Submitted:

07 June 2023

Posted:

08 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

2.1. Suspensions’ Preparation and Characterization

2.2. Coatings’ Preparation and Characterization

3. Results and Discussions

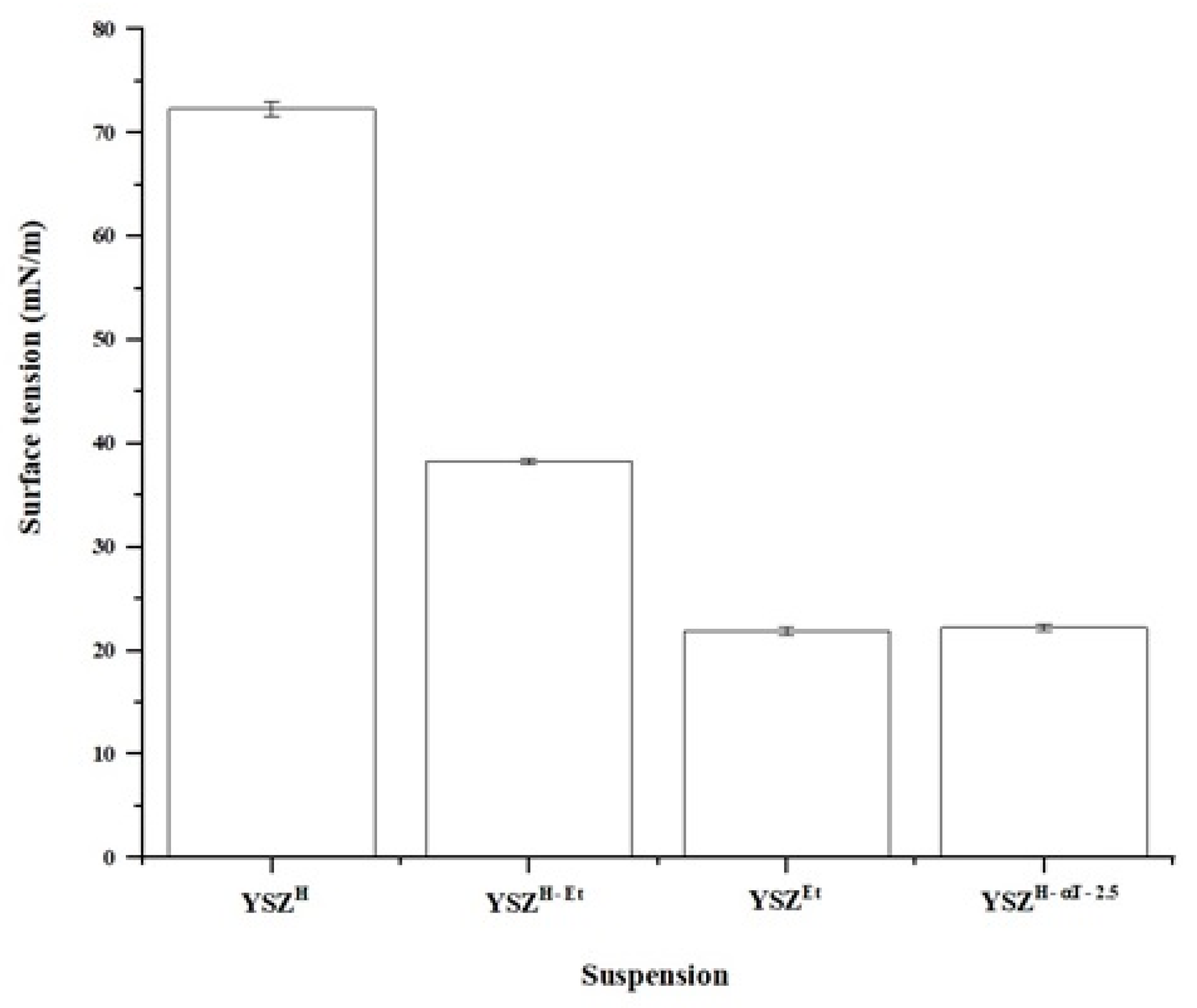

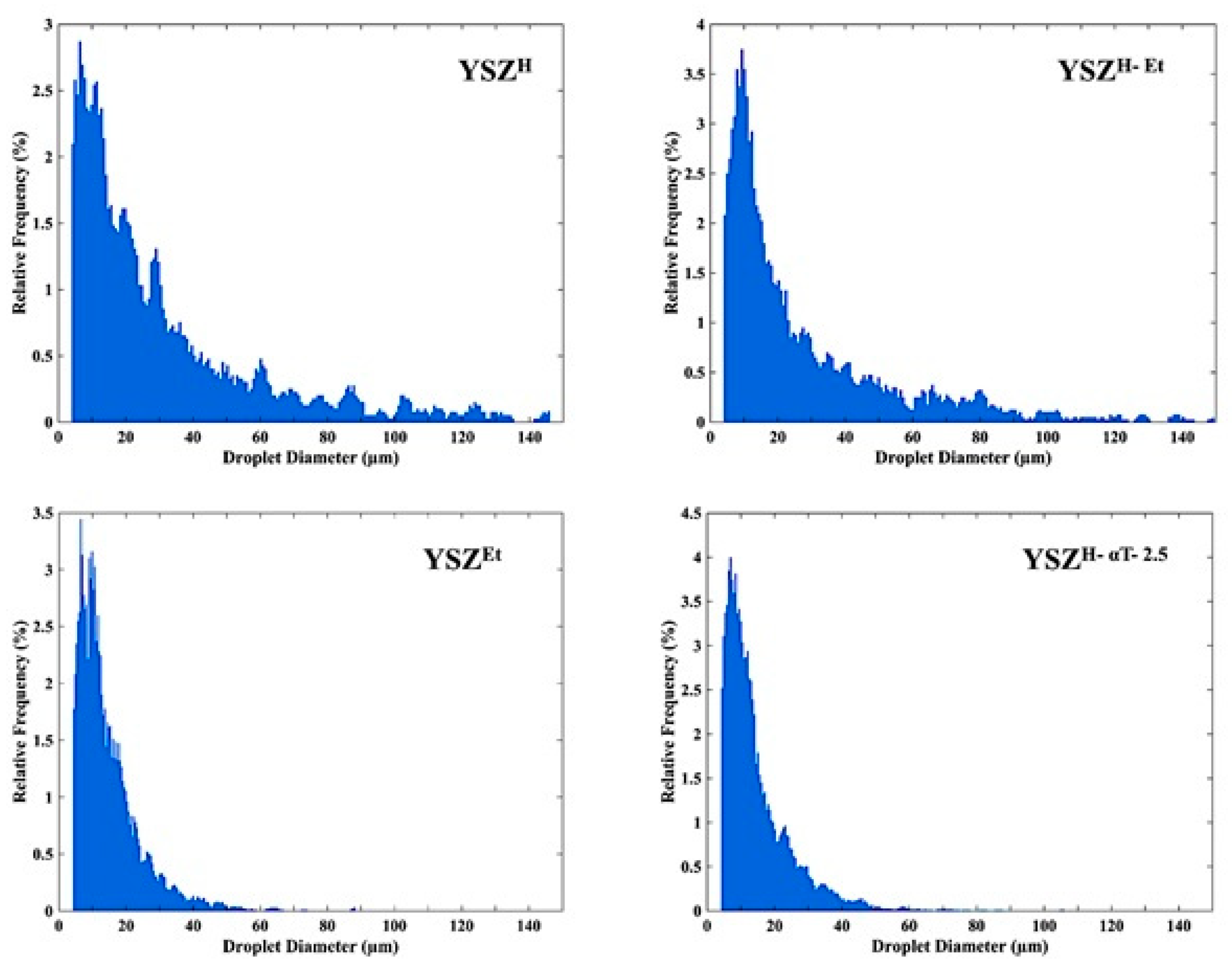

3.1. Suspensions Characterization

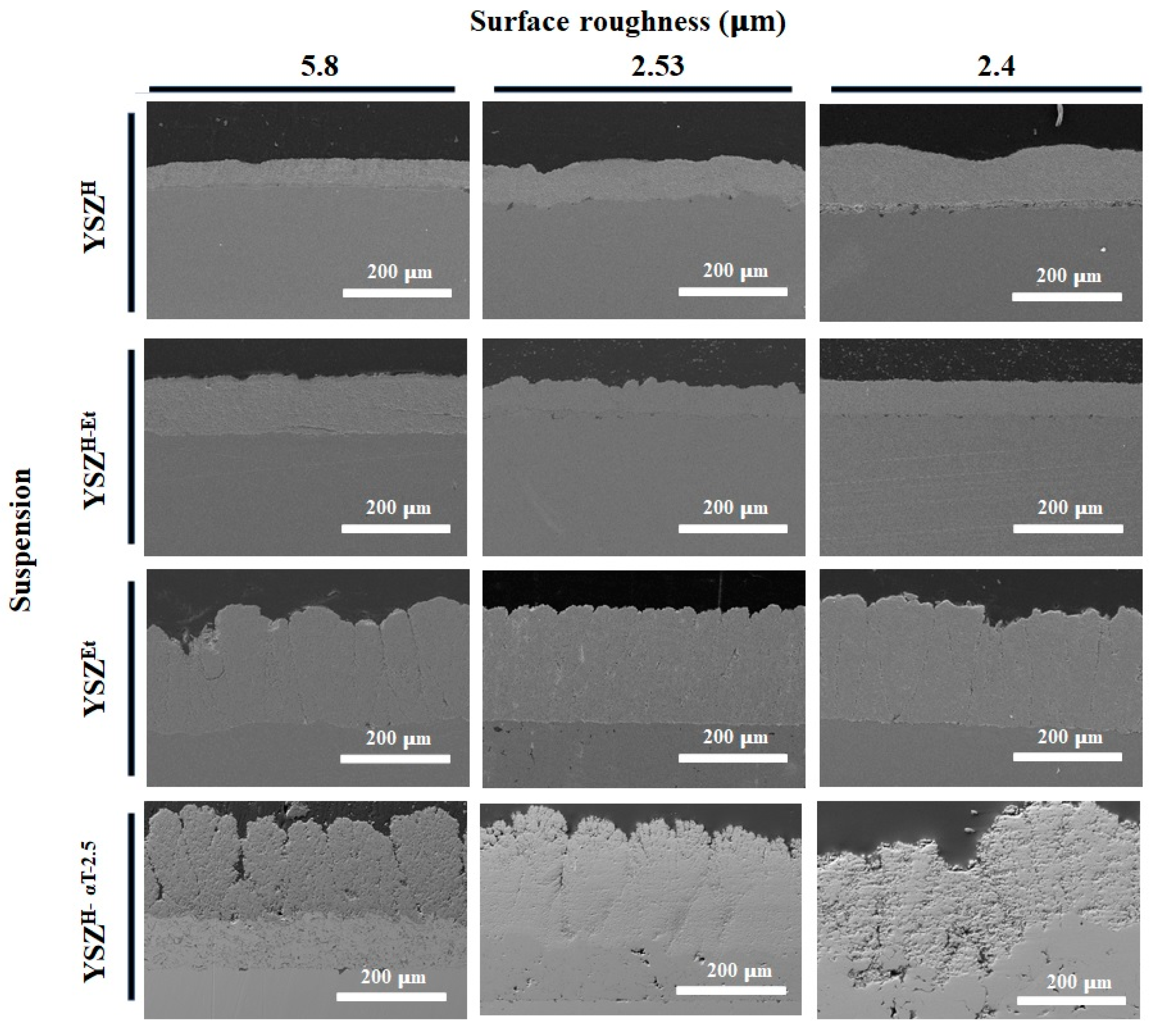

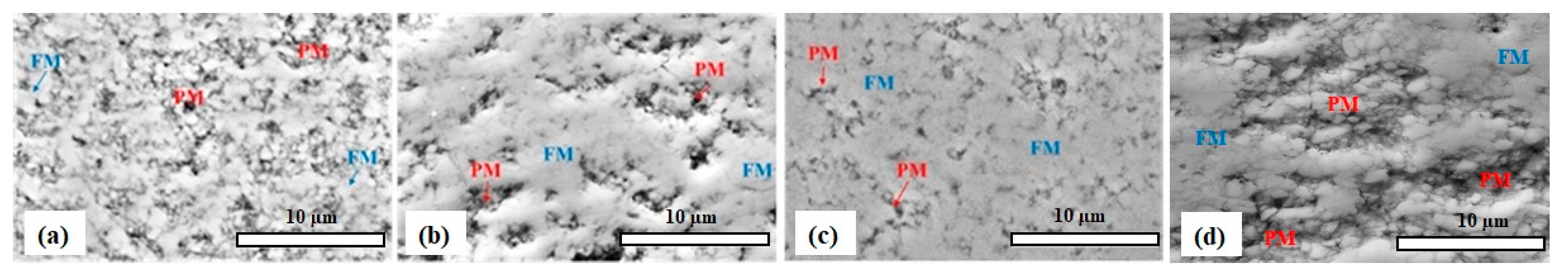

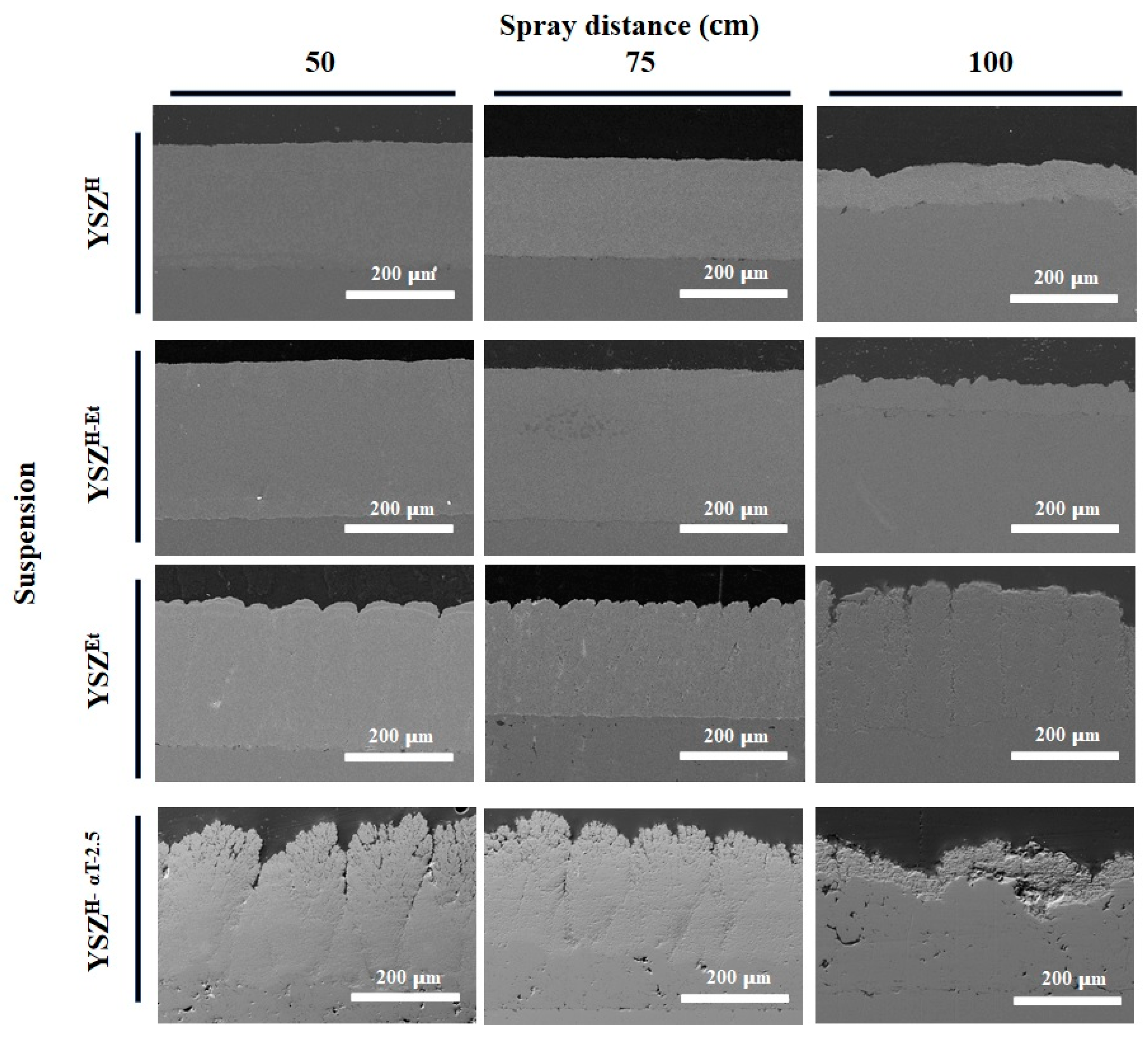

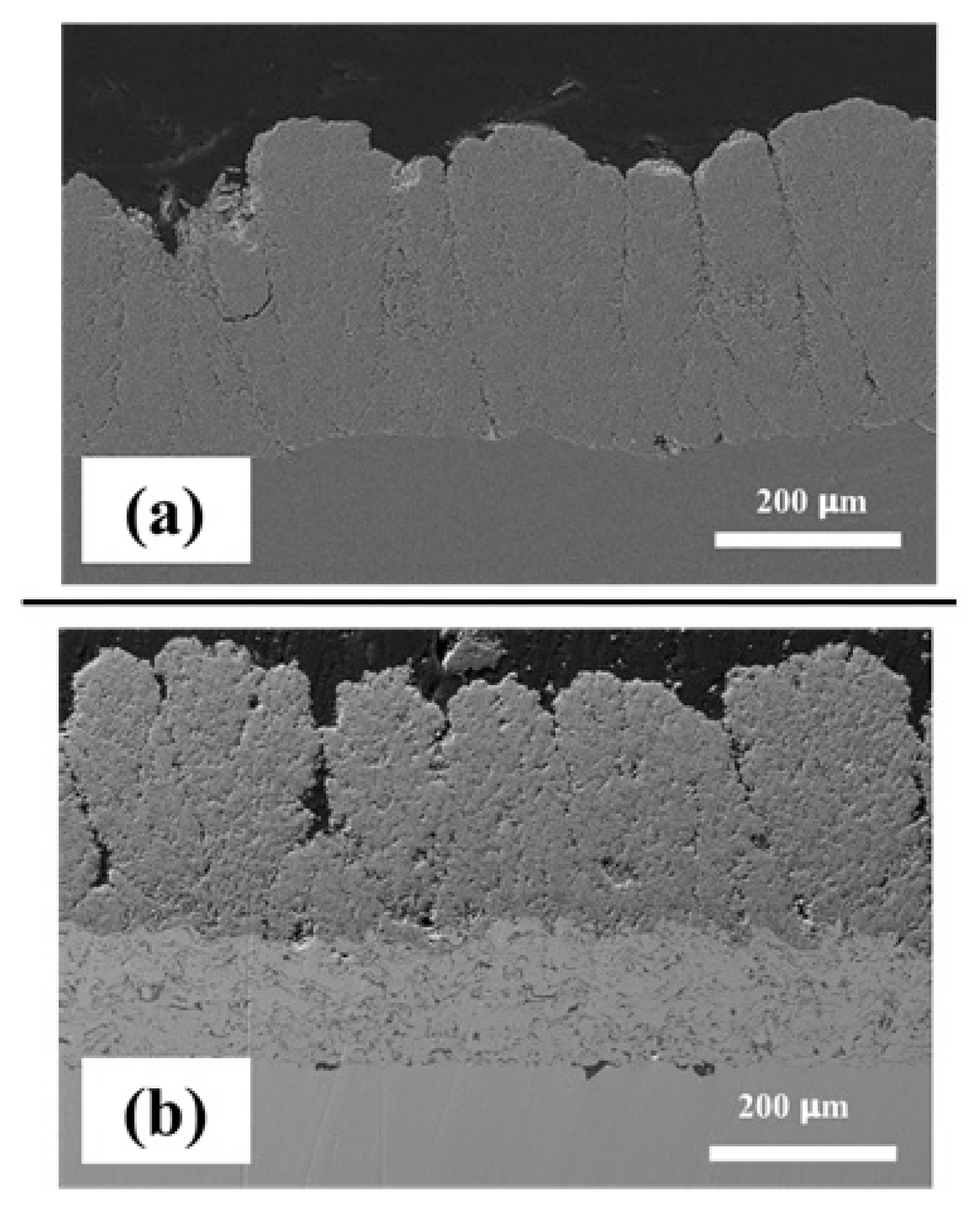

