1. Introduction

Aeroponic cultivation has the characteristics of extreme water and fertilizer conservation and is currently a more advanced mode of farming. Current aeroponics control is mainly based on environmental factors, such as temperature, humidity, crop light intensity, CO

2 concentration, pH, and EC of nutrient solutions. Hikosaka et al. [

1] conducted an aeroponic experiment on lettuce with aeroponic nozzles with an average droplet size of 8.85 µm and compared it with the deep flow technique (DFT) and found that the yield and quality of aeroponic lettuce were not affected. Nevertheless, the root-to-shoot ratio of aeroponic crops was significantly more extensive, and leaf growth was inhibited. By comparing the growth performance of lettuce and silver-leaf chrysanthemum in aeroponics with hydroponics and substrate culture, aeroponics significantly promoted root growth and biomass accumulation, especially the root-to-shoot ratio, which significantly increased. Nevertheless, aboveground growth was inhibited [

2]. In many aeroponic trials, our group also found that the root-to-shoot ratio of lettuce in an aeroponic condition was significantly greater than that of hydroponics and substrate culture [

3,

4]. A large root-to-shoot ratio of leafy vegetables means that the proportion of edible stems and leaves to the biomass of the whole crop is too low. The study of aeroponics is less involved in regulating the root-to-shoot ratio of crops.

Combining aeroponics with automation technology to achieve intelligent control of aeroponics is an inevitable trend in the development of aeroponics. Scholars at home and abroad have also performed related work in recent years [

5]. In 2017, Montoya and his team developed an automated aeroponic system based on the Arduino platform by using a recirculating nutrient solution in hydroponics, and the aim was to measure the temperature, flow rate, pH, and EC of the nutrient solution in the greenhouse using various sensors. In contrast, others used the method of storing the measured data in the Secure Digital (SD) memory and loading the information to the web page in real-time, thus achieving continuous monitoring and automatic operation to improve cultivation efficiency [

6]. Gao et al. 2017 developed an intelligent control system for an aeroponic test bench based on 51 microcontrollers in series, equipped with an upper computer and a lower computer to transmit signals between wireless communication modules to realize automatic monitoring and management of the cultivation room [

7]. In 2019, Shen proposed a control system that can microregulate the environment of three-dimensional aeroponic cultivation [

8]. In 2022, our research team developed an intelligent control system for the rhizosphere temperature of aeroponic lettuce via the Internet of Things [

9]. There is a lack of an aeroponic control system with plant growth information as the primary feedback signal.

In recent years, fuzzy logic control systems have been widely used in agricultural cultivation systems. Chen et al. [

10] designed a hydroponic system to maintain the EC and pH of nutrient solution at specific values by using a fuzzy logic controller to control the adjustment of EC and pH in hydroponics. P. Correa et al. [

11] proposed a method to monitor the growth of bean plants from images taken at the developmental stages of bean by using a fuzzy logic control system and RGB images. In an other study Maya Olalla et al. [

12] applied a fuzzy logic control system for hydroponic strawberry cultivation in a greenhouse, which used parameters such as pH, temperature and humidity in the substrate as input variables to make the automated system supply the necessary amount of water to the plants

Based on the above research status, this study proposed and designed an aeroponic intelligent control system based on fuzzy logic with creamy lettuce as the growing object to realize the feedback signal of the aeroponic system with the leaf shoot area characteristics of lettuce at different growth stages and regulate the aeroponic system in stages. Based on the functions of the traditional aeroponic control system, the system can ensure the average growth of lettuce and simultaneously reduce the root-to-shoot ratio of aeroponic lettuce to a certain extent, thus increasing the effective yield.

2. Materials and Methods

2.1. System Structure and Principle of Operation

2.1.1. The Structure of the Aeroponic Device Test Bench

In this study, based on the existing aeroponic device and the production requirements, an intelligent aeroponic system that can improve the root-to-shoot ratio of lettuce was designed, and the complete structure of the system is shown in

Figure 1.

2.1.2. Aeroponic Device Working Process

The aeroponic system used in this experiment had two modes, a manual mode and an automatic mode. The automatic mode involved self-regulation of spraying frequency and supplemental light settings related to environmental factors and lettuce growth detection results. The manual mode directly sets the spraying frequency and nutrient solution temperature by the central controller. In the manual mode, the same data acquisition was needed. Nevertheless, no control strategy was required to determine when the device was working manually. The workflow diagram of the aeroponic device is shown in

Figure 2.

When the aeroponic system operated automatically, the water pump, cooler, and light worked according to the default settings. In this case, the temperature and humidity, carbon dioxide, light intensity, and other sensors made the corresponding numerical measurements. They sent the measured data to the central controller through the wireless module through the 51 controllers (lower computer). The camera collected the lettuce pictures according to the time set on the personal computer (PC), measured and saved the collected images, and optionally sent the lettuce data to the central controller (host computer) through the PC. The central controller processed all the received data, and the obtained data were displayed on the human-machine interface of the central controller. The control strategy was set according to the relevant algorithm, which sent commands to the 51 controllers to adjust the appropriate devices.

2.1.3. Aeroponic Device System Hardware Selection

The aeroponic system included the nutrient supply system and the cultivation system. The arrangement of the fixing plates, nozzles, liquid supply, and drainage holes in the aeroponic cultivator was significant in the cultivation system. The pressure nozzles were installed at the bottom of the aeroponic cultivation box, and four were installed in each box. The supply and discharge pipes were made of polyvinyl chloride (PVC) plastic flexible water pipes with an inner diameter of 0.2 cm and a wall thickness of 0.2 cm. The supply piping was symmetrically installed to ensure consistent pressure on each nozzle. The supply piping was connected through a conversion head to facilitate piping replacement at a later stage. A previous study found that the researchers set the plant spacing to 20 cm when growing lettuce [

13]. Therefore, the spacing of fixing holes in the fixing plates was set to 20 cm. Twelve fixing holes with diameters of 0.45 cm (depending on the size of the fixing basket) were made in each fixing plate according to the length and width of the aeroponic cultivation box. One team studied the effects of different light sources on lettuce growth and development and found that lettuce grown with a combination of red and blue light had the best quality and could positively affect the growth and development of lettuce [

14]. In a study of different red and blue light ratios, another researcher concluded that a light source with a 4:1 combination of red-to-blue lights was best for the growth of vegetables [

15]. This aeroponic system used plant growth lights with a red-to-blue ratio of 4:1, each having a length of 70 cm and a power of 18 W. This system’s nutrient solution supply container was 65 cm

46 cm

36 cm. The nutrient solution was supplied from the reservoir to the nozzle through a diaphragm pump.

