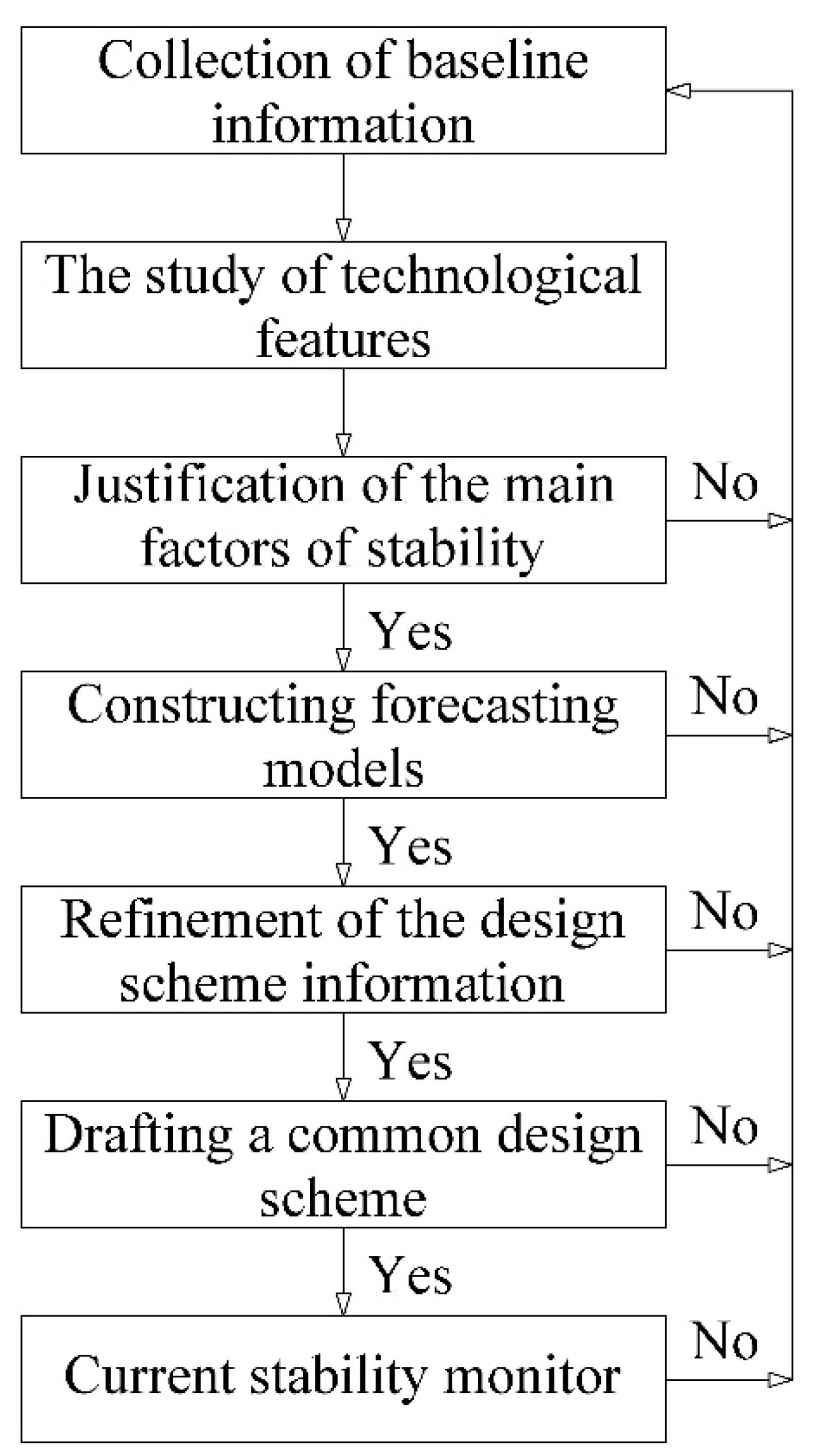

4.1. Design, Construction and Operation

At the design and construction stage, it was changed the construction technology of the tailings dam to form an impervious screen to prevent seepage from the tailings through the dam and increase its stability.

