Submitted:

31 May 2023

Posted:

01 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

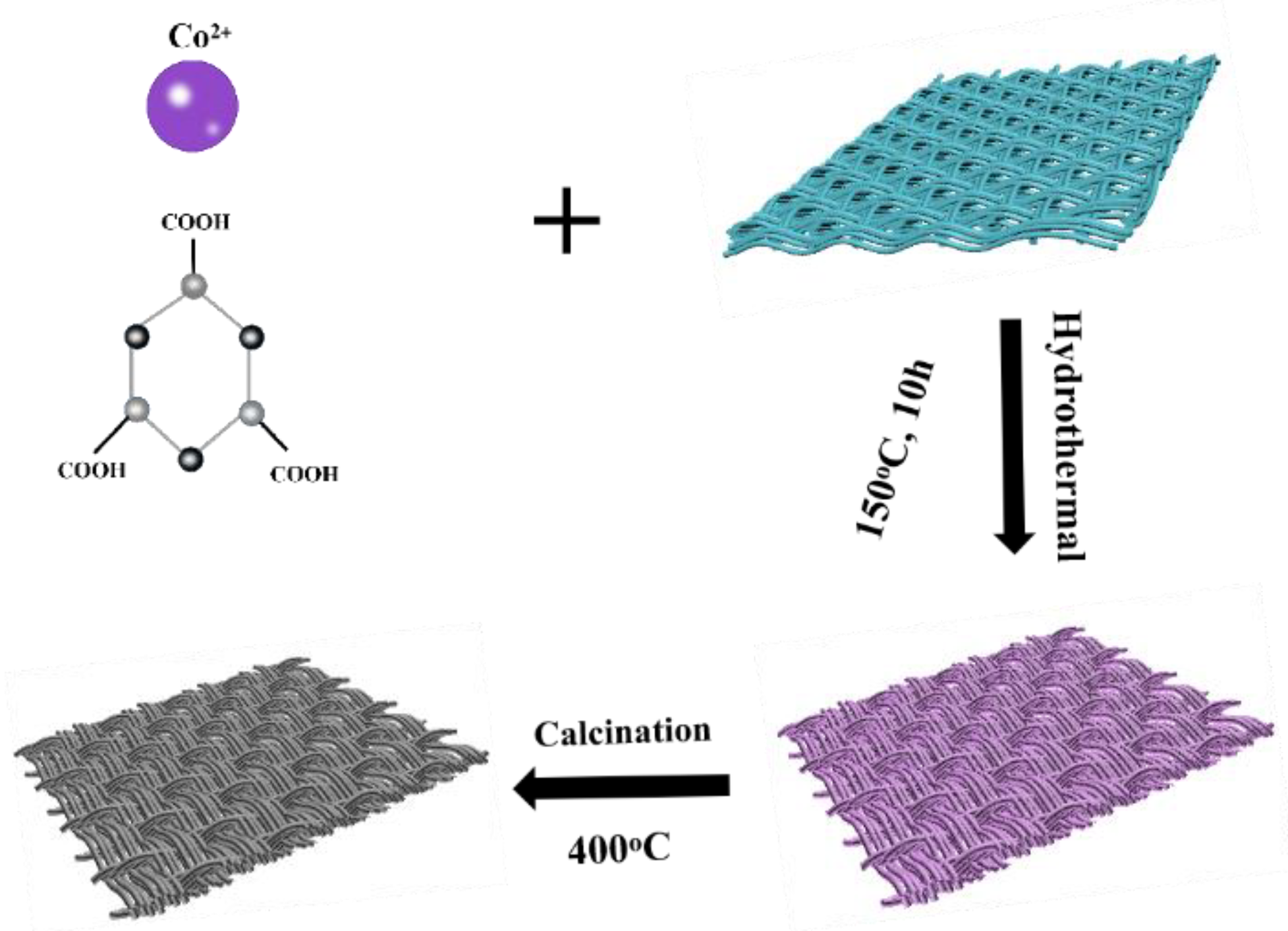

