1. Introduction

Timber harvesting operations including motor-manual tree felling and processing require workers which are in good health to be able to work effectively. This work is considered to be a heavy job with specific level of safety hazard and harmful factors. Workers are influenced by many personal factors as well as external conditions [

1,

2,

3]. Motor-manual fellers are exposed to extreme temperatures [

4], they cover long distances during work or in difficult terrain which can cause physical strain [

5]. Other harmful factors which are often investigated are noise or vibrations [

3] or increased risk of musculoskeletal disorders due to work postures [

6,

7,

8,

9], vascular disorders [

10] or even disobeying safety procedures [

11,

12]. Workers in logging and forest environment during their working activities may be exposed various hazards and risks. The physical workload during manual activities in logging and forest environment are extremely high [

13,

14]. Forest workers during a long-time working activity may work with excessive demands beyond their physical abilities. For proper safety, body long term overload and injury protection is important to know evaluate and analyze real impact of the working activities and potential workload danger and risks [

10].

Based on analytical knowledge, we use to analyze workload danger and risks, a workload model that includes physical characteristics of workers including body heart rate measurement. We expect that current measurement and wearable devices have sufficient performance for measuring biological and physical load data without disturbing the work of the observed people [

15,

16].

From the point of the ergonomics of work activity, work performance is influenced by a number of external conditions, work environment or circumstances of work performance. External factors and readiness for work performance influence the physiological and psychological state of the worker and his overall work performance. Work activity is always a burden for the organism, the size of which depends mainly on the physical and psychological state of the worker, the ability to prepare for the performance of a specific work activity in the given conditions and the work activity itself that is being performed. To assess the workload, we take into account also the fact that the ability and performance of workers changes in the long term with gender and age, but especially in the short term of the body's physiology, there are changes in readiness for performance during the day [

17,

18,

19,

20,

21]. The highest workload on the organism is in the morning and mid-morning hours between 7-12 o'clock, between 1-3 p.m. there is a slight decrease in performance, between 4-9 p.m. physiological performance remains at a stable level and then after 9 p.m. it decreases to minimum level [

1].

From the point of the organization of the workload, it is appropriate that the workload and the cycle of the imposed work pace correspond to the highest possible performance. If the mutual coordination of the physiology of performance and the ability of the organism to handle the load is not observed, the effects of the workload on the health of the employees may gradually begin to manifest. The impact of workload is related not only to the ability to cope with the current physical or mental load, but also to the ability to regenerate between individual performances. The consequences of workload can then be divided into two parts: short-term, which disappear after the end of the work performance or during the recovery period after the performance and do not create functional irreversible changes or permanent consequences on the health of workers, and long-term, which persist even after the recovery period and from a long-term perspective they can cause functional, irreversible changes or deterioration of workers' health [

22,

23,

24,

25].

During the performance of a work activity, the locomotor and cardiovascular apparatus are stressed. Other factors such as metabolism, thermoregulation, fluid loss and others are also related to work performance. According to the intensity of the work activity and the effects of the surrounding environment, the burden on the organism can be divided into low, reasonable, excessive and extreme.

For the evaluation of individual areas of stress, we must take into account both its length, type and intensity, but also the basic physical and physiological prerequisites of the person performing the work activity. When determining the total physical load, we base it on the data of the basic metabolic values of the given person or group of people (basal metabolism) as well as on the energy expenditure during the performance of a specific work activity or a group of activities of a similar nature. From the point of view of the performance of one's work activity, we can also take into account the type of work activity - whether it is static or dynamic work. In static work, actions such as holding tools or objects for the performance of a work activity or maintaining a working position for approximately 2-3 seconds and involving mostly small muscle groups are predominant. Dynamic work is primarily the performance of one's own work without or with the use of tools over a longer period of time and involving mainly large muscle groups. Depending on these main physiological parameters, the body energy required for the performance of the work activity is consumed. The amount of energy consumed is also influenced by the working environment and conditions during the performance of work activities. From the point of the activities performed and the way the body is stressed during work activities, it is necessary to divide physical stress into local and general stress. In the case of local loads, specific body parts are loaded, such as parts of the upper or lower limbs, or individual segments of the spine. For the total physical load, we consider the involvement of large muscle groups in a volume greater than 50% of the total muscle mass. From the point of view of body physiology, we are able to better determine both the energy demand of the work performed, as well as the physiological parameters related to the involvement of a large volume of muscle mass. On the basis of the before mentioned assumptions, we consider that with increasing energy demands, there is both greater energy consumption by muscle activity and greater strain on the cardiovascular and respiratory systems. The activity of the respiratory and cardiovascular system and their selected indicators can be easily monitored and subsequently evaluated during overall physical work in a non-invasive manner. From the point of view of practical assessment of the total physical load of the activities performed, it is advantageous to use the expression of energy demand using heart rate values [

26].

At present, non-invasive measurement of heart activity using various wearable devices appears to be the most suitable for monitoring and evaluating physiological parameters during the performance of work. These devices are capable of sensing heart activity/pulse with relatively high accuracy and also eliminate a number of artifacts arising during the measurement itself [

25,

27,

28,

29,

30,

31,

32].

In a work physiology, physical strain can be described as total body strain or local strain on specific body parts. Above all, large muscle groups need a large amount of oxygen to ensure movement and their own performance, which is why the respiratory and cardiovascular systems are strained in connection with the physiological movements of the muscles. From the point of view of the performance of work activities, the work performed can be divided into several areas: force work, work associated with static loads, manual handling and repetitive work. Power work is work that primarily requires good stability of the human body, and in many cases it is necessary that during this work the muscles contract up to the areas of maximum voluntary contraction. Power work refers to the load of the whole body or its specific parts, such as pushing and pulling. With static load, the body as a whole or a part of the body is usually loaded with work in which the same position is maintained continuously for a long period of work and individual muscles resist the required load during work. In many cases, there is also prolonged muscle tension or muscle activity without variation in muscle movement or stretching. For work associated with manual manipulation, in contrast to strength work, in addition to good body stability and the use of the strength of large muscle groups, it is necessary to emphasize the necessity of performing a specific load of small muscle groups of the upper limbs associated with grasping the manipulated object.

Repetitive work is created by requirements for repetitive cycles of production processes or work activities. Due to the variability of this work activity, there is currently no unified opinion on its definition. Repetitive work can be tied to the duration of the work cycle, the repeatability of work movements or, for example, the repeatability of dynamic and static load during the performance of a work activity. According to statistics, the most used specifications are the task cycle duration of less than 30 seconds or the identification of the same movements, static or dynamic actions that are performed for more than half the time within one work cycle [

22,

24,

25,

33,

34].

2. Materials and Methods

In our case study, heart rate and physical activity were measured using several different wearable equipment’s with a different biosensor. We measured working activities such as tree-cutting, delimbing, crosscutting, chocker-setting, manual axe chopping and cutting with a chainsaw including different cutting conditions using different bar lengths and cutting conditions.

