1. Introduction

7055 aluminum alloy was widely used in the aerospace field because of its excellent properties such as high tensile strength and low density [

1]. However, with the change of the times, the requirements for aircraft performance were becoming more and more stringent, which had prompted researchers to seek ways to improve the mechanical properties of 7055 aluminum alloy. Through continuous exploration and research, researchers had found that it was possible to improve the microstructure and properties of aluminum alloys [

2,

3] by various heat treatment processes [

4], changing the composition of alloying elements and micro-alloying elements. By adding Sc, Er, Sm, La, Ce and other rare earth elements could change the microstructure of aluminum alloy and improve its comprehensive mechanical properties.

The addition of Sc in 7055 aluminum alloy could cause grain boundary effect [

5,

6], effectively refine the grains, which had a good promoting effect on the hardness, tensile strength, ductility and thermal stability [

7]. But its high cost was not conducive to large-scale industrial applications. In recent years, some scholars have studied the effects of rare earth Ce and La on the microstructure and properties of Al-Zn-Mg-Cu-Zr alloy. They found that Ce and La shorten the distance between the dendrites, which refined the intercrystalline eutectic phase. And a small amount of Ce maked the precipitated phase smaller, which improved the mechanical properties of the alloy [

8]. Although Ce increased the recrystallized alloy grains, and refined the GP region, so it had no effect on the properties of the alloy. No precipitated phases such as Al

3(Zr, Sc) were observed after heat treatment of alloys with La and Ce [

9]. In contrast, Sm and Er could form rare earth phase in aluminum alloy, which were cheaper than Sc. The rare earth phase could fix the grain boundary during solid solution treatment, and the rare earth atoms could provide more nucleation sites for the precipitation of the η’ phase, which maked it smaller during the aging treatment, thus refining the grain [

10]. At the same time, the strongest strengthening effect was present in Er, which effectively prevented grain boundary displacement during its melting process and significantly raised the tensile strength and yield strength of aluminum alloy [

11]. The refinement effect of cast aluminum alloy grain was improved after the addition of Sm and it had a considerable effect on the enhancement of plasticity [

12]. The compound addition of Sm + Er in 7055 aluminum alloy had potential advantages in improving strength and toughness.

By optimizing the process parameters of heat treatment, homogenizing the alloy composition and adjusting the size and distribution of the second phase and precipitated phase, the comprehensive properties of aluminum alloy could be further improved [

13]. Solution aging promoted the precipitation of Al

3(Er,Zr) particles, which could inhibit the movement of grain boundaries, fix the dislocation and maintain the subgrain structure, so as to effectively improve the comprehensive properties of the material [

14,

15]. In particular, the precipitation enhancement of Al

3Er or Al

3(Er,Zr) particles could compensate for the precipitation enhancement of η’ and play a major role in improving the hardness [

16]. Similarly, heat treatment in a certain manner could promote the precipitation of the Sm-containing phase, that is, the formation of Al

2Sm particles. The Al

2Sm particles enhanced heterogeneous nucleation, and the grains could be efficiently refined [

17].

The common solution temperature of 7055 aluminum alloy was 460°C, which could promote the gradual dissolution of the second phase, so as to lead to the reduction of the resistance of dislocation movement during heat treatment and improve the plasticity of the alloy to a certain extent [

18,

19]. High temperature solution would cause serious coarsening of the second phase and the grain, which reduced the hardness and tensile strength of the material. And the high temperature was easy to cause overheating and quenching deformation and cracking, which greatly affected the mechanical properties of aluminum alloy [

20]. In order to avoid the coarsing of the second phase size caused by excessive temperature and make the rare earth phase effectively improve the microstructure and mechanical properties of the material, this paper carried out a study on the influence of heat treatment processes at 410℃solution temperature and 150 °C aging temperature on the microstructure and mechanical properties of the as-cast 7055 aluminum alloy with Sm + Er composite addition.

2. Experimental method

2.1. Sample composition

The raw materials used in the experiment were 7055 aluminum alloy (Al-8.2Zn-2.2Mg-2.4Cu-0.2Zr), high-purity Sm ingots (99.99wt.%), high-purity Er ingots (99.99wt.%), high-purity aluminum foil (99.99wt.%), etc. The alloy material was weighed by an electronic balance (Shanghai Huachao Industrial Co., LTD., Shanghai, China) with an accuracy of 0.0001g, and the oxide layer on the surface of the alloy material was polished with 1000 mesh sandpaper before weighing. According to the mass fraction of Sm:Er = 3:1 added to 7055 aluminum alloy, the sum of the added rare earth elements was 0.2-0.8wt.%. The specific sample composition is shown in

Table 1.