2.1. Preparation of Precursors of Co-MOFs/CC

2.2. Synthesis of Co3O4/CC Composites

2.3. Characterization and Measurement

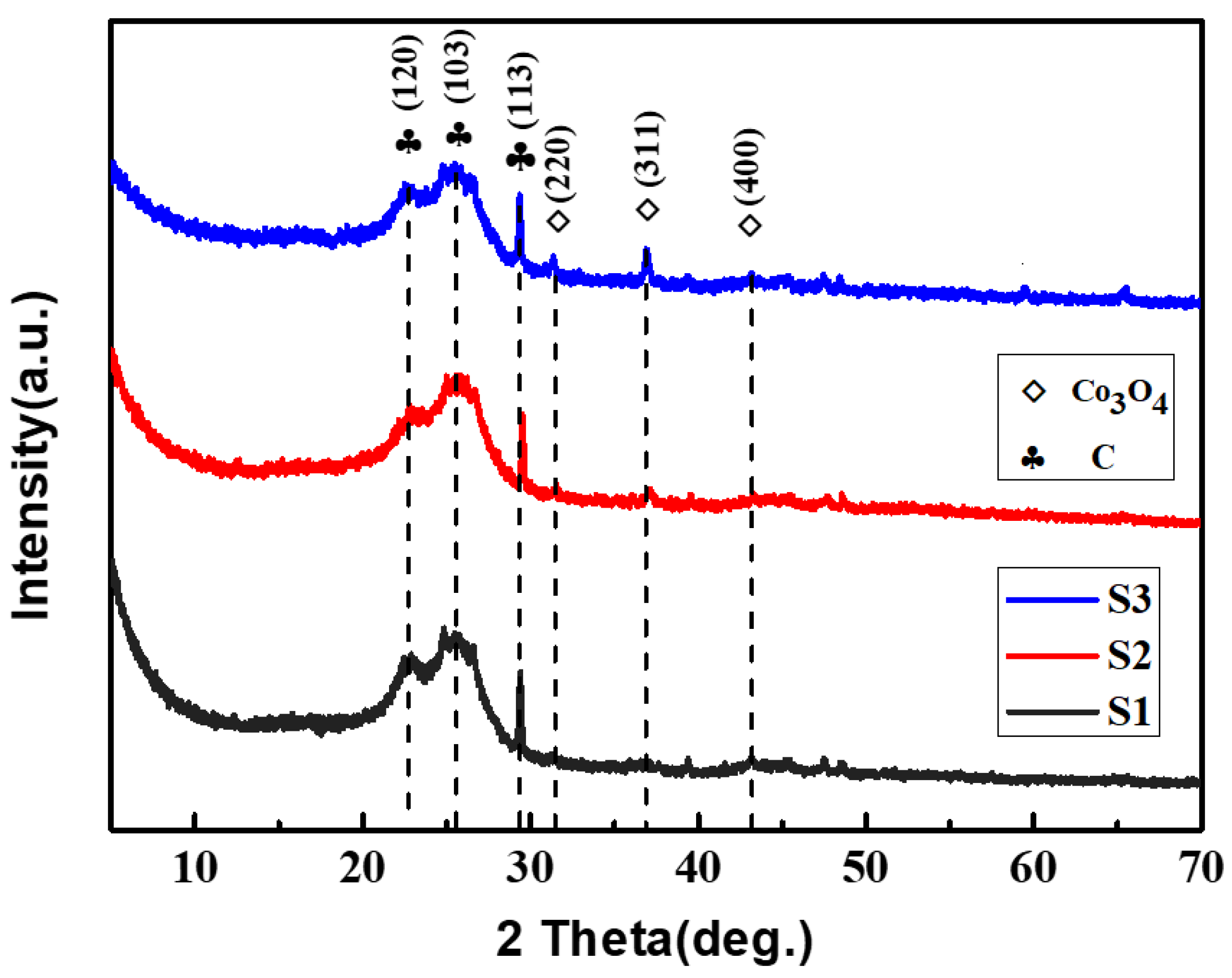