2.2. Aeroponic Fuzzy Control Hardware System Design

The fuzzy logic aeroponic control system contained five parts: data acquisition, transmission, execution, power supply, and signal processing modules (

Figure 3). Data acquisition mainly included temperature, humidity, light intensity, and carbon dioxide sensors. Data transmission modules were made up of multiple wireless serial modules. The execution module contained relays, diaphragm pumps, LED lights, and water chillers. The power supply module included a switching power supply, a constant voltage, and a stable current power supply module. The signal processing module consisted of an upper computer and a lower computer. The work of the upper computer was to process the data, store the sensor measurement data, and send execution commands to the lower computer, using STM32F103ZET6 as the core of the upper computer hardware platform. The system used 51 microcontrollers as the lower computer. The specific model was STC89C52, the primary frequency was 11.0592 M, and the work of the lower computer 1 was mainly the measurement of environmental factors. The work of lower computer 2 was the execution of the commands of the upper computer; the (personal computer) PC and the (high defination) HD camera performed image acquisition, image processing, and image data storage. Each sensor was connected to the 51 lower computer 1 units, and the measured data were sent to the upper computer STM32 through wireless communication. The PC transmitted the image data to the upper computer STM32 through the serial port. Finally, the upper computer’s comprehensive data analysis sent feedback signals via a wireless module to the 51 lower computer 2 units, which controlled the pumps, chillers, LED lights, etc.

2.2.1. Hardware Circuit Design for Lower Computer Data Acquisition

The system had two sets of 51 microcontrollers as the lower computer, and the specific model was STC89C52, with a central frequency of 11.0592. One set of 51 lower computers was responsible for acquiring and transmitting environmental data, acting as the system data acquisition mechanism; the other set of 51 lower computers’ task was to receive the commands sent by the upper computer, serving as the system actuators.

The control system’s temperature and humidity acquisition module was a digital sensor DHT22 unit. The sensor surface was coated with a waterproof material and installed in a box. The box was placed inside the aeroponic cultivation box and used to measure the root temperature and humidity in real-time. The sensor had a single bus digital signal output with a pull-up resistor at the data end. The DHT22 sensor parameters are shown in

Table 1.

- 2.

Carbon dioxide concentration detection circuit

This control system adopted the carbon dioxide sensor model SGP30, having the 1.8 V LDO chip module onboard for the SGP30 power supply while using the Inter-Integrated Circuit (IIC) communication interface. This sensor, and the above temperature and humidity sensor, had the same installation location and waterproof treatment and and waterproof treatment. It was used to measure lettuce root domain carbon dioxide concentration. This study connected the serial clock line (SCL) and serial data line (SDA) to the standard I/O port to allow IIC bus timing access. The carbon dioxide sensor performance parameters are shown in

Table 2.

- 3.

Light intensity acquisition circuit

The control system’s lower computer light intensity acquisition module used a GY-30 digital type output (BH1750FVI) to acquire the light intensity on the fixing board and determine whether it needed replenishment. The module equipped with a built-in 16-bit analog-to-digital (AD) converter allowed direct digital output and included communication level conversion, which was used directly by different microcontrollers. The sensor used the same IIC communication interface, and the connections of the SCL and SDA units to the standard I/0 port as the CO

2 sensor and the sensor pin functions were similar. The light intensity sensor performance parameters are shown in

Table 3.

- 4.

Wireless Module Circuit

The wireless transmission module of this control system was adopted based on a universal asynchronous receiver/transmitter (UART) interface full-duplex wireless transmission module, with CC2530 as the chip-specific model for the DL-20 unit having an operating frequency band of 2400 MHZ ~ 2450 MHZ, a transmission rate of up to 3300 bytes/sec, which can realize point-to-point, or one-to-many, multiple points to one point transmission with a low packet loss rate. In this design, communication between the upper computer and the lower computer was implemented through this module. The relevant parameters of this wireless module are shown in

Table 4 below.

2.2.2. Human-Computer Interaction Interface Design for the Host Computer

This system adopted STM32F103ZET6 as the core of the upper computer hardware platform. After the system lower computer collected data from the sensors, it transmitted it to the STM32 upper computer through a wireless module, and stored it in a secure digital memory (SD) card. The existing simplified Micro C OS Three (UCOSIII) system was transferred to STM32 before the relevant code was written. The transfer process is shown in

Figure 4.

In this study, we designed the human-computer interface in the UCOSIII system using GUI-Builder software. First, we dragged the required controls into the editing interface according to the requirements, generated the software after completing the dialogue box design, saved it as a C file (using File/Save), and finally named this C file in the project file. The GUI-Builder software is shown in

Figure 5a, and the display interface is shown in

Figure 5b.

2.3. Image Acquisition Processing Method Selection

The camera model used for image acquisition in this study was a USBFHD01M unit with a maximum pixel count of 2 megapixels, a full resolution of 19201080 p, a maximum frame rate of 120 fps, a lens focal length of 6 mm, and a vertical distance between the lens and the lettuce of 20-40 cm.

To verify the feasibility of using the results of digital image processing of the lettuce leaf shoot area, Photoshop image processing and MATLAB image processing were used to measure the leaf shoot area of the lettuce. In this study, six lettuce leaf shoots were analyzed by the above two area measurement methods, and the data are shown in

Table 5.

As shown in

Table 5, the leaf shoot area values calculated by the MATLAB image method were similar to the leaf area values obtained by the Photoshop image method, and the average value of the relative errors was 2.6%. This study used the leaf shoot area calculated by the MATLAB image method to determine the actual leaf area.

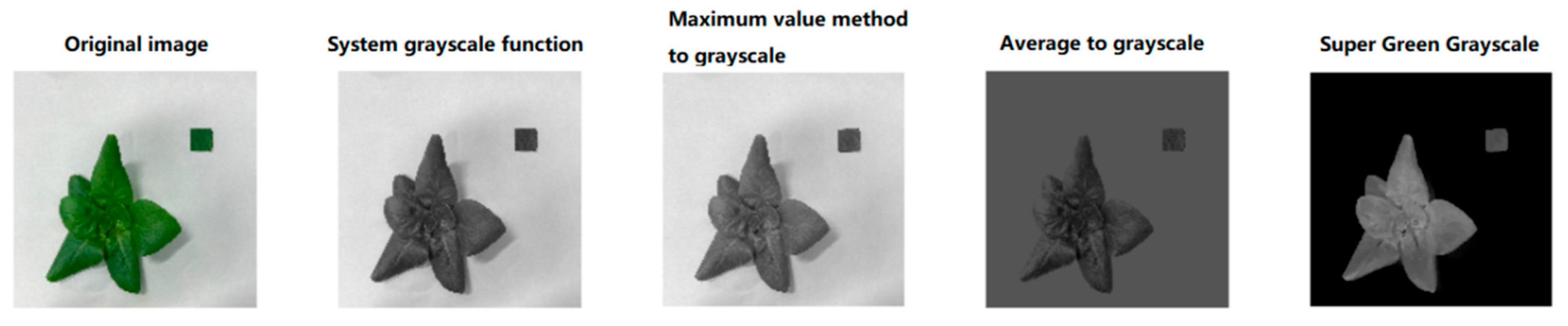

2.3.1. Image Preprocessing Analysis

In image acquisition, image processing results may differ due to different angles and light intensities. Therefore, preprocessing of the images was required to obtain better-quality photos. These methods included greying, filtering, enhancement, digitization, etc. In this study, we compared several image processing methods to extract feature effects on the images and selected the most suitable approach to obtain lettuce parameters. The acquired images were first greyed out, and then data was extracted using the super green feature (2G-R-B) method when dealing with green plant diseases or distinguishing green plants from other objects [

16,

17,

18,

19,

20,

21]. The images of lettuce were greyed out using these methods to compare the greying effect. The greyed-out pictures are shown in

Figure 6.