For each working activity, we examined dependence of the heart rate (HR - number of beats per minute) on physical workload. Biological parameters as moving/ walking pattern and HR were taken both when the worker was at the quite/rest time before the work and continuously during working. Based on measured values we counted level of workloads. The level of the workloads was classified as ration values of the workload and rest HR. Counted final value we divided to the different levels as very low, low, moderate, high, very high load index –

If we investigate work load limit values of energy expenditure per work shift, there is 5.1 MJ (permitted max. 6.1 MJ) for women and 8.25 MJ (permitted 9.9 MJ) for men. In order to assess the shift load, it is also important to know the periods of rest periods, the frequency of movements, working positions and the workplace conditions [

35,

36].

The data we collected 27.08.2022 in the South Moravia location, Věteřov, Czech Republic. The respondent has signed an informed consent. The respondent's ability to perform the required work activity was verified. Before starting the entire study, he was asked to fill out a questionnaire with the data needed for the study. Based on this data, the technical side of the measurement was prepared, including the setting of the participant's personal parameters. In order to carry out the measurements and evaluate the results, it was necessary to enter data into the wearable measuring devices that can affect the measurement results, such as, the age, height and gender of the person being monitored. Several wearable sensors were used for the measurements themselves - the Whoop device (fitness and health wearable monitor WHOOP, USA) and the Biostrap device (Biostrap EVO Recovery set - fitness and health wearable monitor, Biostrap USA, LLC). A Garmin Fenix 3 HR device (Garmin company) was also used. Individual sensors were located on both wrists with rubber wrist bands and on the forearm. Whoop and Biostrap were located on left hand, Biostrap on left forearm, Garmin on the right hand. These wearable sensors were used to monitor workload and to eliminate data distortion and possible loss of data. It also increases the accuracy of data as Biostrap is monitoring the Rest Mode before the workload. We also wanted to be sure that there would be no loss and distortion of data that could arise from the placement of the sensor, movement, sweating or changes in measurement [

37,

38,

39].

The Whoop wearable device allows you to measure sleep duration, sleep stages, strain, recovery, heart rate, resting heart rate, heart rate variability, respiratory rate, workouts and calories burned. The Biostrap wearable device provides the following information and using a 3-axis accelerometer and a 3-axis gyroscope: measurement of sleep phase, resting heart rate, heart rate variability, blood oxygen saturation, respiratory rate, arterial elasticity and peripheral elasticity. The Garmin Fenix 3 HR wearable device allows you to monitor heart rate, running dynamics, step length, vertical ratio, VO2 max, as well as three-axis compass, altimeter and barometer options.

As part of the study, the subject was monitored 5 days before the start of the actual experiment and also 5 days after its end in order to determine the resting value of the heart rate and determine the usual behavior and performance behavior during the performance of work activities and regeneration for the work activities performed. Long-term behavioral measures were not evaluated and were not included in the study itself.

In the case study physiological parameters were monitored in accordance with the required work activity, both during the actual work activity and during breaks and preparation for the work activity. The course of the actual measurement and the individual measured values were checked and monitored remotely during the measurement using applications for the individual monitoring devices used. A working and video recording was kept of the performed activities.

To compare the load, the use of two different types of saws and two different types of cutting sets was chosen. Measurements were carried out during the processing of already felled Populus Alba white poplars. Cross-sections were performed in both vertical and horizontal orientations. Populus Alba is one of several species of poplar, whose original area of distribution includes most of central, eastern and southern Europe. In the Czech Republic, it is native to the Moravian valleys, and it is the predominant type of poplar in floodplain forests. For the measurements, trunks with a thickness in the section mainly from 40 to 100 cm were used. The incisions were made in both horizontal and vertical planes. They were carried out horizontally when cutting off the remaining parts - tree stumps. The wood fibers were therefore always cut perpendicularly - these were transverse cuts.

Cutting set A: was designed with a STIHL guide bar with a cutting length of 90 cm fitted with a chain with a pitch of 3/8 inch. the thickness of the guide link 1.6 mm, the length of the chain was 114 guide links. The cutting links were chisel-shaped. Cutting set B: was designed with a STIHL guide bar with a cutting length of 50 cm fitted with a chain with a pitch of 3/8 inch. the thickness of the guide link 1.6 mm, the length of the chain was 72 guide links. The cutting links were chisel-shaped.

Chainsaw C: a STIHL MS 500i chainsaw was used. This is a saw that is equipped with direct fuel injection, so it is a saw with a very favorable power to weight ratio. The displacement of the saw is 79.2 cc, and the weight of the saw without operating cartridges and cutting set is 6.2 kg. The power of the chainsaw is 5 kW. Chainsaw D: a STIHL MS 362 C-M saw was used. It is a saw of classic construction with an electronically controlled carburetor, so it is a saw with a very favorable power to weight ratio. The displacement of the saw is 59 cc, and the weight of the saw without operating cartridges and cutting set is 5.6 kg. The power of the chainsaw is 3.5 kW. This is a classic universal saw used in the Czech Republic.

Configuration for measurement:

AC - For the first set of measurements, the configuration of the cutting set A was selected, which was mounted on the chainsaw C. The total weight of the set, including the operating charges, was 10.398 kg. The weight of the set per unit of power thus reached 2.08 kg/kW. This kit was able to make almost all cuts in one cut. This was due to the 90 cm active length of the guide bar.

BC - The second set of measurements was realized by the configuration of the cutting set B mounted on the chain saw C. The total weight of the set, including the operating charges, was 8.791 kg. The weight of the set per power unit therefore reached 1.76 kg/kW. The disadvantage was that when cutting thicker trunks than the effective length of the bar (50 cm), these cuts had to be made twice.

BD - The third set of measurements was the configuration of the cutting set C that was mounted on the Chainsaw D. The total weight of the set was 7.961 kg, including the operating charges. The weight of the set per unit of power was 2.27 kg/kW. So it was the worst configuration in terms of power to weight. Thus, the saw's lower performance despite its lower weight resulted in longer cut times compared to other configurations.

3. Results

3.1. Heart Rate Index

Individual measured values were compared with each other with the performed activity and its progress. Average heart rate values measured by wearable devices Whoop, Biostrap and Garmin were used for the case study. By comparing the individual measured data, it was found that the difference between the measured values for the individual devices was in the range of 1-3%, which does not affect the overall result. These changes in values could be caused both by the inaccuracy of the measuring devices themselves and, above all, by their placement on the body of the monitored persons.

For the overall assessment of the workload during the performance of individual work activities, based on the formula (1), the time spent by the respondent in a specific area of the workload index range was evaluated according to the

Table 1.

Based on the comparison of the individual measured data of the duration of the physical load and its level expressed by heart activity during the performance of a specific work activity with the parameters of the permanently permissible load time during the performance of work tasks, an evaluation and analysis of the individual measured values was carried out.

