Submitted:

09 June 2023

Posted:

09 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

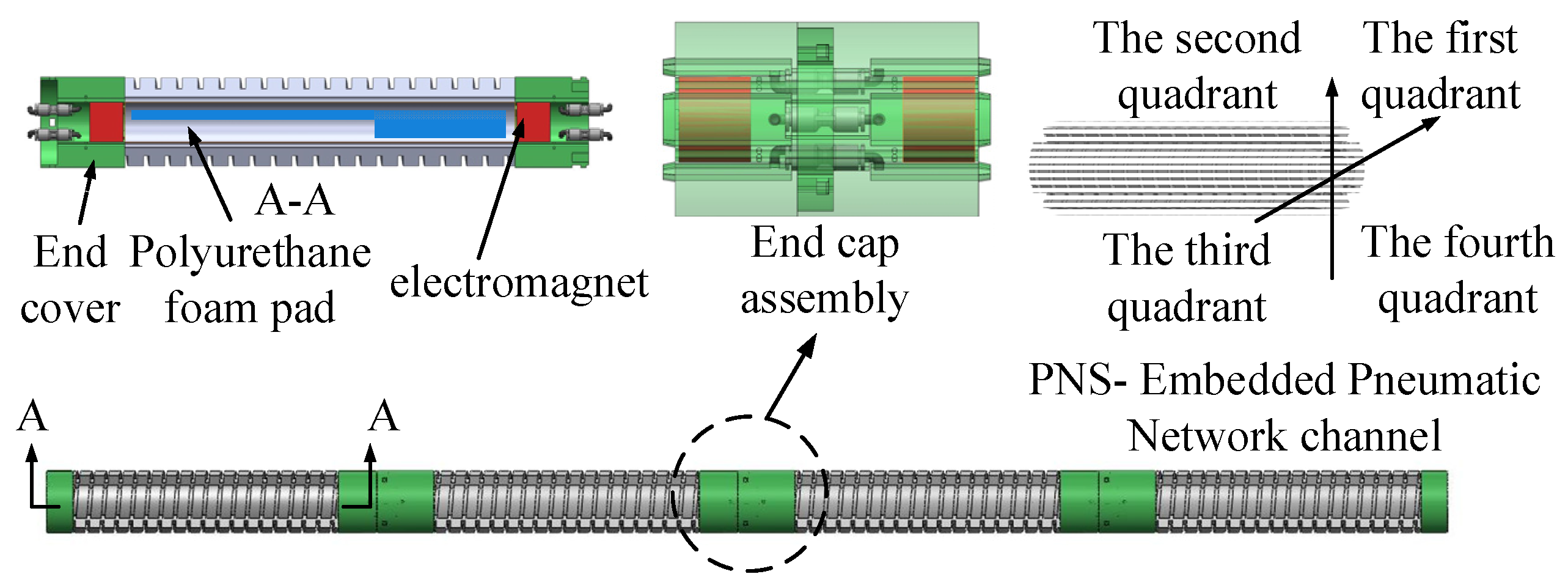

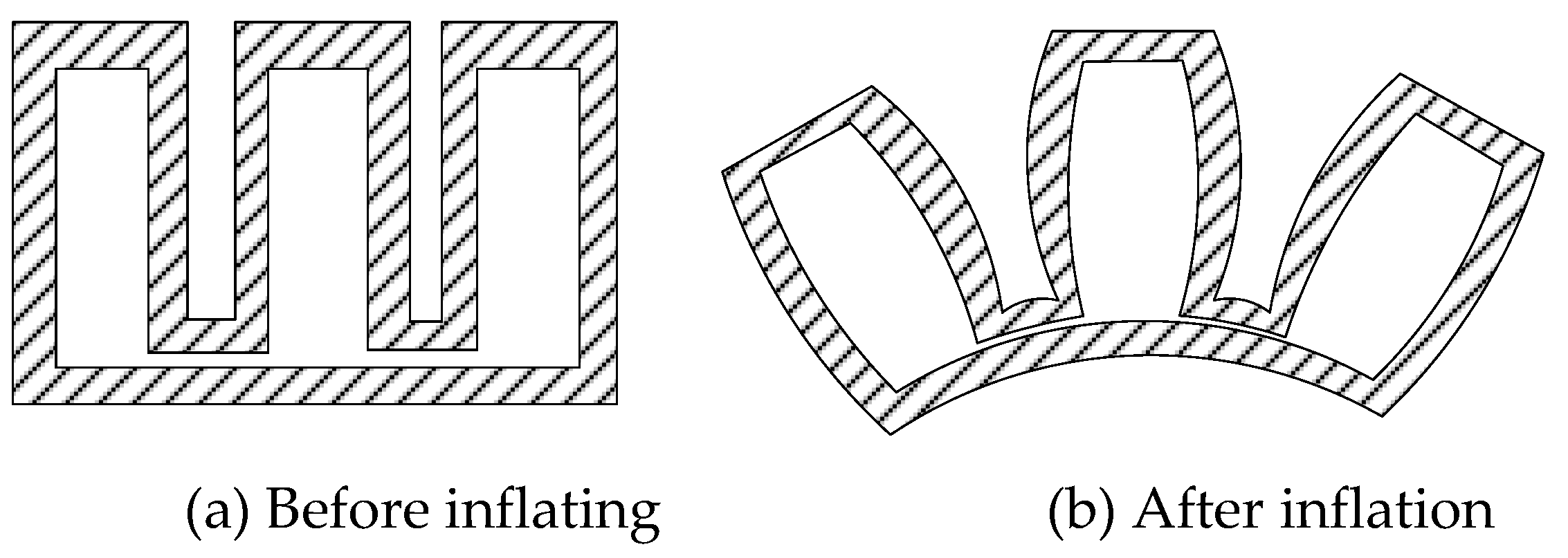

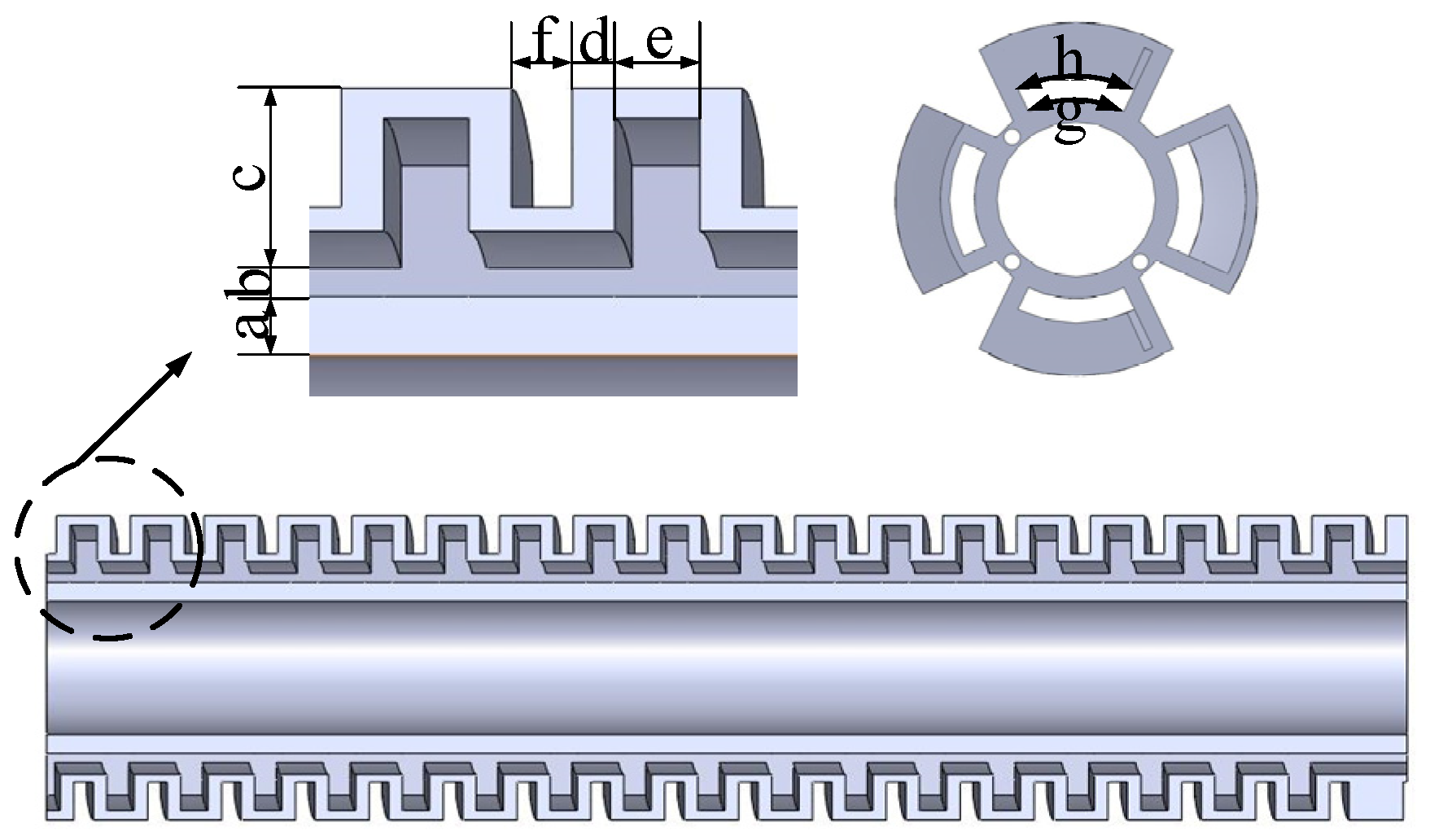

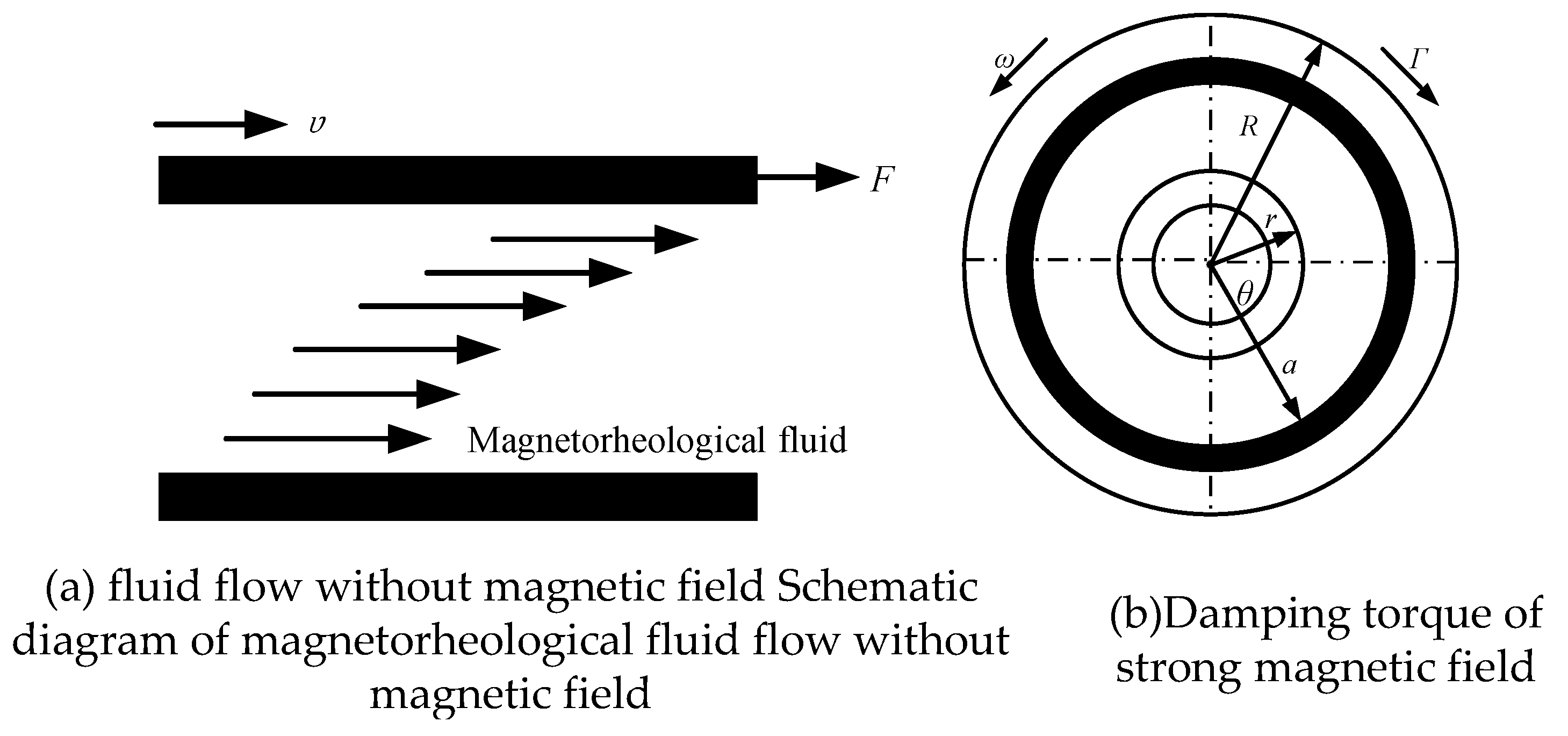

2. Structure Principle

3. Modeling and Solving

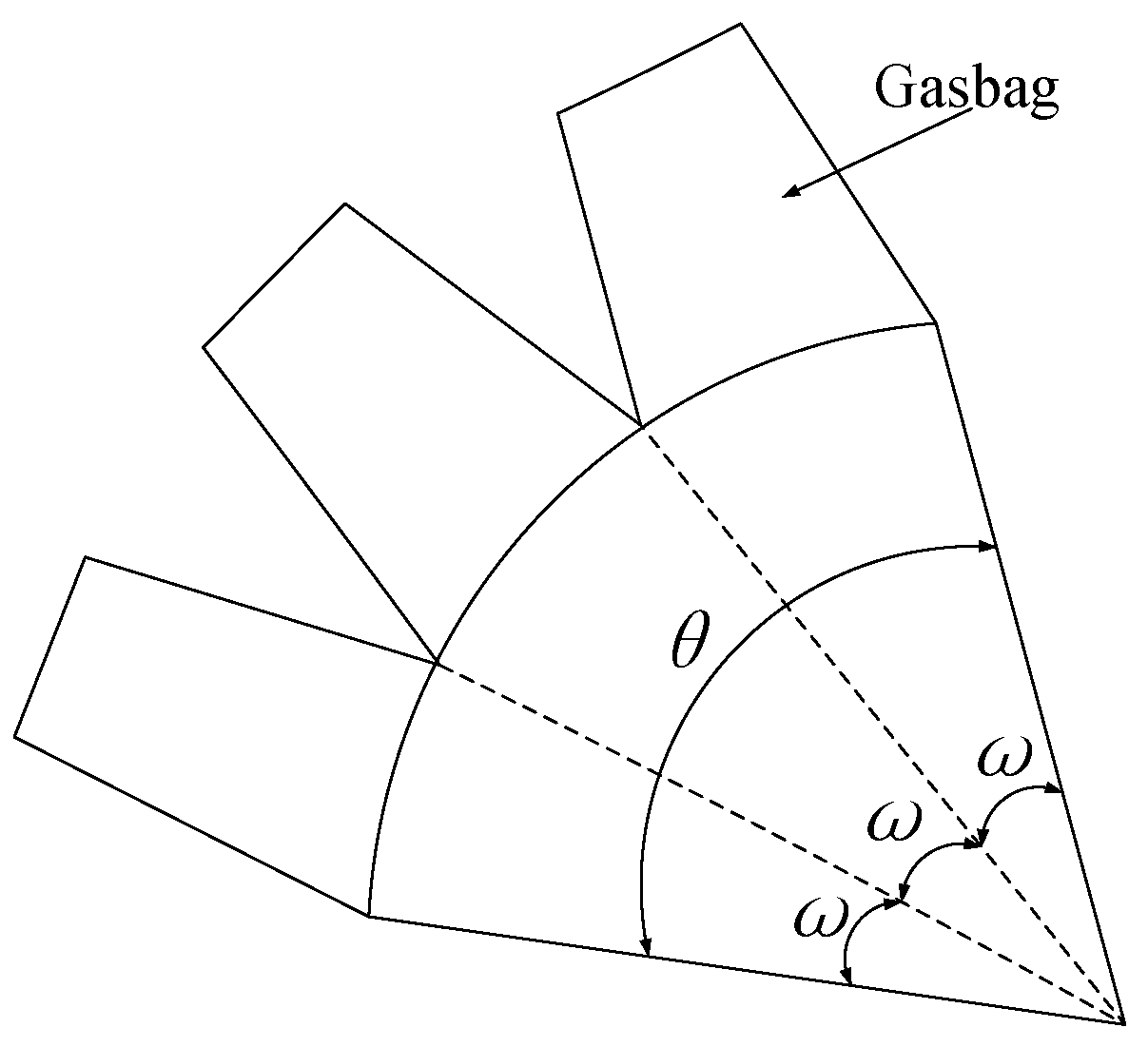

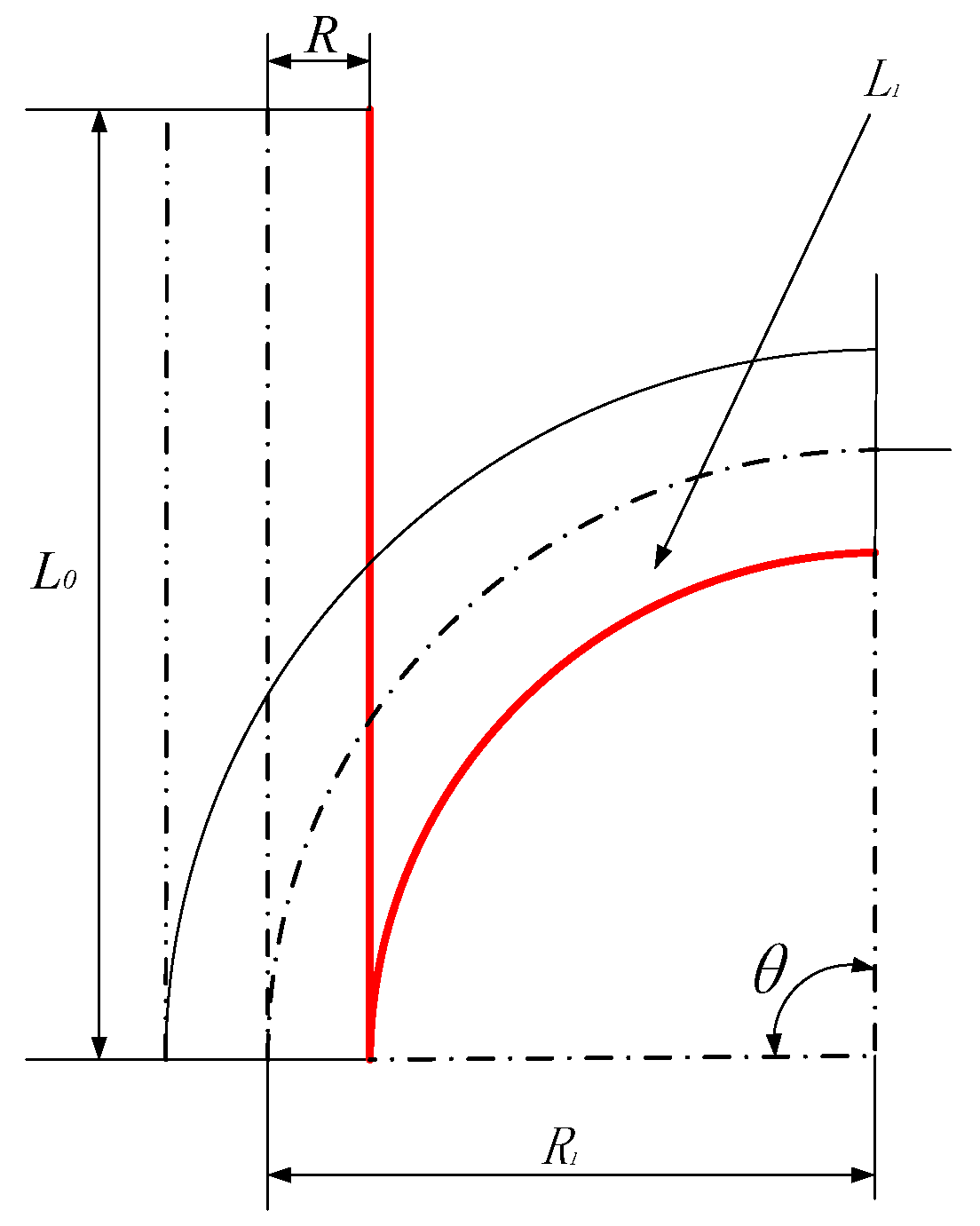

3.1. Deformation Modeling

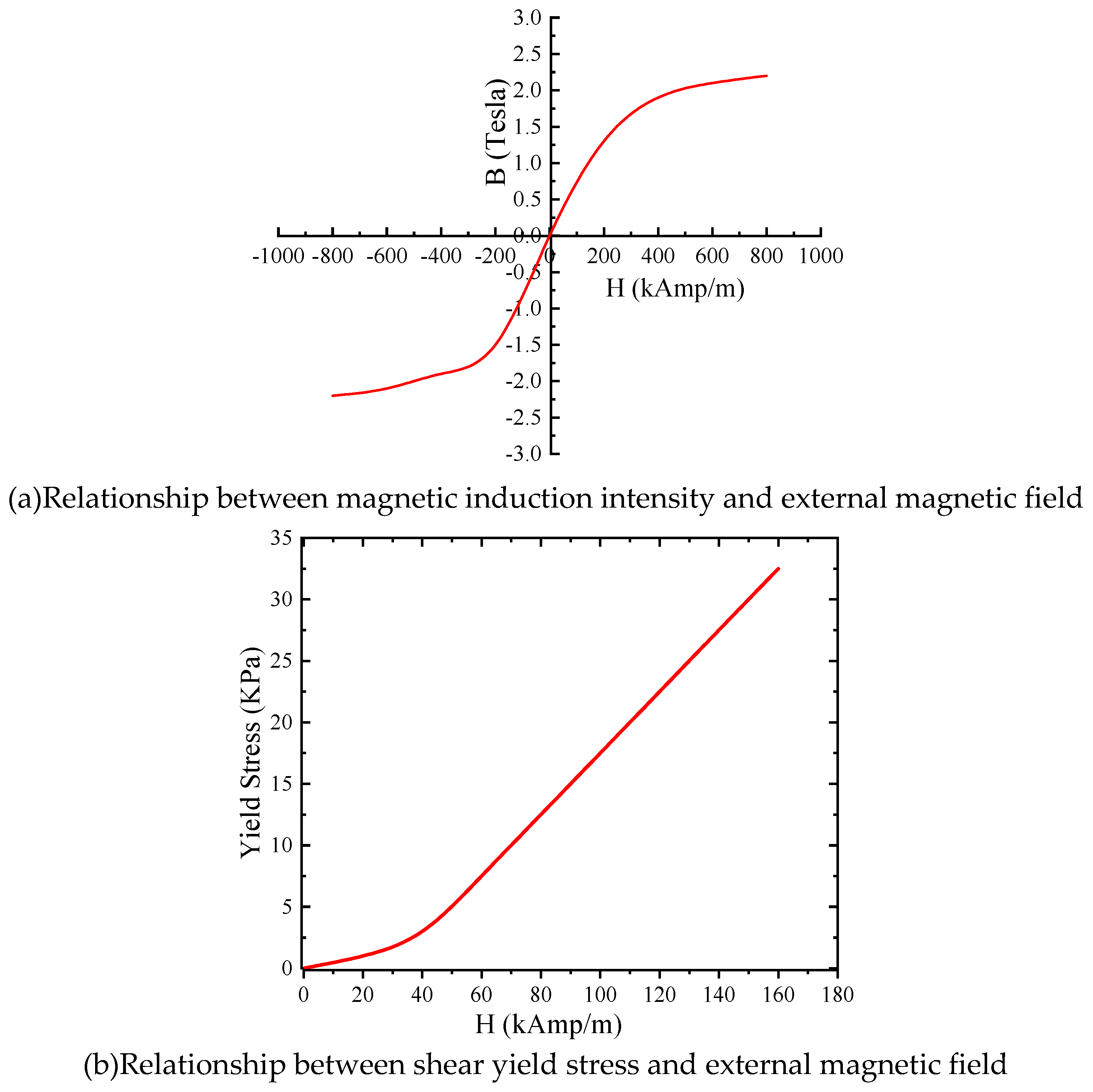

3.2. Variable stiffness modeling

4. Simulation Analysis

4.1. Parameter Settings

