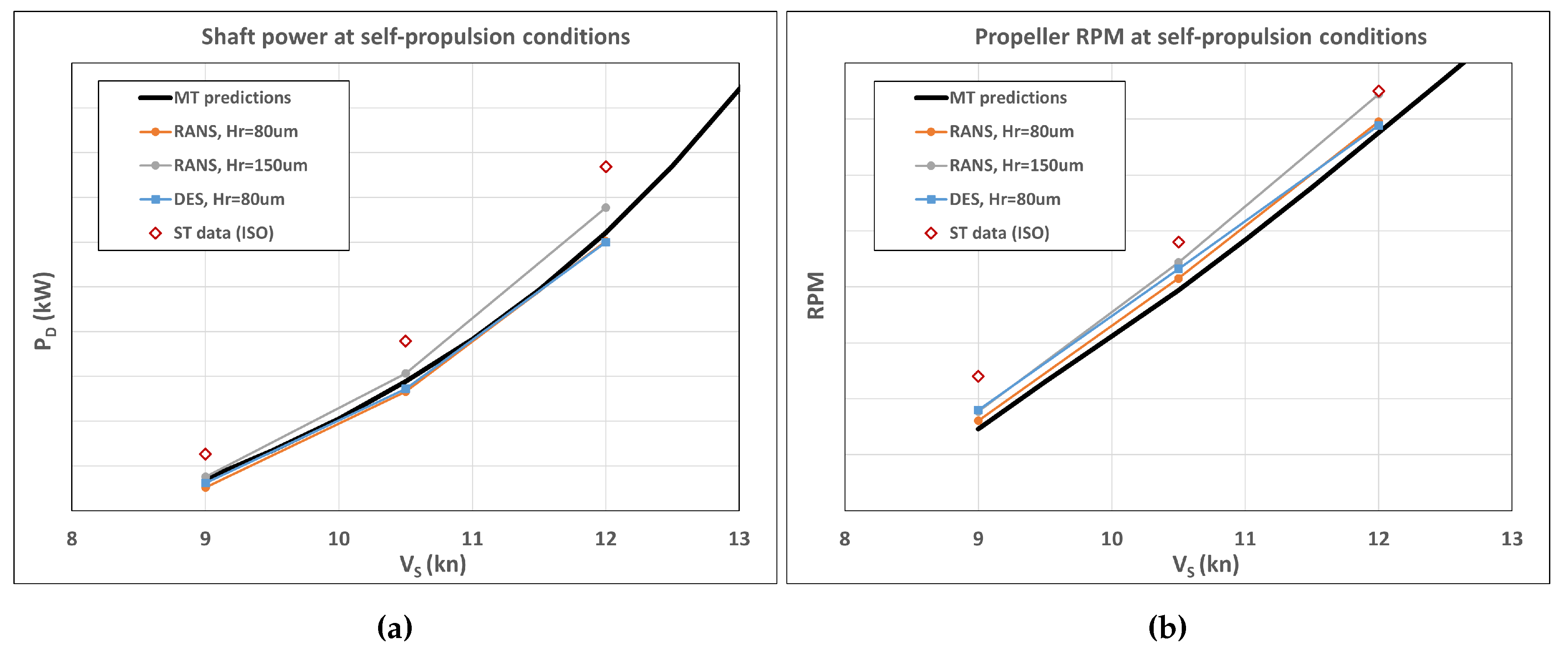

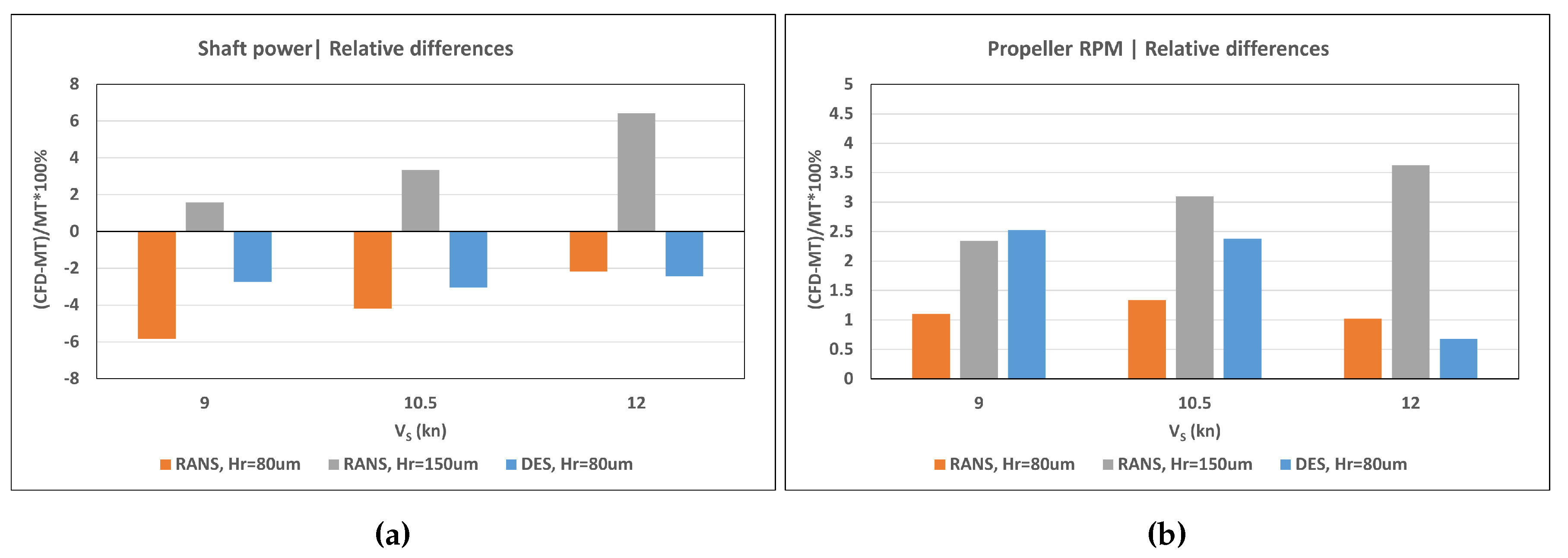

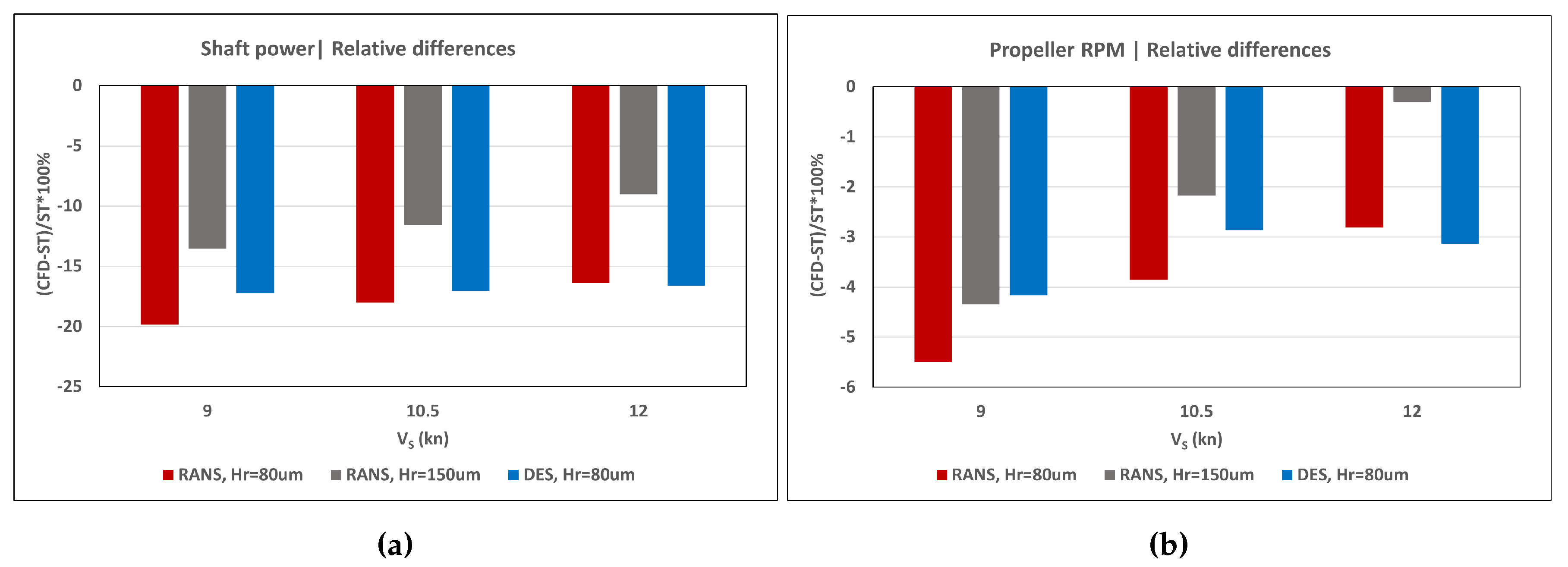

For the numerical simulations conducted in the present study the commercial CFD software STAR-CCM+ (version 15.06.007-R8) was employed. Trimmed hexahedral mesher with prism layers on the wall boundaries was used in all the main types of simulations (towing resistance, propeller in open water and ship self-propulsion calculations) as well as additional simulations with flat plate which were used to assess the influence of surface roughness height. All simulations, except for the flat plate calculations, were carried out in a time-dependent manner, using the implicit unsteady segregated flow solver. Simulations involving rotating propeller (open water, and self-propulsion) were performed using the Sliding Mesh technique to fully account for the interaction between the rotating and stationary components in the setup. Water and air properties applied in the simulations were derived from values recorded during the sea-trials of MV REGAL. Simulations were performed for full-scale conditions corresponding to sea trials, as specified in the case description for the JoRes CFD Workshop regarding the MV REGAL vessel [

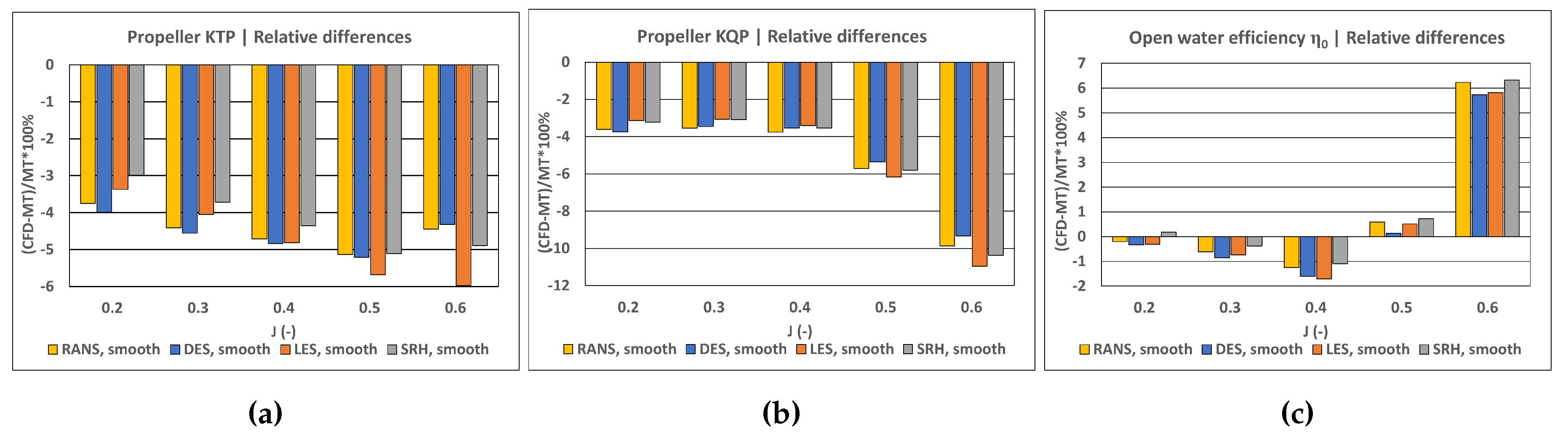

11]. Three ship speeds (9, 10.5 and 12 knots) were subject to investigation in the resistance and self-propulsion scenarios, while in the open water case, the advance coefficient (J) values of 0.2, 0.3, 0.4, 0.5 and 0.6 were used. The case specific details of numerical setups are addressed below for each individual simulation scenario.