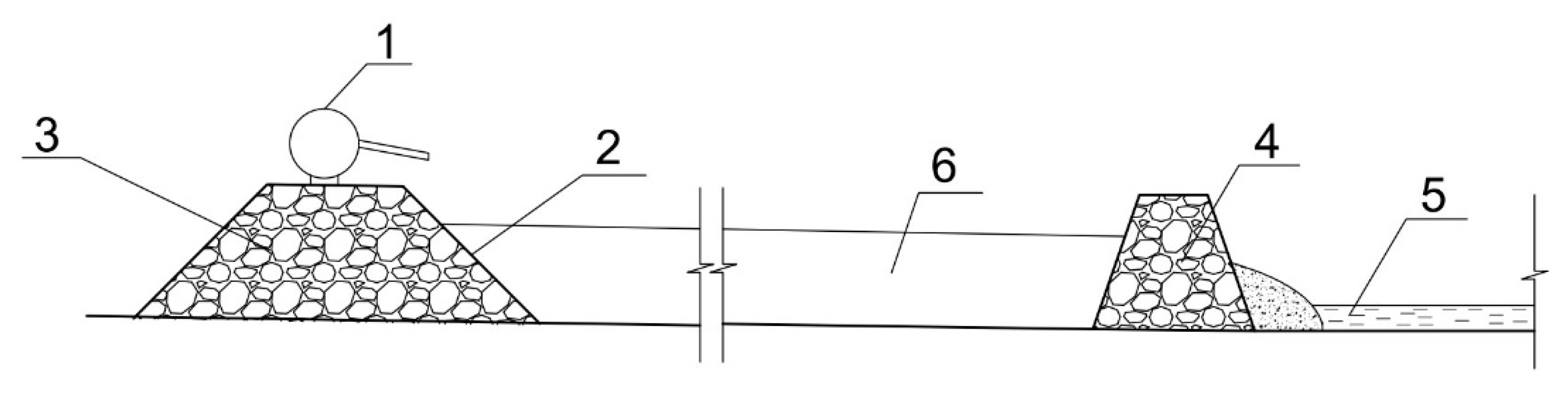

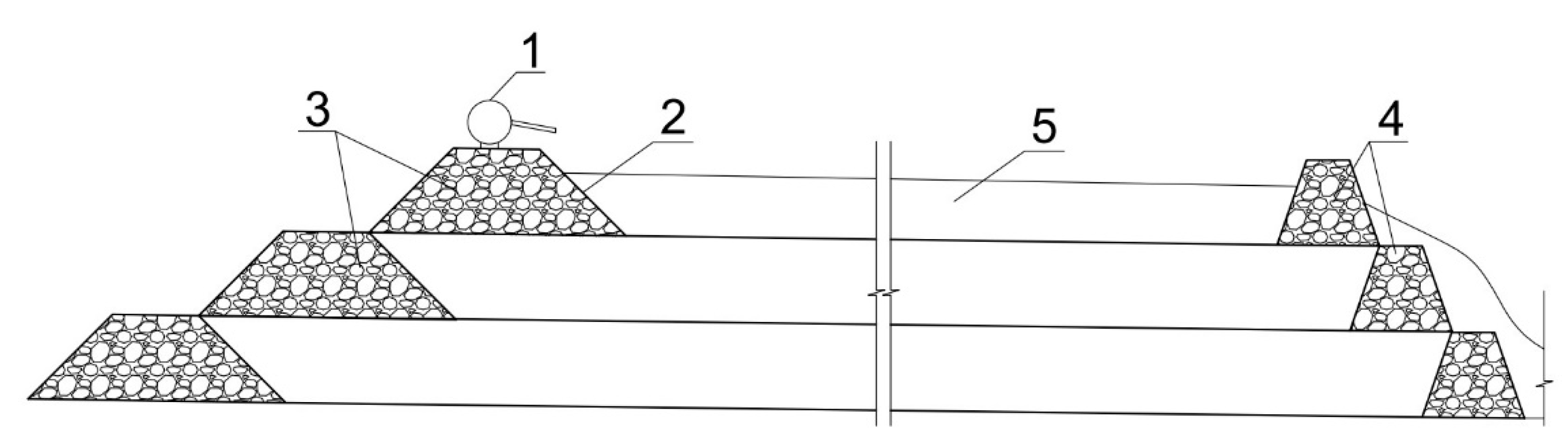

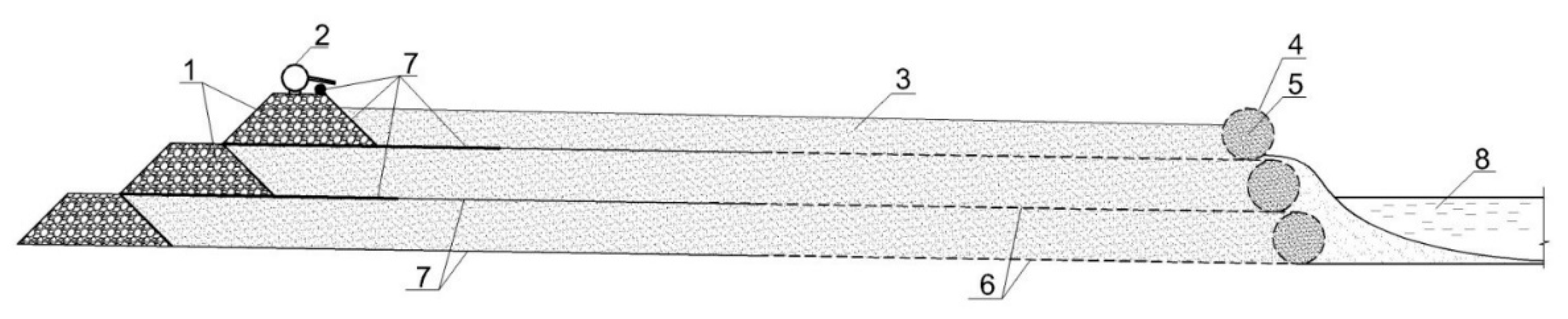

The technical solution consists of placing sleeves made of nonwoven geotextile filtering material in layers perpendicular to the flow propagation, with the sleeves filled with tails to form an earth dam in a bay from the side of the tailings pond (

Figure 10). On the side of the enclosing dam, an impermeable screen made of non-filtering geotextile material is installed to prevent filtration from the tailings pond. The impermeable screen is directed towards the inner slope of the enclosing slag prism of the next layer, it is folded until the next layer is deposited, and then unfurled on top of the deposited tails, covering at least the width of the supporting part of the prism of the next layer for clamping [

24].

The method of constructing a tailings dam is carried out as follows: the construction of the enclosing dam in the form of slag prisms and a dividing dam, the installation of main and distribution pipelines, and the layer-by-layer dispersed deposition of tails on the inner beach. The dividing dam is constructed by placing a sleeve made of nonwoven geotextile filtering material perpendicular to the flow propagation, filling the sleeve with tails to form an earth dam in a bay from the side of the tailings pond. On the side of the enclosing dam, an impermeable screen made of non-filtering geotextile material is installed to prevent filtration from the tailings pond. The impermeable geotextile material is placed along the bottom of the tailings pond, directed towards the inner slope of the enclosing slag prism of the next layer, folded until the next layer is deposited, and then unfurled on top of the deposited tails, covering at least the width of the supporting part of the prism of the next layer for clamping. The diameter of the sleeve made of filtering geotextile material is determined based on the desired thickness of the deposited layer. Upon reaching the desired thickness of the layer, a new sleeve made of geotextile material is laid. The same operations are repeated for each subsequent layer.

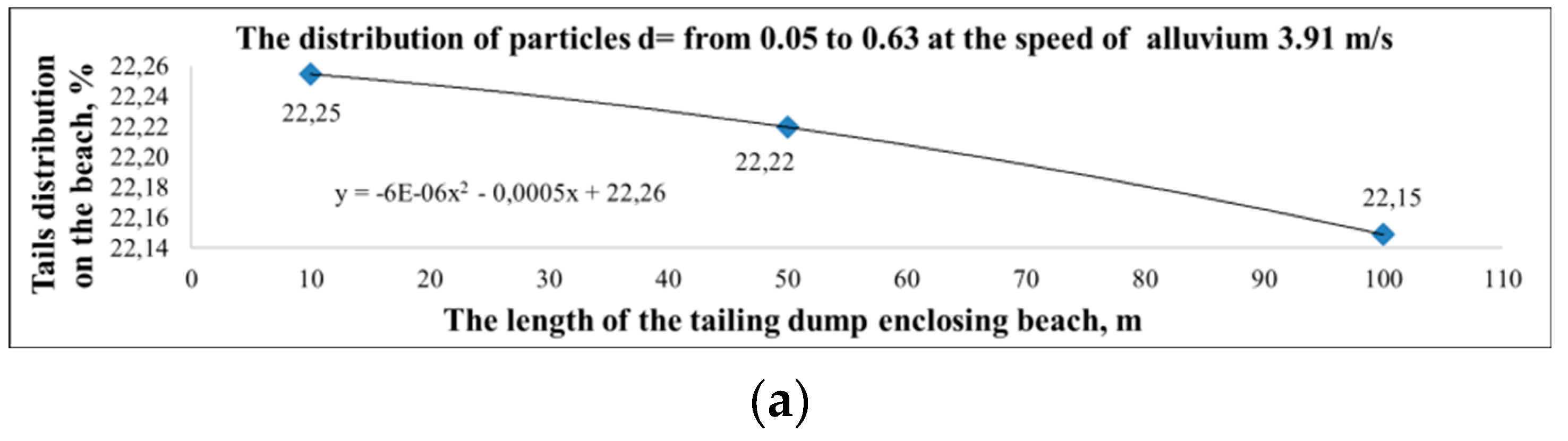

During the tests, the influence of technological parameters of inwash on the characteristics of tailings distribution along the beach of the tailings storage facility was investigated.

The inwash technological parameters were as follows:

values of the weighted average particle diameter - 0.05 – 0.63 mm;

the pulp pace - 3,91; 4,05 and 4,31 m/sec;

the solid phase to liquid phase ratio - 1:2; 1:2.5; 1:3.5 and 1:4.

The laboratory experiments were conducted on laboratory-scale plant made accord-ing to the requirements of the similarity theory criteria [

10,

25]. In accordance with the conditions of the theory of similarity, the geometric scale was chosen to be 1:100 (

Table 6,

Table 7 and

Table 8).

The tails distribution along the beach zone with optimum pulp quality depending on the pulp speed are presented in

Table 9.