4.2. Deformation simulation

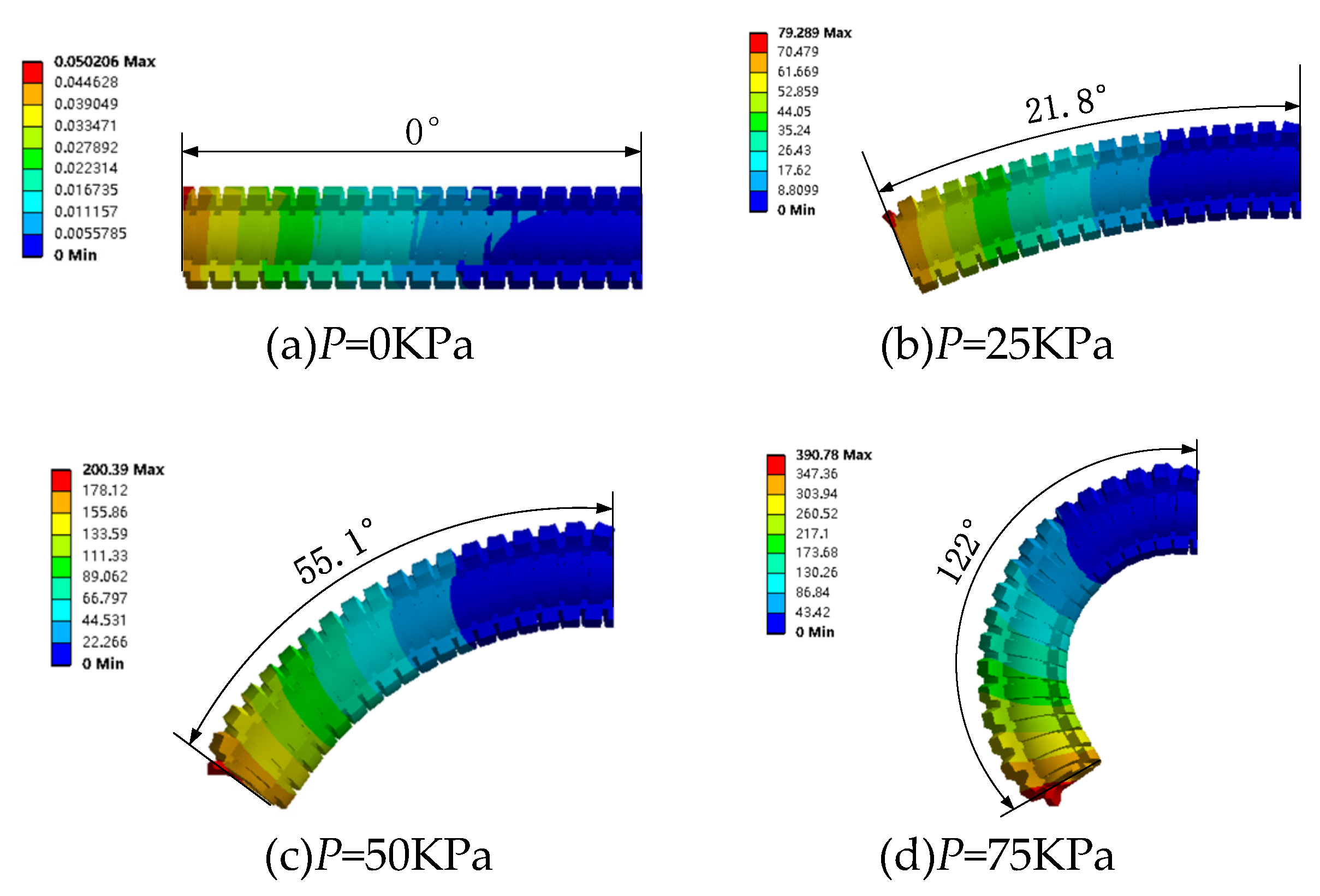

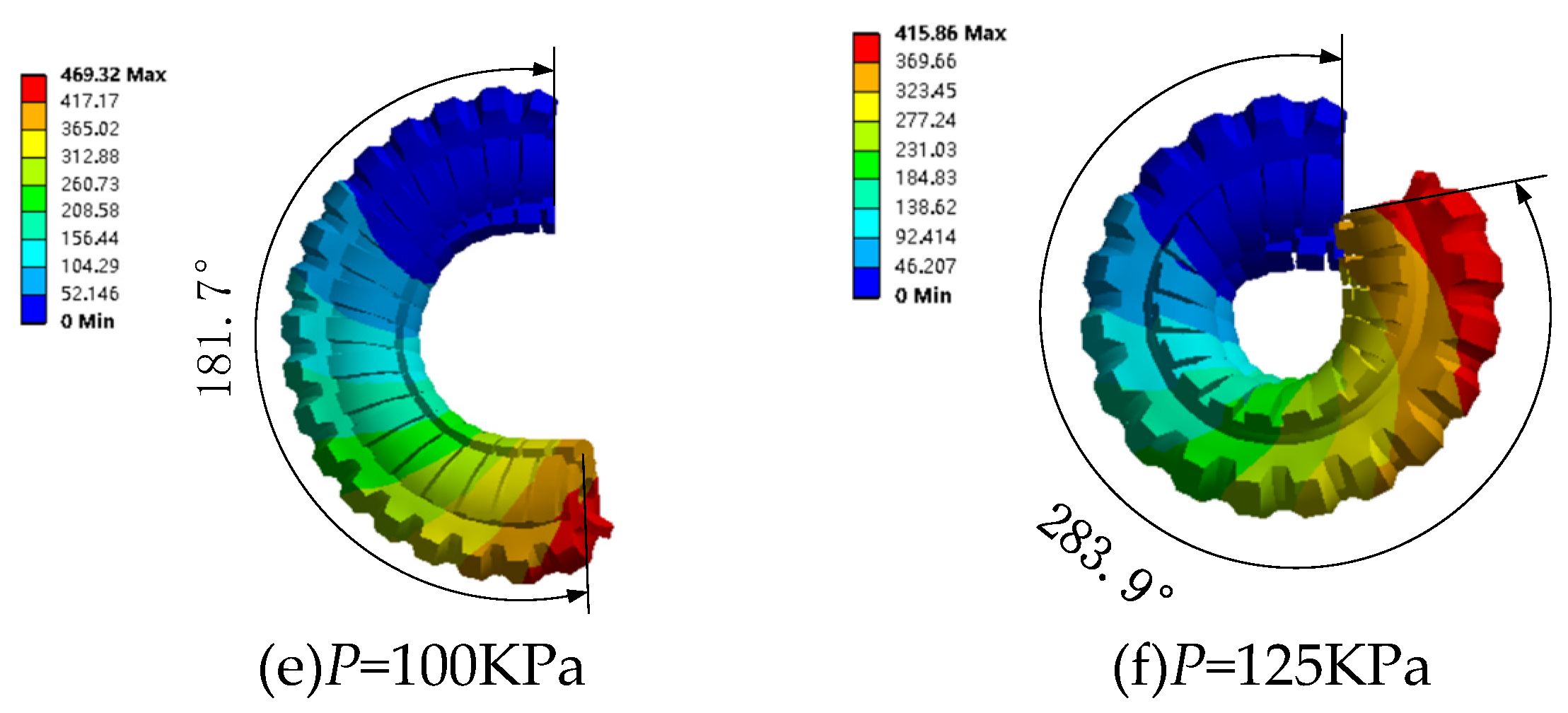

4.2.1. Deformation simulation without magnetic field

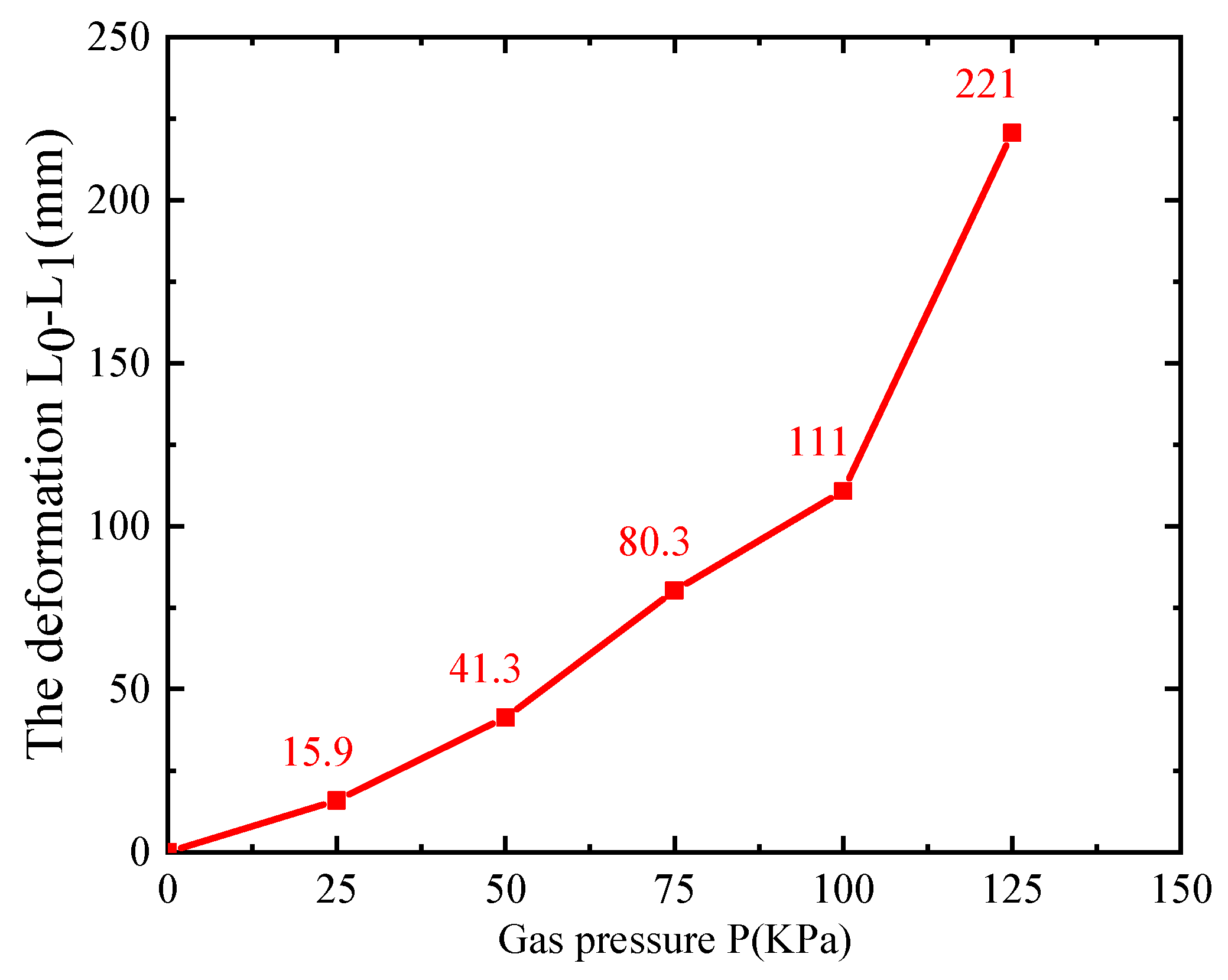

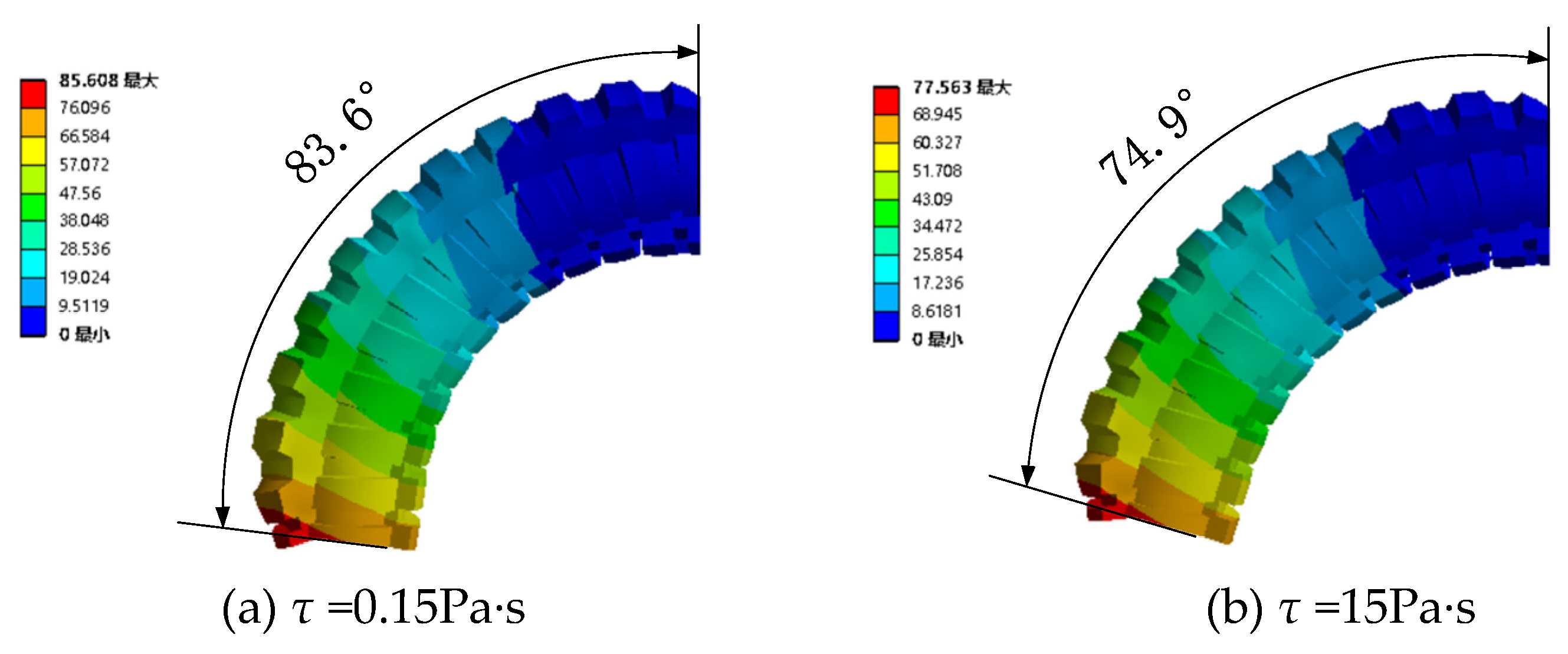

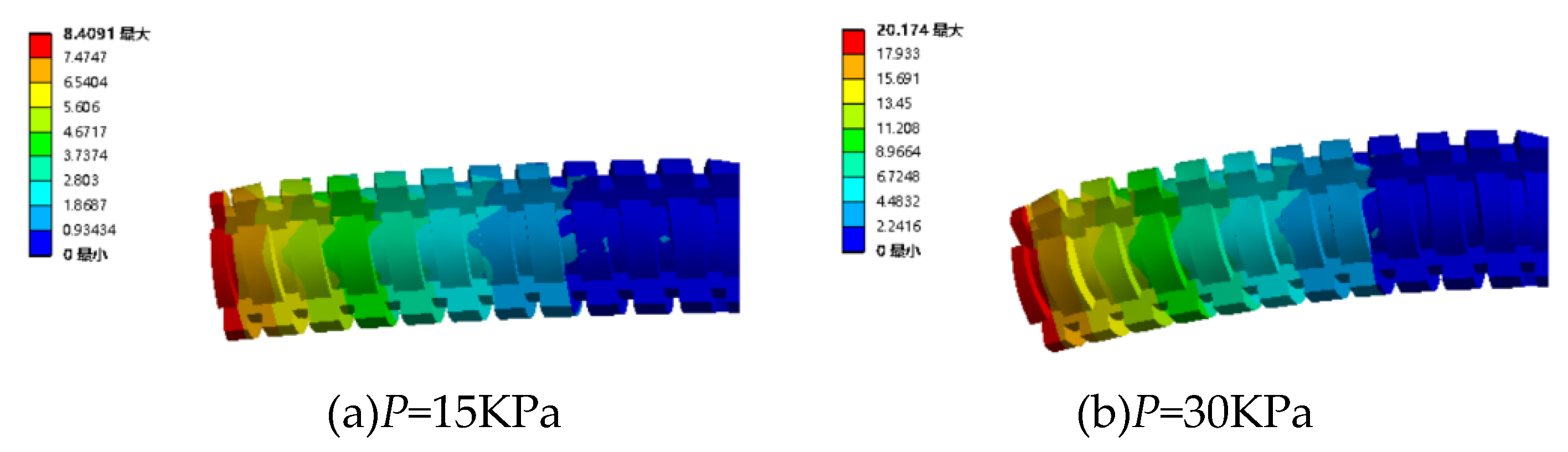

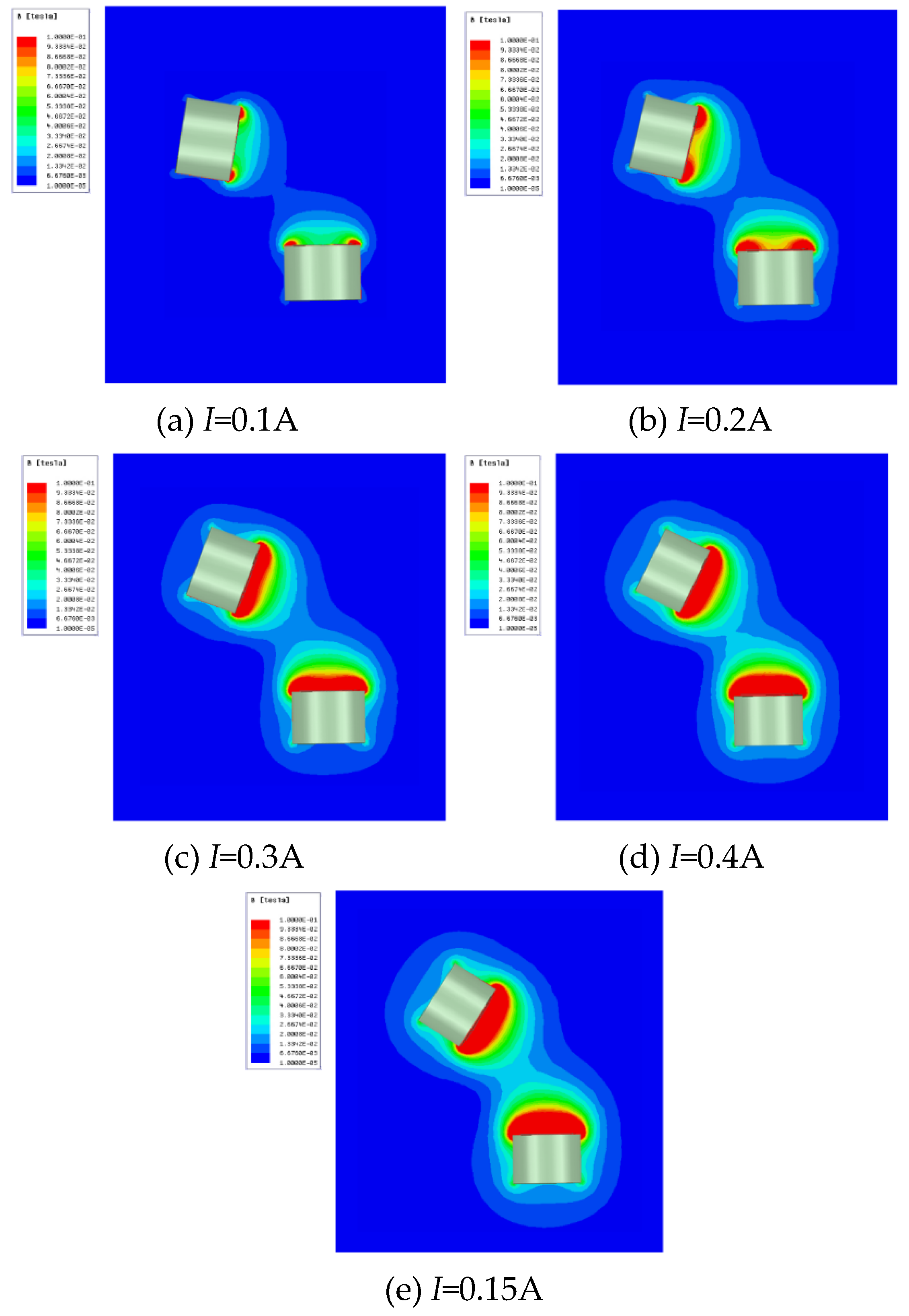

4.2.2. Pressurize single channel with different magnetic fields

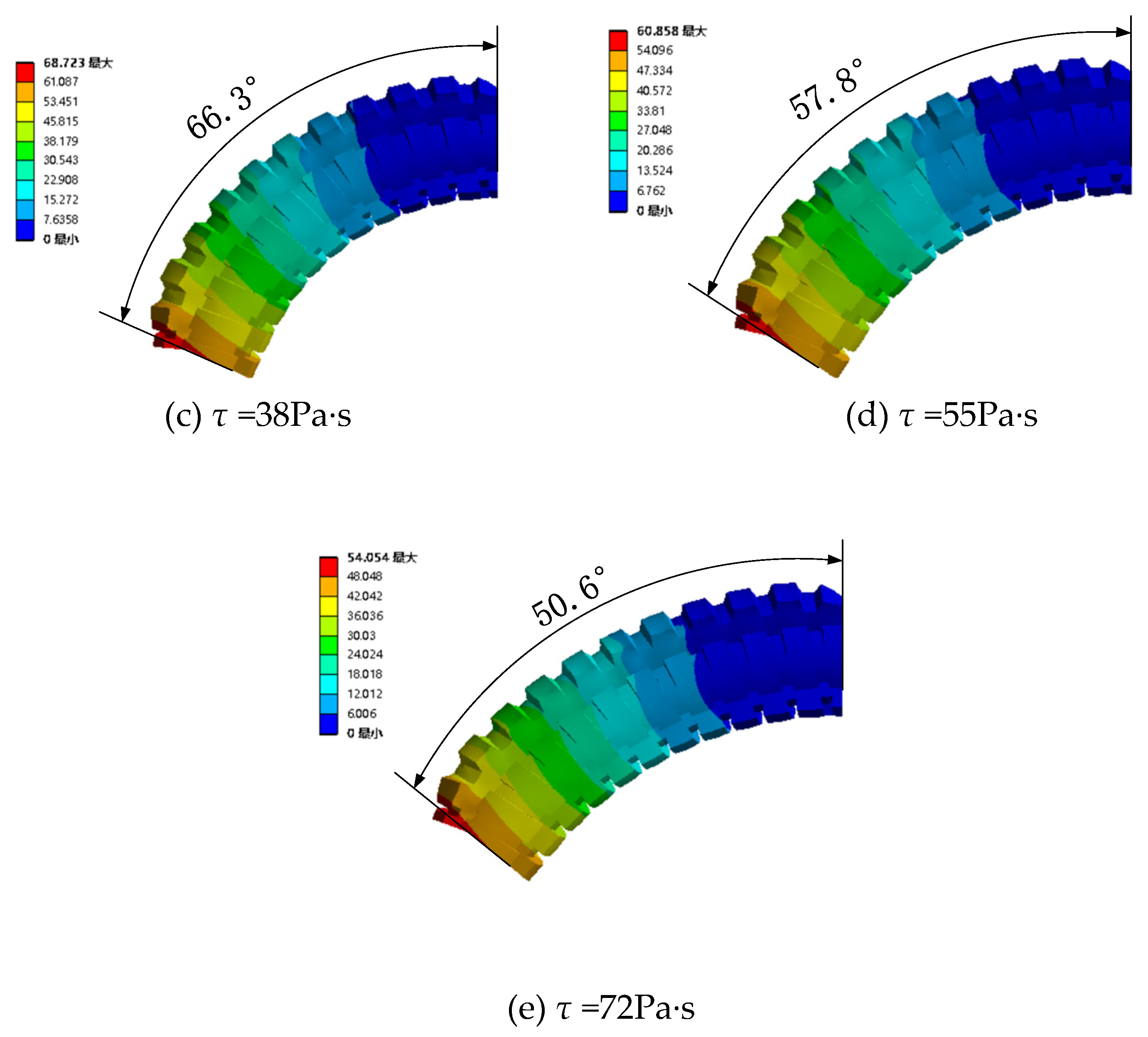

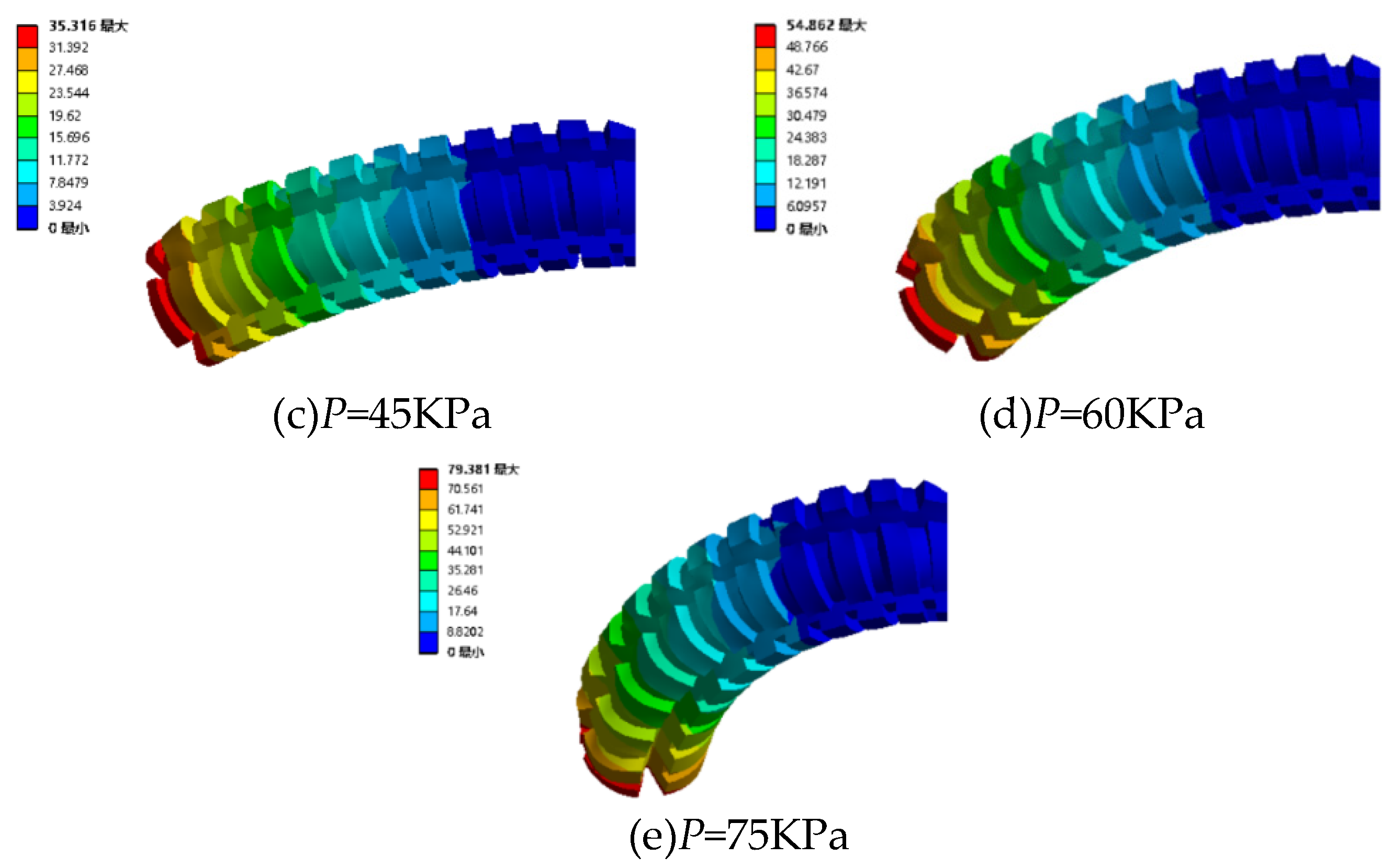

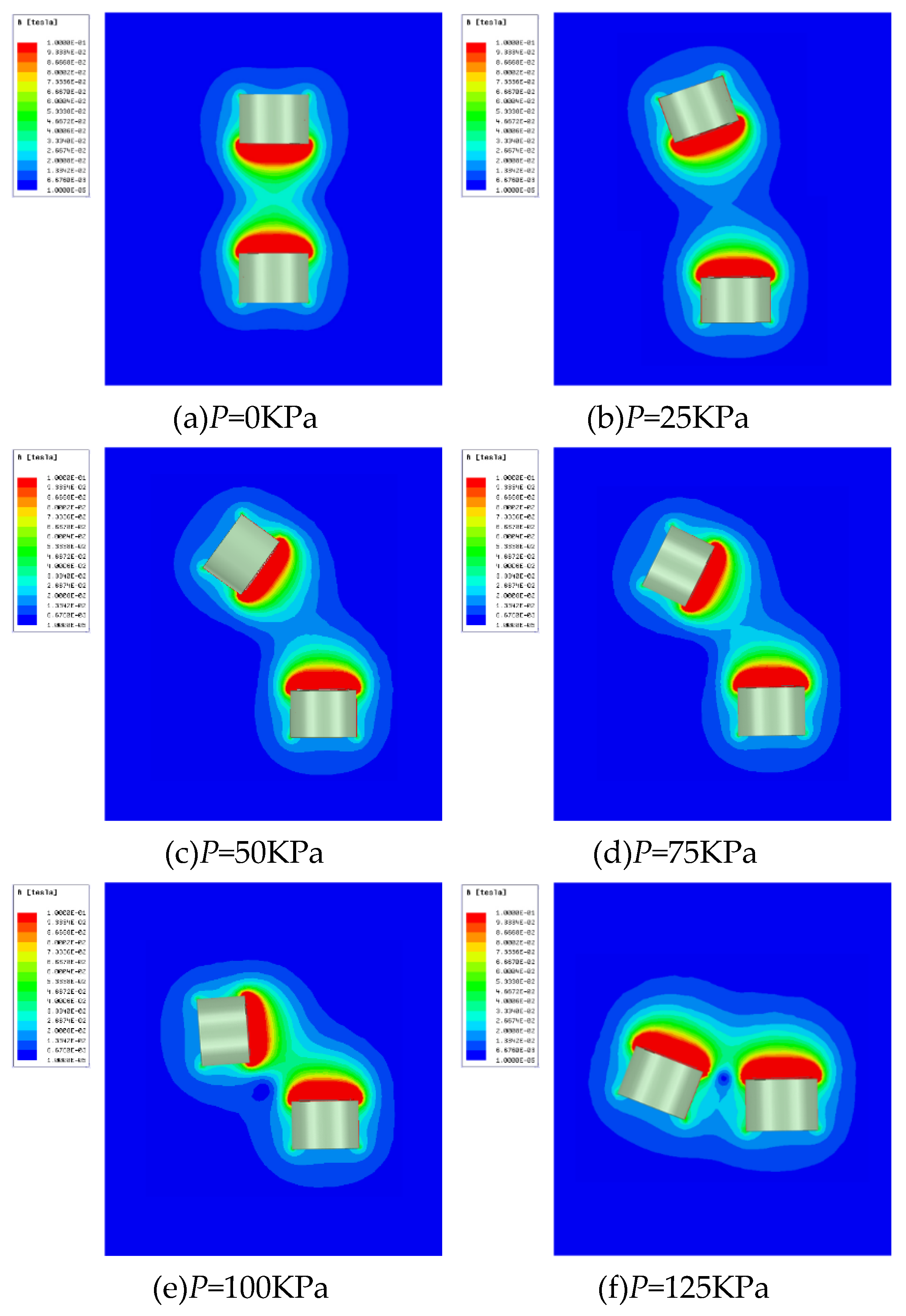