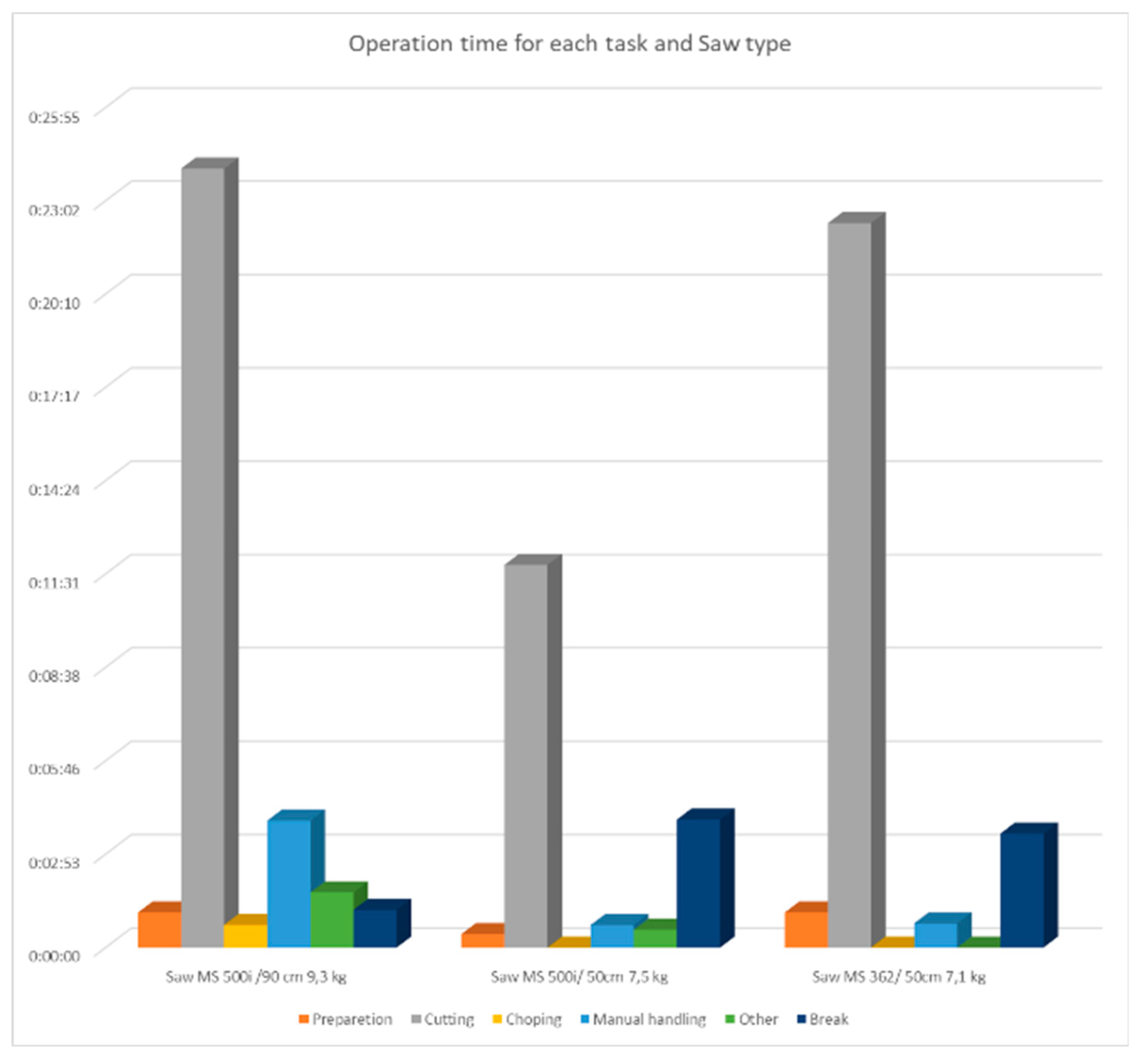

The main phases of wood processing included Preparation, Cutting, Chopping and Manual handling. Other activities included for example changing of working place or a saw preparation. The section for breaks provides cumulative values for all breaks during work.

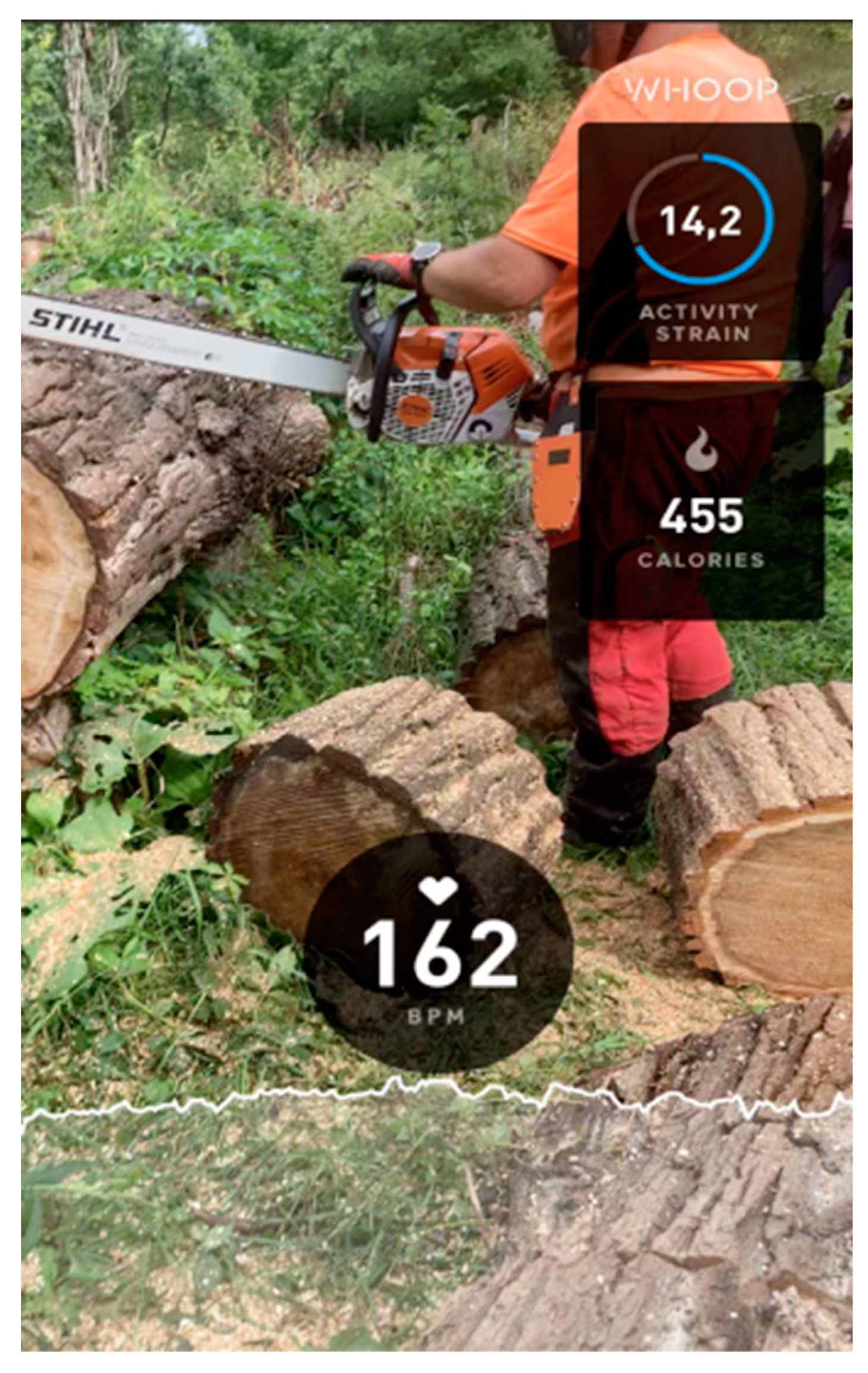

Figure 1.

