2. Virtual Simulation System for Reactor Decommissioning

The research on the application of virtual simulation technology in the decommissioning of nuclear facilities in foreign countries started early and has made important contributions to the economy of decommissioning and various indicators of decommissioning plans. Studying the decommissioning technology of nuclear facilities through virtual simulation technology, verifying the feasibility of technical solutions, and optimizing the process have become an important direction for studying the decommissioning of nuclear facilities, and have become an essential technical means to solve the key problems of nuclear facility decommissioning.

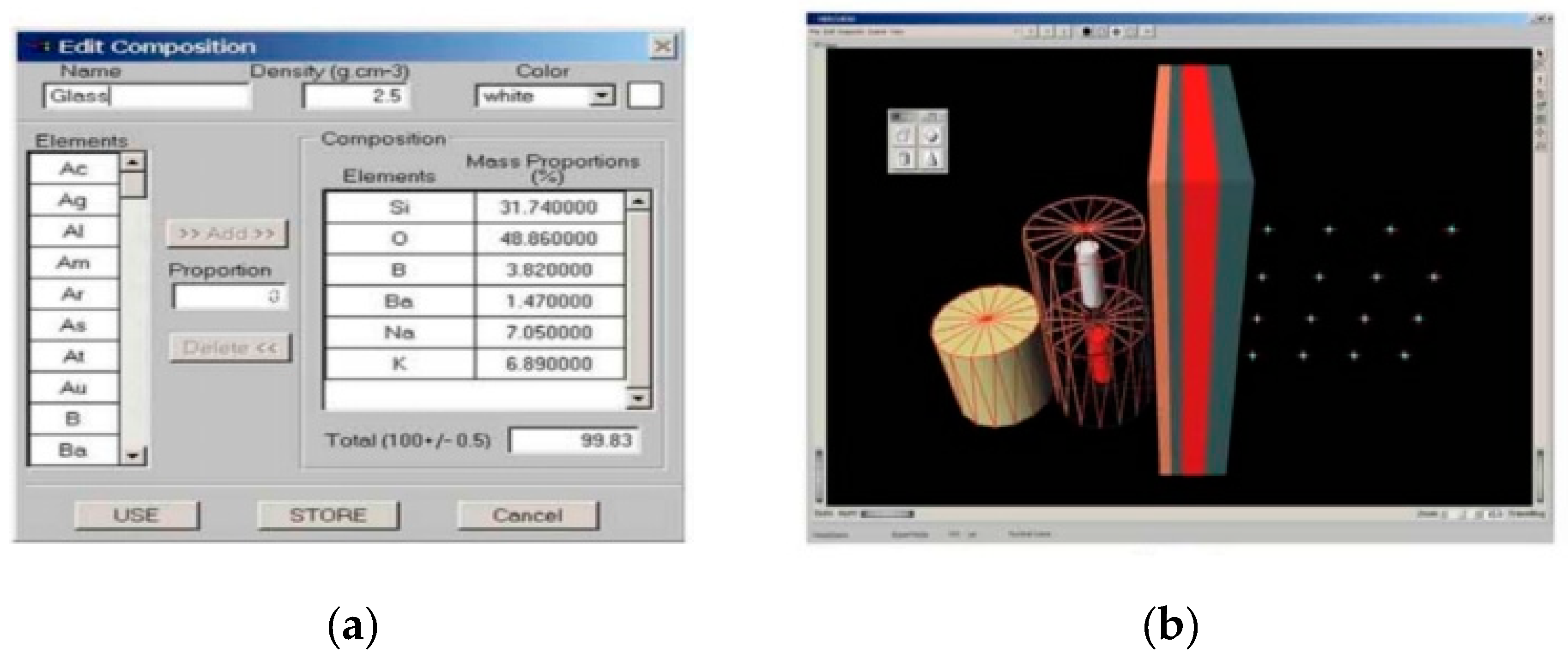

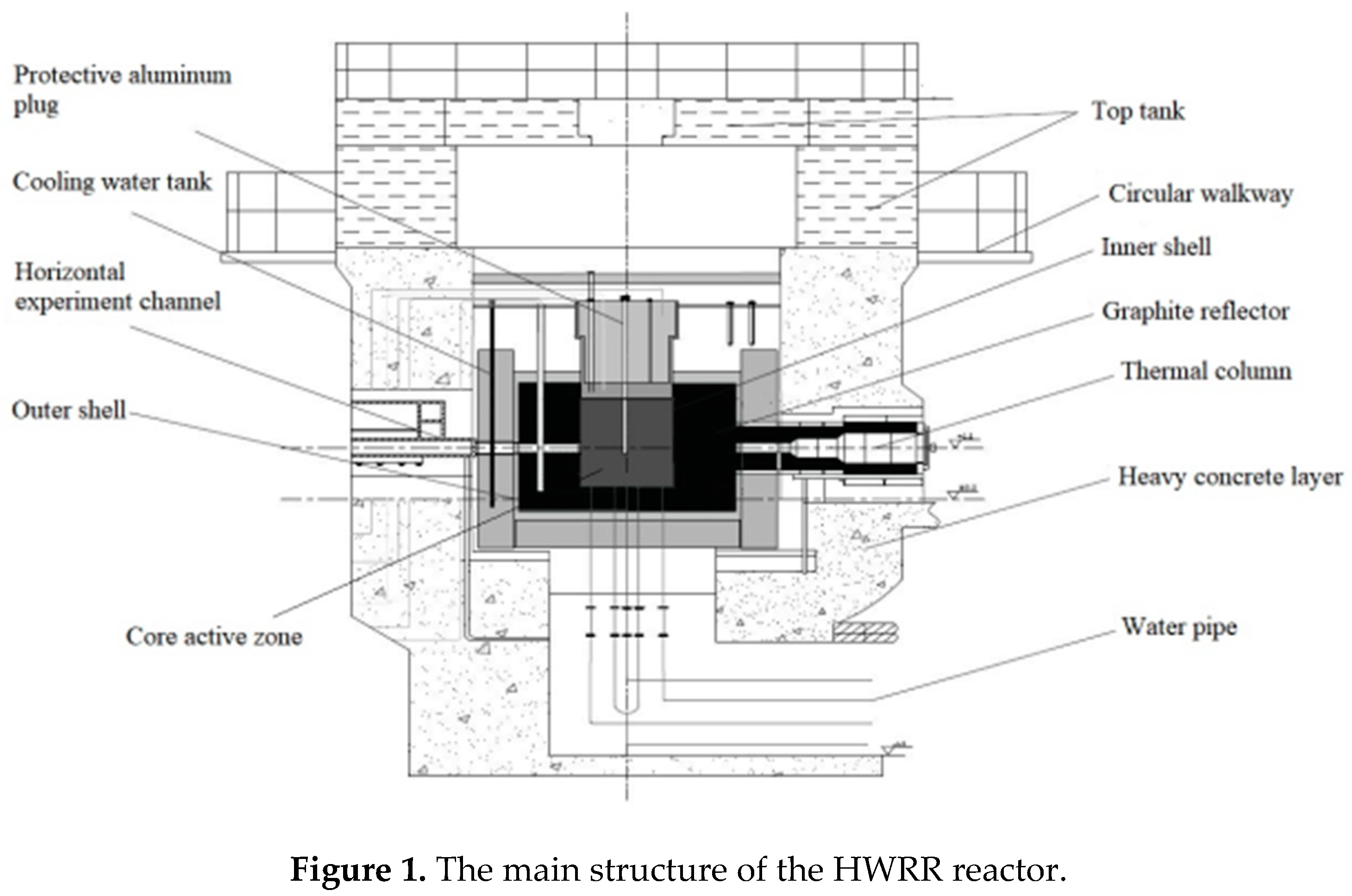

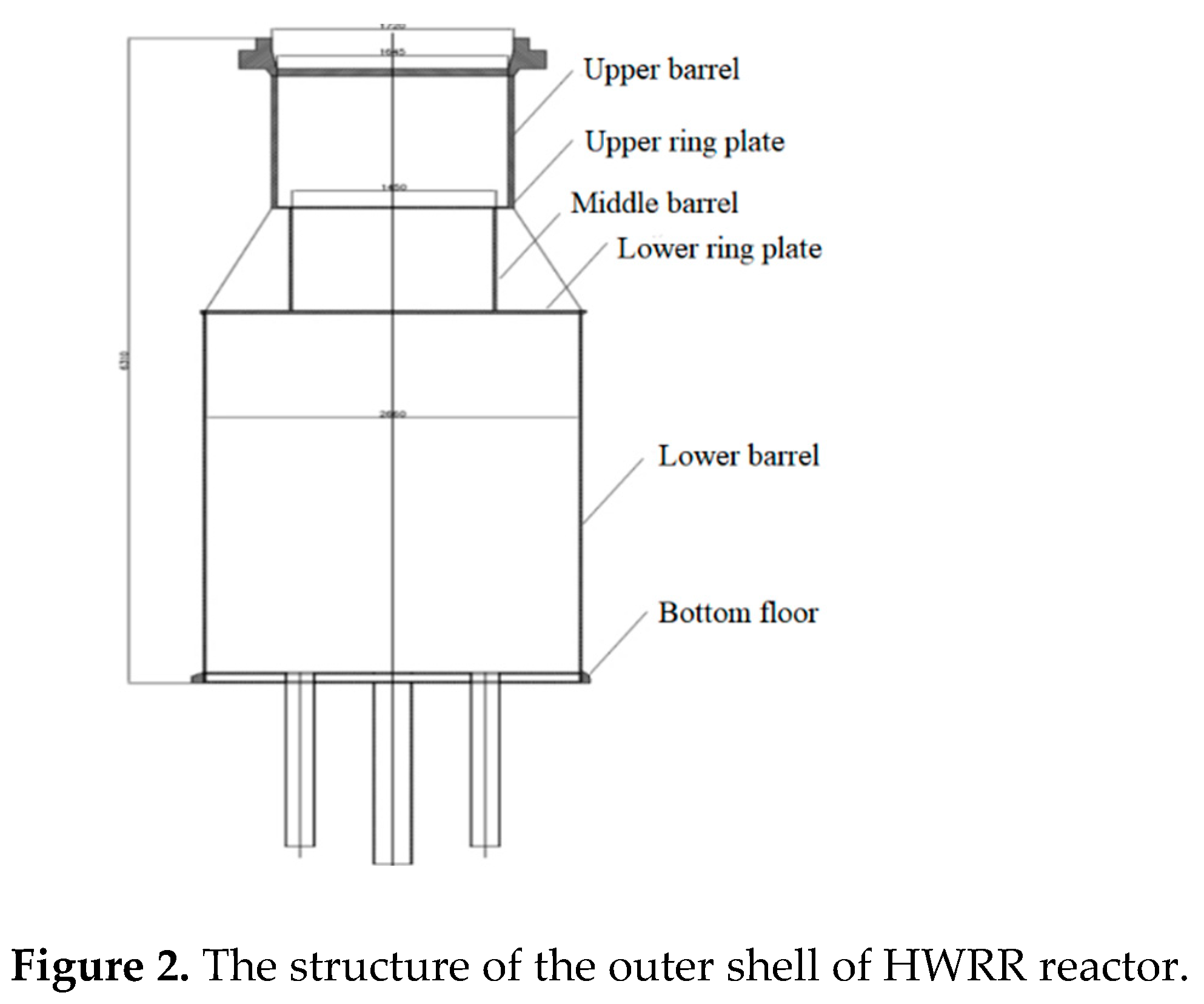

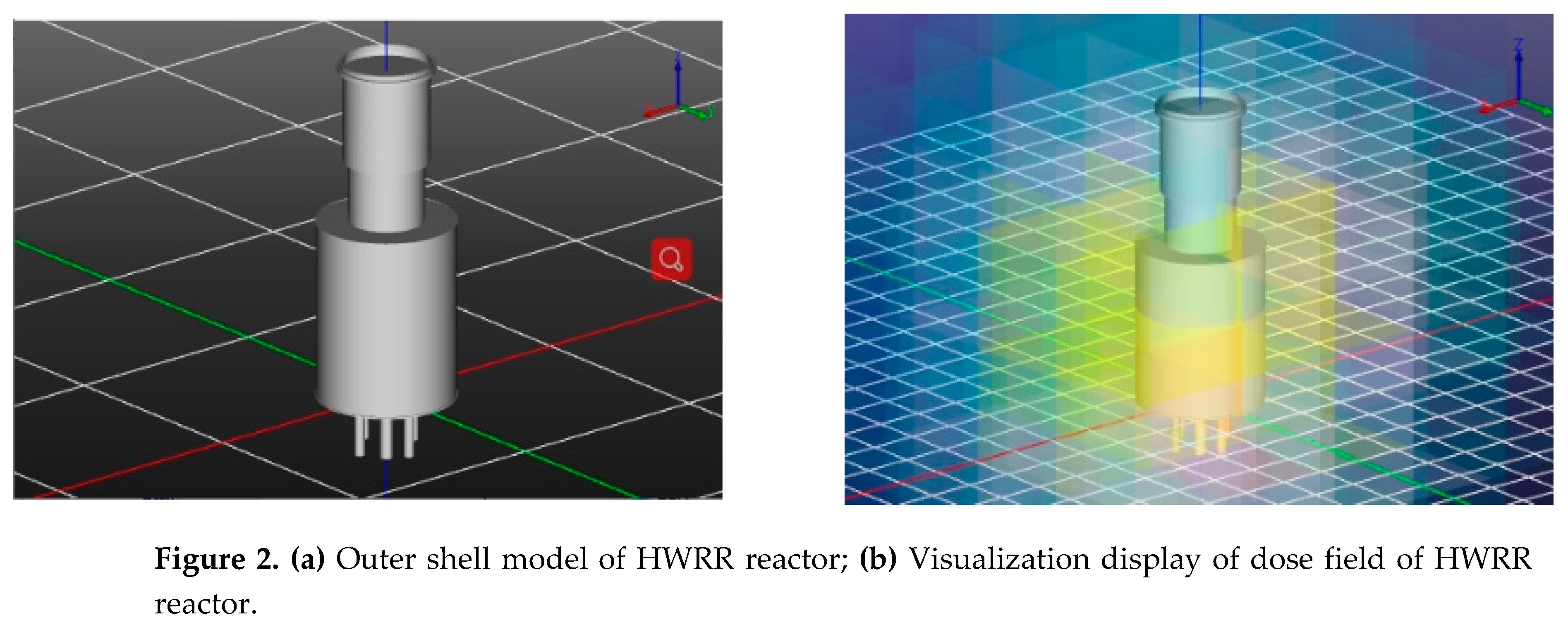

Figure 1.

(a) Selection of Multilayer Shielding Materials in MERCURAD code; (b) Visualize display in MERCURAD code.

Figure 1.

(a) Selection of Multilayer Shielding Materials in MERCURAD code; (b) Visualize display in MERCURAD code.

Since the 1980s, the French Atomic Energy Commission (CEA) has developed multiple simulation programs and software, including MERCURAD [

4,

5], CHAVIR [

6,

7], and NARVEOS [

8,

9]. MERCURAD is a three-dimensional dose field simulation program that uses the point kernel method to calculate dose rates. This program establishes several function modules such as shielding material library, cumulative factor calculation, energy group division, dose point definition, dose field calculation, and printing calculation reports. When calculating the dose fields, multiple layers of different shielding materials can be selected, which can be seen in

Figure 2.1. The total cumulative factor of shielding for different materials can be calculated, the dose field calculation grid can be defined. Furthermore, the calculation of the dose field and the output of the dose field calculation results can be achieved, and the entire process can be visualized and displayed [

5], which can be seen in

Figure 2.2 [

5].