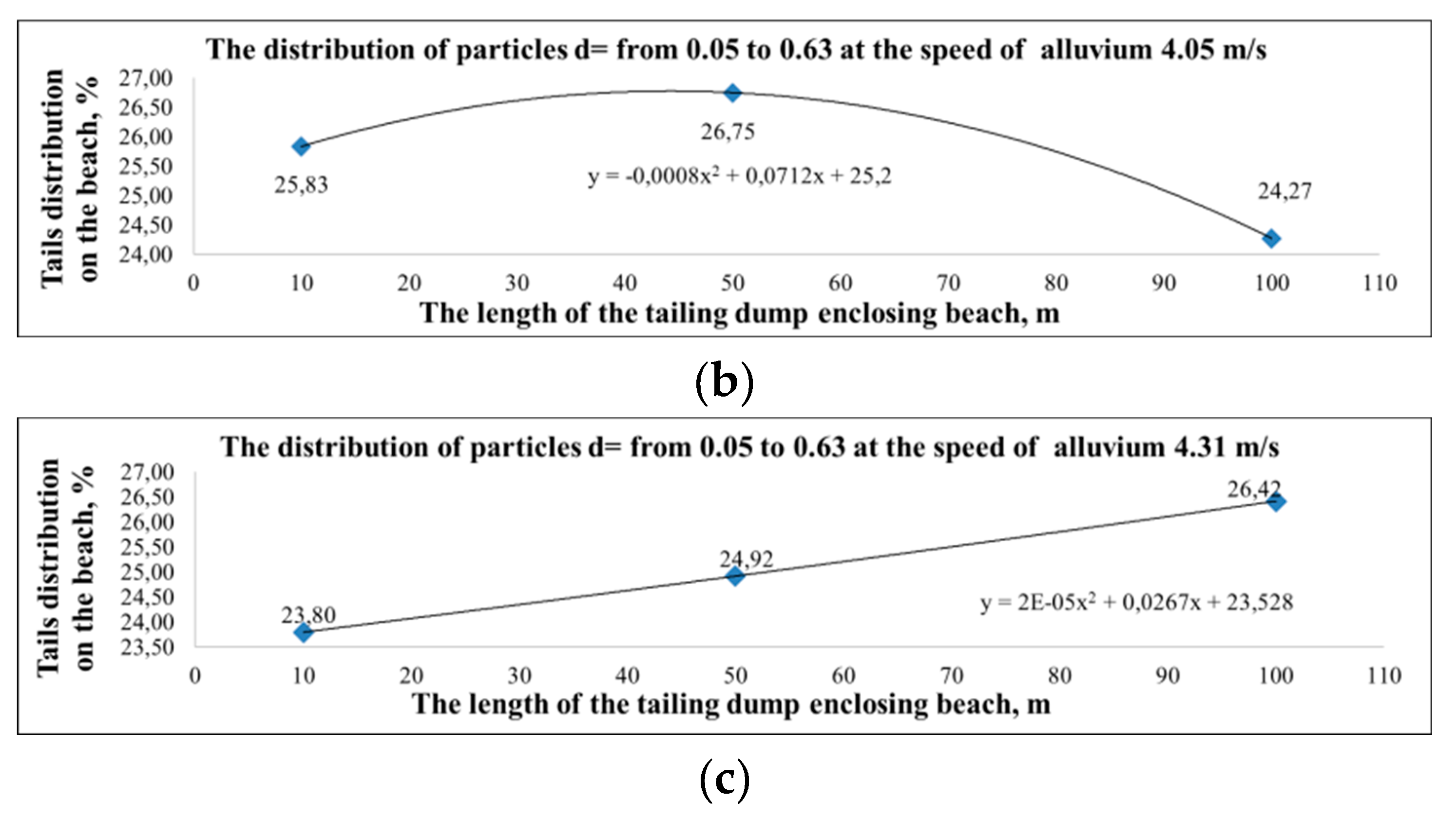

As a result of the experiments, polynomial trend lines of tails distribution along the beach area were obtained with optimum pulp consistency (liquid to solid ratio) depending on the speed of the pulp (

Figure 11).

Figure 12 shows a summary graph of the tails distribution along the beach at a dis-tance of 10, 40 and 70 m from the distribution slurry pipeline.

According to the data in

Figure 12 the tails distribution along the beach has quadratic dependence on the pulp velocity, the height of the pulp axis, and the weighted average particle diameter.

Figure 2 shows the dam's coefficient of stability

kst depending on its construction parameters- the height of the dam, the bottom slope layout and the duration of the shore.

The results indicate that raising the height of the dam and the bottom slope layout decreases its stability coefficient substantially. But the raising the duration of the shore from 50 to 150 meters increases stability coefficient [

10,

25].

In the aggregate, these parameters will be dominant for any task of increasing the stability of a certain part of the beach due to the redistribution of tails.

To determine the influence of geometric characteristics on the stability of the tailing dam, three variants of calculations were performed with beach lengths of 50, 100, and 150 meters.

Regularities of changes in the coefficient of stability (

kst) of the dam against its design parameters - the height and steepness of the bottom slope and the length of the beach - are shown in

Figure 2.

The results of calculations show that with the same initially given data, an increase in the height of the dam leads to a significant decrease of its stability coefficient.

Figure 13.

The kst value depending on the geometrical parameters: (a) the influence of the height of the dam; (b) the bottom slope layout; (c) beach length effect.

Figure 13.

The kst value depending on the geometrical parameters: (a) the influence of the height of the dam; (b) the bottom slope layout; (c) beach length effect.

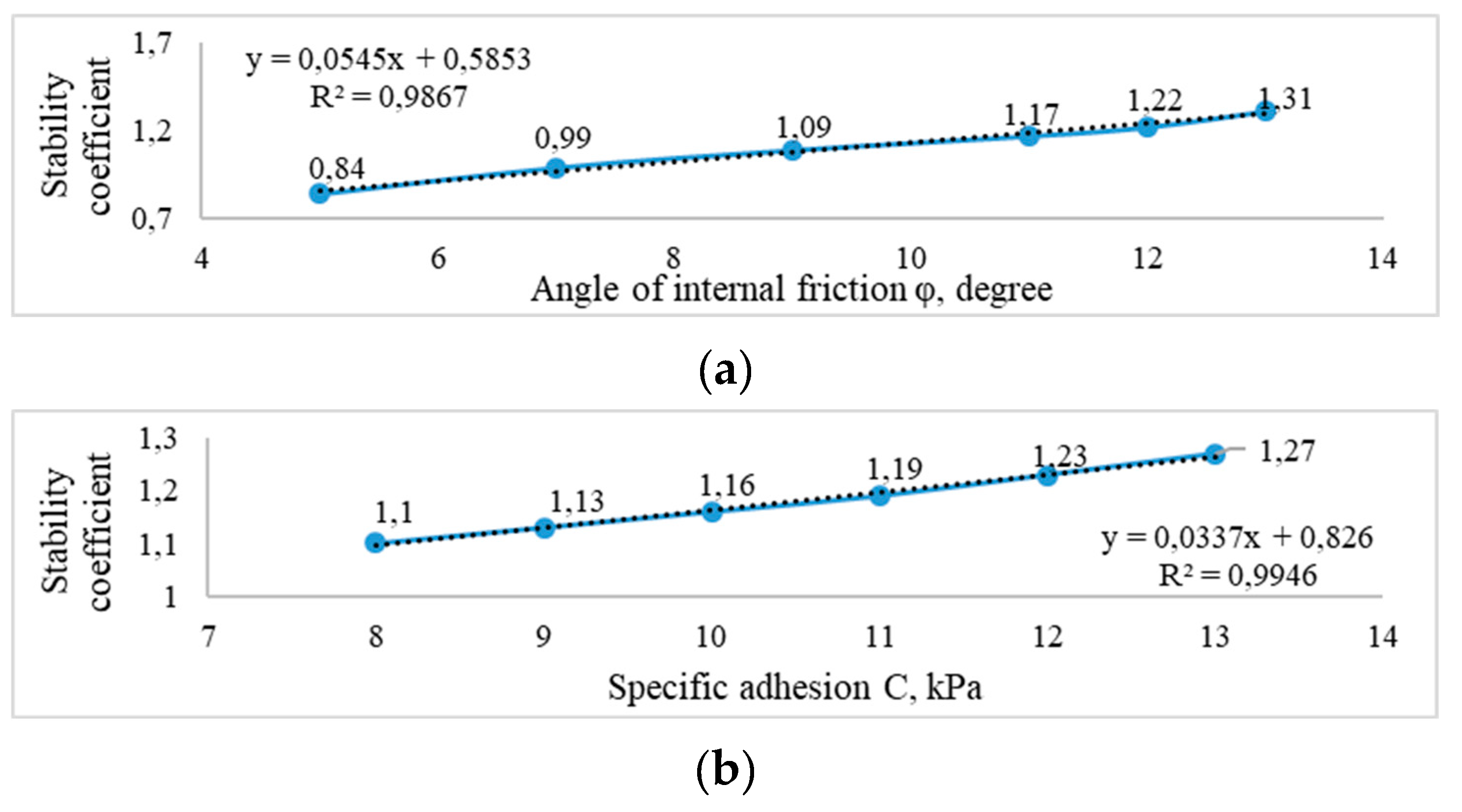

The influence of physical and mechanical properties has been studied using physical modeling of the enclosing tailing dam formation. The change of such criteria for assessing the accident and stability - as the strength characteristics of man-made soils - the angle of internal friction and specific adhesion were investigated.

To establish the effect of changes in the physical and mechanical properties on stability, the values of specific adhesion and angle of internal friction of the soils com-posing the dam body were changed in the design scheme (

Figure 3).

In the aggregate, these parameters will be dominant for any task of increasing the stability of a certain part of the beach due to the redistribution of tails.

To determine the influence of geometric characteristics on the stability of the tailing dam, three variants of calculations were performed with beach lengths of 50, 100, and 150 meters.

Regularities of changes in the coefficient of stability (

kst) of the dam against its design parameters - the height and steepness of the bottom slope and the length of the beach - are shown in

Figure 2.

The results of calculations show that with the same initially given data, an increase in the height of the dam leads to a significant decrease of its stability coefficient.

The influence of physical and mechanical properties has been studied using physical modeling of the enclosing tailing dam formation. The change of such criteria for assessing the accident and stability - as the strength characteristics of tails - the angle of internal friction and specific adhesion were investigated.

To establish the effect of changes in the physical and mechanical properties on stability, the values of specific adhesion and angle of internal friction of the soils composing the dam body were changed in the design scheme (

Figure 14).

Analysis of the results showed a proportional dependence of the change in the stability coefficient on the soils’ physical and mechanical properties, while the specific adhesion is a more important parameter determining stability than the angle of internal friction.