Whoop wearable device software.

Figure 1.

Whoop wearable device software.

Based on

Figure 2 we can see that the all the devices were used during case study with all phases of wood processing, which corresponds to the everyday common practice. The biggest time slot is logically covered by cutting, followed by manual handling in case AC or breaks in other cases. Ergonomic evaluation is mostly related to the time of cutting which was for the combination AC 24:02 minutes, for BD 22: 21 minutes and for BC 11:48 minutes. It can be concluded that for combination AC and BD the time indicates high workload.

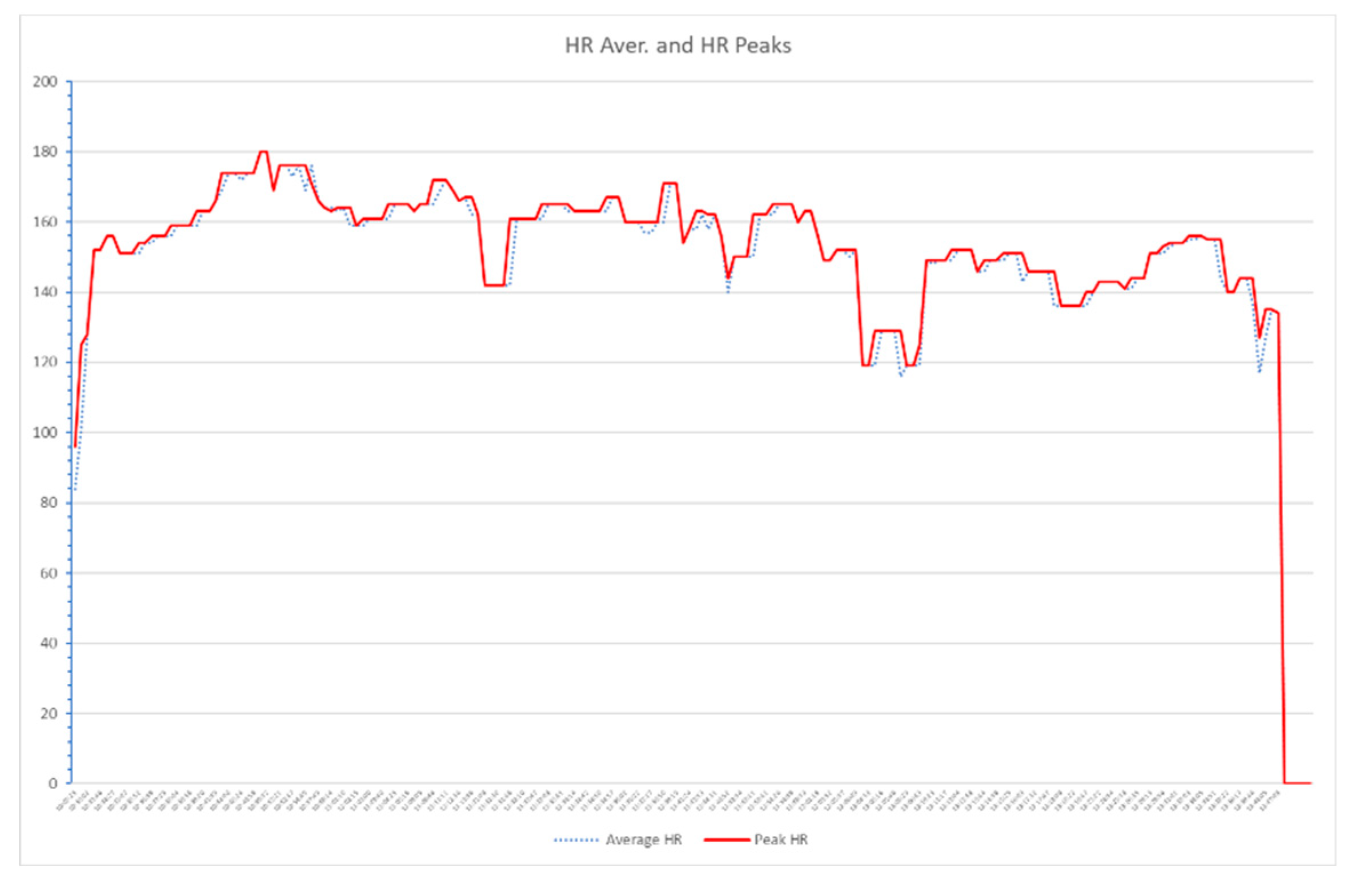

The

Figure 3 shows the average value of heart rate for all three devices – Garmin, Biostrap and Whoop during working cycle. The peak represents the highest value of any of them. We can see that the results of all three devices used are very similar. This figure can be used for interpretation of inaccuracy in measurement. Although the devices are different, the recorded very similar value of heart rate which can be used for further analysis. There might be minor inaccuracy in values but it will not influence the final results.