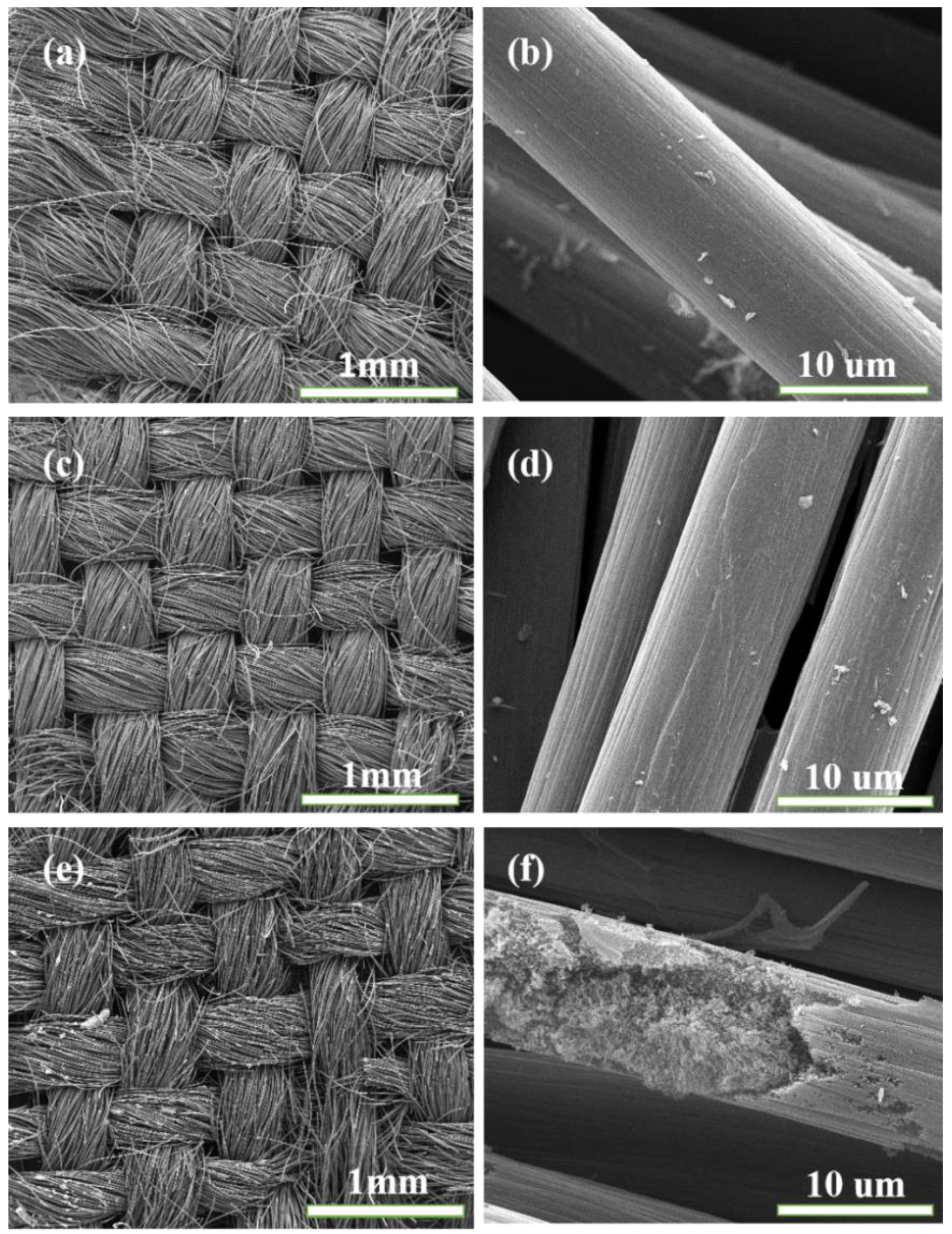

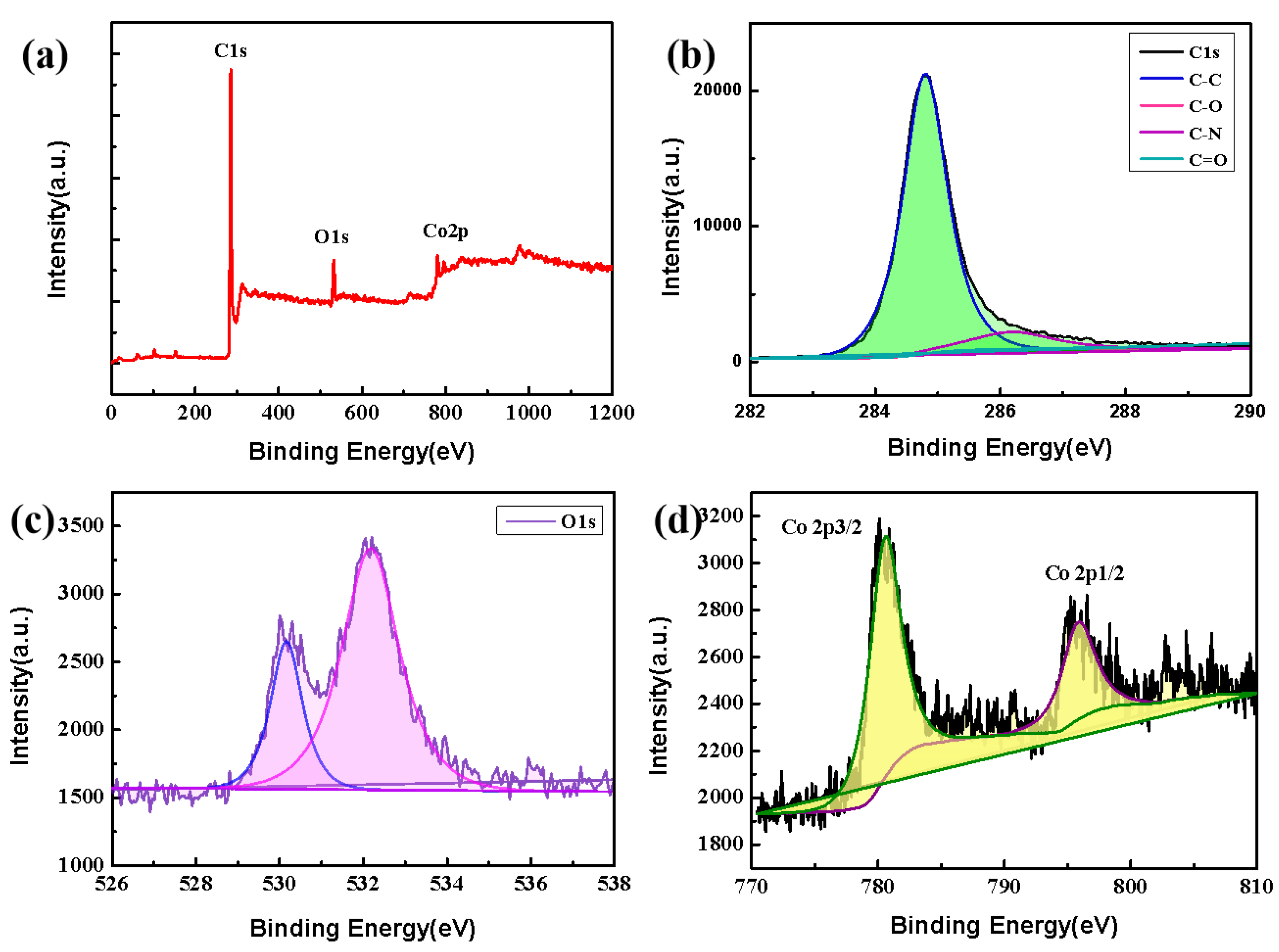

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Z, Zhang.; F, Wang, X, Q.; Zhang, W.; Li, J.; G, Guan. Research progress of low frequency wideband thin layer absorbing materials. J. Funct. Mater. 2019, 50(06), 606038–606045.