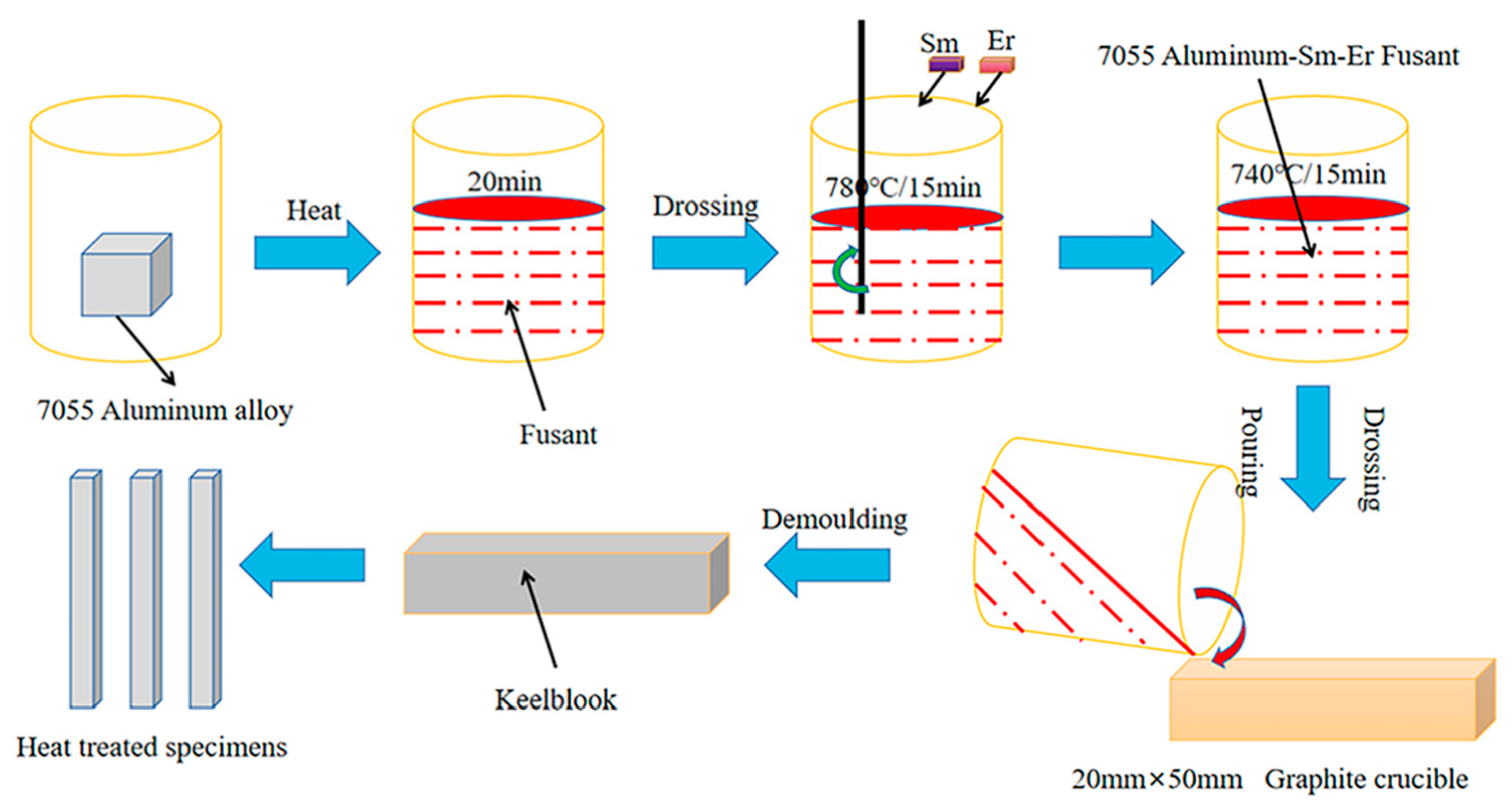

2.2. Melting sample

The 7055 aluminum alloy with different rare earth composition was smelted and cast. The temperature of the pit furnace (Xiangtan Samsung Instrument Co., LTD., Xiangtan, China) was raised to 780 °C for insulation. 7055 aluminum ingots were loaded with alumina crucible and put into the pit furnace, and argon gas was used to protect them. When the 7055 aluminum ingots were melted, the rare earth elements were wrapped in aluminum foil during the smelting process, which were press into 7055 aluminum alloy melt with ceramic rod and stirred evenly. After holding for 15min, the temperature was reduced to 740 °C for refining, so that the gas in the melt was removed to prevent the formation of pores and slag inclusion in the casting. Finally, after holding for 15min, the crucible was taken out and cast along the mold wall. When the ingot was cold to room temperature, it was taken out, which was wired cut. Details of the smelting, casting and sample making processes are shown in

Figure 1.

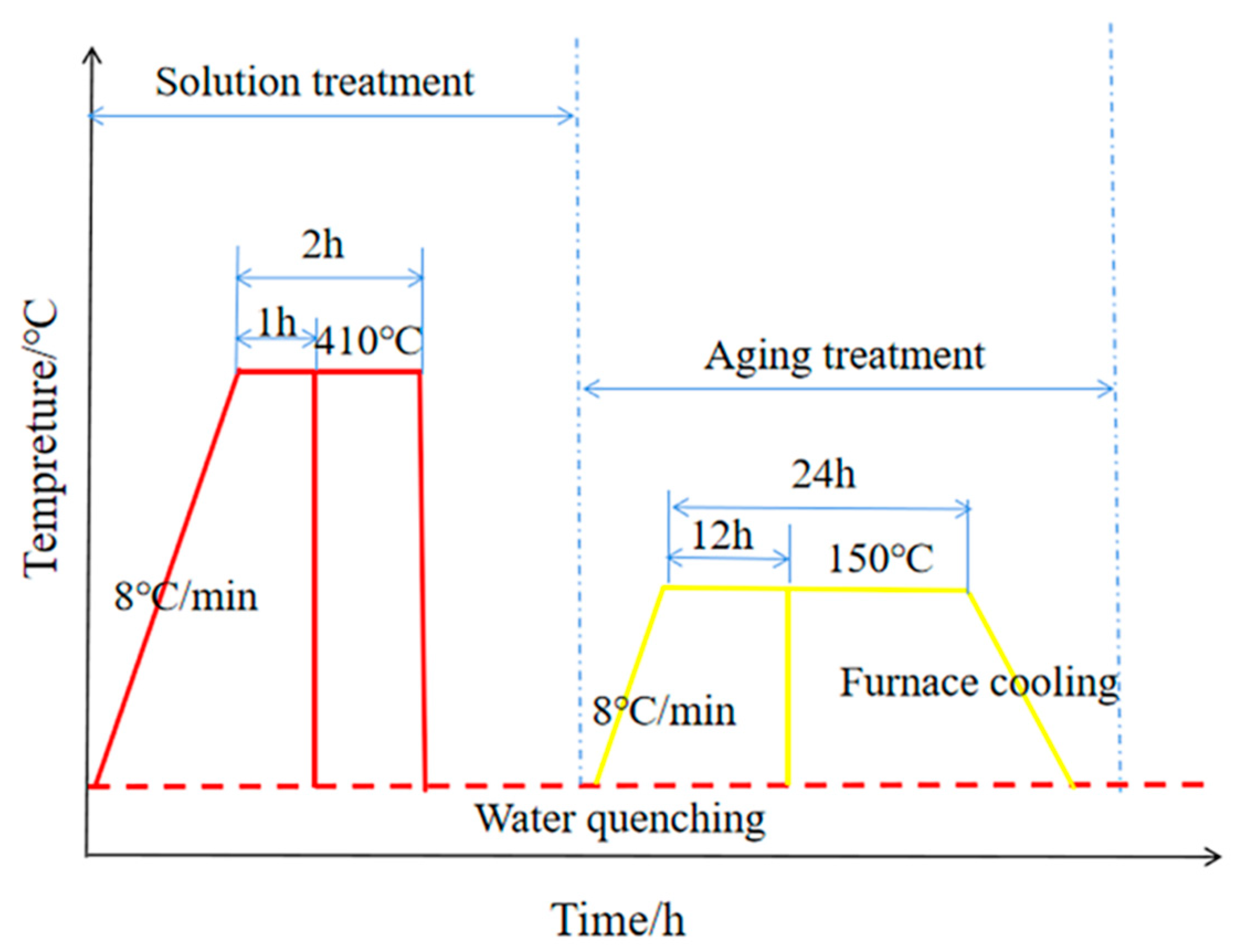

2.3. Heat treatment

As-cast 7055 aluminum alloy with Sm + Er were treated with single-stage solution and single-stage aging in this experiment. When we selected the solution temperature of 410 °C and the aging temperature of 150 °C and we set the solution time to 1h or 2h and the aging time to 12h or 24h, which formed four different heat treatment processes. The four groups of heat treatment processes were performed as follows: 410 °C×1h solid solution treatment + 150 °C×12h aging treatment, 410 °C×1h solid solution treatment + 150 °C×24h aging treatment, 410 °C×2h solid solution treatment + 150 °C×12h aging treatment, and 410 °C×2h solid solution treatment + 150 °C×24h aging treatment. The heat treatment process diagram is shown in

Figure 2.