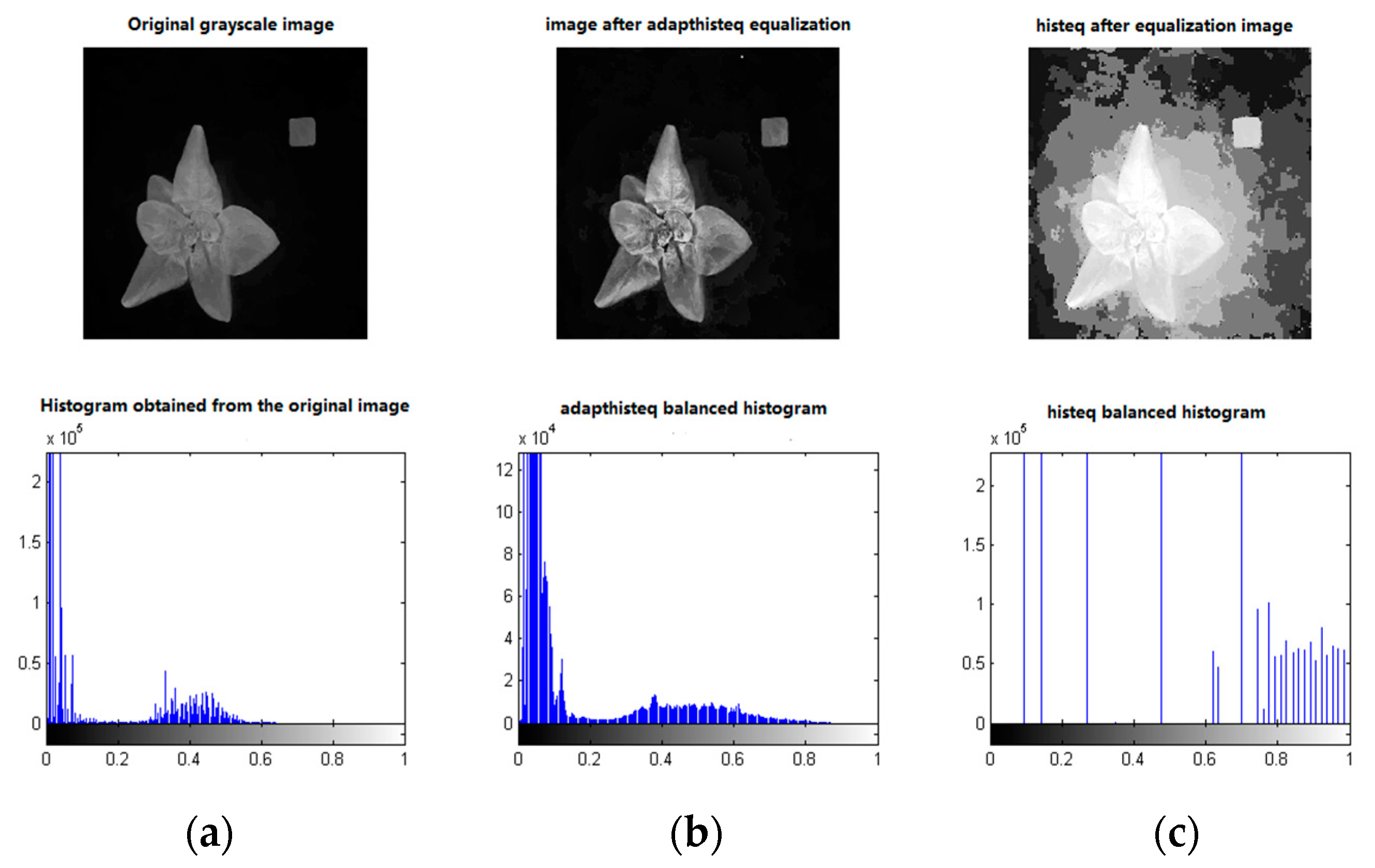

2.3.2. Image Enhancement

After grayscale processing of the images, the contrast tended to decrease, and image enhancement was needed to improve image quality. By this, the histogram equalization method in spatial domain image enhancement was used for image processing [

22,

23]. As shown in

Figure 7, the contrast in

Figure 7b was significantly improved after enhancement.

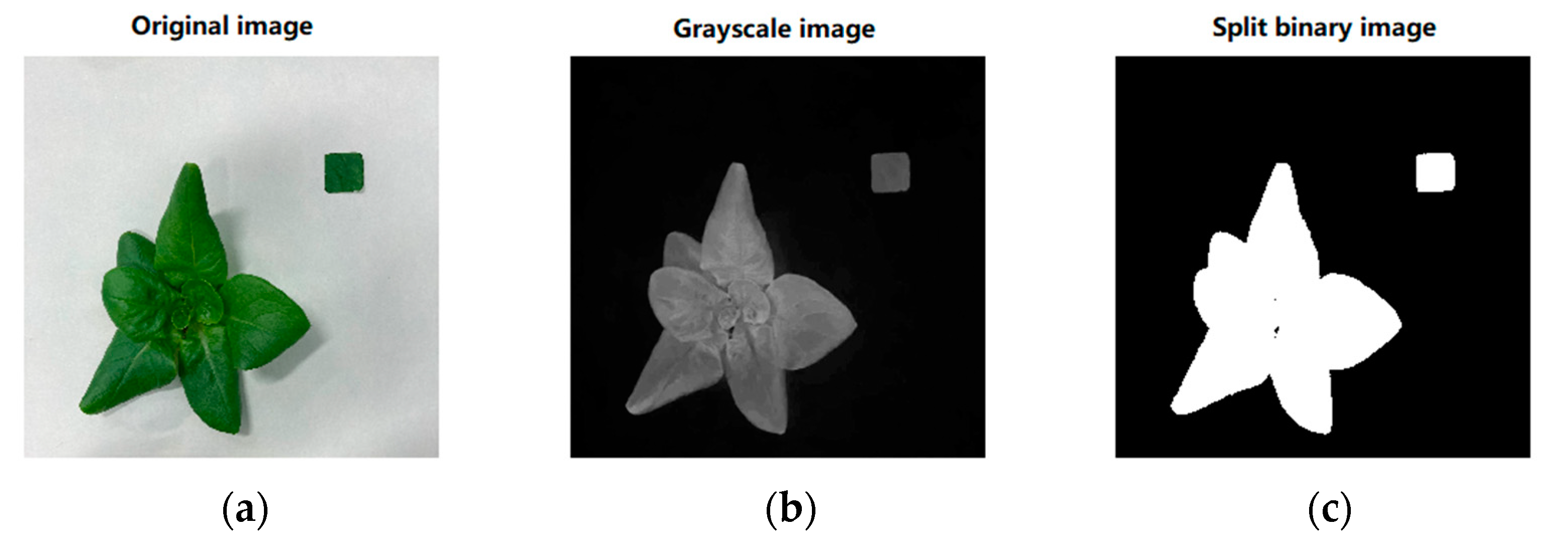

2.3.3. Image Segmentation

After grayscale processing, each image was digitized and segmented based on the threshold value. Each image was read using MATLAB, as shown in

Figure 8, and the optimal threshold values were calculated automatically using the maximum interclass variance method (Ostu method). The grayscale values of the pixel points in each image were compared to the threshold value. Each plant was segmented from the background according to the comparison result, as shown in

Figure 8c. After segmentation, the gaps were filled or filtered according to the demand [

24,

25,

26].