Separately, as a part of the JoRes project SINTEF Ocean have conducted a model test campaign with the MV REGAL vessel, comprising towing resistance, open water and propulsion tests in calm water, at the scale of 1:23.111. The results of model tests were used in full-scale performance prediction for the sea trial conditions, following the standard procedure applied at SINTEF Ocean to single-screw ships [

12]. The results of performance prediction were compared against the sea-trials data post-processed according to the ISO15016 standard [

13] and CFD calculations in full-scale in terms of propeller RPM and propeller shaft power, P

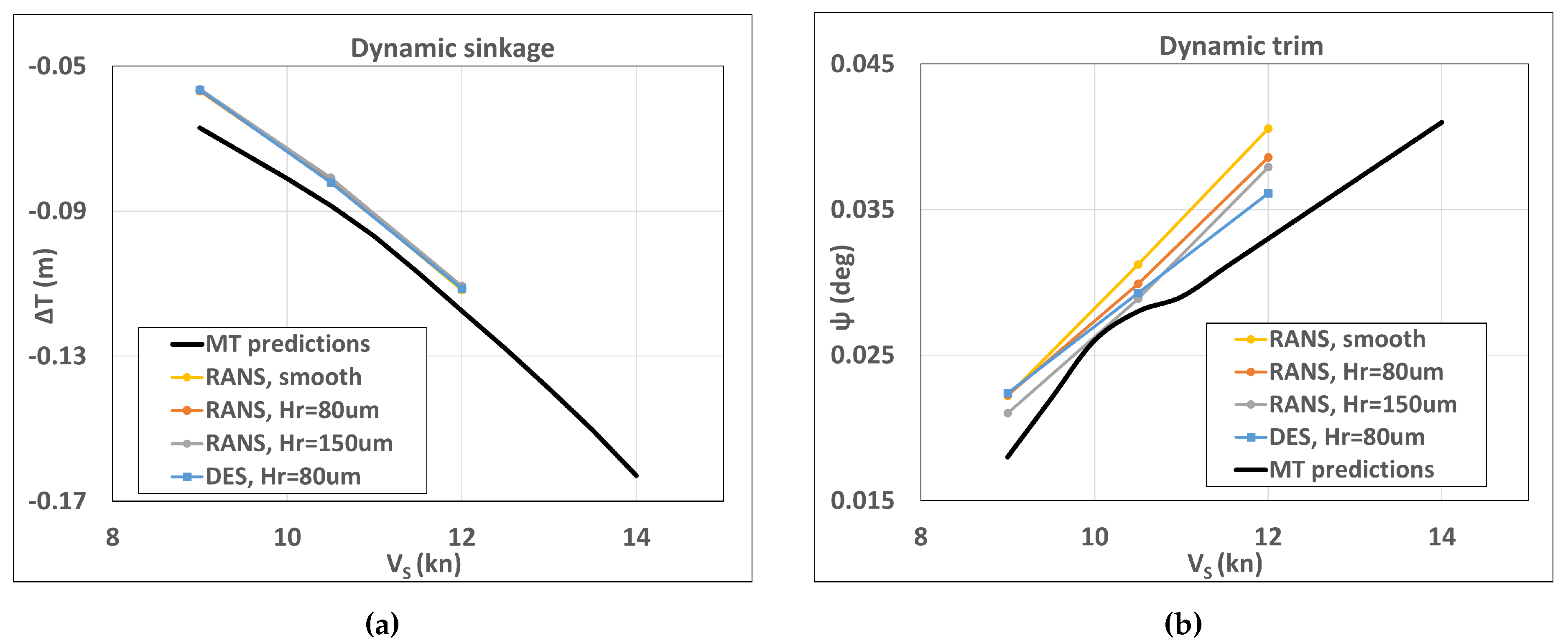

D. Additional comparisons were made between the CFD calculations and model test results extrapolated to full-scale conditions in terms of towing resistance of the ship, its dynamic position, and propeller characteristics in open water.

MV REGAL is a single-screw general cargo vessel having the length between perpendiculars LPP = 138 m, breadth B = 23 m, and gross tonnage 11542 t. It is equipped with a 4-bladed fixed pitch propeller having the diameter D = 5.2 m, pitch ratio P(0.7)/D = 0.6781, and blade area ratio Ae/Ao = 0.57. The ship features a semi-balanced rudder with fixed horn. The main particulars of the MV REGAL vessel, its propeller and rudder arrangements can be found in [

9,

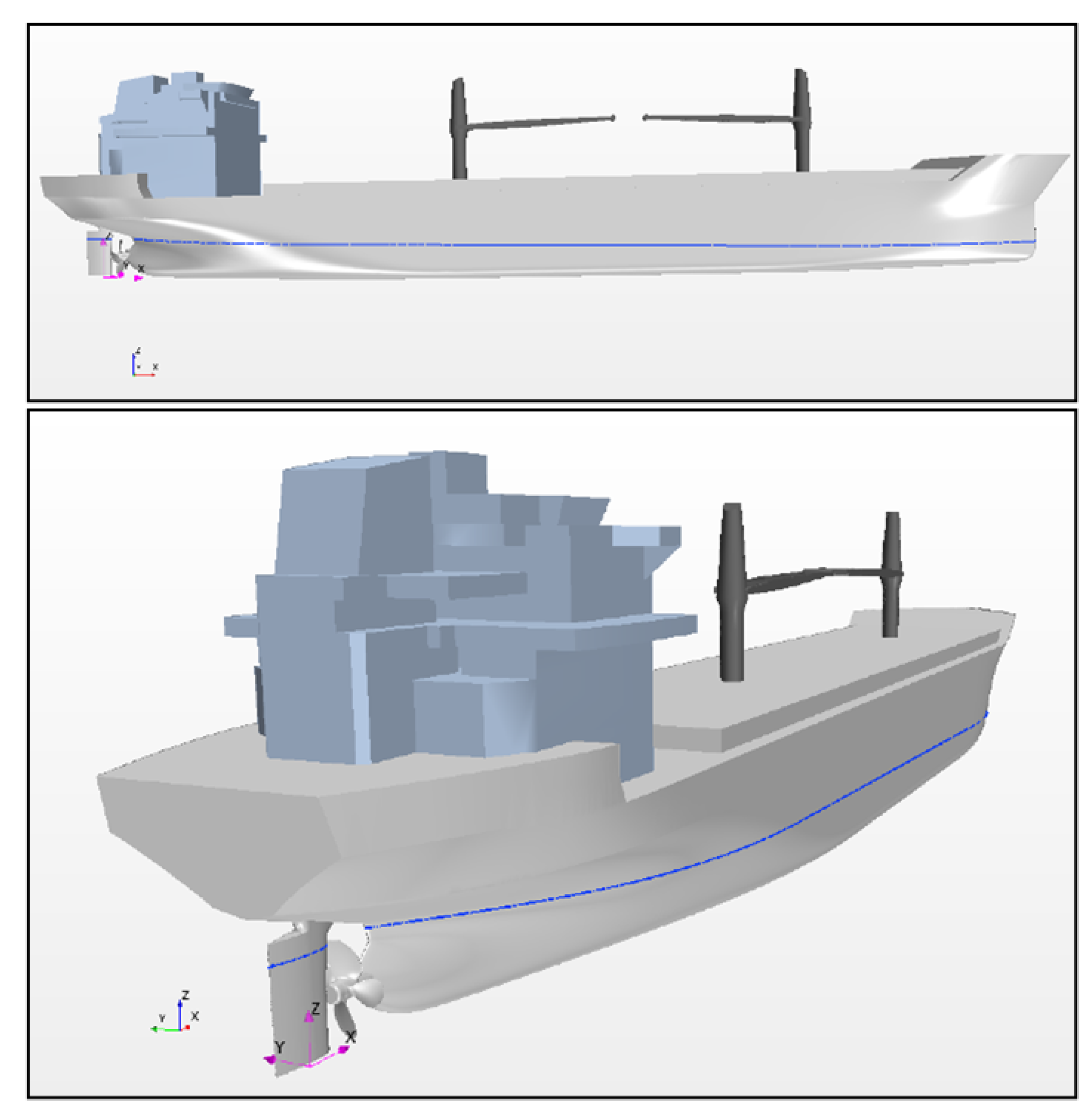

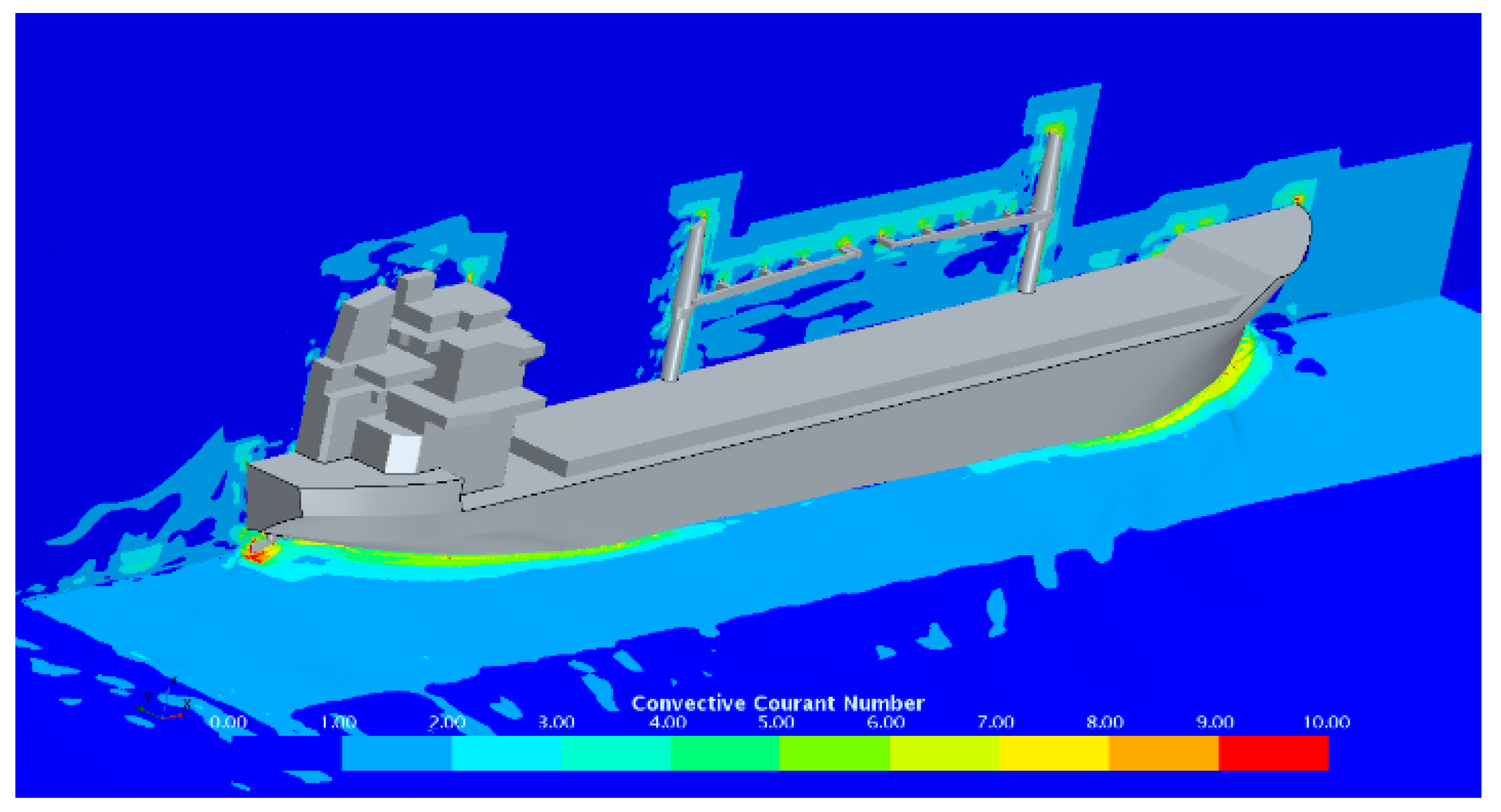

11]. It needs to be remarked that the geometries provided for the JoRes CFD Workshop are different from those used in the earlier Lloyd’s Register Workshop organized in 2016 on the same ship case. While the 2016 Workshop used the STL models of ship hull, propeller and rudder derived from the 3D laser scan data, the present JoRes geometries were provided as clean solids which were prepared using both the reconstructed 3D laser scan data and original documentation and drawings. Further, such constructive features as bilge keels and protective anodes installed on the ship hull and rudder were removed from the CFD model, and no respective corrections were applied in the performance prediction based on model tests. The ship does not have tunnel thrusters. The approximate geometry models of the superstructure, deck hatches and coamings, and the two cranes on the deck were included in the resistance and self-propulsion CFD simulations to account for aerodynamic resistance of the ship in a more accurate manner. The initial hydrostatic position of the ship was set according to the draft measurements before the JoRes sea trials, resulting in the draught values at the fore and aft marks of 2.97 m and 5.865 m, respectively, which corresponds to ballast condition. The presence of hull sagging, hogging and list are disregarded in the draught measurements. The general view of MV REGAL self-propulsion simulation setup is shown in

Figure 2.