- F, Wu.; A, Xie.; M, Sun.; Y, Wang.; M, Wang.Reduced Graphene Oxide (RGO) Modified Spongelike Polypyrrole (PPy) Aerogel for Excellent Electromagnetic Absorption. J. Mater. Chem. 2015, A3(27), 14358–14369. [CrossRef]

- Y, Wang.; Z, Peng.; W, Jiang. Controlled synthesis of Fe3O4@SnO2/RGO nanocomposite for microwave absorption enhancement. Ceram. Int. 2016, 42(9), 10682–10689. [CrossRef]

- G, Wang.; Y, Wu.; X, Zhang.; Y, Li.; L, Guo.; M, Cao. Controllable Synthesis of Uniform ZnO Nanorods and Their Enhanced Dielectric and Absorption Properties. J. Mater. Chem. 2014, A2(23), 8644–8651. [CrossRef]

- N, Zhou.; Q, D, An.; Z, Y, Xiao.; S, R, Zhai.; Z, Shi.Solvothermal synthesis of three-dimensional, Fe2O3 NPs-embedded CNT/N-doped graphene composites with excellent microwave absorption performance. RSC. Adv. 2017, 7(71), 45156–45169. [CrossRef]

- M, S, Cao.; W, L, Song.; Z, L, Hou.; B, Wen.; J, Yuan.The effects of temperature and frequency on the dielectric properties, electromagnetic interference shielding and microwave-absorption of short carbon fiber/silica composites. Carbon. 2010, 48(3), 788–796. [CrossRef]

- G, Yilmaz.; K, M, Yam.; C, Zhang.; H, J, Fan.; G, Ho, W. In Situ Transformation of MOFs into Layered Double Hydroxide Embedded Metal Sulfides for Improved Electrocatalytic and Supercapacitive Performance. Adv. Mater. 2017, 29, 1606814. [CrossRef]

- J, Qian.; T, T, Li.; Y, Hu.; S, Huang. A Bimetallic Carbide Derived from a MOF Precursor for Increasing Electrocatalytic Oxygen Evolution Activity. Chem. Commun. 2017, 53, 13027–13030. [CrossRef]

- X, Liang.; B, Quan.; Y, Sun.; G, Ji.; Y, Zhang.; J, Ma.; D, Li.; B, Zhang.; Y, Du. Multiple Interfaces Structure Derived from Metal–Organic Frameworks for Excellent Electromagnetic Wave Absorption. Part. Part. Syst. Charact. 2017, 34, 1700006. [CrossRef]

- Y, Yin.; X, Liu.; X, Wei.; R, Yu.; J, Shui. Porous CNTs/Co Composite Derived from Zeolitic Imidazolate Framework: A Lightweight, Ultrathin, and Highly Efficient Electromagnetic Wave Absorber. ACS Appl. Mater. Interfaces. 2016, 8, 34686–34698. [CrossRef]

- W, Liu.; Q, Shao.; G, Ji.; X, Liang.; Y, Cheng.; B, Quan.; Y, Du. Metal–Organic Frameworks Derived Porous Carbon-Wrapped Ni Composites with Optimized Impedance Matching as Excellent Lightweight Electromagnetic Wave Absorber. Chem. Eng. J. 2017, 313, 734–744.

- J, Ma.; W, Liu.; X, Liang. Nonporous TiO2/C composites synthesized from directly pyrolysis of a Ti-based MOFs MIL-125(Ti) for efficient microwave absorption. J. Alloy. Compd 2017, 728, 138–144. [CrossRef]

- F, Shi.; Y, Hu.; X, Wang. Decomposition of MOFs for the preparation of nano porous Co3O4 fibers and sheets with excellent microwave absorption and photocatalytic properties. Dalton. T. 2017, 46(6), 1936–1942. [CrossRef]

- W, Liu.; S, J, Tan.; Z, H, Yang.; G, B, Ji. Enhanced Low-Frequency Electromagnetic Properties of MOF-Derived Cobalt through Interface Design. ACS Appl. Mater. Interfaces. 2018, 10. 37, 31610–31622. [CrossRef]

- Run Yang a.; Jiaqing Yuan a.; Cuihong Yu a.; Kun Yan a.; Yao Fu a.; Hangqing Xie a.; Jian Chen b.; Paul K. Chu c.; Xinglong Wu. Efficient electromagnetic wave absorption by SiC/Ni/NiO/C nanocomposites. Journal of Alloys and Compounds. 2020, 816, 152519. [CrossRef]

- Peng Miao.; Rui Zhou.; Kaijie Chen*.; Jin Liang.; Qingfu Ban.; and Jie Kong. Tunable Electromagnetic Wave Absorption of Supramolecular Isomer-Derived Nanocomposites with Different Morphology. Adv. Mater. Interfaces. 2020, 7, 1901820. [CrossRef]