3.2. Coatings’ Morphological Characteristics

4. Conclusions

Author Contributions

Data Availability Statement

Conflicts of Interest

References

- Fauchais, P.L.; Heberlein, J.V.R.; Boulos, M.I. Gas Flow-Particle Interaction, Thermal Spray Fundamentals; Springer: New York, NY, USA, 2014; pp. 102–156. [Google Scholar]

- Ganvir, A.; Curry, N.; Govindarajan, S.; Markocsan, N. Characterization of Thermal Barrier Coatings Produced by Various Thermal Spray Techniques Using Solid Powder, Suspension, and Solution Precursor Feedstock Material. Int. J. Appl. Ceram. Technol. 2016, 13, 324–332. [Google Scholar] [CrossRef]

- Feuerstein, A.; Knapp, J.; Taylor, T.; Ashary, A.; Bolcavage, A.; Hitchman, N. Technical and Economical Aspects of Current Thermal Barrier Coating Systems for Gas Turbine Engines by Thermal Spray and EBPVD: A Review. J. Therm. Spray Technol. 2008, 17, 199–213. [Google Scholar] [CrossRef]

- Ganvir, A.; Calinas, R.F.; Markocsan, N.; Curry, N.; Joshi, S. Experimental visualization of microstructure evolution during suspension plasma spraying of thermal barrier