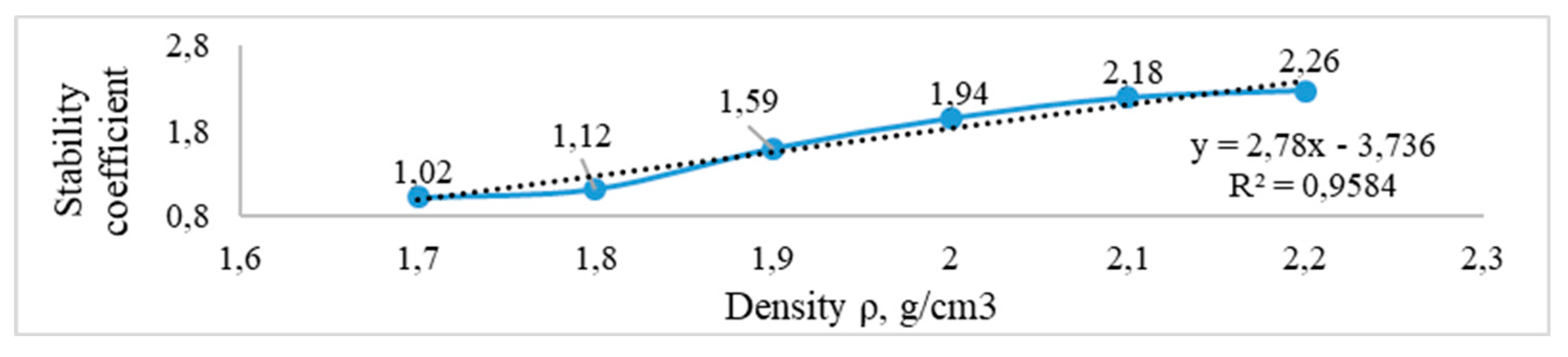

In order to control the strength characteristics and, accordingly, the stability of the enclosing dam, the process of the tailings’ in-wash on the beach area with the use of a compactor of dynamic action was modeled. The values of the stability coefficient are shown in

Figure 15.

From the analysis of the test results, it can be concluded that the coefficient of technogenic deposit enclosing dam stability linearly depends on the geometrical parameters of the dam, the strength characteristics of the in-washed deposits, and the degree of their compaction [

25].

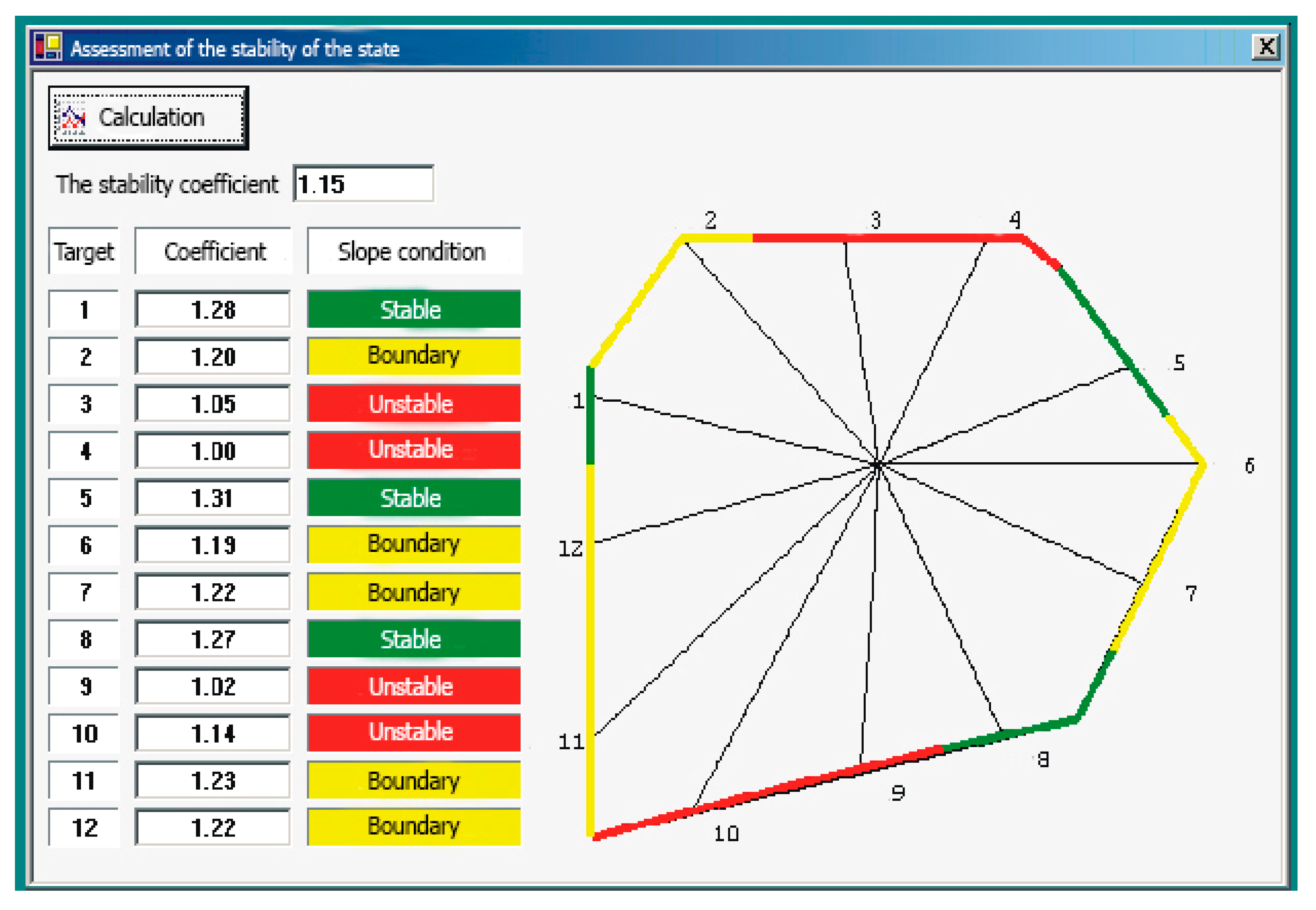

The developed method of estimated performance monitoring the stability of tailing dam was tested and implemented in a number of design decisions for the tailing dumps of the mining and non-ferrous metallurgy industrial enterprise in the North of Siberia.

The results of calculations used for zoning and to visualize the state of the tailings of tailing dump. Normally the legend to the map serves as a table, in which different colors marked valid, invalid, and above the permissible values safety factor of sustainability as indicated in

Table 10 [

25].

