Submitted:

03 June 2023

Posted:

05 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

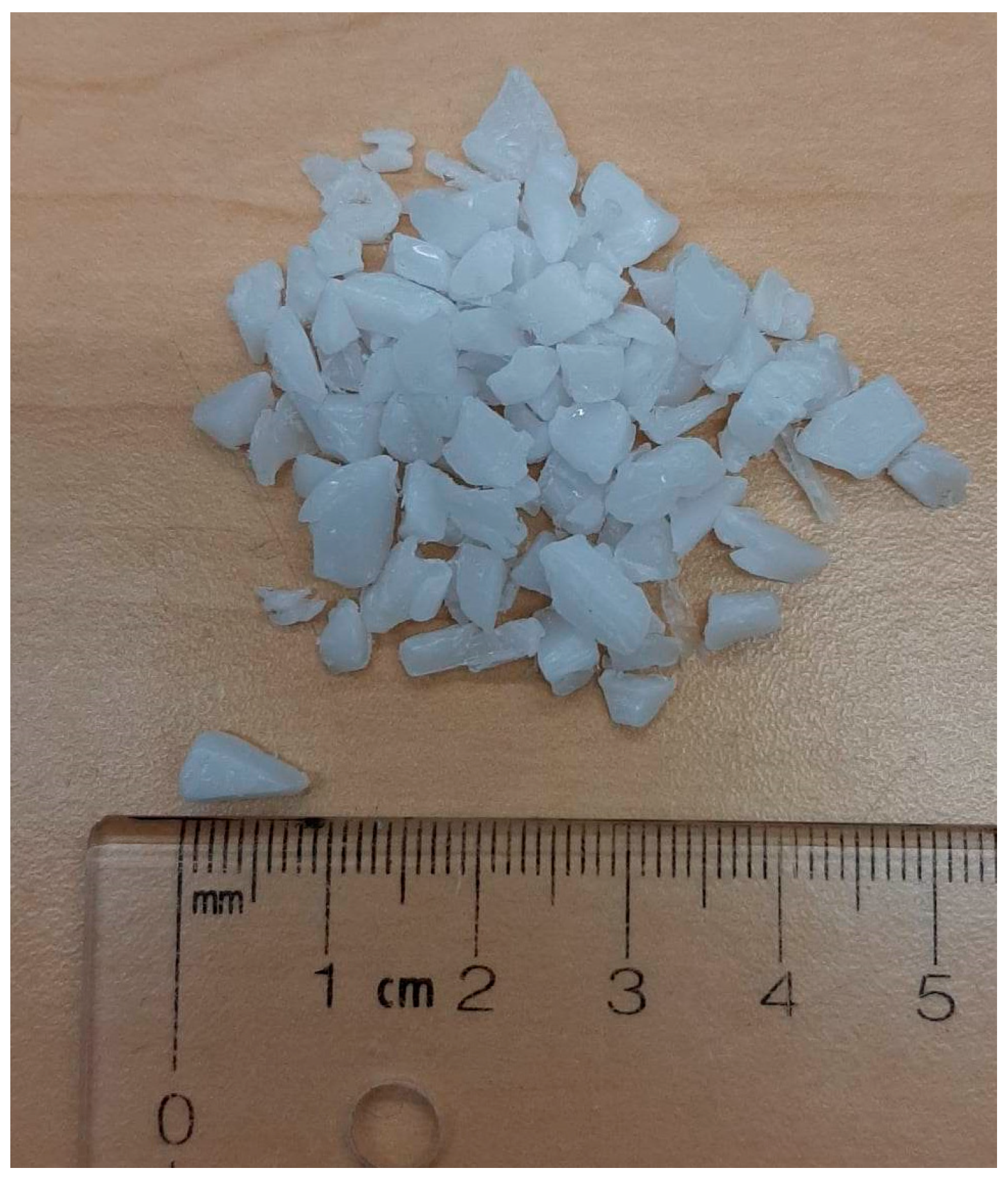

2.1. Materials

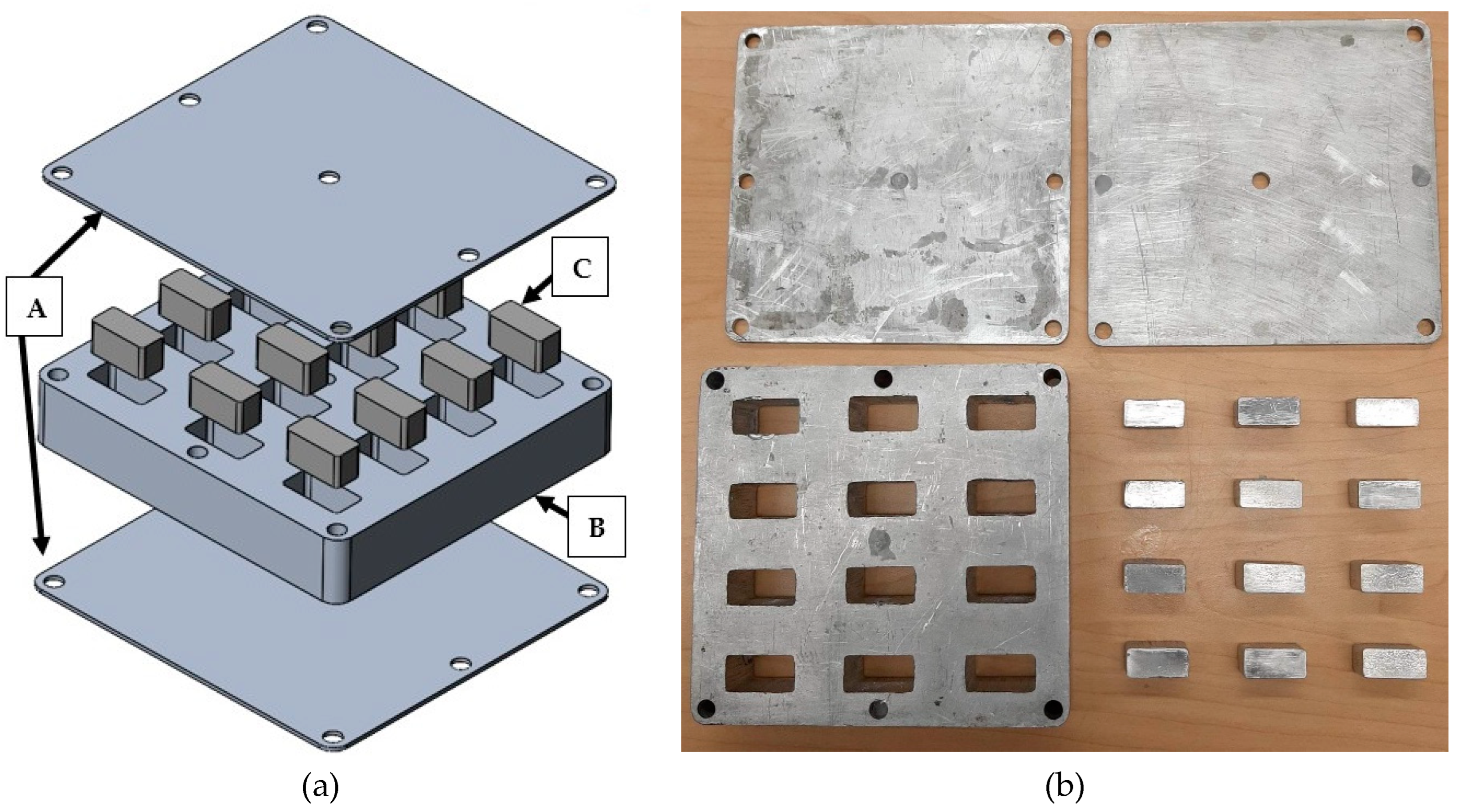

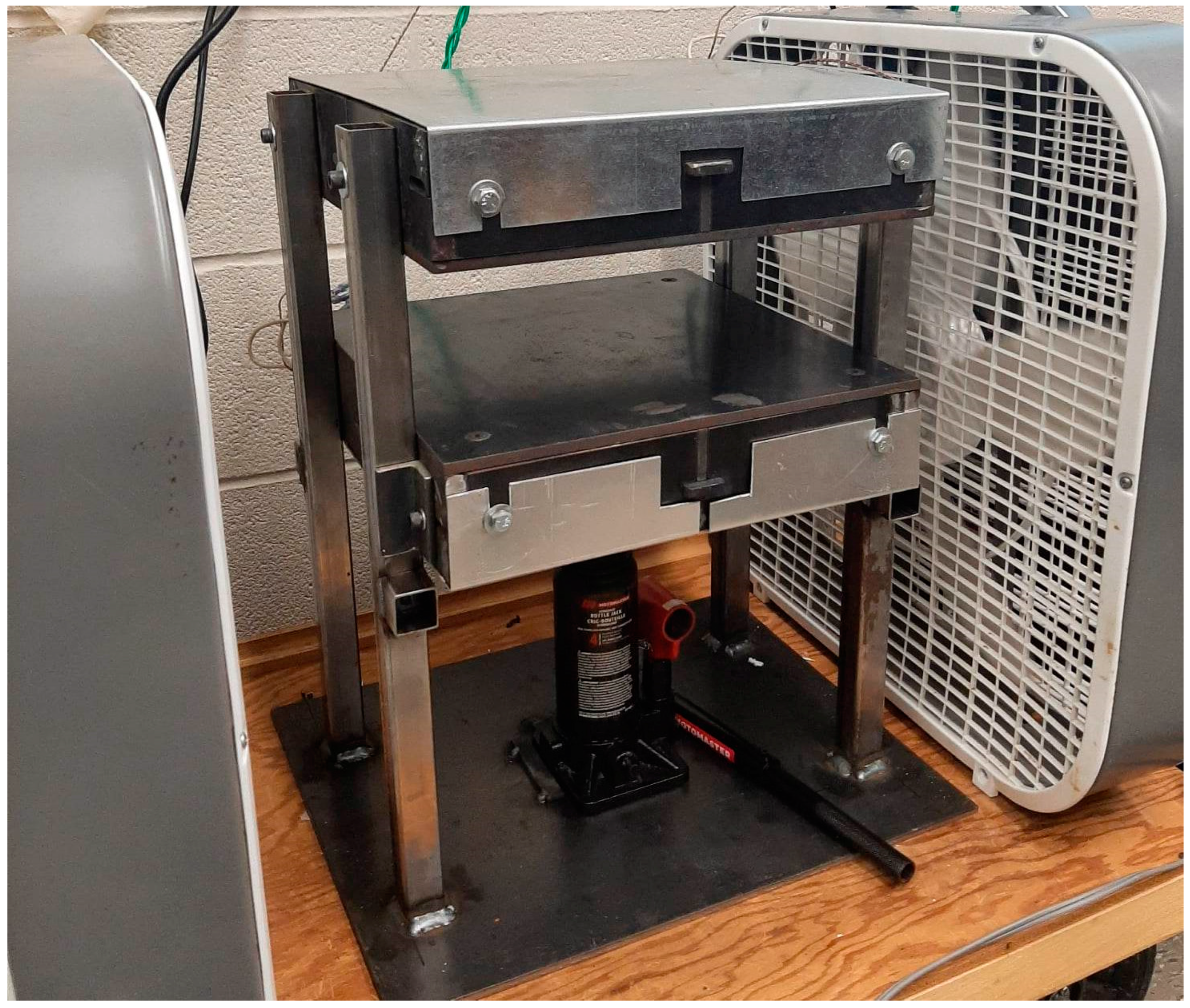

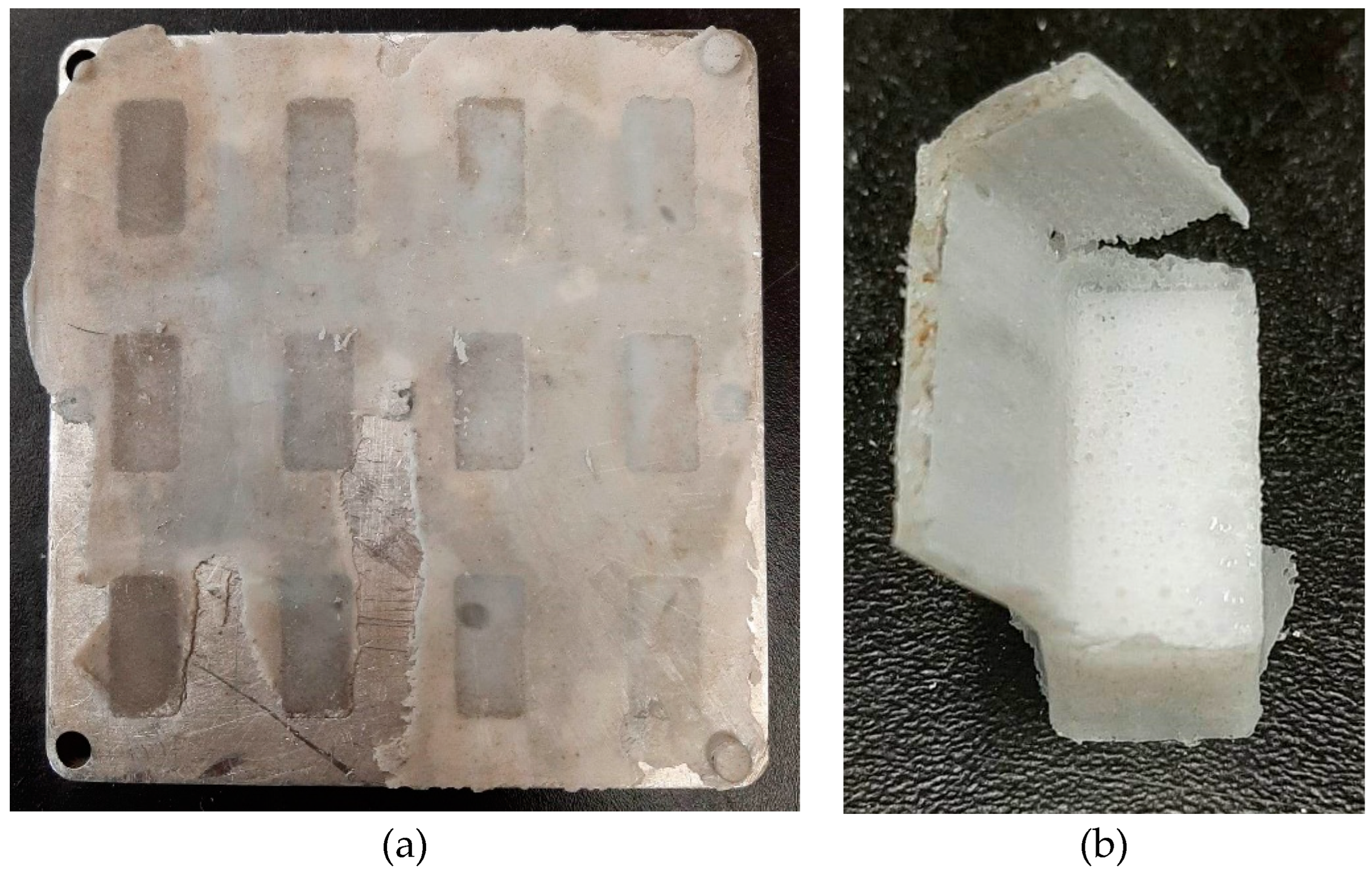

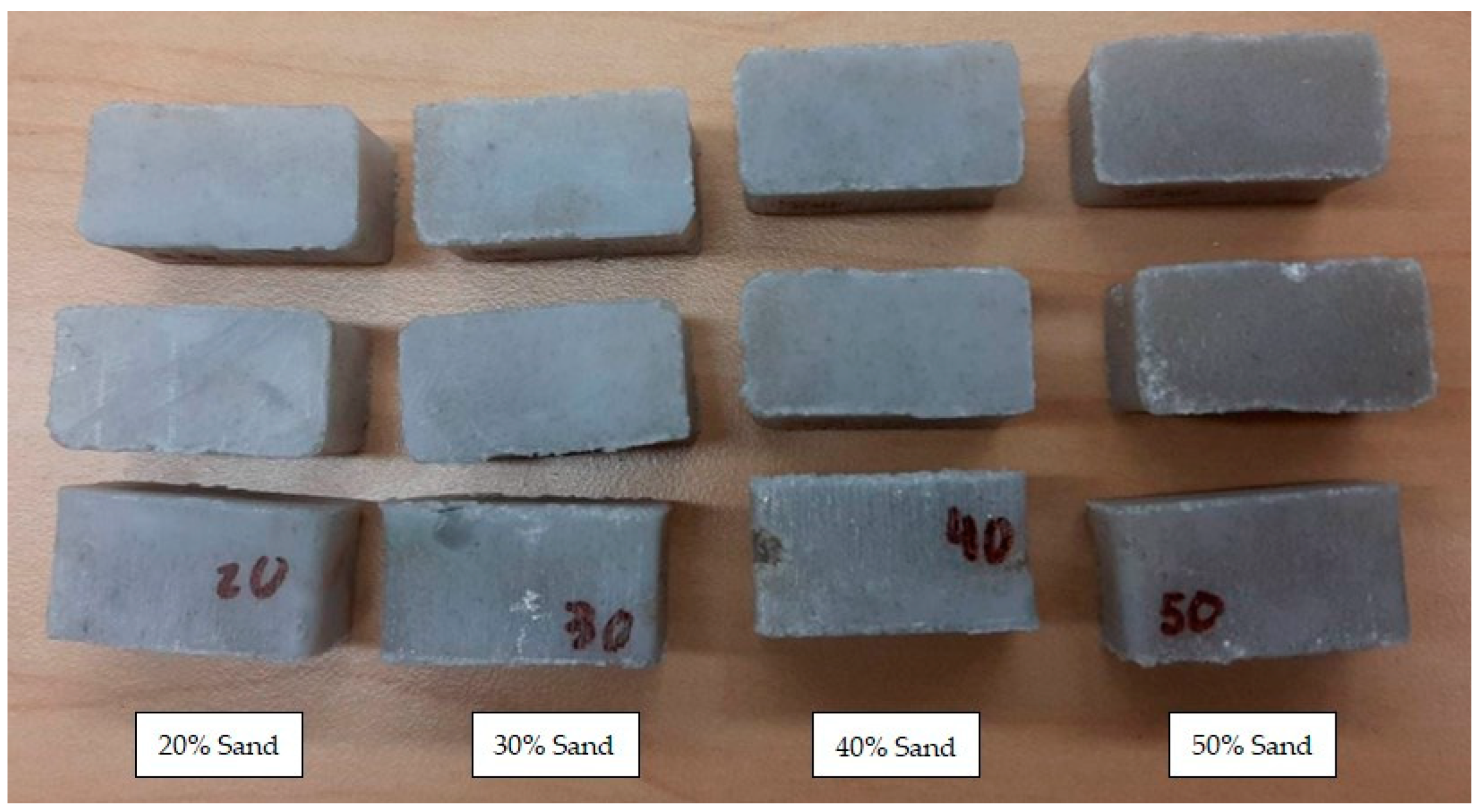

2.2. Production of Sand-Plastic Composite Samples

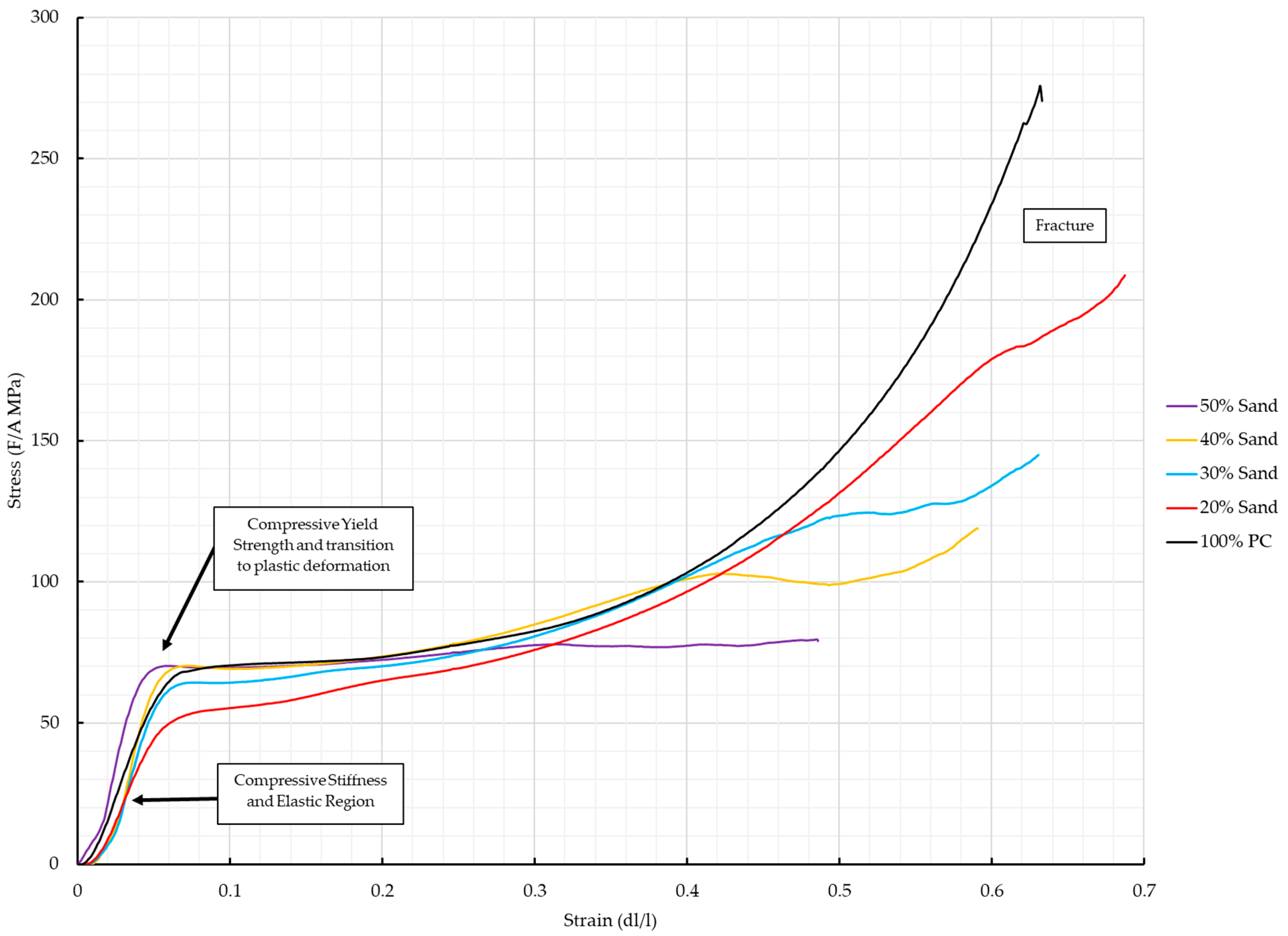

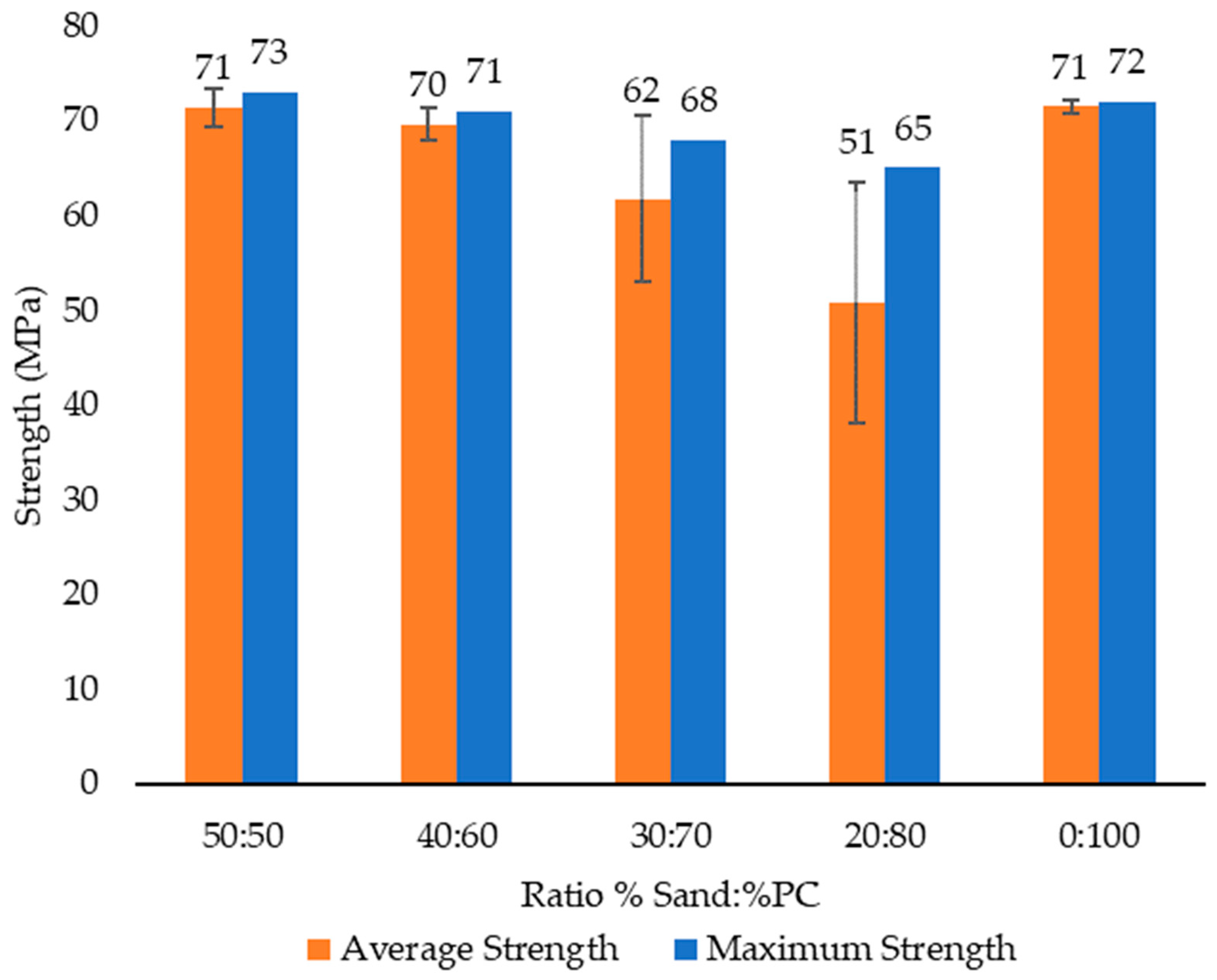

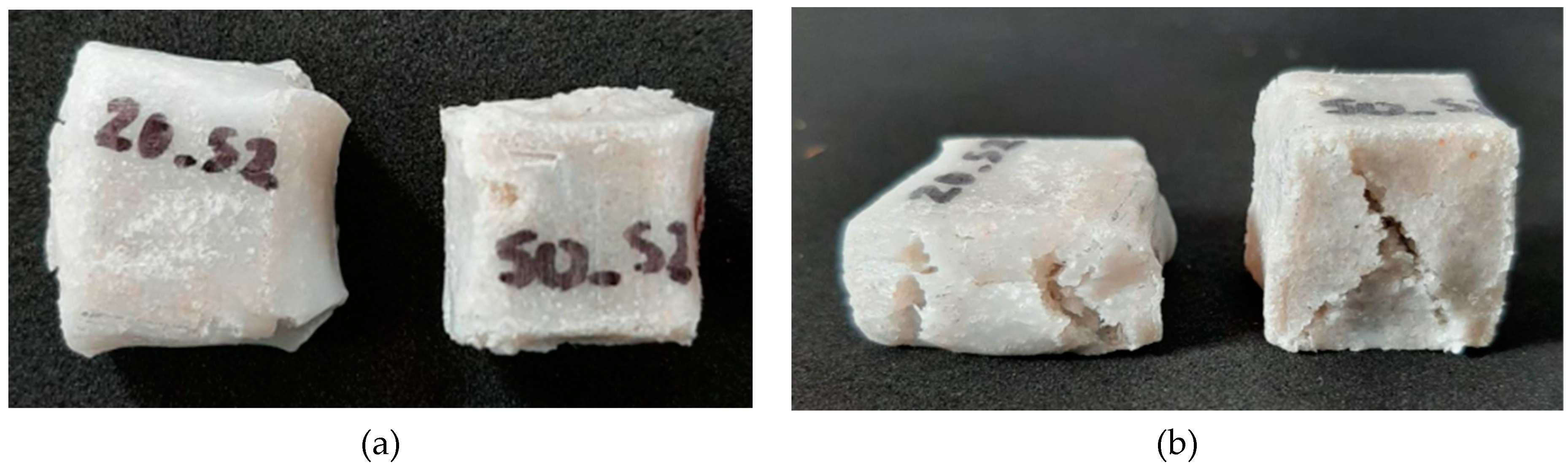

3. Results

4. Discussion

4.1. Applications