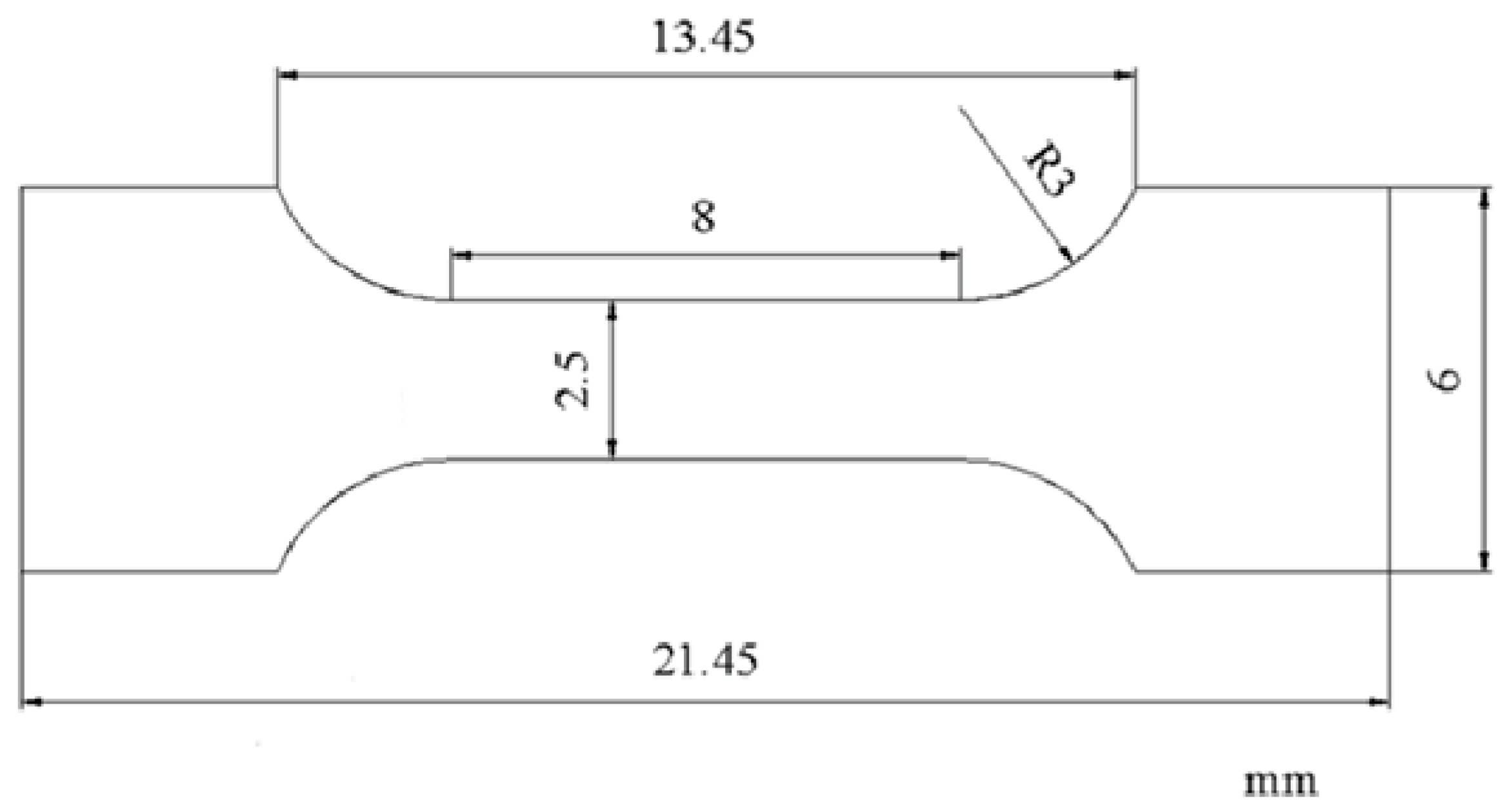

2.4. Test characterization

OM (ZEISS, Zeiss, Jena, Germany), SEM-EDS (ZEISS, EVO MA10, Zeiss, Jena, Germany), XRD (Ultima IV, Rigaku Co., Tokyo, Japan) characterized the grain size, micro-organization, phase composition about the as-cast and heat-treated samples. The etching agent for the metallographic sample was Keller reagent (95ml water, 2.5ml HNO

3, 1.5ml HCl, 1.0ml HF). The macroscopic hardness (SHYCHVT-30,Laizhou Huayin Hardness Meter Factory, Lai Zhou China) was measured. The middle part of the cuboid sample was measured for three times, and the macroscopic hardness value was obtained by taking the average value. The tensile samples shown in

Figure 3 were prepared by wire-cut method. The yield strength and tensile strength of the samples were measured by electronic multifunctional tensile machine (WDW-100C, Jinan Fangyuan Instrument Co., Ltd., Jinan, China).

3. Experimental Results and Analysis

3.1. Microscopic morphology and physical phase analysis of the alloys

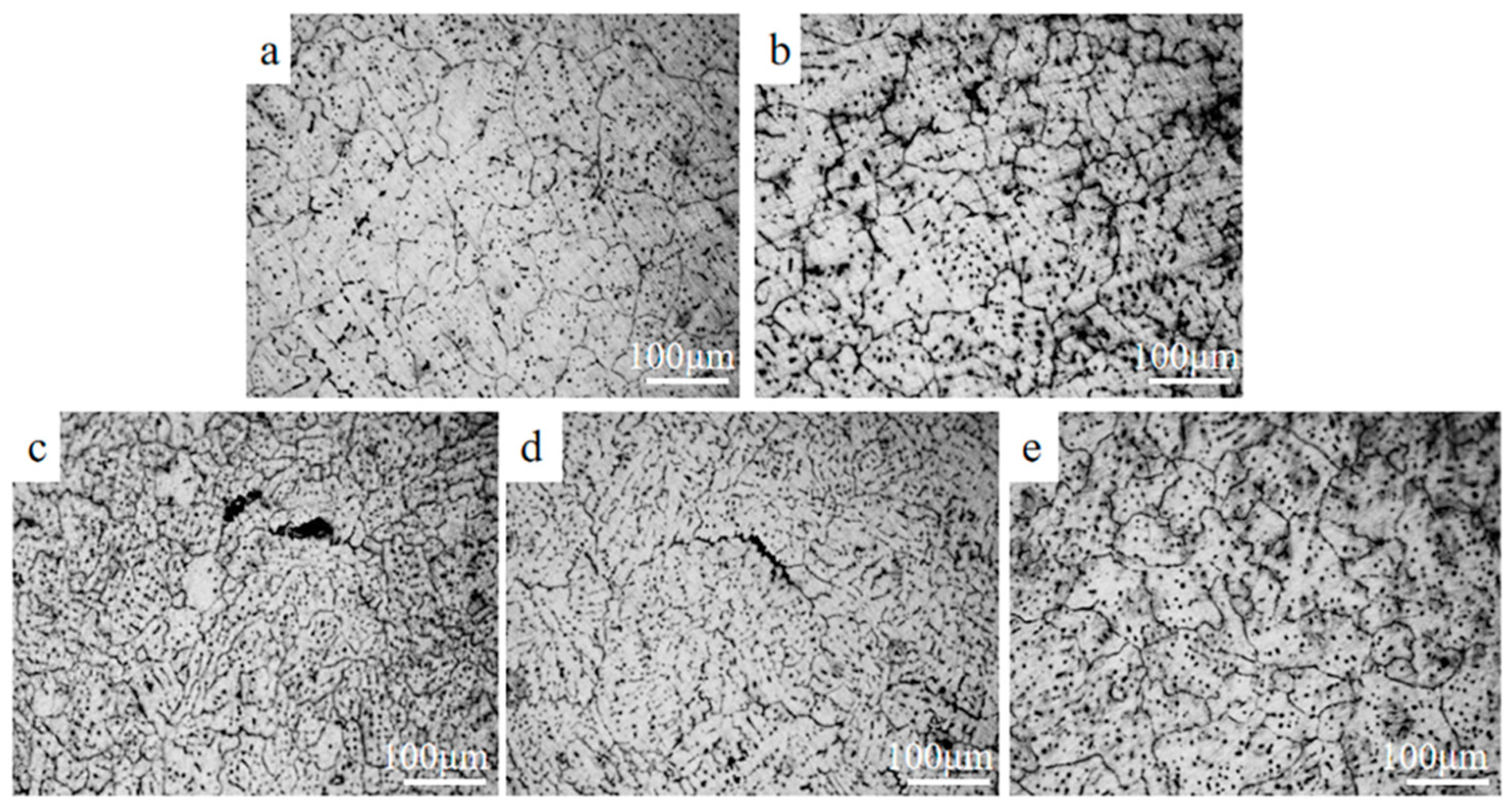

As can be seen from

Figure 4, the grain size of the as-cast 7055 aluminum alloy without adding Sm + Er was 119 μm. The grain size of the as-cast 7055 aluminum alloy was obviously refined by adding Sm + Er. When the total contents of Er and Sm increased from 0.2 to 0.8wt.%, the grain sizes were 122 μm, 53 μm, 88 μm and 95 μm, respectively. With the increase of the total content of Er and Sm, the grain refining effect first increased and then decreased. And the grain refining effect was most obvious when the total content reached 0.4wt.%. The addition of Sm + Er caused the composition at the nucleation position to be supercooled [

