1. Introduction

Micro-energy harvesting consists one of the most interesting perspectives of energy harnessing, having numerous applications; for example, such a characteristic application is powering of Wireless Sensor Networks (WSN), where millimetre-scale energy harvesting devices are required. WSN comprise small dimensions sensors that have been proposed and used in industrial process monitoring, control, machine health monitoring, structural health, bridge monitoring, predictive maintenance, environment monitoring, forest surveillance, intelligent buildings, etc. However, their main drawback is their limited duration of operation, so effective ways to recharge their batteries are sought [

1].

Various energy sources are offered for micro-energy harvesting: mechanical, flow, thermal, solar, electromagnetic, etc. In case of converting flow energy to electricity, the proposed miniature pneumatic power systems usually make use either of micro-turbines [

2] or bluff bodies [

3]. The former pose requirements for precise fabrication of millimetre-scale turbomachinery components, while the latter offer the advantages of simple design, easy fabrication and application [

3]. In case of using bluff bodies, one or more of them are appropriately installed into the flow in order to cause enhanced vortex shedding behind them for a wide range of Reynolds numbers. Vortex shedding induces pressure fluctuations that can be exploited by energy-converting materials to generate electrical power; such materials are for example piezoelectric membranes. Usually, flexible structures that can exploit fluid structure interaction phenomena, are used to utilize the piezoelectric effect and harvest flow energy. Various configurations using flexible membranes in conjunction with bluff bodies, both in external and internal flows, have been proposed and assessed in the literature [

4,

5]. Often, fabricated prototype configurations are experimentally and/or numerically tested to assess their performance. Some of these studies aim to find the appropriate bluff body shape that produces significant vortex shedding; this is the same objective with that used in designing an effective flow meter [

6]. Furthermore, using multiple bluff bodies in tandem instead of one, consists an interesting perspective towards enhancing the associated vortex shedding [

7]. A very good and compact literature review on these topics can be found in [

3].

In [

3], a miniature pneumatic energy generating device was originally proposed and tested. This device utilizes one or two bluff bodies in tandem installed in a micro-channel. A flexible diaphragm, with a piezoelectric film on it, is located above the bodies at the upper channel wall. Pressure fluctuations and unsteady forces induced on the diaphragm due to vortex shedding cause vibrations to it and convert mechanical energy to electrical. Such a device, involves ease fabrication and installation, facilitates miniaturization and massive production avoiding the need for micro-assembling processes and could be used in liquid or gas pipeline systems. Its main drawback is the low power output, so further research is required aiming to enhance its performance. This device was studied in [

8], in order to assess its prospective operation and performance, based on numerical simulations. To this end, a CFD model was appropriately set-up and validated. While the device was experimentally tested in [

3] by measuring its actual electric power output, in [

8], extended use of the CFD model was made in order to study the driving force for the operation of the device, i.e. the pressure fluctuation induced on the diaphragm due to the flow-field in the channel. Various bluff body shapes and configurations were simulated for a fixed inlet flow Reynolds number and channel blockage ratio. Pressure fluctuation characteristics (amplitude and frequency) acting on the center of the diaphragm were numerically predicted. Vortex shedding severity was quantified and assessed in terms of the maximum unsteady pressure fluctuation amplitude. The conclusions of [

8] focused on the most effective configuration with respect to body geometry and diaphragm position. The work of [

8] was partially continued in [

9], where, by means of numerical simulations on the same case, the effect of the inlet Reynolds number was studied.

The present study focuses on studying further the most effective configuration found in [

8]. This case with the original Reynolds number and blockage ratio is considered herein to be the baseline case. The set-up of the CFD model is described in detail and appropriate metrics to assess the energy harvesting potential are defined. Grid independence study is carried out, followed by corresponding time-step independence study, in order to use grid of sufficient size and appropriately select time-step value for the various simulations. Aiming to assess the effect of inlet Reynolds number and of blockage ratio in the channel on the prospective performance of the device, several cases are simulated. Results are presented and discussed, conclusions are drawn and future research directions are proposed.

2. Set-up of the CFD Model

The academic version of the ANSYS commercial CFD software FLUENT [

10] was used for the numerical simulations. The necessary geometric modeling and grid generation tasks were accomplished by using the relevant software modules available in this software.

2.1. Flow Domain Geometry

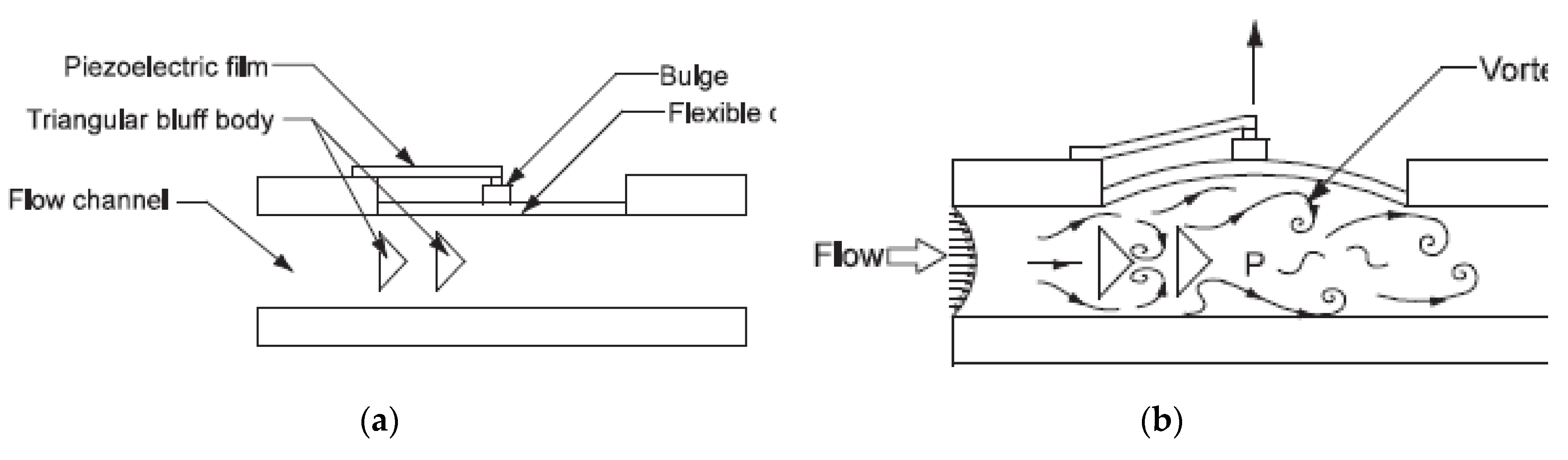

Figure 1 presents the device under consideration, where two triangular bodies are located in a flow channel of very small height. A flexible diaphragm is installed above the bodies and causes vibrations to a piezoelectric film connected to it, converting mechanical energy to electrical, under the action of the unsteady flow pressure forces; the latter are induced by the vortex shedding, occurring behind the bodies. Contrary to most applications where vortex shedding suppression is sought, in such an application, vortex shedding enhancement is sought for a better performance of the device.

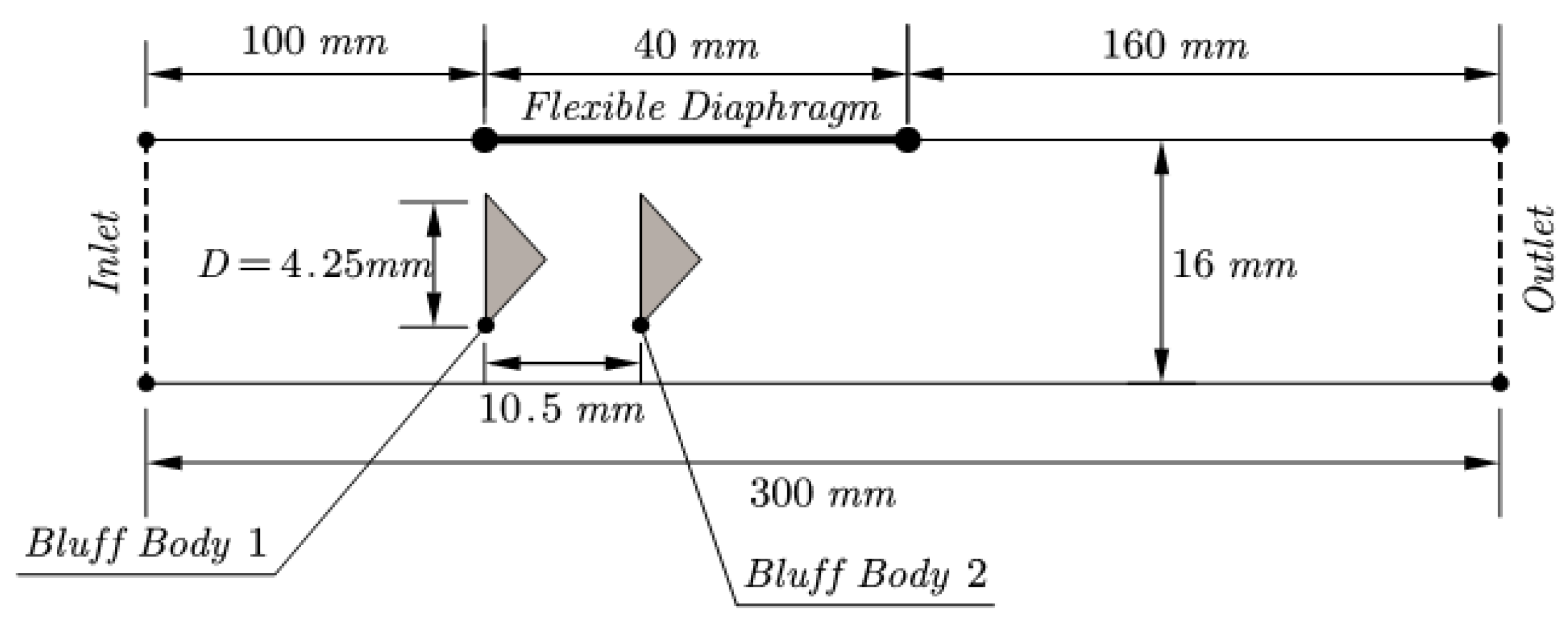

The flow domain used for the numerical simulations in [

8] is shown in

Figure 2. The bluff body shape is an isosceles triangle, the base of which faces the incoming flow from the left. The length of the channel is L=77.06D and its height is H=3.76D, where the width of the bluff body (length of the triangle base) is D=4.25mm. The blockage ratio of the channel is defined by the ratio BR=D/H=0.27. The aspect ratio of each triangle, i.e. ratio of height to base is 1.95. The flexible diaphragm is located on the upper wall of the channel. Its origin is exactly above the position of the first triangle base. The distance from channel inlet to the origin of the diaphragm is 23.53D=100mm. The length of the diaphragm is 8.94D=40mm and the distance downstream the diaphragm up to the flow outlet is 44.59D=160mm. The whole upper and lower boundaries of the channel are treated as solid walls. The left boundary is the inlet of the flow domain and the right one is the outlet domain and the right one is the outlet.

2.2. Governing Equations and Numerical Solver

In order to simulate the low-speed flow of air in the micro-channel, the two-dimensional unsteady, incompressible, Reynolds Averaged Navier-Stokes (RANS) equations are numerically solved, i.e. the continuity and momentum ones (mean-flow equations). Turbulence is taken into account by means of the realizable variant of the k-ε two-equation model; this variant ensures that only physically realistic viscous stresses will be allowed to arise during the simulations [

11]. The mean flow equations are solved by means of FLUENT software [

10], based on the SIMPLE pressure correction scheme, in the context of finite volume method, on unstructured grids consisting of triangular elements. Second-order spatial accuracy is used for the convective terms of the mean flow equations, while first order is used for the turbulence model ones. Transient solution of the governing equations is sought by means of first-order Euler scheme in physical time with constant time step, while 20 sub-iterations are applied to converge the solution between two successive time steps. Inlet velocity is prescribed at flow inlet (termed as ‘velocity inlet’ in the software), while zero pressure value is set at outlet (termed as ‘pressure outlet’). No-slip condition is used for the velocity at walls (channel and bodies). Wall functions are implemented to model velocity profiles at walls. In particular, the option of ‘scalable wall functions’ is used, ensuring that the wall distance employed in wall functions will be such that y

+≥11.126. Thus, erroneous modelling of the laminar and buffer boundary layer regions (occurring in the range y

+<11.126), is avoided by effectively shifting the near-wall mesh point to y

+=11.126, irrespective the level of the actual near-wall grid refinement.

2.3. Description of Case Studies

In the present work, the effect of two parameters is investigated on the energy harvesting potential of the device under consideration. These are the inlet Reynolds number (Re) and the blockage ratio (BR), i.e. the ratio of body width to channel height. To this end, two different studies were carried out; the first concerns the effect of varying blockage ratio and Reynolds number on the device performance, while the second refers to finding the critical value of blockage ratio that causes vortex shedding suppression in the channel. In what follows, the cases that had to be simulated in order to accomplish the two studies, are described and organized.

2.3.1. Cases to study the effect of blockage ratio and Reynolds number

The bluff body width D is the characteristic length of the flow. Reynolds number (Re) based on inlet velocity V

in and body width D is Re=ρV

inD/μ. By writing D in terms of blockage ratio BR, as D=BR.H (H being the channel width), the above formula becomes Re=ρV

in BR.H /μ. Air was used as the working fluid in all the simulations with a density of ρ=1.225kg/m

3 and a dynamic viscosity coefficient of μ=1.789x10

-5Pa.s. For the baseline case studied in [

8], where V

in=20.7m/s and BR=0.27, the Reynolds number is Re=6024.

Apart from the baseline value of BR=0.27, six more BR values were simulated, i.e. seven cases in total. For each of these seven BR values, seven different Re numbers are simulated (the corresponding cases are named after C1,…,C7), resulting in a total number of 49 simulations with respect to the variation of both Re and BR. In each of these cases, the value of the inlet velocity is set according to the formula V

in=(μ.Re)/(ρ.BR.H).

Table 1 summarizes the values of inlet velocity used for the various values of Re and BR.