The overhead leaf canopy area values were calculated as follows.

The leaf shoot area in the overhead view is the area projected on the ground by the leaf shoot when the lettuce plant is viewed from above. In this paper, we use image processing software to analyze the overhead view image, segment the leaf shoot area from the picture, and calculate the projected area. The number of pixels of the leaf shoot area is the number of pixels in the leaf shoot area in the lettuce top view image. It indicates the size of the area occupied by the leaf shoot in the image and is a relative measure.

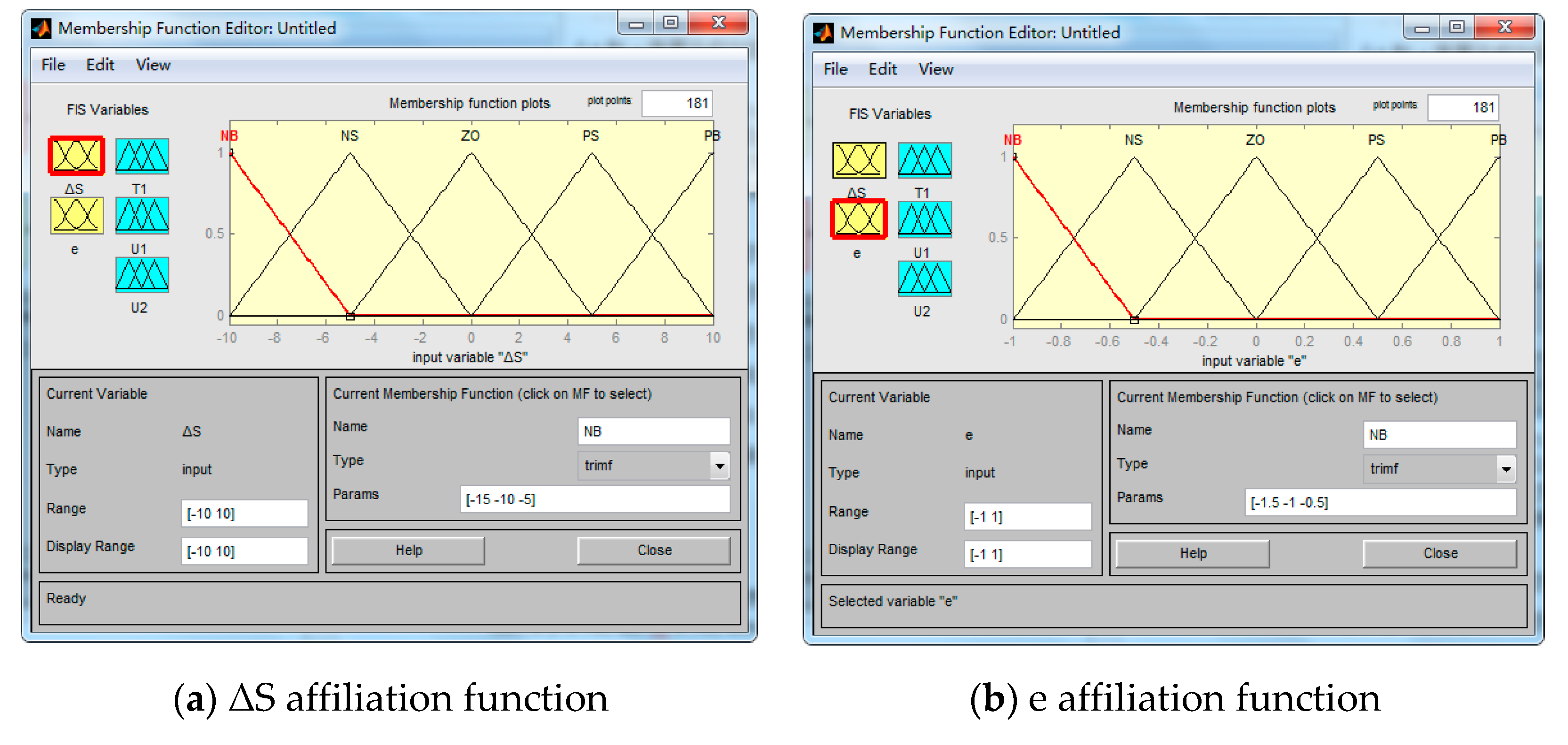

2.4. Aeroponic Fuzzy Control System Software

The system used the leaf shoot area of lettuce under different stages as the primary control object and adopted segmentation control. When the leaf shoot area parameters of lettuce differed from the set value, a fuzzy controller changed the nutrient solution temperature and spray frequency as well as the light intensity cause the leaf shoot area of lettuce to reach the control range after a specific time. The system used the lettuce leaf shoot area difference ΔS and the rate of change of the difference e as the inputs to the fuzzy controller, where ΔS is equal to S minus S0 actual and e is similar to the ratio of ΔS to the time increment. The output quantity of the fuzzy controller was the control command of the actuator, and the linguistic variable selection outputs of output U are pump spray frequency control (pump start interval U1), nutrient solution temperature control (chiller U2), and light intensity regulation (fill light U3). The lettuce leaf canopy area regulation system was thus treated as a two-dimensional fuzzy control.

The fuzzy domain was set at [-25,25] for ΔS, and the fuzzy domain was set at [-10,10] for e. The fuzzy domain of the rate of change of lettuce leaf shoot area difference was set to [-1,1]. In this study, ΔS and e set five fuzzy subsets with linguistic values were denoted as negative significant (NB), negative small (NS), zero (ZO), positive small (PS), and positive large (PB). This study used triangles as the affiliation function types of ΔS and e. The ΔS and e affiliation functions are shown in

Figure 8.

According to the principle that the shorter the spray interval was, the larger the crop leaf canopy area and the smaller the root-to-shoot ratio within a specific range with constant spray duration [

4], the output variable U1 fuzzy subset was set to {N, ZO, P}, and the domain was set to [[0,2]], with the linguistic values of spray interval increasing, spray interval constant, and spray interval decreasing. In contrast, the output variables U2 and U3 were controlled by relay switches with only two states (1/0), so their domain values were set to [0,1], and their linguistic values were ON and OFF.