21], which increased the nucleation rate so as to reduces the as-cast grain size. At the same time, the precipitation of rare earth phase containing Sm effectively inhibited the grain boundary movement and refined grains, which greatly improved the plastic properties of aluminum alloy [

22]. However, when the added content exceeded a certain amount, a large number of Er aggregated to form coarse compounds and existed in the grain boundaries due to the small solubility of Er in the Al substrate, which coarsened the grain boundaries and weakened the undercooling effect of rare earth elements on the alloy components [

23]. Therefore, adding proper amount of Sm + Er could refine the cast structure and improve the uniformity of the cast structure.

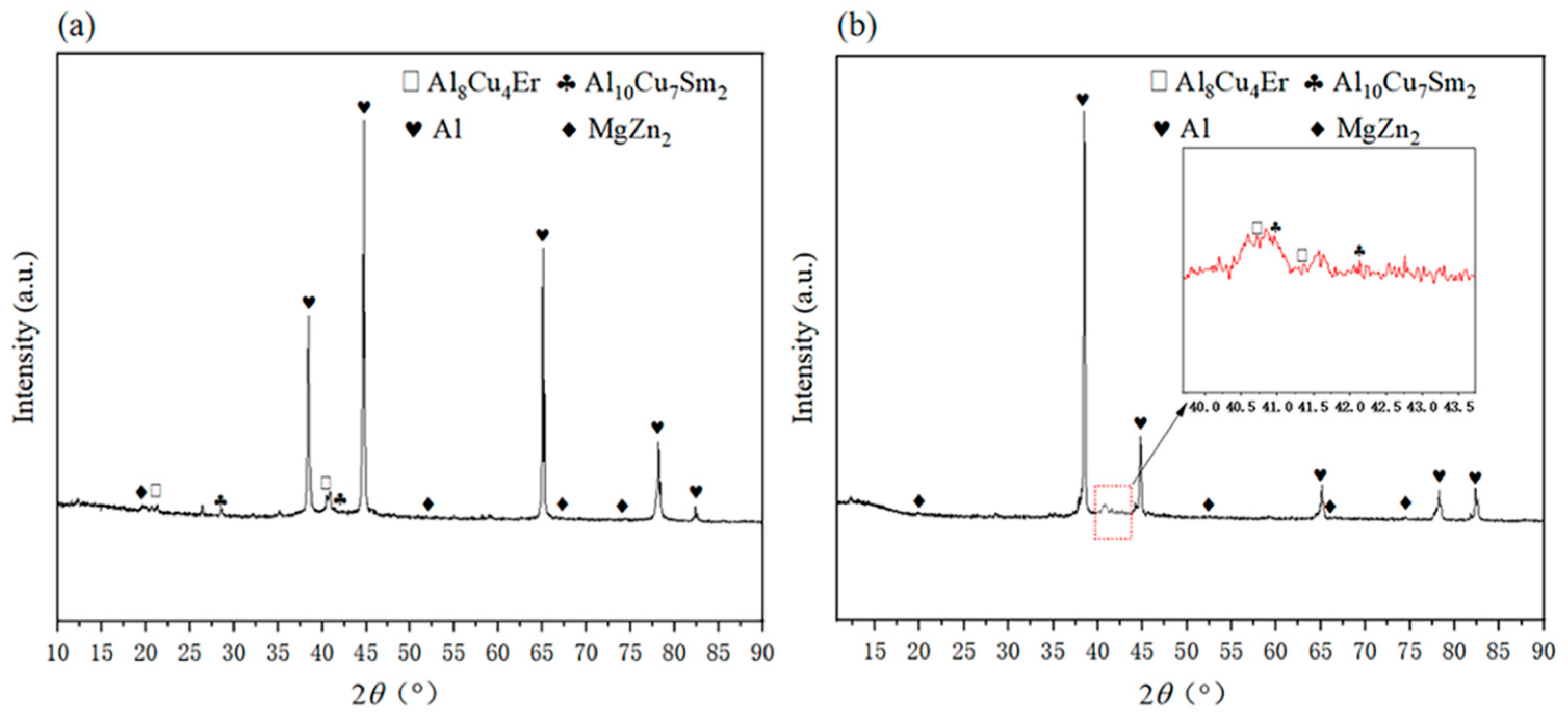

Figure 5 shows the XRD pattern of sample 2# before and after heat treatment. After the addition of rare earth elements Sm + Er, a new Al-RE(-Cu) phase appeared, namely rare earth phases Al

10Cu

7Sm

2 (PDF 36-1267) and Al

8Cu

4Er (PDF 33-0006), appeared a diffraction peak of Al

8Cu

4Er near 20°. The diffraction peak of Al

8Cu

4Er appeared near 20°, and that for Al

10Cu

7Sm

2 near 30°, and for both phases around 41°.