2.3.2. Cases to find the value of blockage ratio causing suppression of vortex shedding

According to the literature, the increase of blockage ratio generally enhances vortex shedding; however, in confined geometries, there is a critical value of BR that causes suppression of vortex shedding [

3]. In order to find this value, a number of simulations was carried out, in which the baseline inlet velocity (V

in=20.7m/s) was kept constant, while the value of the blockage ratio, was gradually increased, starting from a low value, up to finding the required critical value.

2.4. Fluid Data for the Simulations

Since the Reynolds number based on channel width H is greater than that based on body width D, i.e. Re

H=ρV

inH/μ > ρV

inD/μ=Re

D. Thus, according to

Table 1, in all cases Re > 4000 that dictates turbulent flow. In order to set boundary conditions for turbulence, the values of turbulence intensity I

t and turbulent length scale L

t are prescribed at the inlet. Assuming fully developed flow, this is estimated by L

t=0.07D, while turbulence intensity is computed as I

t=0.16(Re

D)

-1/8 [

3,

8,

9].

A constant time step is used to march the flow-field in physical time. A characteristic time scale of the problem at hand is the so-called ‘convective time’, defined by T

C=D/V

in. As in [

3], a value of 5% of T

c, is proposed for the physical time-step in the simulations, i.e. Δt=Δt

c=(0.05)T

c. For the baseline case, where D=0.00425m and V

in=20.7m/s, this value is Δt

bsl=10

-5s=0.01ms. At each case, starting from an ambient initial velocity field, the solution is marched using the corresponding physical time step for sufficient time to establish periodicity and then the flow field is let to evolve for at least three periods.

2.5. Assumptions Involved in the Simulations

All of the numerical simulations performed in the present work, rely on the following assumptions:

The flexible diaphragm is considered to be rigid wall, fluid-structure interaction phenomena are ignored, displacement of the fluid due to diaphragm motion is ignored and feedback effects from the diaphragm to the flow were neglected.

The diaphragm has small inertia and oscillates with the frequency of vortex shedding, the piezoelectric film is supposed to be strained laterally, following the vibrations of the diaphragm and, according to the piezoelectric phenomenon, produce electrical power.

Although the actual geometry is three-dimensional, two-dimensional simulations along the symmetry plane of the channel are performed to model the phenomenon.

The greater the calculated vortex shedding intensity, the better the expected performance of the device.

2.6. Definition of metrics to assess the energy harvesting potential of the device

The assessment of flow energy harvesting potential in the present work, is made on the basis of some appropriately selected and defined metrics. These are quantities of interest, either being indicative for assessing the potential to cause a greater effect on the piezoelectric membrane or characteristic quantities of the flow-field, like for example pressure drop along the channel.

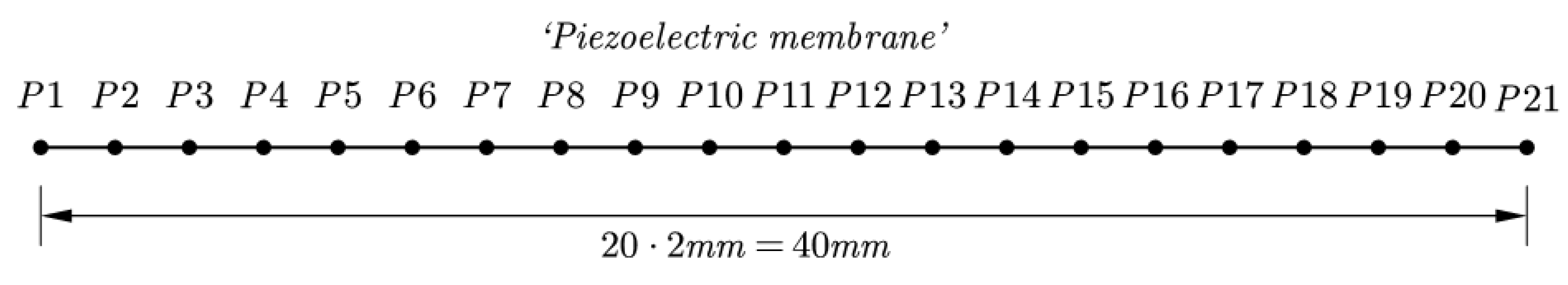

Since the time evolution of pressure acting on the center of the diaphragm exhibits periodicity, its amplitude, i.e. its maximum fluctuation width, is considered to be the basic criterion to comparatively assess the energy harvesting potential of the flow from such a device [

8]. To monitor pressure on the diaphragm, 21 distinct equidistant positions are defined along it on the upper channel wall, denoted by the points P1, P2, …, P21 (

Figure 3). These points serve to evaluate and compare local pressure signals, as well as estimate corresponding amplitude values. The latter is towards searching for the maximum energy harvesting potential of the device, in the sense that the best performance will be exhibited if the center of the membrane is located at the position experiencing the maximum amplitude of pressure p

i(t), i=1,2,…,21.

In the light of the above, the selected metrics that are computed in each case after establishing flow periodicity, are:

The position (point Pi,max among the 21 points), where the maximum pressure fluctuation amplitude Δpi,max is predicted.

The value of the maximum pressure fluctuation amplitude Δpi,max and the corresponding non-dimensional quantity (pressure coefficient) Cpi,max=Δpi,max/0.5ρVin2.

The frequency and the non-dimensional frequency, i.e. Strouhal number St=fD/Vin, of the pressure signal at point Pi,max.

The average pressure drop Δpdrop in the duct, calculated as the difference between inlet and outlet average pressures, as well as the same quantity in non-dimensional form, i.e. Cpdrop=Δpdrop/0.5ρVin2.

The grid independence study for the baseline case, as well as the assessment of vortex shedding severity for the various inlet Reynolds numbers and blockage ratios, to be presented in the following sections, have been based on the above defined metrics.

5. Conclusions – Future Research

A millimeter-scale flow energy harvesting device proposed in the literature [

3] was studied numerically. The device contains two bluff bodies installed in a very small flow channel. It exploits vortex shedding behind them to cause oscillations on a flexible diaphragm above them and convert flow energy to electrical one by means of the piezoelectric phenomenon.

In [

8], a CFD model was set-up for the numerical simulation of this case and different body shapes and configurations were simulated for a fixed flow Reynolds number. The achieved vortex shedding severity was assessed in terms of the predicted unsteady pressure fluctuation on the diaphragm in order to find the most efficient configuration, which involved two bodies of triangular section. The study of this configuration was continued herein by scrutinizing the CFD model of [

8] and performing parametric studies to understand the effect of various parameters on the expected performance of the device. In particular, grid independence study and investigation on the selection of a sufficient time step for the resolution of the flow phenomena under consideration were performed. The device performance was then numerically assessed in a range of different inlet Reynolds numbers and blockage ratios. Furthermore, the behaviour of vortex shedding with respect to blockage ratio increase was studied in detail and the critical value of BR (for which vortex shedding suppression occurs) was sought and found.

5.1. Conclusions

The conclusions drawn in the present work can be summarized (from a designer’s point of view) as:

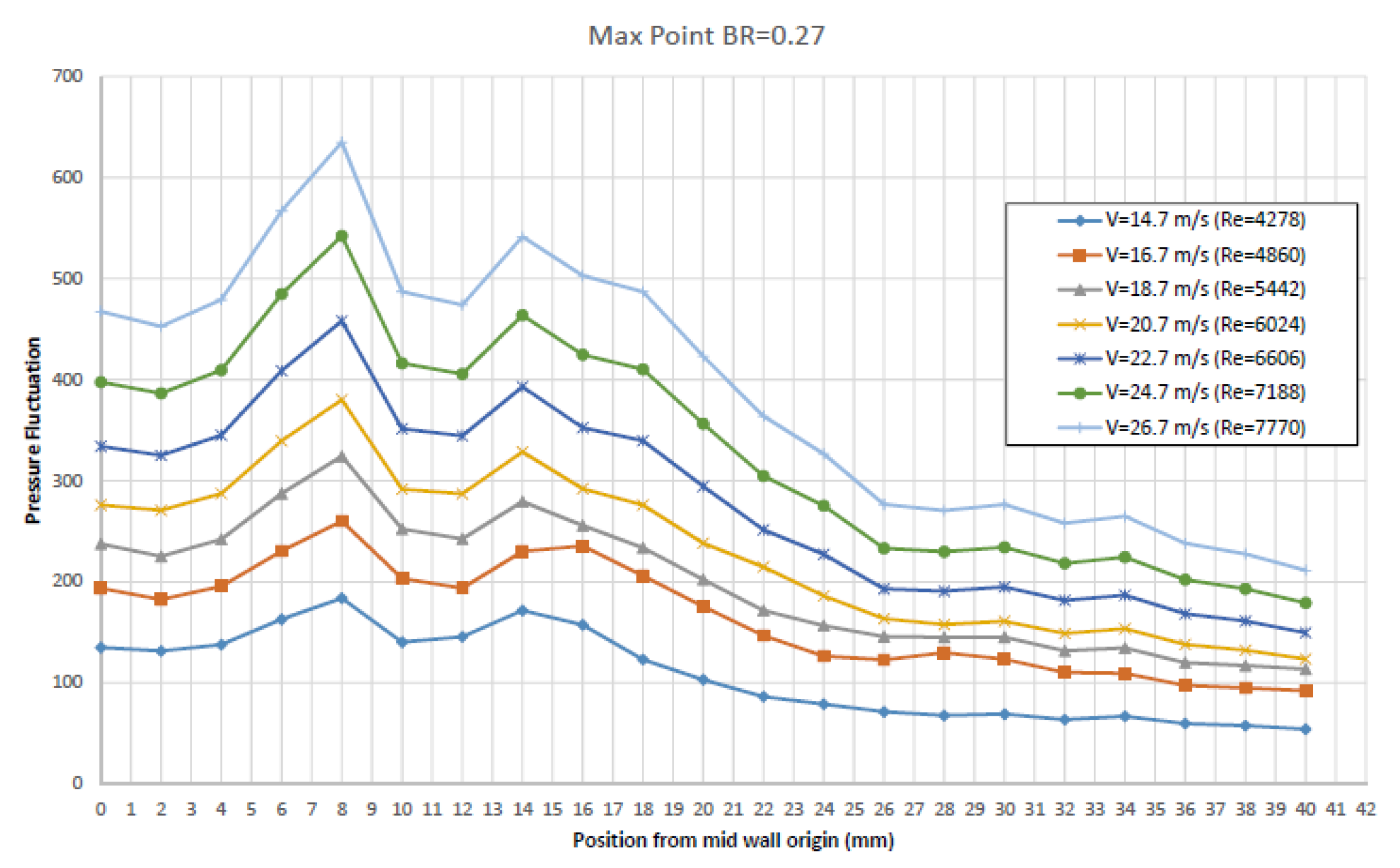

The maximum pressure amplitude (Δpmax) in all cases occurs at the same position, located upstream the center of the diaphragm (at distance 8mm from its beginning). Thus, in order to maximize the effect of vortex shedding on the diaphragm, the center of the latter should be placed upstream at the point where maximum pressure amplitude is predicted.