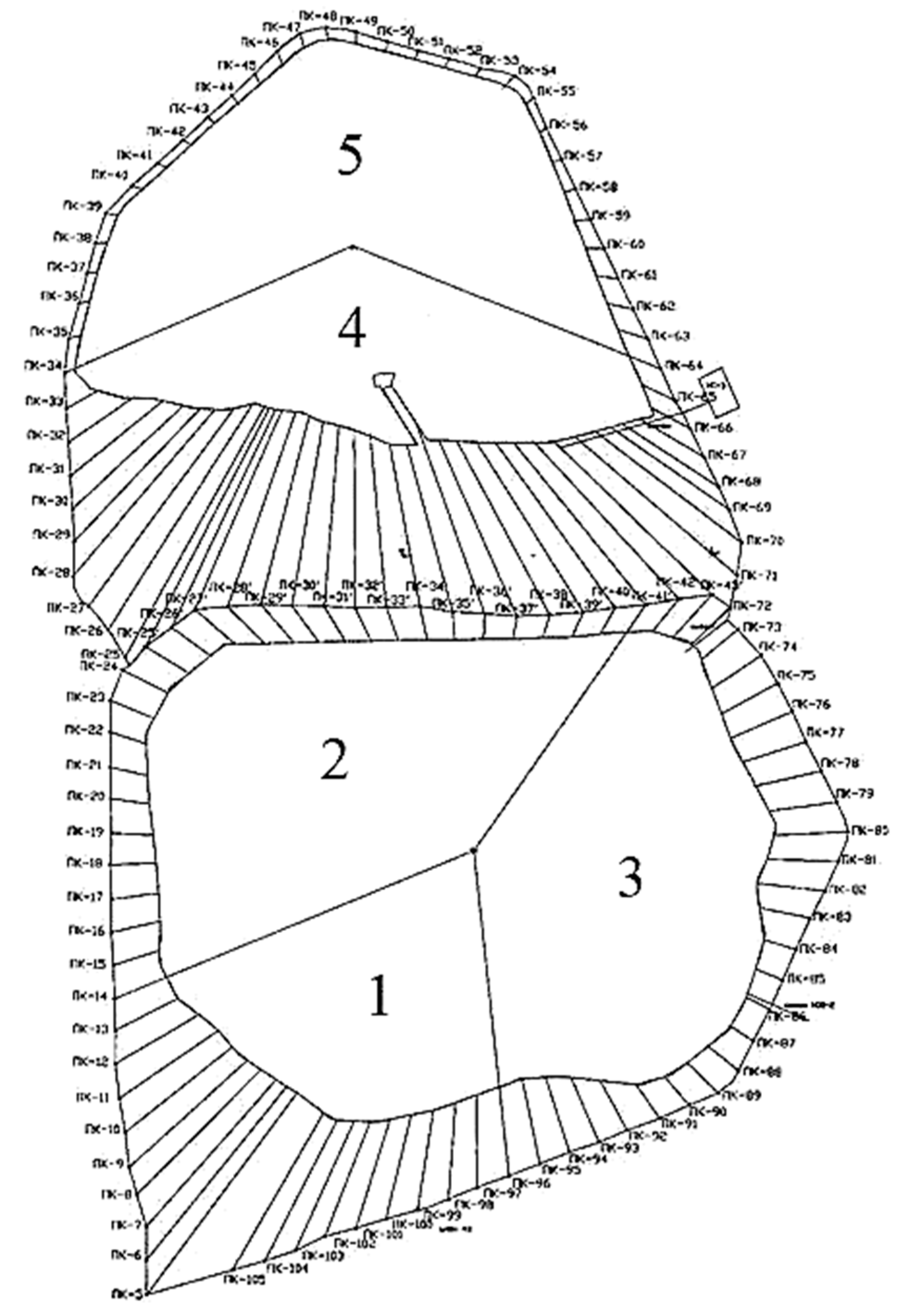

The scheme is represented as a cartographic model with dedicated it clearing blocks by color the status of the tailing dam stability (

Figure 16).

According to the results of calculations it is established:

plots along areas 1, 5 and 8 are in a steady state – slope condition is stable;

plots along areas 2, 6, 7, 11 and 12 should be operated with careful observance of the requirements of the project for the operation of the tailing dump – slope condition is boundary;

dam sites along cross-sections 3, 4, 9, and 10 need urgent measures to increase the bearing capacity of the dam – slope condition is unstable.

In these areas (3, 4, 9, 10), various methods must be applied to prevent an accident.

It is possible to do by technological ways. We will consider the results of approbation of some of them [

26].

Intensity of the inwash process increases on the sites where the secondary coating of tails of the beach area at a distance of 5 m were carried out by tails with the help of excavating equipment. The schematic circuit of banking is shown in

Figure 17.

This allows to form an additional embankment dam, which in turn leads to a change of:

geometric parameters of the dam with an increase in the size of the dam along the top;

processes of consolidation of inwashed tailings, their acceleration and natural im-provement of the dam base.

Creation of a secondary dam with the help of an excavator has shown high efficiency.

Average speed of arrangement of a secondary dam from stale tails with the help of an excavator comes to ~10-30 meters per hour.

At realization of the technology with the use of banking by excavating equipment, the following operations are being occasionally excluded from the technology used now:

Using the technology of levee embankment allows increasing its volume up to 6%.

The next technological way of compression process and dumps volume increasing has been used by compacting of inwashed beach zone by rollers (

Figure 18)

During compaction process of tails the next rules were observed:

The selection of the type of the roller has been carried out under the average characteristics of compacting tails;

The compacting was made with keeping of a technological pause for two weeks, after inwashing of the next layer of tails and achieving of the optimum humidity by 15÷20 %;

Each subsequent compacting trace of roller overlaped previous on 20÷30 cm;

The direction of movement of road-roller has been chosen from a retaining prism of a dam to a slurry collecting slag prism;

The number of one trace passes has been defined in dependence from the weight characteristics of the roller, initial density, humidity of tails, and from the demanded final density of tails.

As a result of compacting it is possible to receive reserves of volume of depositing tails up to 25÷30 %.

Parameters of compression process depend on humidity, density, and grain-size composition of tails.

Compression was carried out in two weeks after the completion of an inwash of the next sector. The use of compression allows increasing the capacity of a beach up to 30 %. Besides, due to compression, filtration factor reduction of a body of a dam is observed and value of stability factor increases

The results of the obtained data were compared with the results of the basic version of the calculation of the stability of the structure. They show the dynamics of changes in the properties of soils, which effects on the stability coefficient, proving the legitimacy of the technology application (

Table 11).

Thus the approach on accident factors allow for monitoring construction in the process of exploitation and to take urgent measures in hazardous areas surrounding the tailings dam.

When choosing a technological scheme of construction and operation the influence of climatic conditions on the geotechnical massif technological scheme forming process is of particular importance.

On available samples of tails 15 series of samples of the set moisture content and density for carrying out of the further trials have been generated. At planning out of quantity of experiments the methods of probability theory and the mathematical statistics were used. The given conclusion has been taken as principle definitions of quantity of tests at the set parameters of experiment. Physical properties of the tested samples are presented in

Table 12 [

25,

27,

28].

The compression curves for the tail samples with specified moisture content and density are shown in

Figure 19. From that data we can see that the behavior of tails at different moisture content and density remains invariable. It testifies that the given factor of consolidation can be applied to definition of consolidation characteristics of tails that considerably will reduce labour input.

The time, required for consolidation of the layer and also the description of the process of the sample deformation in height h depending on its deformation properties were defined by the equation (1). The results are presented in

Table 13.

As known, the process of tailings inwash is divided into two stages: tails inwash and consolidation of inwashed tails.

The obtained values of the inwash and tails consolidation times presented in

Table 14.

On the basis of the obtained results, it follows that with successive washing of sec-tors, the duration of the inwash will be:

where H - the inwash process; K – the consolidation process of the tails; 1-5 – the sector numbers.

However, according to the climatic conditions of the region, tailings can be in-washed only for 195 days.

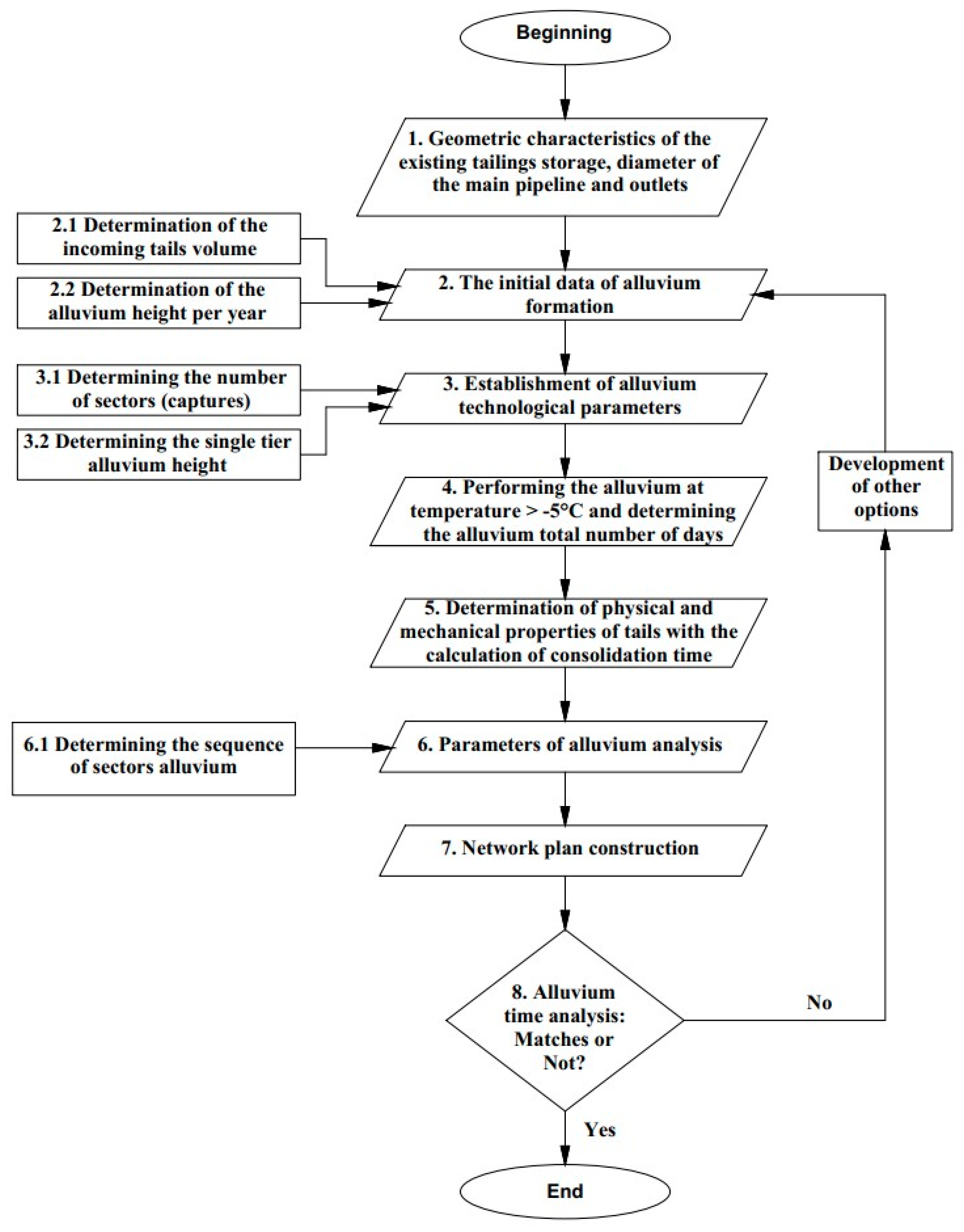

In order to meet the regulatory requirements, optimization of the process of reclamation has been applied to network planning (

Figure 20).