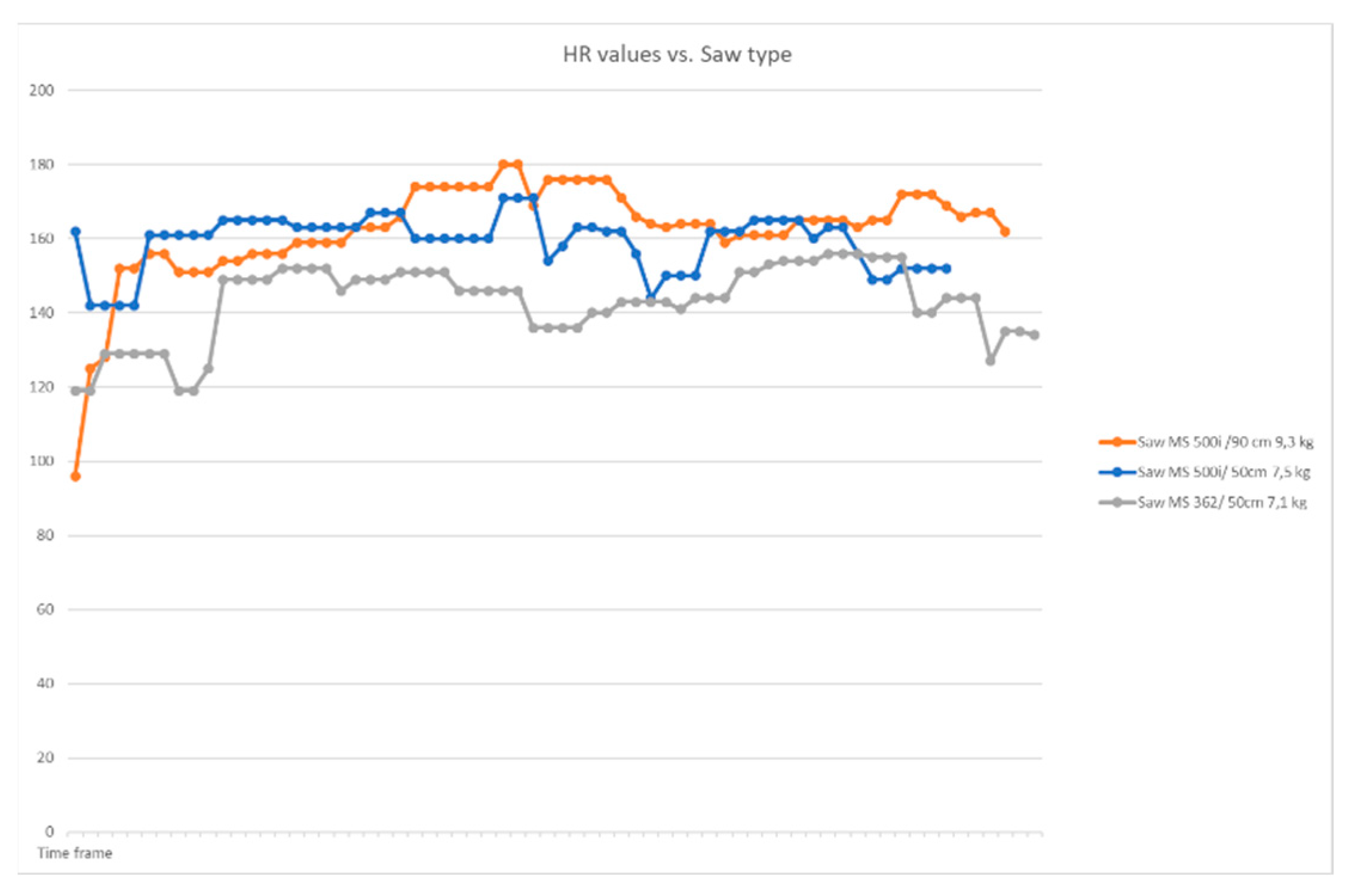

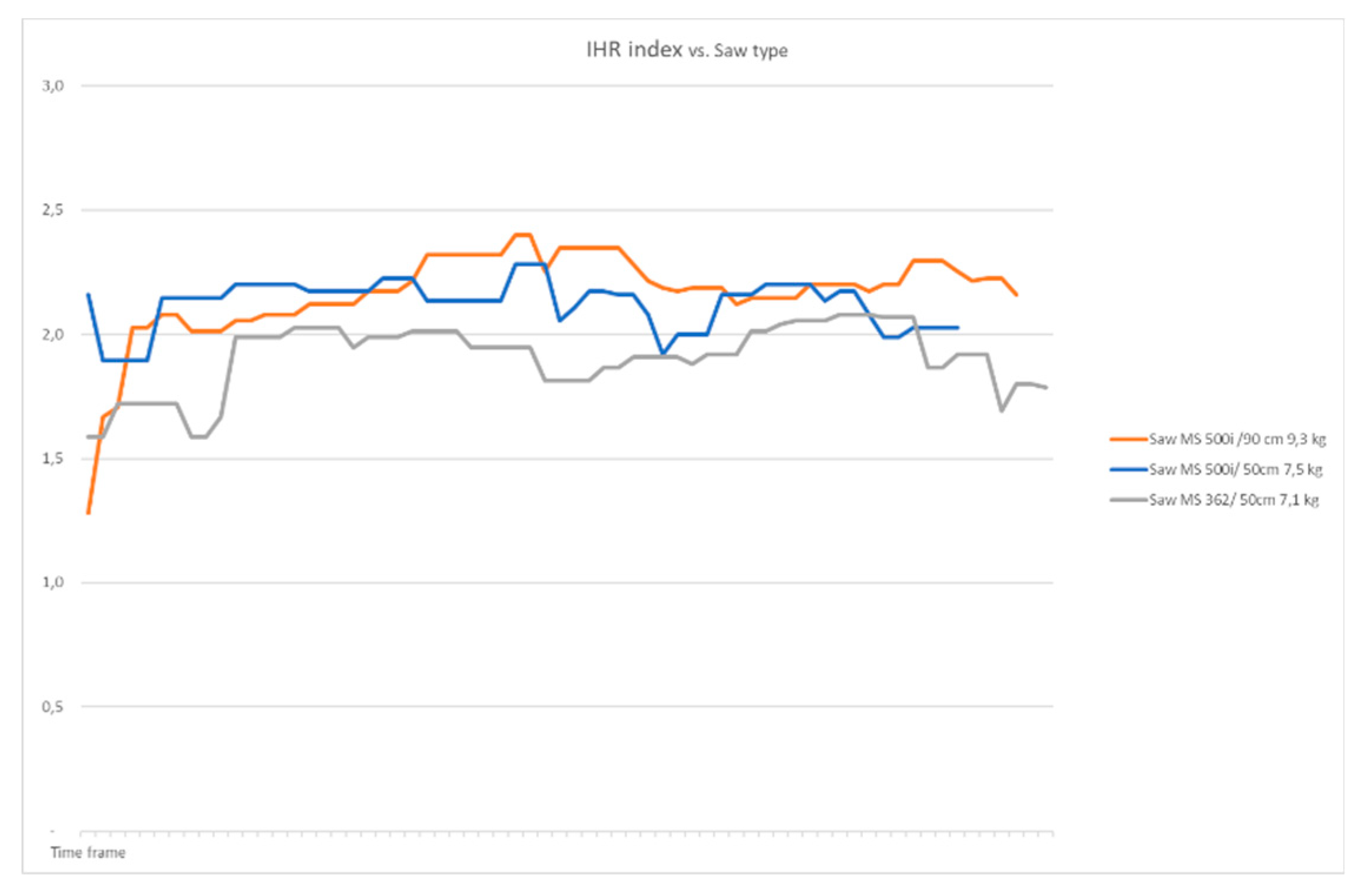

Figure 4 is monitoring the heart rate values and a saw type. It is evident, that heavy working instrument, here a saw type MS 500i /90 cm 9,3 kg, can influence the workload which is much higher than in the two other cases of lighter saws. The physical workload of a worker can be influenced not only by the character of work but also by the weight of the working tool as a burden.