2.1. Open water propeller simulations

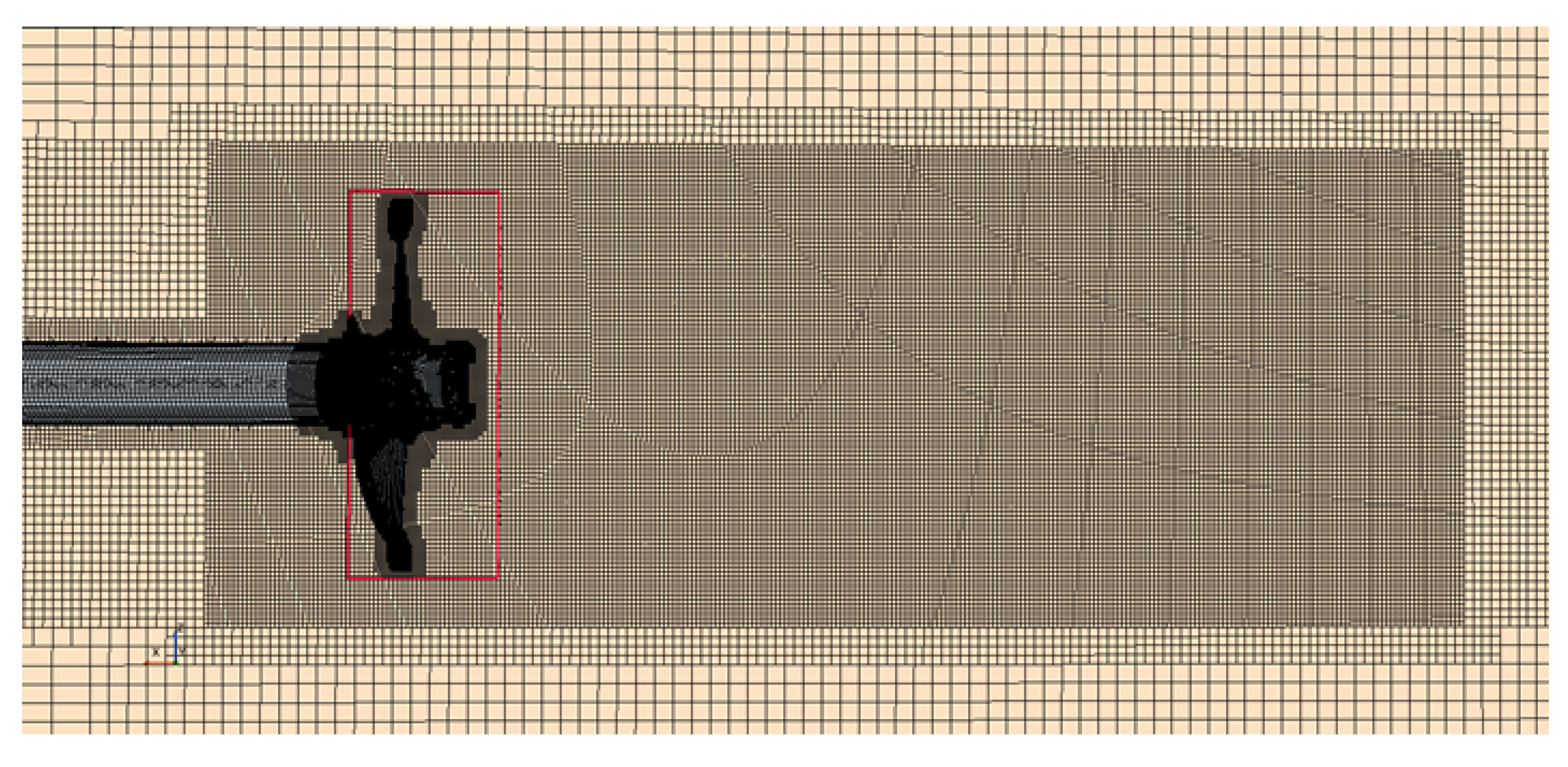

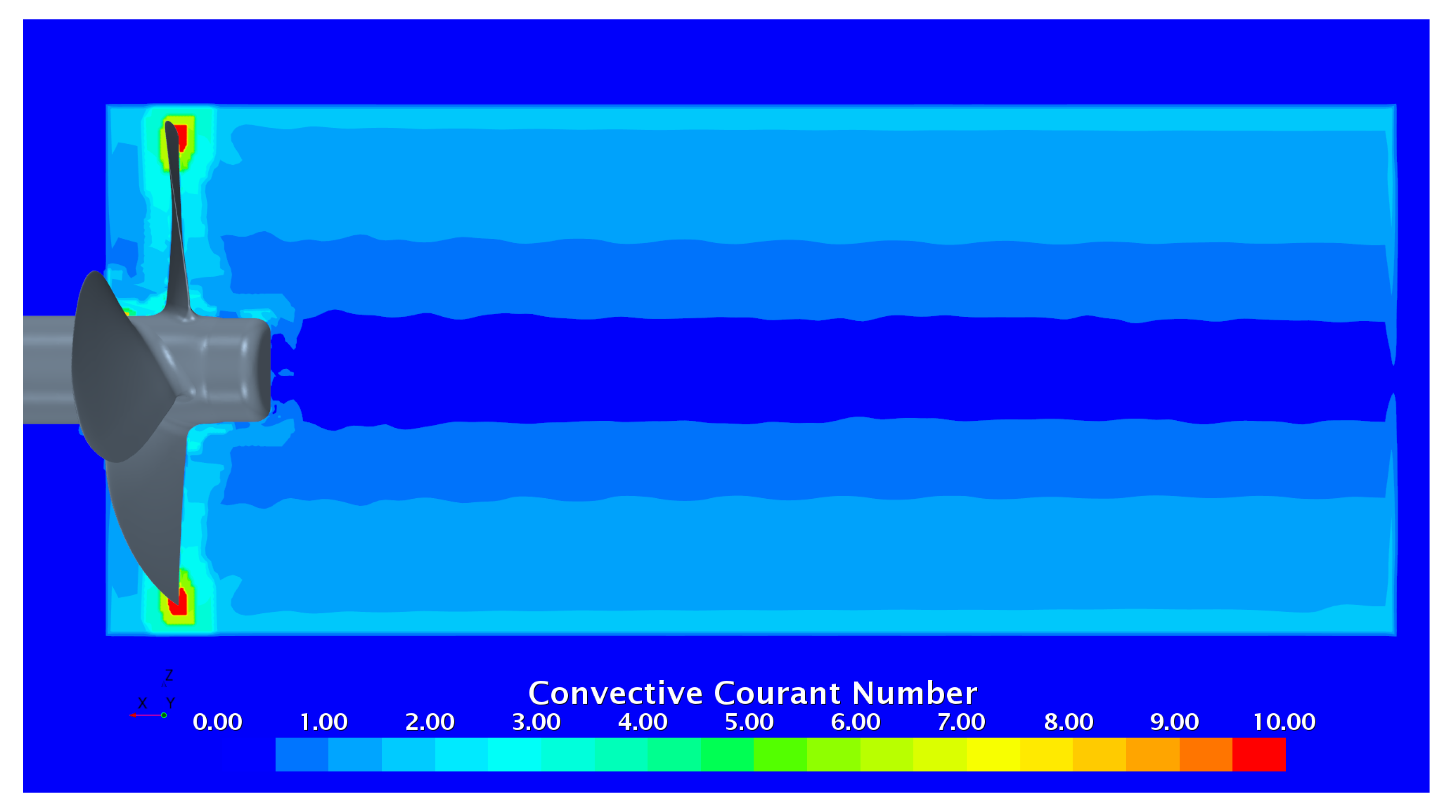

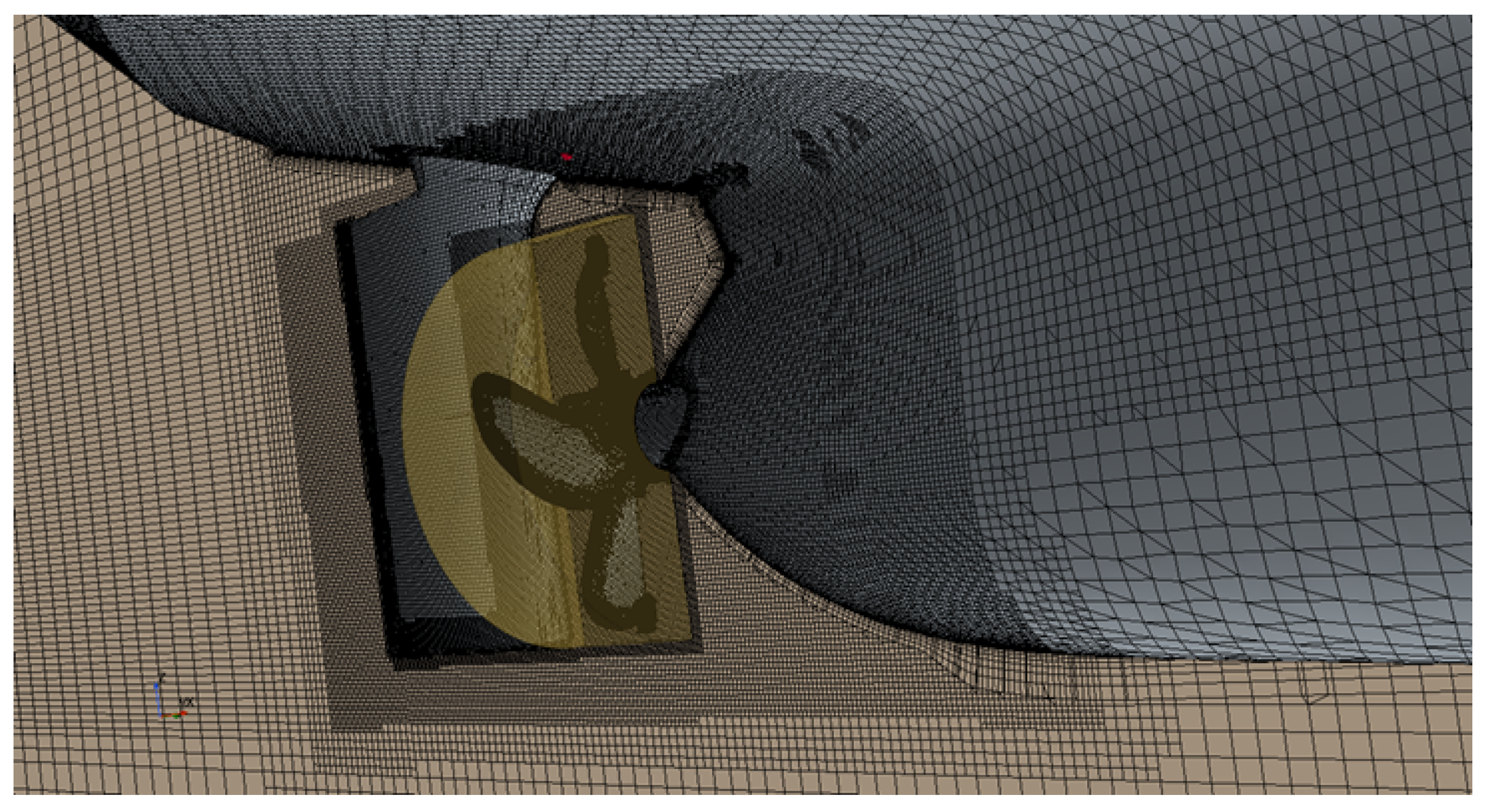

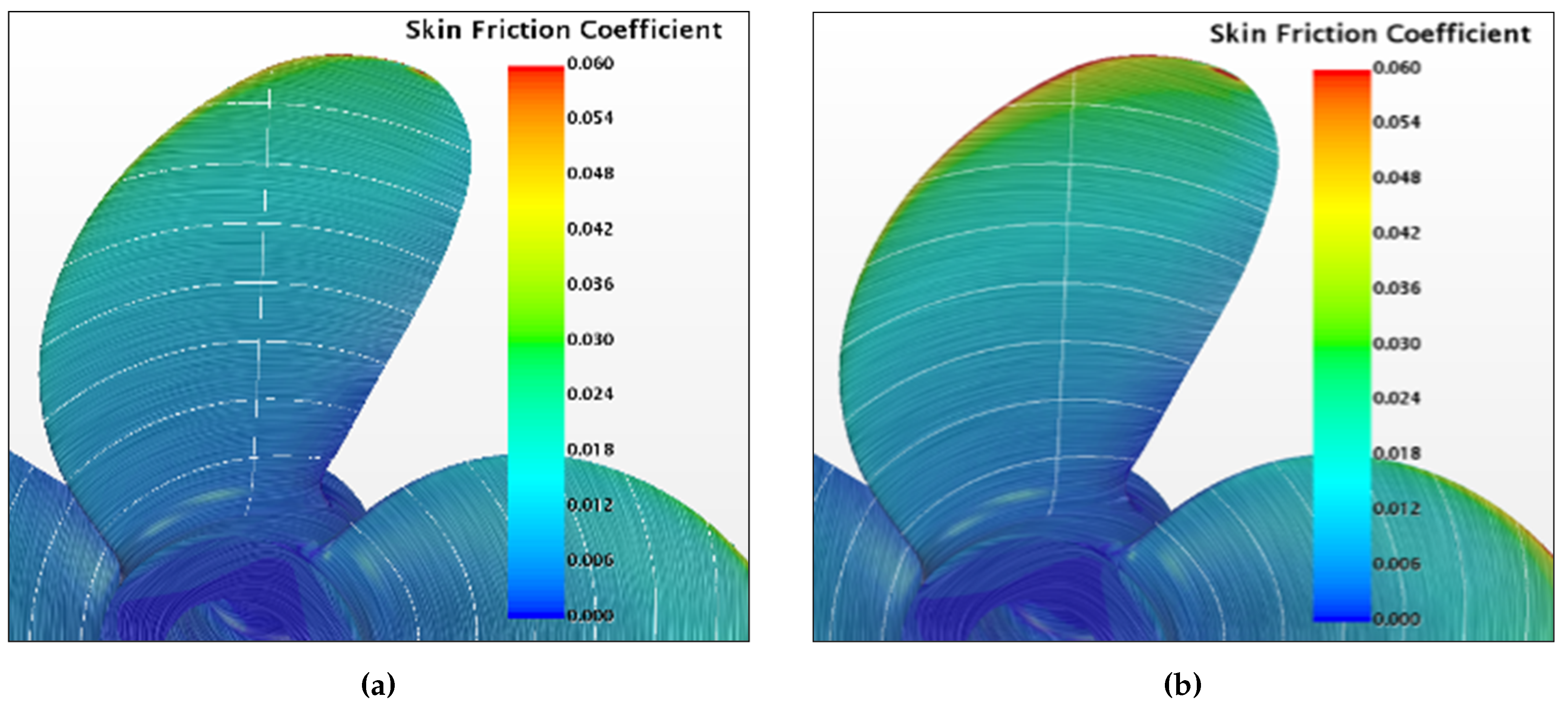

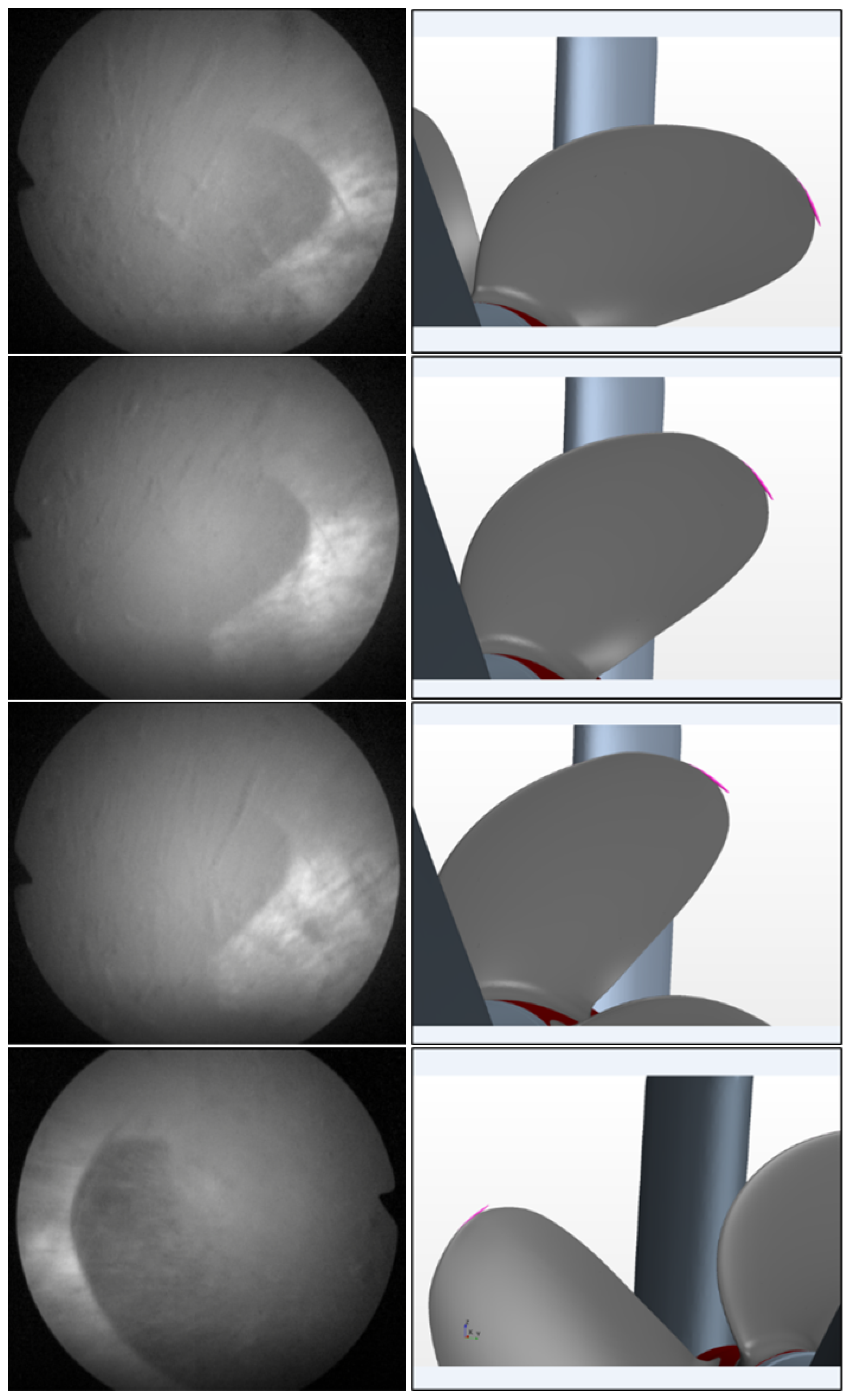

The open water simulations were performed in full scale using the same propeller setup as in self-propulsion conditions. It means that, unlike conventional open water model test setup, the propeller is driven not from downstream but from upstream, thus operating in pushing mode as behind ship hull in the propulsion setup, and also having the same hub cap. This setup is illustrated in

Figure 3, which also gives appreciation of overall mesh refinement pattern around the propeller.

The cylindrical rotating propeller region used in Sliding Mesh calculation has the dimensions 0.125D (upstream), 0.288D (downstream) and 0.5385D (radius), as measured from propeller plane, where D is the propeller diameter. Such dimensions are smaller than normally applied in the SINTEF Ocean standard open water CFD setup, since in the self-propulsion case studied in this work, the propeller region had to be fit in a quite tight space between the ship hull and rudder, as it can be seen in

Figure 2. The rationale was then to use the same region dimensions in open water calculations to avoid the influence of region size when deriving propulsion factors. The respective dimensions of the main fluid region (also cylindrical in this case) were 5D (inlet), 15D (outlet), and 5D (radius), as measured from propeller center. Additional simulations were performed to assess the influence of the downstream extension of the sliding mesh region on propeller open water characteristics and quality of resolution of propeller slipstream.