The inwash is proposed to start from the 4th sector of H4, since the time required for its inwash is 16 days and is the longest in duration. After the end of the H4 wash-up, the consolidation process of K4 begins, simultaneously with it 5th sector H5 - inwash for 15 days.

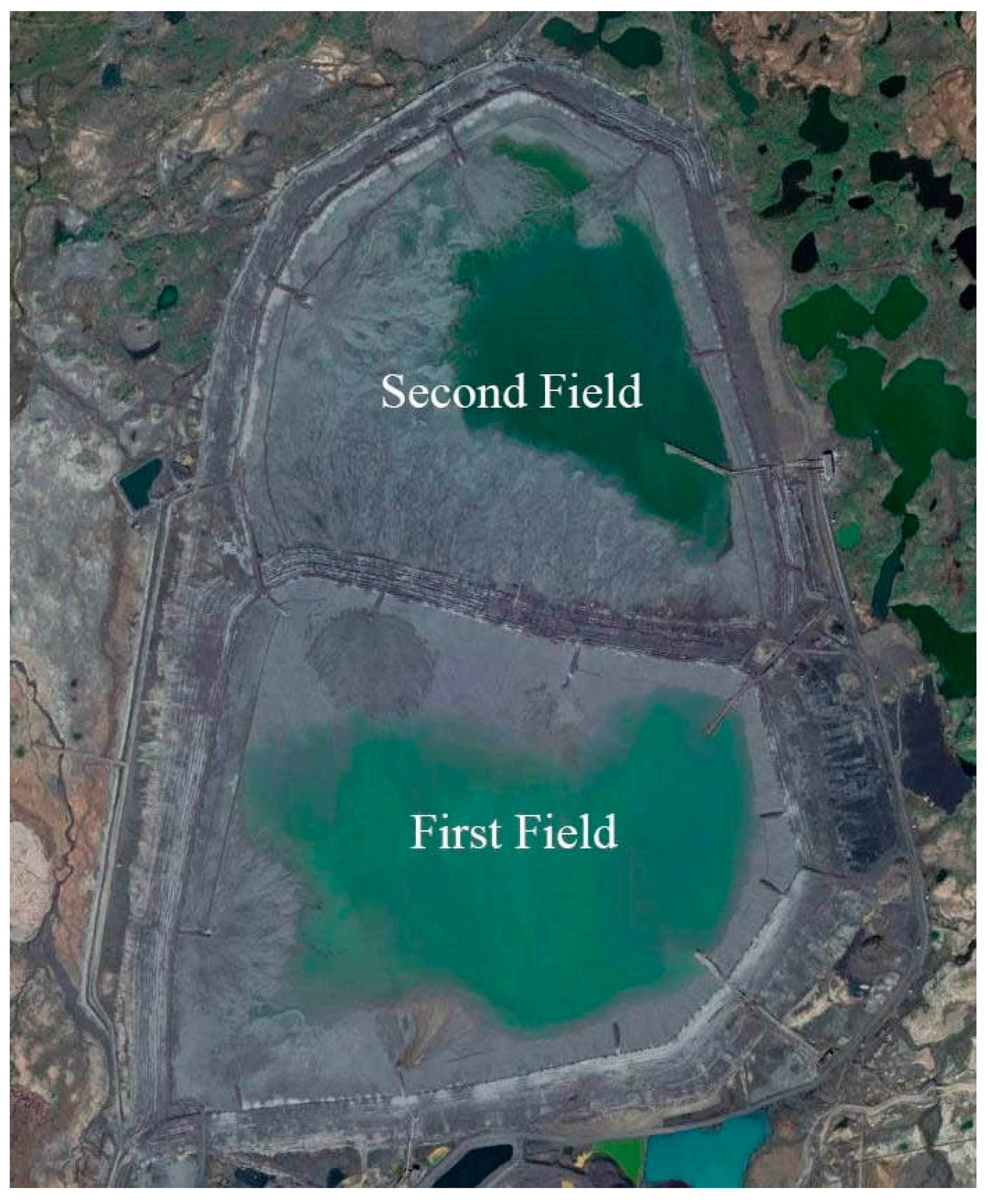

In addition, in the case of two fields, it is advisable to go through all the stages of reclamation and consolidation in one field, and then move on to another, since in longer distances this will be more rational and ergonomic.

As a result of the construction and calculation of the network schedule, it was de-termined that the critical path duration is 189 days, which allows us to conclude that the entire volume of tailings will be laid in the required time.

Further, complex studies of the composition, structure and properties of tailings were carried out for the engineering and geological justification of the formation of alluvial technogenic massifs.

The results of research have shown that tailings have their own characteristic features of structure, composition and properties.

The results of the analysis of the granulometric composition of soils obtained by microaggregate, standard and dispersion methods are presented in

Table 15:

The results of determining the granulometric composition were used to calculate the microaggregate coefficients (K

ma) for six fractions based on the difference in their contents during dispersed and aggregate sample preparation, presented in

Table 16.

A negative coefficient indicates the number of aggregates of the corresponding value. The coefficient of microaggregates with a positive sign - an increase of particles of smaller sizes that released from aggregates.

Thus, during dispersion, a natural process occurs: larger elements destroyed, and the smallest ones collected in a fraction less than 0.001 mm.

The degree of soil aggregation and the size of their aggregates and particles determined by the microaggregationality coefficients. Experiments and calculations made it possible to determine the features of tailings microstructure, types of microstructures and structural models of soils (

Table 17).

The next step is to get the total content of primary particles + particles in the composition of the aggregates (

Table 18).

The degree of soil aggregation and the size of their aggregates and particles determined by the microaggregationality coefficients. Experiments and calculations made it possible to determine the features of tailings microstructure, types of microstructures and structural models of soils (

Table 19).

Air-dry samples were used to determine indicators of physical and physical-chemical properties of soils. The research results presented in (

Table 20).

Due to the specific values of the strength of technogenic soils, which is associated with their specific composition (ore dressing wastes), it is not possible to use any recommendations of regulatory documents and reference calculated values "c" and "φ". Experimental data are required for calculations.

According to dispersed granulometry (boiling with sodium pyrophosphate) and on the basis of the calculations performed, the following information can be provided:

The tailings of the tailing dump are sandy loams, the content of the medium-coarse sandy fraction (>0.25 mm) is 49.2%, the fine-fine sandy fraction (0.25-0.05 mm) - 30.1%. The amount of clay particles is 10.0%. According to the total number of aggregates, an aggregated-skeletal (A=9.5%) microstructure was established. The type of structural model is medium-coarse sandy (medium-coarse sandy structural elements prevail), elementary (G2=82%).

Mathematical modelling of various schemes of refining tails and magnetic pyrite concentrate, with the forecast of stability of frame fillings, was done in order to develop effective technique. Drilling and maintenance of inspection equipment, measuring of temperatures and water levels in a dam body were executed. Exploration drilling including full testing of core samples was carried out on the territory of the magnetic pyrite depository №2.

To forecast the levee stability a number of programs was used. The program complex UWay FEM package was applied to calculate temperature condition on the basis of finite elements. To forecast the levee stability, the program UniFos was used [

12].

The program complex UWay permits to forecast the stress-strained state of soil and rocky massifs, the change of temperature and hydrological modes of soil massif.

