3.2. Structural aspects of the hydrothermal synthesis of SrZr1-xTixO3 and SrTi1-xZrxO3 SS

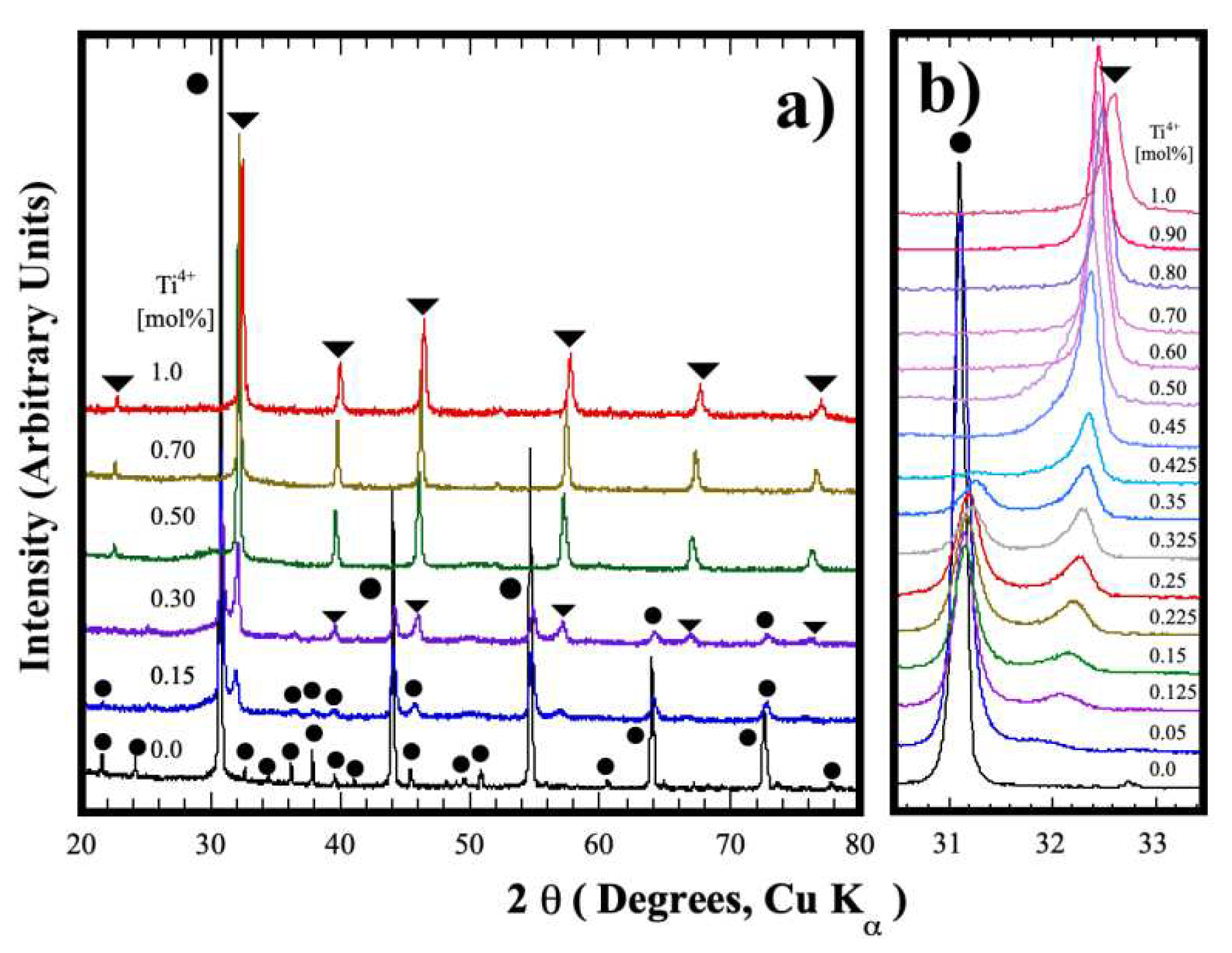

Figure 3 shows the typical XRD patterns of selected powders produced under hydrothermal conditions at 200 °C for 4 h under constant stirring (130 rpm), varying the content of Ti

4+ in the mixture. Generally, the single-step chemical reaction between the SrSO

4 and the pasty gels is enhanced under stirring conditions, triggering the formation of a fine white powder, as confirmed in all treatments by naked-eye observations. When the Zr-gel was solely used as a precursor of the tetravalent metal perovskite, the peaks in the XRD pattern were indexed by those of the SrZrO

3 perovskite with orthorhombic structure (ICDD 70-0283 space group

Pbnm,

Figure 3a). On the contrary, at Ti

4+ contents over 10.0 mol%, new peaks located at 2θ angles of 32.25°, 39.7°, 45.8° and 56.9° were determined in the PXRD pattern, as seen in

Figure 3a. To determine the formation pathway of the new compound, experiments were conducted with a Ti

4+ compositional span variation of 2.5 mol% Ti

4+. The new phase was formed under alkaline hydrothermal conditions in the Ti

4+ compositional range between 7.5 and 47.5 mol% Ti

4+, as depicted by the signal that appeared at 32.25° 2θ angle (see

Figure 3b). It deserves emphasising that this peak exhibited a gradual shift toward higher 2θ angles coupled with peak intensity increment. These crystalline structural features are likely due to the Ti

4+ gradual incorporation into the crystalline structure, and its bulk content produced over 7.5 mol% Ti

4+ contents in the reaction media. Simultaneously, the central peak corresponding to the orthorhombic structured SrZrO

3:Ti

4+ (SS1) did not exhibit further compositional variations because it remained at a mean 2θ angle of 31.09°. Therefore, these results suggest that the chemical composition of this solid solution is SrZr