2.4.1. Fuzzy Control Rules

The fuzzy decoupling controller in this study was dual-input and three-output fuzzy control system, where ΔS and e had five-level fuzzy spaces, so there were 25 control rules. Some of the fuzzy control rules developed in this experiment were based on practical experience (

Table 6)

2.5. Experimental Arrangement and Plant Material

The nutrient solution temperature, relative humidity, spray frequency, spray time, and root droplet adhesion area also have essential effects on lettuce growth in an aeroponics system. In this study, the effects of three factors, namely, the adhesion area of the nutrient solution in lettuce roots, the temperature of the nutrient solution, and spray frequency, on the growth of lettuce were obtained through experiments to determine the basic parameters of the fuzzy control system. From our previous study it was concluded that the root-to-shoot ratio of lettuce was the smallest when the spraying time was 5 minutes, and the spraying interval was 30 minutes [

27]. Hence for this study, the spraying time and interval was kept 5-min, and 30-minutes. The nutrient solution temperature was set at 18±1 °C and 22±1 °C. The daily illumination time was set at 20 hours [

28,

29], and the light source was plant growth lamps with a red to blue ratio of 4:1 [

30]. The experimental treatments were arranged as T

1 (18±1 °C), T

2 (22±1 °C), and CK (without control) with two replications. Lettuce seedlings were transplanted into growth boxes (the same standard) 15 days after sowing. A seedling root length value of 4.5-6 cm was measured on the transplant day. After transplanting, the nutrient solution was changed every seven days to keep the pH and EC of the nutrient solution within the suitable range for lettuce growth.

2.6. Growth Characteristics and Measurement of Edible and Inedible Parts

After transplanting, shoot length, root length, and shoot area were measured on every fifth day after transplant (DAT) until harvest. After harvest, the plant height was measured using a measuring scale. The number of lettuce leaves from randomly selected plants were measured by counting. The shoot fresh weight, and root fresh weight was measured with electric weighing balance with an accuracy of 0.1 mg. After the measurement, the samples were placed in paper envelopes and dried at 85 °C for 72 hours, and the dry weights of the leaf shoots and roots were measured in the same way.

2.7. Statistical Analyses

The Microsoft Excel 2016 and SPSS Statistics 19.0 software was used to analyze the data. The analysis of variance (ANOVA) was employed to determine the effect of different nutrient solution temperatures and control group. The correlation of the proposed parameters was tested by regression analyses and Duncan’s multiple tests at the p < 0.05 level of significance.

3. Results

To verify the function of the aeroponic control system, an indoor experiment was conducted. It was verified that the system presented overall good results of growth characteristics, and root-to-shoot ratio in T1 as compared to T2 and CK treatments.

3.1. Growth Characteristics

The analyzed results of shoot length, root length and shoot area with regards to days is depicted in

Figure 10. The results indicated that the increasing trend of these parameters were observed in all treatments. However, the root length and shoot length increased less in first two weeks and more after two weeks. The maximum growth of shoot length (24.3 cm) was observed in T

1 treatments and minimum of 16.5 cm was observed in CK treatment. Furthermore, the root length (51 cm) was higher in T

2 treatment and shorter in CK treatment. The maximum and minimum shoot area of 345 cm2 and 241.8 cm

2 was observed in T1 and CK treatments respectively. The analysed results indicated that T

1 and T

2 was not significantly different (p> 0.05), but the CK treatment was significantly different (p<0.05) from both treatments. The best fitting curve was linear curve, and the R

2 values are near to 1 indicated that there is less variation within the data set. These results directed that fuzzy logic control system and 18

0C temperature of nutrient solution gives better results as compared to 22

0C and without control treatment.

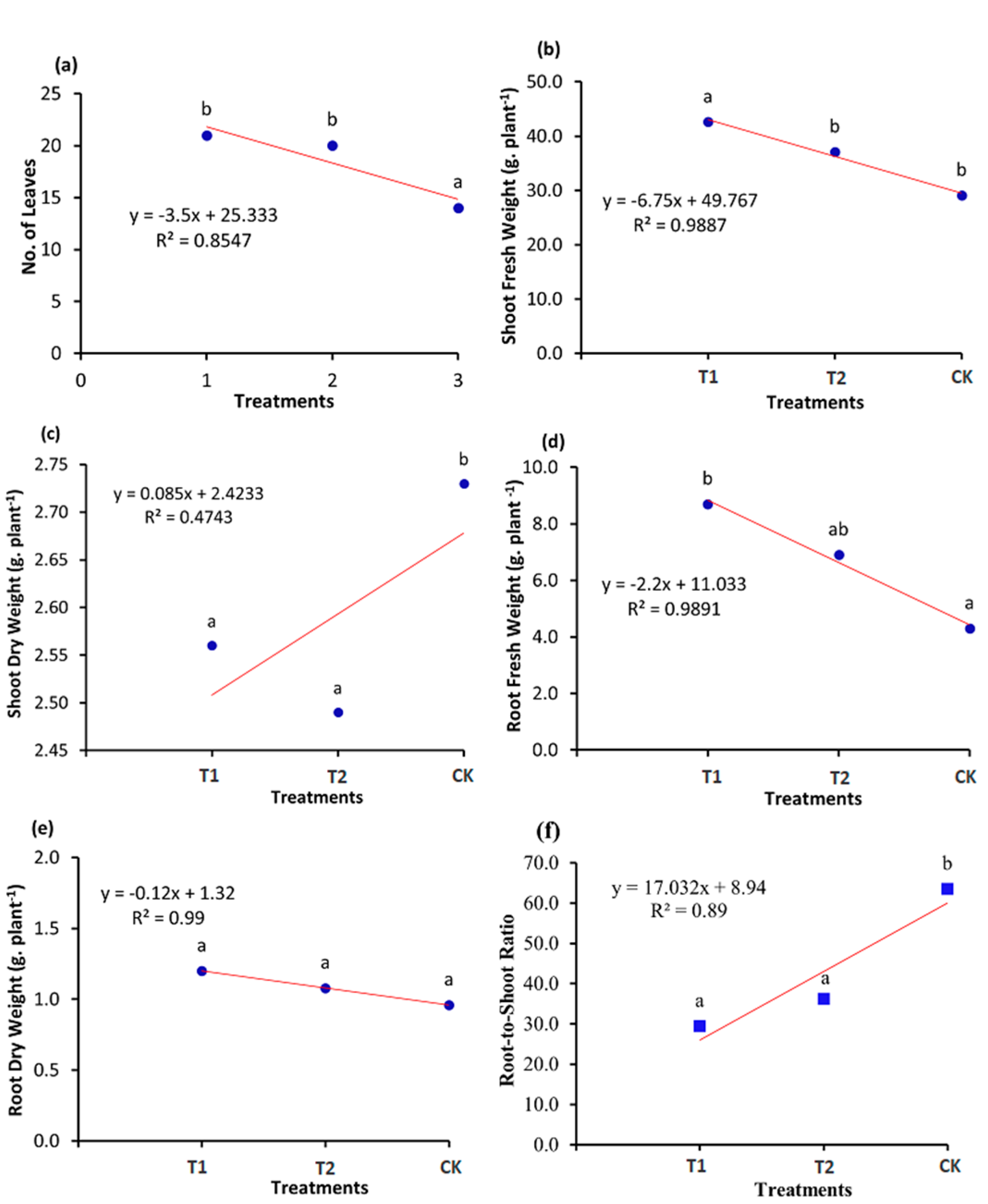

3.2. Measurement of Edible, Inedible Parts, and Root-to-Shoot Ratio

The statistical analyzed results of edible, inedible and root-to-shoot ratio of lettuce in different treatments are depicted in

Figure 11. The results clearly indicated that the T

1 and T

2 are not significantly (p<0.05) different. The higher number of leaves, shoot fresh weight, shoot dry weight, root fresh weight, root dry weight, and root-to-shoot ratio of 21, 42.6 g. plant

-1, 2.56 g. plant

-1, 8.7 g. plant

-1, 1.2 g. plant

-1 in T

1 treatment followed by T

2 treatment. However, the lower values of these parameters were measured in CK treatment. The root-to-shoot ratio of 29.43%, 36.09%, and 63.49% in T

1, T

2, and CK treatments respectively. The root-to-shoot ratio was greater 18.5% and 53.7% in T

2 and CK treatments than T

1 treatment. These results revealed that by using fuzzy control aeroponics system and 18

0C temperature gives higher yield and reduces the root, resulted in a lower root-to-shoot ratio. The R

2 values are very near to 1 except shoot dry weight show that there is small difference within the data set. The standard errors were also within the optimal range.

