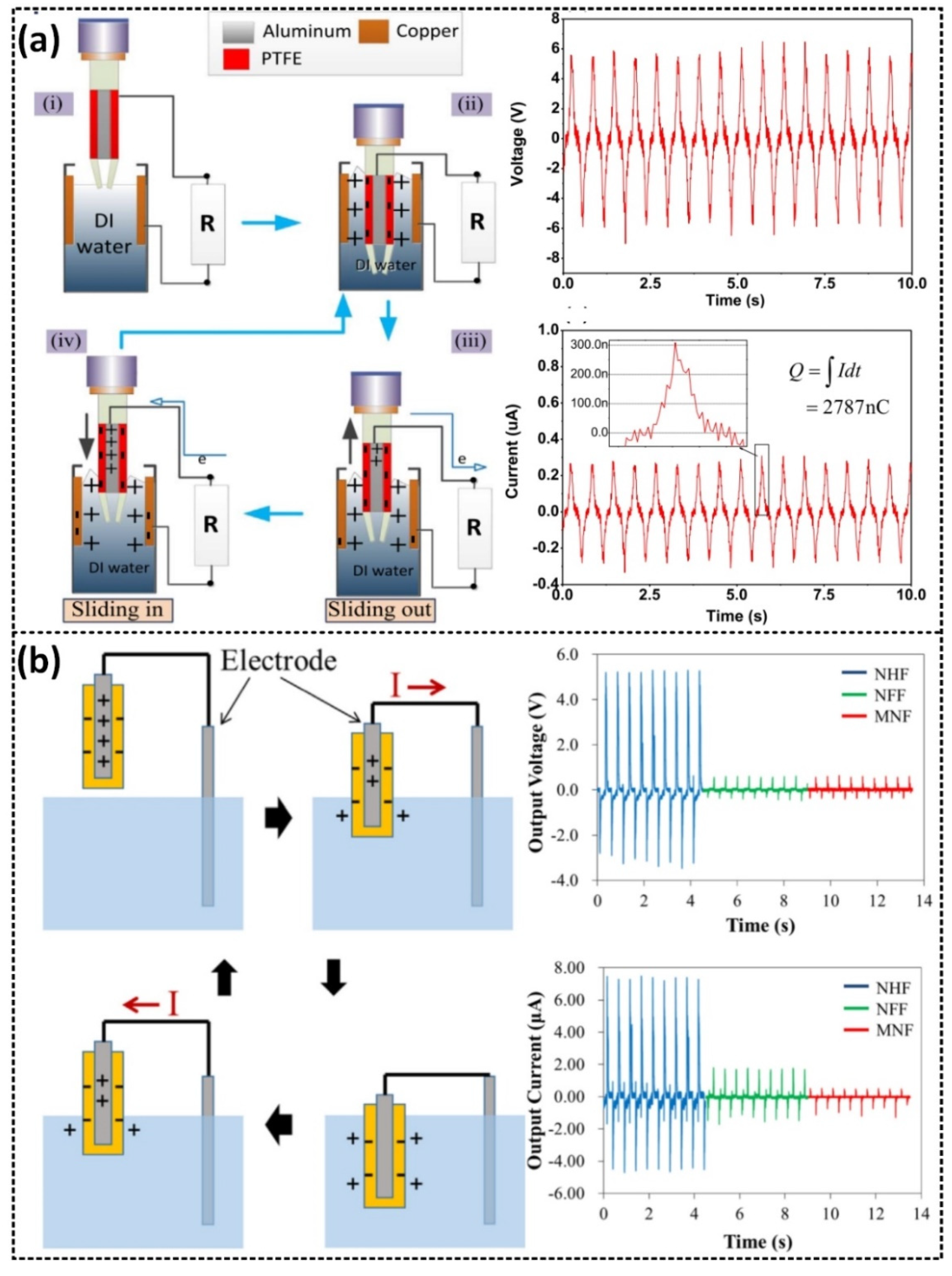

2.2.2. Lateral Sliding Mode

2.2.3. Free-standing Mode

2.2.4. Single-electrode Mode

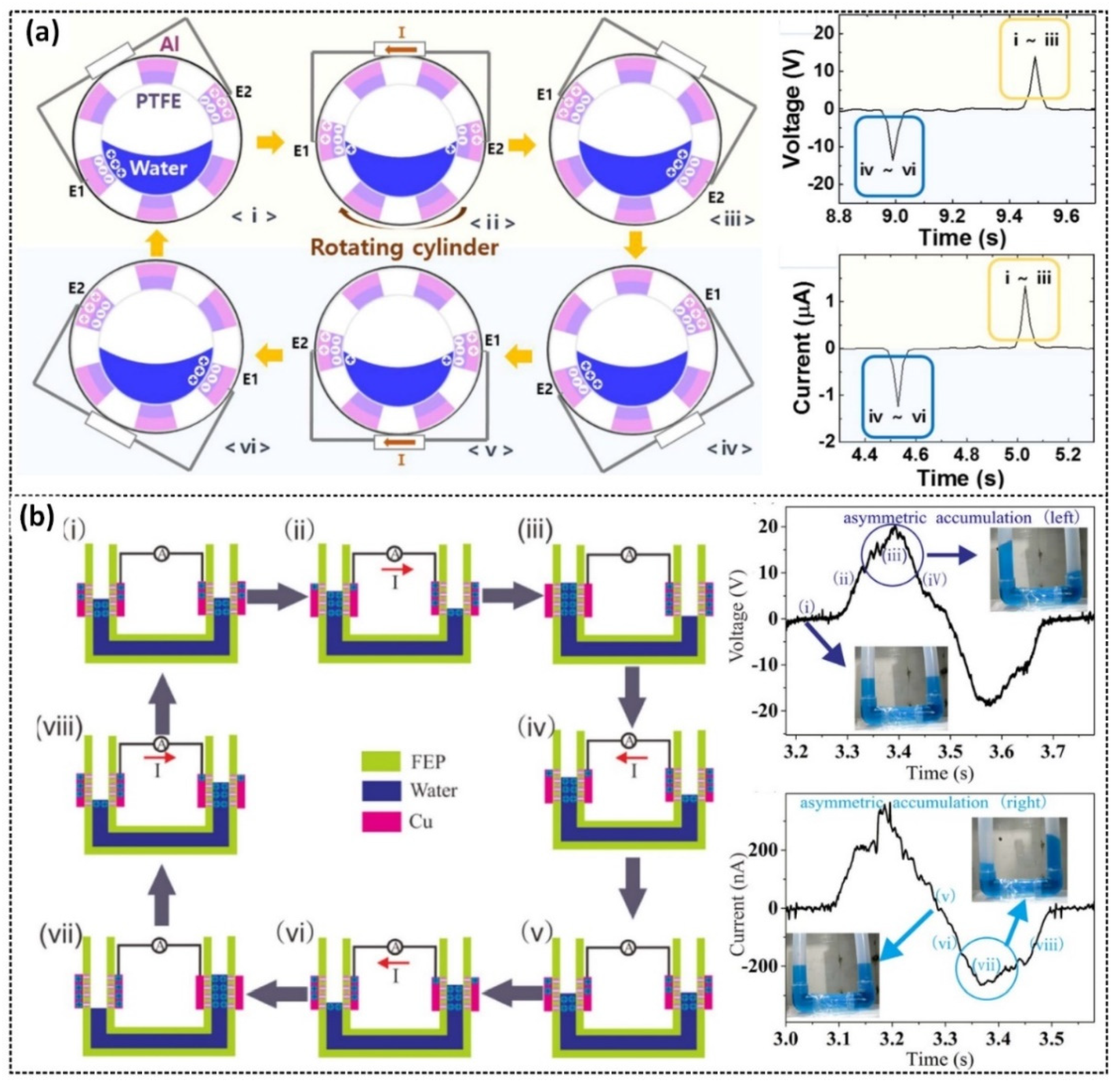

2.3. Interacting Modes of Liquid-Solid Triboelectric Nanogenerator

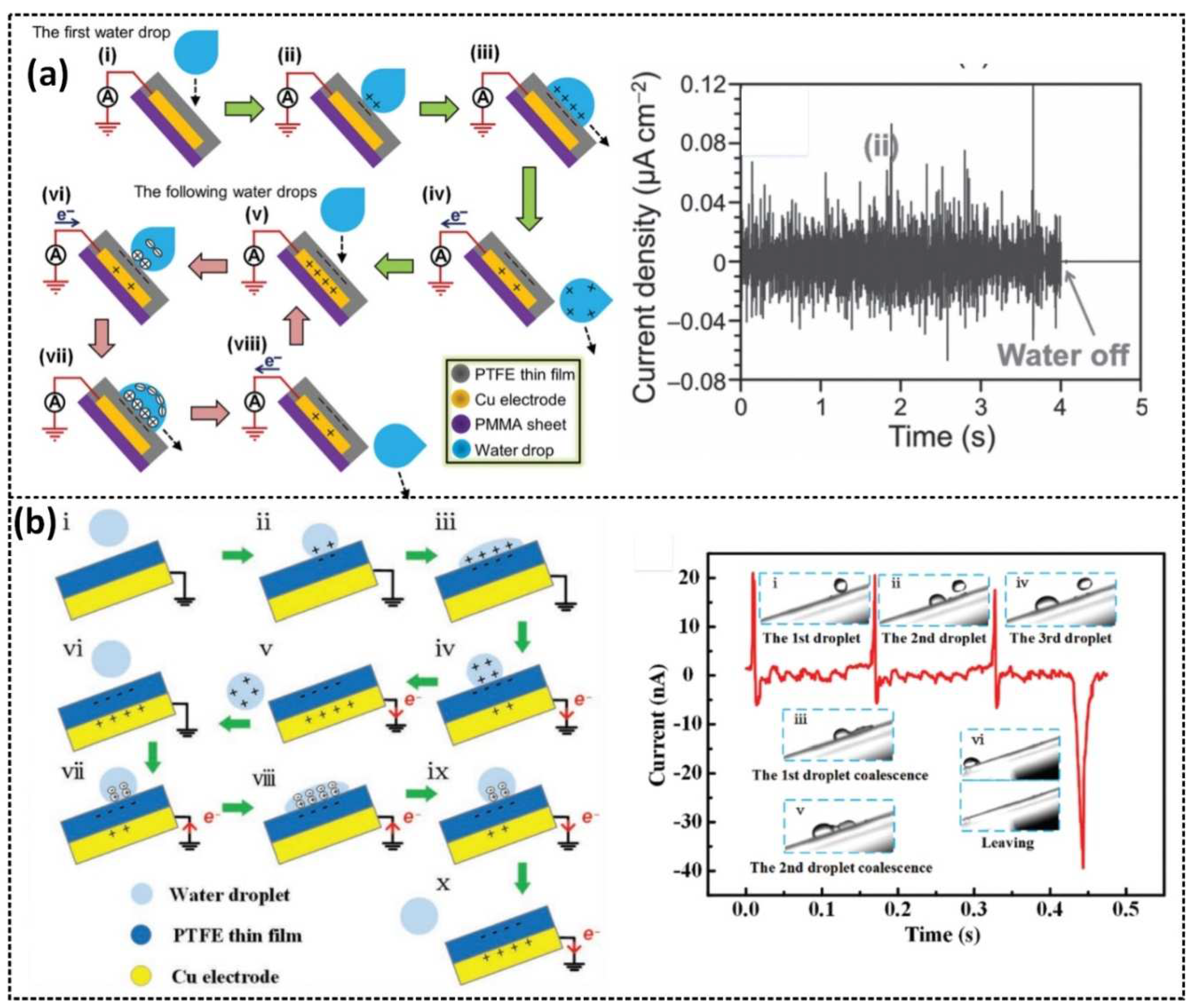

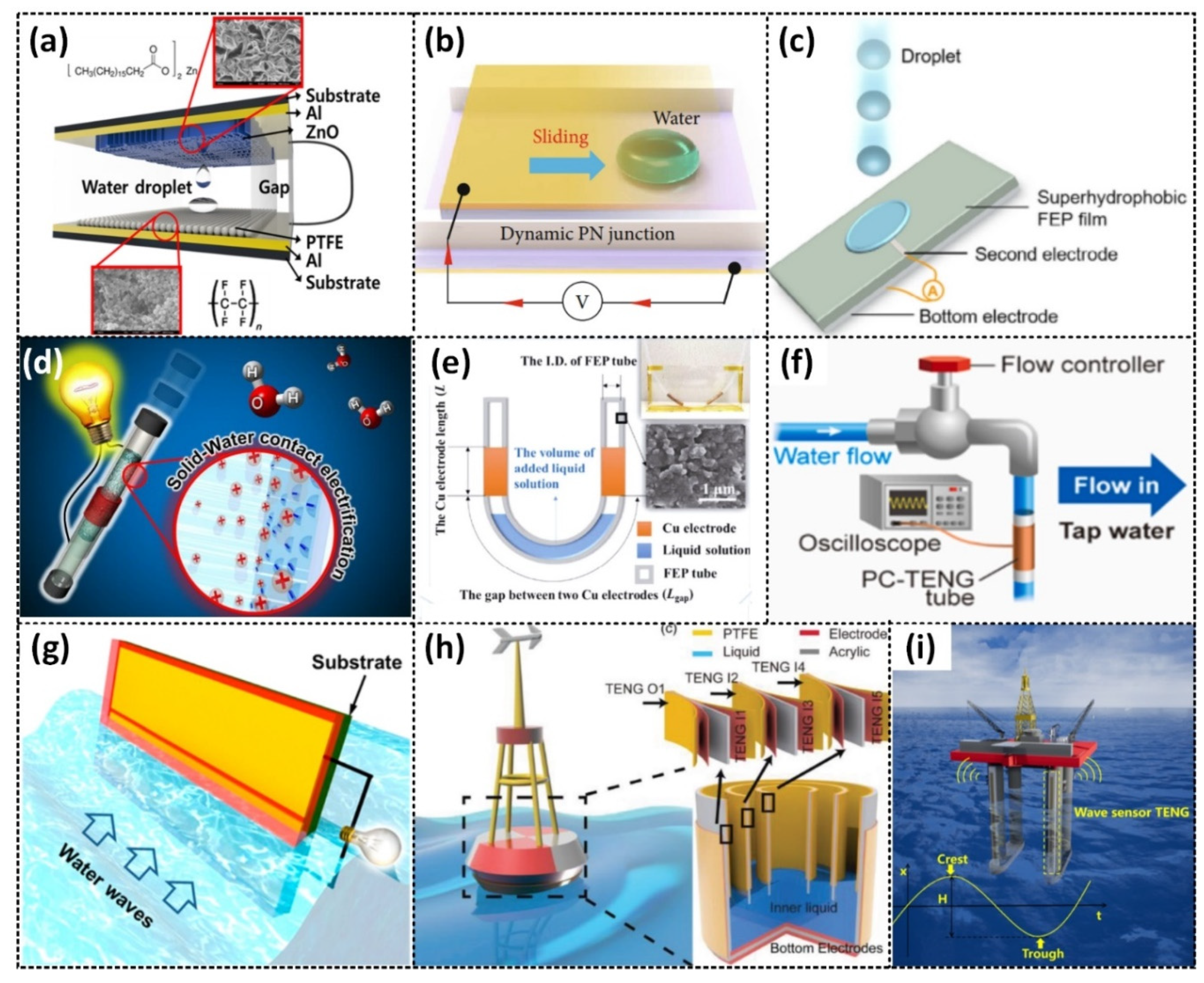

2.3.1. Droplet-based L-S TENG

2.3.2. Flow-based LS-TENG

2.3.3. Wave-based LS-TENG

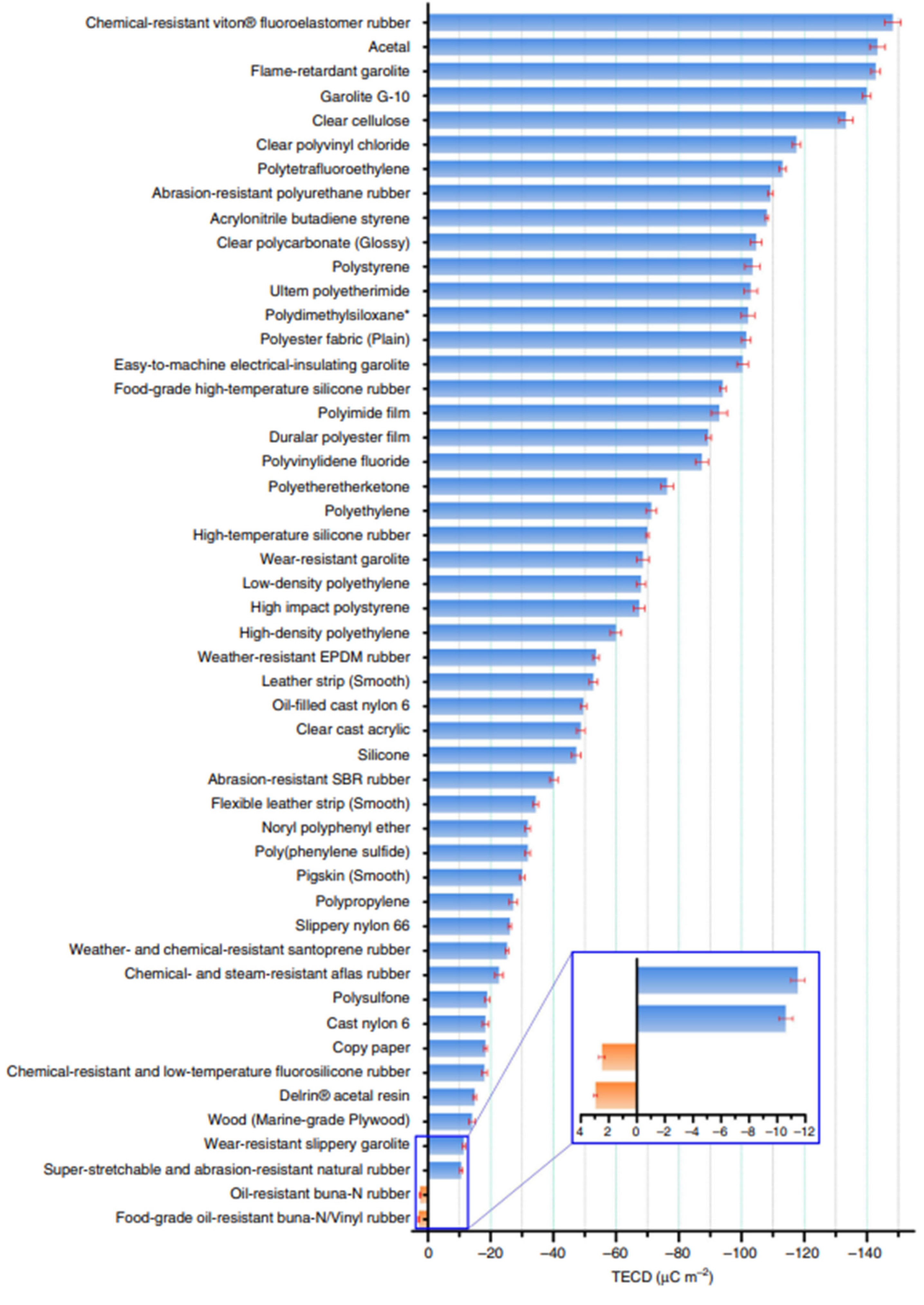

3. Affecting parameter on L-S TENG performance

4. L-S TENG as self-powered active pressure/touch sensors

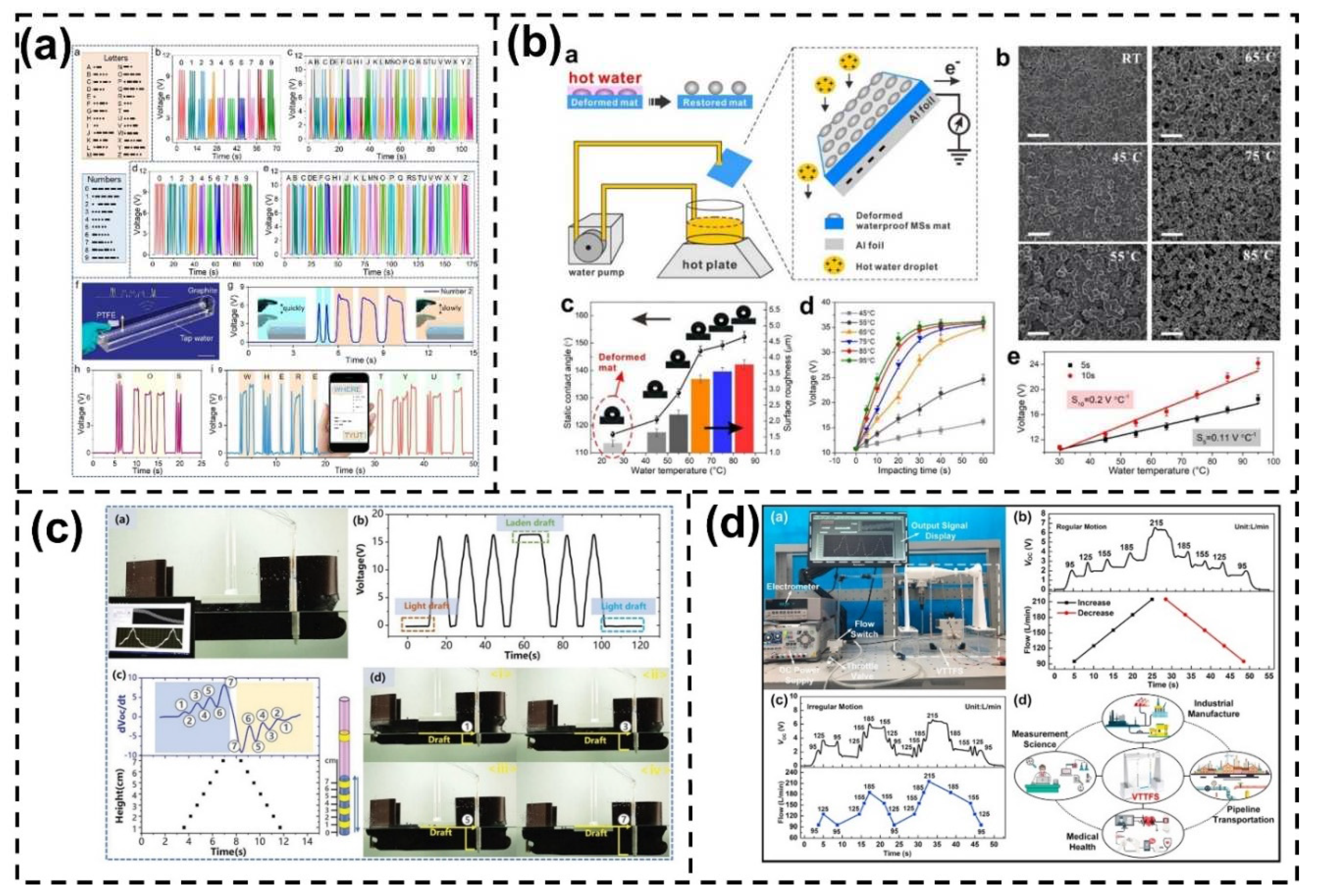

4.1. L-S TENGs as self-powered physical sensors

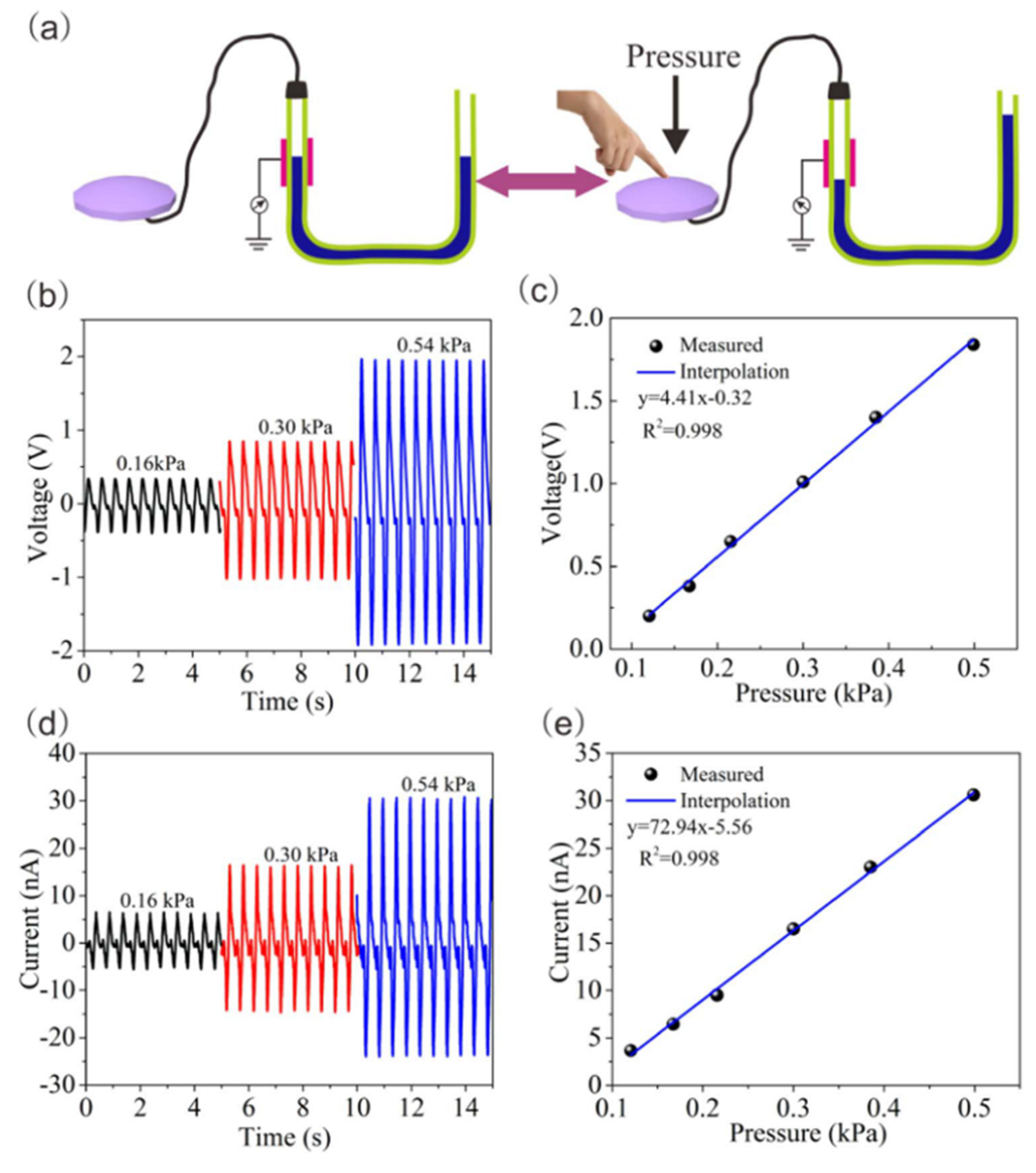

4.2. L-S TENGs as self-powered pressure/force sensors

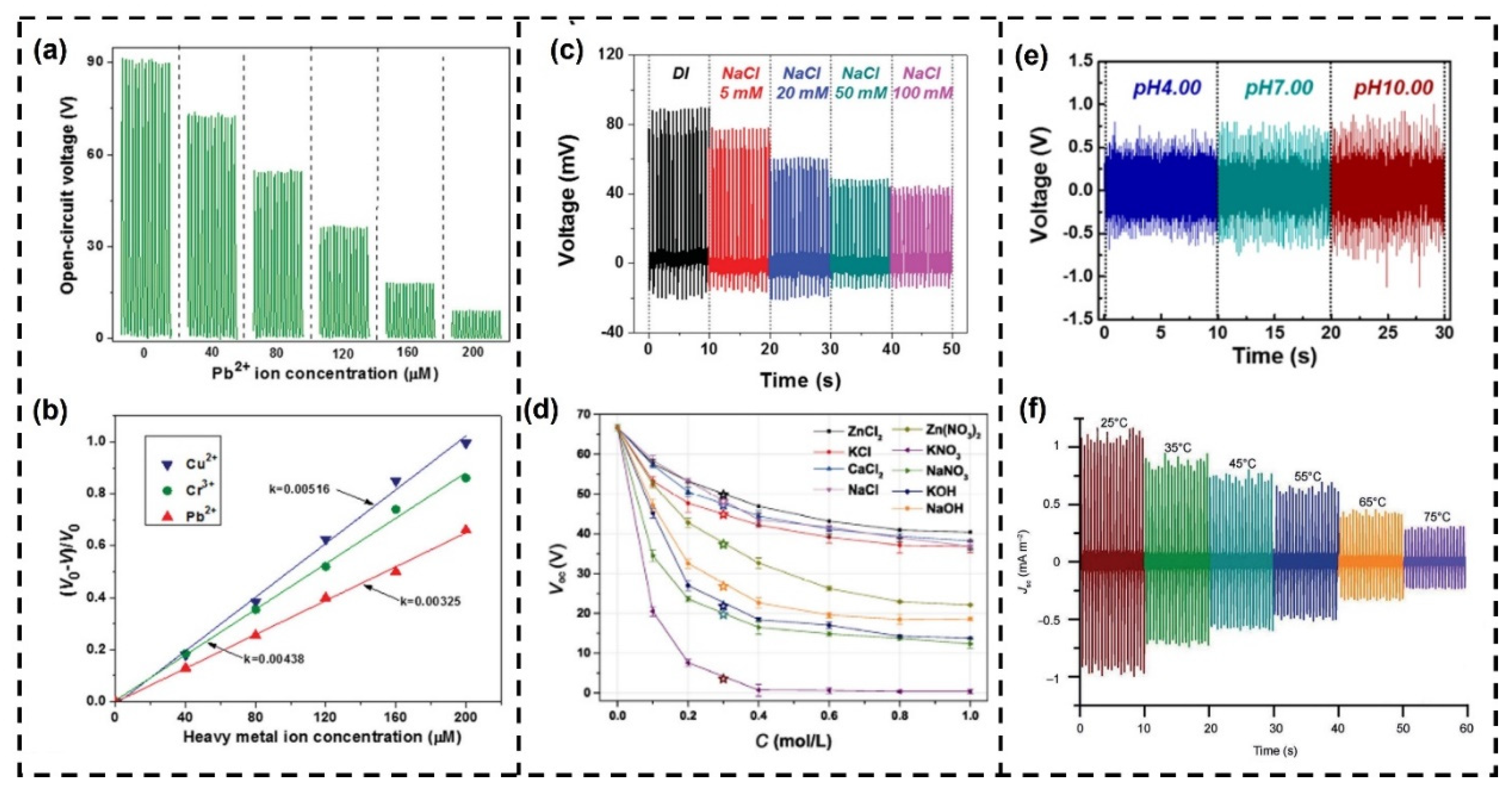

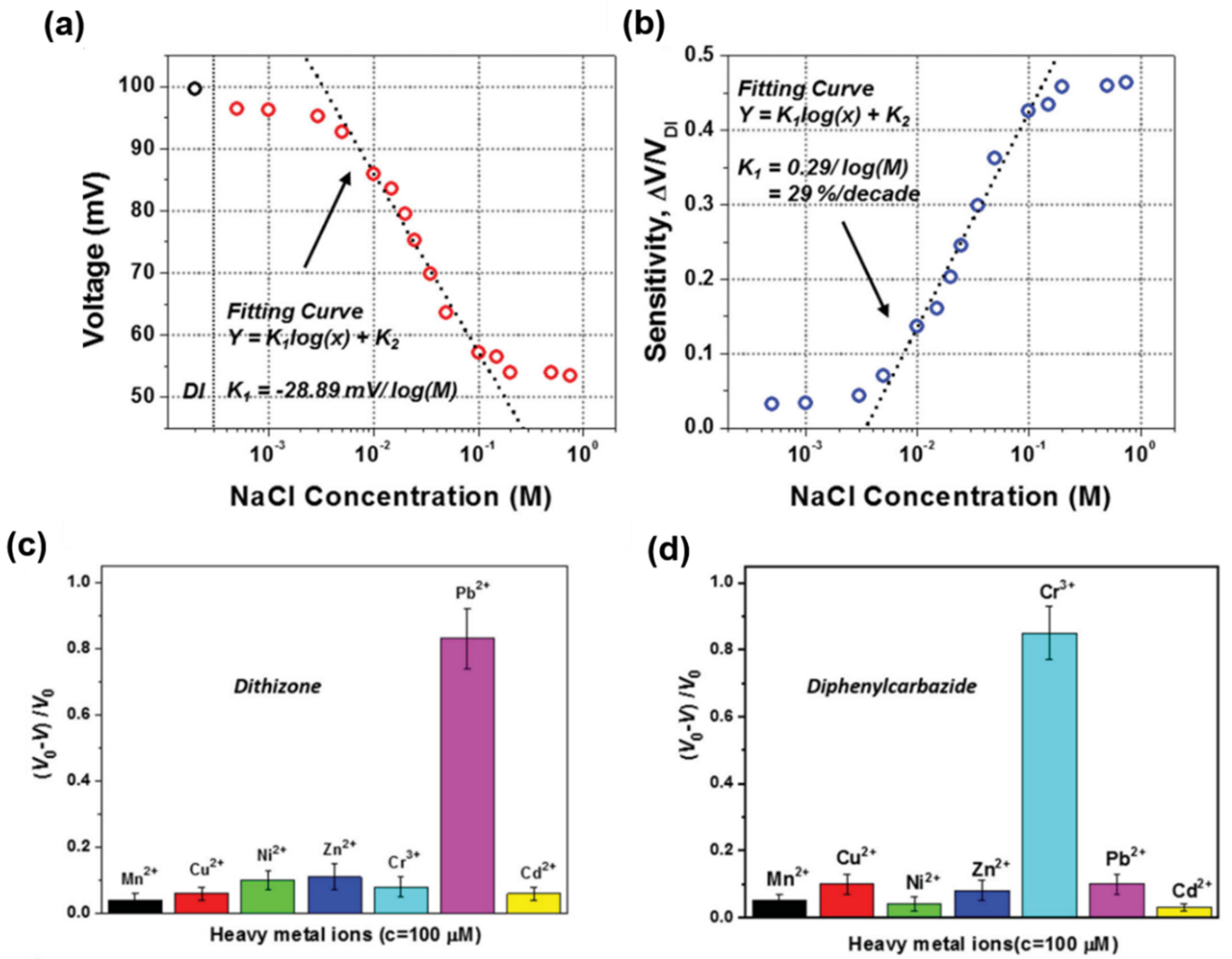

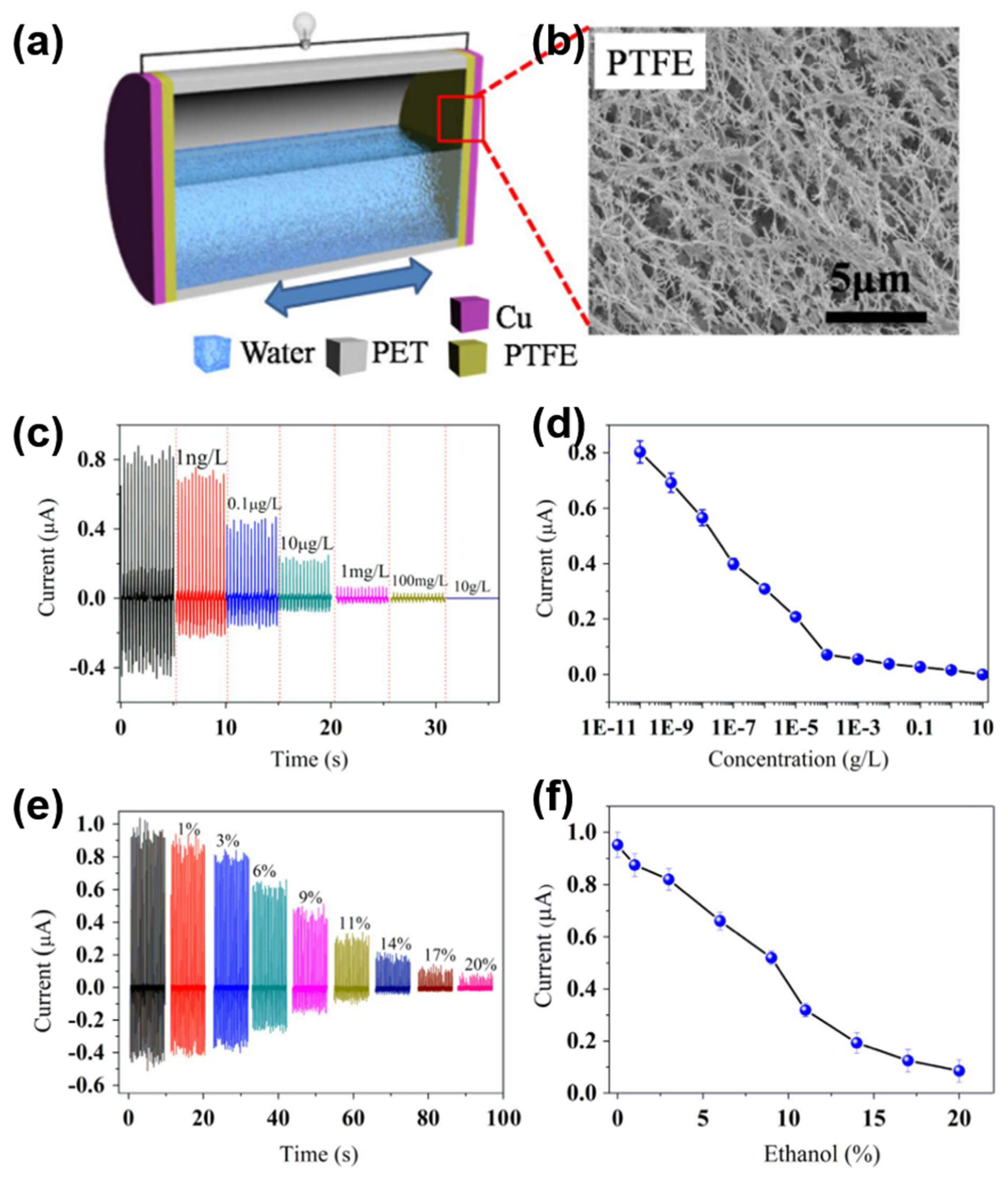

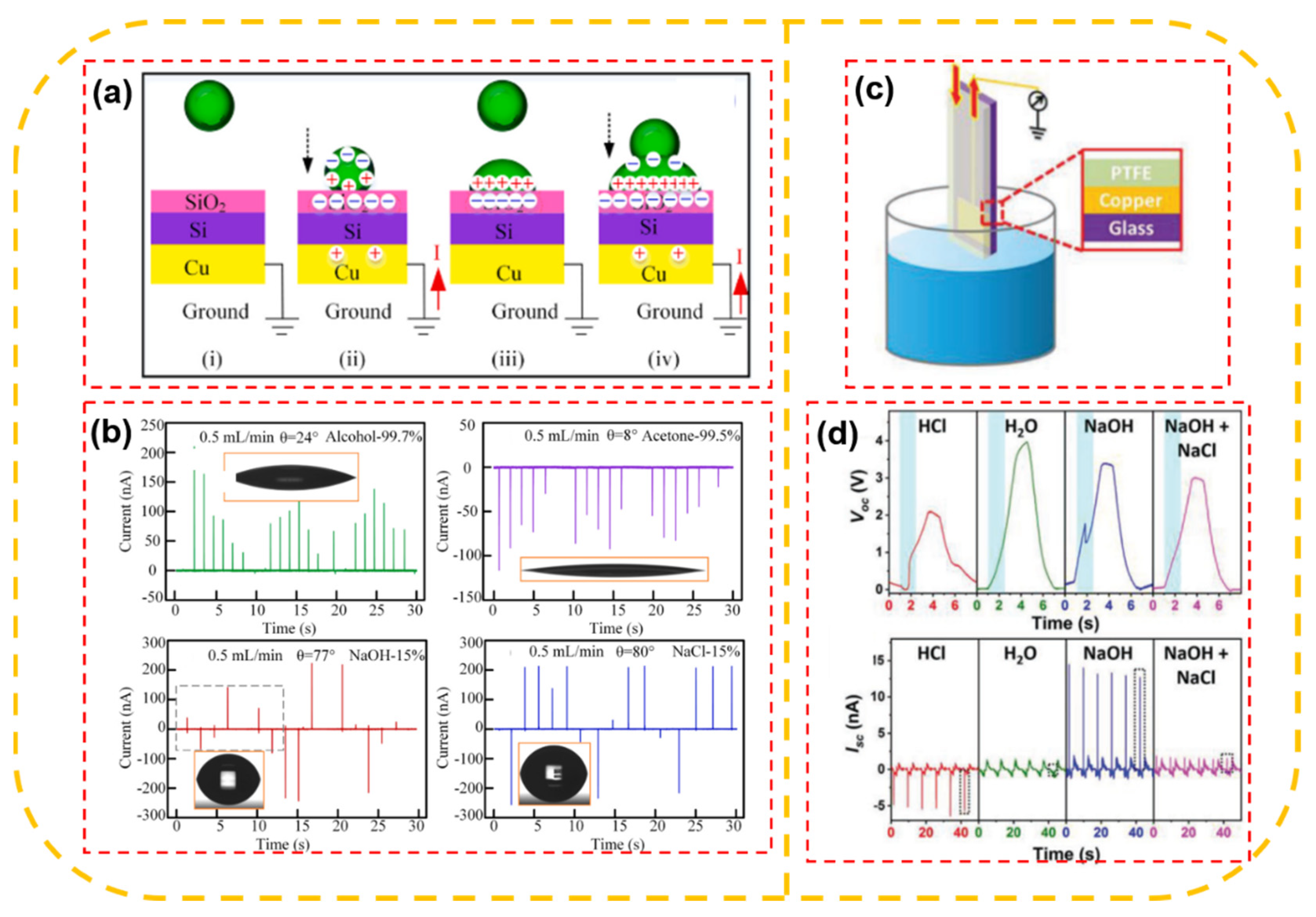

5. L-S TENGs as self-powered chemical/environment sensors

6. Conclusion

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Cai, G.; Liang, Y.; Liu, Z.; Liu, W. Design and optimization of bio-inspired wave-like channel for a PEM fuel cell applying genetic algorithm. Energy. 2020, 192. [Google Scholar] [CrossRef]