0.925Ti

0.075O

3. However, the content of this stable phase was proportionally reduced by increasing the Ti

4+ amount, as indicated by the progressive reduction of the orthorhombic phase peaks in the PXRD pattern (

Figure 3a). Above 50.0 mol% Ti

4+ peaks corresponding to a new secondary SS2 phase were obtained. Based on these structural results, we infer that the crystalline structure of the SS2 single-phase can be indexed with the cubic structured SrTiO

3 perovskite (space group

Pm3m, ICDD card no. 40-1500) because it agrees with the peaks distribution of the SrTiO

3 single pattern. These results depict that the cubic perovskite SS2 crystalline phase is chemically stable under hydrothermal conditions in the compositional range of 7.5–100.0 mol% Ti

4+. In addition, the powder crystallised without contaminant by-products, namely SrCO

3, which is predominantly formed due to its low solubility in alkaline solutions [

22]. Furthermore, a steady-state chemical reaction involving the solute saturation of the hydrothermal media is likely to proceed and trigger the simultaneous crystallisation of both crystalline compounds under fluid stirring [

23].

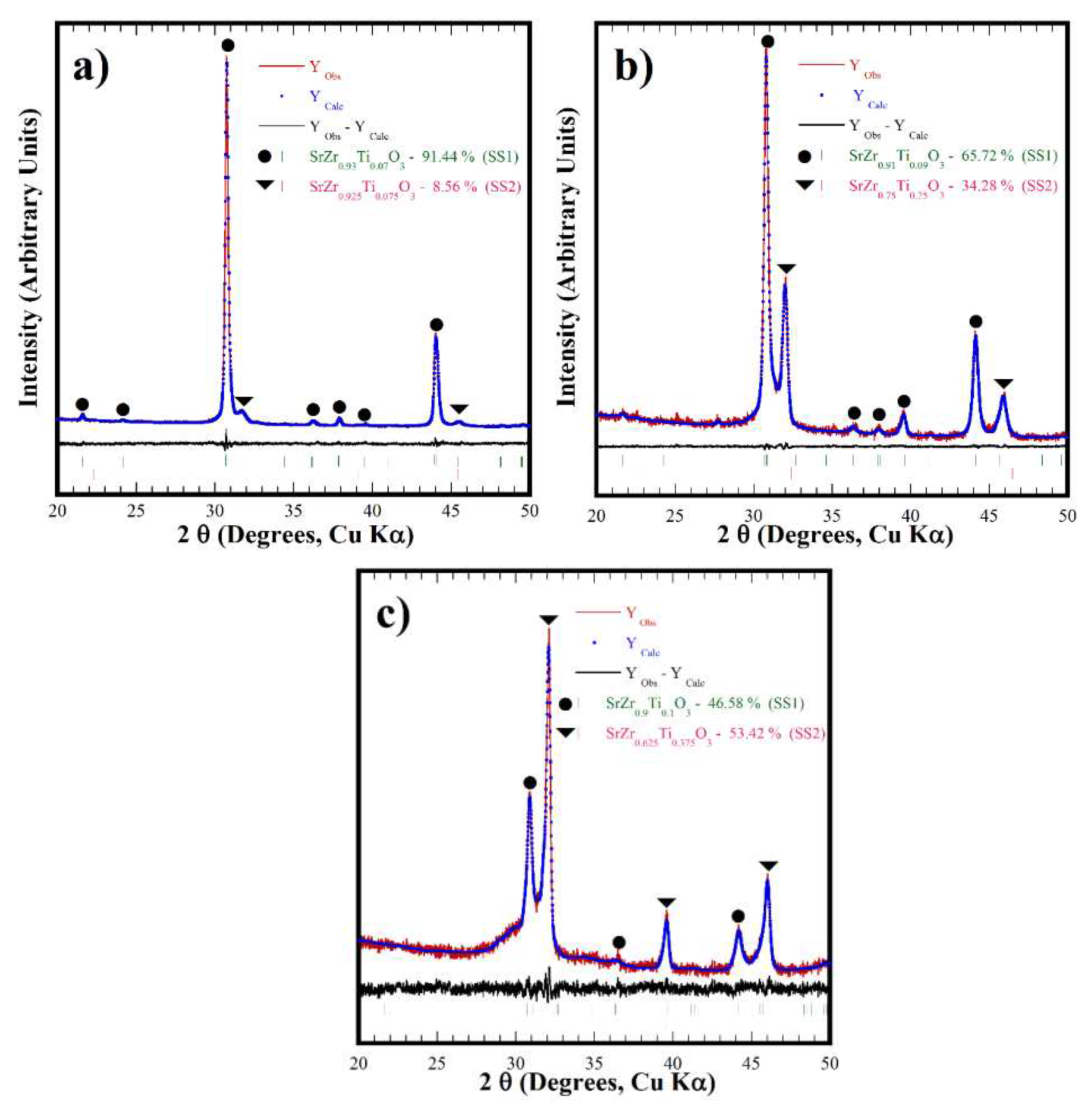

The compositional variation suggested by the PXRD analyses was observed in the SS2 phase. Stoichiometric computation was carried out to determine the Ti

4+ content incorporated in the cubic perovskite secondary SS2 phase and into the orthorhombic SS1; this procedure considered the nominal Ti

4+ molar content added as a raw material. Likewise, the fraction of each solid solution that constitutes the ultimate powder produced was calculated by the expression [(1-x)SS1 + xSS2′] = 1, which depicts the quantitative variation in the phase content revealed by the diffraction patterns of

Figure 3b. The typical Rietveld refined plots that correlate the quantitative stoichiometric computation abovementioned are shown in

