Submitted:

14 June 2023

Posted:

15 June 2023

You are already at the latest version

Abstract

Keywords:

1. Introduction

2. Materials and Methods

- -

- Nanosilver was synthesized through a chemical process using silver nitrate and sodium citrate as the reducing agent. A solution was prepared by dissolving 0.088 g of silver nitrate (1.061 mM) in 500 mL of water. The solution was then heated to boiling with magnetic stirring at 800 rpm. Once the temperature reached 90 °C, 10 mL of 1% sodium citrate (0.1 g / 10 mL) was added dropwise while maintaining continuous stirring until the solution turned bright yellow. The final dispersion had a concentration of 112 ppm.

- -

- Nanocopper was also prepared by a chemical process. A solution was made by dissolving 0.156 g of Cl2Cu in 150 mL of solution. The solution was then stirred while adding 90 mL of a 1.5 M sodium hydroxide solution (6 g/100 mL) as a hydrolysis agent. Glucose (approximately 7 g) was gradually added to the solution until it turned yellowish-brown. Stirring was stopped, and the solution was placed in a 90 °C bath until it turned black (approximately 20 minutes). The final dispersion had a concentration of 324 ppm.

3. Results

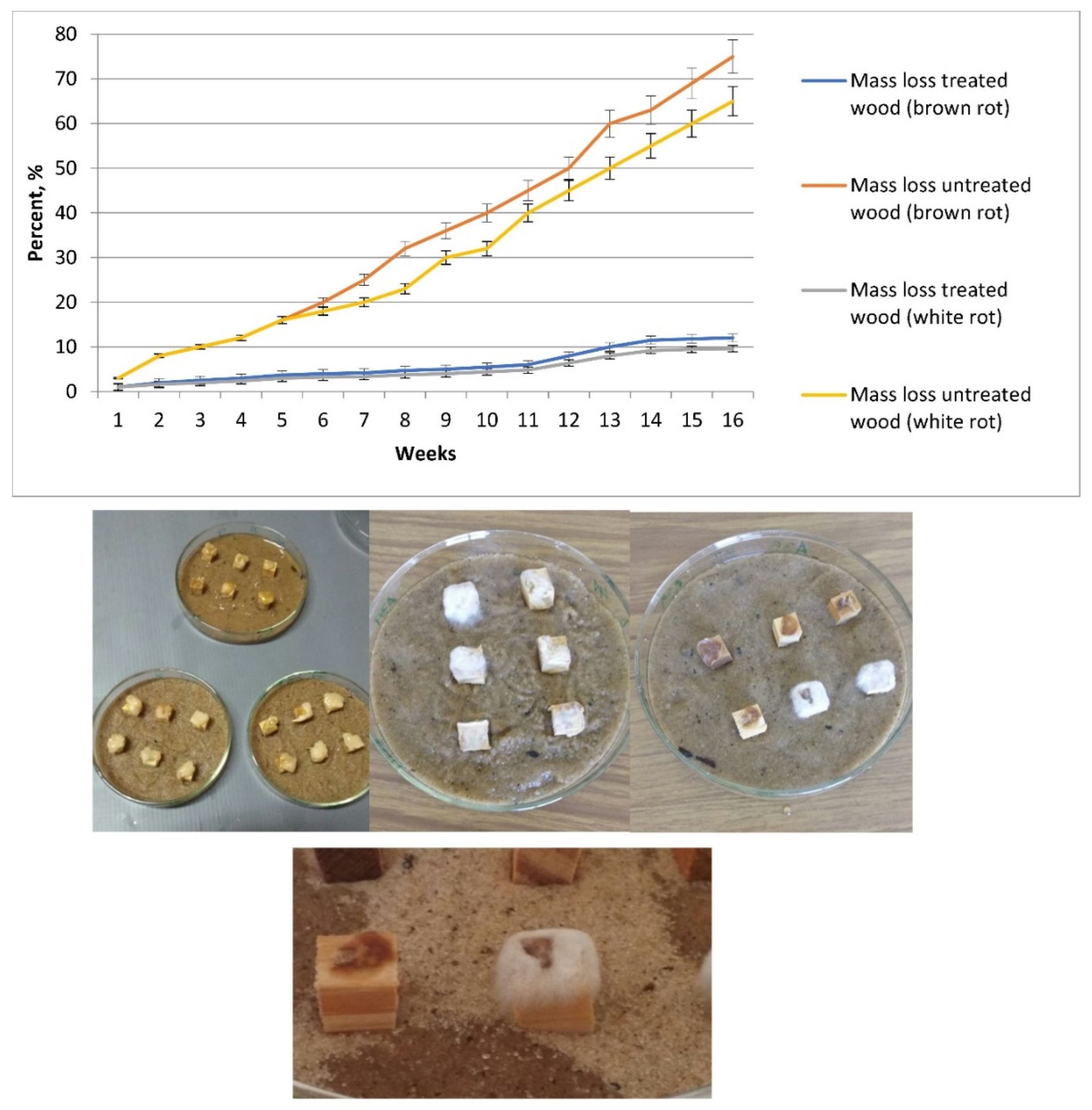

3.1. Decay resistance and leaching test

3.2. Figures, Tables and Schemes

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Embacher, J.; Zeilinger, S.; Kirchmair, M.; Rodriguez-R, L.M.; Neuhauser, S. Wood decay fungi and their bacterial interaction partners in the built environment – A systematic review on fungal bacteria interactions in dead wood and timber. Fungal Biology Reviews. 2023, 45, 100305 ISSN 1749-4613. [CrossRef]

- Broda, M; Dąbek, I.; Dutkiewicz, A.; Dutkiewicz, M.; Popescu, C.M.; Mazela, B.; Maciejewski, H. Organosilicons of different molecular size and chemical structure as consolidants for waterlogged archaeological wood – a new reversible and retreatable method. Scientific Reports, 2020, 10, 2188. [CrossRef]