- Muetze, A.; Vining, J.G. Ocean Wave Energy Conversion - A Survey. Conference Record of the 2006 IEEE Industry Applications Conference Forty-First IAS Annual Meeting2006. p. 1410-7.

- Sabzehgar, R.; Moallem, M. A review of ocean wave energy conversion systems. 2009 IEEE Electrical Power & Energy Conference (EPEC)2009. p. 1-6.

- Chang, C.; Tran, V.H.; Wang, J.; Fuh, Y.-K.; LinL. Direct-write piezoelectric polymeric nanogenerator with high energy conversion efficiency. Nano Lett. 2010, 10, 726–731. [Google Scholar] [CrossRef] [PubMed]

- Zhang, C.; Tang, W.; Han, C.; Fan, F.; Wang, Z.L. Theoretical comparison, equivalent transformation, and conjunction operations of electromagnetic induction generator and triboelectric nanogenerator for harvesting mechanical energy. Adv Mater. 2014, 26, 3580–3591. [Google Scholar] [CrossRef] [PubMed]

- Wang, X.; Song, J.; Liu, J.; Wang, Z.L. Direct-current nanogenerator driven by ultrasonic waves. Science. 2007, 316, 102–105. [Google Scholar] [CrossRef] [PubMed]

- Wang, Z.L.; Jun, L.L.; Simiao, C.; Zi, N.Y. Triboelectric Nanogenerators2016.