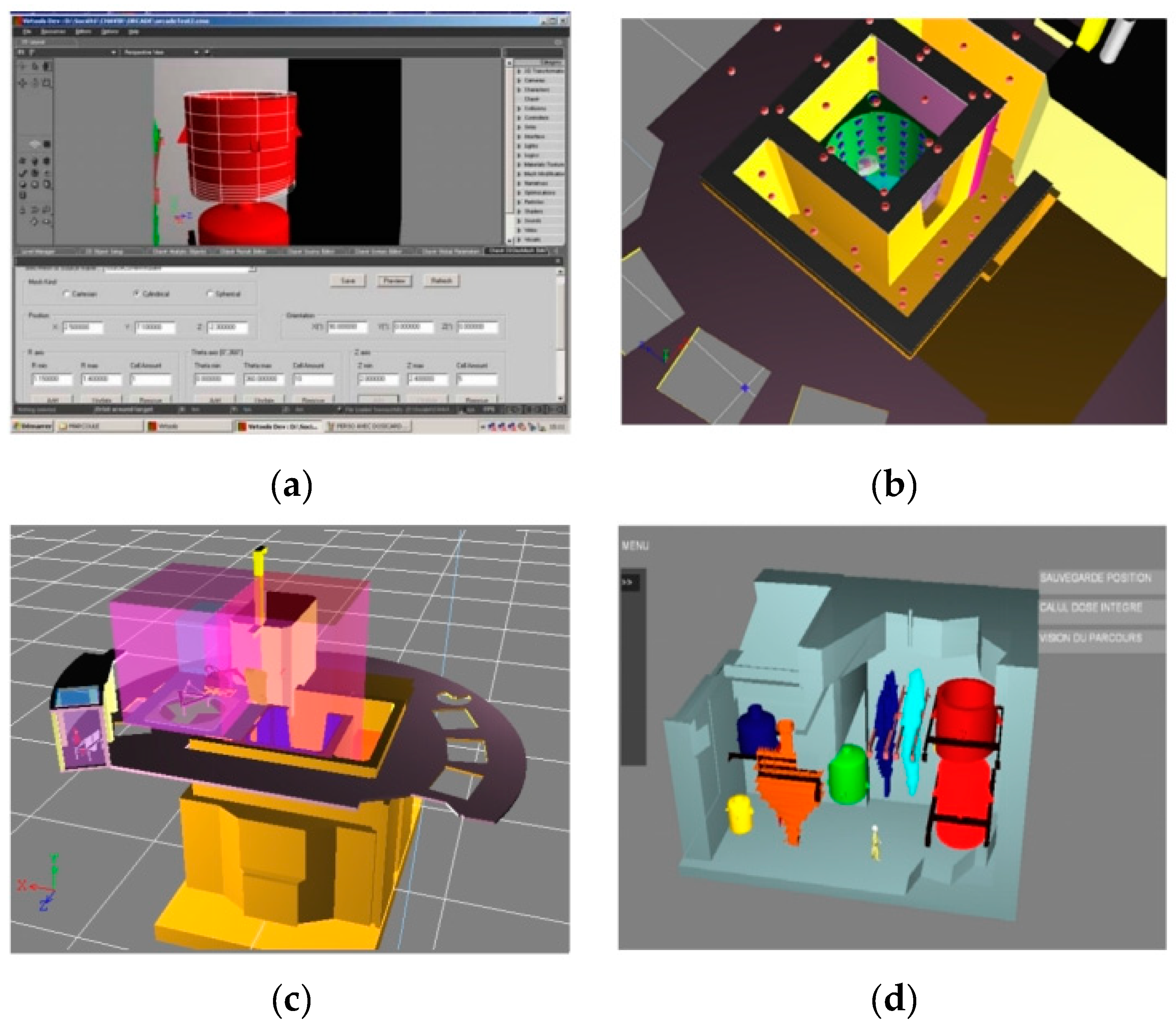

CHAVIR is a software used for nuclear facility maintenance and decommissioning, which can realize scene setting and fast calculation of radiation exposure. The scenario definition function of this software is established by the Dassault software package VIRTOOLS, and the dose calculation function is partially implemented using the algorithm and function modules in the MERCURE code package, such as material selection, cumulative factor calculation, energy group division, etc. The scene CAD model of CHAVIR software can be established from predefined basic objects within the software, or can be imported into other CAD models, with a complete interface to support the implementation of this function. CHAVIR software can calculate the radiation exposure of point source and body source. The point source uses the point kernel method to calculate the radiation exposure, and the body source uses the Monte Carlo method to calculate the radiation exposure by gridding the body source, which can be seen in

Figure 2.3. The coupling calculation of the two methods can be realized simultaneously to simulate the dose field. However, because the Monte Carlo method takes a long time to calculate, the overall calculation time of the software will be long. This software can define measurement points in the scene, and then calculate the dose rate of each measurement point, which can be seen in

Figure 2.4. At the same time, CHAVIR can achieve dynamic calculation of the dose field and calculation of staff exposure dose, which can guide the simulation calculation during the dismantling of retired facilities [

7].

Figure 2.5 and

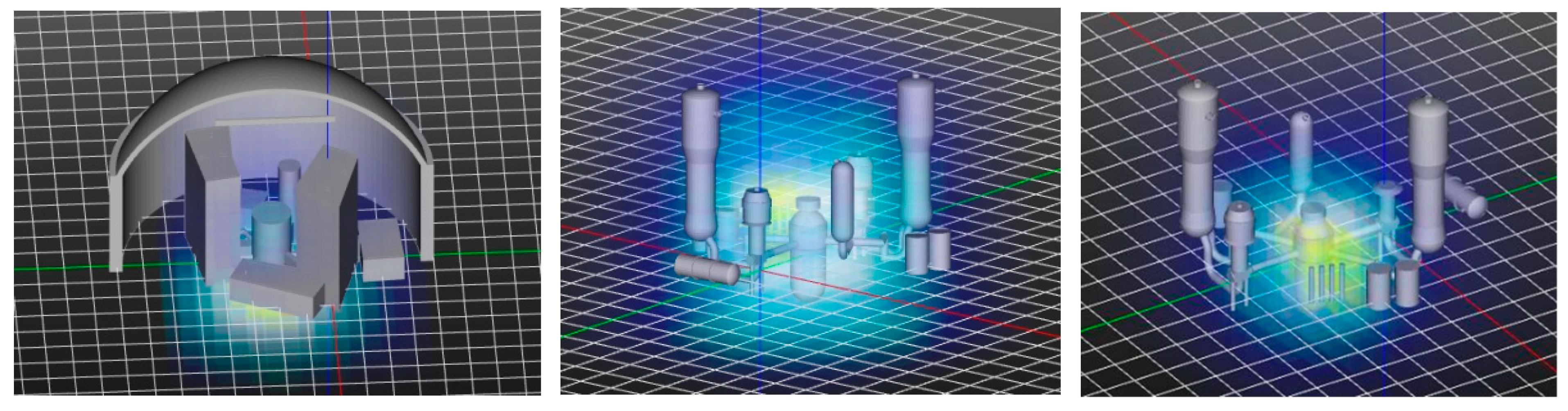

Figure 2.6 show the Visualization Model of Nuclear Power Plants and equipment room in a certain post-treatment plant.

NARVEOS is a software system that combines virtual reality technology and point kernel method to calculate dose field. The software supports retirement scenario design and rapid dose calculation, which based on the principle of radiation assessment optimization (ALARA) to estimate the dose rates, simulate the operational feasibility, and optimize costs. This software can import 3DXML format files from CAD and use Dassault's 3DVia XM player to achieve virtual simulation of retirement scenarios, which can be seen in

Figure 2.7, so that the operating environment of personnel in dose scenarios can be visualized, which can be seen in

Figure 2.8. Besides,

Figure 2.9 shows the exposure dose in personnel operation paths, and then NARVEOS can provide optimization suggestions for personnel protection to reduce personnel exposure dose [

9].