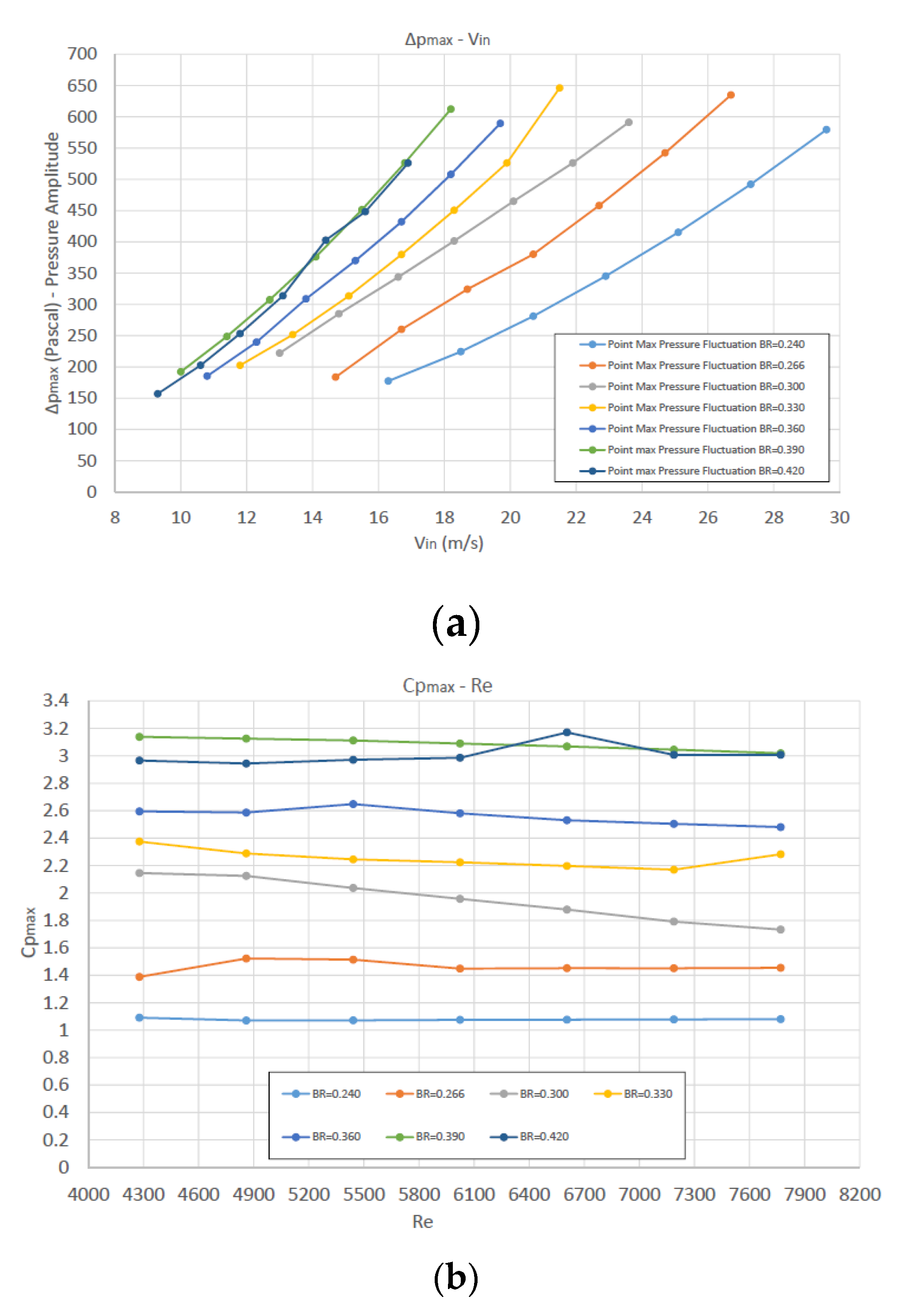

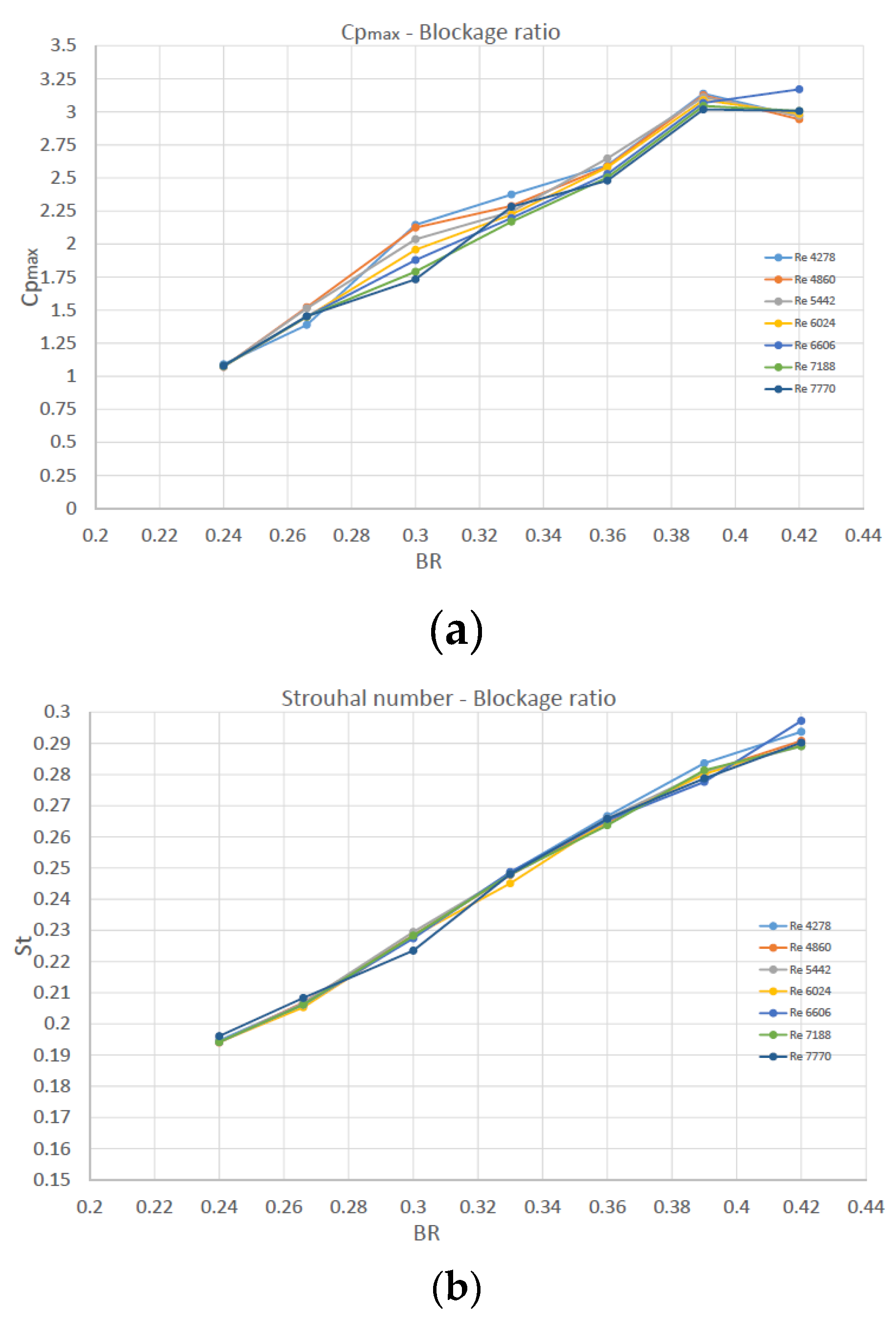

The maximum pressure amplitude increases almost linearly with the inlet velocity for all the values of blockage ratio (BR); the greater the BR, the more abrupt is the increase. Thus, using greater inlet velocity and greater blockage ratio, greater maximum pressure fluctuation amplitude can be achieved.

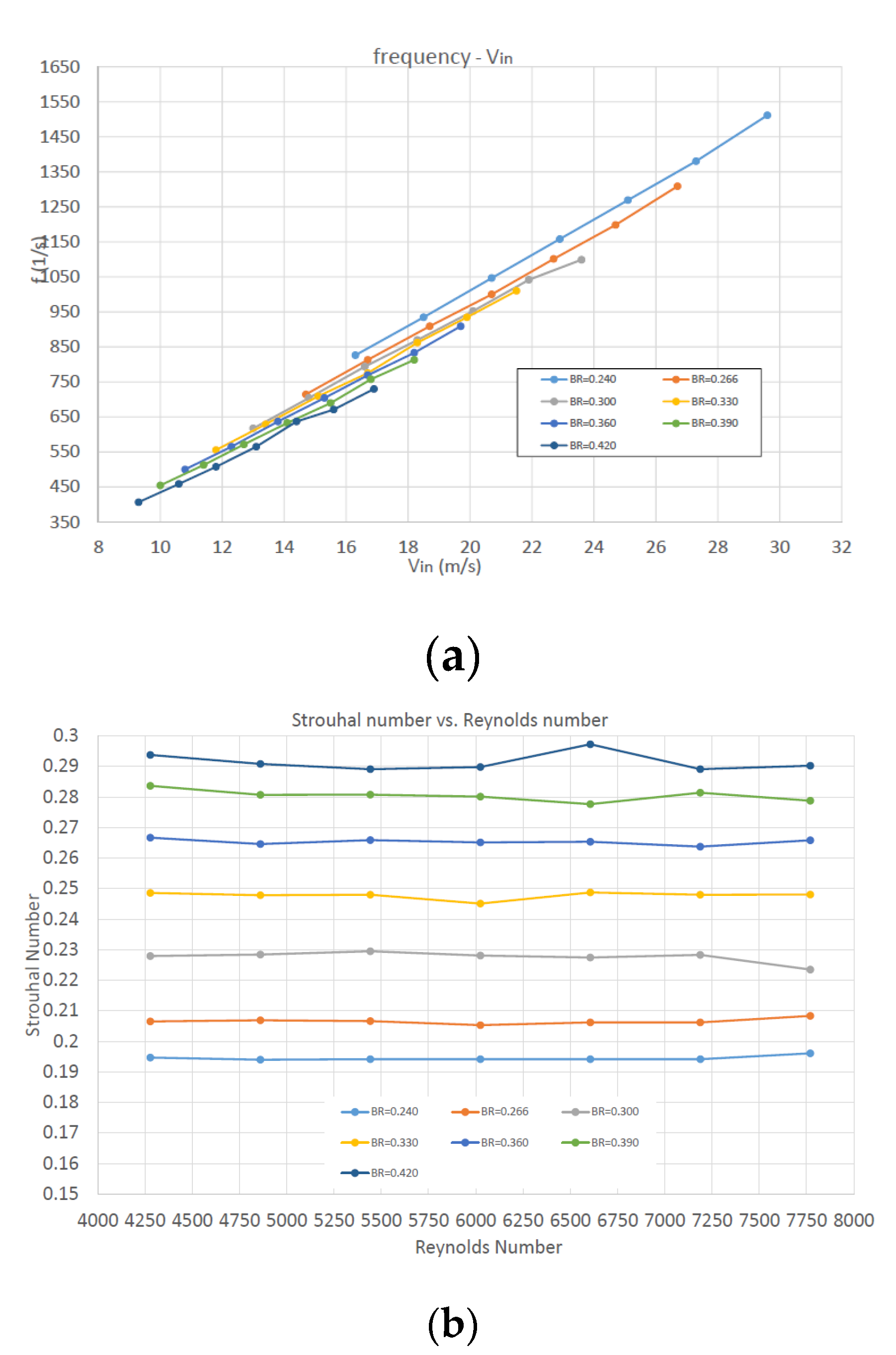

The fundamental frequency of the predicted pressure signal at the point where Δpmax occurs, increases almost linearly with inlet velocity for all values of BR; the slope of the linear increase remains almost constant for all BR. This frequency slightly decreases with the increase of BR for the same Reynolds number. Since a high frequency is rather desired, maximizing the pressure amplitude (as proposed above) will also lead to a frequency increase.