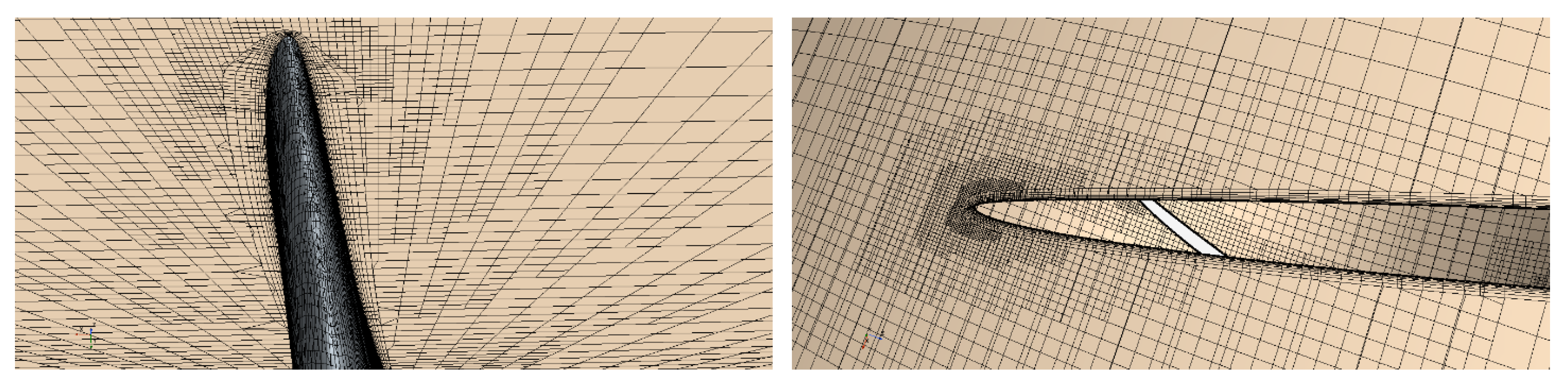

The cell size in the propeller region and the first (finest) volumetric control around the propeller and slipstream (seen in

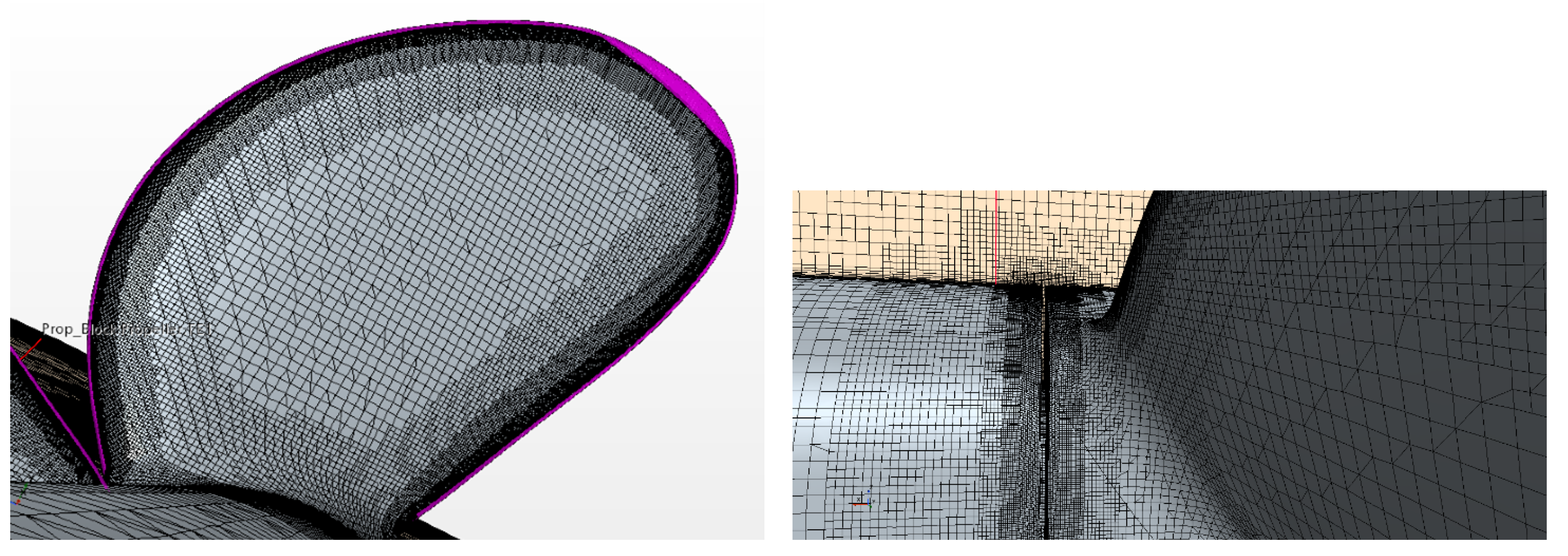

Figure 3) was set to 1.3 % of the base size which was equal to propeller diameter, D. The said volumetric control extends to the distance of 3D downstream. On the propeller blades, the maximum target cell size equals to 0.65 % of base, and it is reduced to the minimum size of 0.0203125 % of base at the blade edges and tip. The edge and tip refinements are achieved using the surface patches extracted from the initial CAD geometry of propeller, as shown in

Figure 4. In absence of such patches, similar refinement can be achieved by means of volumetric controls in the shape of a tube following the leading edge feature curve, which is usually easy to extract from blade surface wireframe. The propeller model included a gap between the rotating propeller hub and stationary shaft, which had the size of 17 mm, exactly as in the self-propulsion setup. The inclusion of hub gap in the numerical model allows to compute forces acting on the propeller more accurately by avoiding the uncertainty related to the integration of pressure on the side of propeller hub facing the shaft. The total number of cells in the open water setup was 22.1 million cells, of which 18.6 million cells were accommodated in the propeller region.