Figure 4. Interestingly, a minimal variation of the residual difference was also revealed in those samples exhibiting the formation of SS1 and SS2 perovskite phases. These results show that the calculated Zr

4+:Ti

4+ stoichiometric contents in the orthorhombic and cubic phases with

Pbnm and

Pm3m space groups highly fitted the atomic occupation in the Rietveld refinement algorithm. The algorithm ultimately computed the fraction content of each perovskite phase in the powder sample prepared with nominal molar Zr

4+:Ti

4+ ratios of (a) 92.5:7.5 (b) 75.0:25.0 and (c) 62.5:37.5, as it can be seen in

Figure 4. Furthermore, the structural crystalline refinement approach also considered other fitting parameters such as background, thermal isotropy, lattice parameters, scale factor, profile half-width, crystallite size and local strain; the details regarding the atomic Wyckoff elemental spatial distribution are given in the supplementary supporting information file, which includes Table S1 that summarises the results of the crystalline structural refinement. This approach was adequate to fit the structural differences of the reaction products obtained after the hydrothermal reaction, which is depicted by both the low mean values of the goodness-of-fit factor (GOF, mean χ

2 value of 3.48%) and

Rwp = 3.26. It deserves to emphasise that the analyses confirmed that the orthorhombic and cubic crystalline perovskite particles were simultaneously formed under hydrothermal conditions employing the highly soluble SrSO

4 powder and the mixture of Zr

4+ and Ti

4+ gels.

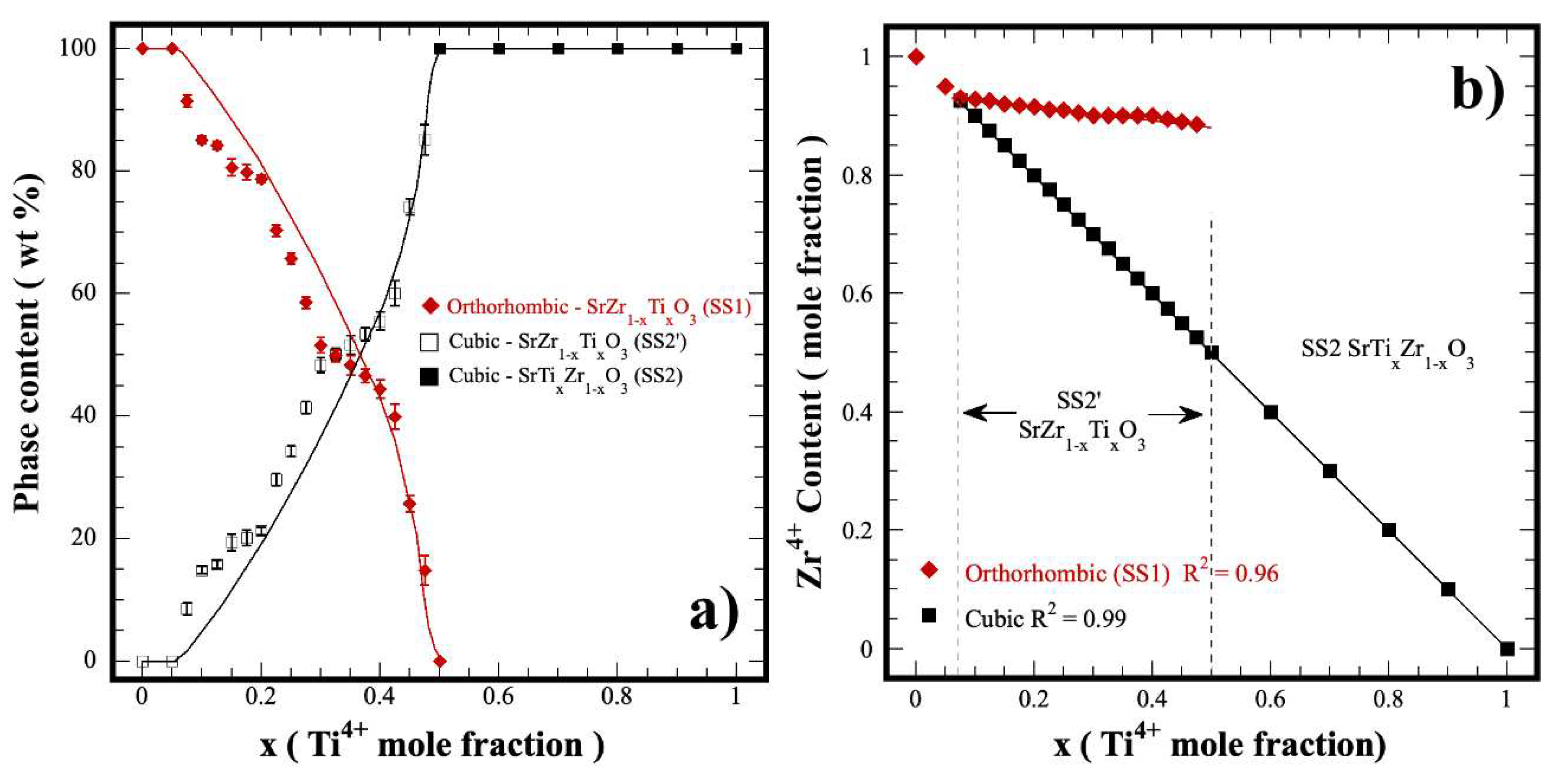

The variation in the content of both orthorhombic and cubic structured solid solutions, which were hydrothermally produced within the whole compositional range of the binary system SrZrO

3-SrTiO

3; using a KOH 5 M solution, is portrayed in

Figure 5a. Generally, the formation of the new cubic perovskite phase (SS2′) occurred in the compositional range between 7.5 mol% and 47.5 mol% Ti