- Jiang, D.; Xu, M.; Dong, M.; Guo, F.; Liu, X.; Chen, G.; et al. Water-solid triboelectric nanogenerators: An alternative means for harvesting hydropower. Renew Sustain Energy Rev. 2019, 115. [Google Scholar] [CrossRef]

- Wang, Z.L.; Jiang, T.; Xu, L. Toward the blue energy dream by triboelectric nanogenerator networks. Nano Energy. 2017, 39, 9–23. [Google Scholar] [CrossRef]

- Bai, P.; Zhu, G.; Lin, Z.-H.; Jing, Q.; Chen, J.; Zhang, G.; et al. Integrated multilayered triboelectric nanogenerator for harvesting biomechanical energy from human motions. ACS Nano. 2013, 7, 3713–3719. [Google Scholar] [CrossRef]

- Wang, Z.L.; Chen, J.; Lin, L. Progress in triboelectric nanogenerators as a new energy technology and self-powered sensors. Energy Environ Sci. 2015, 8, 2250–2282. [Google Scholar] [CrossRef]

- Fan, F.-R.; Tian, Z.-Q.; Lin Wang, Z. Flexible triboelectric generator. Nano Energy. 2012, 1, 328–334. [Google Scholar] [CrossRef]

- Lee, S.; Chung, J.; Kim, D.Y.; Jung, J.Y.; Lee, S.H.; Lee, S. Cylindrical water triboelectric nanogenerator via controlling geometrical shape of anodized aluminum for enhanced electrostatic induction. ACS Appl Mater Interfaces. 2016, 8, 25014–25018. [Google Scholar] [CrossRef]