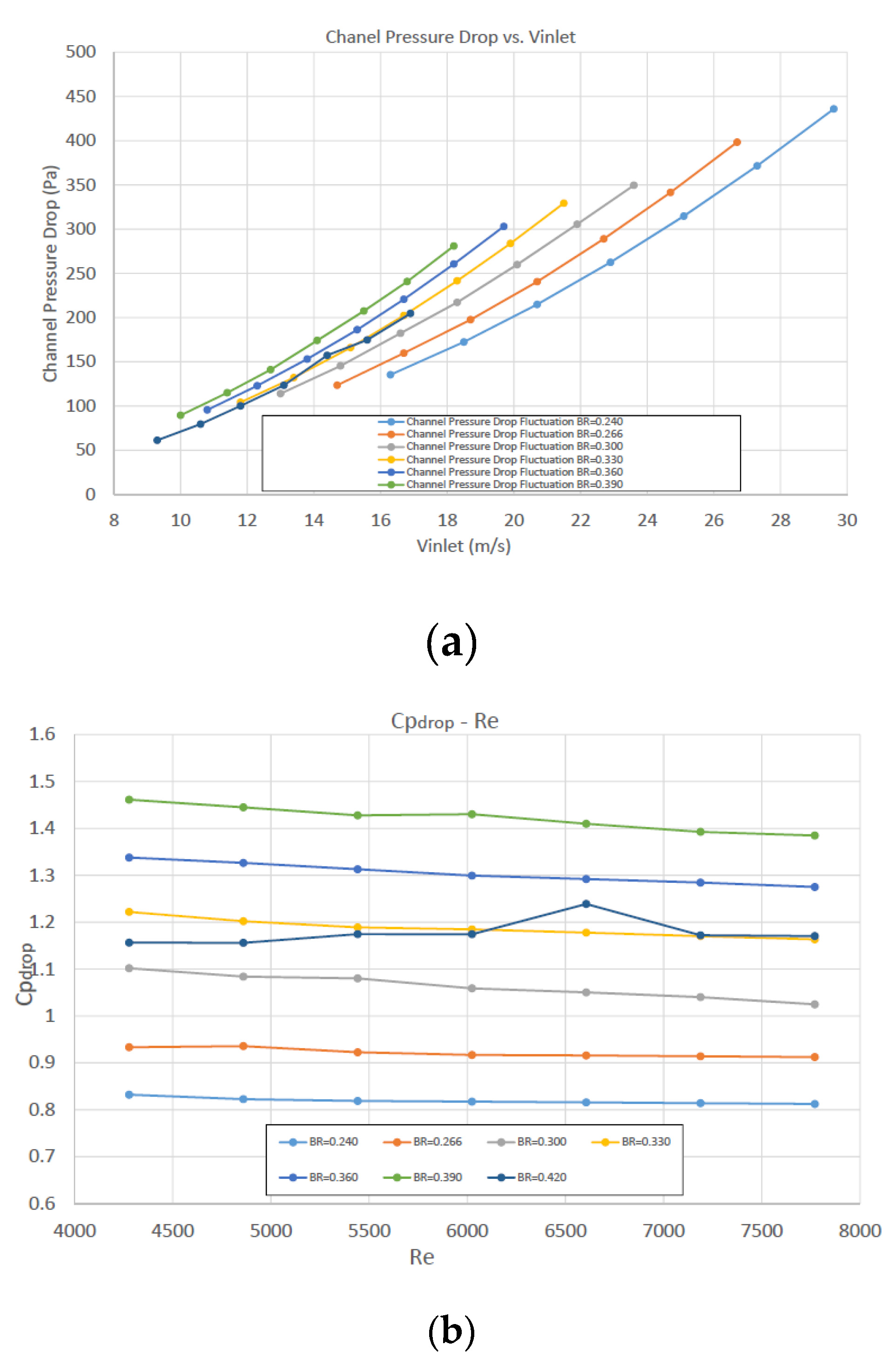

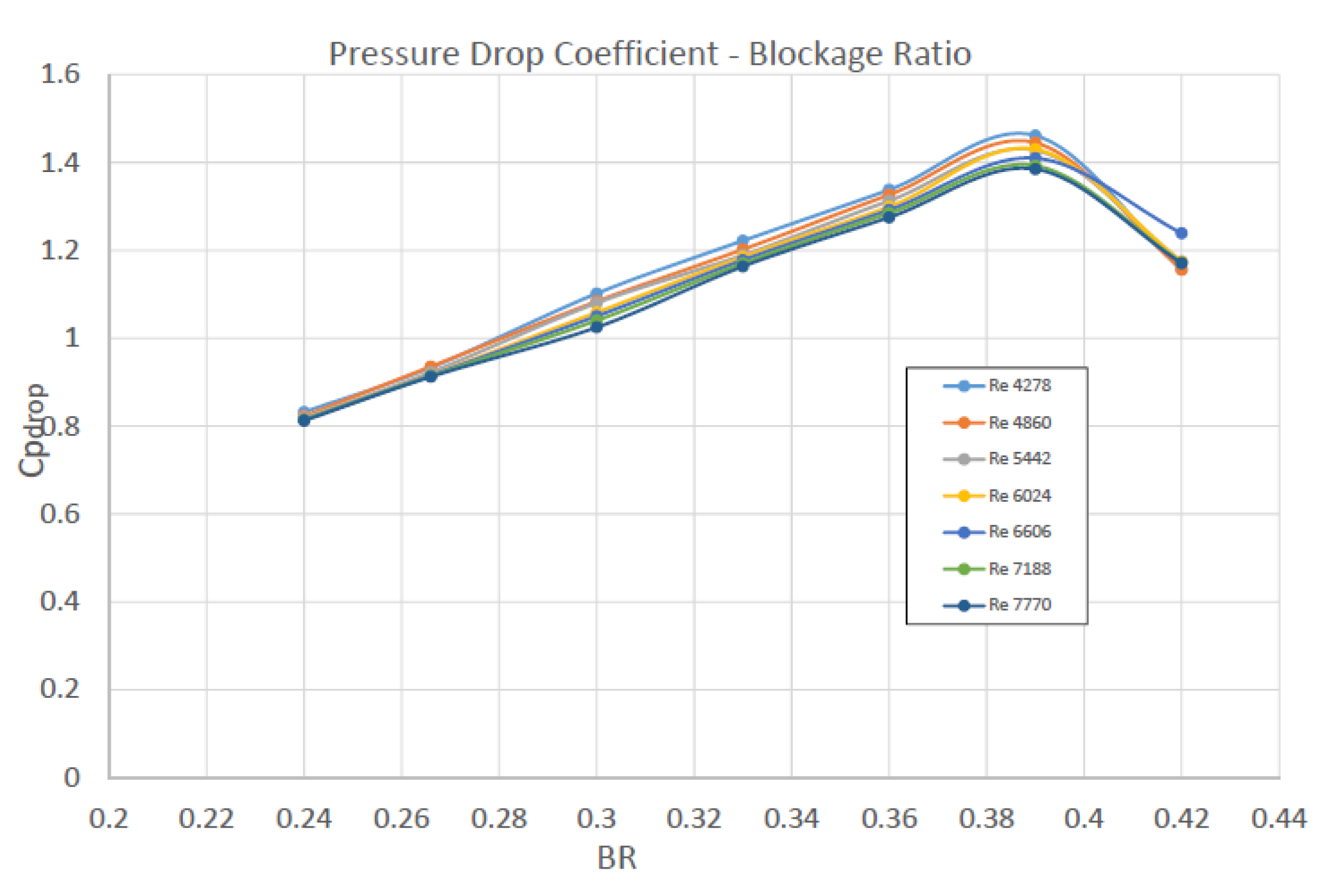

The channel pressure drop (Δpdrop) increases with the square of inlet velocity for all values of BR. For the same inlet velocity, pressure drop increases with BR. As expected, increase of pressure amplitude causes increase in pressure drop.

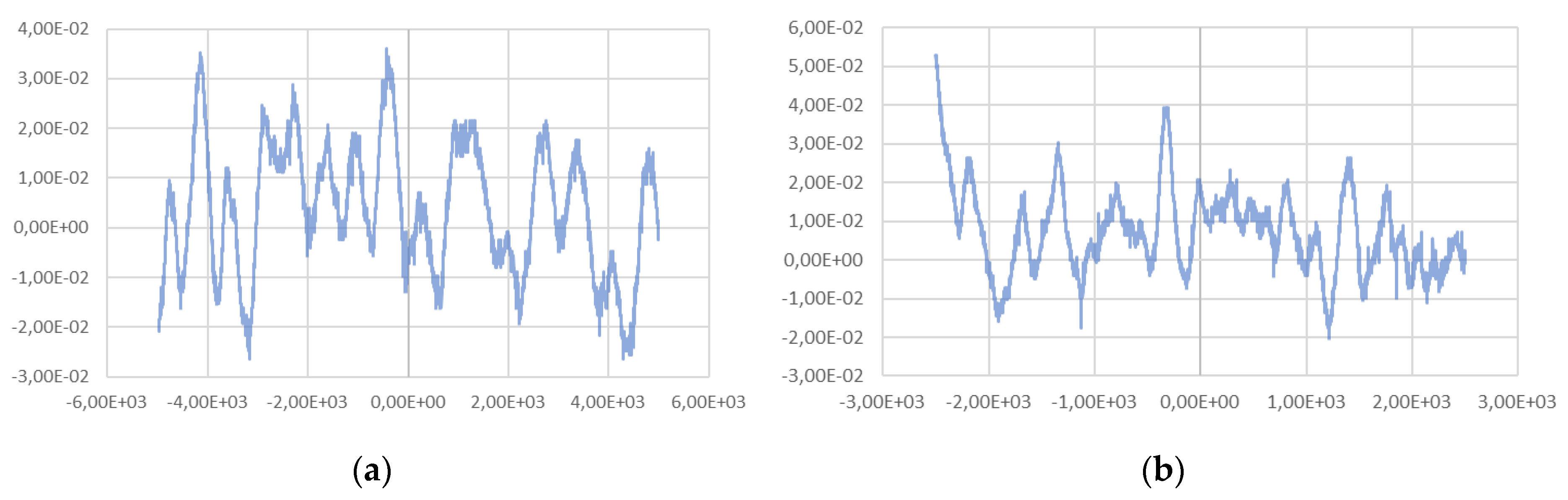

Contrary to similar previous research in the literature [

3] for the baseline case, the critical blockage ratio for which vortex shedding suppression occurs, was found in the present study to have a significantly greater value and this seems to be validated by corresponding experiments [

14].

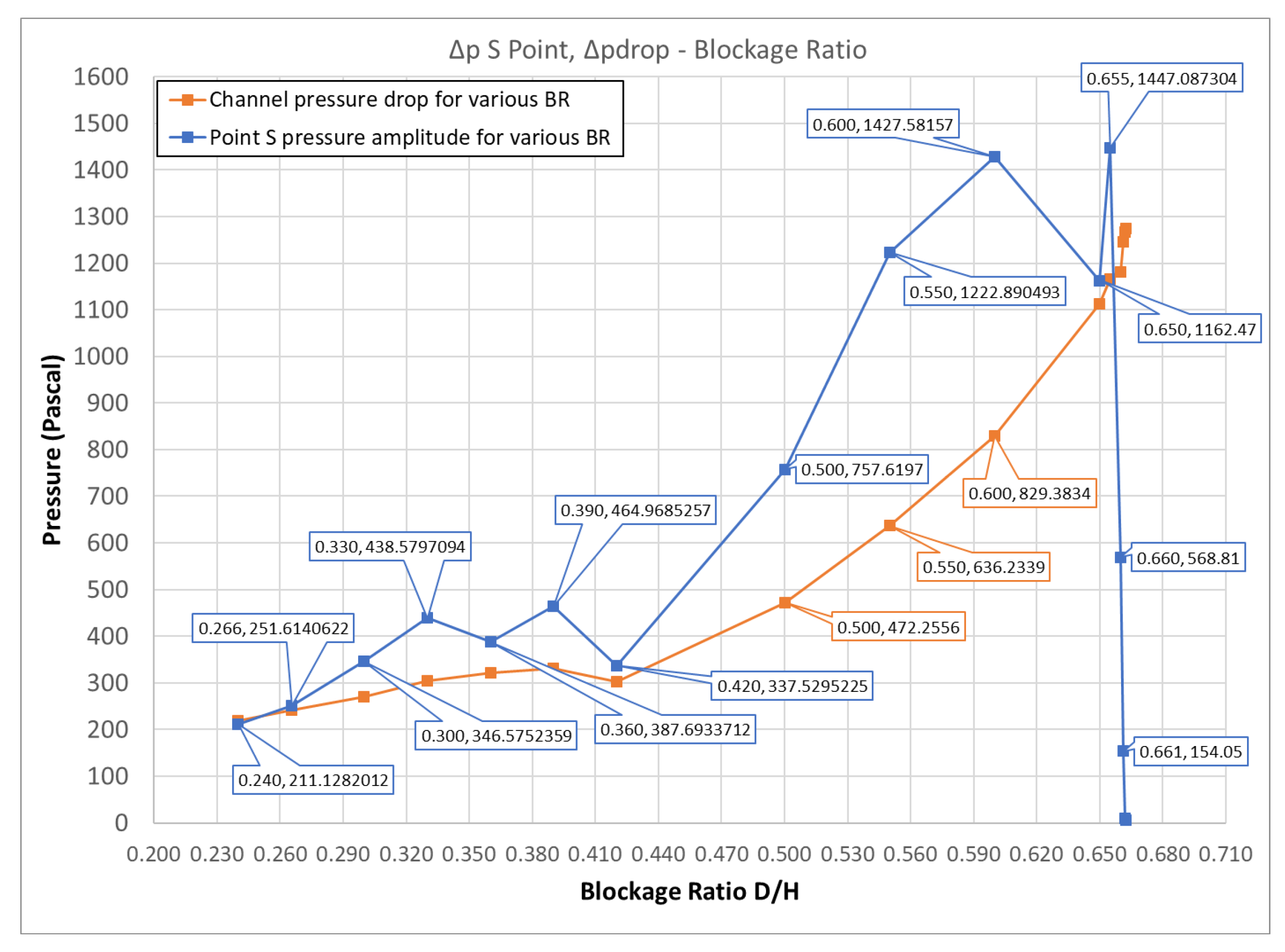

As a contribution of this work, from a designer point of view, and under the prerequisite that these results would be validated by experiments, a great value of BR but lower than its critical one, seems to provide a great value of amplitude in the expense of a moderate pressure drop (

Figure 20).

5.2. Further Discussion

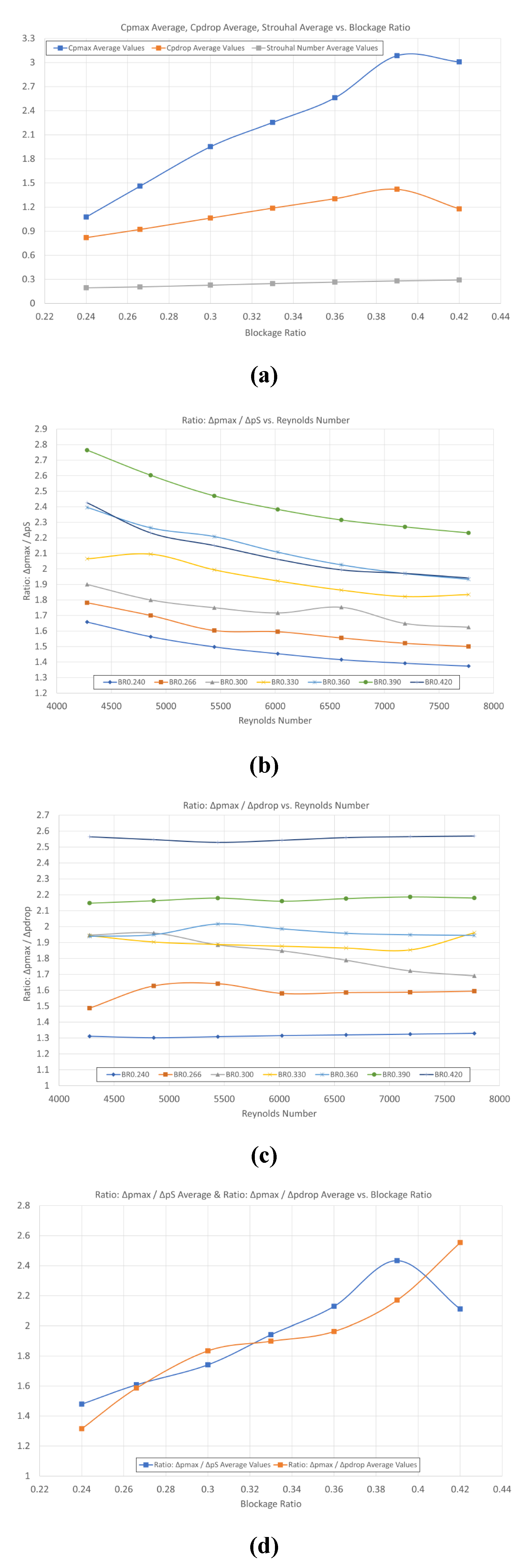

The non-dimensional quantities Cp,max, Strouhal number and Cp,drop, all exhibit the same behavior, i.e. are almost constant irrespective the Re number for the same value of BR. This constant value is an increasing function of BR and could be estimated by averaging for various Re (for example from Figures 15(a), 15(b) and 16 for Cp,max, Strouhal number and Cp,drop, respectively).

Figure 26(a) presents the variation of the Re-averaged values of Cp,max, St and Cp,drop versus BR. It can be clearly seen that the increase in BR increases all these three quantities. However, the rate of increase in Cp,max is greater than that of Cp,drop, which again dictates that appropriate increase in BR may be an efficient way to enhance the vortex shedding effect on the piezoelectric membrane.

Figure 26(b) shows plot of the ratio Δpmax / ΔpS, i.e. pressure fluctuation amplitude at P5 to pressure fluctuation amplitude at the center S of the diaphragm, versus Reynolds number, for various values of BR. This ratio slightly decreases with Reynolds and for each Re it increases with BR.

Figure 26(c) shows plot of the ratio Δpmax / Δpdrop, i.e. maximum pressure amplitude at P5 to the average channel pressure drop, versus Reynolds, for various blockage ratios. This ratio seems also to be independent the Reynolds number and be an increasing function of BR.

Figure 26(d) presents the Re-averaged value for the two above presented pressure ratios for each value of BR. The following information that could be extracted from this figure:

Δpmax is, over the BR range, from 1.3 to 2.6 times the value of ΔpS (about double in average) and the same is valid for Δpdrop. This means that if the diaphragm was positioned with its center at S at point P5, the achieved pressure amplitude could be multiplied by the corresponding ratio (greater than 100% increase).

The value of Δpdrop is of the order of that of ΔpS and definitely lower than Δpmax.

Based on the above statements and according to

Figure 20, the greater the BR, the greater the enhancement of Δp

S, for BR values lower than the critical one. In particular, for a 44.4% increase of BR (from the baseline value 0.27 to 0.39), the increase in ΔpS is about 125%. Furthermore, beyond the value of 0.42 that the authors in [

3] claim vortex suppression to take place, the increase in ΔpS is much more significant, i.e. for a 41% increase (from 0.39 to 0.55) the increase in ΔpS becomes about 167%. The value of Δp

S for the baseline case according to

Figure 9 and

Figure 20 is Δp

S=252kPa. By further considering the above claim (

Figure 27(d)) that Δp

max~1.5Δp

S (using a moderate estimation), it is concluded that for BR=0.55, a value of about (252)(1.67)(1.5)=631.3kPa could be attained if the center of the membrane was placed at point P5. However, this case corresponds to Re=12473 which is outside the range studied in

Figure 13(b). Furthermore, experimental validation of these important statements becomes absolutely necessary. Anyway, according to all the above, there is evidence that the relevant research field is fruitful and open to further research.