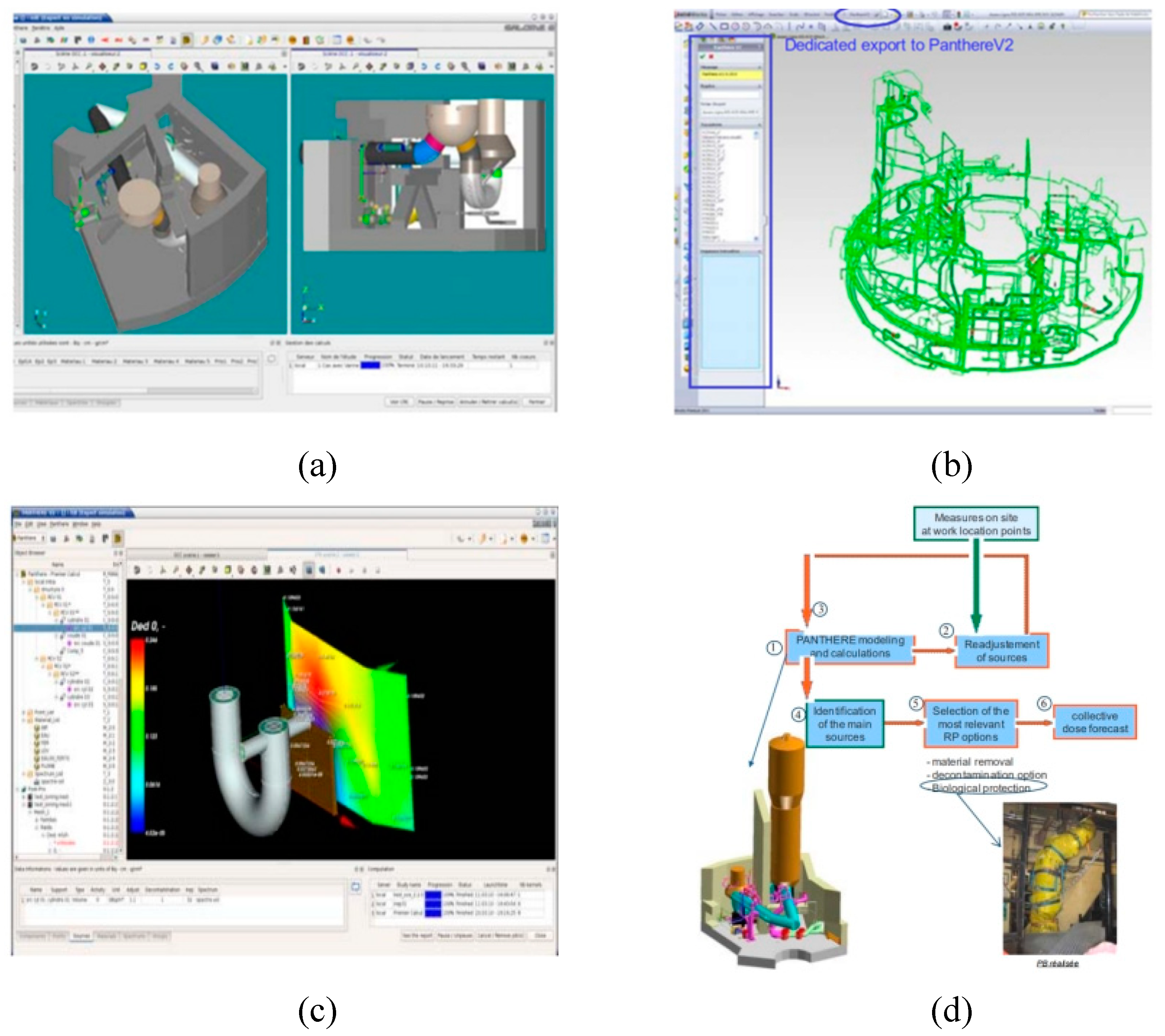

Électricité de France has developed a PANTHERE software [

10], which uses the point kernel method to calculate the radiation exposure rate of complex source terms and a large number of observation points in a three-dimensional scene. At the same time, it can achieve custom geometry and import other CAD models, which can be seen in

Figure 2.10 and

Figure 2.11. The visual display of dose field distribution in PANTHERE is shown in

Figure 2.12. Besides, a dose optimization system is embedded in PANTHERE and can be used for optimizing work dose in high radiation environments by scheduling tasks including combining with actual models, clarifying the distribution and source of source terms, and selecting certain protective measures to optimize the collective exposure dose, ultimately achieving the goal of reducing personnel exposure dose rates. The optimization process is shown in

Figure 2.13 [

10].

Figure 4.

(a) Visualization Model of a Nuclear Power Plant in PANTHERE code; (b) Pipeline Layout Model for a Nuclear Power Plant in PANTHERE code; (c) Visualization display of dose field in PANTHERE code; (d) Radiation protection optimization process in PANTHERE code.

Figure 4.

(a) Visualization Model of a Nuclear Power Plant in PANTHERE code; (b) Pipeline Layout Model for a Nuclear Power Plant in PANTHERE code; (c) Visualization display of dose field in PANTHERE code; (d) Radiation protection optimization process in PANTHERE code.