coatings. J. Eur. Ceram. Soc. 2019, 39, 470–481. [Google Scholar] [CrossRef]

- Curry, N.; VanEvery, K.; Snyder, T.; Susnjar, J.; Bjorklund, S. Performance Testing of Suspension Plasma Sprayed Thermal Barrier Coatings Produced with Varied Suspension Parameters. Coatings 2018, 5, 338–356. [Google Scholar] [CrossRef]

- Rampon, R.; Marchand, O.; Filiatre, C.; Bertrand, G. Influence of suspension characteristics on coatings microstructure obtained by suspension plasma spraying. Surf. Coatings Technol. 2008, 202, 4337–4342. [Google Scholar] [CrossRef]

- Yaghtin, M.; Yaghtin, A.; Tang, Z.; Troczynski, T. Improving the rheological and stability characteristics of highly concentrated aqueous yttria stabilized zirconia slurries. Ceram. Int. 2020, 46, 26991–26999. [Google Scholar] [CrossRef]

- Yaghtin, M.; Yaghtin, A. ….; Najafisayar, P.; Tang, Z.; Troczynski, T. Aging Behavior of Water-Based YSZ Suspensions for Plasma Spraying of Thermal Barrier Coatings. J. Therm. Spray Technol. 2021, 30, 97–107. [Google Scholar] [CrossRef]

- Fan, W.; Bai, Z. Review of suspension and solution precursor plasma sprayed thermal barrier coatings. Ceram. Int. 2016, 42, 14299–14312. [Google Scholar] [CrossRef]

- Aghasibeig, M.; Tarasi, F.; Lima, R.S.; Dolatabadi, A.; Moreau, C. A Review on Suspension Thermal Spray Patented Technology Evolution. J. Therm. Spray Technol. 2019, 28, 1579–1605. [Google Scholar] [CrossRef]

- Caio, F.; Moreau, C. Influence of Substrate Shape and Roughness on Coating Microstructure in Suspension Plasma Spray. Coatings 2019, 9, 746–758. [Google Scholar] [CrossRef]