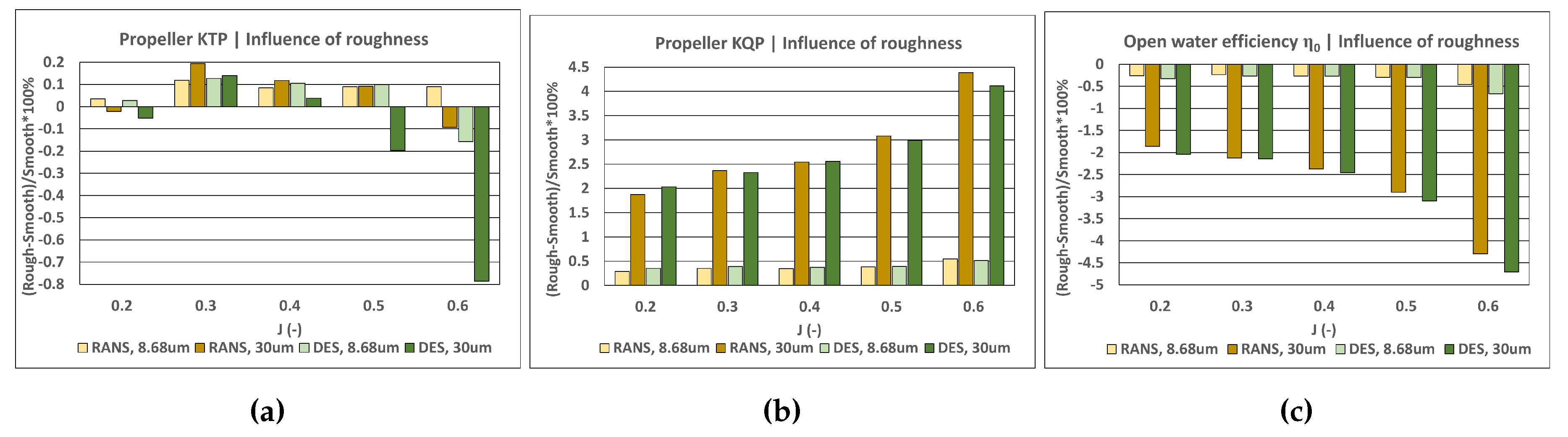

Figure 5 illustrates the arrangement of prism layers on propeller blades. The prism layer mesh consists of 10 layers. The height of the first near-wall cell is chosen to target the average Wall Y+ around 60 in the middle part of the blade, thus implying the use of wall functions, for the reasons of computational efficiency and inclusion of surface roughness. The total thickness of prism layers is 0.235 % of propeller diameter. The present settings result in the layer stretch factor about 1.35 and Wall Y+ distribution shown in

Figure 6. With a coarse near-wall mesh, one cannot achieve a uniform distribution of Y+ over the whole blade, but as it can be seen, the applied settings provide a favorable Y+ range between 30 and 100, avoiding buffer zone everywhere except the gap and hub vortex separation area. The same Y+ range on propeller is also met at other advance coefficients and in self-propulsion calculations.

In the open water scenario, several turbulence modelling approaches were subject to investigation. These included: (i) the traditional unsteady RANS method using the k-

SST model with linear constitutive relation [

14]; (ii) the Improved Delayed Detached Eddy Simulation (IDDES) method [

15] where the subgrid length-scale includes a dependence on the wall distance and therefore allows the RANS part of the solution to be used in the thin near-wall region where the wall distance is smaller than the boundary layer thickness. The DES formulation with the k-

SST turbulence model in the RANS zones was used [

16]; (iii) Large Eddy Simulation (LES) method with the Smagorinsky Subgrid Scale model [

17] and Modified Van Driest damping function [

18]; (iv) Scale-Resolving Hybrid (SRH) turbulence model [

19] which is a continuous hybrid RANS-LES technique that switches continuously (unlike the DES method) from the RANS model to LES model when the mesh resolution is fine and the time step is small. Similar to the DES solution, the SRH method was applied with the k-

SST model in the RANS part of the solution. Open water calculations were conducted with both the smooth and rough propeller surfaces. The influence of surface roughness was accounted for by using roughness-modified wall functions which move the log layer of the inner part of the boundary layer closer to the wall. Mathematically, it is achieved by means of a roughness function [

20] that modifies the log law offset coefficient depending on the equivalent sand-grain roughness height, viscosity and velocity scale. The influence of roughness was investigated only with the RANS and DES method, assuming the two values of roughness height; 8.68 µm resulting from the JoRes propeller surface roughness measurements, and 30.0 µm which is a standard value of sand-grain roughness used at SINTEF Ocean in CFD calculation on older ship propellers in-service that have been subject to cleaning and polishing before trials.

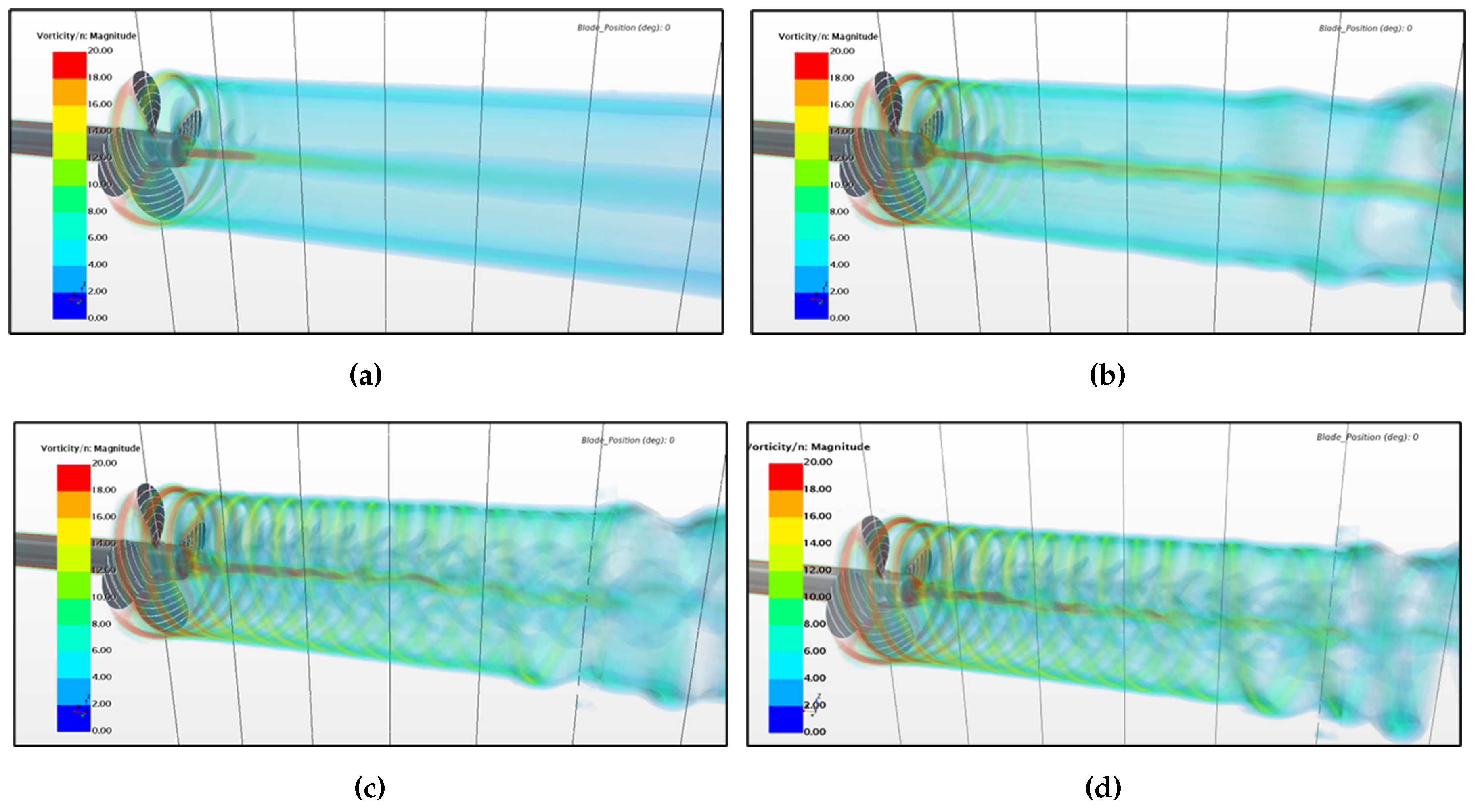

The time-accurate solution is achieved by rotating the sliding mesh region (propeller region) about the shaft axis for a certain angular step. The time step corresponding to 2 deg of propeller rotation was applied in both the open water and self-propulsion calculation, which in authors’ experience is sufficient in most practical cases. However, an additional test with the step of 1 deg was made to assess the sensitivity of the LES and SRH models to time step. Representative levels of Courant number obtained with the time step of 2 deg are shown in

Figure 7. Reduction of time step to 1 deg lowers the Courant number by the factor of 2.

The open water simulations were performed using the multi-phase flow formulation with the Volume of Fluid (VOF) model, like in self-propulsion calculations, but with the reference pressure set to atmospheric conditions to prevent occurrence of cavitation.