- Q, Zhang.; Y, X, Song.; J, L, Guo.; S, Wu.; N, Chen.; H, G, Fan.; M, Gao.; J, H, Yang.; Z, F, Sheng.; J, H, Lang. One-step hydrothermal synthesis of the modified carbon cloth membrane: Towards visible light driven and self-cleaning for efficient oil-water separation. Surf. Coat. Tech. 2021, 409. [CrossRef]

- L, M, Yang.; W, D, Chen.; C, H, Sheng.; H, L, Wu.; N, T, Mao.; H, Zhang. Fe/N-codoped carbocatalysts loaded on carbon cloth (CC) for activating peroxymonosulfate (PMS) to degrade methyl orange dyes. Appl. Surf. Sci. 2021, 549. [CrossRef]

- S, M, Sui.; J, W, Sha.; X.Y. Deng.; S. Zhu.; L.Y. Ma.; C.N. He.; E.Z. Liu.; F. He.; C.S. Shi.; N.Q. Zhao. Boosting the charge transfer efficiency of metal oxides/carbon nanotubes composites through interfaces control. J. Power. Sources 2021, 489. [CrossRef]

- L, Xie.; S, X, Chen.; Y, C, Hu.; Y, Q, Lan.; X, Li.; Q, Deng.; J, Wang.; Z, L, Zeng.; S, G, Deng. Construction of phosphatized cobalt nickel-LDH nanosheet arrays as binder-free electrode for high-performance battery-like supercapacitor device. J. Alloy. Compd. 2021, 858. [CrossRef]

- Z, T, Nie.; H, J, Zhang.; Y, F, Lu.; C, Y, Han.; Y, H, Du.; Z, C, Sun.; Y, B, Yan.; H, Yu.; X, J, Zhang.; J, X, Zhu. Manipulation of porosity and electrochemical artificial separator interphase for durable lithium-sulfur batteries. Chem. Eng. J. 2021, 409. [CrossRef]

- Z, F, Liu.; D, D, Ye.; X, Zhu.; S, L, Wang.; R, Chen.; Y, Yang.; Q, Liao. A self-pumping microfluidic fuel cell powered by formatted with Pd coated carbon cloth electrodes. J. Power. Sources. 2021, 490. [CrossRef]

- K, Q, Dai.; N, Zhang.; L, L, Zhang.; L, X, Yin.; Y, F, Zhao.; B, Zhang. Self-supported Co/CoO anchored on N-doped carbon composite as bifunctional electrocatalyst for efficient overall water splitting. Chem. Eng. J. 2021, 414. [CrossRef]

- X, H, Luo.; J, Zhang.; C, G, Ci.; R, L, Bai.; D, Y, Shi.; K, M, Xia.; D, W, Wu. Preparation of NiSe2/ CC composite and its electrocatalytic performance for hydrogen evolution. Micro/Nano Electronic Technology 2021, 58(03), 207–213.

- J, Zhan.; X, Cao.; J, M, Zhou.; G, Xu.; B, Lei.; M, H, Wu. Porous array with CoP nanoparticle modification derived from MOF grown on carbon cloth for effective alkaline hydrogen evolution. Chem. Eng. J. 2021, 416. [CrossRef]

- Lei Wang.; Xiao Li.; Qingqing Li.; Xuefeng Yu.; Yunhao Zhao.; Jie Zhang.; Min Wang.; and Renchao Che. Oriented Polarization Tuning Broadband Absorption from Flexible Hierarchical ZnO Arrays Vertically Supported on Carbon Cloth. Small. 2019, 1900900. [CrossRef]

- Panbo Liu a*.; Chenyu Zhu b, 1.; Sai Gao a, 1.; Cao Guan b **.; Ying Huang a.; Wenjuan He. N-doped porous carbon nanoplates embedded with CoS2 vertically anchored on carbon cloths for flexible and ultrahigh microwave absorption. Carbon. 2020, 163, 348–359. [CrossRef]