- Zhu, G.; Lin, Z.H.; Jing, Q.; Bai, P.; Pan, C.; Yang, Y. , et al. Toward large-scale energy harvesting by a nanoparticle-enhanced triboelectric nanogenerator. Nano Lett. 2013, 13, 847–853. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.H.; Cheng, G.; Lee, S.; Pradel, K.C.; Wang, Z.L. Harvesting water drop energy by a sequential contact-electrification and electrostatic-induction process. Adv Mater. 2014, 26, 4690–4696. [Google Scholar] [CrossRef]

- Wang, Y.; Yang, Y.; Wang, Z.L. Triboelectric nanogenerators as flexible power sources. npj Flex Electron. 2017, 1. [Google Scholar] [CrossRef]

- Cheedarala, R.K.; Duy, L.C.; Ahn, K.K. Double characteristic BNO-SPI-TENGs for robust contact electrification by vertical contact separation mode through ion and electron charge transfer. Nano Energy. 2018, 44, 430–437. [Google Scholar] [CrossRef]

- Shi, Q.; He, T.; Lee, C. More than energy harvesting – Combining triboelectric nanogenerator and flexible electronics technology for enabling novel micro-/nano-systems. Nano Energy. 2019, 57, 851–871. [Google Scholar] [CrossRef]