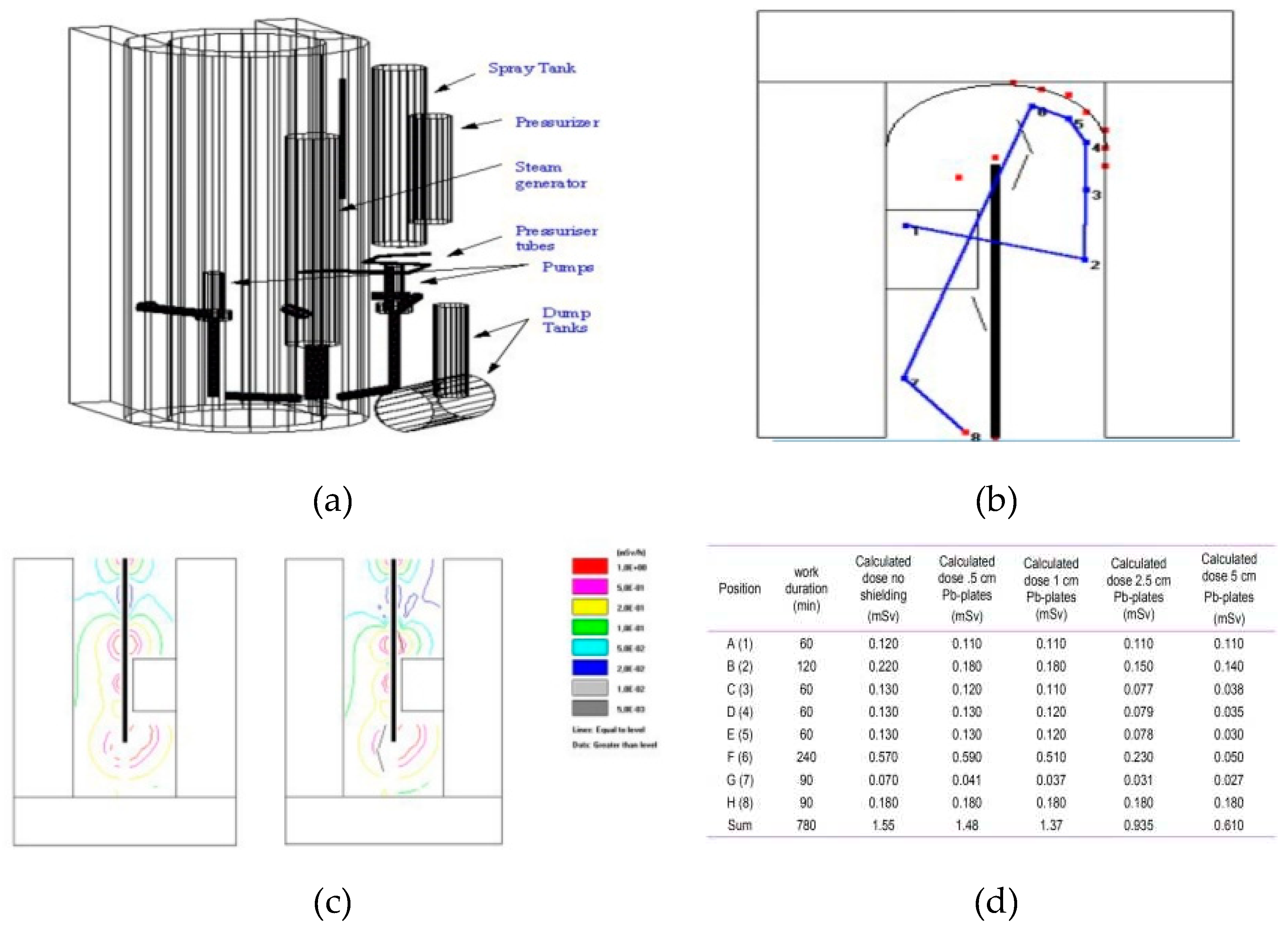

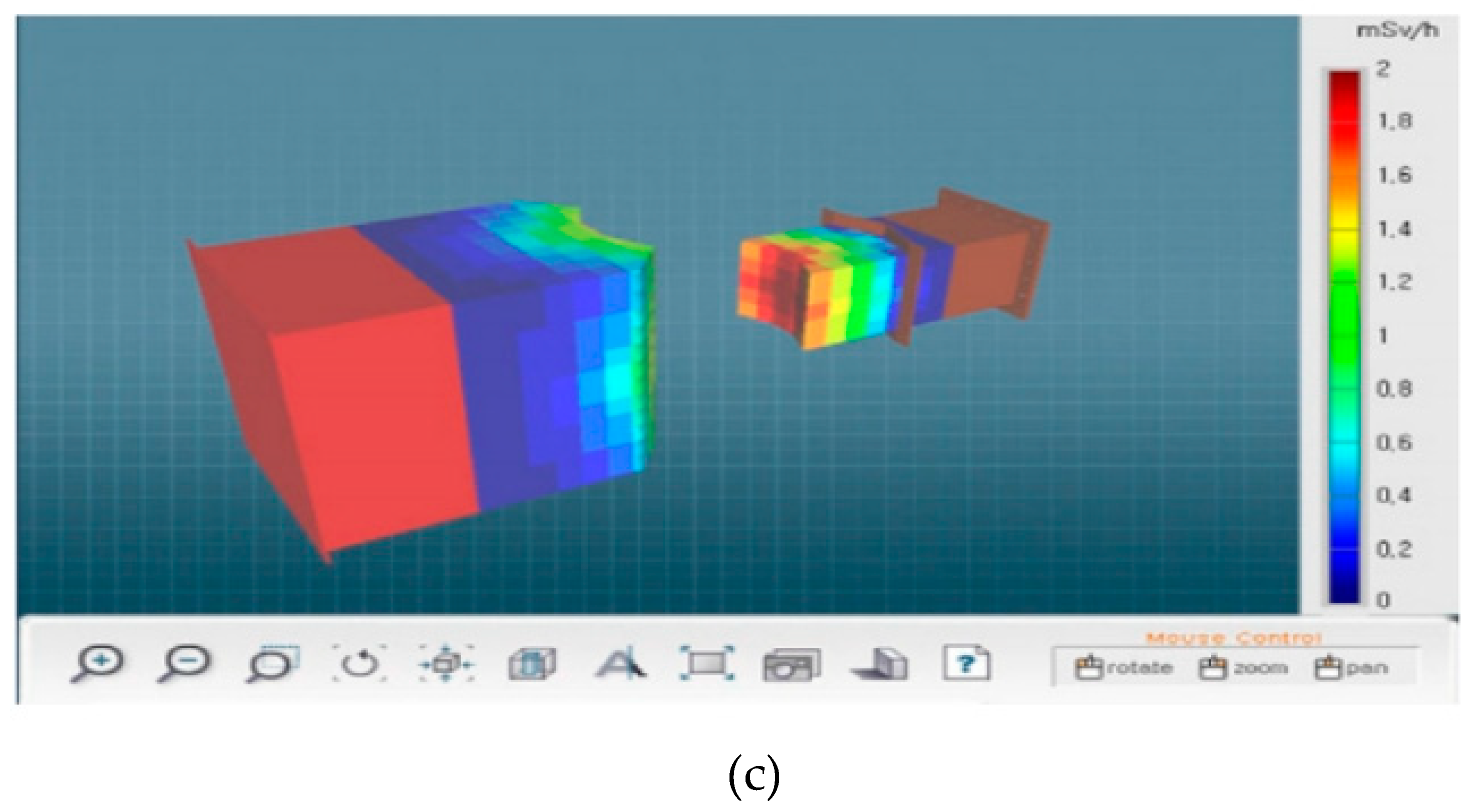

SCK·CEN in Belgium has developed a VISIPLAN 3D-ALARA software [

11,

12] that can be used to simulate dose distribution in decommissioning scenarios based on geometry, material, and source term information. This software adopts the point kernel calculation model, which can achieve dynamic calculation of the dose field in three-dimensional scenes. This software can take into account the changes in personnel operation positions and geometric and source terms in the work scene. The scene can be customized for modeling, and there is also an interface to import CAD models. By introducing different shielding structures in the model, the dose field distribution under different shielding materials can be calculated, and its effectiveness can be analyzed to achieve the development of shielding optimization plans. Detailed planning can achieve personnel work trajectory simulation and dose assessment, and flexible editing of radioactive environments and work trajectories can be used to optimize planned tasks, thereby achieving the radiation protection optimization [

11], which can be seen from

Figure 2.14 to

Figure 2.17.

Figure 5.

(a) Building the reactor model in VISIPLAN 3D-ALARA code; (b) Setting of personnel work trajectory in VISIPLAN 3D-ALARA code; (c) Dose field distribution when selecting different shielding materials in VISIPLAN 3D-ALARA code; (d) Calculation of the personnel exposure dose under different shielding materials in VISIPLAN 3D-ALARA code.

Figure 5.

(a) Building the reactor model in VISIPLAN 3D-ALARA code; (b) Setting of personnel work trajectory in VISIPLAN 3D-ALARA code; (c) Dose field distribution when selecting different shielding materials in VISIPLAN 3D-ALARA code; (d) Calculation of the personnel exposure dose under different shielding materials in VISIPLAN 3D-ALARA code.