- Hasan, M.F.; Wang, J.; Berndt, C.C. Effect of Power and Stand-Off Distance on Plasma Sprayed Hydroxyapatite Coatings. Mater. Manuf. Process. 2013, 28, 1279–1285. [Google Scholar] [CrossRef]

- Yaghtin, M.; Yaghtin, A.; Najafisayar, P.; Tang, Z.; Troczynski, T. Deposition of Columnar-Morphology Lanthanum Zirconate Thermal Barrier Coatings by Solution Precursor Plasma Spraying. J. Therm. Spray Technol. 2021, 30, 1850–1861. [Google Scholar] [CrossRef]

- Rampon, R.; Marchand, O.; Filiatre, C.; Bertrand, G. Influence of suspension characteristics on coatings microstructure obtained by suspension plasma spraying. Surf. Coat. Technol. 2008, 202, 4337–4342. [Google Scholar] [CrossRef]

- Fazilleau, J.; Delbos, C.; Rat, V.; Coudert, J.F.; Fauchais, P.; Pateyron, B. Phenomena Involved in Suspension Plasma Spraying Part 1: Suspension Injection and Behavior. Plasma Chem. Plasma Process. 2006, 26, 371–391. [Google Scholar] [CrossRef]

- Curry, N.; Tang, Z.; Markocsan, N.; Nylén, P. Influence of bond coat surface roughness on the structure of axial suspension plasma spray thermal barrier coatings-Thermal and lifetime performance. Surf. Coat. Technol. 2015, 268, 15–23. [Google Scholar] [CrossRef]

- Oberste-Berghaus, J.; Bouaricha, S.; Legoux, J.G.; Moreau, C. Suspension Plasma Spraying of Nano-Ceramics Using an Axial Injection Torch. Proc International Thermal Spray Conference, Basel, Switzerland, May, 2005.

- Vanevery, K.; Krane, M.J.K.; Trice, R.W.; Wang, H.; Porter, W. Column Formation in Suspension Plasma-Sprayed Coatings and Resultant Thermal Properties. J. Therm. Spray Technol. 2011, 20, 817–828. [Google Scholar] [CrossRef]

- Vaen, R.; Kaner, H.; Mauer, G.; Stöver, D. Suspension Plasma Spraying: Process Characteristics and Applications. J. Therm. Spray Technol. 2010, 19, 219–225. [Google Scholar]

- Wiśniewska, M.; Chibowski, S.; Urban, T. Adsorption of cationic polyacrylamide on the surface of mesoporous nanozirconia and its influence on the solid aqueous suspension stability Colloids. Surf. A Physicochem. Eng. Asp. 2016, 509, 214–223. [Google Scholar] [CrossRef]

- Fengqiu, F.; Xiaoxian, H.; Yufeng, Z.; Jingkun, G. Effect of dispersants on surface chemical properties of nano-zirconia suspensions. Ceram. Int. 2000, 26, 93–97. [Google Scholar] [CrossRef]

- Liu, Y.; Gao, L.; Yu, L.; Guo, J. Adsorption of PBTCA on Alumina Surfaces and Its Influence on the Fractal Characteristics of Sediments. J. Colloid Interface Sci. 2000, 227, 164–170. [Google Scholar] [CrossRef]

- Cesarano, J.; Aksay, I.A.; Bleier, A. Stability of Aqueous α-Al2O3 Suspensions with Poly(methacrylic acid) Polyelectrolyte. J. Am. Ceram. Soc. 1988, 71, 250–255. [Google Scholar] [CrossRef]

- Reed, J.S. Principles of Ceramics Processing; John Wiley & Sons: New York, NY, USA, 1995; pp. 245–310. [Google Scholar]

- Biggs, S.; Healy, T.W. Electrosteric stabilisation of colloidal zirconia with low-molecular-weight polyacrylic acid. An atomic force microscopy study. J. Chem. Soc. Faraday Trans. 1994, 90, 3415–3421. [Google Scholar] [CrossRef]