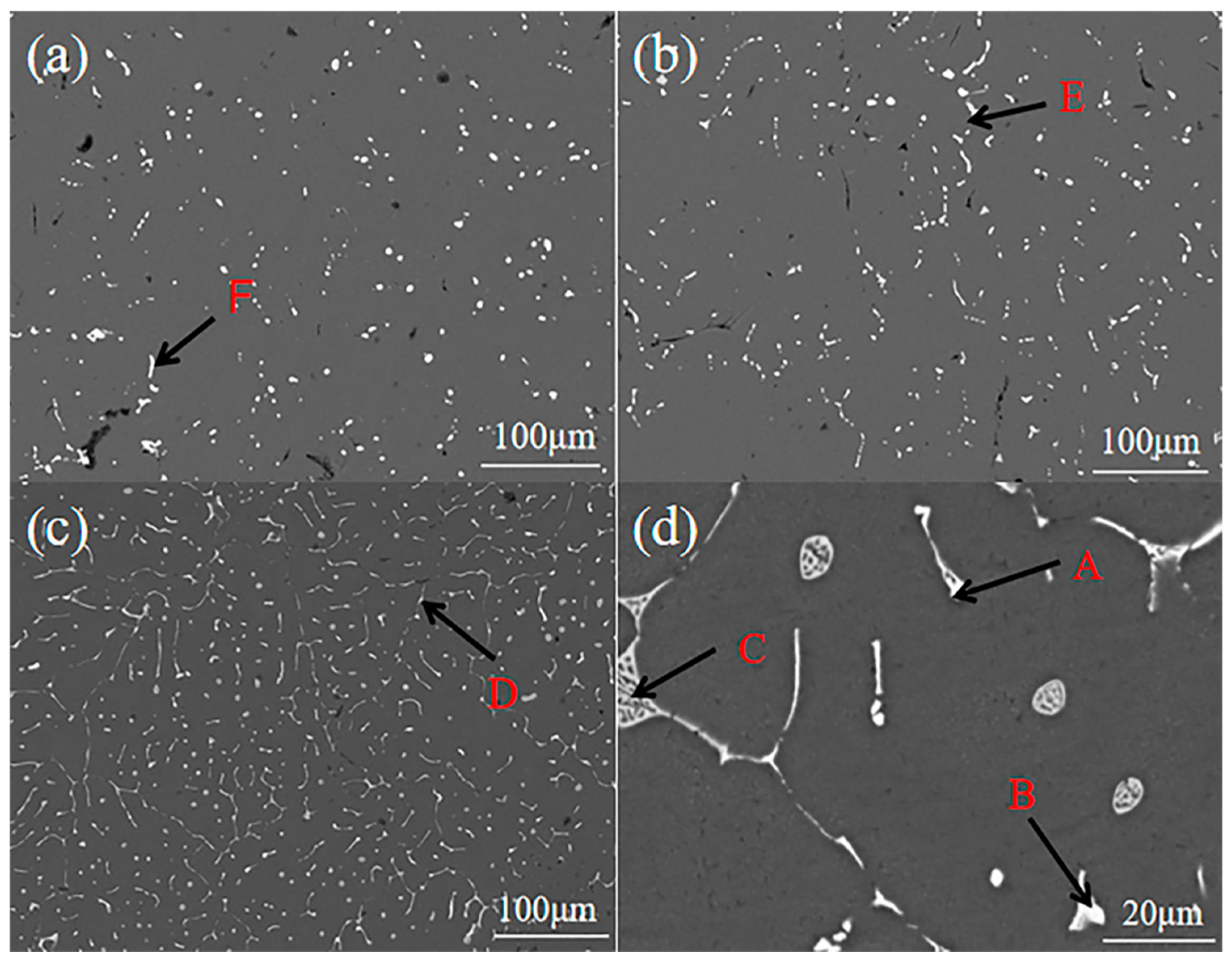

Figure 6 is The SEM micro-organization of 2# alloy before and after heat treatment.

Table 2 shows the EDS results for each point in

Figure 6. According to the EDS results, the atomic ratio of Al, Cu and Sm in the polygon block phase of point A in

Figure 6d was close to 10:7:2, which contained a small amount of Zn elements. And the control XRD result in

Figure 5 could be confirmed to be Al

10Cu

7Sm

2. The atomic ratio of Al, Cu, and Er in the polygon block phase of the point B in

Figure 6d was close to 8:4:1, which also contained a small amount of Zn elements. The Al

8Cu

4Er phase was confirmed by the XRD results in

Figure 5.

Figure 6 shows that a large number of coarse-grained alloy phases are distributed at the grain boundaries. After heat treatment (

Figure 6c), the precipitation amount of the rare earth phase increased and was uniformly distributed, which had the role of stabilizing the grain boundary. Phases C, D, E, and F in

Figure 6 were lamellar eutectic structures, which mainly contained Zn, Mg, Al and Cu elements. The XRD results in

Figure 5 confirmed the α-Al+η-Mg(Zn,Al,Cu) eutectic microstructure. The crystal structure of η-Mg(Zn, Al, Cu)

2 was the same as the MgZn

2 containing few Al and Cu atoms, where a small portion of Al and Cu atoms were soldered [

24,

25]. When rare earth elements were added, the rare earth phase was preferred over α-Al generation. And when α-Al began to nucleate, part of the rare earth phase was pushed to the front end of the solid-liquid interface, thus hindering the further growth of the grain. The lamellar eutectic microstructure in

Figure 6c was significantly thinner, which indicated that a large number of second phases at the grain boundary dissolved in the α-Al substrate after heat treatment.

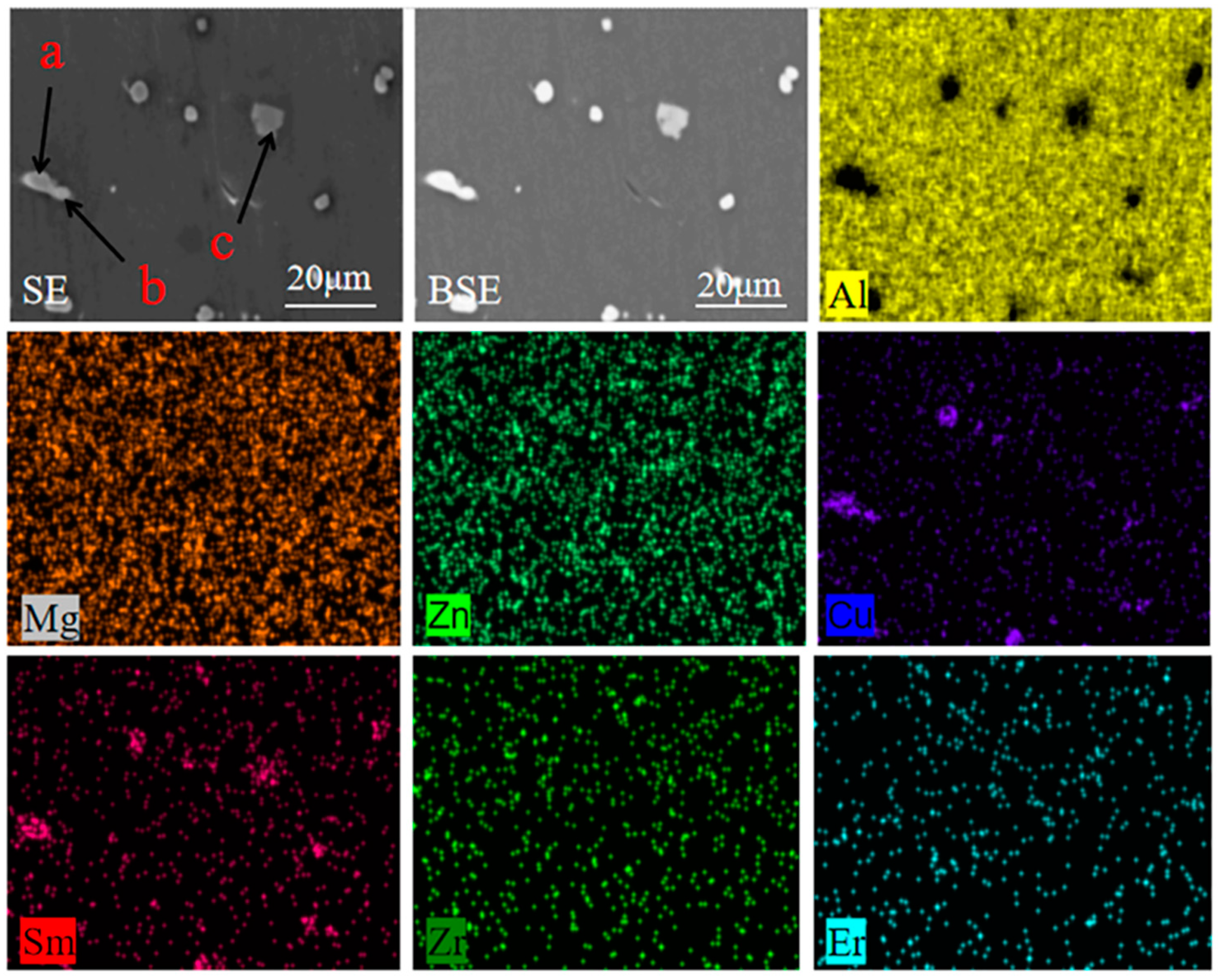

According to the EDS scan results in

Figure 7, Cu tended to combine with rare earth elements to form rare earth phases. Sm tended to be enriched in rare earth alloy phase compared with Er, furthermore Mg, Zn and Zr were uniformly dispersed in the substrate.