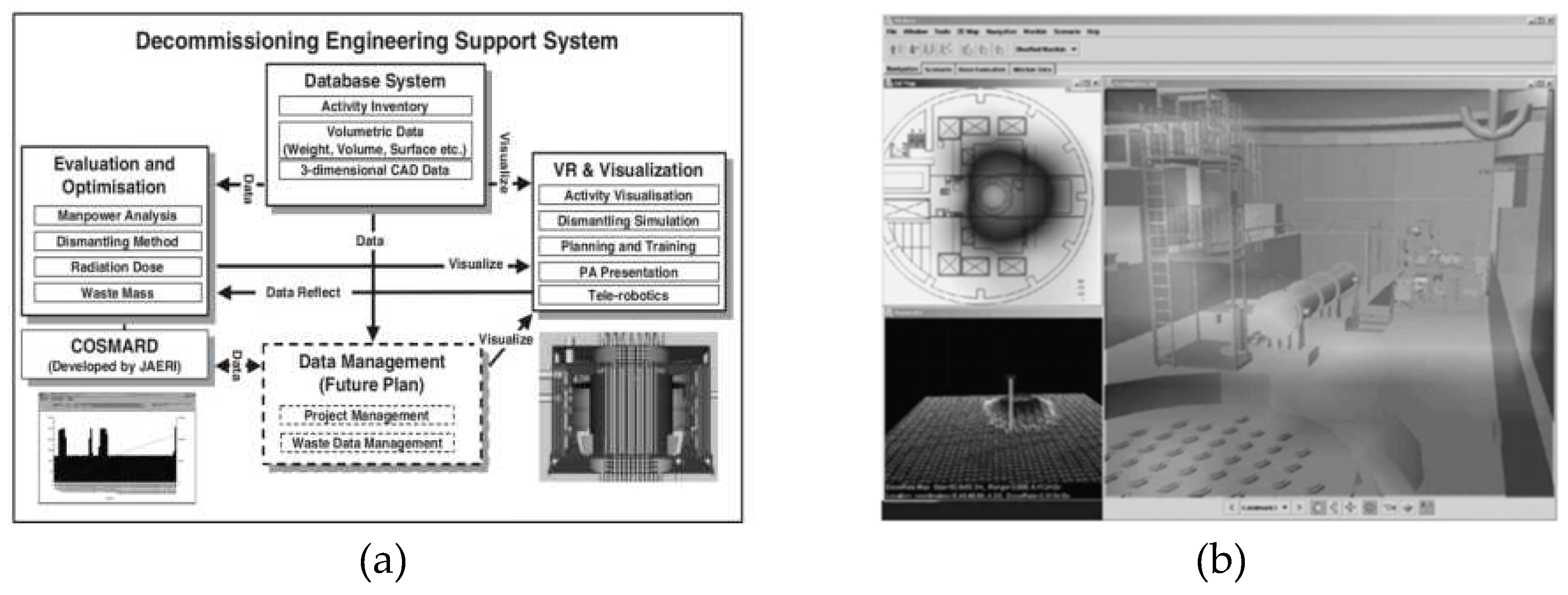

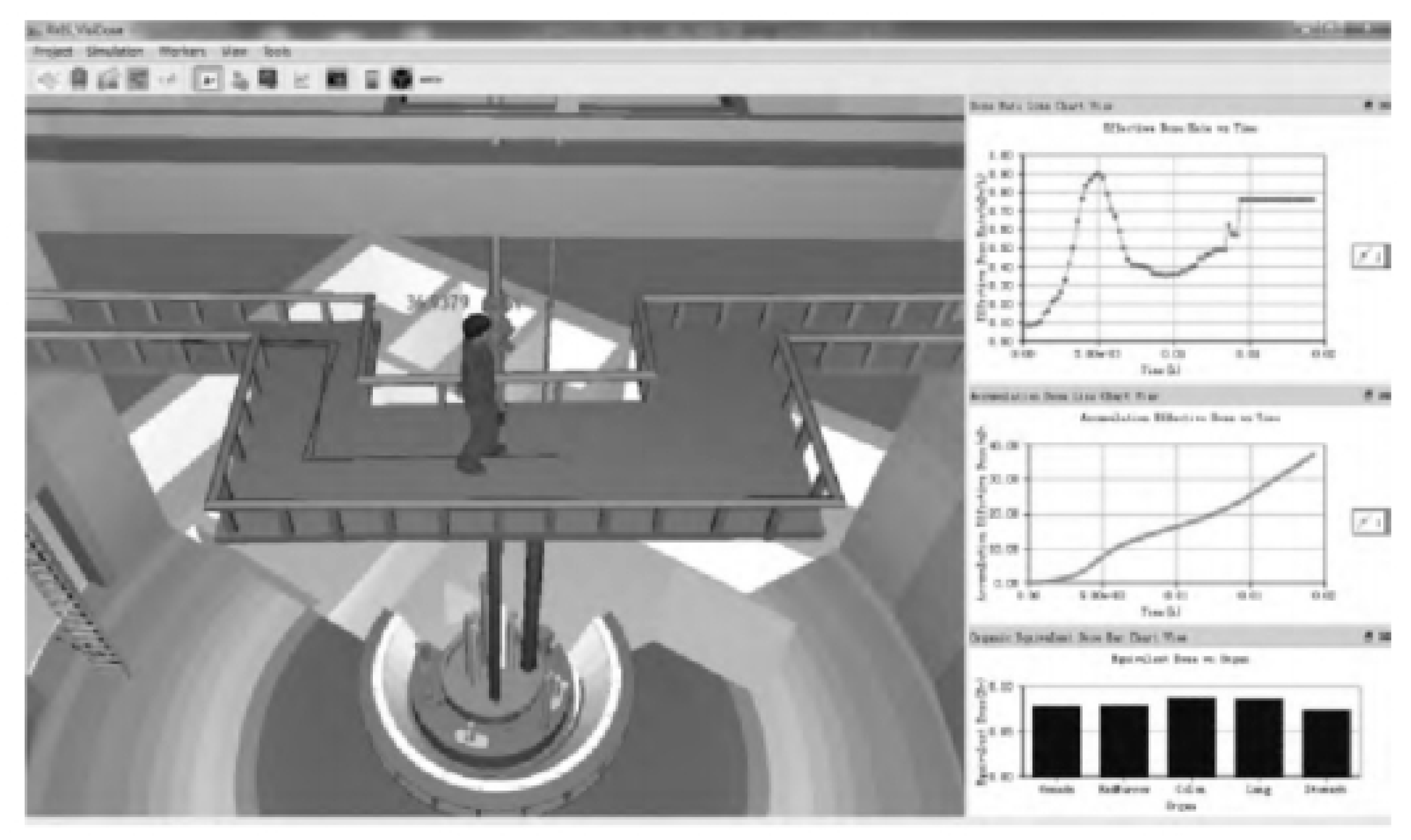

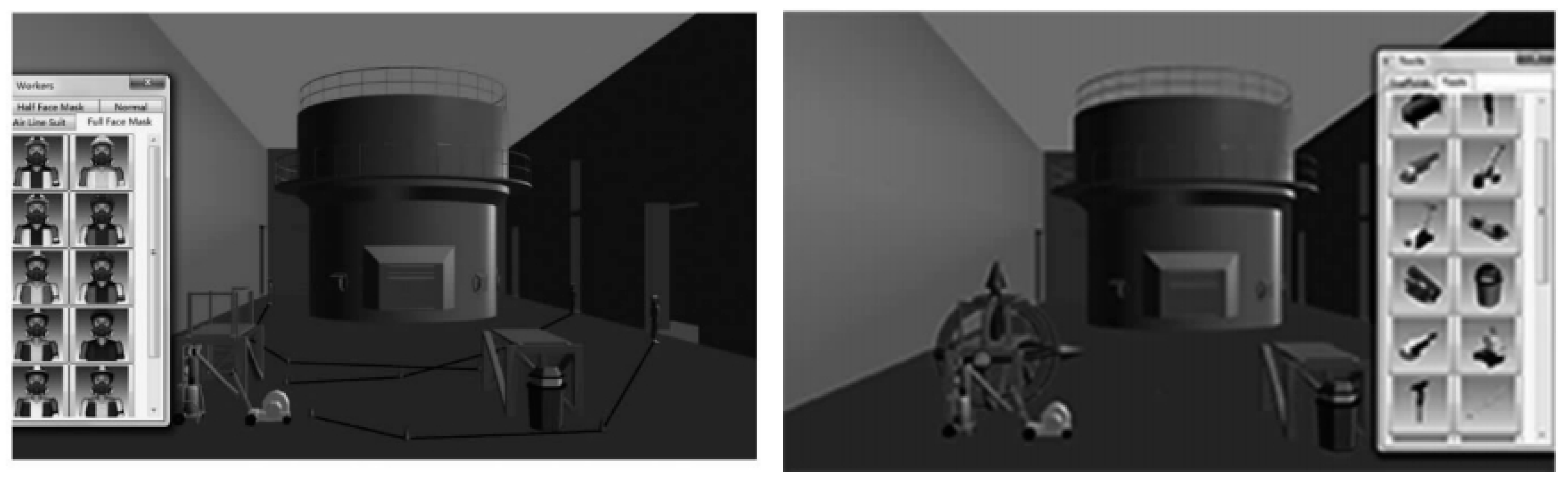

The Japanese Nuclear fuel cycle Development Agency (JNC), the Japanese Atomic Energy Research Institute (JAERI) and the Norwegian Energy Technology Institute (IFE) developed a decommissioning engineering support system DEXUS [

13] using 3D-CAD, virtual reality (VR) and visualization technology, the system functional module composition of DEXUS is shown in

Figure 2.18. This system is mainly used for the Fugen NPS decommissioning project in Japan. The DEXUS system consists of a database system, evaluation and optimization system, virtual reality and visualization system, and data management system. It can achieve functions such as loading CAD models, dose field calculation, data storage, and visualization display. In addition, the software can also use virtual reality technology to achieve workload simulation for decommissioning plans and demolition plans, worker simulation, safety inspection evaluation and optimization functions. Among them, VRDose [

14] is the main module of the system, which considers personnel exposure dose, workload, etc. in the implementation and formulation of nuclear facility retirement plans, and VRDose can achieve functions such as dose assessment and optimization of retirement plans, which can be seen in

Figure 2.19.

Figure 6.