The UWay program makes the following types of calculations:

changes of geometry of settlement area (for example, the registration of phases of buildings);

changes of properties of materials;

changes of boundary conditions (both power, and displacement);

operation of materials according to various models of behaviour of soils under load

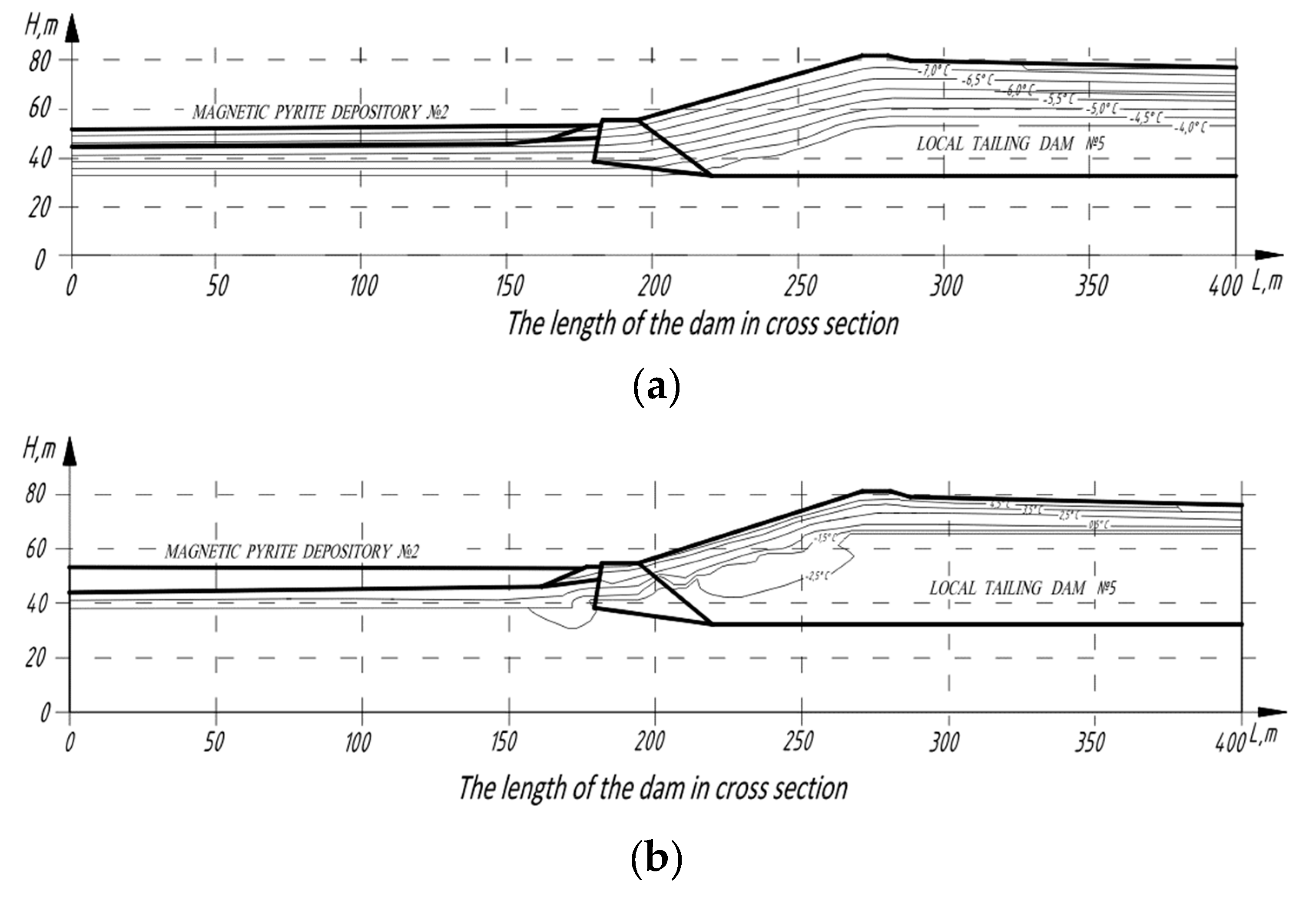

At the first stage the calculations of the temperature conditions in tailing dam’s massif for winter and summer periods were made. The results of calculations are shown in

Figure 21.

The given results were used for the appointment of physical and mechanical characteristics of soils composing the dam’s body and have formed the basis of the calculations of dam’s coefficient stability. The calculations were carried out by means of the UniFos program.

The UniFos program is a part of the UWay complex and is assigned for calculations of stability of soil constructions. It is written in the object-oriented language C ++ with the usage of optimizing compiler Borland C ++ Borland International v.5.02 with the library OWL usage v.5.0 [

12]

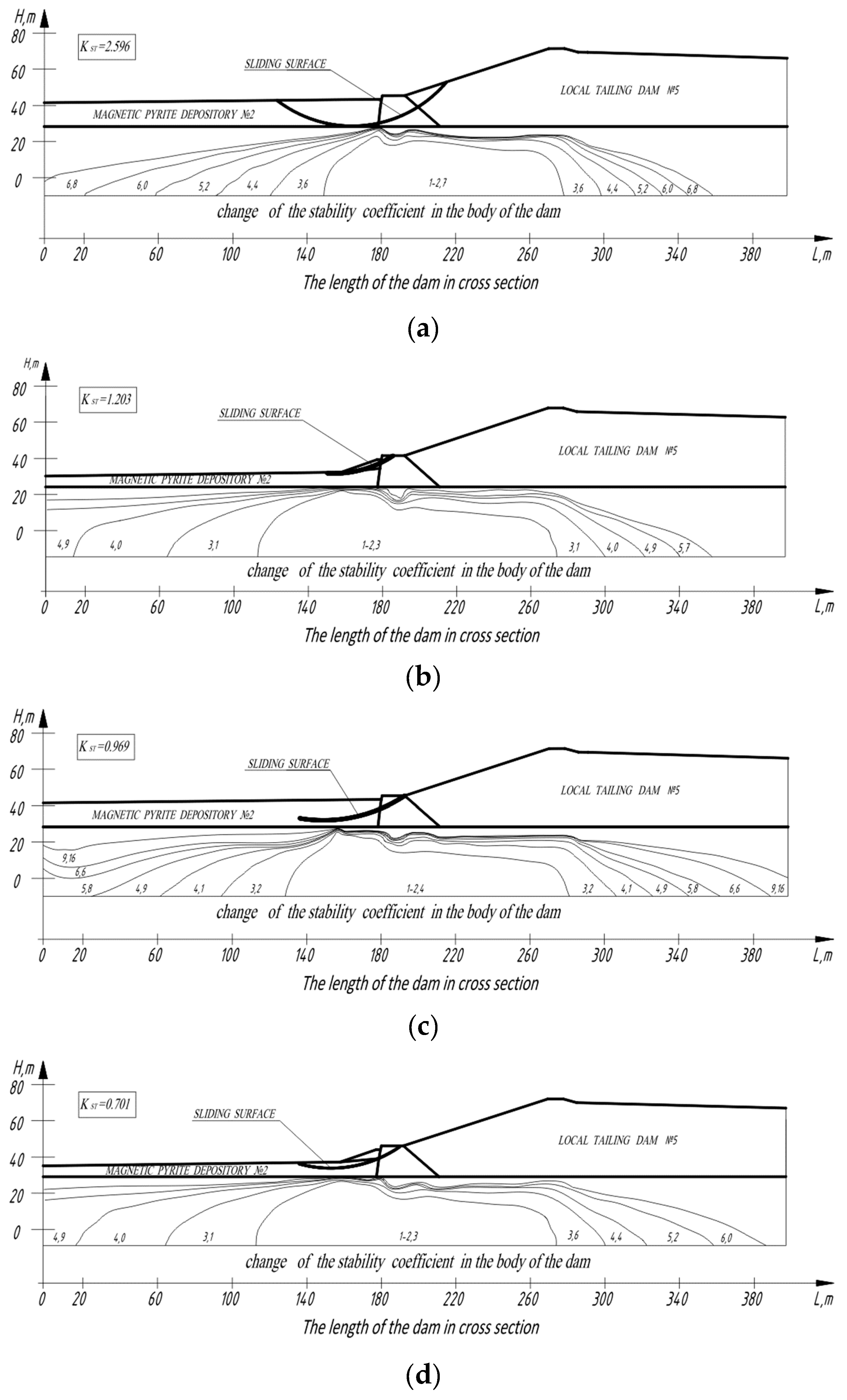

At the next stage the calculations of the stability coefficient of the tailing dam were carried out for four conditions:

a) in winter time before excavating works;

b) in winter time on termination of excavating;

c) in summer time on termination of excavating works and flooding by water;

d) in summer time without flooding by water.

The results of calculations of the dam’s stability coefficient are shown in

Figure 22.