In summary, the microstructure of as-cast 7055 aluminum alloy could be effectively improved by the addition of Sm + Er, and the mechanical properties of the alloy could be improved by the dispersion of rare earth alloy. The heat treatment process of solution + aging had significant effect on the microstructure of 7055 aluminum alloy.

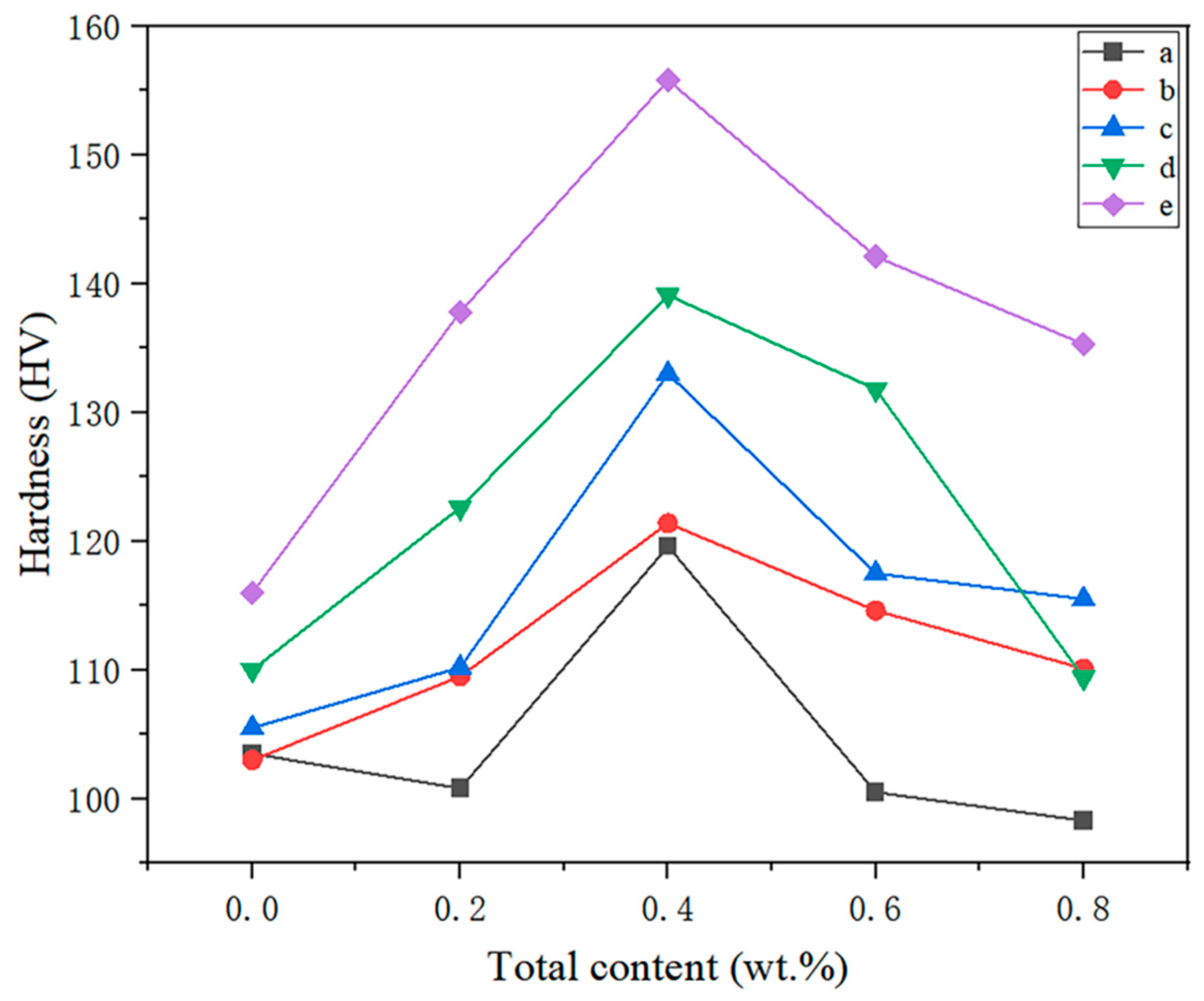

3.2. Mechanical property

Figure 8 shows the change of the macroscopic hardness of the four as-cast alloys before and after the four heat treatments. In general, after heat treatment, the hardness of the as-cast alloy increased by 16.7% on average. Among them, the hardness increase of 410 °C×2h solid solution treatment + 150 °C×12h aging was the highest which reached 31.4%.And the hardness of 2# alloy reached 155.8HV. Regardless of whether there was heat treatment or not, the hardness of the cast alloy increased with the rare earth content, with a trend of increasing first and then decreasing.