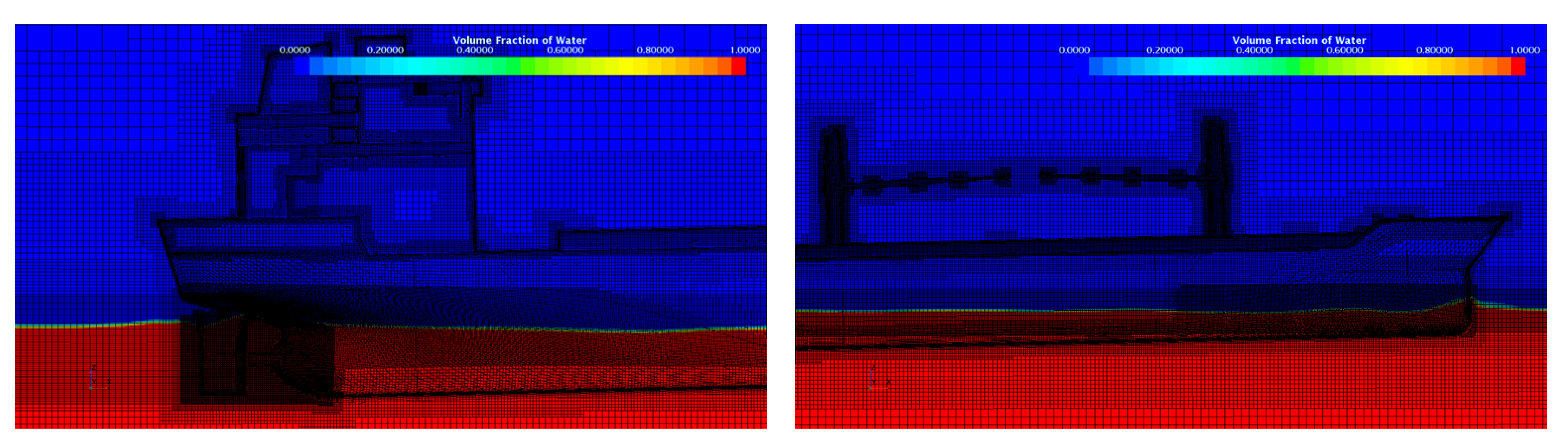

2.2. Hull resistance simulations

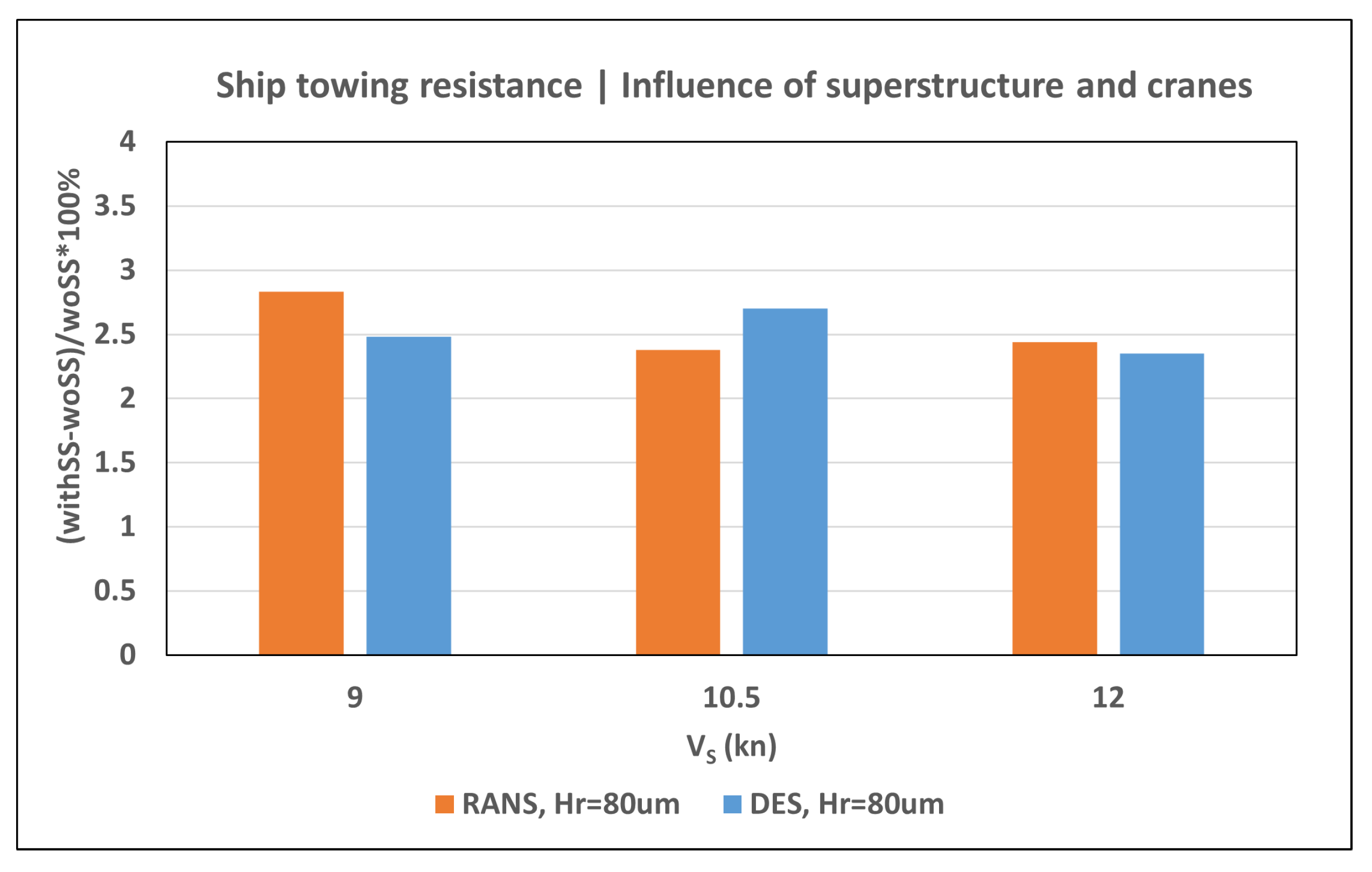

The resistance simulations were performed in full scale for the geometry model consisting of the ship’s hull, rudder, and propeller hub. The calculation matrix included both the cases with and without superstructure and cranes to evaluate the influence of the said on-deck features on the resistance of the ship and its dynamic position. The initial hydrostatic position for the resistance simulations was the same as in the self-propulsion case, and it corresponded to the draught marks provided by JoRes as specified above. The dimensions of the rectangular computation domain were assigned according to the existing practices to minimize the influence of the outer boundaries on the quality of numerical solution: 4LPP in X (inlet and outlet) / Y (side boundaries) directions from the ship’s aft perpendicular/center plane, 2LPP in Z direction to the bottom boundary, and 1LPP in Z direction to the top boundary, from base. As an additional measure to mitigate wave reflections, VOF Damping method described in [

21] was employed with the damping zone extending to the distance of 2LPP from the inlet, outlet and side boundaries. The resistance simulations were performed using the full hull model.

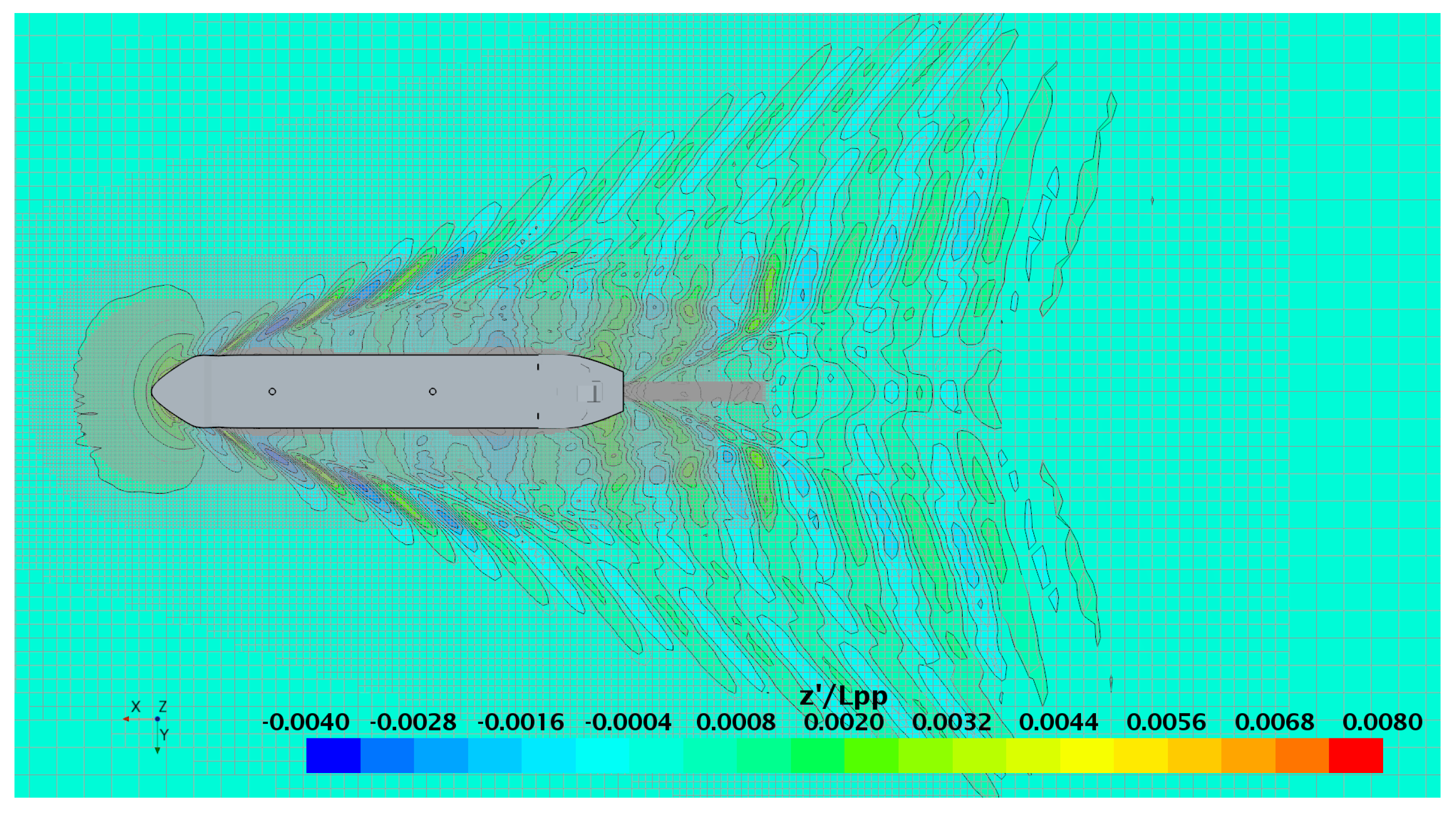

The Trimmer hexahedral mesh used in the resistance case was built to provide the refinement in the vicinity of free surface equal to 0.1 % of LPP in Z direction. In the bow and stern regions, this is also the size of isotropic cells around the hull. In the mid-ship area, the cells are anisotropic, their aspect ratio varying from 2 to 4. Conventional Kelvin’s wake refinement controls were used to capture the wave systems generated by the ship.

Figure 8 and

Figure 9 give illustrations of the mesh around ship hull with superstructure and cranes, and in the area of free surface.

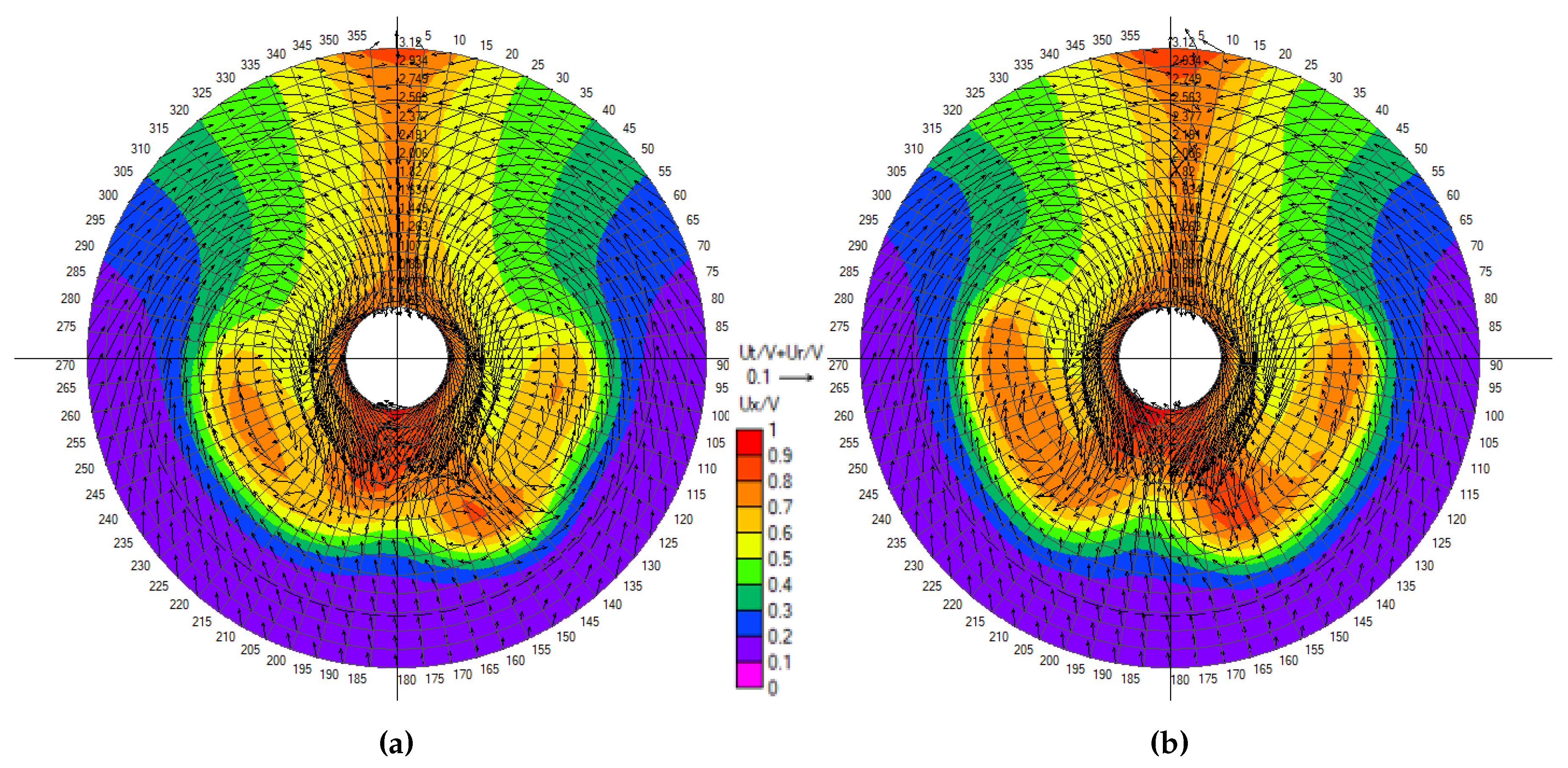

Additional mesh refinement controls are placed around the location of propeller and rudder to provide the refinement level sufficient to capture the salient features of separated hull wake. In this area, the refinement pattern is isotropic, and the cell size equals to 1.35 % of propeller diameter – the same size as applied in the propeller slipstream in open water and self-propulsion calculations.