4.2.3. Pressurize the two channels under various magnetic fields

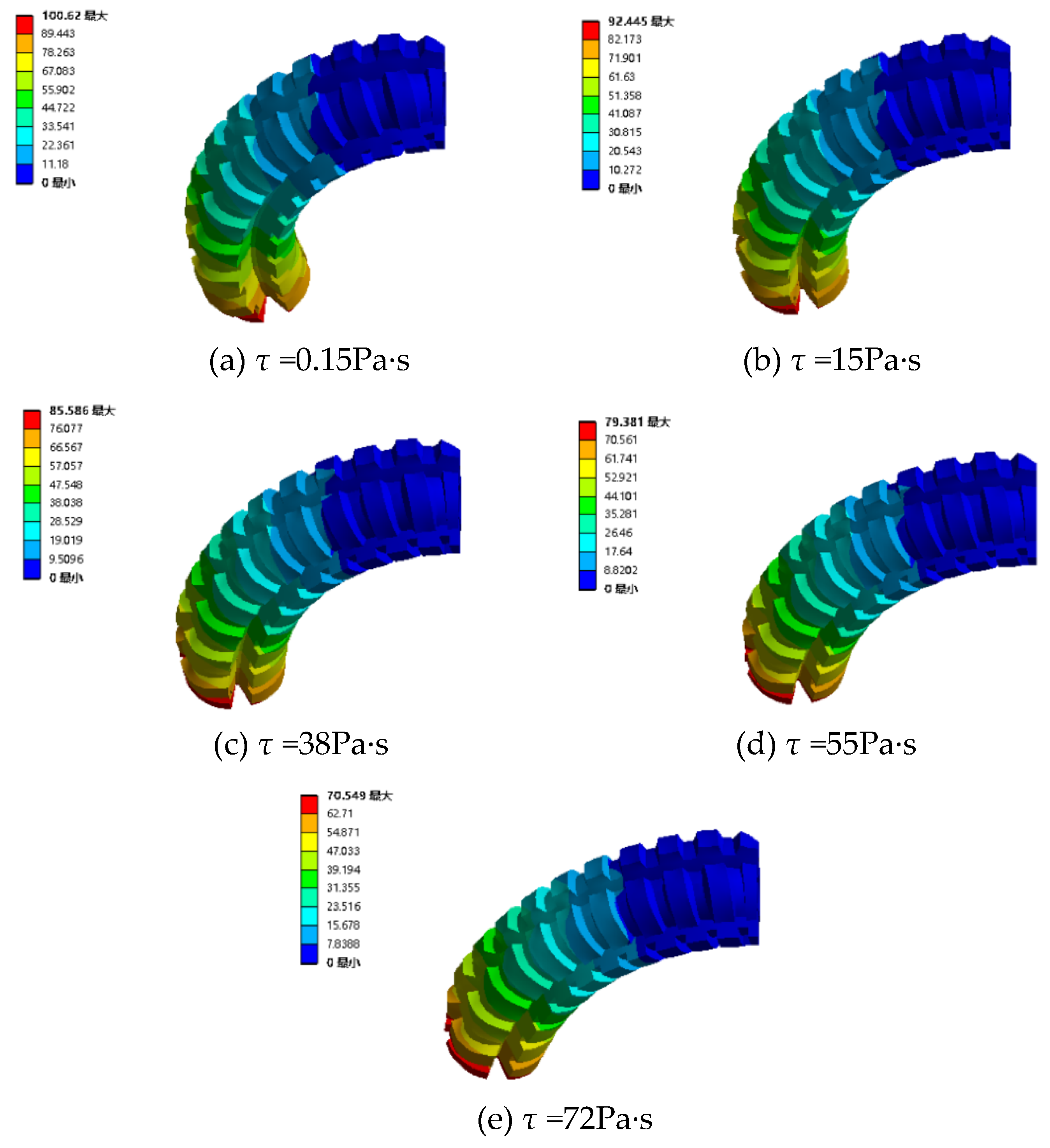

4.3. Variable stiffness simulation

5. Test

5.1. Experimental Design

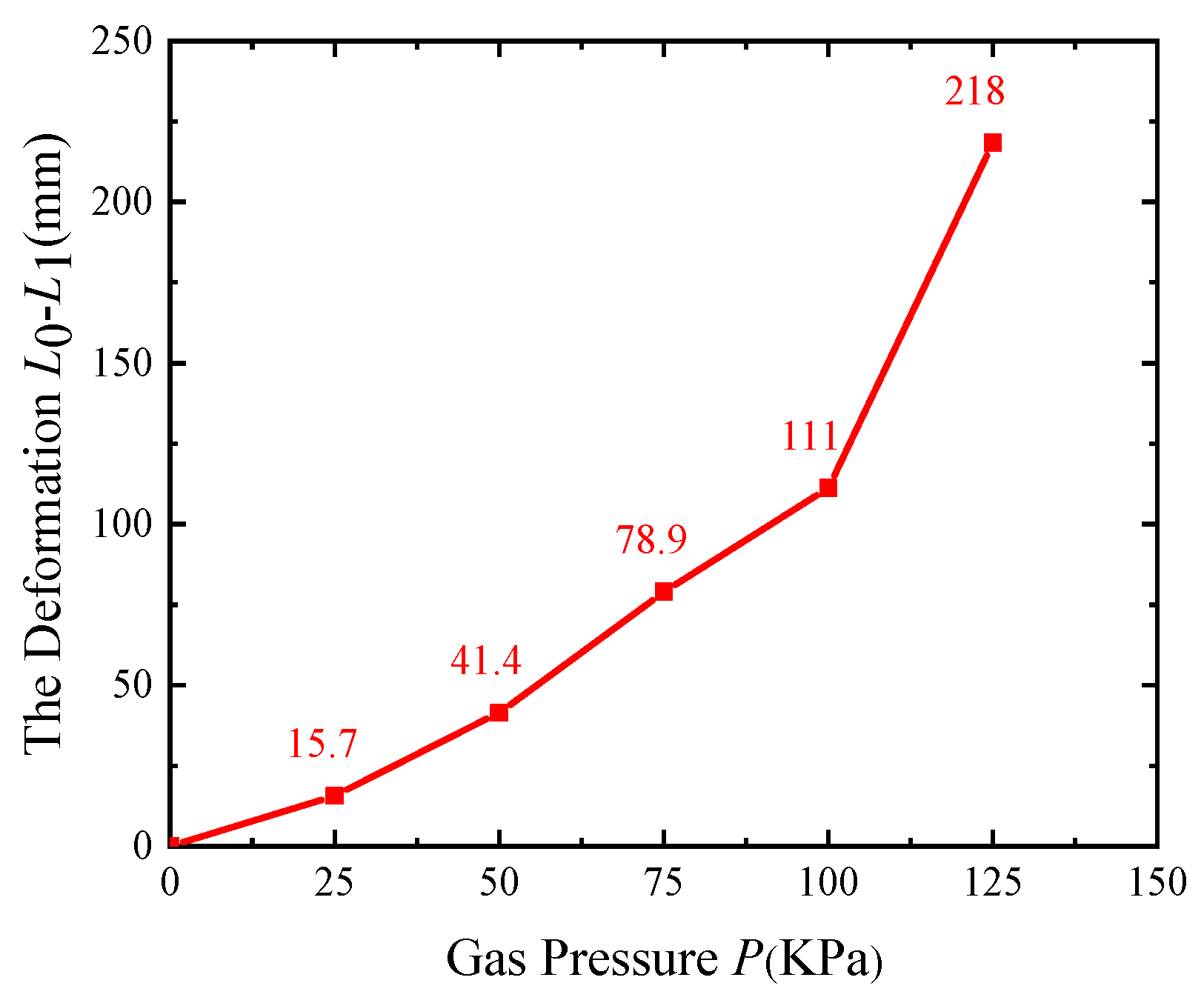

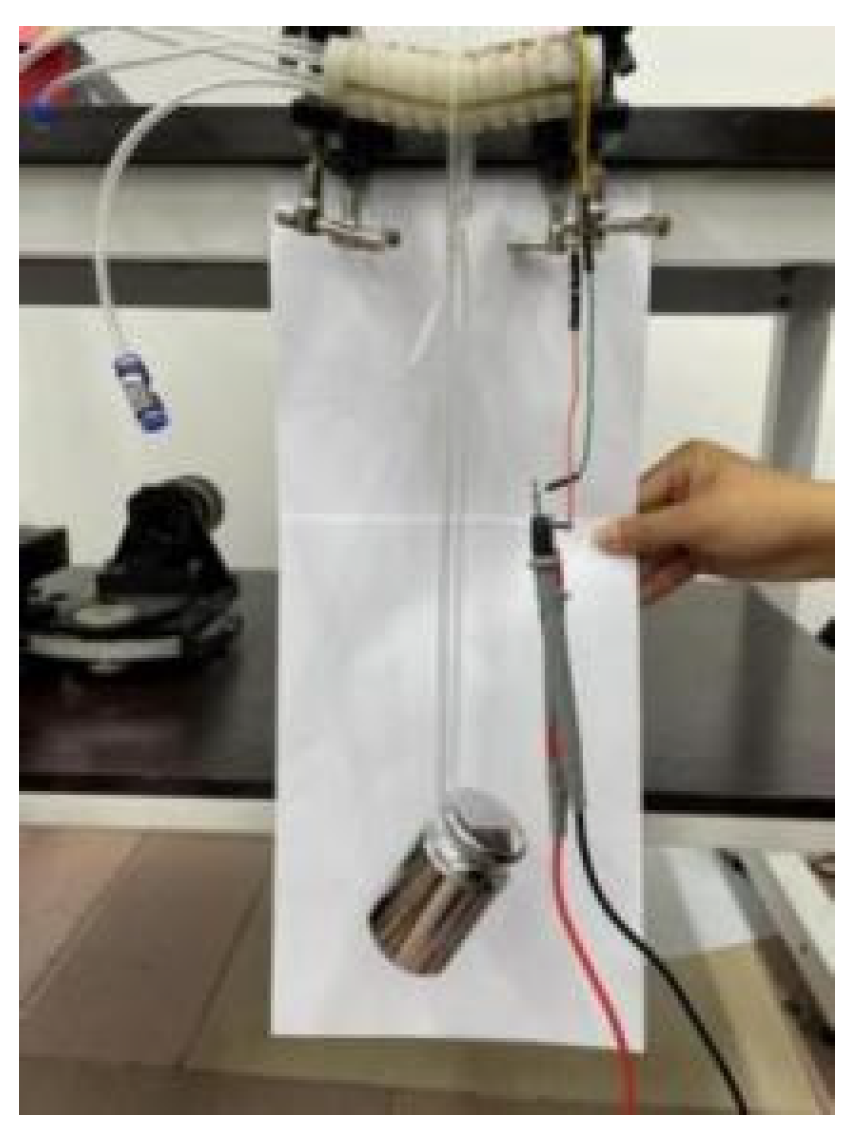

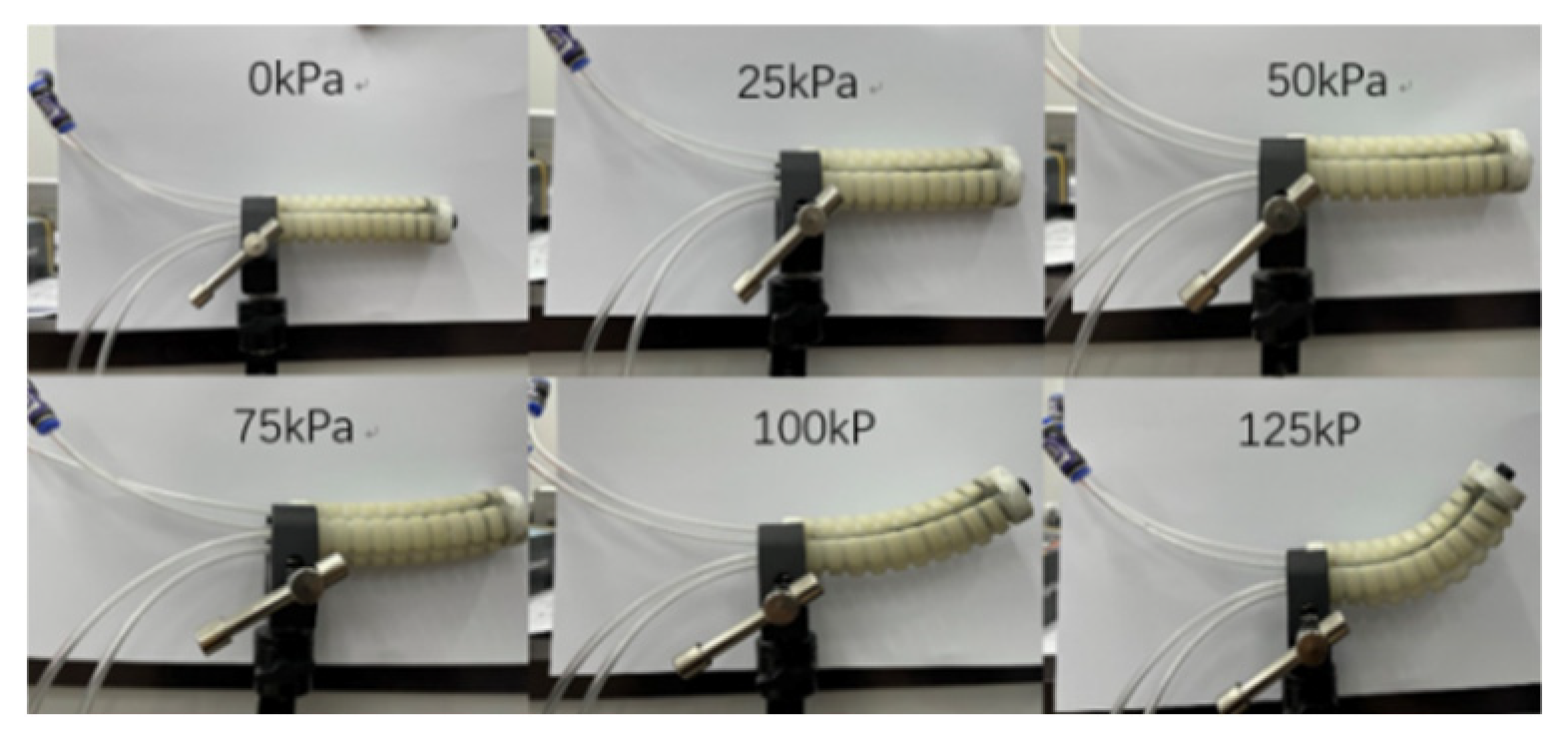

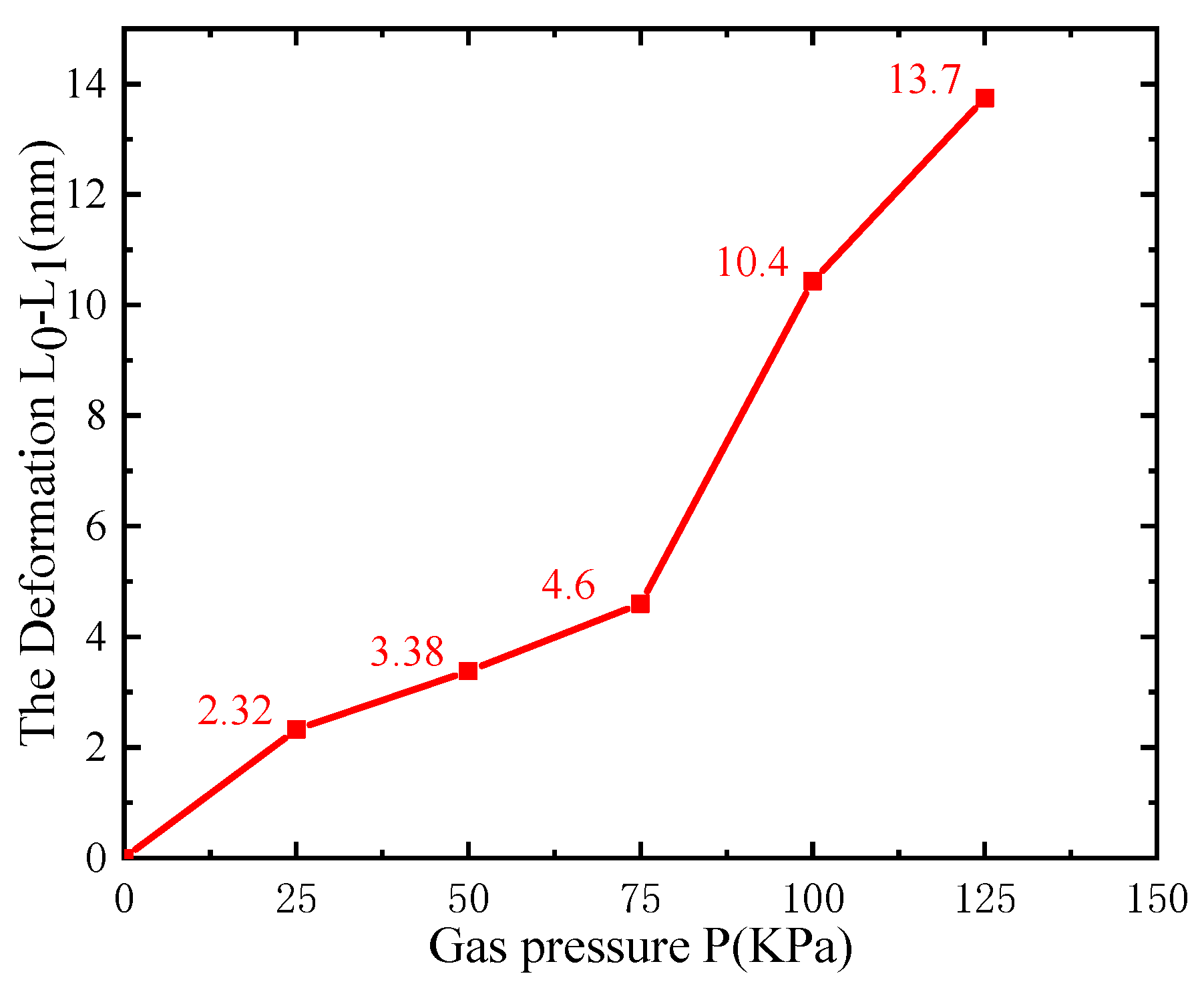

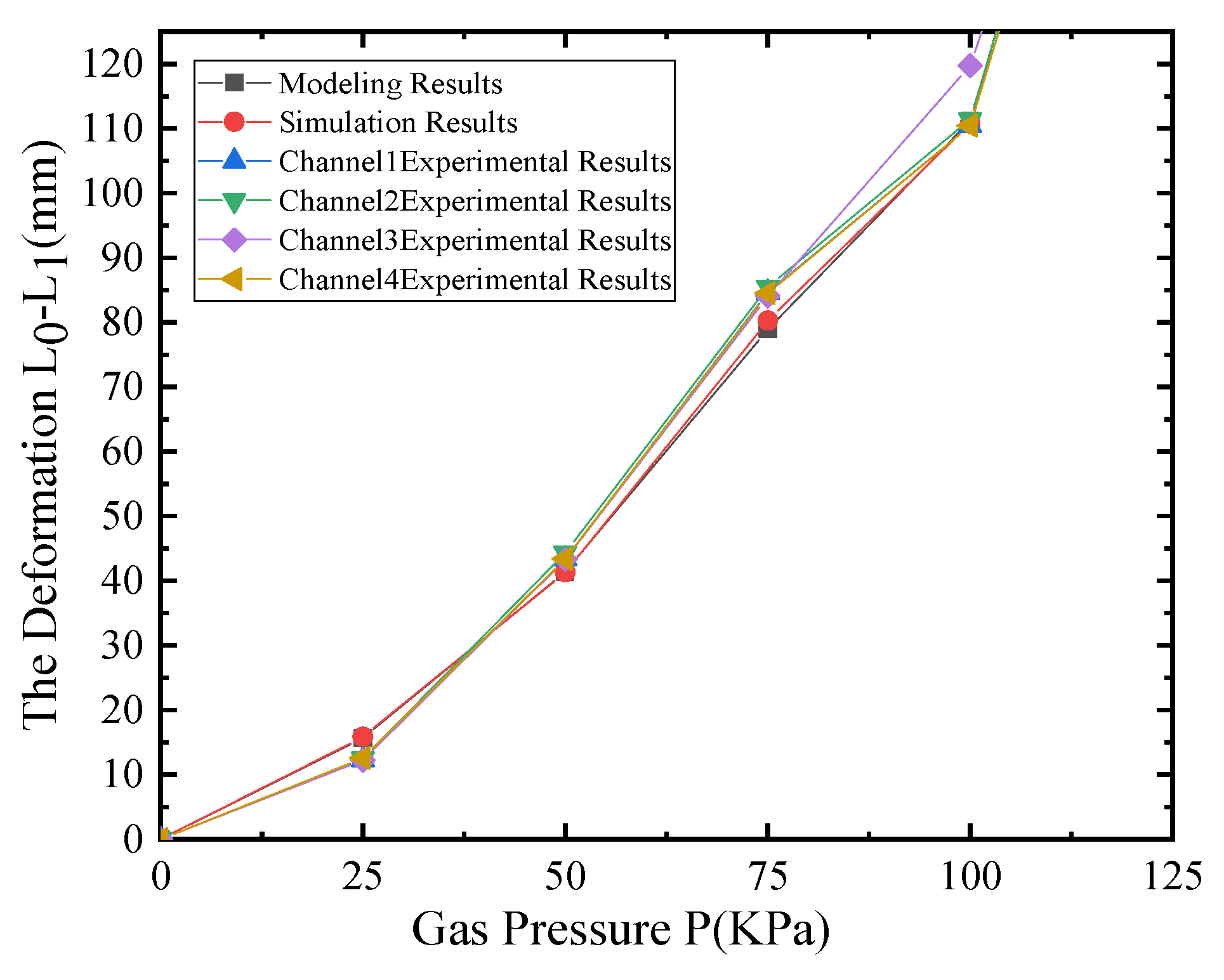

5.1.1. Deformation test

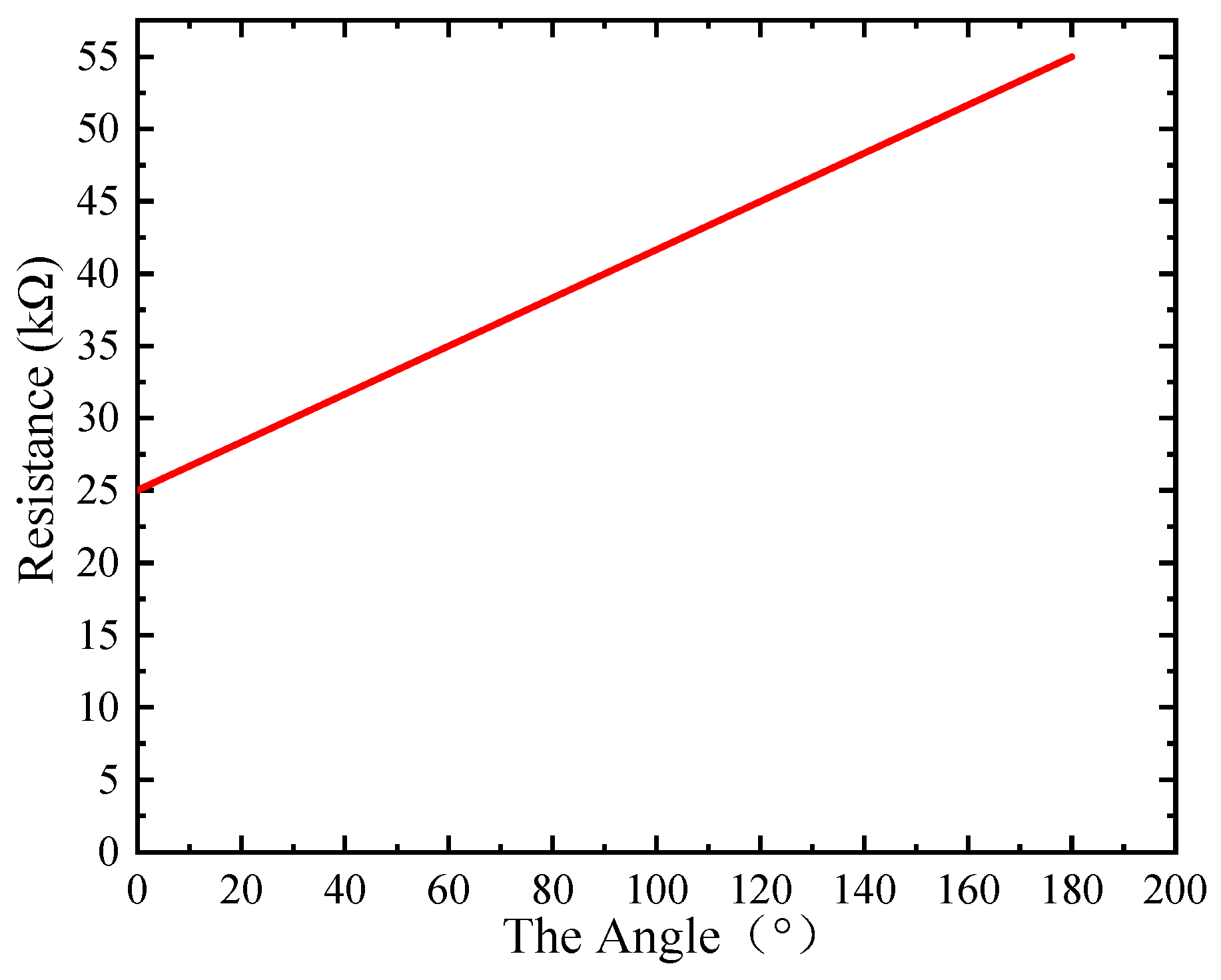

| Air pressure (Kpa) | 0 | 25 | 50 | 75 | 100 | 125 |

|---|---|---|---|---|---|---|