- Pan, L.; Wang, J.; Wang, P.; Gao, R.; Wang, Y.-C.; Zhang, X.; et al. Liquid-FEP-based U-tube triboelectric nanogenerator for harvesting water-wave energy. Nano Res. 2018, 11, 4062–4073. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, Y.; Wang, D.; Zhou, F. Solid-liquid triboelectrification in smart U-tube for multifunctional sensors. Nano Energy. 2017, 40, 95–106. [Google Scholar] [CrossRef]

- Seol, M.-L.; Jeon, S.-B.; Han, J.-W.; Choi, Y.-K. Ferrofluid-based triboelectric-electromagnetic hybrid generator for sensitive and sustainable vibration energy harvesting. Nano Energy. 2017, 31, 233–238. [Google Scholar] [CrossRef]

- Zhao, X.J.; Tian, J.J.; Kuang, S.Y.; Ouyang, H.; Yan, L.; Wang, Z.L.; et al. Biocide-free antifouling on insulating surface by wave-driven triboelectrification-induced potential oscillation. Adv Mater Interfaces. 2016, 3, 1600187. [Google Scholar] [CrossRef]

- Vu, D.L.; Ahn, K.K. Triboelectric enhancement of polyvinylidene fluoride membrane using magnetic nanoparticle for water-based energy harvesting. Polymers (Basel). 2022, 14, 1547. [Google Scholar] [CrossRef]