4+. The quantitative analyses conducted on the nominal stoichiometric tetravalent metal compositions depict that the new cubic SS2′ phase reach in Zr

4+ (SrZr

1-xTi

xO

3) exhibited a marked increase in its content when the Ti

4+ concentration increased progressively in the solvent fluid. Interestingly, the variation in the bulk content of this phase likely resembles a typical sigmoidal kinetic behaviour. On the contrary, the residual content of the hydrothermally crystallised orthorhombic phase (SS1) powder proportionally decreased following a reverse sigmoidal behaviour. The simultaneous crystallisation of both perovskite phases is likely triggered under hydrothermal conditions because the continuous gel dehydration promotes a cooperative reaction steady state; thereby, a constant increase in the Ti

4+ mass gradient provoked a rise in the cubic SS2′ single phase amount. This inference is supported by the fact that the Zr

4+ atomic ratio in the SS2’ cubic phase exhibited a linear decrease, proportional to the rise of the Ti

4+ content, as seen in

Figure 5b.

Furthermore, the orthorhombic SS1 phase showed a slight reduction of 4.0 mol % in the amount of Zr4+ within the compositional range where both crystalline phases coexist in the binary system SrZrO3-SrTiO3. According to these compositional results, three chemical reaction equilibria drive the crystallisation of chemically stable perovskite SS in the hydrothermal system studied. These are included in the supplementary supporting information file.

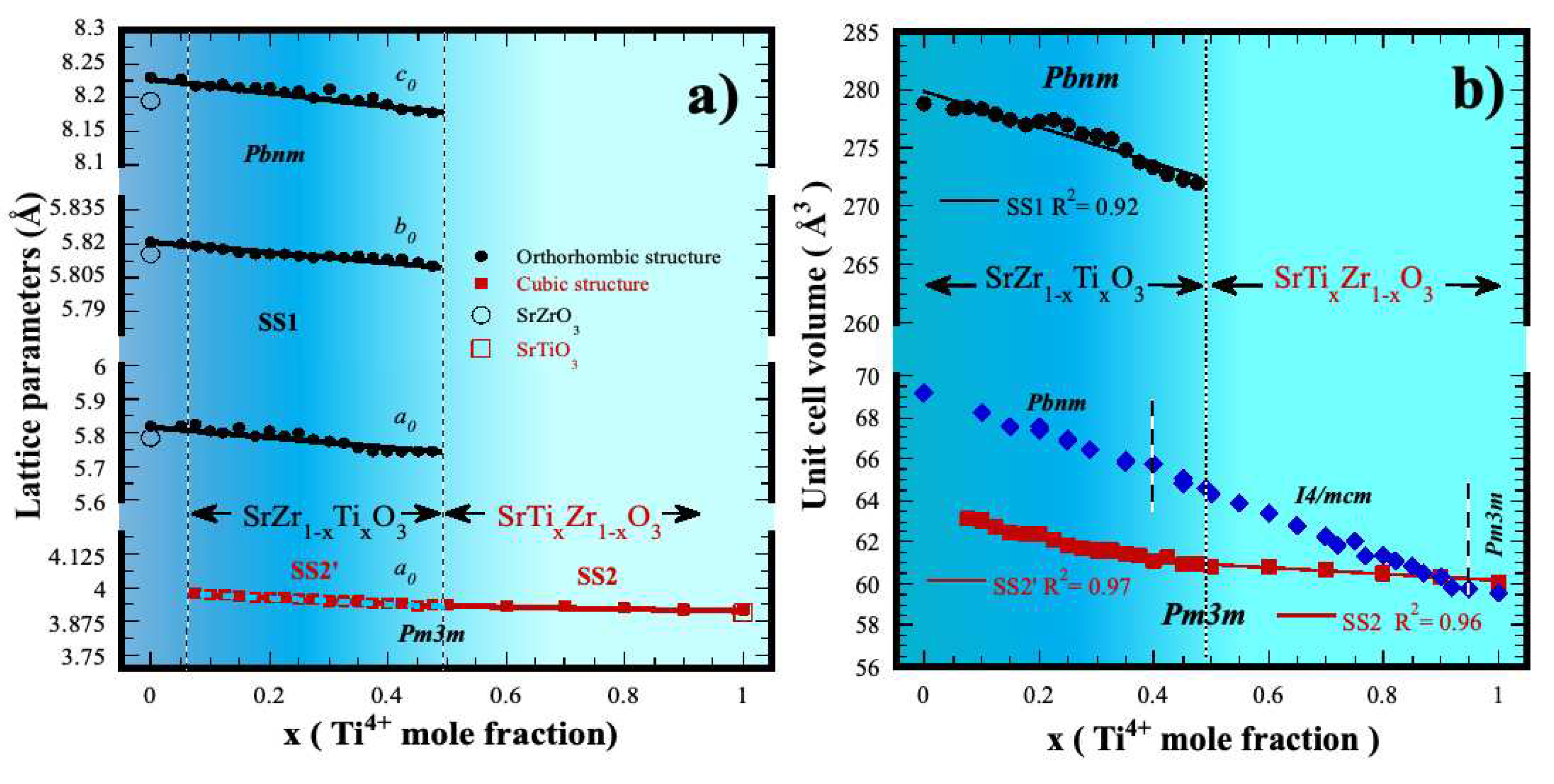

Additionally, details on the crystalline unit cell, lattice parameters and volume cell, corresponding to the perovskite solid solutions, which were produced under hydrothermal conditions in a 5 M KOH solution at 200 °C for 4 h with a constant stirring speed of 130 rpm, are portrayed in the graphs in

Figure 6. Generally, the lattice constants corresponding to the end members of the perovskite binary system SrZrO