| The sensor (KΩ) | 25 | 26.5 | 27.2 | 28.1 | 31.8 | 34.2 |

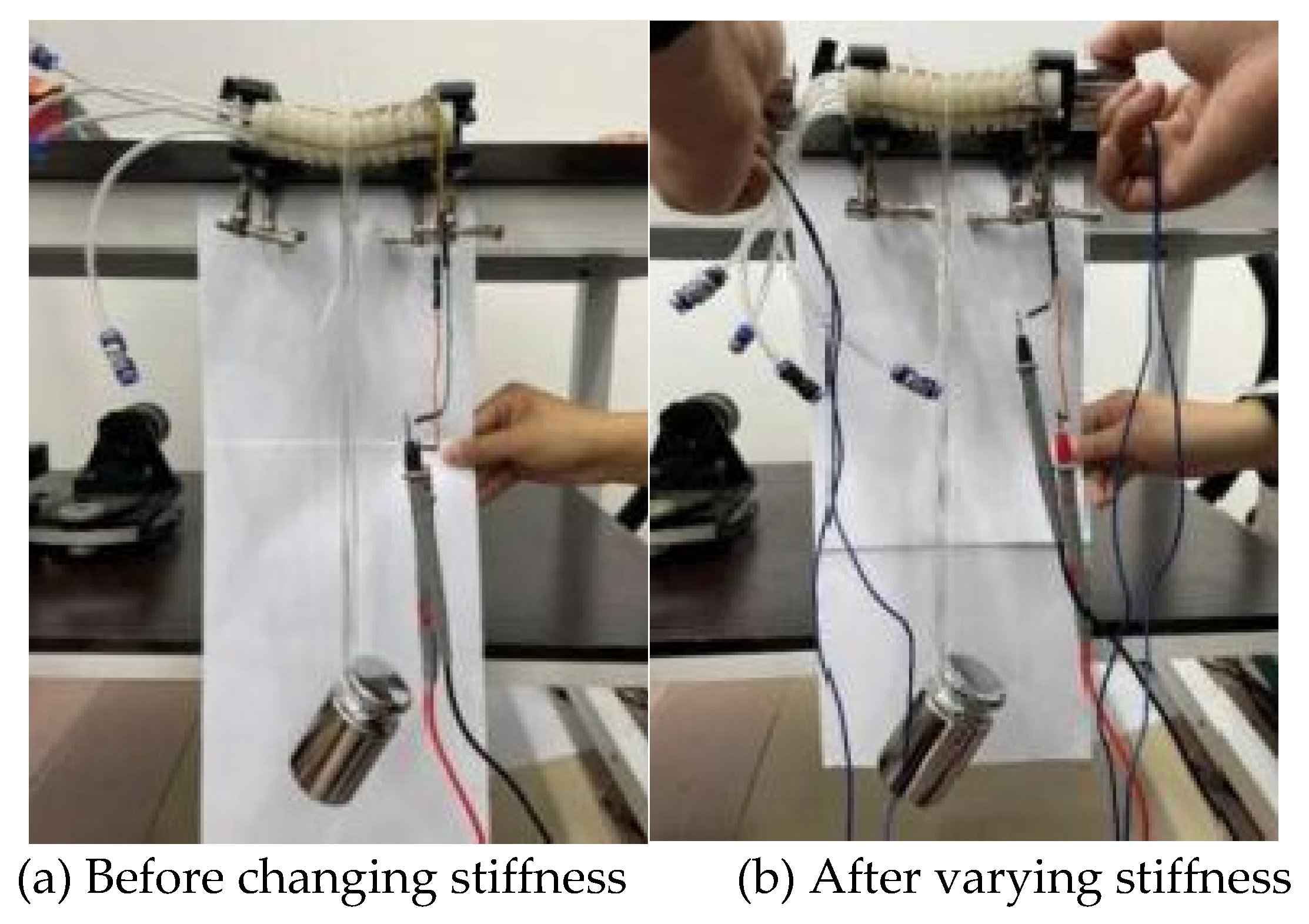

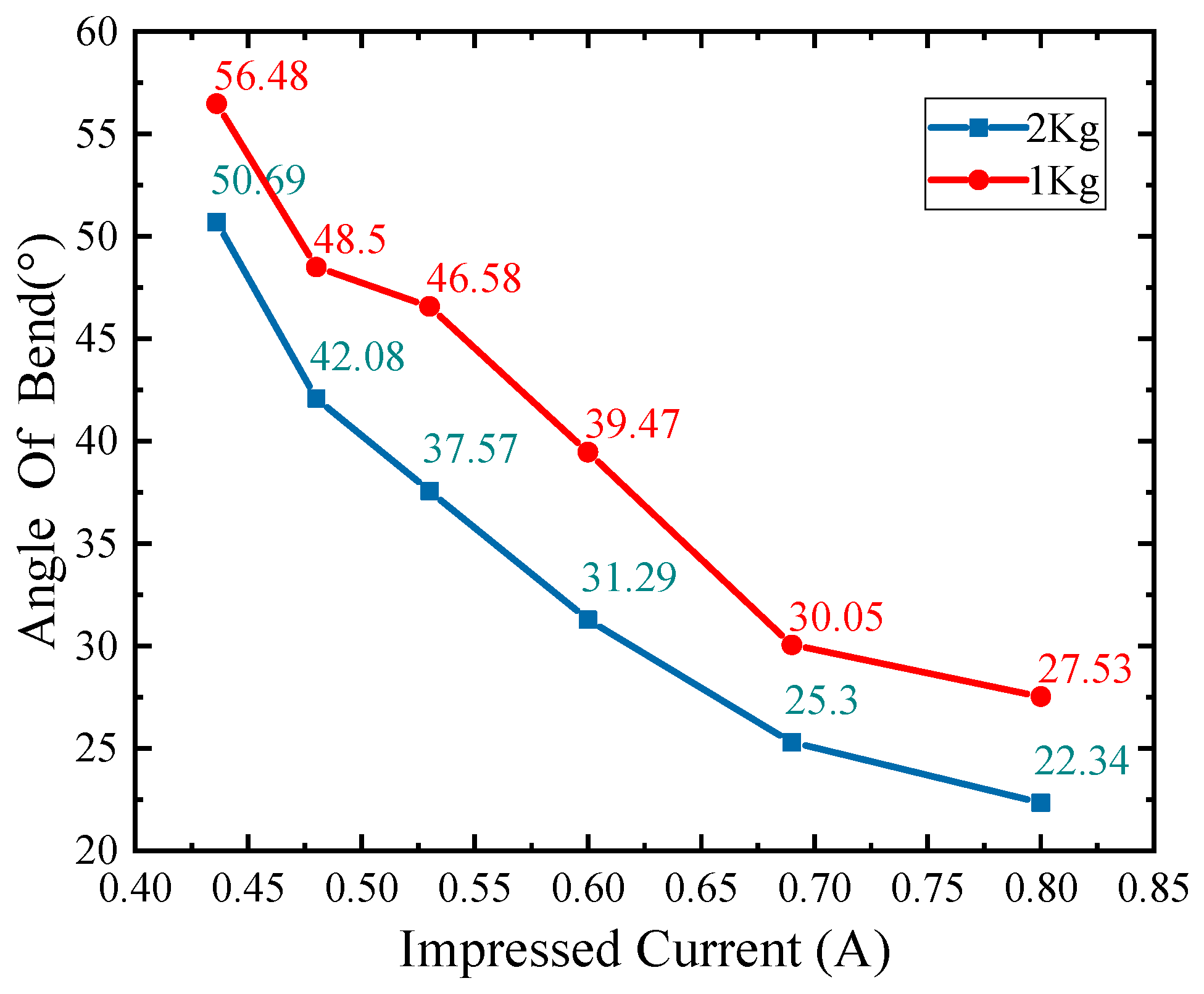

5.1.2. Variable stiffness test

6. Conclusion

7. Patents

Author Biography

Author Contributions

Funding

Conflicts of Interest

References

- Xu, F.-Y.; Jiang, F.-Y.; Jiang, Q.-S.; Lu, Y.-X. Soft Actuator Model for a Soft Robot With Variable Stiffness by Coupling Pneumatic Structure and Jamming Mechanism. IEEE Access 2020, 8, 26356-26371. [CrossRef]