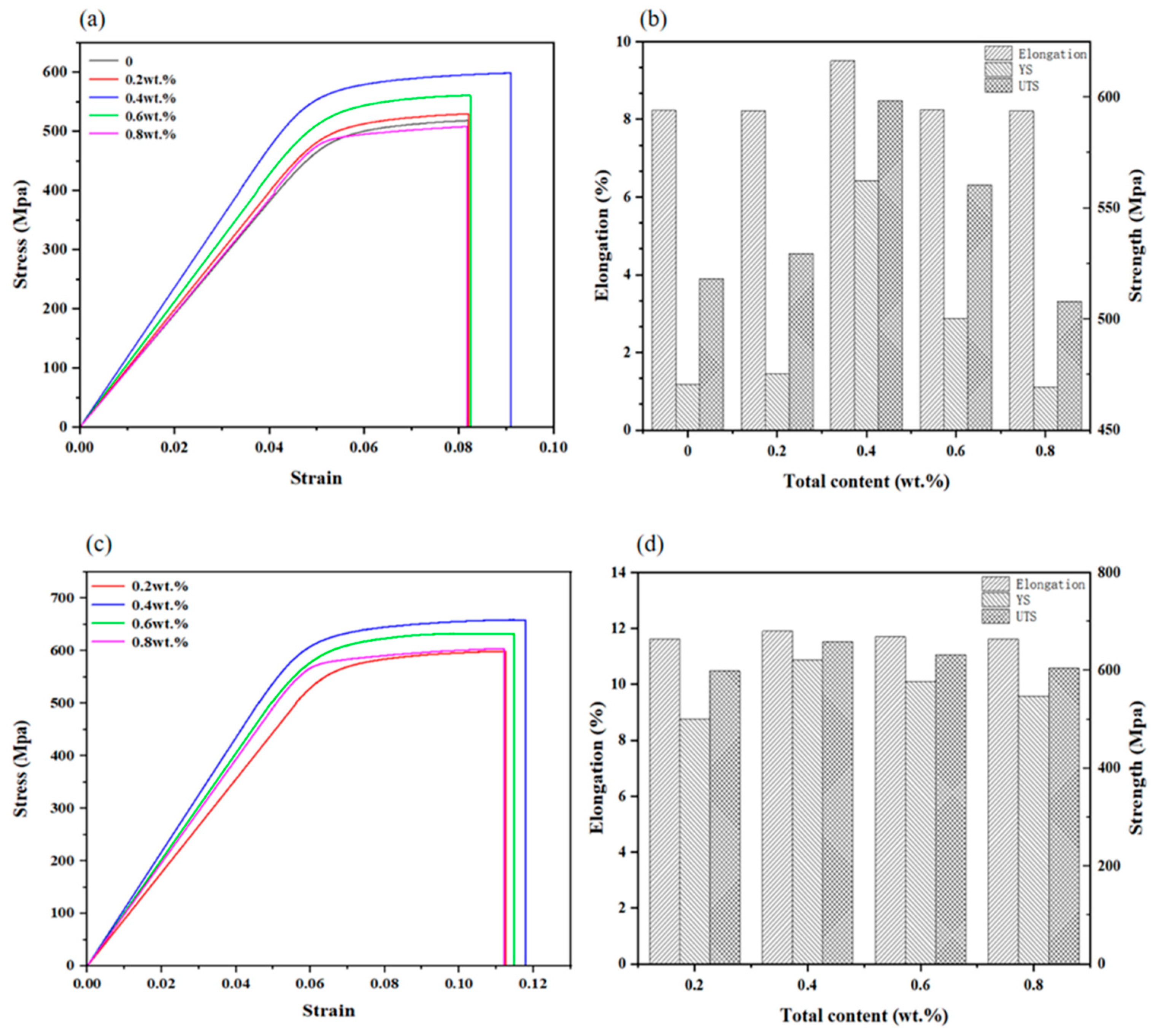

There was a positive relationship between hardness and tensile strength of materials. In this study, various as-cast alloys treated with 410 °C×2h solid solution treatment + 150 °C×12h aging treatment were selected for comparative tensile mechanical properties before and after heat treatment.

Figure 9 shows the tensile properties of different total contents of Sm + Er before and after heat treatment. It was obvious that the mechanical properties of 7055 aluminum alloy before and after heat treatment were generally improved. The tensile strength, yield strength and elongation were respectively increased by 13.5%, 11.9% and 37.0%. 7055 aluminum alloy with a total content of 0.4wt.% Sm + Er reached the maximum tensile strength and yield strength, 658.1Mpa and 620.5Mpa, respectively, and the maximum elongation reached 11.90%. Compared with the original as-cast aluminum alloy, the tensile strength increased by 27.0%, the yield strength increased by 31.9%, and the elongation increased by 30.8%. However, with the increase of the content, the alloy strength began to decline and the strengthening effect was significantly weakened. For example, the tensile strength, yield strength and elongation of 7055 aluminum alloy with a total content of 0.8wt.% Sm + Er before heat treatment decreased by 2.0%, 0.2% and 8.9%, respectively, which compared with 7055 aluminum alloy without rare earth.

With the 7055 aluminum alloy of the rare earth elements Sm + Er, a certain amount of rare earth phases Al

10Cu

7Sm

2 and Al

8Cu

4Er were precipitated at the grain boundary to inhibit the movement of the grain boundary and improve the mechanical properties. After heat treatment, the rare earth phase increased and the distribution was more dispersed. The solubility of Er in Al substrate was less than Sm, which could effectively inhibit the grain boundary movement and refine the grain [

26]. In addition, the Er element would provide more nucleation sites for the precipitation of the η phase and made it smaller during the aging process, which effectively inhibited the growth of the lamellar phase and greatly improved the hardness and tensile strength. This can also be seen from the alloy strain uniformity enhancement in

Figure 9. Because the composite of 7055 aluminum alloy average grain size was less than 7055 aluminum alloy, it led to the coordinated development of deformation between adjacent grains and timely alleviating stress concentration. Therefore it reduced the possibility of crack nucleation, improved the ability of alloy uniform deformation, and reduced the influence of the defect of the alloy performance [

27,

28]. When the rare earth content exceeded a certain value, the grain boundary would be coarsened, which reduced the effect of rare earth elements on the over-cooling of the alloy, so as to weak the reinforcement effect.

4. Conclusions

Through the composite addition of 7055 aluminum alloy with different Sm + Er contents, we found that rare earth had a significant influence on improving the comprehensive mechanical properties of 7055 aluminum alloy. Based on comprehensive analysis, the following conclusion can be drawn:

(1). With the increase of the total amount of Sm + Er, the alloy grain size decreased and then increased. When the total amount reached 0.4 wt.% (0.3 wt.% Sm and 0.1 wt.% Er), the minimum grain size was refined to 84μm, which had an obvious refinement effect.

(2). The composite addition of Sm + Er produced Al10Cu7Sm2 and Al8Cu4Er rare earth phases, which could effectively improve the microscopic structure in the solidification process. In the subsequent solid aging treatment, the rare earth phase was more diffusely distributed and the eutectic layer α-Al+η-Mg(Zn,Al,Cu)2 also became significantly thinner.

(3). In the solid process (410 °C×2h) and aging process (150 °C×12h), the mechanical properties of 7055 aluminum alloy with Sm + Er = 0.4 wt.% reached the best, which were hardness of 155.8HV, yield strength of 620.5Mpa, tensile strength of 658.1Mpa, elongation of 11.90%. Compared with the heat treatment, the hardness was increased by 30.3%, the yield strength increased by 10.3%, the tensile strength was increased by 10.0%, and the elongation increased by 25.1%.

Author Contributions

Investigation, Experiment, Data curation, and Writing—original draft, J.W.; Project administration, Methodology, and Writing—revised, F.L. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by the Hunan Provincial Natural Science Foundation of China (No. 2021JJ30672), Science and Technology Project of Education Department of Hunan Province (No. 22A0100), College Students’ innovation and entrepreneurship training program of Xiangtan University.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors gratefully acknowledge the support provided by Materials Intelligent Design College Students’ Innovation and Entrepreneurship Education Center, Xiangtan University, Xiangtan, Hunan, China.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Wang, T.; Yang, L.; Tang, Z.; Liu, C.; Ma, Y.; Wu, L.; Yan, H.; Yu, Z.; Liu, W. Effect of aging treatment on microstructure, mechanical and corrosion properties of 7055 aluminum alloy prepared using powder by-product. Mater. Sci. Eng. A 2021, 822, 141606. [Google Scholar] [CrossRef]

- Liang, S.; Ma, J.; Guo, K.; Wen, S.; Wei, W.; Wu, X.; Huang, H.; Gao, K.; Liu, B.; Xiong, X.; et al. Effect of Er and Si co-microalloying on mechanical properties and microstructures of AlCuMg alloys. J. Mater. Res. Technol. 2023, 24, 430–439. [Google Scholar] [CrossRef]

- Dong, B.; Xia, Y.; Cai, X.; Lin, S.; Fan, C. Addition of Sc in wire-based directed energy deposition of Al–Mg–Zn–Cu alloy: Microalloying to refine grains and improve mechanical properties. Addit. Manuf. 2023, 67. [Google Scholar] [CrossRef]

- Khan, M.A.; Wang, Y.; Anjum, M.J.; Yasin, G.; Malik, A.; Nazeer, F.; Khan, S.; Ahmad, T.; Zhang, H. Effect of heat treatment on the precipitate behaviour, corrosion resistance and high temperature tensile properties of 7055 aluminum alloy synthesis by novel spray deposited followed by hot extrusion. Vacuum 2020, 174, 109185. [Google Scholar] [CrossRef]

- Jin-feng LENG, Bing-hui REN, Qing-bo ZHOU, Ji-wei ZHAO. Effect of Sc and Zr on recrystallization behavior of 7075 aluminum alloy. Journal of Alloys and Compounds. 2021, 31, 2545–2557.