3-SrTiO

3 are slightly higher in comparison with the values reported in Table S3 (SSFI) for the same compounds. Meanwhile, a marked continuous decrease of ‘‘

a0”, “

b0”, and “

c0” parameters was determined in the orthorhombic solid solution (SS1, ●), with

Pbnm space group, by increasing the Ti

4+ content uptake in the resulting crystalline particles, as seen in

Figure 6a. Likewise, the “

a0” lattice parameter corresponding to the new cubic SS2′ and SS2 (

■) constituents (space group

Pm3m) exhibited a linear decrease within the Ti

4+ compositional variation, which occurred within the ranges of 7.5 ≥ x ≤ 50.0 mol% Ti

4+ and 50.0 ≥ x ≤ 100.0 mol% Ti

4+, as seen in

Figure 6a. In both cases, the variation determined for lattice parameter values of either orthorhombic or cubic perovskite structures agree with the systematic peak displacement determined in the X-ray results shown in

Figure 3. Interestingly, all the lattice constants calculated exhibited a linear variation, which is depicted by the mean data dispersion coefficient R

2 that varied between 0.912 and 0.987. This behaviour indicates a linear dependence of the structural parameters occurred by incorporating Ti

4+ content in the orthorhombic and cubic structured perovskite compound produced under hydrothermal conditions. Furthermore, the linear variation of the lattice parameters agrees with Vegard’s law, despite two simultaneous perovskite-related compounds crystallising within the compositional range of 7.5 ≥ x ≤ 50.0 Ti

4+ mol%. Therefore, in the context of the chemical composition, the processing approach investigated is devoted to determining the chemical reaction pathway related to the formation of stable perovskite solid solution compounds in the binary system SrZrO

3-SrTiO

3; the results suggest that a steady-state single-step reaction is triggered under stirring hydrothermal condition, preferentially crystallise two solid solutions at the B site of the perovskite SrZr

1-xTiO

3 with orthorhombic and cubic structures. The reaction pathway is likely controlled by the tetravalent metal gel dehydration process inherent to the proposed system.

In addition, a similar trend was observed for the lattice constants variation for the unit cell volume of the perovskite solid solutions. These values are portrayed in the plot shown in

Figure 6b, and this plot also includes the unit cell volume values calculated for the SrTi

xZr

1-xO

3 (solid

♦ symbol) solid solutions prepared at 1400 °C for 96 h [

8]; these data were included for comparison purposes. Some data are likely similar to those determined in our case, namely at Ti

4+ contents above ≤ 90.0 mol%. The authors demonstrate that the formation of stable solid solution preferentially occurs within the entire compositional range of the system SrZrO

3-SrTiO

3, as depicted by the data plotted in

Figure 6b. Exhaustive crystalline structural analyses conducted by neutron and synchrotron diffraction confirmed the dependence of the SS´s composition with the crystalline structural transformations, which leads to obtaining orthorhombic, tetragonal and cubic structures stable at specific Ti

4+ contents incorporated into the SS SrTi

xZr

1-xO

3. Superlattice reflections revealed near 2θ = 33 and 41° (021 and 122/212 Miller indexes) corresponding to the orthorhombic structure were detected up to 40.0 mol% Ti

4+; above this content, tetragonal structure predominates as sole phase produced at high temperature, the new reflection at 2θ ≈ 40° (121) confirmed the formation of SrTi

xZr

1-xO

3 SS that belongs to this structure, which predominates at the highest Ti

4+ content of 90.0 mol% at low temperature [

8].

Interestingly, the PXRD analyses conducted on the hydrothermally prepared specimens with Ti

4+ contents between 7.5 mol% and 90.0 mol% did not reveal the superlattice peaks associated with the perovskite tetragonal structure, despite the observation of a similar variation trend on the unit cell volume of both reaction products with orthorhombic and cubic structures prepared here, compared with the continuous solid solutions obtained via solid-state reaction at high temperature [

8]. We infer from these results that the Ti-gel dehydration yield plays an essential role in achieving a steady-state chemical reaction, which enhances a specific solute supersaturation stage that causes the simultaneous crystallisation of both phases. This process proceeds faster than the solid-state reaction producing a broad compositional series of solid solutions in the system SrZrO

3–SrTiO

3 [

8].

On the other hand, according to the crystalline structural results calculated by Rietveld refinement given in the Table S3 of the SSI file, the minor structural differences revealed on the unit cell parameters in both perovskite compounds (orthorhombic and cubic) are caused by the variation in the Sr-O, Ti-O and Zr-O bond lengths. A systematic increase in the Ti-O bond length proportionally occurred by decreasing the Ti

4+ content incorporated into the octahedral BO

6 site in the cubic structured SS2, in the compositional range of 7.5 ≤ x ≤ 90 mol% Ti

4+. Similarly, the Sr-O bond length is considerably affected, reaching a maximum value of 2.822 Å, which is remarkably more extensive than that for the cubic structured SrTiO

3 single phase (2.769 (1) Å, as seen in Table S3). From these results, we surmise that this structural phenomenon maintains the cubic structured solid solution thermodynamically stable at low contents of Ti

4+ below 50.0 mol%. This inference is supported by the fact that under solid-state reaction conditions, a series of intermediate tetragonal structured solid solutions were successfully formed in a shorter range of Ti

4+ (40.0 ≤ x ≤ 90.0 mol% Ti

4+). It deserves to emphasise that the tetragonal structure remains stable because it corresponds to the primitive cell of the orthorhombic structured perovskite. Therefore, this structural transformation is favoured by a slight structural tilt in the BO

6 octahedra caused by the Ti

4+ partial incorporation. This structural transformation is markedly provoked under solid-state reaction conditions at high temperatures [

8]. Another factor that might cause the predominant formation of the SS2 solutions with cubic structure and their structural variations is associated with the processing conditions (reaction temperature and stirring speed), as suggested elsewhere [

21]. This inference is likely supported by the marked differences determined for the lattice strain caused in the unit cell by the partial incorporation of Ti

4+ in the cubic SS2′ SS. Large lattice strain values were calculated from the Rietveld refinements for the SS2′ SS prepared with Ti

4+ contents between 7.5 and 50 mol% and are shown in Table S3 of the supplementary supporting information.