4.2. Future Directions

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Statista Research Department Global Plastic Production 1950-2021. Available online: https://www.statista.com/statistics/282732/global-production-of-plastics-since-1950/ (accessed on 8 May 2023).

- OECD Global Plastics Outlook Database Plastic Pollution Is Growing Relentlessly as Waste Management and Recycling Fall Short, Says OECD. Available online: https://www.oecd.org/environment/plastic-pollution-is-growing-relentlessly-as-waste-management-and-recycling-fall-short.htm (accessed on 8 May 2023).

- Plastics and the Environment; Andrady, A.L., Ed.; 1st ed.; Wiley, 2003; ISBN 978-0-471-09520-0.

- Gu, L.; Ozbakkaloglu, T. Use of Recycled Plastics in Concrete: A Critical Review. Waste Management 2016, 51, 19–42. [Google Scholar] [CrossRef] [PubMed]

- Monteiro, P.J.M.; Miller, S.A.; Horvath, A. Towards Sustainable Concrete. Nature Mater 2017, 16, 698–699. [Google Scholar] [CrossRef] [PubMed]

- Babor, D.; Plian, D.; Judele, L. Environmental Impact of Concrete. Buletinul Institutului Politehnic din lasi. Sectia Constructii, Arhitectura 2009, 55, 27. [Google Scholar]

- Ellis, L.D.; Badel, A.F.; Chiang, M.L.; Park, R.J.-Y.; Chiang, Y.-M. Toward Electrochemical Synthesis of Cement—An Electrolyzer-Based Process for Decarbonating CaCO3 While Producing Useful Gas Streams. Proceedings of the National Academy of Sciences 2020, 117, 12584–12591. [Google Scholar] [CrossRef]

- Cement Industry Accounts for about 8% of CO2 Emissions. One Startup Seeks to Change That. Available online: https://www.cbsnews.com/news/cement-industry-co2-emissions-climate-change-brimstone/ (accessed on 11 May 2023).

- Tiseo, I. Global Carbon Dioxide Emissions from Cement Manufacturing 1990-2021, by Country. Available online: https://www.statista.com/statistics/1091672/carbon-dioxide-emissions-global-cement-manufacturing/ (accessed on 10 May 2023).

- Watts, J. Concrete: The Most Destructive Material on Earth. The Guardian 2019.

- Tiseo, I. Global CO₂ Emissions from Cement Manufacturing 1960-2021. Available online: https://www.statista.com/statistics/1299532/carbon-dioxide-emissions-worldwide-cement-manufacturing/ (accessed on 8 May 2023).