- Xie, Z.; Ma, J.; Xu, Q.; Huang, Y.; Cheng, Y.B. Effects of dispersants and soluble counter-ions on aqueous dispersibility of nano-sized zirconia powder. Ceram. Int. 2004, 30, 219–224. [Google Scholar] [CrossRef]

- Carnicer, V.; Orts, M.J.; Moreno, R.; Sánchez, E. Microstructure assessment of suspension plasma spraying coatings from multicomponent submicronic Y-TZP/Al2O3/SiC particles. Ceram. Int. 2018, 44, 12014–12020. [Google Scholar] [CrossRef]

- Carpio, P.; Salvador, M.D.; Borrell, A. Alumina-zirconia coatings obtained by suspension plasma spraying from highly concentrated aqueous suspensions. Surf. Coat. Technol. 2016, 307, 713–719. [Google Scholar] [CrossRef]

- Carnicer, V.; Alcazar, C.; Sánchez, E.; Moreno, R. Aqueous suspension processing of multicomponent submicronic Y-TZP/Al2O3/SiC particles for suspension plasma spraying. J. Eur. Ceram. Soc. 2018, 38, 2430–2439. [Google Scholar] [CrossRef]

- Ganvir, A.; Curry, N.; Björklund, S. Characterization of Microstructure and Thermal Properties of YSZ Coatings Obtained by Axial Suspension Plasma Spraying (ASPS). J. Therm. Spray Technol. 2015, 24, 1195–1204. [Google Scholar] [CrossRef]

- Latka, L.; Goryachev, S.B.; Kozerski, S.; Pawlowski, L. Sintering of Fine Particles in Suspension Plasma Sprayed Coatings. Materials 2010, 3, 3845–3866. [Google Scholar] [CrossRef]

- Pawlowski, L. Suspension and solution thermal spray coatings. Surf. Coat. Technol. 2009, 203, 2807–2829. [Google Scholar] [CrossRef]

- Carpio, P.; Bannier, E.; Salvador, M.D.; Borrell, A.; Moreno, R.; Sánchez, E. Effect of particle size distribution of suspension feedstock on the microstructure and mechanical properties of suspension plasma spraying YSZ coatings. Surf. Coat. Technol. 2015, 268, 293–297. [Google Scholar] [CrossRef]

- Lima, R.S.; Marple, B.R. Thermal Spray Coatings Engineered from Nanostructured Ceramic Agglomerated Powders for Structural, Thermal Barrier and Biomedical Applications: A Review. J. Therm. Spray Technol. 2007, 16, 40–63. [Google Scholar] [CrossRef]

- Cotler, E.M.; Chen, D.; Molz, R.J. Pressure-Based Liquid Feed System for Suspension Plasma Spray Coatings. J. Therm. Spray Technol. 2011, 20, 967–973. [Google Scholar] [CrossRef]

- Chin, C.H.; Muchtar, A.; Azhari, C.H.; Razali, M.; Aboras, M. Optimization of pH and dispersant amount of Y-TZP suspension for colloidal stability. Ceram. Int. 2015, 41, 9939–9946. [Google Scholar] [CrossRef]

| Suspension name | Solvent type | Dispersant type | Dispersant concentration (wt.%) | Native pH | Adjusted pH |

|---|---|---|---|---|---|

| YSZH | Water | --- | --- | 7.4 | --- |

| YSZH- Et | Water-Ethanol | --- | --- | 7.3 | --- |

| YSZEt | Ethanol | --- | --- | 7.3 | --- |

| YSZH- αT- 2.5 | Water | α-Terpineol | 0.1 | 7.7 | 2.5 |

| Suspension/Liquid | Mean droplet size (µm) |

Median droplet size (µm) |

|---|---|---|

| YSZH | 31.9 | 21.7 |

| YSZH- Et | 27.6 | 18.7 |

| YSZEt | 15.3 | 12.4 |

| YSZH- αT- 2.5 | 15.4 | 12.2 |

| Coating | Porosity (%) |

|---|---|

| YSZH | 16-19 |

| YSZH- Et | 9-11 |

| YSZEt | 3-5 |

| YSZH- αT- 2.5 | 17-18 |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).