- Konsa, K. et al. Wooden objects in museums: managing biodeterioration situation International. Biodeterioration & Biodegradation, 2nd International Conference on Biodeterioration of Wood and Wood Products, 2014, Tartu, Estonia. [CrossRef]

- Korb, W. and Avérous, L. Recent developments in the conservation of materials properties of historical wood. Progress in Materials Science. 2019, 102, 167-221. [CrossRef]

- Broda, M.; Plaza, N.Z. Durability of model degraded wood treated with organosilicon compounds against fungal decay. International Biodeterioration & Biodegradation. 2023, 178, 105562. [CrossRef]

- Broda, M.; Dąbek, I.; Dutkiewicz, A. et al. Organosilicons of different molecular size and chemical structure as consolidants for waterlogged archaeological wood – a new reversible and retreatable method. Sci Rep. 2020 ,10, 2188. [CrossRef]

- Yona, A.M.C.; Žigon, J.; Matjaž, P. et al. Potentials of silicate-based formulations for wood protection and improvement of mechanical properties: A review. Wood Science Technology. 2021, 55, 887–918. [CrossRef]

- Salanti, A.; Zoia, L.; Zanini, S.; Orlandi, M. Synthesis and characterization of lignin–silicone hybrid polymers as possible consolidants for decayed wood. Wood Science Technology. 2016, 50(1), 117–134. [Google Scholar] [CrossRef]

- Teaca, C.A.; Ro¸su, D.; Musta¸ta, F.; Rusu, T.; Ro¸su, L.; Ro¸sca, I.; Varganici, C.-D. Natural Bio-Based Products for Wood Coating and Protection against Degradation: A Review. BioResources 2019, 14, 4873–4901. [Google Scholar] [CrossRef]

- Semenzin, E.; Subramanian, V.; Pizzol, L.; Zabeo, A.; Fransman, W.; Oksel, C.; Hristozov, D.; Marcomini, A. Controlling the risks of nano-enabled products through the life cycle: The case of nano copper oxide paint for wood protection and nano-pigments used in the automotive industry. Environment International. 2019, 131, 104901. [Google Scholar] [CrossRef] [PubMed]

- Eduok, U.; Faye, O.; Szpunar, J. Recent developments and applications of protective silicone coatings: A review of PDMS functional materials. Progress in Organic Coatings. 2017, 111, 124–163. [Google Scholar] [CrossRef]