- Gilday, K.; Hughes, J.; Iida, F. Wrist-driven passive grasping: Interaction-based trajectory adaption with a compliant anthropomorphic hand. Bioinspir Biomim 2021, 16. [CrossRef]

- Zhou, P.; Yao, J.; Zhang, S.; Wei, C.; Zhang, H.; Qi, S. A bioinspired fishbone continuum robot with rigid-flexible-soft coupling structure. Bioinspir Biomim 2022, 17. [CrossRef]

- Chen, J.; Jin, H.; Iida, F.; Zhao, J. A design concept of parallel elasticity extracted from biological muscles for engineered actuators. Bioinspir Biomim 2016, 11, 056009. [CrossRef]

- Wockenfus, W.R.; Brandt, V.; Weisheit, L.; Drossel, W.-G. Design, Modeling and Validation of a Tendon-Driven Soft Continuum Robot for Planar Motion Based on Variable Stiffness Structures. IEEE Robotics and Automation Letters 2022, 7, 3985-3991. [CrossRef]

- Wang, Y.; Yang, X.; Chen, Y.; Wainwright, D.K.; Kenaley, C.P.; Gong, Z.; Liu, Z.; Liu, H.; Guan, J.; Wang, T.J.S.R. A biorobotic adhesive disc for underwater hitchhiking inspired by the remora suckerfish. 2017, 2, eaan8072. [CrossRef]

- Gu, G.; Zou, J.; Zhao, R.; Zhao, X.; Zhu, X.J.S.R. Soft wall-climbing robots. 2018, 3, eaat2874. [CrossRef]

- Seok, S.; Onal, C.D.; Cho, K.-J.; Wood, R.J.; Rus, D.; Kim, S.J.I.A.T.o.m. Meshworm: A peristaltic soft robot with antagonistic nickel titanium coil actuators. 2012, 18, 1485-1497. [CrossRef]

- Kashima, S.; Miyasaka, F.; Hirata, K.J.I.T.o.m. Novel soft actuator using magnetorheological elastomer. 2012, 48, 1649-1652. [CrossRef]

- Wang, H.; Wang, C.; Chen, W.; Liang, X.; Liu, Y.J.I.A.T.o.M. Three-dimensional dynamics for cable-driven soft manipulator. 2016, 22, 18-28. [CrossRef]