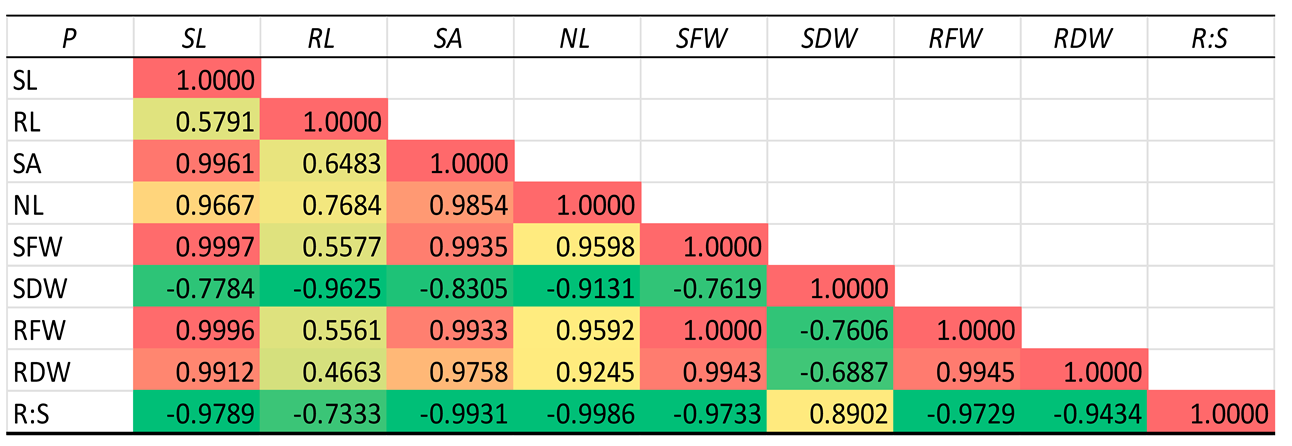

3.3. Correlation between Growth Characteristics and Biomass

The analyzed results of the correlation between growth characteristics and biomass parameters are presented in

Table 7. The values in different colors show the strong, moderate, and weak correlation between the parameters. The results revealed that most of the parameters had a positive correlation. However, some parameters had a negative correlation. The overall parameters had moderate to strong positive and negative correlations.

4. Discussion

The study presented in this paper applied image processing technology to the aeroponics system, built an aeroponics device and control system, introduced the scheme of aeroponics control system design in detail, and conducted related aeroponics experiments that affected the root-to-shoot ratio and biomass of lettuce. Some similar kinds of studies were reviewed such as; Reyes J L conducted aeroponics experiments in greenhouses to meet the growth requirements of different crops by controlling humidity, temperature, pH, and water conductivity [

31]. Kiran Sahu designed a greenhouse environmental parameter measurement and control system with ATMEL as the controller to control the light, ventilation, and drainage of the greenhouse by the growing conditions required by the crops, as well as to record and display the indoor temperature and humidity, soil moisture and sunlight values in real time [

32]. Most of these aeroponics systems used the environmental factors around the crop or changes in the nutrient solution as variables for various regulations during the cultivation process and lack of knowledge is available for aeroponics control systems that used the direct growth characteristics of the plant in different growth stages as the primary feedback signal.

Due to the ability of fuzzy logic to handle complex input-output relations and nonlinear dynamic properties, it has good adaptability and performance in the control of many nonlinear systems. Alimuddin A et al. proposed a novel integrated fuzzy control for greenhouse aeroponics system with real-time detection of temperature and carbon dioxide effects on red pepper cultivation [

33]. Argo B D et al. developed a fuzzy logic controller for indoor aeroponics system for the control of environmental factors such as temperature, relative humidity and light intensity [

34]. The above study showed that the fuzzy logic has better response and lower error for good plant growth. In this paper, the authors first designed the aeroponics test bench and then determined the control system design scheme using an STM32 microcontroller as the upper computer of the control system, two sets of 51 microcontrollers as the lower computer, and a PC as a way to process lettuce images and obtain lettuce growth parameters to achieve reasonable control in the process of lettuce aeroponics. The software and hardware of the aeroponics system were designed according to the control scheme to realize wireless data acquisition, equipment control, data processing, and storage of the system. The MATLAB platform was used to design the image processing interface, obtain the parameters of each growth stage of lettuce, and transmit some of the images to the host computer in steps. The host computer, after receiving the data, sent corresponding commands to the lower computer according to the fuzzy control strategy to achieve control of the spraying frequency, nutrient solution temperature, and light intensity The results showed that the machine vision and fuzzy logic based mist culture system in this study can effectively reduce the root to shoot ratio of lettuce while increasing the leaf shoot area of lettuce.

5. Conclusions

In conclusion, the study demonstrated the effectiveness of using image processing technology and a fuzzy logic control system in aeroponics cultivation. The results indicated a consistent increase in shoot length, root length, and shoot area across all treatments, with higher growth observed after the initial two weeks. The maximum shoot length was achieved in the T1 treatment, while the T2 treatment exhibited the highest root length. The T1 treatment also showed the maximum shoot area. Statistical analysis revealed significant differences between the control treatment (CK) and the T1/T2 treatments. The study highlighted the superior performance of the fuzzy logic control system and an 18°C nutrient solution temperature compared to the control treatment and a 22°C temperature. The analysis of edible and inedible portions of lettuce, as well as the root-to-shoot ratio, demonstrated higher values in the T1 and T2 treatments, indicating improved yield and reduced root-to-shoot ratio. These findings support the potential of using a fuzzy logic control system in aeroponics to optimize lettuce cultivation.Different vegetables have different environmental requirements at different growth stages, and this control system can only achieve automatic spraying settings for a single crop. In the future, the database can automatically develop control strategies according to crop types to achieve unmanned intelligent management of the entire crop growth cycle.

Author Contributions

Conceptualization, J.G.; methodology, J.G.; software, J.C.; validation, J.G. and Y.G.; formal analysis, Y.G.; investigation, J.G.; resources, J.G.; data curation, J.G.and M.H.T.; writing—original draft preparation, J.G. and Y.G.; writing—review and editing, J.G.; visualization, J.C.; supervision, Y.G. and J.C.; project administration, J.G.; funding acquisition, J.G. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported in part by the National Natural Science Foundation of China Program (NSFC) (No. 51975255); and in part by the Priority Academic Program Development of Jiangsu Higher Education Institutions (No. PAPD-2018-87).