- Liu, W.; Hu, C.; Zhang, W.; Liu, Z.; Shu, J.; Gu, J. Modification of birch wood surface with silane coupling agents for adhesion improvement of UV-curable ink. Progress in Organic Coatings, 148, 2020, 105833. [CrossRef]

- Pour, M.F; Mehdinia, M.; Kiamahalleh, M.V.; Hoseini, K.D.; Hatefnia, H.; Dorieh, A. Biological durability of particleboard: fungicidal properties of Ag and Cu nanoparticles against Trametes versicolor white-rot fungus. Wood Material Science & Engineering, 2022. 17:6, 929-936. [CrossRef]

- Dai, X.; Qi, Y.; Luo, H.; He, Z.; Wei, L.; Dong, X.; Ma, X.; Yang, D.-Q.; Li, Y. Leachability and Anti-Mold Efficiency of Nanosilver on Poplar Wood Surface. Polymers 2022, 14, 884. [Google Scholar] [CrossRef] [PubMed]

- Nair, S., K S, S., R, S. Advancements in Nanotechnological Applications for Wood Protection. In: Sundararaj, R. (eds), 2022, Science of Wood Degradation and its Protection. Springer, Singapore. [CrossRef]

- Khadiran, T., Jasmani, L., Rusli, R. Application of Nanomaterials for Wood Protection. In: Taghiyari, H.R., Morrell, J.J., Husen, A. (eds) 2023, Emerging Nanomaterials. Springer, Cham. [CrossRef]

- Aguayo, M.G.; Oviedo, C.; Reyes, L.; Navarrete, J.; Gómez, L.; Torres, H.; Gaviño, G.; Trollund, E. Radiata Pine Wood Treated with Copper Nanoparticles: Leaching Analysis and Fungal Degradation. Forests 2021, 12, 1606. [Google Scholar] [CrossRef]

- Piętka, J.; Adamczuk, A.; Zarzycka, E.; Tulik, M.; Studnicki, M.; Oszako, T.; Aleksandrowicz-Trzcińska, M. The Application of Copper and Silver Nanoparticles in the Protection of Fagus sylvatica Wood against Decomposition by Fomes fomentarius. Forests, 2022, 13, 1724. [CrossRef]

- Blanchet, P.; Pepin, S. Trends in Chemical Wood Surface Improvements and modifications: A Review of the Last Five Years. Coatings, 2021, 11, 1514. [CrossRef]

- Andriulo, F.; Vespignani, L.; Steindal, C. C.; Bortolini, M.; de Ferri, L. Evaluation of sol-gel hybrid nanocomposites for dry medieval wood. Journal of Cultural Heritage, 2022, 56, 96-107. [CrossRef]

- Spear, M.J.; Curling, S.F.; Dimitriou, A.; Ormondroyd, G.A. Review of Functional Treatments for Modified Wood. Coatings, 2021, 11, 327. [CrossRef]

- Jirouš-Rajković, V.; Miklečić, J. Enhancing Weathering Resistance of Wood—A Review. Polymers, 2021, 13, 1980. [CrossRef]

- Wu, X.; Yang, F.; Gan, J.; Kong, Z.; Wu, Y. A Superhydrophobic, Antibacterial, and Durable Surface of Poplar Wood. Nanomaterials, 2021, 11, 1885. [CrossRef]

- Shilova, O.A.; Tsvetkova, I.N.; Vlasov, D.Y.; Ryabusheva, Y.U.; Sokolov, G.S.; Kychkin, A.K.; Nguyên, C.; Khoroshavina, Y.V. Microbiologically induced deterioration and environmentally friendly protection of wood products, Editor(s): Hafiz M.N. Iqbal, Muhammad Bilal, Tuan Anh Nguyen, Ghulam Yasin, 2022. In Micro and Nano Technologies, Biodegradation and Biodeterioration at the Nanoscale, Elsevier, 283-321. [CrossRef]

- Kozłowski, R.M; Walentowska, J. Prevention of fungi and bacteria growth in natural fibres, Editor(s): Ryszard M. Kozłowski, Maria Mackiewicz-Talarczyk, 2020. In Woodhead Publishing Series in Textiles, Handbook of Natural Fibres (Second Edition), Woodhead Publishing, 693-714. [CrossRef]

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).