- Le, C.-D.; Vo, C.-P.; Nguyen, T.-H.; Vu, D.-L.; Ahn, K.K. Liquid-solid contact electrification based on discontinuous-conduction triboelectric nanogenerator induced by radially symmetrical structure. Nano Energy. 2021, 80, 105571. [Google Scholar] [CrossRef]

- Tang, W.; Jiang, T.; Fan, F.R.; Yu, A.F.; Zhang, C.; Cao, X.; et al. Liquid-Metal Electrode for High-Performance Triboelectric Nanogenerator at an Instantaneous Energy Conversion Efficiency of 70. 6%. Adv Funct Mater. 2015, 25, 3718–3725. [Google Scholar] [CrossRef]

- Zhao, X.J.; Zhu, G.; Fan, Y.J.; Li, H.Y.; Wang, Z.L. Triboelectric Charging at the Nanostructured Solid/Liquid Interface for Area-Scalable Wave Energy Conversion and Its Use in Corrosion Protection. Acs Nano. 2015, 9, 7671–7677. [Google Scholar] [CrossRef] [PubMed]

- Cheedarala, R.K.; Shahriar, M.; Ahn, J.H.; Hwang, J.Y.; Ahn, K.K. Harvesting liquid stream energy from unsteady peristaltic flow induced pulsatile Flow-TENG (PF-TENG) using slipping polymeric surface inside elastomeric tubing. Nano Energy. 2019, 65. [Google Scholar] [CrossRef]

- Wang, Z.L. Triboelectric nanogenerators as new energy technology and self-powered sensors - principles, problems and perspectives. Faraday Discuss. 2014, 176, 447–458. [Google Scholar] [CrossRef] [PubMed]

- Kwon, S.-H.; Park, J.; Kim, W.K.; Yang, Y.; Lee, E.; Han, C.J.; et al. An effective energy harvesting method from a natural water motion active transducer. Energy Environ Sci. 2014, 7, 3279–3283. [Google Scholar] [CrossRef]

- Cheng, G.; Lin, Z.-H.; Du Z-l Wang, Z.L. Simultaneously Harvesting Electrostatic and Mechanical Energies from Flowing Water by a Hybridized Triboelectric Nanogenerator. ACS Nano. 2014, 8, 1932–1939. [Google Scholar] [CrossRef]

- Zhang, L.; Zhang, N.; Yang, Y.; Xiang, S.; Tao, C.; Yang, S.; et al. Self-powered all-in-one fluid sensor textile with enhanced triboelectric effect on all-immersed dendritic liquid-solid interface. ACS Appl Mater Interfaces. 2018, 10, 30819–30826. [Google Scholar] [CrossRef]

- Jeon, S.-B.; Seol, M.-L.; Kim, D.; Park, S.-J.; Choi, Y.-K. Self-powered ion concentration sensor with triboelectricity from liquid-solid contact electrification. Adv Electron Mater. 2016, 2, 1600006. [Google Scholar] [CrossRef]

- Xu, M.; Wang, S.; Zhang, S.L.; Ding, W.; Kien, P.T.; Wang, C.; et al. A highly-sensitive wave sensor based on liquid-solid interfacing triboelectric nanogenerator for smart marine equipment. Nano Energy. 2019, 57, 574–580. [Google Scholar] [CrossRef]

- Kim, W.; Choi, D.; Kwon, J.-Y.; Choi, D. A self-powered triboelectric microfluidic system for liquid sensing. J Mate Chem A. 2018, 6, 14069–14076. [Google Scholar] [CrossRef]

- Yi, F.; Wang, X.; Niu, S.; Li, S.; Yin, Y.; Dai, K.; et al. A highly shape-adaptive, stretchable design based on conductive liquid for energy harvesting and self-powered biomechanical monitoring. Sci Adv. 2016, 2, e1501624. [Google Scholar] [CrossRef]

- Cui, S.; Zheng, Y.; Zhang, T.; Wang, D.; Zhou, F.; Liu, W. Self-powered ammonia nanosensor based on the integration of the gas sensor and triboelectric nanogenerator. Nano Energy. 2018, 49, 31–39. [Google Scholar] [CrossRef]

- Wang, H.; Wu, H.; Hasan, D.; He, T.; Shi, Q.; Lee, C. Self-powered dual-mode amenity sensor based on the water-air triboelectric nanogenerator. ACS Nano. 2017, 11, 10337–10346. [Google Scholar] [CrossRef]

- Zhou, L.; Liu, D.; Wang, J.; Wang, Z.L. Triboelectric nanogenerators: Fundamental physics and potential applications. Friction. 2020, 8, 481–506. [Google Scholar] [CrossRef]

- Wang, Z.L.; Wang, A.C. On the origin of contact-electrification. Mater Today. 2019, 30, 34–51. [Google Scholar] [CrossRef]

- Lin, S.; Chen, X.; Wang, Z.L. Contact Electrification at the Liquid–Solid Interface. Chemical Reviews. 2021, 122, 5209–5232. [Google Scholar] [CrossRef]

- Lin, S.; Xu, L.; Chi Wang, A.; Wang, Z.L. Quantifying electron-transfer in liquid-solid contact electrification and the formation of electric double-layer. Nat Commun. 2020, 11, 399. [Google Scholar] [CrossRef]

- Nie, J.; Ren, Z.; Xu, L.; Lin, S.; Zhan, F.; Chen, X.; et al. Probing Contact-Electrification-Induced Electron and Ion Transfers at a Liquid-Solid Interface. Adv Mater. 2020, 32, e1905696. [Google Scholar] [CrossRef]

- Lin, Z.H.; Cheng, G.; Lin, L.; Lee, S.; Wang, Z.L. Water-solid surface contact electrification and its use for harvesting liquid-wave energy. Angew Chem Int Ed Engl. 2013, 52, 12545–12549. [Google Scholar] [CrossRef]

- Kim, T.; Kim, D.Y.; Yun, J.; Kim, B.; Lee, S.H.; Kim, D.; et al. Direct-current triboelectric nanogenerator via water electrification and phase control. Nano Energy. 2018, 52, 95–104. [Google Scholar] [CrossRef]

- Lee, J.H.; Kim, S.; Kim, T.Y.; Khan, U.; Kim, S.-W. Water droplet-driven triboelectric nanogenerator with superhydrophobic surfaces. Nano Energy. 2019, 58, 579–584. [Google Scholar] [CrossRef]

- Yang, X.; Chan, S.; Wang, L.; Daoud, W.A. Water tank triboelectric nanogenerator for efficient harvesting of water wave energy over a broad frequency range. Nano Energy. 2018, 44, 388–398. [Google Scholar] [CrossRef]

- Lee, J.-W.; Hwang, W. Theoretical study of micro/nano roughness effect on water-solid triboelectrification with experimental approach. Nano Energy. 2018, 52, 315–322. [Google Scholar] [CrossRef]

- Nahian, S.A.; Cheedarala, R.K.; Ahn, K.K. A study of sustainable green current generated by the fluid-based triboelectric nanogenerator (FluTENG) with a comparison of contact and sliding mode. Nano Energy. 2017, 38, 447–456. [Google Scholar] [CrossRef]

- Zhang, X.; Zheng, Y.; Wang, D.; Rahman, Z.U.; Zhou, F. Liquid–solid contact triboelectrification and its use in self-powered nanosensor for detecting organics in water. Nano Energy. 2016, 30, 321–329. [Google Scholar] [CrossRef]

- Huang, T.; Hao, X.; Li, M.; He, B.; Sun, W.; Zhang, K.; et al. A Multifunction Freestanding Liquid-Solid Triboelectric Nanogenerator Based on Low-Frequency Mechanical Sloshing. ACS Appl Mater Interfaces. 2022, 14, 54716–54724. [Google Scholar] [CrossRef]

- Guang Zhu, Y.S.; Bai, P.; Chen, J.; Jing, Q.; Yang, W.; Wang, Z.L. Harvesting Water Wave Energy by Asymmetric Screening of Electrostatic Charges on a Nanostructured Hydrophobic Thin-Film Surface. ACS Nano. 2014, 8, 6031–6037. [Google Scholar]

- Zhao, X.J.; Kuang, S.Y.; Wang, Z.L.; Zhu, G. Highly adaptive solid-liquid interfacing triboelectric nanogenerator for harvesting diverse water wave energy. ACS Nano. 2018, 12, 4280–4285. [Google Scholar] [CrossRef]

- Choi, D.; Kim, D.W.; Yoo, D.; Cha, K.J.; La, M.; Kim, D.S. Spontaneous occurrence of liquid-solid contact electrification in nature: Toward a robust triboelectric nanogenerator inspired by the natural lotus leaf. Nano Energy. 2017, 36, 250–259. [Google Scholar] [CrossRef]

- Jang, S.; La, M.; Cho, S.; Yun, Y.; Choi, J.H.; Ra, Y.; et al. Monocharged electret based liquid-solid interacting triboelectric nanogenerator for its boosted electrical output performance. Nano Energy. 2020, 70. [Google Scholar] [CrossRef]

- Kil Yun, B.; Soo Kim, H.; Joon Ko, Y.; Murillo, G.; Hoon Jung, J. Interdigital electrode based triboelectric nanogenerator for effective energy harvesting from water. Nano Energy. 2017, 36, 233–240. [Google Scholar] [CrossRef]

- Kim, T.; Chung, J.; Kim, D.Y.; Moon, J.H.; Lee, S.; Cho, M.; et al. Design and optimization of rotating triboelectric nanogenerator by water electrification and inertia. Nano Energy. 2016, 27, 340–351. [Google Scholar] [CrossRef]