Data Availability Statement

All datasets used in this study are included in the manuscript.

Acknowledgments

We acknowledge that this work was financially supported by the National Natural Science Foundation of China Program (NSFC) (No. 51975255), and the Project Funded by the Priority Academic Program Development of Jiangsu Higher Education Institutions (No. PAPD-2018-87).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Hikosaka Y, Kanechi M, Uno Y. A novel aeroponic technique using dry-fog spray fertigation to grow leaf lettuce (Lactuca sativa L. var. crispa) with watersaving hydroponics. Adv Hortic Sci, 2014, 28(4): 184-189.

- Li Q S, Li X Q, Zhang X, Wan M M, Tang B. Application of air atomizer in aeroponics. Agricultural engineering technology, 2018, 38(22): 53-57. (in Chinese).

- Lakhiar I A, Gao J M, Xu X, Syed T N, Chandio F A, Jing Z, et al. Effects of various aeroponic atomizers (droplet sizes) on growth, polyphenol content, and antioxidant activity of leaf lettuce (Lactuca sativa L.). Transactions of the ASABE, 2019, 62(6): 1475–1487.

- Tunio M H, Gao J M, Qureshi W A, Sheikh S A, Chen J D, Chandio F A, et al. Effects of droplet size and spray interval on root-to-shoot ratio, photosynthesis efficiency, and nutritional quality of aeroponically grown butter head lettuce. Int J Agric & Biol Eng, 2022,15(1): 79–88.

- Kerns S C, Lee J L. Automated aeroponics system using IoT for smart farming. Proceedings of the 8th International Scientific Forum, ISF, UNCP, Pembroke, NC, USA. 2017: 7-8.

- Montoya A P, Obando F A, Morales J G, et al. Automatic aeroponic irrigation system based on Arduino’s platform. J Phys Conf Ser, 2017, 850(1): 012003. [CrossRef]

- Gao J M, Huang G Z, Yin W C, Lu D P, Li J Y, Liu C J. Variation of root-zone droplet deposition, temperature and humidity of truss ultrasonic atomization cultivator, Transactions of the CSAE, 2013, 29(06): 185-192.

- Shen Z H. Design and Realize of the Monitoring system for the Aeroponic Stereoscopic Cultivation in Micro-environment. ‘ ‘Master’s Thesis, Taiyuan University of Technology, Taiyuan, China, 2019. (in Chinese).

- Mohamed T M K, Gao J M, Tunio M. Development, and experiment of the intelligent control system for rhizosphere temperature of aeroponic lettuce via the Internet of Things. Int J Agric & Biol Eng, 2022; 15(3): 225–233.

- Chen C H, Jeng S Y, Lin C J. Fuzzy logic controller for automating electrical conductivity and pH in hydroponic cultivation. Applied Sciences, 2022, 12(1): 405.

- Correa P, Bautista P, Lopez M, et al. An Approach of Beans Plant Development Classification Using Fuzzy Logic. Journal of Sensors, 2019, 2019. [CrossRef]

- Maya Olalla E, Lopez Flores A, Zambrano M, et al. Fuzzy Control Application to an Irrigation System of Hydroponic Crops under Greenhouse: Case Cultivation of Strawberries (Fragaria Vesca). Sensors, 2023, 23(8): 4088.

- Liu Z S. Italian Lettuce -- Super-resistant Lettuce. Agricultural Science and Technology and Information, 2002(09): 21. (in Chinese).

- Fan X X, Song B, Xu H, et al. Effects of different LED light sources on growth and quality of lettuce. Journal of hubei university for nationalities (natural science edition), 2015, 33(03): 330-333. (in Chinese).

- Sun H Z, Wang H, Shen J H, et al. Effects of different proportions of red and blue light on seed germination and seedling growth of lettuce. Acta Agriculturae Zhejiangensis, 2014, 26(3): 603-608. (in Chinese).

- Li Kai, Chen Li-an, Cao Ji-chang. ID card number identification based on gray scale multi-level. Computer Engineering and Applications, 2015, 51(13):191-196.(in Chinese).

- Wang Y Q. Research on weed recognition method in wheat field based on machine vision. ‘ ‘Master’s Thesis, China Agricultural University, Beijing, China, 2004. (in Chinese).

- Su W, Zhang R, Wu D Y, Liu Z, Zhang M Z, Zhu D H, Huang J X. A method and device for calculating maize seedling emergence rate based on UAV remote sensing image. Beijing: CN107016674A, 2017-08-04.(in Chinese).

- Zhao D S. Real-time weed identification technique of precise spraying intelligent weeding device based on machine vision. ‘ ‘Master’s Thesis, Jiangsu University, Zhenjiang, China, 2009. (in Chinese).

- TAN L, LI Y. Research on Rape Image Automatic Segmentation Method Based on RGB Color Space. 2020 International Conference on Communications, Information System and Computer Engineering (CISCE). Kuala Lumpur, Malaysia, 2020, pp. 411-415.

- Hu L, Liu C, Wu X. Image Segmentation of Rape Based on EXG and Lab Spatial Threshold Algorithms. Proceedings of the 2019 International Conference on Artificial Intelligence and Computer Science. New York, NY, USA, 2019: 384-389.

- Yuan X P, Zhang X, Zhang Y. An improved image enhancement technology algorithm based on frequency domain. Science technology and engineering, 2019, 19(31): 246-250.(in Chinese).

- Xu X C. The research of embedded machine vision System based on image features. ‘ ‘Master’s Thesis, Hangzhou Dianzi University, Hangzhou, China, 2015.(in Chinese).

- Jothiaruna N, Sundar K J, Karthikeyan B, et al. A segmentation method for disease spot images incorporating chrominance in Comprehensive Color Feature and Region Growing. Comput. Electron. Agric, 2019, 165, 104934. [CrossRef]

- Morlon Marcon, Kleber Mariano. Estimation of total leaf area in perennial plants using image analysis, R. Bras. Eng. Ambiental, 2011, 15, 96-101. [CrossRef]

- Zhao X L. Greenness Identification from Crop Growth Monitoring Images. ‘ ‘Master’s Thesis, Hebei University, Baoding, China, 2015. (in Chinese).

- Tunio M H , Gao J, Lakhiar I A , et al. Influence of Atomization Nozzles and Spraying Intervals on Growth, Biomass Yield, and Nutrient Uptake of Butter-Head Lettuce under Aeroponics System. Agronomy, 2021, 11(1). [CrossRef]

- Mao Jinzhu, Qiu Quan, Zhang Fang, et al. Effect of different light duration on growth of lettuce under LED light source. Journal of Agricultural Mechanization Research, 2014, 36(03): 141-145.

- Yan Y. Effects of temperature and photoperiod on growth of hydroponic lettuce and its growth model. Huazhong Agricultural University, Wuhan, China, 2008.(in Chinese).

- Sun H Z. Effects of red and blue light ratio on physiological characteristics and quality of green leafy vegetables. Nanjing Agricultural University, nanjing, China, 2014. (in Chinese).

- Reyes J L, Montoya R, Ledesma C, et al. Development of an aeroponic system for vegetable production. International Symposium on Soilless Culture and Hydroponics 947. 2011: 153-156.