Figure 5 shows on the axis Y the value of Heart Rate Workload Index in combination with different devices for motor-manual tree processing. When we compare type MS 500i /90 cm 9,3 kg and type MS 500i/ 50cm 7,5 kg, the value of Heart Rate Workload Index is bigger than workload level 2. In this case, the work should be done between 10-20 min. In case of the type MS 500i /90 cm 9,3 kg, almost all working time on level 2 exceed 20 minutes, as shown in

Table 2. This means that workers should be aware about the time of working operations. The more time they will work and exceed recommended times given by the Heart Rate Workload Index, the more tired they can become which might lead to mistakes or even accidents. It is important to monitor how long we work and what are our tools, specifically how heavy the tool is.

3.2. Ergonomic evaluation of working position

Based on recommendations for ergonomic and non-ergonomic working position [

26,

36], we use the following definition for non-ergonomic position:

For the trunk position, the forward tilt is greater than 60 degrees, the tilt is unsupported, the tilt or rotation of the trunk is greater than 20 degrees, for the head and neck, the forward tilt of the head is greater than 25 degrees, the head tilt, tilt and rotation are greater than 15 degrees, for the lower limbs, hips, knees or ankles are in extreme positions (e.g. kneeling), for the hands it is the rotation of the forearm. All other working positions are for the use in this case study considered as ergonomically accepted.

The aim in this evaluation is to monitor the most critical working positions, workload and critical points for increased workload which is caused by working position. We have not focused on ergonomic evaluation of the working position but on the load parameters.

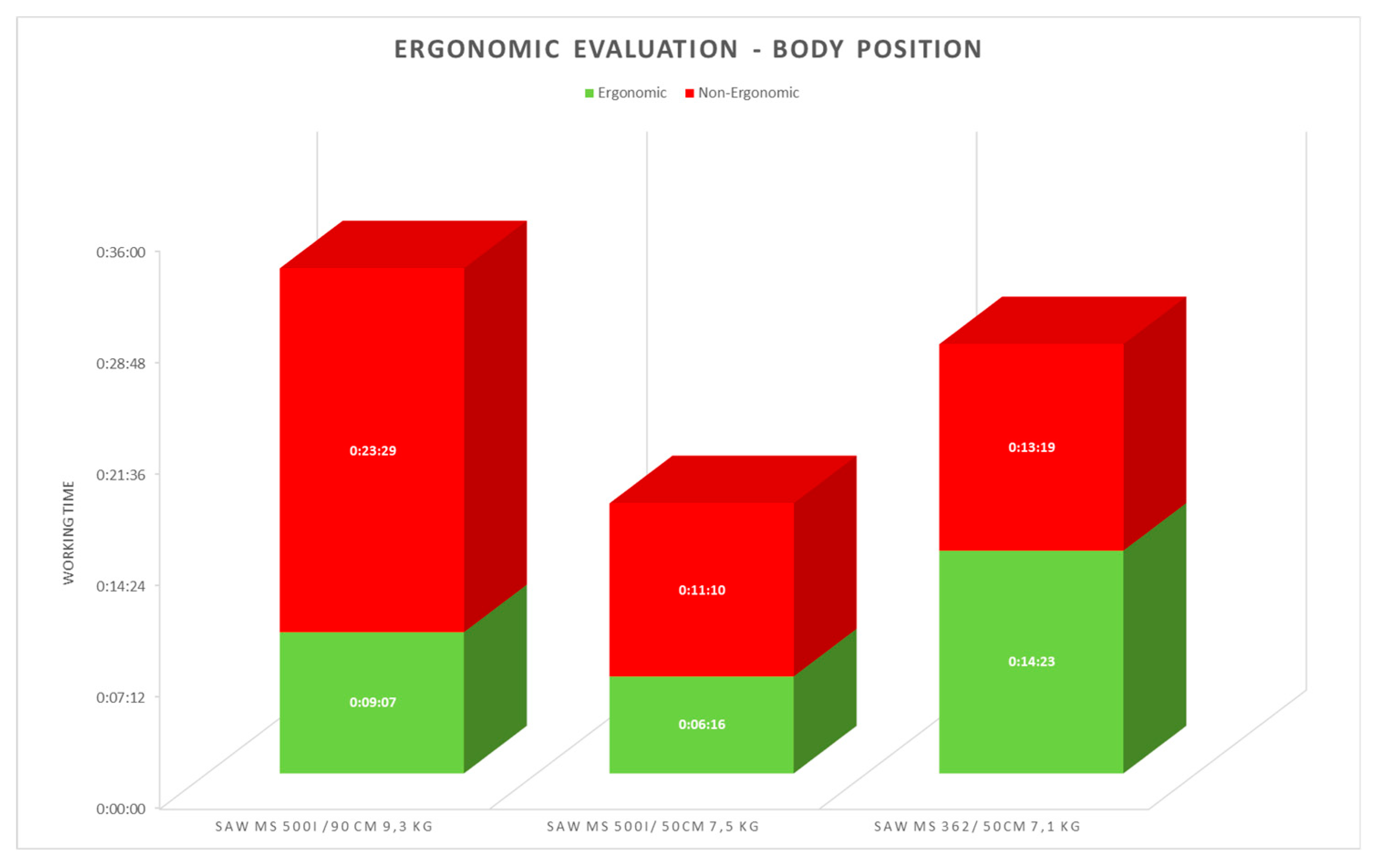

Figure 6 presents ergonomic and non-ergonomic working positions in motor-manual tree processing. It contains time line and working phases of cutting, chopping and manual handling as the main parts of motor-manual tree processing which can cause overload of the musculoskeletal system

It is evident, that the weight of the load affects whether the working position is physiological or not and whether we exceed the set parameters. It turned out that when working with the heaviest tool (AC - MS 500i /90 cm 9,3 kg), the worker's body is burdened in non-ergonomic positions for the longest time.

The presented results document that working with a chainsaw includes ergonomic and non-ergonomic activities. The worker should know which are ergonomic positions and the critical load level with respect to non-ergonomic positions. From the point of view of health and safety at work, it is important to plan an appropriate distribution of work and rest periods between individual tasks. For the purposes of working with motor-manual tree processing tools, it would be appropriate to develop a recommendation that takes into account both the working position and the physical load during the work activity, as well as the load caused by the work tool itself.

4. Discussion

From the ergonomic point of view, the primary goal of the activities carried out was to find the conditions to achieve the optimal well-being of the worker during the performance of work, while increasing efficiency and protecting health and preventing risks at work. A number of measurements and analyzes has been carried out in the field of ergonomics not only to provide information about the current state of a particular worker while performing work, but also to predict possible overload and health risks. Above all, information from the area of physical load has a significant long-term contribution to setting and planning of working conditions.

In practice, to evaluate the performance of a work activity and the workload resulting from it, we must consider not only the performance of the work itself, but also the surrounding influences of the work environment, including the structure of the surrounding terrain, the work aids and tools used, and the method and intensity of the activity performed. When performing combined work activities, as in our case, it is therefore necessary to consider the weight of the work tool and the method of deriving the force or lever, which is important for the performance of the work, as part of the total load.