- Le, C.-D.; Vo, C.-P.; Nguyen, T.-H.; Vu, D.-L.; Ahn, K.K. Liquid-solid contact electrification based on discontinuous-conduction triboelectric nanogenerator induced by radially symmetrical structure. Nano Energy. 2021, 80. [Google Scholar] [CrossRef]

- Li, C.; Liu, X.; Yang, D.; Liu, Z. Triboelectric nanogenerator based on a moving bubble in liquid for mechanical energy harvesting and water level monitoring. Nano Energy. 2022, 95. [Google Scholar] [CrossRef]

- Liu, L.; Shi, Q.; Ho, J.S.; Lee, C. Study of thin film blue energy harvester based on triboelectric nanogenerator and seashore IoT applications. Nano Energy. 2019, 66. [Google Scholar] [CrossRef]

- Yoo, D.; Park, S.-C.; Lee, S.; Sim, J.-Y.; Song, I.; Choi, D.; et al. Biomimetic anti-reflective triboelectric nanogenerator for concurrent harvesting of solar and raindrop energies. Nano Energy. 2019, 57, 424–431. [Google Scholar] [CrossRef]

- Yu, J.; Ma, T. Triboelectricity-based self-charging droplet capacitor for harvesting low-level ambient energy. Nano Energy. 2020, 74. [Google Scholar] [CrossRef]

- Choi, D.; Lee, S.; Park, S.M.; Cho, H.; Hwang, W.; Kim, D.S. Energy harvesting model of moving water inside a tubular system and its application of a stick-type compact triboelectric nanogenerator. Nano Research. 2015, 8, 2481–2491. [Google Scholar] [CrossRef]

- Lu, Y.; Yan, Y.; Yu, X.; Zhou, X.; Feng, S.; Xu, C.; et al. Polarized Water Driven Dynamic PN Junction-Based Direct-Current Generator. Research (Wash D C). 2021, 2021, 7505638. [Google Scholar] [CrossRef]

- Zhang, J.; Lin, S.; Zheng, M.; Wang, Z.L. Triboelectric Nanogenerator as a Probe for Measuring the Charge Transfer between Liquid and Solid Surfaces. ACS Nano. 2021, 15, 14830–14837. [Google Scholar] [CrossRef]

- Li, X.; Tao, J.; Wang, X.; Zhu, J.; Pan, C.; Wang, Z.L. Networks of High Performance Triboelectric Nanogenerators Based on Liquid-Solid Interface Contact Electrification for Harvesting Low-Frequency Blue Energy. Adv Energy Mater. 2018, 8. [Google Scholar] [CrossRef]

- Yang, L.; Wang, Y.; Guo, Y.; Zhang, W.; Zhao, Z. Robust Working Mechanism of Water Droplet-Driven Triboelectric Nanogenerator: Triboelectric Output versus Dynamic Motion of Water Droplet. Adv Mater Interfaces. 2019, 6. [Google Scholar] [CrossRef]

- Nguyen, Q.T.; Vo, C.P.; Nguyen, T.H.; Ahn, K.K. A Direct-Current Triboelectric Nanogenerator Energy Harvesting System Based on Water Electrification for Self-Powered Electronics. Applied Sciences. 2022, 12. [Google Scholar] [CrossRef]

- Wang, L.; Song, Y.; Xu, W.; Li, W.; Jin, Y.; Gao, S.; et al. Harvesting energy from high-frequency impinging water droplets by a droplet-based electricity generator. EcoMat. 2021, 3. [Google Scholar] [CrossRef]

- Helseth, L.E. Electrical energy harvesting from water droplets passing a hydrophobic polymer with a metal film on its back side. Journal of Electrostatics. 2016, 81, 64–70. [Google Scholar] [CrossRef]

- Park, H.-Y.; Kim, H.K.; Hwang, Y.-H.; Shin, D.-M. Water-through triboelectric nanogenerator based on Ti-mesh for harvesting liquid flow. J Korean Phys Soc. 2018, 72, 499–503. [Google Scholar] [CrossRef]

- Cho, H.; Chung, J.; Shin, G.; Sim, J.-Y.; Kim, D.S.; Lee, S.; et al. Toward sustainable output generation of liquid–solid contact triboelectric nanogenerators: The role of hierarchical structures. Nano Energy. 2019, 56, 56–64. [Google Scholar] [CrossRef]

- Li, Z.; Yang, D.; Zhang, Z.; Lin, S.; Cao, B.; Wang, L.; et al. A droplet-based electricity generator for large-scale raindrop energy harvesting. Nano Energy. 2022, 100. [Google Scholar] [CrossRef]

- Munirathinam, K.; Kim, D.-S.; Shanmugasundaram, A.; Park, J.; Jeong, Y.-J.; Lee, D.-W. Flowing water-based tubular triboelectric nanogenerators for sustainable green energy harvesting. Nano Energy. 2022, 102. [Google Scholar] [CrossRef]

- Kwak, S.S.; Lin, S.; Lee, J.H.; Ryu, H.; Kim, T.Y.; Zhong, H.; et al. Triboelectrification-Induced Large Electric Power Generation from a Single Moving Droplet on Graphene/Polytetrafluoroethylene. ACS Nano. 2016, 10, 7297–7302. [Google Scholar] [CrossRef]

- Yan, Y.; Zhou, X.; Feng, S.; Lu, Y.; Qian, J.; Zhang, P.; et al. Direct Current Electricity Generation from Dynamic Polarized Water–Semiconductor Interface. The Journal of Physical Chemistry C. 2021, 125, 14180–14187. [Google Scholar] [CrossRef]

- Dong, J.; Xu, C.; Zhu, L.; Zhao, X.; Zhou, H.; Liu, H.; et al. A high voltage direct current droplet-based electricity generator inspired by thunderbolts. Nano Energy. 2021, 90. [Google Scholar] [CrossRef]

- Helseth, L.E. A water droplet-powered sensor based on charge transfer to a flow-through front surface electrode. Nano Energy. 2020, 73. [Google Scholar] [CrossRef]

- Li, X.; Ning, X.; Li, L.; Wang, X.; Li, B.; Li, J.; et al. Performance and power management of droplets-based electricity generators. Nano Energy. 2022, 92. [Google Scholar] [CrossRef]

- Wijewardhana, K.R.; Shen, T.-Z.; Jayaweera, E.N.; Shahzad, A.; Song, J.-K. Hybrid nanogenerator and enhancement of water–solid contact electrification using triboelectric charge supplier. Nano Energy. 2018, 52, 402–407. [Google Scholar] [CrossRef]

- Xu, W.; Zheng, H.; Liu, Y.; Zhou, X.; Zhang, C.; Song, Y.; et al. A droplet-based electricity generator with high instantaneous power density. Nature. 2020, 578, 392–396. [Google Scholar] [CrossRef] [PubMed]

- Sun, W.; Zheng, Y.; Li, T.; Feng, M.; Cui, S.; Liu, Y.; et al. Liquid-solid triboelectric nanogenerators array and its applications for wave energy harvesting and self-powered cathodic protection. Energy. 2021, 217. [Google Scholar] [CrossRef]

- Liu, Y.; Zheng, Y.; Li, T.; Wang, D.; Zhou, F. Water-solid triboelectrification with self-repairable surfaces for water-flow energy harvesting. Nano Energy. 2019, 61, 454–461. [Google Scholar] [CrossRef]

- Tan, J.; Duan, J.; Zhao, Y.; He, B.; Tang, Q. Generators to harvest ocean wave energy through electrokinetic principle. Nano Energy. 2018, 48, 128–133. [Google Scholar] [CrossRef]

- Yang Dong SX, Chi Zhang, Liqiang Zhang, Daoai Wang,, Yuanyuan Xie NL, Yange Feng, Nannan Wang, Min Feng, Xiaolong Zhang,, Feng Zhou ZLW. Gas-liquid two-phase flow-based triboelectric nanogenerator with ultrahigh output power. Science advances. 2022, 8. [Google Scholar]

- Vu, D.L.; Le, C.D.; Ahn, K.K. Functionalized graphene oxide/polyvinylidene fluoride composite membrane acting as a triboelectric layer for hydropower energy harvesting. Int J Energy Res. 2022, 9549–9459. [Google Scholar] [CrossRef]

- Vu, D.L.; Ahn, K.K. High-Performance Liquid-Solid Triboelectric Nanogenerator Based on Polyvinylidene Fluoride and Magnetic Nanoparticle Composites Film. 2021 24th International Conference on Mechatronics Technology (ICMT)2021; pp. 1–5.