- Sahu K, Mazumdar S G. Digitally greenhouse monitoring and controlling of system based on embedded system. International Journal of Scientific & Engineering Research, 2012, 3(1): 41-48.

- Alimuddin A, Arafiyah R, Subrata D M, et al. Development and Performance of a Fuzzy Logic Control System for Temperature and Carbon Dioxide for Red Chili Cultivation in an Aeroponic Greenhouse System. IJASEIT, 2021, 10(6): 2355-2361. [CrossRef]

- Argo B D, Hendrawan Y, Ubaidillah U. A fuzzy micro-climate controller for small indoor aeroponics systems. TELKOMNIKA (Telecommunication Computing Electronics and Control), 2019, 17(6): 3019-3026. [CrossRef]

Figure 1.

Aeroponic device structure; 1. Red and blue LED, 2. Growth box, 3. Cultivation rack, 4. Nozzle, 5. Drain pipe, 6. Nutrient solution supply tank, 7. Camera, 8. Light intensity sensor, 9. Temperature, humidity, and carbon dioxide sensor, 10. Nozzle inlet pipe, 11. 51 Lower machine control boxes, 12. Cold water machine, 13. 18B20 temperature probe, 14. Water pump, 15. Computer, 16. Upper computer controller.

Figure 1.

Aeroponic device structure; 1. Red and blue LED, 2. Growth box, 3. Cultivation rack, 4. Nozzle, 5. Drain pipe, 6. Nutrient solution supply tank, 7. Camera, 8. Light intensity sensor, 9. Temperature, humidity, and carbon dioxide sensor, 10. Nozzle inlet pipe, 11. 51 Lower machine control boxes, 12. Cold water machine, 13. 18B20 temperature probe, 14. Water pump, 15. Computer, 16. Upper computer controller.

Figure 2.

Flow chart of the aeroponic device.

Figure 2.

Flow chart of the aeroponic device.

Figure 3.

System design flow chart.

Figure 3.

System design flow chart.

Figure 4.

Operating system transplantation flow chart.

Figure 4.

Operating system transplantation flow chart.

Figure 5.

Interface design visualization.

Figure 5.

Interface design visualization.

Figure 6.

Greyed images process during the experiment.

Figure 6.

Greyed images process during the experiment.

Figure 7.

Grey image enhancement during the experiment.

Figure 7.

Grey image enhancement during the experiment.

Figure 8.

Image processing of lettuce leaves during experiment.

Figure 8.

Image processing of lettuce leaves during experiment.

Figure 9.

ΔS and e membership function.

Figure 9.

ΔS and e membership function.

Figure 9.

Experimental setup used during the effectiveness test of system.

Figure 9.

Experimental setup used during the effectiveness test of system.

Figure 10.

The analyzed results of lettuce plant in different treatments with regards to experimental days; (a) shoot length, (b) root length, and (c) shoot area. The same letters within the treatment presented not statistically different (n = 9).

Figure 10.

The analyzed results of lettuce plant in different treatments with regards to experimental days; (a) shoot length, (b) root length, and (c) shoot area. The same letters within the treatment presented not statistically different (n = 9).

Figure 11.

The analyzed results of lettuce plant in different treatments; (a) number of leaves, (b) shoot fresh weight, (c) shoot dry weight, (d) root fresh weight, (e) root dry weight, and (f) root-to-shoot ratio. The same letters presented not statistically different (n = 9).

Figure 11.

The analyzed results of lettuce plant in different treatments; (a) number of leaves, (b) shoot fresh weight, (c) shoot dry weight, (d) root fresh weight, (e) root dry weight, and (f) root-to-shoot ratio. The same letters presented not statistically different (n = 9).

Table 1.

Performance parameters of the temperature and humidity sensors.

Table 1.

Performance parameters of the temperature and humidity sensors.

| Parameters |

Values |

Parameters |

Values |

| Humidity measurement range |

0~100% RH |

Input Voltage |

3.0 V~5.5 V |

| Temperature measurement range |

-40~80 °C |

Humidity response time |

<5 s |

| Humidity measurement accuracy |

±2% RH |

Temperature response time |

6 s~20 s |

| Temperature measurement accuracy |

±0.5 °C |

|

|

Table 2.

CO2 sensor performance parameters.

Table 2.

CO2 sensor performance parameters.

| Parameters |

Values |

Parameters |

Values |

| Measurement range |

400~60000 ppm |

Input Voltage |

3.0 V~5.5 V |

| Operating temperature range |

-40~85 °C |

Power consumption |

40mA,1.8 V |

| Humidity Range |

10~90% (Noncondensing) |

Sampling Rate |

1 HZ |

Table 3.

Performance Parameters of the Light Intensity Sensor.

Table 3.

Performance Parameters of the Light Intensity Sensor.

| Parameters |

Values |

Parameters |

Values |

| Light level range |

0~65535 lx |

Operating temperature |

-40~85 °C |

| Operating Voltage |

3.0 V~5.5 V |

Interface Type |

IIC |

| Working current |

200 μA |

|

|

Table 4.

Performance Parameter Wireless Module.

Table 4.

Performance Parameter Wireless Module.

| Parameters |

Values |

Parameters |

Values |

| Wireless Frequency Band |

2400~2450 MHz |

Point-to-point transmission rate |

Up to 3300 Bps |

| Operating Current |

Less than 30mA |

Transmitting power |

4.5 dBm |

| Input Voltage |

3.0 V~5.5 V |

Receive Sensitivity |

-97 dBm |

| Transmission distance |

Less than 250 m |

Point-to-point error bit rate |

0.00% |

| Operating temperature |

-40 °C~80 °C |

Broadcast error bit rate |

0.50% |

Table 5.

Comparison of the leaf shoot area index measurement results generated by using the MATLAB image method and Photoshop image method.

Table 5.

Comparison of the leaf shoot area index measurement results generated by using the MATLAB image method and Photoshop image method.

| Lettuce numbers |

MATLAB super green feature method/cm2

|

Photoshop image method/cm2

|

Relative error (%) |

| 1 |

12.712 |

13.46 |

-5.56 |

| 2 |

11.544 |

11.75 |

-1.75 |

| 3 |

11.530 |

11.89 |

-3.03 |

| 4 |

11.331 |

11.21 |

1.08 |

| 5 |

11.046 |

11.36 |

-2.76 |

| 6 |

10.975 |

10.8 |

1.62 |

Table 6.

Partial control rule table.

Table 6.

Partial control rule table.

| Parameters |

Execution device status |

| ΔS |

e |

Chiller U1 |

Fill light U2 |

Water pump U3 |

| NB |

NB |

OFF |

OFF |

N |

| NB |

NS |

OFF |

OFF |

N |

| NB |

ZO |

OFF |

OFF |

ZO |

| NS |

PS |

ON |

OFF |

ZO |

| NS |

PB |

ON |

OFF |

ZO |

| ZO |

NB |

ON |

OFF |

ZO |

| ZO |

NS |

ON |

OFF |

ZO |

| PS |

ZO |

ON |

ON |

ZO |

| PB |

PS |

ON |

ON |

P |

| PB |

PB |

ON |

ON |

P |

Table 7.

Partial control rule table.

Table 7.

Partial control rule table.

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).