3.3. Particle morphology variation for the hydrothermally synthesised SrZr1-xTixO3 and SrTi1-xZrxO3 (SS)

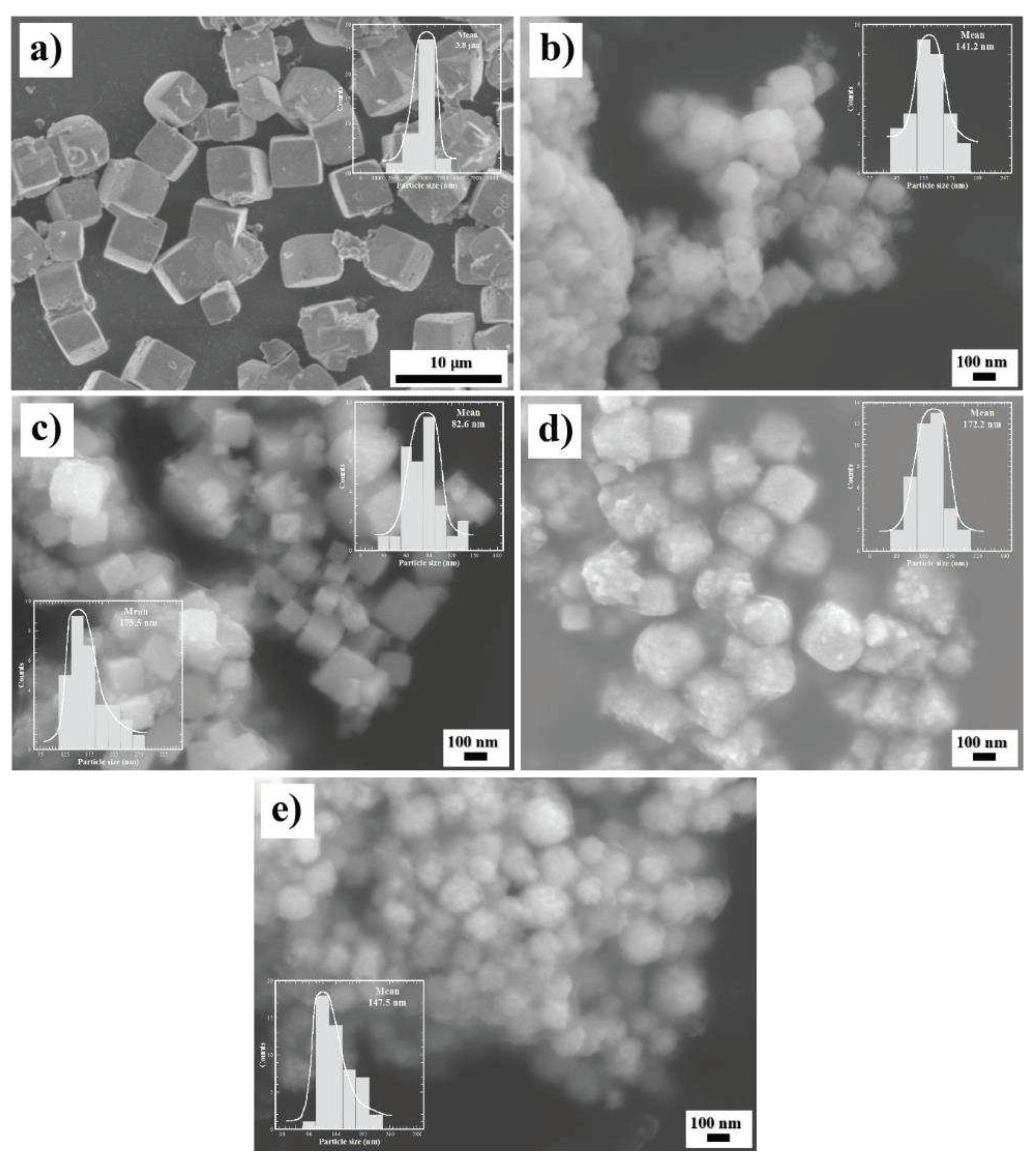

Recently, the morphological habit features for SrZrO

3 particles were elucidated; the hydrothermal treatments conducted without stirring in an alkaline media (5 M KOH) using the same reaction precursors resulted in the crystallisation of micron-sized (averaging 10 μm) SrZrO

3 particles with cuboidal morphology [

21]. On the contrary, our results depicted that continuous stirring (130 rpm) of the hydrothermal media remarkably improved the size reduction of the cuboidal-like SrZrO

3 particles, which were produced free of reaction by-products, namely SrCO

3, at 200 °C for 4 h. The monodispersed SrZrO

3 particles had a unimodal particle size distribution with an average size of 3.8 μm, as seen in the inlet graph of

Figure 7a. Under these conditions, the continuous agitation caused a homogeneous distribution of solute dissolved in the alkaline solvent.