- Müller, H.S.; Haist, M.; Vogel, M. Assessment of the Sustainability Potential of Concrete and Concrete Structures Considering Their Environmental Impact, Performance and Lifetime. Construction and Building Materials 2014, 67, 321–337. [Google Scholar] [CrossRef]

- Alnahhal, M.F.; Alengaram, U.J.; Jumaat, M.Z.; Abutaha, F.; Alqedra, M.A.; Nayaka, R.R. Assessment on Engineering Properties and CO2 Emissions of Recycled Aggregate Concrete Incorporating Waste Products as Supplements to Portland Cement. Journal of Cleaner Production 2018, 203, 822–835. [Google Scholar] [CrossRef]

- Alsubari, B.; Shafigh, P.; Ibrahim, Z.; Jumaat, M.Z. Heat-Treated Palm Oil Fuel Ash as an Effective Supplementary Cementitious Material Originating from Agriculture Waste. Construction and Building Materials 2018, 167, 44–54. [Google Scholar] [CrossRef]

- Nwankwo, C.O.; Bamigboye, G.O.; Davies, I.E.E.; Michaels, T.A. High Volume Portland Cement Replacement: A Review. Construction and Building Materials 2020, 260, 120445. [Google Scholar] [CrossRef]

- Beyond Portland Cement: Low-Carbon Alternatives - The Institution of Structural Engineers. Available online: https://www.istructe.org/resources/guidance/beyond-portland-cement-low-carbon-alternatives/ (accessed on 22 May 2023).

- Oliveira, T.C.F.; Dezen, B.G.S.; Possan, E. Use of Concrete Fine Fraction Waste as a Replacement of Portland Cement. Journal of Cleaner Production 2020, 273, 123126. [Google Scholar] [CrossRef]

- Scrivener, K.; Martirena, F.; Bishnoi, S.; Maity, S. Calcined Clay Limestone Cements (LC3). Cement and Concrete Research 2018, 114, 49–56. [Google Scholar] [CrossRef]

- Miller, S.A.; Horvath, A.; Monteiro, P.J.M. Impacts of Booming Concrete Production on Water Resources Worldwide. Nat Sustain 2018, 1, 69–76. [Google Scholar] [CrossRef]

- Al-Sinan, M.A.; Bubshait, A.A. Using Plastic Sand as a Construction Material toward a Circular Economy: A Review. Sustainability 2022, 14, 6446. [Google Scholar] [CrossRef]

- Suriyaa, M.; Hareharan, P.; Nageshwaran, J.; Nandhini, S.; Sathyamoorthy, R. Experimental Study on Strength Behaviour of Plastic Sand Bricks. 2020, 9.

- Sahani, K.; Joshi, B.; Khatri, K.; Thapa Magar, A.; Chapagain, S.; Karmacharya, N. Mechanical Properties of Plastic Sand Brick Containing Plastic Waste. Advances in Civil Engineering 2022, 2022, 1–10. [Google Scholar] [CrossRef]

- Bamigboye, G.; Ngene, B.; Ademola, D.; Jolayemi, K. Experimental Study on the Use of Waste Polyethylene Terephthalate (PET) and River Sand in Roof Tile Production. Journal of Physics: Conference Series 2019, 1378, 042105. [Google Scholar] [CrossRef]

- Susila, I.M.; Suardana, N.P.G.; Kencanawati, C.I.P.K.; Thanaya, I.N.A.; Adnyana, I.W.B. The Effect of Composition of Plastic Waste Low Density Polythylene (LDPEI) with Sand to Pressure Strength and Density of Sand/LDPE Composites. IOP Conf. Ser.: Mater. Sci. Eng. 2019, 539, 012043. [Google Scholar] [CrossRef]

- Yu, Q.L.; Spiesz, P.; Brouwers, H.J.H. Development of Cement-Based Lightweight Composites–Part 1: Mix Design Methodology and Hardened Properties. Cement and concrete composites 2013, 44, 17–29. [Google Scholar] [CrossRef]

- Leung, C.K.Y. Concrete as a Building Material. In Encyclopedia of Materials: Science and Technology; Buschow, K.H.J., Cahn, R.W., Flemings, M.C., Ilschner, B., Kramer, E.J., Mahajan, S., Veyssière, P., Eds.; Elsevier: Oxford, 2001; pp. 1471–1479. ISBN 978-0-08-043152-9. [Google Scholar]

- Bendler, J.T. Handbook of Polycarbonate Science and Technology; CRC press, 1999; ISBN 0-8247-9915-1.

- Gohil, M.; Joshi, G. Chapter 18 - Perspective of Polycarbonate Composites and Blends Properties, Applications, and Future Development: A Review. In Green Sustainable Process for Chemical and Environmental Engineering and Science; Altalhi, T., Inamuddin, Eds.; Elsevier, 2022; pp. 393–424 ISBN 978-0-323-99643-3.

- Polycarbonate Industry Installed Capacity and Capital Expenditure (CapEx) Forecast by Region and Countries Including Details of All Active Plants, Planned and Announced Projects, 2021-2025. Market Research Reports & Consulting | GlobalData UK Ltd.

- Overview of Materials for Polycarbonate, Molded. Available online: https://www.matweb.com/search/DataSheet.aspx?MatGUID=84b257896b674f93a39596d00d999d77&ckck=1 (accessed on 11 May 2023).

- Raheem, Z. Designation: D695 − 15 Standard Test Method for Compressive Properties of Rigid Plastics 1; 2019.

- Woods, M. OSF. Available online: https://osf.io/jmvu2 (accessed on 11 May 2023).

- Woods, M. OSF. Available online: https://osf.io/7rbae (accessed on 11 May 2023).

- Woods, M. OSF. Available online: https://osf.io/tu7bd (accessed on 11 May 2023).

- Woods, M.C.; Brooks, C.; Kulkarni, A.; Pearce, J.M. Open Source Cold and Hot Scientific Sheet Press for Investigating Polymer-Based Material Properties. HardwareX To be Published.