5.3. Future Research

In view of the above, aiming to further develop research on the study and design of flow energy piezoelectric harvesting micro-devices, the following directions are proposed for ongoing research and future work:

Study of the effect of the distance between the two bluff bodies on the device performance, since there is already experimental evidence [

13], that a greater distance between the bodies may lead to a greater pressure amplitude.

Study the device performance for a particular membrane and attempt to correlate maximum pressure fluctuation amplitude predicted by CFD with measured electric power from corresponding experiments, i.e. to extract the operational curve of the device.

To perform design optimization studies with respect to characteristic geometric quantities (location and distance between the two bodies, location of the diaphragm, channel blockage ratio, etc) for maximum performance. A stochastic-based approach can be implemented (e.g. genetic algorithms), which would utilize either the present CFD solver or any reduced order model of the phenomenon. The solution of a multiobjective problem could be sought, e.g. maximization of Δpmax with minimization of Δpdrop. Furthermore, this could be a constrained problem, e.g. by requiring the frequency to be near the resonant frequency of the membrane.

To model the phenomenon more accurately, like for example to compare 3D against 2D simulations and/or model membrane dynamics and consider fluid-structure interaction in the simulations.

Figure 1.

Miniature energy harvesting devise using two triangles in tandem (from [

3]): (

a) Configuration; (

b) Operational principle.

Figure 1.

Miniature energy harvesting devise using two triangles in tandem (from [

3]): (

a) Configuration; (

b) Operational principle.

Figure 2.

View of the computational flow domain used for the numerical simulations (not to scale).

Figure 2.

View of the computational flow domain used for the numerical simulations (not to scale).

Figure 3.

Positions P1, P2,…, P21 along the membrane.

Figure 3.

Positions P1, P2,…, P21 along the membrane.

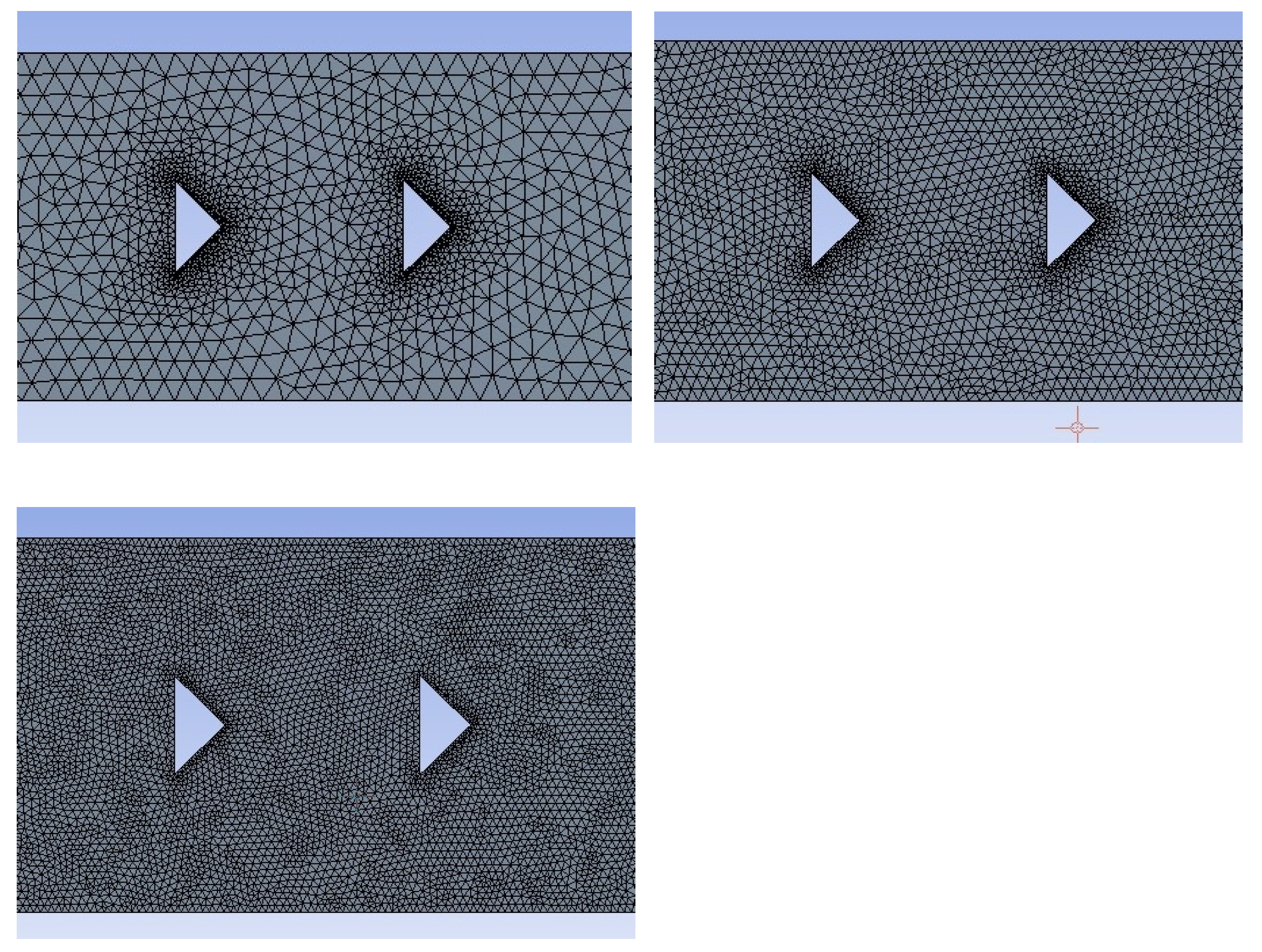

Figure 4.

Grids corresponding to mesh size values of 1mm (left), 0.5mm (middle) and 0.3mm (right).

Figure 4.

Grids corresponding to mesh size values of 1mm (left), 0.5mm (middle) and 0.3mm (right).

Figure 5.

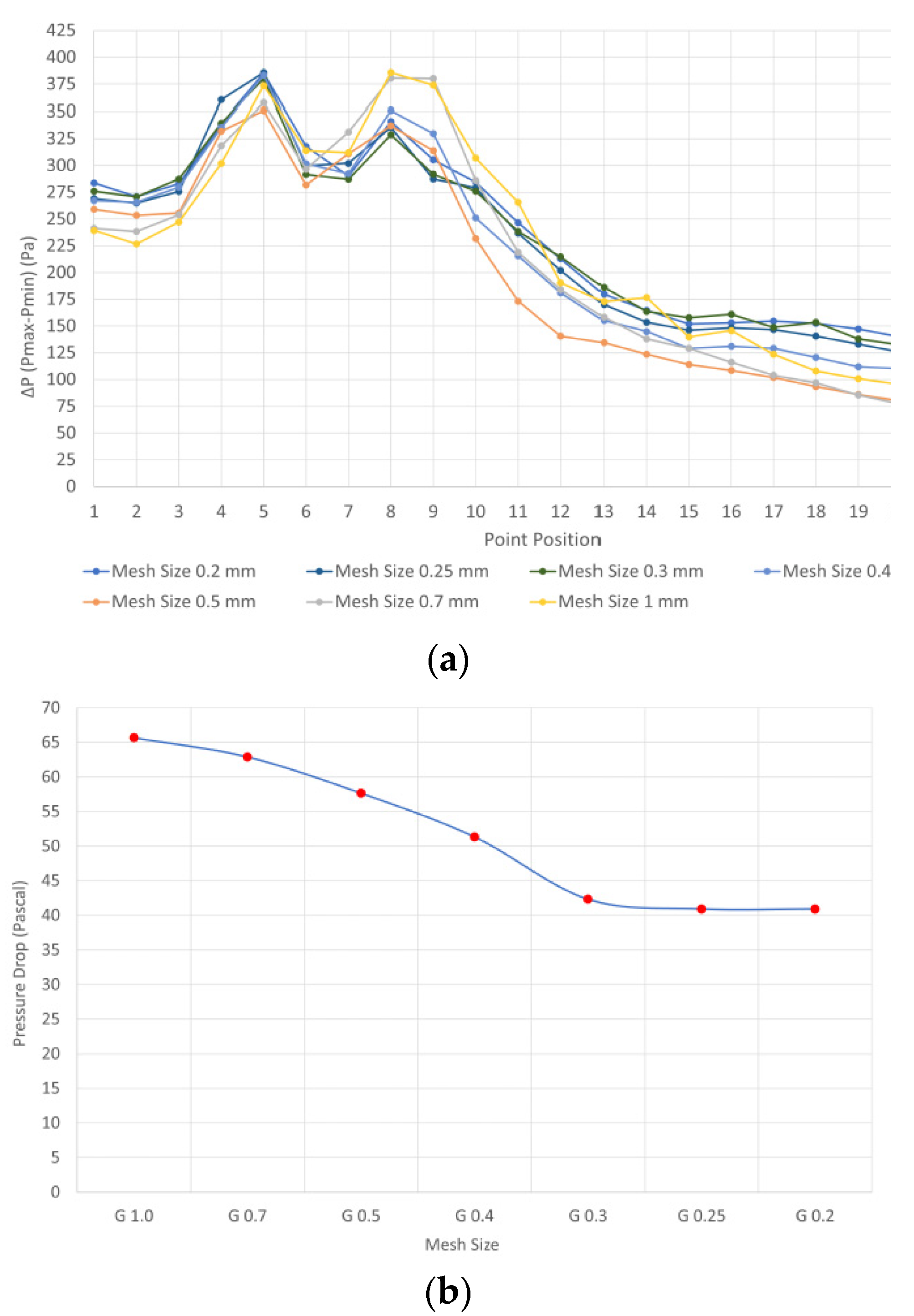

(a) Position of maximum pressure fluctuation amplitude along diaphragm for various grid sizes. (b) Average pressure drop predicted for various size grids.

Figure 5.

(a) Position of maximum pressure fluctuation amplitude along diaphragm for various grid sizes. (b) Average pressure drop predicted for various size grids.

Figure 6.

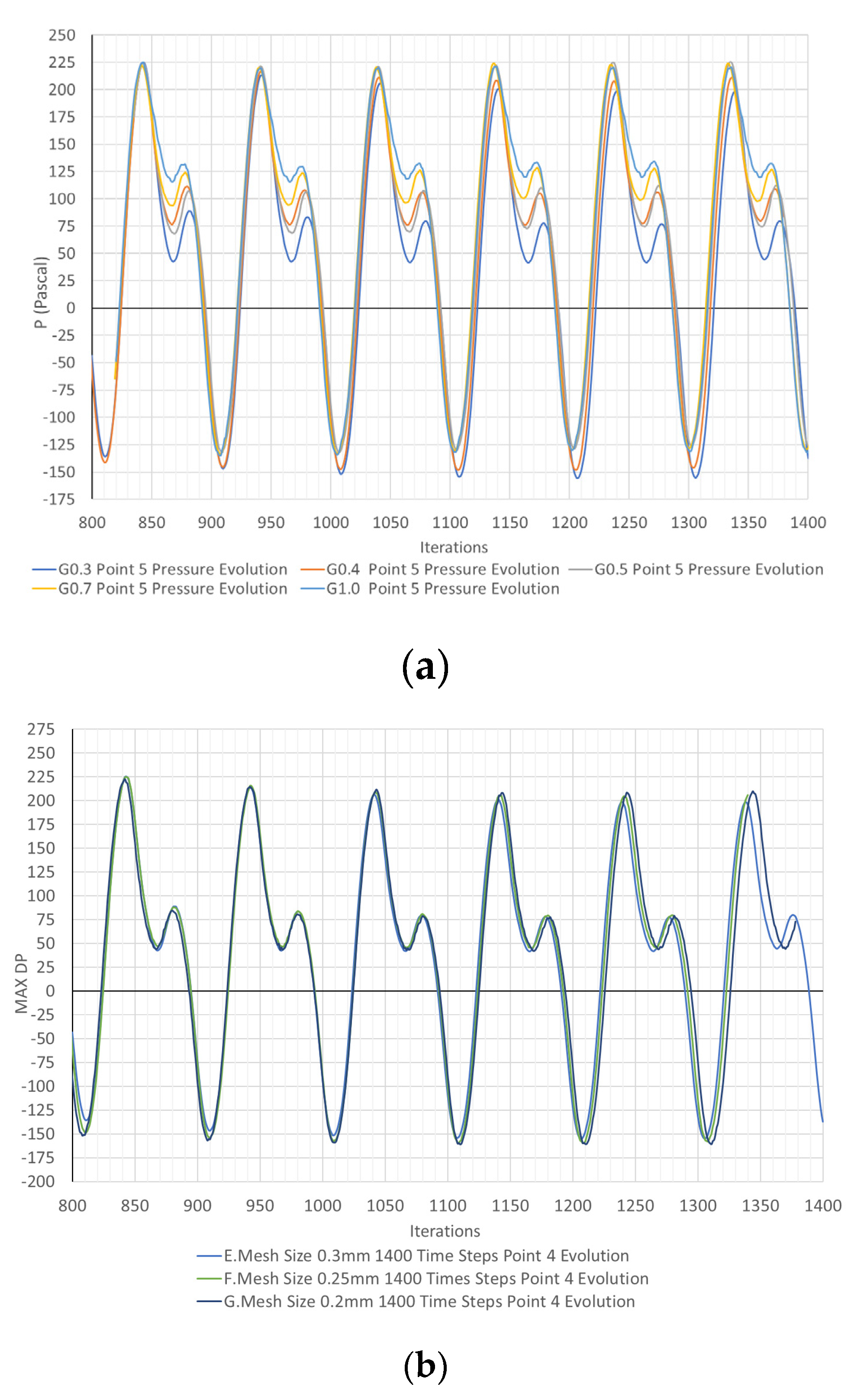

Local pressure evolution at point P5, for grids (a) G1.0 to G0.3 and (b) G0.3 to G0.2 .

Figure 6.

Local pressure evolution at point P5, for grids (a) G1.0 to G0.3 and (b) G0.3 to G0.2 .