On the contrary, a marked particle reduction occurred on the perovskite particles produced when the Ti

4+ pasty gel was stoichiometrically introduced into the reaction system. Above Ti

4+ contents of 5.0 mol%, the single phase SrZr

0.95Ti

0.05O

3 powders exhibited a mean particle size of 141.2 nm. The morphology resembling cuboidal-shaped particles forming some irregularly shaped agglomerates,

Figure 7b. Furthermore, the formation of a noticeable number of fine meso-crystals (average size 82.6 nm) with a pseudo cuboidal shape were formed together with a large amount of cubic-like shaped large particles having an average size of 175.5 nm,

Figure 7c. It deserves to emphasise that these particles were formed using the content of 30 mol% Ti

4+, and the FE-SEM observation agrees with the PXRD results which revealed the coexistence of two SrZr

1-xTi

xO

3 solutions with different Ti

4+ content (

Figure 3a). Likewise, the difference on the Zr

(Lα) and Ti

(Kα) peak intensities between the fine sized pseudo cuboidal and large cubic-like particles confirmed the variation on the bulk chemical composition of the SS1 and SS2′ (as seen in Figure S3b in SSI file). Based on the Rietveld refinement analyses, their chemical formulas correspond to SrZr

0.9Ti

0.1O

3 and SrZr

0.70Ti

0.3O

3, respectively.

The pseudocubic meso-crystals were formed preferentially under hydrothermal stirring conditions with Ti

4+ contents over 50 mol%. Generally, the new pseudocubic-shaped meso-crystals were monodispersed and exhibited a unimodal size distribution with an average size of 172.2 nm. Furthermore, the single-phase SrZr

0.5Ti

0.5O

3 (SS2) cubic structured meso-crystals were likely formed from tiny particles self-assembled via a 3D hierarchical architecture; this assumption was inferred from the roughness surface of the meso-crystals shown in

Figure 7d. Additionally, the FE-SEM observations conducted on the hydrothermally produced single phase SrTiO

3 meso-crystals (see

Figure 7e), allowed to infer that these meso-crystals underwent a crystallisation process analogous to that observed on samples containing low contents of Ti

4+ up to 50.0 mol%. Thus, the meso-crystals solely prepared with Ti(OH)

40 gel had a slight reduction in their particle size, which averaged 147.5 nm. According to the experimental results, it can be inferred that the chemical compositional variation in the crystalline phases produced (SS1, SS2′ and SS2) and the particle coarsening differences are strongly dependent on the Ti(OH)

40 gel content variation in the hydrothermal treatments conducted under vigorous agitation. Details of the crystallisation mechanism and its correlation with the precursor gels (Zr(OH)

40 and Ti(OH)

40) are discussed in the following section 3.4.

3.4. Crystallisation of SrZr1-xTixO3 and SrTi1-xZrxO3 meso-crystals under alkaline hydrothermal conditions

HR-TEM observations and compositional EDS analyses systematically investigated the crystallisation process for both SrZr

1-xTi

xO

3 and SrTi

1-xZr

xO

3 promoted under hydrothermal treatment conducted with vigorous fluid agitation, according to the differences in morphology revealed by the FE-SEM analyses (

Figure 7, and Figure S4 in the SSI), the growth process of the meso-crystals depends on the Ti(OH)

40 gel. This inference is supported by the remarkable reduction of either Zr

4+ rich orthorhombic or cubic structured particles preferentially formed on the hydrothermal treatments conducted with compositional variations between 7.5 mol to 50.0 mol% of Ti

4+. Indeed, some of the present authors reported the differences in the chemical reactivity of metal transition hydroxide gels in the alkaline hydrothermal media [

20,

21]. It deserves to emphasise that the crystallisation of cuboidal-shaped SrZrO

3 particles rapidly occurred using powders of SrSO

4 and Zr(OH)

40 dried gel in a 5 M KOH solution at 240 °C for 24 h, in comparison with an analogous reaction system employing a Zr(OH)

40 coprecipitated gel. The pasty hydroxide gel undergoes a dehydration process that markedly hinders the SrSO

4 dissolution; consequently, the bulk solute saturation proceeded slowly, triggering the nucleation of flower-shaped SrZrO

3 crystals. These crystals grew epitaxially along the [111] direction, resulting in large particles (mean size of 60 μm) for reaction intervals of 96 h [

21].