(a) System functional modules in DEXUS code; (b) S Visual display of a certain scene in DEXUS code.

Figure 6.

(a) System functional modules in DEXUS code; (b) S Visual display of a certain scene in DEXUS code.

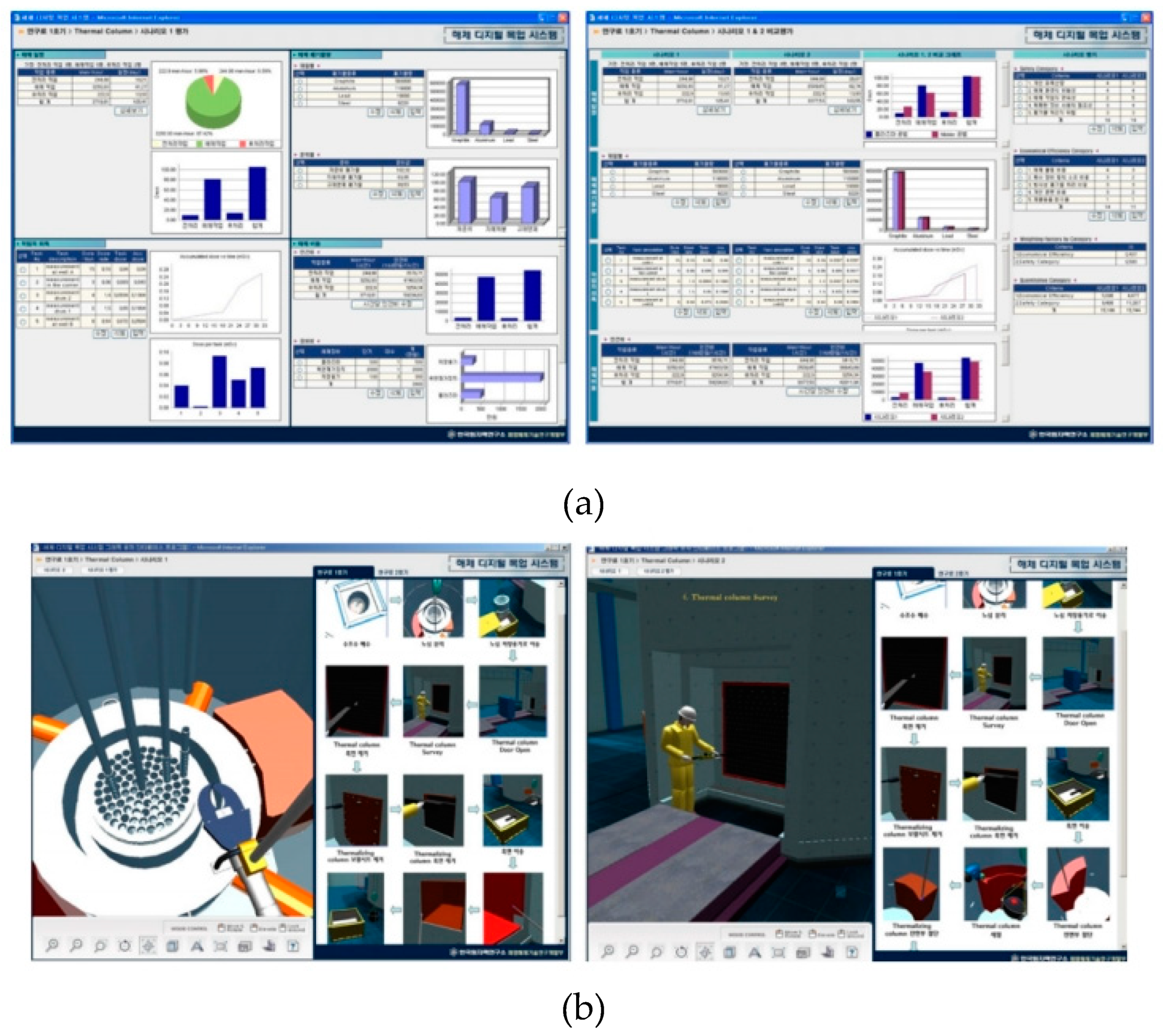

In addition, the Korean Atomic Energy Research Institute (KAERI) has developed the decommissioning digital simulator system DMU (Digital Mock Up) [

15], which is mainly used for simulating the decommissioning and dismantling of the KRR-1 reactor, and DMU can achieve visual display of simulated decommissioning processes and radiation fields. The DMU system uses the Monte Carlo method to calculate the dose field, including the decommissioning database system, demolition simulation, and data calculation modules, which can be seen in

Figure 2.20. DMU can import models established by SE (Solid Edge) software and 3DSM (3D Studio Max) software, which can be seen in

Figure 2.21. Besides, DMU can achieve virtual simulation of the decommissioning process in specific scenarios and it can calculate the demolition time, estimate the demolition cost, optimize the demolition plan, display the dose field in 3D in

Figure 2.22.

Figure 7.

(a) Data management and calculation module of DMU code system; (b) Visualization display of model loading and simulation operations in DMU; (c) Visualization display of dose field distribution in a certain thermal column in DMU.

Figure 7.

(a) Data management and calculation module of DMU code system; (b) Visualization display of model loading and simulation operations in DMU; (c) Visualization display of dose field distribution in a certain thermal column in DMU.

In the 1970s, China gradually began to use computer virtual simulation technology in the field of nuclear energy to carry out some related technical research. In recent years, with the rapid development of China's nuclear energy industry and related technologies, more standardized and professional requirements have been put forward for the technical research and engineering preparation of nuclear facility retirement. Currently, some domestic nuclear industry related units have conducted in-depth research on the development of virtual simulation technology for nuclear facility decommissioning, including the calculation of decommissioning dose field and the development of visual display software. Some technologies have also been applied in practice.

The Department of Computer Science and Engineering of Beijing Institute of Technology carried out the research on the reactor decommissioning simulation system based on virtual reality [

1], and determined the stage goals: initially realize the simulation of the reactor body and surrounding environment, decontamination process, disassembly process, and radiation dose distribution; In the mid-term, the main research focuses on waste management, remote operation, and cost estimation for decommissioning; The long-term goal is to achieve the optimization and comparison of retirement plans. The scene construction of this system can preliminarily achieve the conversion between VR models, CAD models, and CAE models. Virtual demolition operations can achieve non-destructive and destructive demolition. Virtual decontamination can simulate the operation process and decontamination effect. Virtual operations can enable operators to evaluate workload and exposure dose while walking and operating, the exposure dose is calculated using the point kernel method.

The FDS team of the Institute of Nuclear Safety Technology, Chinese Academy of Sciences, has developed a universal, intelligent, and accurate nuclear design and radiation safety evaluation software SuperMC [

16,

17,

18]. The software uses Monte Carlo and deterministic methods to support radiation transport, including calculation functions such as burnup, radiation source term, dose, biological hazards, material activation and transmutation. SuperMC can achieve the automatic and accurate conversion from complex engineering CAD models to Monte Carlo computational models. At the same time, it supports automatic modeling of computational physical properties, achieving the establishment of a complete computational model. SuperMC includes the universal nuclear and radiation safety simulation system Super MC/RVIS2.3 [

19]. SuperMC can achieve complex system modeling and virtual assembly simulation, 3D dynamic data field and model superposition visualization analysis, personnel virtual roaming simulation in nuclear radiation environment. At present, the Super MC software system has been applied to the international thermonuclear experimental reactor program ITER, the lead based reactor ADS-CLEAR of China, the U.S. fusion nuclear science device FNSF, the HPR1000 of China etc [

19].

Figure 8.

Virtual Simulation of Dose Field in SuperMC.

Figure 8.

Virtual Simulation of Dose Field in SuperMC.