- Teng, G.; Liu, C.; Ma, Z.; Zhou, W.; Wei, L.; Chen, Y.; Li, J.; Mo, Y. Effects of minor Sc addition on the microstructure and mechanical properties of 7055 Al alloy during aging. Mater. Sci. Eng. A 2018, 713, 61–66. [Google Scholar] [CrossRef]

- Liu, C.; Zhang, B.; Ma, Z.; Jiang, H.; Zhou, W. Effect of Sc addition, friction stir processing, and T6 treatment on the damping and mechanical properties of 7055 Al alloy. J. Alloy. Compd. 2018, 772, 775–781. [Google Scholar] [CrossRef]

- Hu, G.; Zhu, C.; Xu, D.; Dong, P.; Chen, K. Effect of cerium on microstructure, mechanical properties and corrosion properties of Al-Zn-Mg alloy. J. Rare Earths 2020, 39, 208–216. [Google Scholar] [CrossRef]

- Wu, YL. , Li, C. , (Sam) Froes, F.H.. Microalloying of Sc, Ni, and Ce in an Advanced Al-Zn-Mg-Cu Alloy. Metallurgical and Materials Transactions A. 1999, 30, 1017–1024. [Google Scholar]

- Zhao, X.; Jin, T.; Ding, L.; Wan, B.; Lei, X.; Xu, C.; Zhang, C.; Jia, Z.; Liu, Q. The effect of combined cold rolling and homogenization on the microstructures and mechanical properties of twin-roll casted 8021 aluminum alloy. J. Alloy. Compd. 2023, 937. [Google Scholar] [CrossRef]

- Fenglong Zhai1, Liping Wang, Xin Gao1, Yicheng Feng1, Sicong Zhao1, Lei Wang. Study on Phases Formation and Modifification Ability of Rare Earth Elements La, Ce, Sm and Er in Al–Zn–Mg–Cu–Zr Alloy. Transactions of the Indian Institute of Metals. 2021, 74, 2639–2649.

- Li, Z.; Hu, Z.; Yan, H. Effect of samarium (Sm) addition on microstructure and mechanical properties of Al-5Cu alloys. J. Wuhan Univ. Technol. Sci. Ed. 2016, 31, 624–629. [Google Scholar] [CrossRef]

- Ditta, A.; Wei, L.; Xu, Y.; Wu, S. Effect of hot extrusion and optimal solution treatment on microstructure and properties of spray-formed Al-11.3Zn-2.65Mg-1Cu alloy. J. Alloy. Compd. 2019, 797, 558–565. [Google Scholar] [CrossRef]

- H. Wu, Z.K. Zheng, W.C. Li, J.T. Lu, S.P. Wen, H. Huang, Z.R. Nie. Effect of Retrogression and Re-aging Treatment on Properties and Microstructure of a New Type of Al–Zn–Mg–Er–Zr Alloy. Journal of Materials Engineering and Performance. 2022, 31, 4282–4293. [CrossRef]

- Li, M.; Yao, S.; Wang, J.; Chen, Z.; Zhang, G.; Zhang, S.; Li, Y. Role of Er on the densification, microstructure and mechanical properties of 7075 aluminium alloys manufactured by laser powder bed fusion. J. Mater. Res. Technol. 2022, 20, 2021–2033. [Google Scholar] [CrossRef]

- Yichang Wang, Xiaodong Wu, Lingfei Cao, Xin Tong, Malcolm J. Couper, Qing Liu. Effect of trace Er on the microstructure and properties of Al–Zn–Mg–Cu–Zr alloys during heat treatments. Materials Science & Engineering A. 2020, 792, 139807.

- Cunlong Wang, Jichun Dai, Wencai Liu, Liang Zhang, Guohua Wu. Effect of Al additions on grain refifinement and mechanical properties of Mg–Sm alloys. Journal of Alloys and Compounds. 2015, 620, 172–179.

- Guosheng Peng, Kanghua Chen, Songyi Chen, Huachan Fang. Evolution of the second phase particles during the heating-up process of olution treatment of Al–Zn–Mg–Cu alloy. Materials Science & Engineering A. 2015, 641, 237–247.

- Deng, Y.-L.; Wan, L.; Zhang, Y.; Zhang, X.-M. Evolution of microstructures and textures of 7050 Al alloy hot-rolled plate during staged solution heat-treatments. J. Alloy. Compd. 2010, 498, 88–94. [Google Scholar] [CrossRef]

- Xianna Meng, Datong Zhang, Weiwen Zhang, Cheng Qiu, Guangxing Liang, Junjie Chen. Influence of solution treatment on microstructures and mechanical properties of a naturally-aged Al–27Zn–1.5Mg–1.2Cu–0.08 Zr aluminum alloy. Materials Science & Engineering A. 2021, 802, 140623.

- Wen-Long Zhang, Dai-Hong Xiao, Ting Li, Jian-Di Du, Dong-Yang Ding. Microstructure and Mechanical Properties of Two-Stage Aged Al-Cu-Mg-Ag-Sm Alloy. Rare Metals. 2019, 38, 42–51.

- Xingrui Chen, Yonghui Jia, Qichi Le, Shaochen Ning, Xiaoqiang Li, Fuxiao Yu. The interaction between in situ grain refifiner and ultrasonic treatment and its influence on the mechanical properties of Mg–Sm–Al magnesium alloy. jmr&t. 2020, 9, 9262–9270.

- Guo, Y.; Wei, W.; Shi, W.; Zhang, B.; Zhou, X.; Wen, S.; Wu, X.; Gao, K.; Rong, L.; Huang, H.; et al. Effect of Er and Zr additions and aging treatment on grain refinement of aluminum alloy fabricated by laser powder bed fusion. J. Alloy. Compd. 2022, 912. [Google Scholar] [CrossRef]

- Deng, Y.; Yin, Z.; Cong, F. Intermetallic phase evolution of 7050 aluminum alloy during homogenization. Intermetallics 2012, 26, 114–121. [Google Scholar] [CrossRef]

- H Wu,SP Wen,JT Lu,ZP Mi,XL Zeng,H Huang,ZR Nie. Microstructural Evolution of New Type Al Zn-Mg-Cu Alloy with Er and Zr Additions During Homogenization. Transactions of Nonferrous Metals Society of China. 2017, 27, 1476–1482.

- XU Guo-fu, MOU Shen-zhou, YANG un-jun, JIN Tou-nan, NIE Zuo-ren, YIN Zhi-min. Effect of Trace Rare Earth Element Er on Al-Zn-Mg Alloy. Transactions of Nonferrous Metals Society of China. 2006, 16, 598–603.

- Yang, H.; Gao, T.; Liu, G.; Zhao, X.; Chen, H.; Wang, H.; Nie, J.; Liu, X. Simultaneously improving strength and ductility for Al–Cu–Mg alloy via threadiness array of TiC nanoparticles. Materialia 2019, 6, 100333. [Google Scholar] [CrossRef]

- Yang, C.; Liu, Z.; Zheng, Q.; Cao, Y.; Dai, X.; Sun, L.; Zhao, J.; Xing, J.; Han, Q. Ultrasound assisted in-situ casting technique for synthesizing small-sized blocky Al3Ti particles reinforced A356 matrix composites with improved mechanical properties. J. Alloy. Compd. 2018, 747, 580–590. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2024 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).