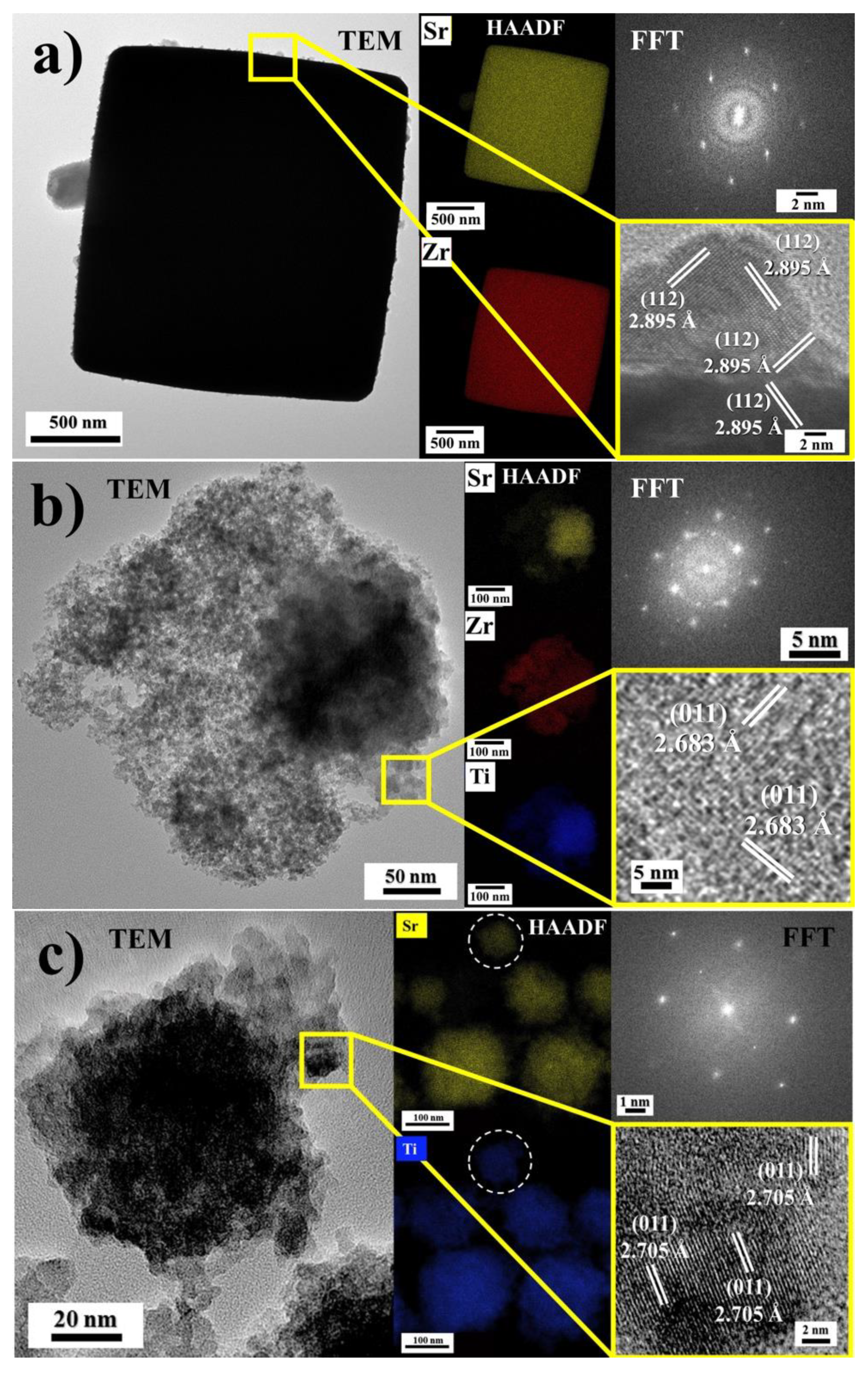

By these results, we infer that the vigorous fluid agitation accelerated the SrSO

4 dissolution and the pasty Zr(OH)

40 gel dehydration, consequently triggering a rapid solute supersaturation within 4 h at a relatively low temperature of 200 °C, which rapidly provoked the crystallisation of SrZrO

3 cuboidal-shaped monodispersed crystals. The structural details determined by the TEM diffraction spot image indicated that the hydrothermally prepared SrZrO

3 crystals are single crystals in nature (

Figure 8a). In contrast, the HR-TEM images depicted their high crystallinity, as confirmed by the 2D finger lattice atomic distribution. Interestingly, the observation conducted at the crystal edge in areas exhibiting SrZrO

3 fine particles grown on the surface indicated that the micron-sized SrZrO

3 single crystals grew epitaxially along the direction of the plane (112) that, corresponding to the lattice plane distance of 2.895 Å of the orthorhombic structure (card ICDD 70-0283). However, the dissolution-crystallisation mechanism provoked the SS1 and SS2 perovskite structured particles, irrespective of the Ti(OH)

4•4.5H

2O gel content. Likewise, the reactivity of the Zr(OH)

40 precursor gel seemingly proceeded faster when compared with the sample prepared solely with Zr(OH)

4•9.64H

2O. The bulk alkalinity of the solvent fluid remains high when the Ti

4+ concentration varies because the alkalinity reduction caused by the large water content released by the Zr(OH)

4•9.64H

2O dissolution is progressively hindered. Therefore, a specific reaction steady-state reaction is reached, triggering an accelerated solute supersaturation state that results in a fast crystallisation of orthorhombic (SS1) and cubic (SS2′), or solely the SS2 meso-crystals. Consequently, the primary crystal growth is hindered, as revealed by the HR-TEM micrographs taken for single-phase SrZr

0.5Ti

0.5O

3 and SrTiO

3 fine particles shown in

Figure 8b and

Figure 8c, respectively. These images also revealed features regarding the self-assembly process for primary anhedral nanosized crystals (20–45 nm), which proceeds along the {011} crystallographic planes of the cubic structure. We surmise that their surface facets favour the fine crystals assembly with (011) indexes, seemingly exhibiting low surface energy, allowing them to coalesce rapidly.

Consequently, the 3D hierarchical assembly produces highly crystalline agglomerates with pseudocubic morphology. This inference is supported by 2D finger lattice atomic distribution images and FFT diffraction patterns, as shown in

Figure 8b,c. These results revealed that the single-phase cubic structured SrZr

0.5Ti

0.5O

3 and SrTiO

3 primary crystals grew along (011) planes and subsequently coalesced to form the nanosized (140 – 175 nm) meso-crystals agglomerates, which exhibited single crystal areas as revealed by the FFT diffraction patterns. Interestingly, the 3D assembly process irrespectively proceeded by varying the Ti

4+ content in the 7.5–100 mol% range. According to these results, we inferred that under hydrothermal conditions, the continuous vigorous stirring of the alkaline fluid triggered a homogeneous dispersion of the raw precursors (SrSO

4 powder and the mixture of the pasty gel species), yielding a controlled dissolution-crystallisation reaction carried out in a single step to synthesise various perovskite solid solution in the binary system SrZrO

3–SrTiO

3. Indeed, the proposed soft chemistry process is faster than that even conducted under highly alkaline 5 M NaOH fluid to produce SrZrO

3 without stirring under hydrothermal conditions [

21].