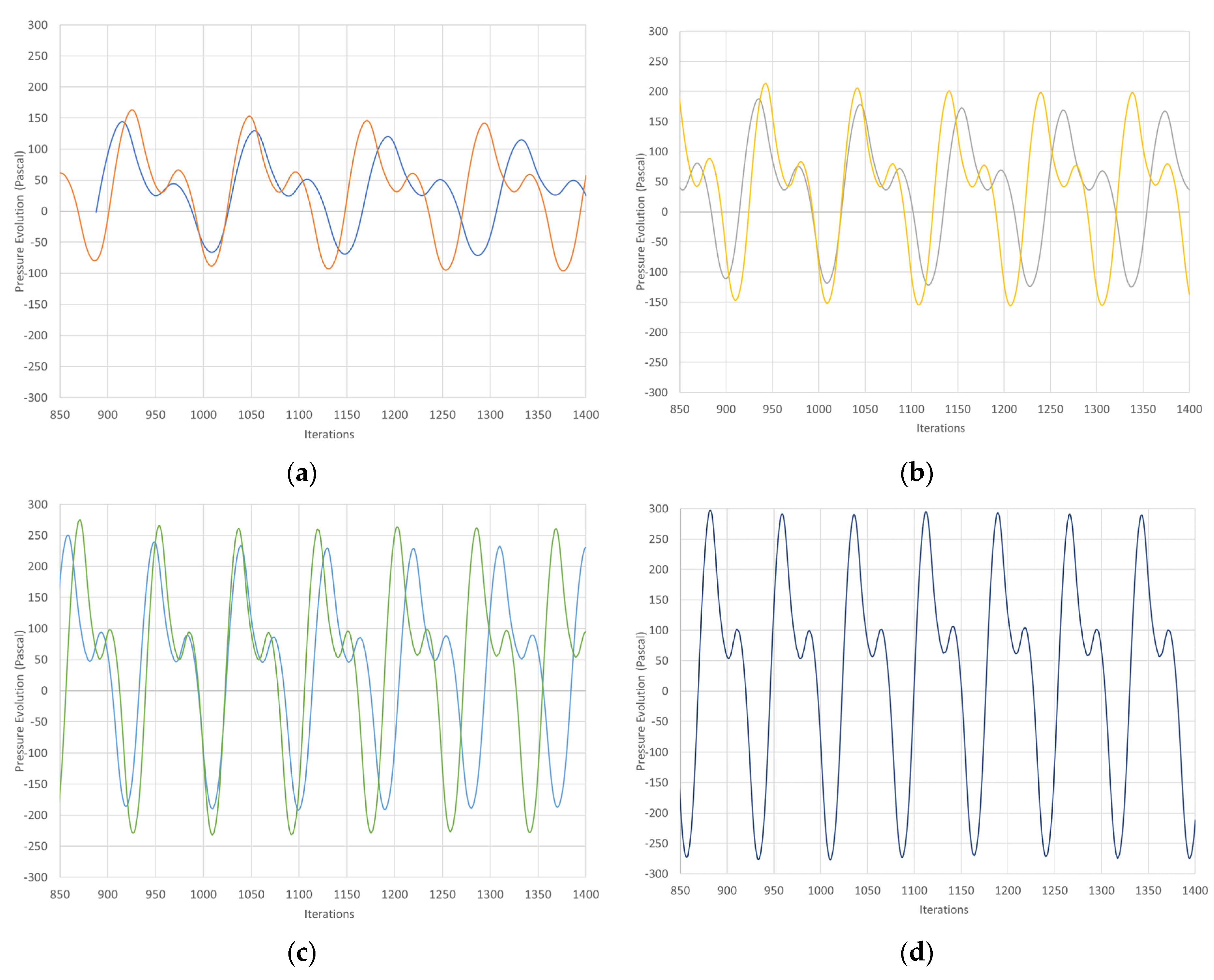

Figure 7.

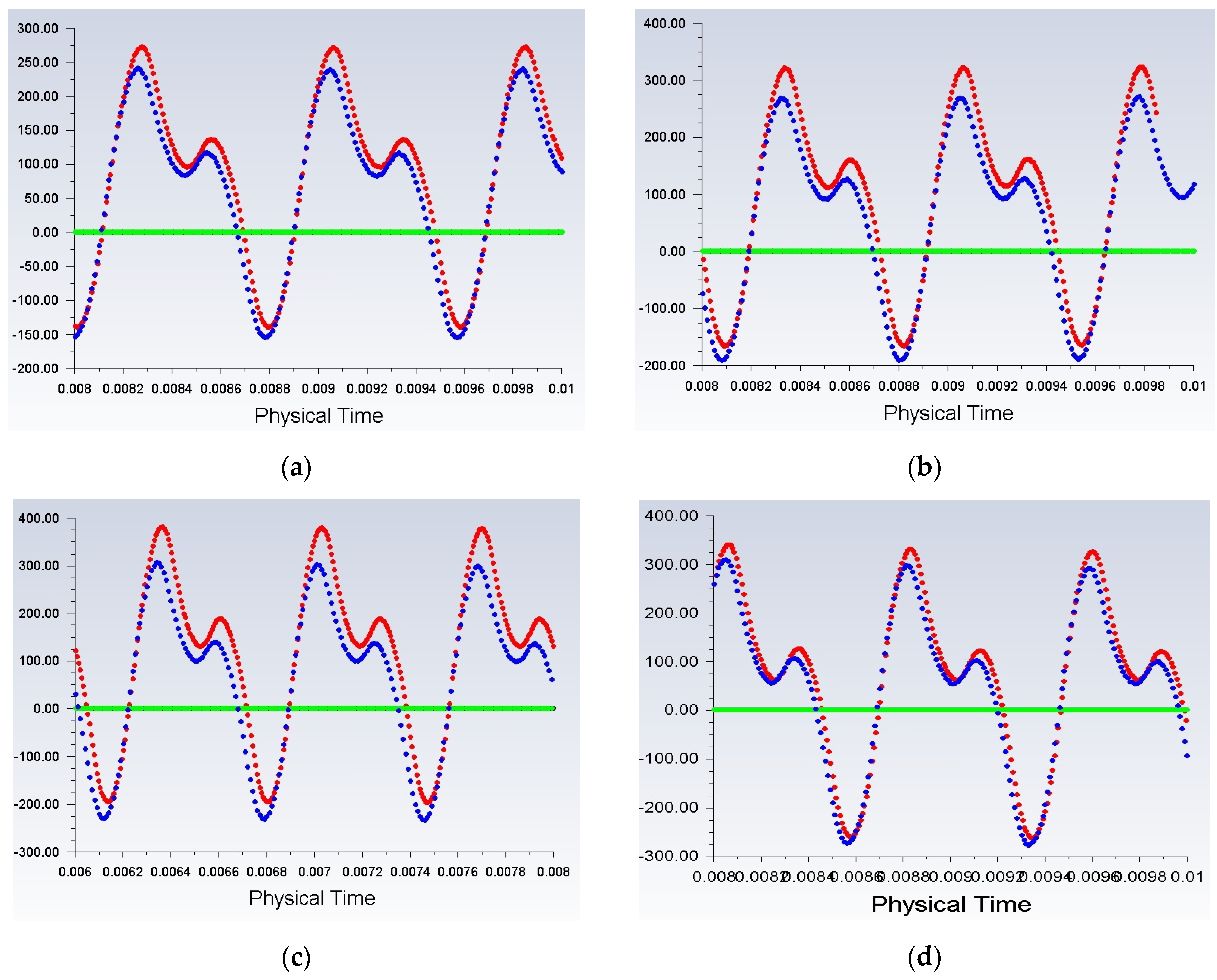

Pressure evolution at point P5 for cases (a) C5 with BR=0.24, (b) C6 with BR=0.24, (c) C7 with BR=0.24 and (d) C7 with BR=0.27. The blue curves correspond to results obtained with Δt=Δtbsl=10-5s, while the red ones to results obtained with Δt=Δtc<Δtbsl.

Figure 7.

Pressure evolution at point P5 for cases (a) C5 with BR=0.24, (b) C6 with BR=0.24, (c) C7 with BR=0.24 and (d) C7 with BR=0.27. The blue curves correspond to results obtained with Δt=Δtbsl=10-5s, while the red ones to results obtained with Δt=Δtc<Δtbsl.

Figure 8.

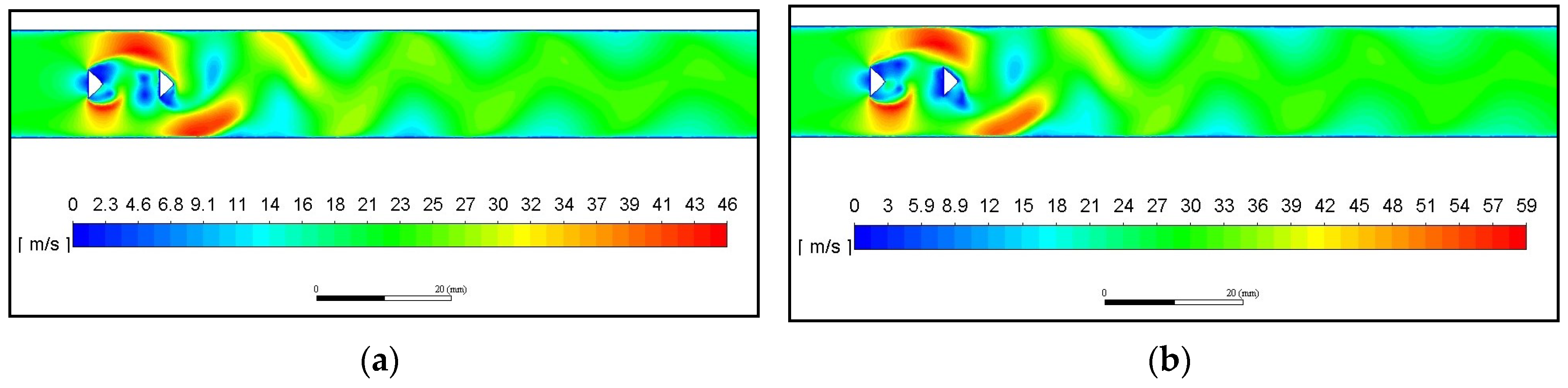

Iso-velocity contours predicted at 8ms in the baseline geometry (BR=0.27) for cases (a) C4 (Re=6024, Vin=20.7m/s) and (b) Re=7770 (Vin=26.7m/s).

Figure 8.

Iso-velocity contours predicted at 8ms in the baseline geometry (BR=0.27) for cases (a) C4 (Re=6024, Vin=20.7m/s) and (b) Re=7770 (Vin=26.7m/s).

Figure 9.

Pressure fluctuation amplitude versus distance from the beginning of the diaphragm for baseline geometry (BR=0.27) and various inlet velocities (Re).

Figure 9.

Pressure fluctuation amplitude versus distance from the beginning of the diaphragm for baseline geometry (BR=0.27) and various inlet velocities (Re).

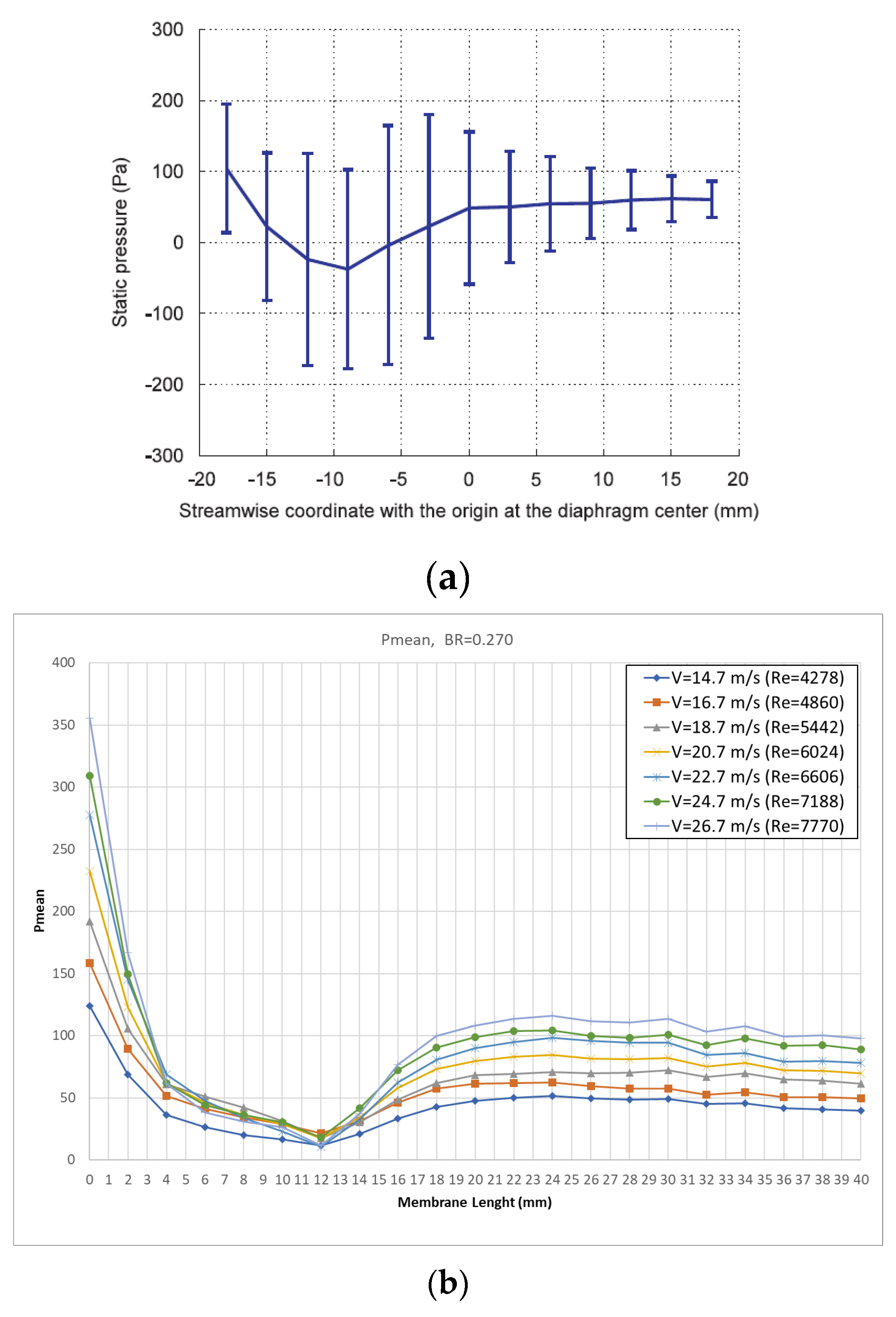

Figure 10.