Wearable devices have become in the last decade more comfortable, lightweight, and cost-effective. The physiological signals recorded by wearables can have clinical, research and practical impacts on the monitoring of personal conditions. Wearable devices are used in different kinds of applications such as fitness and wellness, personal recovery, mobile health wellness, and sleep analysis, as well as work-related load and diseases, medical surveillance, non-invasive medical care, and telemedicine. The physiological signals recorded by wearables can have immediate clinical, research and practical impacts in the monitoring of fitness and medical conditions, so there is a need to determine whether their measurements are within clinical limits of agreement. Current technology allows not only recording measurement data to individual devices, but also to transfer and process data through wireless interfaces to fixed or mobile devices. With a combination of cloud solutions, one may also benefit from high-level data processing engines and AI (artificial intelligence) technologies which help to analyze measured raw data for better use. We are through processing engines and AI also able to predict different kinds of insufficiencies, critical changes and personal health limits which may in the short- or long-term impact people's performance or their health conditions.

The current gold-standard method for assessing HR is the standard 12-lead electrocardiogram (ECG), while HR measurements from wrist-worn wearables are predominantly obtained from photo plethysmography (PPG). PPG is an optical measurement technique that allows the collection of volumetric changes in blood perfusion under the skin using a light source and a photodetector. PPG (photo plethysmography) works in the following way: an LED light source shines onto the skin and light bounces back into the photodetector, recording how the light’s intensity changes as blood perfuses through the tissue. Data picked up by the photodetector use signal processing algorithms to convert the variations into a heart rate [

37,

38,

39,

40].

At present technologies, there are different kinds of sensors for various applications from green, and red to infrared and their combinations. Green light PPG sensors (for example GARMIN, BIOSTRAP) are used in the majority of optical heart rate monitor (OHRM) products for a few reasons: there is a vast amount of existing knowledge of the technology because of its common use, there is a great signal-to-noise ratio, and more resistance to motion artefacts. Our skin absorbs green light from the light emitting diodes (LEDs) very well—this is problematic as it severely limits the amount of light that passes through the tissue and weakens the overall signal. Skin tone, specifically the amount of melanin, affects the skin’s ability to absorb green light and further increases the variation in result accuracy. Finally, hemoglobin strongly absorbs green light, making it unable to reach the deeper tissue to extract any deeper physiological insights.

Red light PPG sensors (for example BIOSTRAP), also called pulse oximeters utilize light in near-infrared spectroscopy (NIRS) and are widely used in medical applications, where accuracy is closely monitored and absolutely essential for medical use. Our bodies do not absorb red light well which is actually a good thing; it allows the transmission to penetrate deeper into multiple tissue layers in order to obtain a number of biometric signals (such as hydration, muscle saturation, total hemoglobin, and more) that a green light sensor can never see. High quality sensors uses a proprietary IR/Red optical sensor that captures high signal-to-noise and high-resolution PPG measurements from deep beneath the skin (up to 10x deeper than usual green light) to extract reliable biometrics. Taken PPG signal is not impacted also by any skin parameters as high melanin content or skin tone, tattoos, small scars or other physiological variations that impact the reliability of usual simple PPG devices which use a green light source. Despite the massive benefits, red light/ Infra-red PPG sensors have their development challenges, including a higher signal-to-noise ratio and susceptibility to motion artifacts. This creates a need for advanced and robust signal processing with the ability to filter out the noise (motion) in order to produce a high fidelity signal—not an easy task [

17,

37,

38,

39,

40].

The future suggested topics for research could implement another element which might influence the performance of the worker such as: parameters related to processed wood, relations between physical workload, working positions and body fatigue, the time needed for regeneration, measurement of muscles, idle mode, nutrition and others.

5. Conclusions

Based on the measurements and evaluation of the results, it was proven that the use of a heavier work tool with a long cutting blade, type AC: MS 500i /90 cm 9,3 kg, significantly contributes both to the creation of a non-physiological working position and to an increase in the energy required to perform work, which in our case was represented by an increase in heart rate. On the other hand, with a lighter work tool with a shorter cutting blade, both a decrease in heart rate and a reduction in the time during which work activities are performed in a non-physiological position were observed when performing a similar work activity.

Author Contributions

Conceptualization, Eva A.P. and M.R.; methodology, Eva A.P. and M.R.; software, M.R.; validation, P.N., M.R.; formal analysis, Eva A.P. and M.R.; investigation, Eva A.P., M.R., P.N.; resources, Eva A.P. and M.R.; data curation, M.R.; writing—original draft preparation, Eva A.P. and M.R.; writing—review and editing, Eva A.P.; visualization, M.R.; supervision, Eva A.P. All authors have read and agreed to the published version of the manuscript.”

Funding

The work was supported by the Department of Engineering, Faculty of Forestry and Wood Technology, Mendel University in Brno, Czech Republic. Funds for covering the costs to publish in open access (APC) were supported by the authors.

Data Availability Statement

Data sharing not applicable.

Conflicts of Interest

The authors declare no conflict of interest

References

- Marek, J. , Škréta, K., Skřehot P.A. Bezpečnost práce při těžbě dříví; VUBP, Praha, 2011.

- Stramler, J.H. 1993. The Dictionary for Human Factors/Ergonomics. CRC Press, Inc., Boca Raton, FL.

- Cheţa, M.; Marcu, M.V.; Borz, S.A. Workload, Exposure to Noise, and Risk of Musculoskeletal Disorders: A Case Study of Motor-Manual Tree Feeling and Processing in Poplar Clear Cuts. Forests 2018, 9, 300. [Google Scholar] [CrossRef]

- Afshari, D.; Shirali, G. The effect of heat exposure on physical workload and maximum acceptable work duration (MAWD) in a hot and dry climate. Urban Clim. 2019, 27, 142–148. [Google Scholar] [CrossRef]

- Shemwetta, D.T.K. January 2002. The Physical workload of employees in logging and forest

industries.Sokoine University of Agriculture (SUA).

- Cecchini, M., Massantini,R., Monarca, D. 2010. The ergonomics analysis tools for the assessment of the risk

of musculoskeletal disorders due to the repetitive movements of the upper limbs of the workers employed

in agriculture, Towards environmental technologies, International Conference on Agricultural

Engineering, Clermont-Ferrand , France, 6-8 September 2010.

- Martinic, I, K. Segotic, S. Risovic and V. Goglia. 2006. The effect of body mass on physiological indicators in the performance of forestry workers. Coll. Anthropology. No 30, p. 305-311.

- Cremasco, M. et Al. 2019. Risk assessment for musculoskeletal disorders in forestry: A comparison between

RULA and REBA in the manual feeding of a wood-chipper. International journal of environmental research

and public health 16 (5), 793.