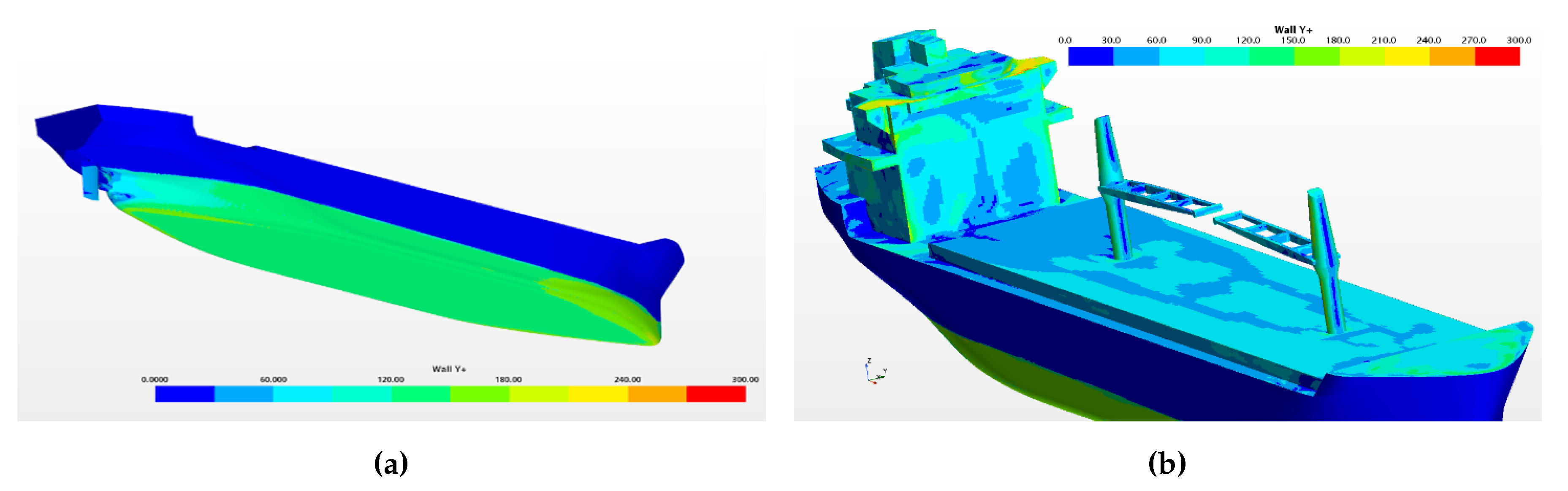

The prism layer mesh on the hull is constructed of 16 layers, where the height of the first near-wall cell is chosen to target average Wall Y+ about 130 on the hull and 50 on the rudder. The total boundary layer thickness is chosen from the considerations of stretch factor (varies between 1.30 and 1.35) and reasonably smooth transition to the core mesh, which is particularly relevant in the stern area. A typical distribution of Wall Y+ on the ship is presented in

Figure 10a. Like in the case of propeller, it is impossible to provide a uniform distribution of Y+, but its values are kept above the buffer region (i.e., above 30) everywhere expect the flow separation zones.

The number of prism layers on the deck, superstructure and cranes is reduced to 6. Since these parts are subject to intensive separation of the air flow with multiple stall areas, the Y+ varies significantly. However, the range of Y+ between 30 and 240 is well preserved, as shown in

Figure 10b. The total number of cells in the present resistance setup was 15.8 million, a higher cell count than commonly used in routine resistance calculations, which is mainly due to the inclusion of the on-deck features and finer resolution of propulsor area.

The numerical solution for the free surface is obtained using the VOF method with Flat VOF Wave model and the blended High-Resolution Interface Capturing (HRIC) scheme [

22]. The Courant number limits in the blended HRIC scheme are set to high values (Co

l = 200 and Co

u = 250) to ensure that the HRIC is used irrespective of the time step. These settings mitigate solution dependency on chosen time step, which is essential when processing the results of resistance and self-propulsion calculations to, for example, derive thrust deduction factor. A representative distribution of Courant number around the ship observed in the present resistance simulations is shown in

Figure 11.

The Courant number is below 2.0 for the greatest part of the domain, and it is elevated to 7.0 - 8.0 in the areas of generation of ship’s bow and stern wave systems, and to 9.0 - 10.0 in the area where the stern wave interacts with rudder. These higher values of Courant number are the natural result of high induced velocities and finer mesh size in the mentioned areas. In propulsion simulations, due to the small time step (t ∼ 2 deg), the Courant number is well below 1.0 everywhere. Special tests were carried out to verify that the mentioned differences in Courant number have little, if any, impact on the computed ship resistance. The Dynamic Fluid-Body Interaction (DFBI) model with two degrees of freedom in heave and pitch was used to solve the hydrodynamic position of the ship. The DFBI solver was applied to the whole domain. The Equilibrium body motion option was chosen to accelerate convergence towards the sought steady-state solution. On a caution side it needs to be noted that, depending on the case, the equilibrium solution may lead to large variations in body’s position at the intermediate time steps and introduce disturbances which exist in the numerical solution for a long time. This effect is particularly noticeable in the DFBI solutions conducted without mesh morphing.

The studies regarding the turbulence model were primarily focused on two solutions: the RANS method with the k- SST model, and the IDDES method with the k- SST model in the RANS domain. Preliminary studies on the case without superstructure also included the LES method which was found to provide good prognosis of total resistance of the smooth hull, but larger discrepancies with the RANS and DES solutions in terms of pressure and viscous resistance components. Besides, the LES model is not applicable with rough surfaces, which limits its use in the present case where the influence of hull roughness is essential. The results obtained with the SRH model reveal dependency on time step, since as the time step decreases, a larger part of the solution is treated by LES, and eventually when the time step is small (as in the self-propulsion case) the SRH solution is found equivalent to that of LES.

Assigning appropriate value of sand-grain roughness on ship hull required separate investigations. Surface roughness of 3.244 mm was initially provided in the JoRes case description from measurements on the hull using an underwater roughness scanner. One can hypothesize that such a high value is caused by two main factors: vessel age and quality of underwater hull cleaning. Further, the available photos of the hull surface revealed numerous patches, pits and bumps. These imperfections may be regarded as a macro-scale roughness that measures in mm rather than µm. At a later stage, JoRes provided another estimation of hull roughness using an alternative approach and resulting in the value of 440 µm. Converting the measured value of technical averaged hull roughness (AHR) to the equivalent sand-grain roughness height used in the wall functions is not straightforward. Therefore, the value of this parameter was derived from additional calculations with a flat plate model.

In these calculations, the computational domain consisted of a rectangular box of the length equal to ship LPP. The bottom surface of the domain was set as the no-slip wall boundary (flat plate). The upstream boundary was set as the velocity inlet, the downstream and top boundaries were set as pressure outlet, while on both side boundaries the symmetry boundary condition was imposed. The computation mesh was constructed in such a way that it replicated the prism layer mesh settings used in the ship resistance calculations and provided the same target Wall Y+. At the inlet, the Blasius velocity profile representing theoretical solution for the streamwise and normal velocities in the laminar boundary layer over the smooth plate was used. This was done in the attempt to mitigate a slight acceleration in the boundary layer that may occur locally when using a constant velocity profile. The Blasius profile applied at the inlet was calculated at the distance of x/L = 0.005 from the plate leading edge. The calculations were performed with the smooth surface and equivalent roughness height (r

g) equal to 50, 100, 150 and 200 µm.

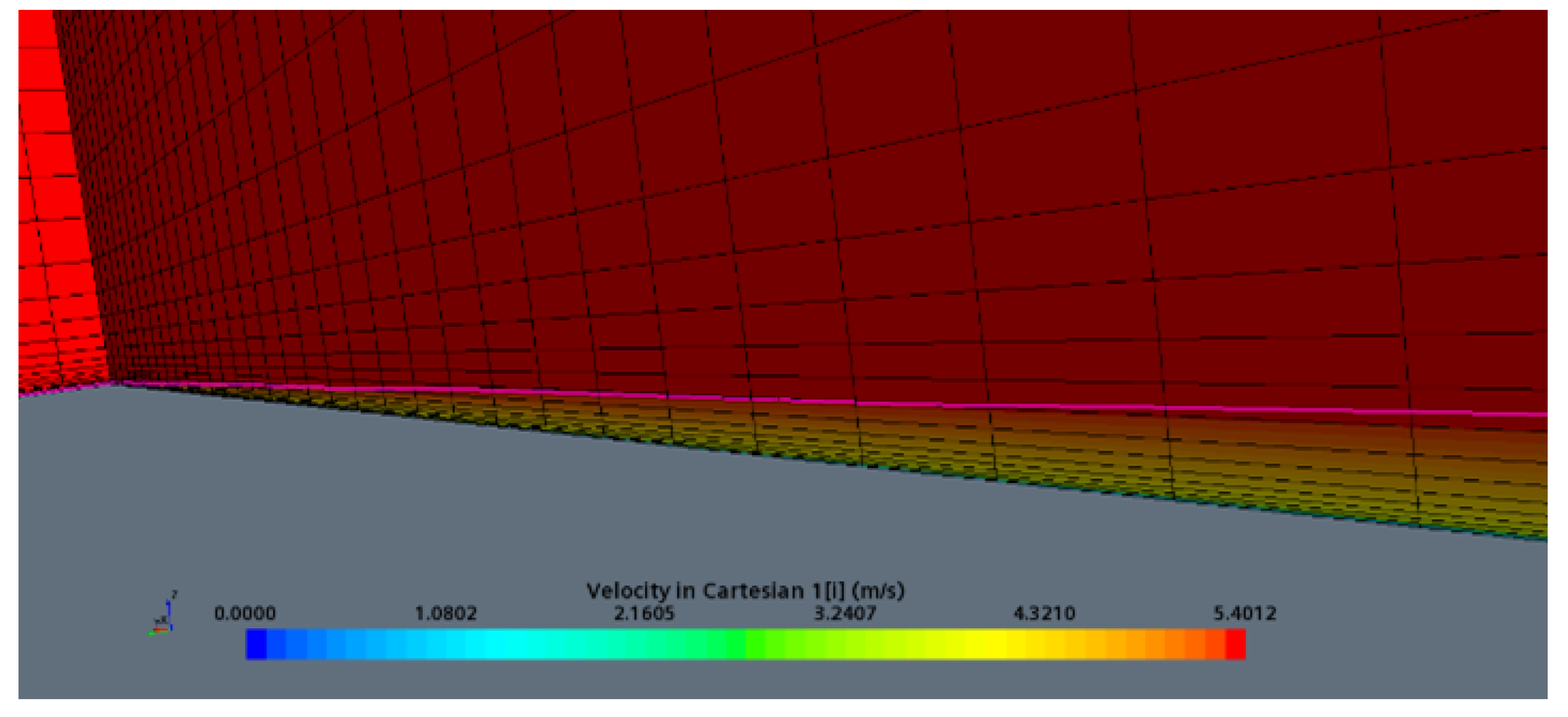

Figure 12 shows the computation mesh and field of streamwise (axial) velocity in the near-wall region of the smooth flat plate.