- Vu, D.L.; Le, C.D.; Vo, C.P.; Ahn, K.K. Surface polarity tuning through epitaxial growth on polyvinylidene fluoride membranes for enhanced performance of liquid-solid triboelectric nanogenerator. Compos Pt B-Eng. 2021, 223, 109135. [Google Scholar] [CrossRef]

- Helseth, L.E.; Guo, X.D. Contact electrification and energy harvesting using periodically contacted and squeezed water droplets. Langmuir. 2015, 31, 3269–3276. [Google Scholar] [CrossRef] [PubMed]

- Lin, Z.H.; Cheng, G.; Wu, W.Z.; Pradel, K.C.; Wang, Z.L. Dual-Mode Triboelectric Nanogenerator for Harvesting Water Energy and as a Self-Powered Ethanol Nanosensor. Acs Nano. 2014, 8, 6440–6448. [Google Scholar] [CrossRef]

- Bardeen, J. Electrical Conductivity of Metals. J Appl Phys. 1940, 11, 88–111. [Google Scholar] [CrossRef]

- Yang, Y.; Park, J.; Kwon, S.H.; Kim, Y.S. Fluidic Active Transducer for Electricity Generation. Sci Rep. 2015, 5, 15695. [Google Scholar] [CrossRef]

- Song, Y.; Chen, H.; Su, Z.; Chen, X.; Miao, L.; Zhang, J.; et al. Highly Compressible Integrated Supercapacitor–Piezoresistance-Sensor System with CNT–PDMS Sponge for Health Monitoring. Small. 2017, 13, 1702091. [Google Scholar] [CrossRef]

- Jung, S.; Lee, J.; Hyeon, T.; Lee, M.; Kim, D.-H. Fabric-Based Integrated Energy Devices for Wearable Activity Monitors. Adv Mater. 2014, 26, 6329–6334. [Google Scholar] [CrossRef]

- Liang Y, Zhao F, Cheng Z, Zhou Q, Shao H, Jiang L, et al. Self-powered wearable graphene fiber for information expression. Nano Energy. 2017, 32, 329–335. [Google Scholar] [CrossRef]

- Liang, J.; Tong, K.; Pei, Q. A Water-Based Silver-Nanowire Screen-Print Ink for the Fabrication of Stretchable Conductors and Wearable Thin-Film Transistors. Adv Mater. 2016, 28, 5986–5996. [Google Scholar] [CrossRef] [PubMed]

- Huang, Y.; Li, H.; Wang, Z.; Zhu, M.; Pei, Z.; Xue, Q.; et al. Nanostructured Polypyrrole as a flexible electrode material of supercapacitor. Nano Energy. 2016, 22, 422–438. [Google Scholar] [CrossRef]

- Zou, H.; Zhang, Y.; Guo, L.; Wang, P.; He, X.; Dai, G.; et al. Quantifying the triboelectric series. Nat Commun. 2019, 10, 1427. [Google Scholar] [CrossRef] [PubMed]

- Wang, S.; Xie, Y.; Niu, S.; Lin, L.; Liu, C.; Zhou, Y.S.; et al. Maximum surface charge density for triboelectric nanogenerators achieved by ionized-air injection: methodology and theoretical understanding. Adv Mater. 2014, 26, 6720–6728. [Google Scholar] [CrossRef]

- Cheng, G.-G.; Jiang, S.-Y.; Li, K.; Zhang, Z.-Q.; Wang, Y.; Yuan, N.-Y.; et al. Effect of argon plasma treatment on the output performance of triboelectric nanogenerator. Appl Surf Sci. 2017, 412, 350–356. [Google Scholar] [CrossRef]

- Zhang, B.; Zhang, L.; Deng, W.; Jin, L.; Chun, F.; Pan, H.; et al. Self-Powered Acceleration Sensor Based on Liquid Metal Triboelectric Nanogenerator for Vibration Monitoring. ACS Nano. 2017, 11, 7440–7446. [Google Scholar] [CrossRef] [PubMed]

- Yang, Y.; Sun, N.; Wen, Z.; Cheng, P.; Zheng, H.; Shao, H.; et al. Liquid-Metal-Based Super-Stretchable and Structure-Designable Triboelectric Nanogenerator for Wearable Electronics. ACS Nano. 2018, 12, 2027–2034. [Google Scholar] [CrossRef]

- Helseth, L.E.; Guo, X.D. Hydrophobic polymer covered by a grating electrode for converting the mechanical energy of water droplets into electrical energy. Smart Mater Struct. 2016, 25. [Google Scholar] [CrossRef]

- Liang, X.; Jiang, T.; Liu, G.; Xiao, T.; Xu, L.; Li, W.; et al. Triboelectric nanogenerator networks integrated with power management module for water wave energy harvesting. Adv Funct Mater. 2019, 29. [Google Scholar] [CrossRef]

- Wei, A.; Xie, X.; Wen, Z.; Zheng, H.; Lan, H.; Shao, H.; et al. Triboelectric Nanogenerator Driven Self-Powered Photoelectrochemical Water Splitting Based on Hematite Photoanodes. ACS Nano. 2018, 12, 8625–8632. [Google Scholar] [CrossRef]

- Li, Z.; Chen, J.; Guo, H.; Fan, X.; Wen, Z.; Yeh, M.H.; et al. Triboelectrification-Enabled Self-Powered Detection and Removal of Heavy Metal Ions in Wastewater. Adv Mater. 2016, 28, 2983–2991. [Google Scholar] [CrossRef] [PubMed]

- Nie, J.; Ren, Z.; Shao, J.; Deng, C.; Xu, L.; Chen, X.; et al. Self-Powered Microfluidic Transport System Based on Triboelectric Nanogenerator and Electrowetting Technique. ACS Nano. 2018, 12, 1491–1499. [Google Scholar] [CrossRef] [PubMed]

- Vo, C.P.; Shahriar, M.; Le, C.D.; Ahn, K.K. Mechanically active transducing element based on solid–liquid triboelectric nanogenerator for self-powered sensing. Int J Pr Eng Man-GT. 2019, 6, 741–749. [Google Scholar] [CrossRef]

- Schwartz, G.; Tee, B.C.; Mei, J.; Appleton, A.L.; Kim, D.H.; Wang, H.; et al. Flexible polymer transistors with high pressure sensitivity for application in electronic skin and health monitoring. Nat Commun. 2013, 4, 1859. [Google Scholar] [CrossRef] [PubMed]

- Wang, C.; Hwang, D.; Yu, Z.; Takei, K.; Park, J.; Chen, T.; et al. User-interactive electronic skin for instantaneous pressure visualization. Nat Mater. 2013, 12, 899–904. [Google Scholar] [CrossRef]

- Someya, T.; Sekitani, T.; Iba, S.; Kato, Y.; Kawaguchi, H.; Sakurai, T. A large-area, flexible pressure sensor matrix with organic field-effect transistors for artificial skin applications. Proceedings of the National Academy of Sciences of the United States of America. 2004, 101, 9966. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, H.; Wang, T.; Lee, C. Self-powered liquid triboelectric microfluidic sensor for pressure sensing and finger motion monitoring applications. Nano Energy. 2016, 30, 450–459. [Google Scholar] [CrossRef]

- Shi, Q.; Wang, H.; Lee, C. Using Water as A Self-Generated Triboelectric Sensor for Pressure and Flow Rate Measurement. . : -12; 2017. Conference on Nano/Micro Engineered and Molecular Systems, Los Angeles, USA, 9-12 April 2017. [Google Scholar]

- Wang, Z.; Wan, D.; Fang, R.; Yuan, Z.; Zhuo, K.; Wang, T.; et al. Water-based triboelectric nanogenerator for wireless energy transmission and self-powered communication via a solid-liquid-solid interaction. Appl Surf Sci. 2022, 605, 154765. [Google Scholar] [CrossRef]

- Xiong, J.; Luo, H.; Gao, D.; Zhou, X.; Cui, P.; Thangavel, G.; et al. Self-restoring, waterproof, tunable microstructural shape memory triboelectric nanogenerator for self-powered water temperature sensor. Nano Energy. 2019, 61, 584–593. [Google Scholar] [CrossRef]

- Zhang, X.; Yu, M.; Ma, Z.; Ouyang, H.; Zou, Y.; Zhang, S.L.; et al. Self-Powered Distributed Water Level Sensors Based on Liquid–Solid Triboelectric Nanogenerators for Ship Draft Detecting. Adv Funct Mater. 2019, 29, 1900327. [Google Scholar] [CrossRef]

- Wang Y, Wang Z, Zhao D, Yu X, Cheng T, Bao G, et al. Flow and level sensing by waveform coupled liquid-solid contact-electrification. Materials Today Physics. 2021, 18, 100372. [Google Scholar] [CrossRef]

- Mosadegh, B.; Polygerinos, P.; Keplinger, C.; Wennstedt, S.; Shepherd, R.F.; Gupta, U.; et al. Pneumatic Networks for Soft Robotics that Actuate Rapidly. Adv Funct Mater. 2014, 24, 2163–2170. [Google Scholar] [CrossRef]

- Shahriar, M.; Vo, C.P.; Ahn, K.K. Self-powered flexible PDMS channel assisted discrete liquid column motion based triboelectric nanogenerator (DLC-TENG) as mechanical transducer. Int J Pr Eng Man-GT. 2019, 6, 907–917. [Google Scholar] [CrossRef]

- Li, X.; Yeh, M.H.; Lin, Z.H.; Guo, H.; Yang, P.K.; Wang, J.; et al. Self-Powered Triboelectric Nanosensor for Microfluidics and Cavity-Confined Solution Chemistry. ACS Nano. 2015, 9, 11056–11063. [Google Scholar] [CrossRef] [PubMed]

- Zhang, H.; Yang, Y.; Su, Y.; Chen, J.; Hu, C.; Wu, Z.; et al. Triboelectric nanogenerator as self-powered active sensors for detecting liquid/gaseous water/ethanol. Nano Energy. 2013, 2, 693–701. [Google Scholar] [CrossRef]

- Zhang, W.; Wang, P.; Sun, K.; Wang, C.; Diao, D. Intelligently detecting and identifying liquids leakage combining triboelectric nanogenerator based self-powered sensor with machine learning. Nano Energy. 2019, 56, 277–285. [Google Scholar] [CrossRef]

- Choi, D.; Tsao, Y.-H.; Chiu, C.-M.; Yoo, D.; Lin, Z.-H.; Kim, D.S. A smart pipet tip: Triboelectricity and thermoelectricity assisted in situ evaluation of electrolyte concentration. Nano Energy. 2017, 38, 419–427. [Google Scholar] [CrossRef]

- Jiang, P.; Zhang, L.; Guo, H.; Chen, C.; Wu, C.; Zhang, S.; et al. Signal Output of Triboelectric Nanogenerator at Oil-Water-Solid Multiphase Interfaces and its Application for Dual-Signal Chemical Sensing. Adv Mater. 2019, 31, e1902793. [Google Scholar] [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).