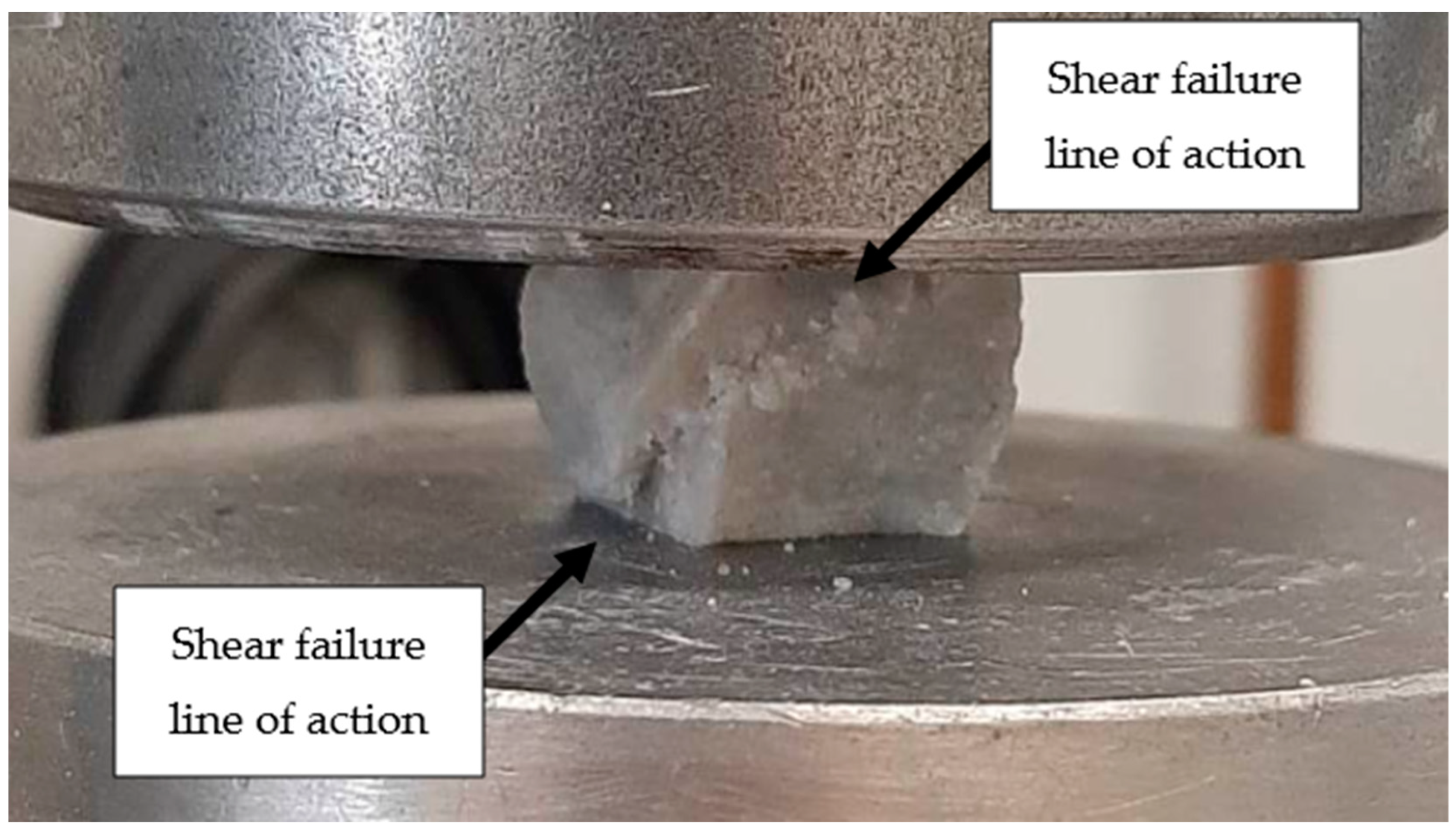

- Santiago, S.D.; Hilsdorf, H.K. Fracture Mechanisms of Concrete under Compressive Loads. Cement and Concrete Research 1973, 3, 363–388. [Google Scholar] [CrossRef]

- Alyousef, R.; Ahmad, W.; Ahmad, A.; Aslam, F.; Joyklad, P.; Alabduljabbar, H. Potential Use of Recycled Plastic and Rubber Aggregate in Cementitious Materials for Sustainable Construction: A Review. Journal of Cleaner Production 2021, 329, 129736. [Google Scholar] [CrossRef]

- Van Gemert, D.; Czarnecki, L.; Maultzsch, M.; Schorn, H.; Beeldens, A.; Łukowski, P.; Knapen, E. Cement Concrete and Concrete–Polymer Composites: Two Merging Worlds: A Report from 11th ICPIC Congress in Berlin, 2004. Cement and Concrete Composites 2005, 27, 926–933. [Google Scholar] [CrossRef]

- Rupal, A.; Meda, S.R.; Gupta, A.; Tank, I.; Kapoor, A.; Sharma, S.K.; Sathish, T.; Murugan, P. Utilization of Polymer Composite for Development of Sustainable Construction Material. Advances in Materials Science and Engineering 2022, 2022, e1240738. [Google Scholar] [CrossRef]

- Jin, D.; Meyer, T.K.; Chen, S.; Ampadu Boateng, K.; Pearce, J.M.; You, Z. Evaluation of Lab Performance of Stamp Sand and Acrylonitrile Styrene Acrylate Waste Composites without Asphalt as Road Surface Materials. Construction and Building Materials 2022, 338, 127569. [Google Scholar] [CrossRef]

- Cruz Sanchez, F.A.; Boudaoud, H.; Camargo, M.; Pearce, J.M. Plastic Recycling in Additive Manufacturing: A Systematic Literature Review and Opportunities for the Circular Economy. Journal of Cleaner Production 2020, 264, 121602. [Google Scholar] [CrossRef]

- Petsiuk, A.; Pearce, J.M. Towards Smart Monitored AM: Open Source in-Situ Layer-Wise 3D Printing Image Anomaly Detection Using Histograms of Oriented Gradients and a Physics-Based Rendering Engine. Additive Manufacturing 2022, 52, 102690. [Google Scholar] [CrossRef]

- Rattan, R.S.; Nauta, N.; Romani, A.; Pearce, J.M. Hangprinter for Large Scale Additive Manufacturing Using Fused Particle Fabrication with Recycled Plastic and Continuous Feeding. HardwareX 2023, 13, e00401. [Google Scholar] [CrossRef]

- Pritschow, G.; Dalacker, M.; Kurz, J.; Gaenssle, M. Technological Aspects in the Development of a Mobile Bricklaying Robot. Automation in Construction 1996, 5, 3–13. [Google Scholar] [CrossRef]

- Dörfler, K.; Sandy, T.; Giftthaler, M.; Gramazio, F.; Kohler, M.; Buchli, J. Mobile Robotic Brickwork. In Robotic Fabrication in Architecture, Art and Design 2016; Reinhardt, D., Saunders, R., Burry, J., Eds.; Springer International Publishing: Cham, 2016; pp. 204–217. ISBN 978-3-319-26378-6. [Google Scholar]