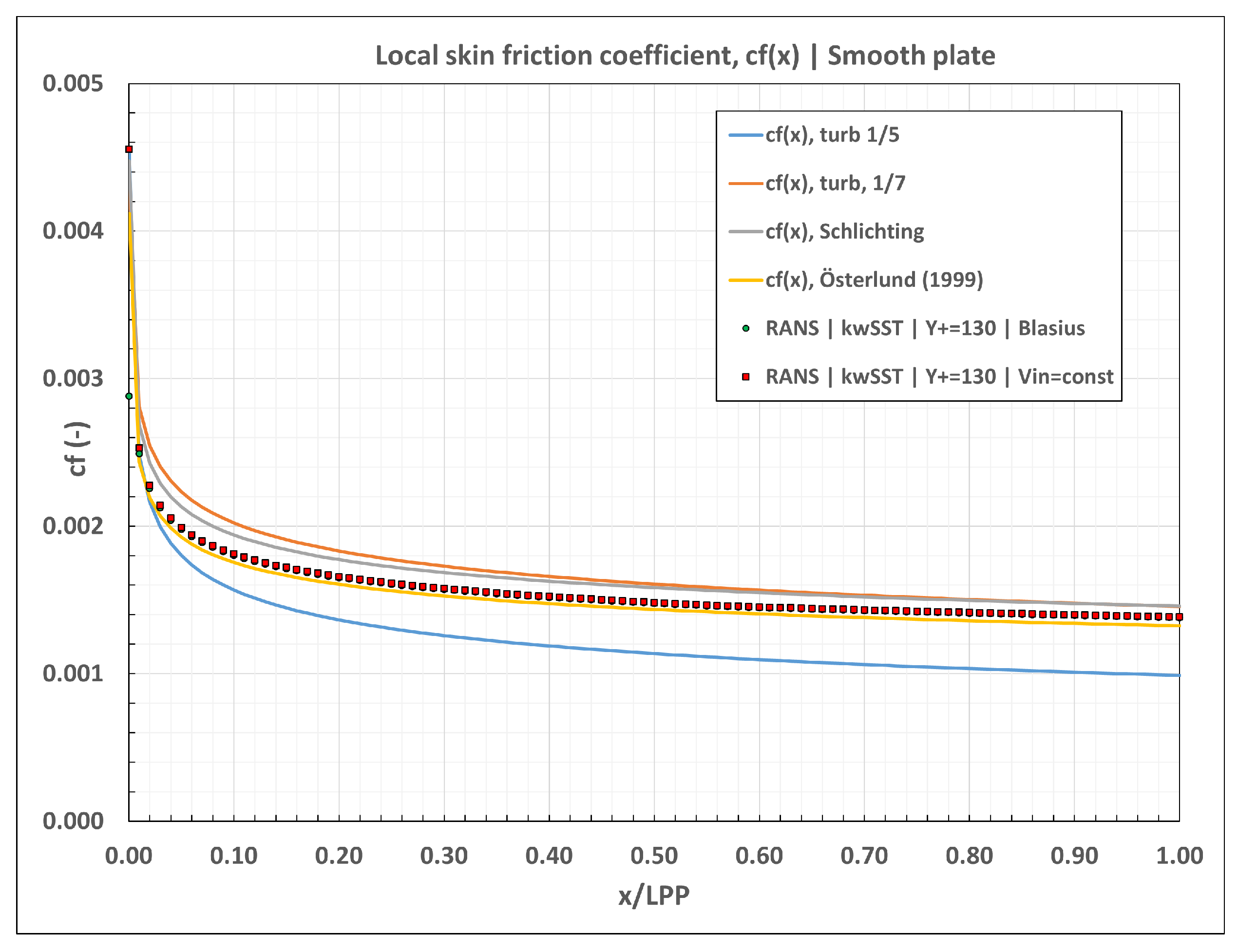

In

Table 1 the computed values of the integral friction coefficient (C

F) are compared with the ITTC friction lines used in the ship performance prediction procedures and experimental correlations by Österlund [

23]. The calculation results for the smooth plate are about 2 % below the ITTC57 friction line, and 1 % above the experimental results by Österlund. The computed streamwise distributions of the local friction coefficient (cf) are presented in

Figure 13 where they are compared with different theoretical solutions and experimental correlations, showing a good agreement with Österlund’s data. Minor difference between the CFD solutions using the constant velocity profile and Blasius profile at the inlet are noticed in the very vicinity of the plate leading edge.

Regarding the case of plate with roughness, the ITTC57 friction line results for C

F corrected with the ITTC78 roughness correction are found to be between the CFD results for the flat plate with sand-grain roughness heights of 50 µm and 100 µm, see

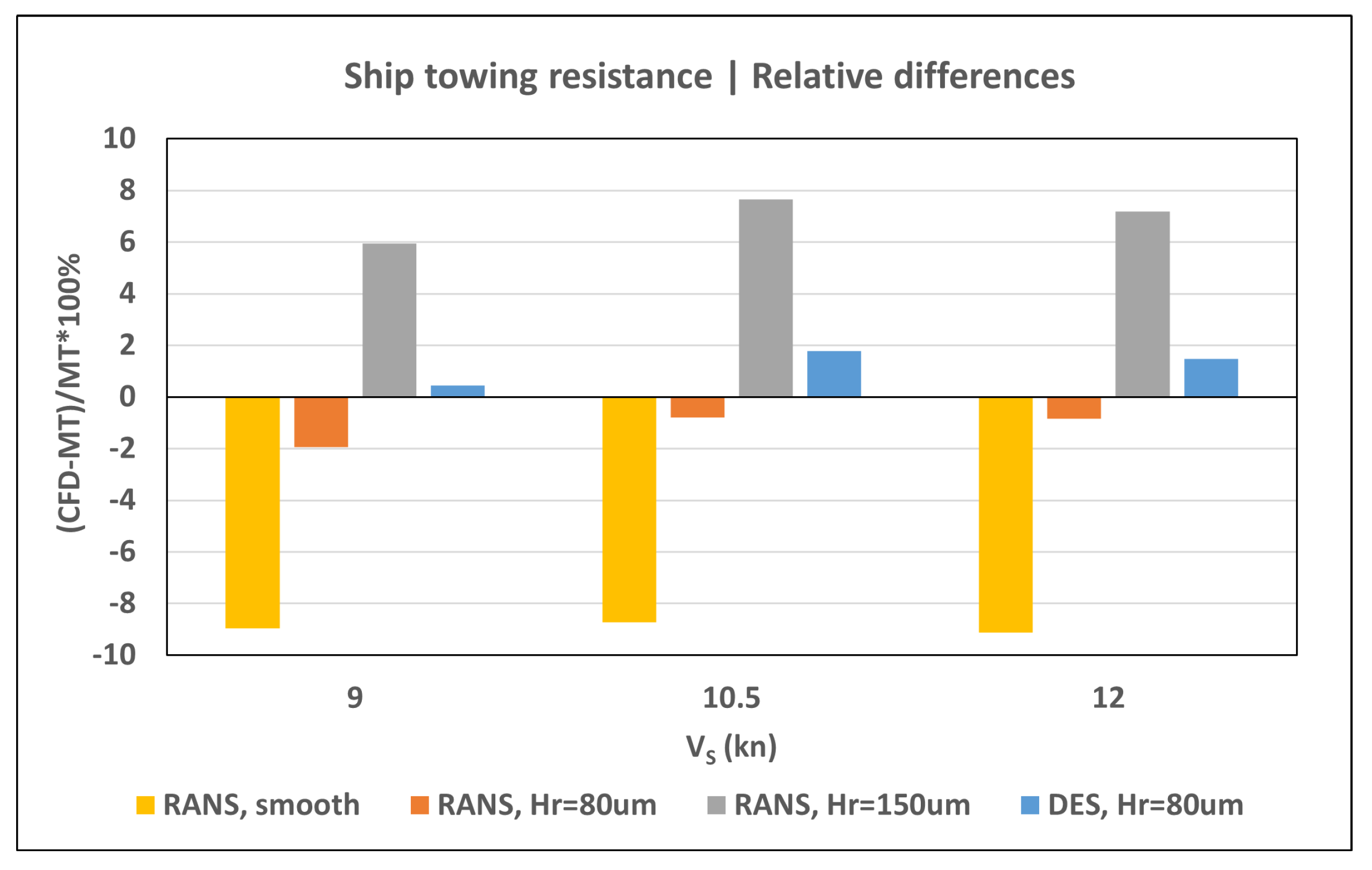

Table 1. Based on these findings, the height of sand roughness equal 80 µm was chosen to be applied in the main resistance and self-propulsion simulations for comparison with the predictions based on model tests data. To assess the influence of higher roughness, and with the high roughness values measured on MV REGAL in mind, additional simulations were performed with r

g = 150 µm. The same values of roughness height were applied on ship hull and rudder surfaces.

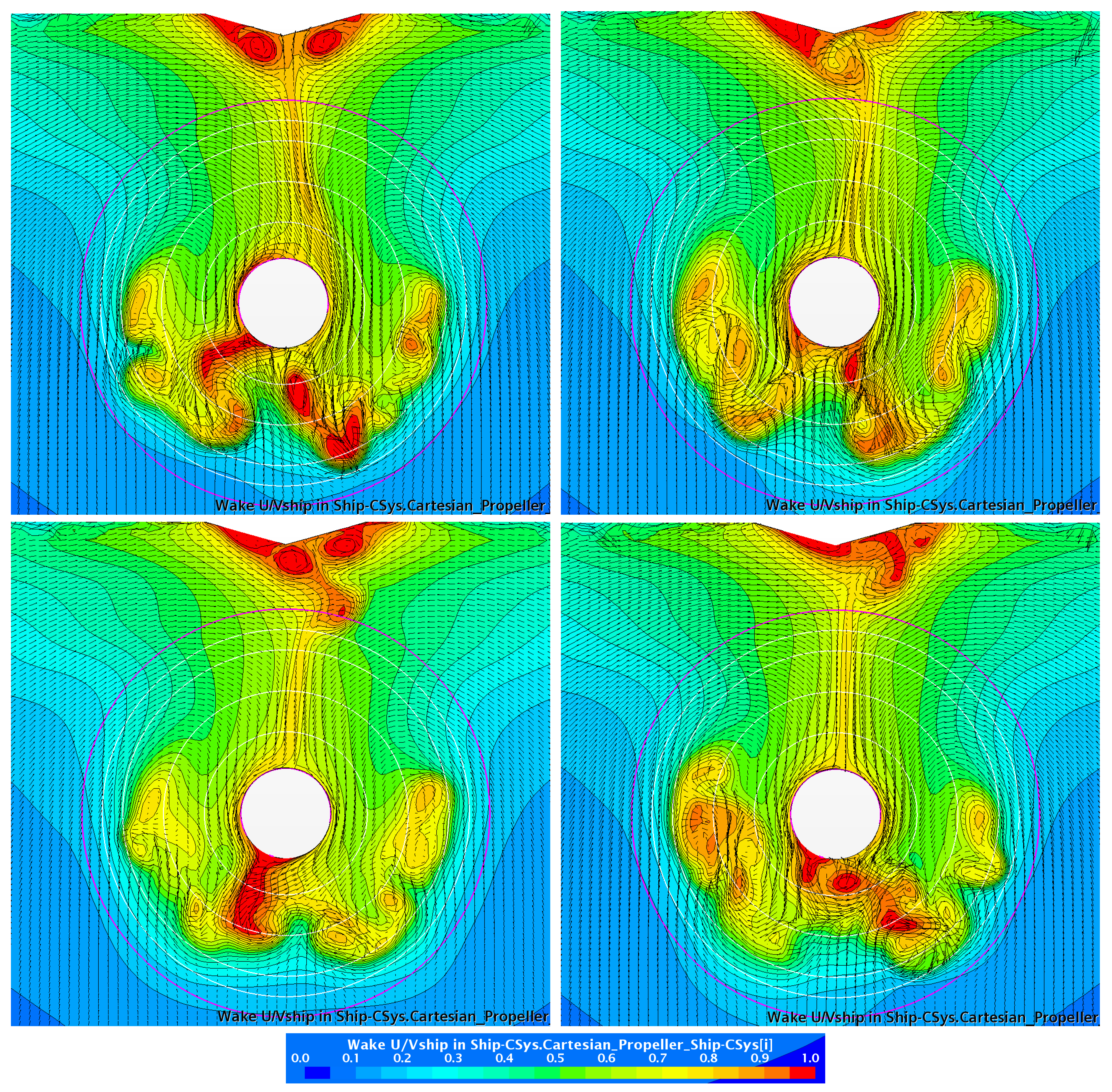

2.3. Self-propulsion simulations

As far as the topology of computation domain and mesh regions, and mesh settings on the ship and propeller are concerned, the self-propulsion simulation setup is, to a large degree, a combination of the setups used in the resistance and open water simulations.

Figure 14 gives an illustration of the mesh in the aftship area, where the sliding mesh propeller region is fit in the space between the ship hull and rudder. As in the open water case, this region accommodates the entire propeller hub and cap. The total number of cells in the self-propulsion setup is 32.8 million of which 13.3 million are in the main fluid region, and 19.5 million are in the propeller region.

The self-propulsion calculation is performed in several steps. At the first step, the propeller region is fixed, and the solution is performed using the Moving Reference Frame (MRF) method until convergence is attained for the free surface flow. At the second step, the sliding mesh region is set in motion with the initial value of propeller RPM, which is thereafter adjusted to find the vessel self-propulsion point where the following force balance equation

1 is satisfied:

where

is the ship resistance with operating propeller,

is the correction accounting for addition resistance components that are not modelled in the simulation (set to 0 in the present case),

is the X-component of propeller thrust, and

is the solution tolerance (set to 0.5 % of propeller thrust).

Finally, at the third step, the phase transfer solver with the cavitation model by Scherr-Sauer [

24] is activated, and the saturation pressure is gradually ramped through the first propeller revolution to its value specified in water properties to address possible occurrence of cavitation. At the stage of cavitation calculation, it is assumed that thrust-resistance balance is not violated, and therefore propeller RPM is fixed to its value found at the second step.

In the present study, the ship was fixed in the self-propulsion analysis at the values of dynamic sinkage and trim found from the DFBI resistance calculation. The RANS and DES turbulence modelling approaches were investigated where the equivalent sand grain roughness height of 80 µm was applied on the ship hull and rudder, and it was assumed equal to 30 µm on the propeller. An additional run with the RANS method using the roughness height of 150 µm on the hull and rudder was conducted after the fashion of resistance analyses.