- G, P, Wan.; G, Z, Wang.; X, Q, Huang.; H, N, Zhao.; X, Y, Li.; K, Wang.; L, Yu.; X, G. Peng.; Y, Qin. Uniform Fe3O4 coating on flower-like ZnO nanostructures by atomic layer deposition for electromagnetic wave absorption. Dalton Trans. 2015, 44(43), 18804–18809. [CrossRef]

- Wu L.; Wang Z.; Long Y. Multishelled NixCo3-xO4 hollow microspheres derived from bimetal-organic frameworks as anode materials for high-performance lithium-ion batteries. Small. 2017, 13(17), 1604270. [CrossRef]

- Y, W, Zhu.; T, Yu.; C, H, Sow.; Y, J, Liu.; A, T, S, wee.; X, J, Xu.; C, T, Lim.; J, T, L, Thong. Efficient field emission from α-Fe2O3 nanoflakes on an atomic force microscope tip. Appl Phys Lett. 2005, 87(2), 023103. [CrossRef]

- W, Feng.; Y, Wang.; J, Chen.; L, Wang.; L, Guo.; J, Ou Yang.; D, Jia.; Y, Zhou. Reduced graphene oxide decorated with in-situ growing ZnO nanocrystals: facile synthesis and enhanced microwave absorption properties. Carbon 2016, 108, 52–60. [CrossRef]

- J, Yan.; Y, Huang.; Z, Zhang.; X, D, Liu. Novel 3D micro sheets contain cobalt particles and numerous interlaced carbon nanotubes for high-performance electromagnetic wave absorption. J. Alloys Compd. 2019, 785, 1206–1214. [CrossRef]

- X, H, Liang.; X, M, Zhang.; W, Liu.; D, M, Tang.; B, S, Zhang.; G, B, Ji. A simple hydrothermal process to grow MoS2 nanosheets with excellent dielectric loss and microwave absorption performance. J. Mater. Chem. C. 2016, 4(28), 6816–6821. [CrossRef]

- X, Q, Cui.; X, H, Liang.; W, Liu.; W, H, Gu.; G, B, Ji.; Y, W, Du. Stable microwave absorber derived from 1D customized heterogeneous structures of Fe3N@C. Chem. Eng. J. 2020, 381, 122589. [CrossRef]

- X, H, Liang.; B, Quan.; G, B, Ji.; W, Liu.; Y, Cheng.; B, S, Zhang.; Y, W. Du. Novel nanoporous carbon derived from metal-organic frameworks with tunable electromagnetic wave absorption capabilities. Inorg. Chem. Front. 2016, 3(12), 1516–1526. [CrossRef]

- M, Cao.; R, Qin.; C, Qiu.; J, Zhu. Matching Design and Mismatching Analysis towards Radar Absorbing Coatings Based on Conducting Plate. Mater. Eng. 2003, 24(5), 391–396. [CrossRef]

- W, Song.; M, Cao.; Z, Hou.; J, Yuan. High-Temperature Microwave Absorption and Evolutionary Behavior of Multiwalled Carbon Nanotube Nanocomposite. Scr. Mater. 2009, 61(2), 201–204. [CrossRef]

- L, N, Wang.; X, L, Jia.; Y, F, Li.; F, Yang.; L, Q, Zhang.; L, P, Liu.; X, Ren.; H, T, Yang. Synthesis and microwave absorption property of flexible magnetic film based on graphene oxide/carbon nanotubes and Fe3O4 nanoparticles. J. Mater. Chem. A 2014, 2(36), 14940–14946. [CrossRef]

- H, L, Lv.; G, B, Ji.; X, H, Liang.; H, Q, Zhang.; Q, Hai.; Y, W, Du. A novel rod-like MnO2@Fe loading on graphene giving excellent electromagnetic absorption properties. J. Mater. Chem. C. 2015, 3(19), 5056–5064. [CrossRef]

- X, Zhang.; G, Ji.; W, Liu.; B, Quan.; X, H, Liang.; C, M, Shang.; Y, Cheng.; Y, W, Du. Thermal conversion of an Fe3O4@metal-organic framework: a new method for an efficient Fe-Co/nanoporous carbon microwave absorbing material. Nanoscale 2015, 7(30), 12932–12942. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).