- Sun, Y.; Zhang, Q.; Chen, X.; Chen, H.J.M.P.i.E. An Optimum Design Method of Pneu-Net Actuators for Trajectory Matching Utilizing a Bending Model and GA. 2019. [CrossRef]

- Zeng, M.; Li, Y.-J.; Ren, T.; Tu, Q.J.P.o.t.I.o.M.E., Part C: Journal of Mechanical Engineering Science. Material stiffness control of compliant tools by using electromagnetic suction. 2019, 233, 4719-4728. [CrossRef]

- Yang, Y.; Chen, Y.; Li, Y.; Wang, Z.; Li, Y.J.S.r. Novel variable-stiffness robotic fingers with built-in position feedback. 2017, 4, 338-352. [CrossRef]

- Li, Y.; Chen, Y.; Yang, Y.; Wei, Y. Passive Particle Jamming and Its Stiffening of Soft Robotic Grippers. IEEE Transactions on Robotics 2017, 33, 446-455. [CrossRef]

- Cheng, N.G.; Lobovsky, M.B.; Keating, S.J.; Setapen, A.M.; Gero, K.I.; Hosoi, A.E.; Iagnemma, K.D. Design and Analysis of a Robust, Low-cost, Highly Articulated manipulator enabled by jamming of granular media. In Proceedings of the 2012 IEEE International Conference on Robotics and Automation, 14-18 May 2012, 2012; pp. 4328-4333. [CrossRef]

- Sadati, S.M.H.; Noh, Y.; Elnaz Naghibi, S.; Althoefer, K.; Nanayakkara, T. Stiffness Control of Soft Robotic Manipulator for Minimally Invasive Surgery (MIS) Using Scale Jamming. In Intelligent Robotics and Applications; Lecture Notes in Computer Science; 2015; pp. 141-151. [CrossRef]

- Shiva, A.; Stilli, A.; Noh, Y.; Faragasso, A.; Falco, I.D.; Gerboni, G.; Cianchetti, M.; Menciassi, A.; Althoefer, K.; Wurdemann, H.A. Tendon-Based Stiffening for a Pneumatically Actuated Soft Manipulator. IEEE Robotics and Automation Letters 2016, 1, 632-637. [CrossRef]

- Wei, Y.; Chen, Y.; Yang, Y.; Li, Y. A soft robotic spine with tunable stiffness based on integrated ball joint and particle jamming. Mechatronics 2016, 33, 84-92. [CrossRef]

- Zhao, Y.; Shan, Y.; Guo, K.; Han, L.; Qi, L.; Yu, H. Principle and Performance Analysis of Soft Continuum Robot with Large Range Variable Stiffness Based on Spherical Particles. In Proceedings of the 2019 IEEE 9th Annual International Conference on CYBER Technology in Automation, Control, and Intelligent Systems (CYBER), 29 July-2 Aug. 2019, 2019; pp. 719-724. [CrossRef]

- Al Abeach, L.A.T.; Nefti-Meziani, S.; Davis, S. Design of a Variable Stiffness Soft Dexterous Gripper. Soft Robot 2017, 4, 274-284. [CrossRef]

- Al Abeach, L.; Nefti-Meziani, S.; Theodoridis, T.; Davis, S. A Variable Stiffness Soft Gripper Using Granular Jamming and Biologically Inspired Pneumatic Muscles. Journal of Bionic Engineering 2018, 15, 236-246. [CrossRef]

- Li, Y.; Ren, T.; Chen, Y.; Chen, M.Z. A variable stiffness soft continuum robot based on pre-charged air, particle jamming, and origami. In Proceedings of the 2020 IEEE International Conference on Robotics and Automation (ICRA), 2020; pp. 5869-5875. [CrossRef]

- Wang, T.; Zhang, J.; Li, Y.; Hong, J.; Wang, M.Y. Electrostatic Layer Jamming Variable Stiffness for Soft Robotics. IEEE/ASME Transactions on Mechatronics 2019, 24, 424-433. [CrossRef]

- Liu, Z.; Wang, Y.; Wang, J.; Fei, Y.; Du, Q. An obstacle-avoiding and stiffness-tunable modular bionic soft robot. Robotica 2022, 40, 2651-2665. [CrossRef]

- Luo, Y.; Wright, M.; Xiao, Q.; Yue, H.; Pan, G. Fluid-structure interaction analysis on motion control of a self-propelled flexible plate near a rigid body utilizing PD control. Bioinspir Biomim 2021, 16. [CrossRef]

- Wang, C.; Tang, H.; Zhang, X.J.B.; Biomimetics. Fluid-structure interaction of bio-inspired flexible slender structures: A review of selected topics. 2022. [CrossRef]

- Moon, D.-H.; Shin, S.-H.; Na, J.-B.; Han, S.-Y. Fluid–Structure Interaction Based on Meshless Local Petrov–Galerkin Method for Worm Soft Robot Analysis. International Journal of Precision Engineering and Manufacturing-Green Technology 2020, 7, 727-742. [CrossRef]

- Shan, Y.; Zhao, Y.; Pei, C.; Yu, H.; Liu, P. A novel design of a passive variable stiffness soft robotic gripper. Bioinspir Biomim 2022, 17. [CrossRef]

- Sun, W.; Yu, J.; Cai, Y. Influence of magnetic field, magnetic particle percentages, and particle diameters on the stiffness of magnetorheological fluids. Journal of Intelligent Material Systems and Structures 2020, 31, 2312-2325. [CrossRef]

- Ilievski, F.; Mazzeo, A.D.; Shepherd, R.F.; Chen, X.; Whitesides, G.M. Soft robotics for chemists. Angew Chem Int Ed Engl 2011, 50, 1890-1895. [CrossRef]

- Yap, H.K.; Ng, H.Y.; Yeow, C.-H. High-Force Soft Printable Pneumatics for Soft Robotic Applications. Soft Robotics 2016, 3, 144-158. [CrossRef]

- S.Y.Liu; J.T.Zhang; J.Wang; Y.J.Deng; C.T.Xin. Design and simulation analysis of fluid-driven modular soft body bionic elephant trunk joint variable stiffness structure %J Hydraulics and Pneumatics. 2022, 46, 152-158.

- Zhang, Y.; Chen, W.; Chen, J.; Cheng, Q.; Zhang, H.; Xiang, C.; Hao, L. Stiffness Analysis of a Pneumatic Soft Manipulator Based on Bending Shape Prediction. IEEE Access 2020, 8, 82227-82241. [CrossRef]

- Taniguchi, H.; Miyake, M.; Suzumori, K. Development of new soft actuator using magnetic intelligent fluids for flexible walking robot. In Proceedings of the ICCAS 2010, 27-30 Oct. 2010, 2010; pp. 1797-1801.

- Xuan, T.; Li, J.; Li, B.; Fan, W.J.J.o.M.; Materials, M. Effects of the non-uniform magnetic field on the shear stress and the microstructure of magnetorheological fluid. 2021, 535, 168066. [CrossRef]

| parameter | value |

|---|---|

| The thickness of a single air chamber constraint layer | |

| The thickness of the cavity wall in the length direction of a single cavity | |

| Cavity wall thickness in the height direction | |

| Cavity wall thickness in the width direction | |

| The length of the cavity in the direction of the height of a single air cavity | |

| Single air cavity length direction empty cavity length | |

| Width direction cavity length | |

| The spacing between air cavities | |

| Width of vent between air cavity and air cavity |

| P(KPa) | 0 | 25 | 50 | 75 | 100 | 125 |

|---|---|---|---|---|---|---|

| θ (°) | 0 | 27.8 | 51.4 | 120.3 | 165.4 | 335.3 |

| Diameter (mm) |

high (mm) | Table magnetic intermediate magnetic field strength (T) | nominal voltage (V) | weight (g) |

| 35 | 30 | 0.1 | 24 | 200 |

| Working condition | Viscosity (Pa·s) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) |

|---|---|---|---|---|---|---|

| 1 | 0 | 25 | 50 | 75 | 100 | 125 |

| 2 | 15 | 25 | 50 | 75 | 100 | 125 |

| 3 | 38 | 25 | 50 | 75 | 100 | 125 |

| 4 | 55 | 25 | 50 | 75 | 100 | 125 |

| 5 | 72 | 25 | 50 | 75 | 100 | 125 |

| Working condition | viscosity (Pa·s) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) | Gas pressure (KPa) |

|---|---|---|---|---|---|---|

| 1 | 0 | 15 | 30 | 45 | 60 | 75 |

| 2 | 15 | 15 | 30 | 45 | 60 | 75 |

| 3 | 38 | 15 | 30 | 45 | 60 | 75 |

| 4 | 55 | 15 | 30 | 45 | 60 | 75 |

| 5 | 72 | 15 | 30 | 45 | 60 | 75 |

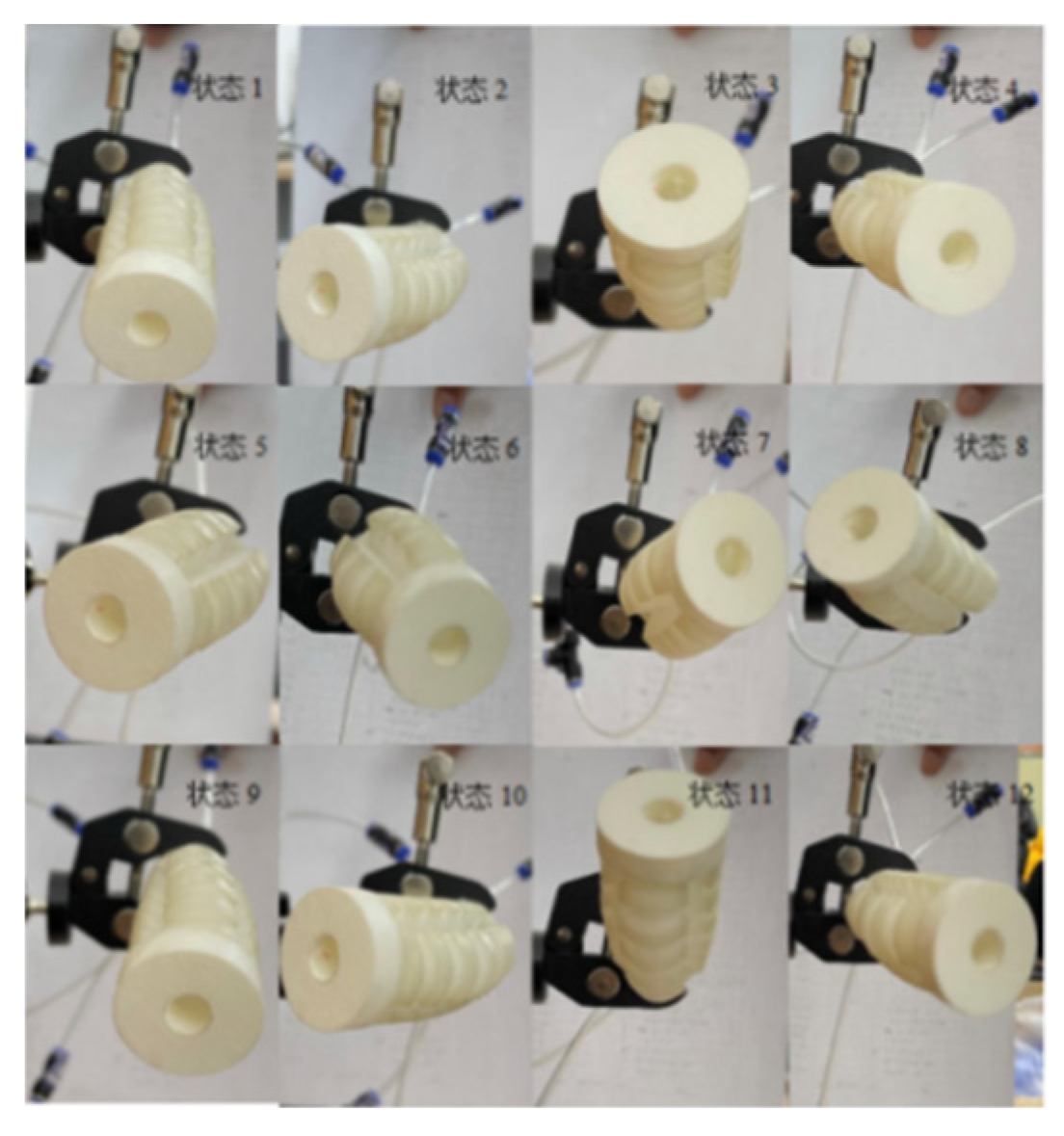

| Channel Number |

1 | 2 | 3 | 4 | The deformation L0-L1 (mm) |

|

|---|---|---|---|---|---|---|

| state | ||||||

| 1 | + | 0 | 0 | 0 | 10 | |

| 2 | 0 | + | 0 | 0 | 10 | |

| 3 | 0 | 0 | + | 0 | 10 | |

| 4 | 0 | 0 | 0 | + | 10 | |

| 5 | + | + | 0 | 0 | 10 | |

| 6 | 0 | + | + | 0 | 10 | |

| 7 | 0 | 0 | + | + | 10 | |

| 8 | + | 0 | 0 | + | 10 | |

| 9 | + | 0 | - | 0 | 13.5 | |

| 10 | 0 | + | 0 | - | 13.5 | |

| 11 | - | 0 | + | 0 | 13.5 | |

| 12 | 0 | - | 0 | + | 13.5 | |

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).