The analysis of results of mathematical modeling shows that the dam stability is not provided during the summer period (stability coefficient is less than 1) when the earlier suggested technology of magnetic pyrite concentrate excavating is used. This result helped to form the basis for changing work technique that provided, in its turn, safe and effective execution phase.

The justification of the minimum sizes of the security zone, and the development of the concentrate excavating technology were executed at the following stage of modelling.

At this stage various options of concentrate refining were considered:

with preservation of a security zone of various width (20, 50, 75, 100 m),

with the backfilling and without,

with a thawing assumption, etc.

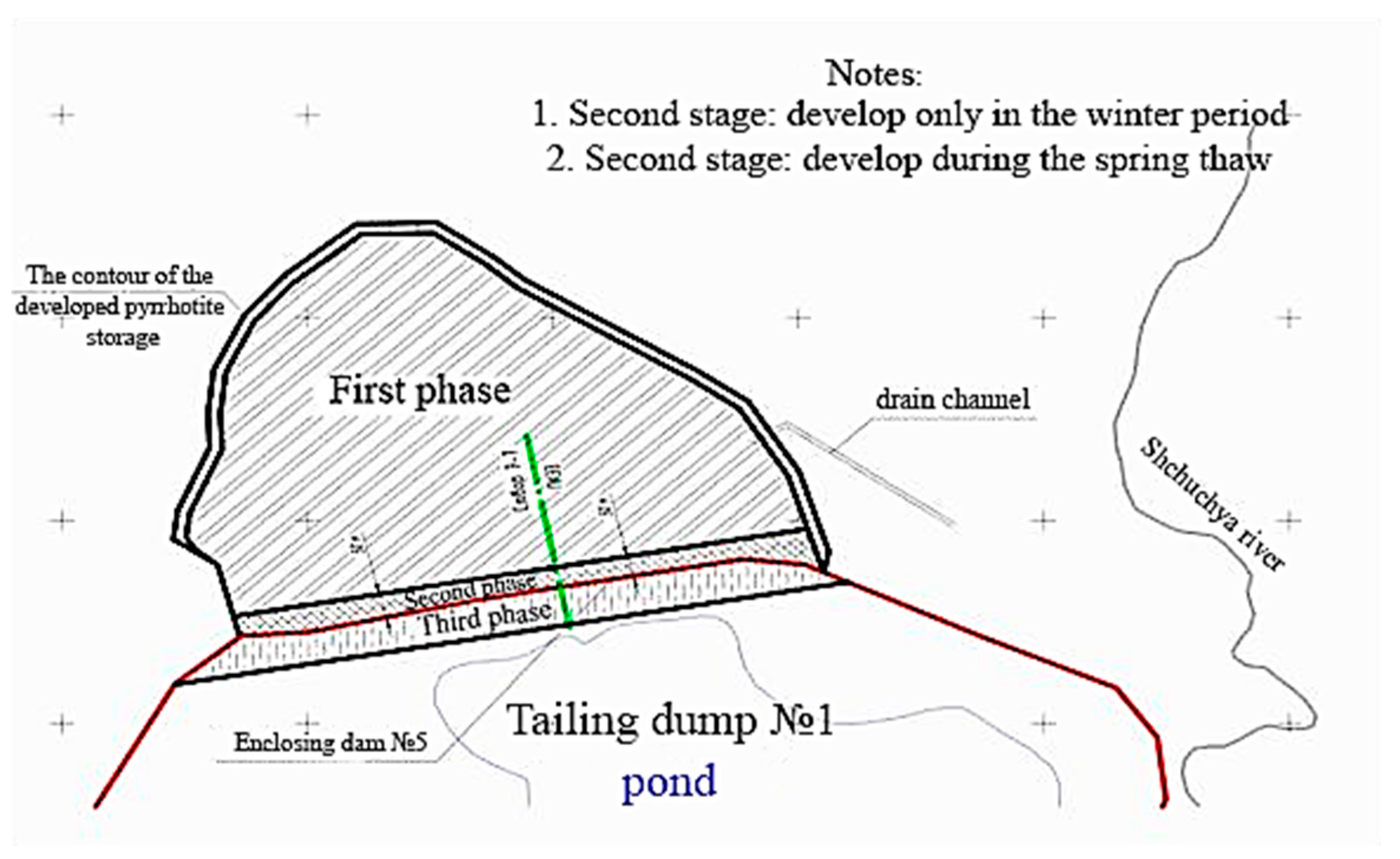

The results of calculations of stability coefficient for the various sizes of a security zone width permit to draw a conclusion that its optimum equals 50 m. This conclusion was based on the development of the excavating technology of magnetic pyrite concentrate.

The excavating technology of the pyrite concentrate is offered to be carried out in the following sequence (

Figure 23):

1 turn: To excavate the concentrate from the whole area of the pyrite depository №2 up to the border of the security zone (about 50 m);

2 turn: To excavate the concentrate within the security zone during winter period;

3 turn: To substitute the excavated volume within the security zone for soil material from the local tailing dam using slope flattening (at the beginning of the summer period).

The crest of a dam will be cut off by 2 meters, i.e. to the mark of 121,0 m (under the condition of preservation of minimum admissible excess of dam crest level over the level of a pond mirror (mark - 117,2 m). The slope inclination will decrease to 1:4 that improves the dam stability.

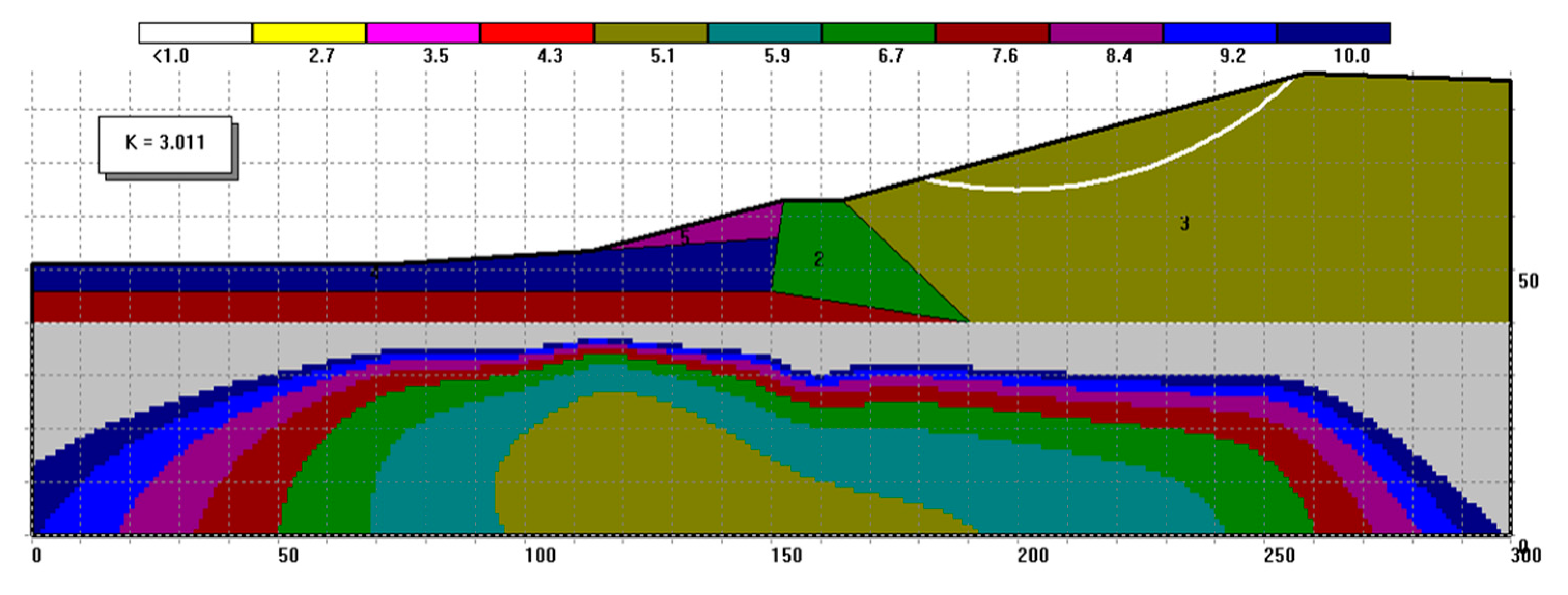

The stability coefficient will grow to 3.0 value that testifies to a steady condition of the tailing dam (

Figure 24).

Program complex UWay FEM package has been applied to the dam’s temperature condition calculation on the basis of finite elements.

Forecasting of stability of a levee is executed by means of the UniFos program.

The carried out calculations permitted to forecast the stability of tailing dam and formed the basis for alteration of work technique that provided safe and effective execution phase.