- Basiri, M.; Gonçalves, J.; Rosa, J.; Vale, A.; Lima, P. An Autonomous Mobile Manipulator to Build Outdoor Structures Consisting of Heterogeneous Brick Patterns. SN Appl. Sci. 2021, 3, 558. [Google Scholar] [CrossRef]

- Anzai, T.; Zhao, M.; Nishio, T.; Shi, F.; Okada, K.; Inaba, M. Fully Autonomous Brick Pick and Place in Fields by Articulated Aerial Robot: Results in Various Outdoor Environments. IEEE Robotics & Automation Magazine 2023, 2–16. [CrossRef]

- Dertinger, S.C.; Gallup, N.; Tanikella, N.G.; Grasso, M.; Vahid, S.; Foot, P.J.S.; Pearce, J.M. Technical Pathways for Distributed Recycling of Polymer Composites for Distributed Manufacturing: Windshield Wiper Blades. Resources, Conservation and Recycling 2020, 157, 104810. [Google Scholar] [CrossRef]

- De Luca, F.; Sernicola, G.; Shaffer, M.S.P.; Bismarck, A. “Brick-and-Mortar” Nanostructured Interphase for Glass-Fiber-Reinforced Polymer Composites. ACS Appl. Mater. Interfaces 2018, 10, 7352–7361. [Google Scholar] [CrossRef]

- Tsala-Mbala, C.; Hayibo, K.S.; Meyer, T.K.; Couao-Zotti, N.; Cairns, P.; Pearce, J.M. Technical and Economic Viability of Distributed Recycling of Low-Density Polyethylene Water Sachets into Waste Composite Pavement Blocks. J. Compos. Sci. 2022, 6, 289. [Google Scholar] [CrossRef]

- Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens. Available online: https://www.astm.org/c0039_c0039m-21.html (accessed on 11 May 2023).

- Plastic Service Centers | Shrinkage Information. Available online: https://www.plasticservice.com/shrinkageinformation.aspx (accessed on 12 May 2023).

- Standard Test Method for Air Content of Freshly Mixed Concrete by the Pressure Method. Available online: https://www.astm.org/c0231_c0231m-22.html (accessed on 12 May 2023).

- Standard Test Method for Air Content of Freshly Mixed Concrete by the Volumetric Method. Available online: https://www.astm.org/c0173_c0173m-16.html (accessed on 12 May 2023).

- Concrete Testing Procedures - Tests for Slump & More - Concrete Network. Available online: https://www.concretenetwork.com/concrete-testing/ (accessed on 12 May 2023).

| Set 1 | Set 2 | Set 3 | Set 4 | |

|---|---|---|---|---|

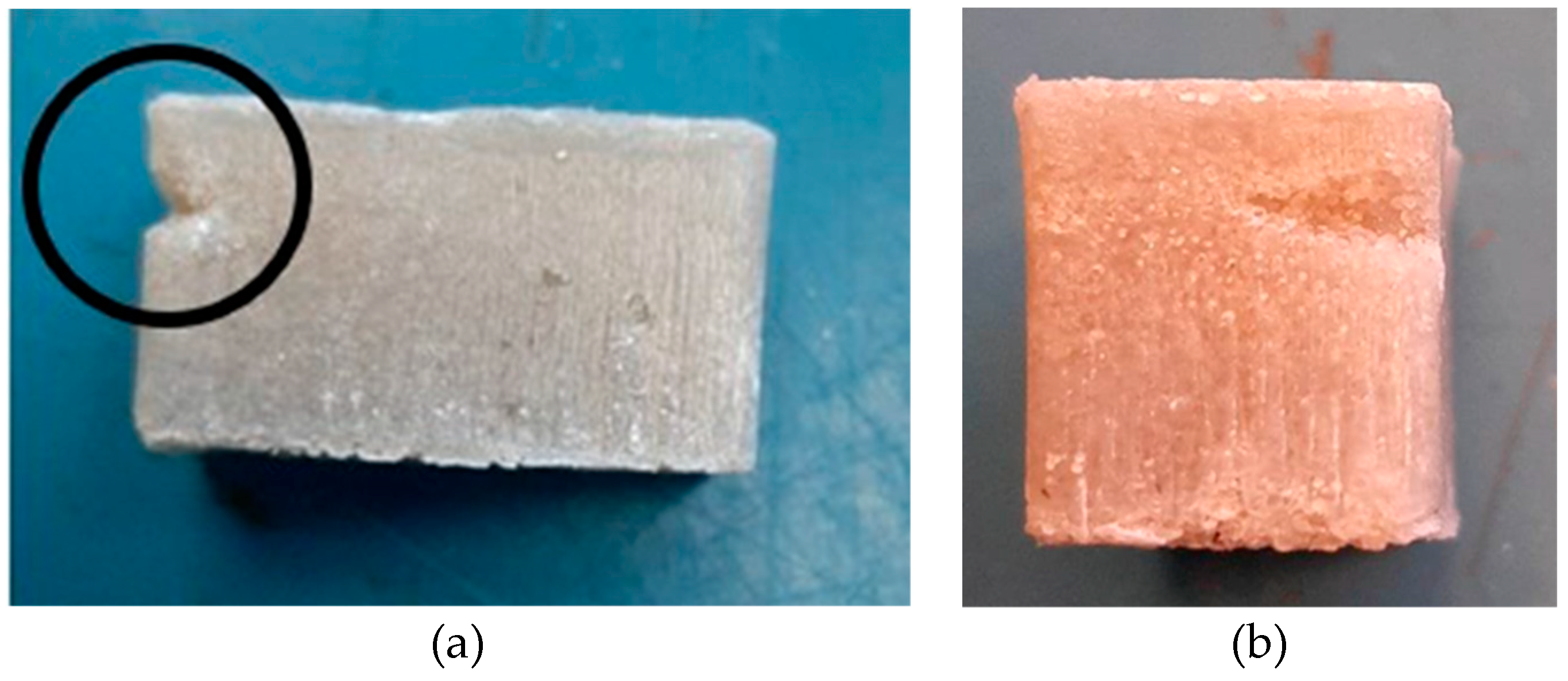

| Percent Sand (%) | 20 | 30 | 40 | 50 |

| Percent PC (%) | 80 | 70 | 60 | 50 |

| Mass sand (g) | 2.30 | 3.45 | 4.60 | 6.70 |

| Mass Pc (g) | 6.65 | 5.82 | 4.99 | 4.16 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).