(a) Pressure amplitude and mean pressure versus streamwise coordinate for the baseline case (from [

3]).

(b) Mean pressure versus distance from the beginning of diaphragm for baseline BR and various Re (present results).

Figure 10.

(a) Pressure amplitude and mean pressure versus streamwise coordinate for the baseline case (from [

3]).

(b) Mean pressure versus distance from the beginning of diaphragm for baseline BR and various Re (present results).

Figure 11.

Comparative pressure evolution for the baseline geometry at point P5 for cases (a) C1-C2, (b) C3-C4, (c) C5-C6 and (d) C7 (the same range has been used in the vertical axis).

Figure 11.

Comparative pressure evolution for the baseline geometry at point P5 for cases (a) C1-C2, (b) C3-C4, (c) C5-C6 and (d) C7 (the same range has been used in the vertical axis).

Figure 12.

(a) Pressure amplitude vs inlet velocity and (b) pressure amplitude coefficient vs Reynolds number.

Figure 12.

(a) Pressure amplitude vs inlet velocity and (b) pressure amplitude coefficient vs Reynolds number.

Figure 13.

(a) Frequency vs inlet velocity and (b) Strouhal vs Reynolds number, for various BR.

Figure 13.

(a) Frequency vs inlet velocity and (b) Strouhal vs Reynolds number, for various BR.

Figure 14.

(a) Average pressure drop vs inlet velocity and (b) average pressure drop coeffficent vs Re, for various values of BR.

Figure 14.

(a) Average pressure drop vs inlet velocity and (b) average pressure drop coeffficent vs Re, for various values of BR.

Figure 15.

(a) Pressure amplitude and (b) Strouhal number against BR for various Re.

Figure 15.

(a) Pressure amplitude and (b) Strouhal number against BR for various Re.

Figure 16.

Average pressure drop coefficient vs BR for various Re.

Figure 16.

Average pressure drop coefficient vs BR for various Re.

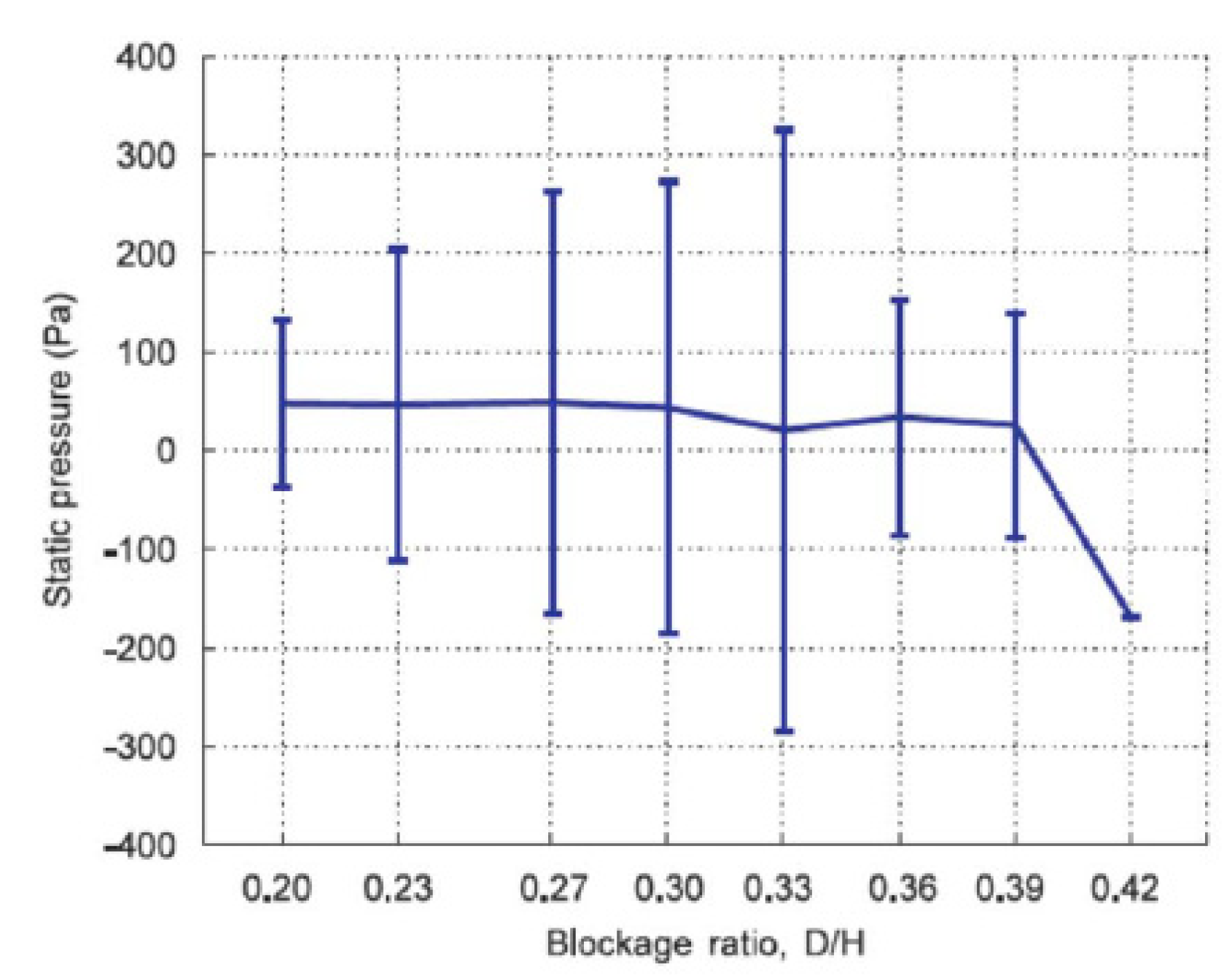

Figure 17.

Pressure mean value and amplitude at the center of the diaphragm vs BR (reproduced by [

3]).

Figure 17.

Pressure mean value and amplitude at the center of the diaphragm vs BR (reproduced by [

3]).

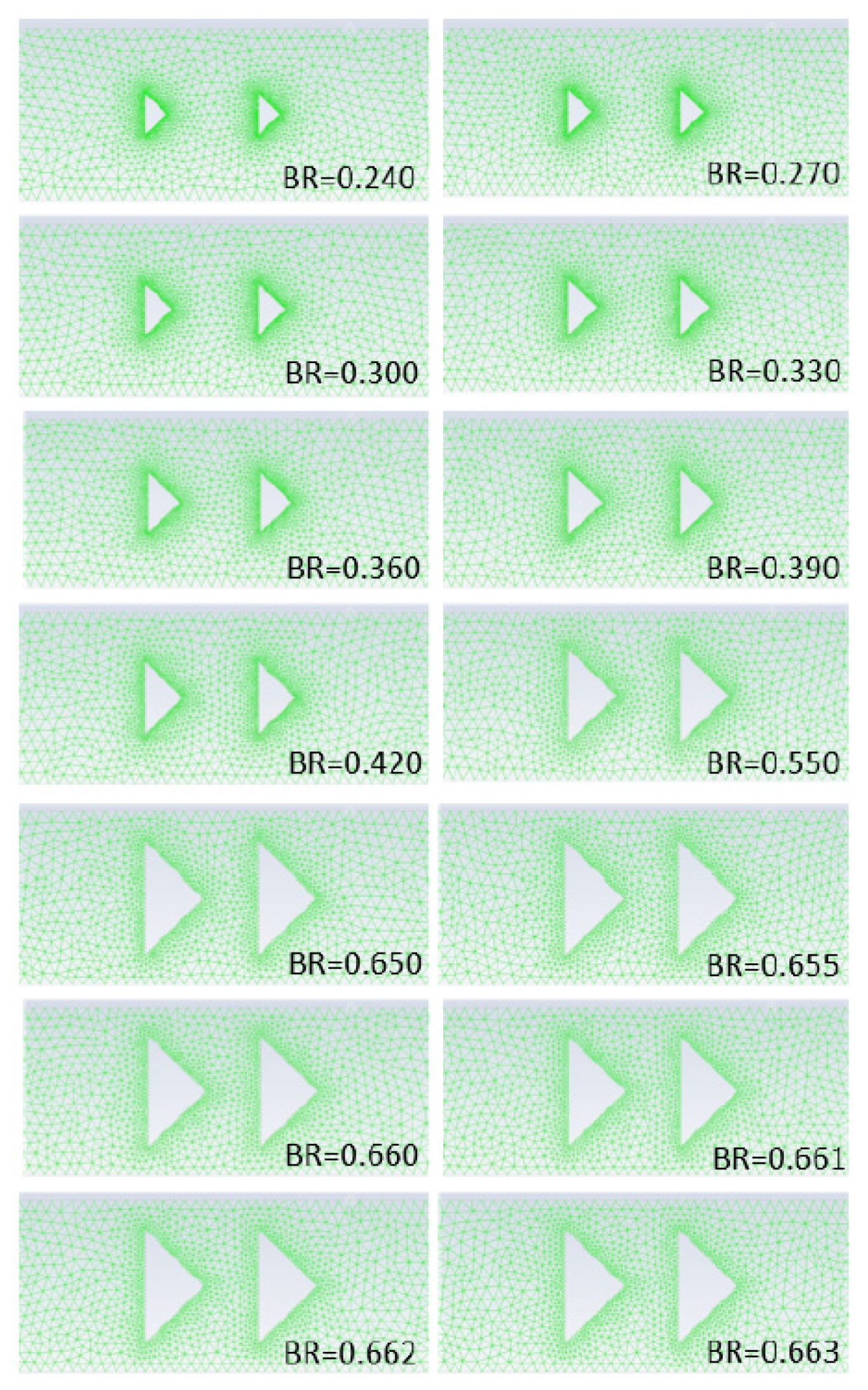

Figure 18.

Focused view of grids near the bluff bodies for various BR values in increasing order.

Figure 18.

Focused view of grids near the bluff bodies for various BR values in increasing order.

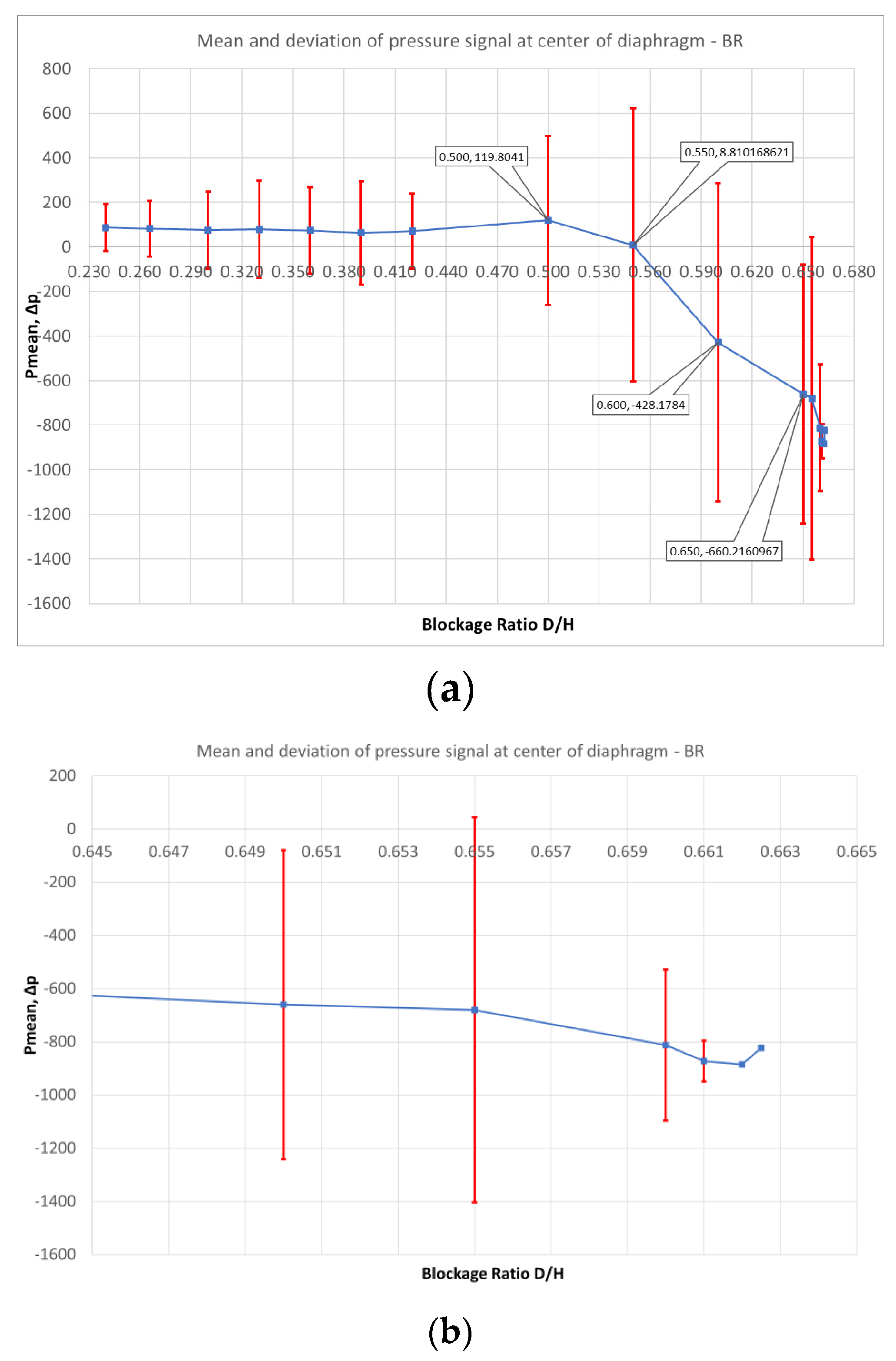

Figure 19.

(a) Mean value and amplitude of pressure at the center of the diaphragm vs BR by the present method. (b) Focused view in the range near the critical BR value.

Figure 19.

(a) Mean value and amplitude of pressure at the center of the diaphragm vs BR by the present method. (b) Focused view in the range near the critical BR value.

Figure 20.

Pressure amplitude on the center S of the diaphragm and average channel pressure drop as functions of BR for constant inlet velocity.