- Bovenzi, M.; Zadini, A.; Franzinelli, A.; Borgogni, F. Occupational musculoskeletal disorders in the neck and upper limbs of forestry workers exposed to hand-arm vibration. Ergonomics 1991, 34, 547–562. [Google Scholar] [CrossRef] [PubMed]

- Arman, Z.; Nikooy, M.; Tsioras, P.A.; Heidari, M.; Majnounian, B. Physiological workload evaluation by means of heart rate monitoring during motor-manual clearcutting operations. Int.J. of For. Eng. 2021, 32, 91–102. [Google Scholar] [CrossRef]

- Robb, W. , Cocking, J., 2014. Review of European chainsaw fatalities, accidents and trends.Arboricultural Journal: The International Journal of Urban Forestry No 36, p.103-126. Available at. [CrossRef]

- Campu, R.V., Robb, W., 2022. Chainsaw Safety and Tree Felling Guide. 1st Edition, p.36-40. Awarding Body

Association International. Brno. ISBN 978-80-908203-0-2.

- Van Loon J. 1976. Human energy expenditure in mechanized agricultural work. IAAMRH J 1:18.

- Apud, E., Meyer, F., Espinoza, J., Onate, E., Freire, J., Maureira, F. 2016. Ergonomics and Labor in Forestry.

IN: Pancel, L. Kohl, M., Tropical Forestry Handbook. Springer-Verlag. Berlin Heidelberg.

- McCraty, R.; Shaffer, F. Heart rate variability: New Perspectives on Physiological Mechanisms, Assessment of Self-regulatory Capacity, and Health risk. Glob. Adv. Health Med. 2015, 4, 46–61. [Google Scholar] [CrossRef] [PubMed]

- Hoover, A.; Singh, A.; Fishel-Brown, S.; Muth, E. Real-time detection of workload changes using heart rate variability. Biomed. Signal Process. Control 2012, 7, 333–341. [Google Scholar] [CrossRef]

- Ergonomie, ZS BOZP, VUBP Praha. Available at: https://zsbozp.vubp.cz/pracovni-vykon-a-pracovnizatez-

cloveka.

- Ganong, W. F. Přehled lékařské fyziologie. 1.vyd. nakl. H+H Jinočany. 1995. 681 p. ISBN 80-85787-36-9.

- Gilbertová, S., Matoušek, O. Ergonomie: optimalizace lidské činnosti. Praha: Grada Publishing, 2002. 239

p. ISBN 80-86022-45-5.

- Glivický, V. a kol. Úvod do ergonomie. 1. vyd. Praha: Práce, 1975. 265 p.

- Helander, M. A Guide to Human Factors and Ergonomics, 2nd ed.; CRC Press: Boca Raton, FL, USA, 2006; pp.

224–255, ISBN 0-203-68775-2.

- Bink, B. The physical working capacity in relation to working time and age. Ergonomics 1962, 5, 25–18. [Google Scholar] [CrossRef]

- Bonjer, F.H. Actual energy expenditure in relation to the physical working capacity. Ergonomics 1962, 5, 29–31. [Google Scholar] [CrossRef]

- Saha, P.N.; Datta, S.R.; Banerjee, P.K.; Narayane, G.G. An acceptable workload for Indian workers. Ergonomics 1979, 22, 1059–1071. [Google Scholar] [CrossRef] [PubMed]

- Rodgers, S.H.; Kenworth, D.A. Heart rate interpretation methodology. In Ergonomic Design for People at Work; Van Nostrand Reinhold: New York, NY, USA, 1986; pp. 178–179. [Google Scholar]

- Nařízení vlády, č. 361/2007 Sb., HLAVA IV, PODMÍNKY OCHRANY ZDRAVÍ PŘI PRÁCI S FYZICKOU ZÁTĚŽÍ. § 23. Příloha 5. Fyzická zátěž, její hygienické limity a postup jejich stanovení. Available at: https://www.zakonyprolidi.cz/cs/2007-361#f5771437. 2007. [Google Scholar]

- Alugubelli, N.; Abuissa, H.; Roka, A. Wearable Devices for Remote Monitoring of Heart Rate and Heart Rate Variability-What We Know and What Is Coming. Sensors 2022, 22, 8903–8924. [Google Scholar] [CrossRef] [PubMed]

- Yokoyama, K.; Hayashi, E.; Ito, H.; Kawahara, Y. Estimation of Heart Rate Variability from Heartrate Measured with Wristwatch-Type Heartrate Monitor. IEEJ Trans. Electron. Inf. Syst. 2022, 142, 46–54. [Google Scholar] [CrossRef]

- Can, Y.S.; Chalabianloo, N.; Ekiz, D.; Ersoy, C. Continuous Stress Detection Using Wearable Sensors in Real Life: Algorithmic Programming Contest Case Study. Sensors 2019, 19, 1849. [Google Scholar] [CrossRef] [PubMed]

- Quiroz, J.C.; Geangu, E.; Yong, M.H. Emotion Recognition Using Smart Watch Sensor Data: Mixed-Design Study. JMIR Ment. Health 2018, 5, e10153. [Google Scholar] [CrossRef] [PubMed]

- Støve, M.P.; Haucke, E.; Nymann, M.L.; Sigurdsson, T.; Larsen, B.T. Accuracy of the wearable activity tracker Garmin Forerunner for the assessment of heart rate during rest and activity. J. Sports Sci. 2019, 37, 895–901. [Google Scholar] [CrossRef] [PubMed]

- Reddy, R.K.; Pooni, R.; Zaharieva, D.P.; Senf, B.; Youssef, J.E.; Dassau, E.; Doyle lii, F.J.; Clements, M.A.; Rickels, M.R.; Patton, S.R.; et al. Accuracy of Wrist-Worn Activity Monitors During Common Daily Physical Activities and Types of Structured Exercise: Evaluation Study. JMIR Mhealth Uhealth 2018, 6, e10338. [Google Scholar] [CrossRef] [PubMed]

- Åstrand, P.O.; Rodal, K.; Dahl, H.A.; Strømme, B.S. Applied Work Physiology. In Textbook of Work Physiology, 4th ed.; Human Kinetics Publishers, Inc.: Champaign, IL, USA, 2003; pp. 503–540. [Google Scholar]

- The Occupational Safety and Health Administration in Finland. Available at: https://www.tyosuojelu.fi/web/en/working-conditions.

- Bencko, V. et al. Hygiene: Textbooks for seminars and practical exercises. 2nd revised and supplemented edition of the edition. Prague: Karolinum, 2002. 205 pp. ISBN 80-7184-551-5.

- Czech Ergonomic Association. Course materials for A Specialist in Ergonomics. Source. 2022. Available at: https://www.ergonomicka.cz/zdroje-informaci-v-ergonomii/.

- BIOSTRAP. Available at:www.biostrap.com.

- WHOOP. Available at: www.whoop.com.

- GARMIN. Available at: www.garmin.com.

- Kinnunen, H. , Rantanen, A., Kentt, T. & Koskimki, H. Feasible assessment of recovery and cardiovascular health: Accuracy of nocturnal HR and HRV assessed via ring PPG in comparison to medical grade ECG. 2020. Physiol. Meas. [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).