Figure 20.

Pressure amplitude on the center S of the diaphragm and average channel pressure drop as functions of BR for constant inlet velocity.

Figure 21.

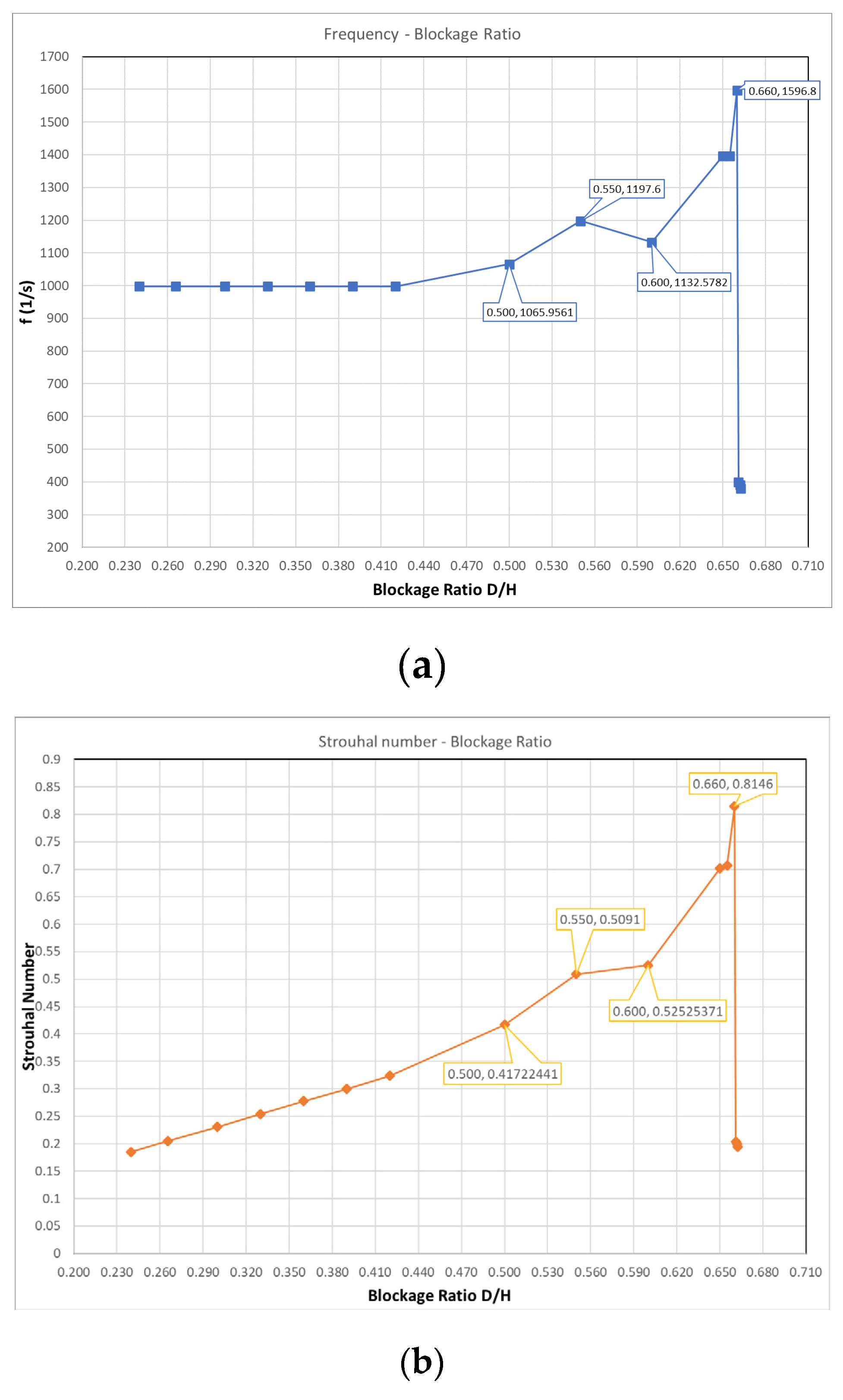

(a) Frequency and (b) Strouhal number of the pressure signal at the center of the diaphragm as functions of BR for constant inlet velocity.

Figure 21.

(a) Frequency and (b) Strouhal number of the pressure signal at the center of the diaphragm as functions of BR for constant inlet velocity.

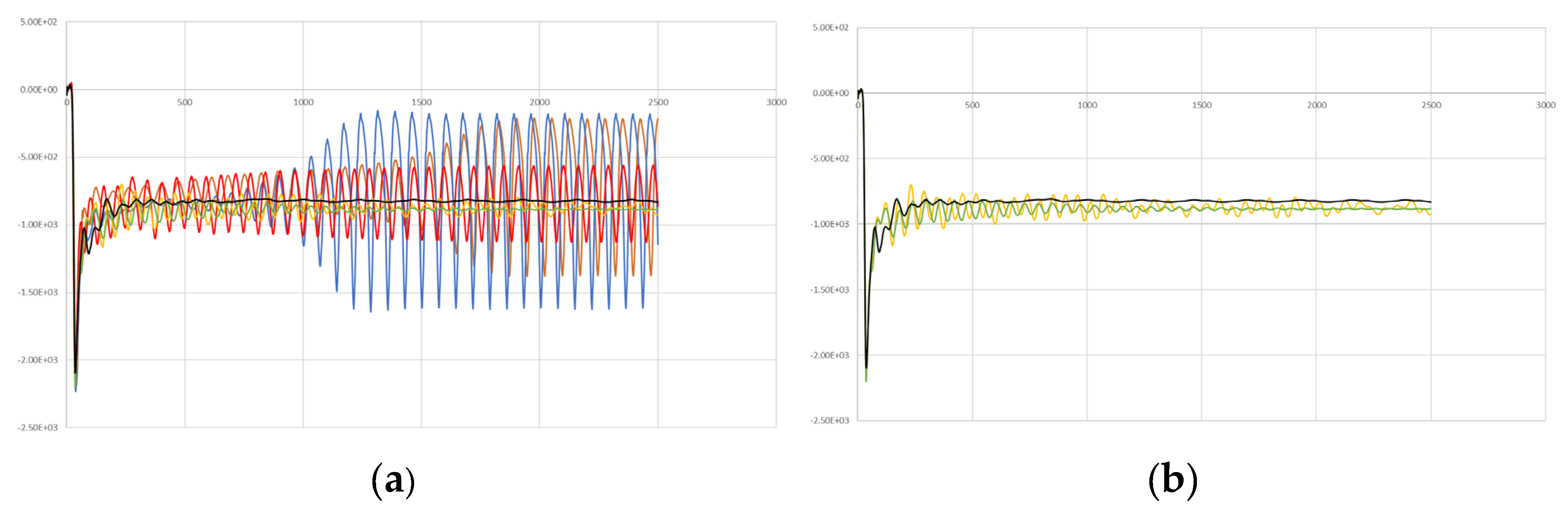

Figure 22.

Pressure signal at the center S of the diaphragm. (a) For values of BR=0.65, 0.655, 0.660, 0.661, 0.662, 0.663. (b) For values of BR=0.661, 0.662, 0.663.

Figure 22.

Pressure signal at the center S of the diaphragm. (a) For values of BR=0.65, 0.655, 0.660, 0.661, 0.662, 0.663. (b) For values of BR=0.661, 0.662, 0.663.

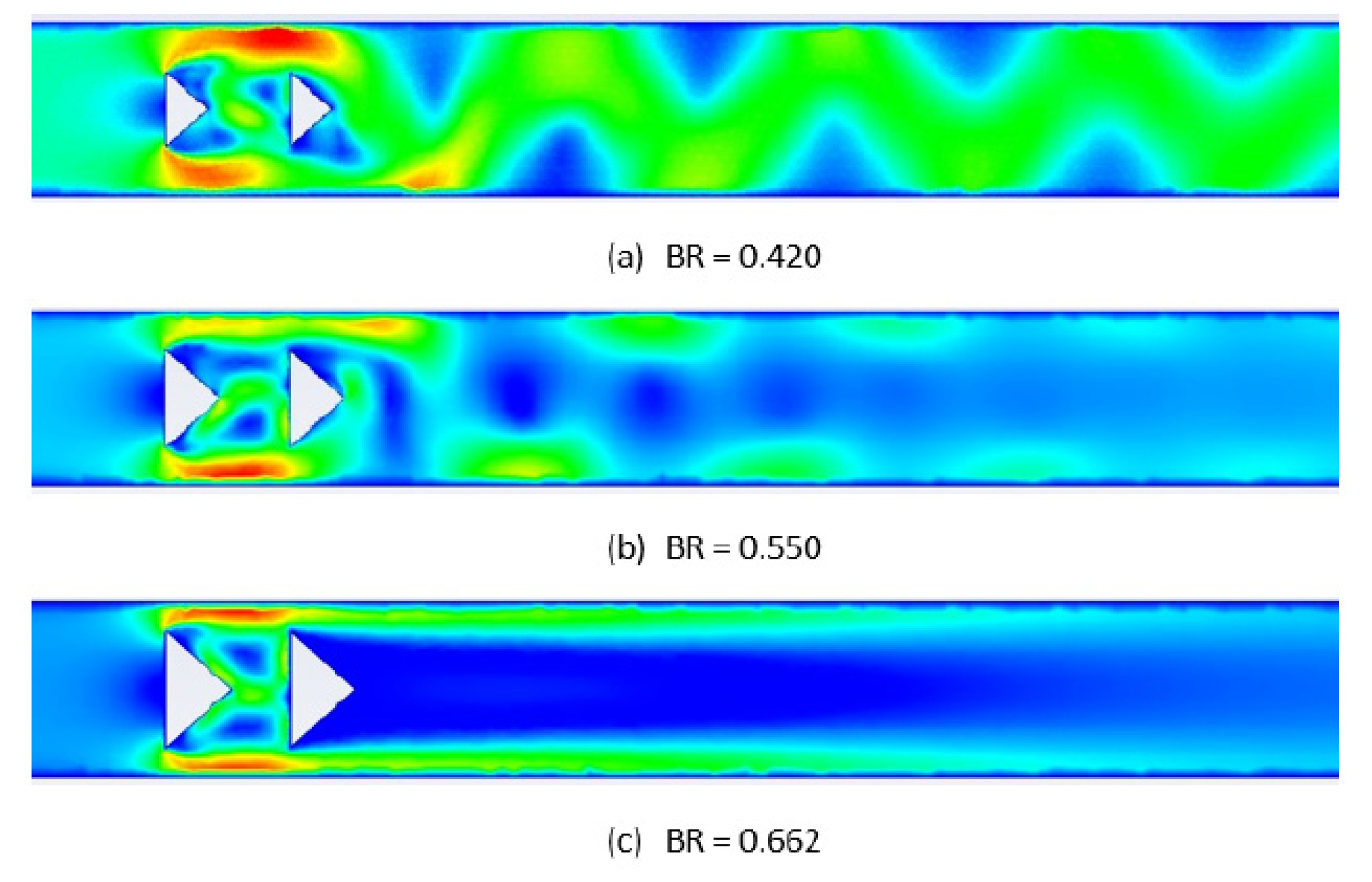

Figure 23.

Instant iso-surfaces of velocity 25ms after beginning the flow solution. Clearly vortex shedding seems to be suppressed for BR=0.662.

Figure 23.

Instant iso-surfaces of velocity 25ms after beginning the flow solution. Clearly vortex shedding seems to be suppressed for BR=0.662.

Figure 25.

Measured voltage in case with two bluff bodies for

(a) BR=0.27 and

(b) BR=0.55 [

14].

Figure 25.

Measured voltage in case with two bluff bodies for

(a) BR=0.27 and

(b) BR=0.55 [

14].

Figure 27.

(a) Re-averaged values of Cp,max, Strouhal and Cp,drop versus BR. (b) Ratio Δpmax / ΔpS versus Re for various BR. (c) Ratio Δpmax / Δpdrop versus Re for various BR. (d) Re-averaged values of Δpmax / ΔpS and Δpmax / Δpdrop versus BR.

Figure 27.

(a) Re-averaged values of Cp,max, Strouhal and Cp,drop versus BR. (b) Ratio Δpmax / ΔpS versus Re for various BR. (c) Ratio Δpmax / Δpdrop versus Re for various BR. (d) Re-averaged values of Δpmax / ΔpS and Δpmax / Δpdrop versus BR.

Table 1.

Inlet velocity used for the various Reynolds numbers and blockage ratios (data for baseline case are in bold).

Table 1.

Inlet velocity used for the various Reynolds numbers and blockage ratios (data for baseline case are in bold).

| Case |

C1 |

C2 |

C3 |

C4 |

C5 |

C6 |

C7 |

|

| Re |

4278 |

4860 |

5442 |

6024 |

6606 |

7188 |

7770 |

BR |

| |

16.3 |

18.5 |

20.7 |

22.9 |

25.1 |

27.3 |

29.6 |

0.24 |

| |

14.7 |

16.7 |

18.7 |

20.7 |

22.7 |

24.7 |

26.7 |

0.27 |

| |

13.0 |

14.8 |

16.6 |

18.3 |

20.1 |

21.9 |

23.6 |

0.30 |

| Vin (m/s) |

11.8 |

13.4 |

15.1 |

16.7 |

18.3 |

19.9 |

21.5 |

0.33 |

| |

10.8 |

12.3 |

13.8 |

15.3 |

16.7 |

18.2 |

19.7 |

0.36 |

| |

10.0 |

11.4 |

12.7 |

14.1 |

15.5 |

16.8 |

18.2 |

0.39 |

| |

9.3 |

10.6 |

11.8 |

13.1 |

14.4 |

15.6 |

16.9 |

0.42 |

Table 2.

Mesh sizes used in the grid independence study.

Table 2.

Mesh sizes used in the grid independence study.

| Name |

G1.0

|

G0.7

|

G0.5

|

G0.4

|

G0.3

|

G0.25

|

G0.2

|

| Mesh size (mm) |

1.00 |

0.70 |

0.50 |

0.40 |

0.30 |

0.25 |

0.20 |

| # Nodes |

6415 |

12623 |

21433 |

30490 |

56529 |

87216 |

105783 |

| # Elements |

12086 |

24230 |

41491 |

59288 |

110840 |

171737 |

208238 |