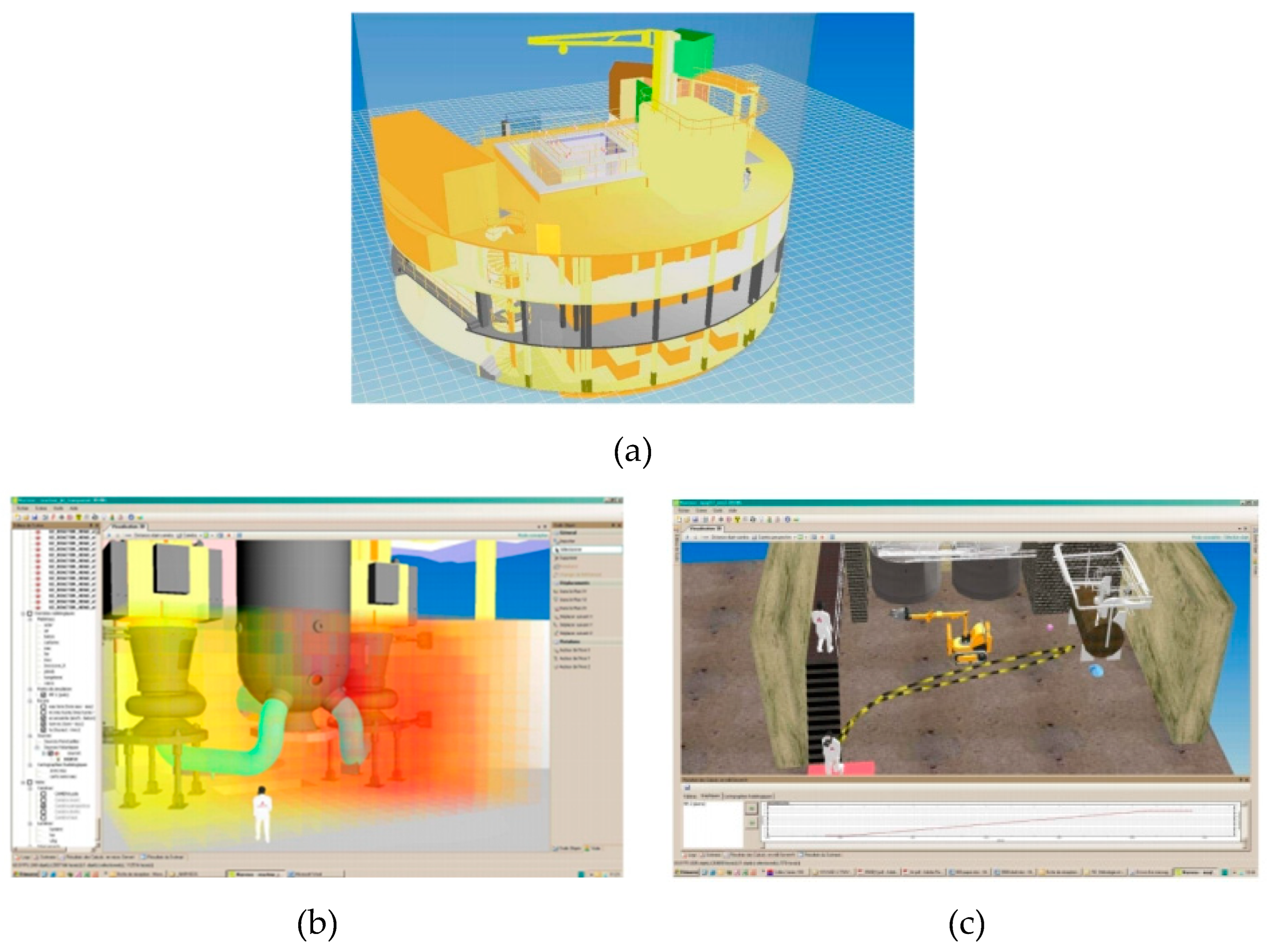

China Nuclear Power Research and Design Institute has developed a reactor decommissioning simulation system based on the DELMIA and VIRTOOLS software platforms [

3,

20]. The overall structure of the system is shown in

Figure 2.27. This system is based on a comprehensive database and consists of subsystems such as virtual scene, retirement process simulation, engineering management, and evaluation and expert support. It has functions such as 3D scene roaming, virtual cutting and demolition process simulation, 3D radiation field visualization display, personnel exposure status display, engineering plan and process management, real-time tracking management of radioactive waste, retirement plan evaluation and expert support. The developed 3D simulation prototype system for reactor decommissioning [

3] proposes a 3D radiation field calculation and visualization technology scheme with independent and integrated simulation systems, databases, and kernel methods. The point kernel integration algorithm is used to establish the 3D radiation field calculation model, and the VS language and SQL server software platform are used to prepare the 3D radiation field calculation program. The real-time computing and data update of the 3D radiation field in the retirement scene are realized, and the visual display is realized in

Figure 2.31. At the same time, the calculation method of the radiation dose of the personnel based on the walking path is proposed. At present, the radiation field calculation results of this program have significant errors, but the developed 3D radiation field calculation program and the visualization display technology of radiation field and personnel exposure dose have made initial breakthroughs.

The Radiation Safety Research Institute of China Institute of Atomic Energy has established a three-dimensional radiation field calculation software system [

21,

22,

23], which uses the FLUKA Monte Carlo code and the point kernel integration method, which includes CAD based 3D automatic modeling, radiation source term and radiation field distribution, radiation field calculation system, dose simulation and optimization system.

Harbin Engineering University (HEU) has established a set of virtual simulation system for nuclear facility decommissioning [

2], the Unigraphics three-dimensional modeling software is used to establish three-dimensional models of retired personnel, tools and nuclear facilities. On this basis, C # 4.0 language and WPF (windows presentation foundation) are used to achieve three-dimensional simulation, scene layout. The system provides two work plan planning methods based on manual simulation and optimized path simulation using local navigation algorithm to search the optimal path. This system can achieve virtual simulation of three-dimensional scenarios for nuclear facility decommissioning [

24], which can be seen in Figures 2.36 and 2.37.

Figure 9.

Virtual path setting and simulation scene display in HEU virtual simulation system for nuclear facility decommissioning.

Figure 9.

Virtual path setting and simulation scene display in HEU virtual simulation system for nuclear facility decommissioning.

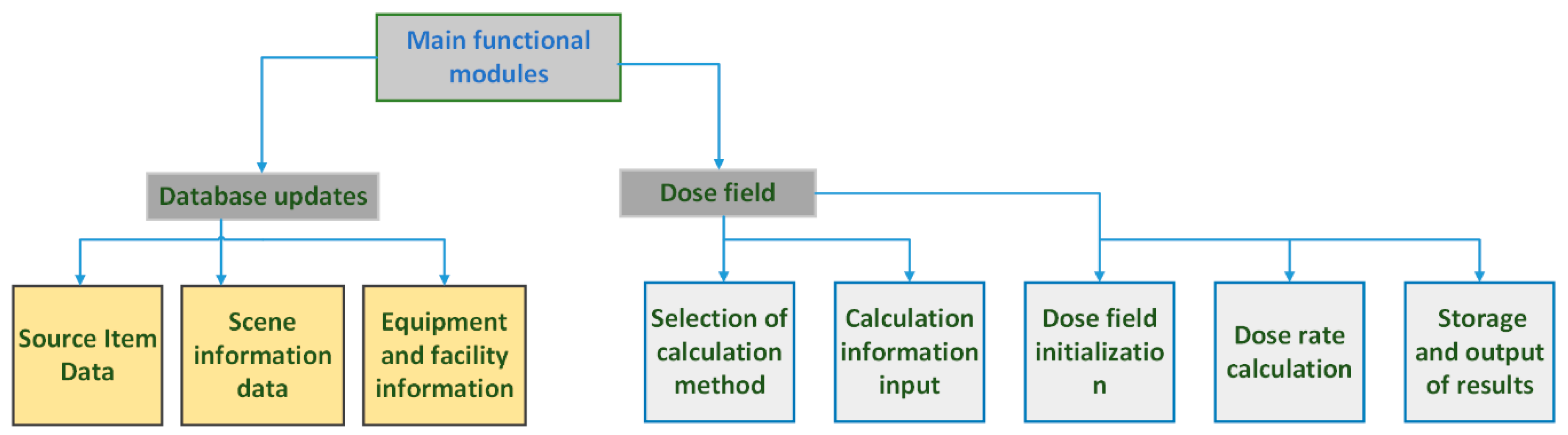

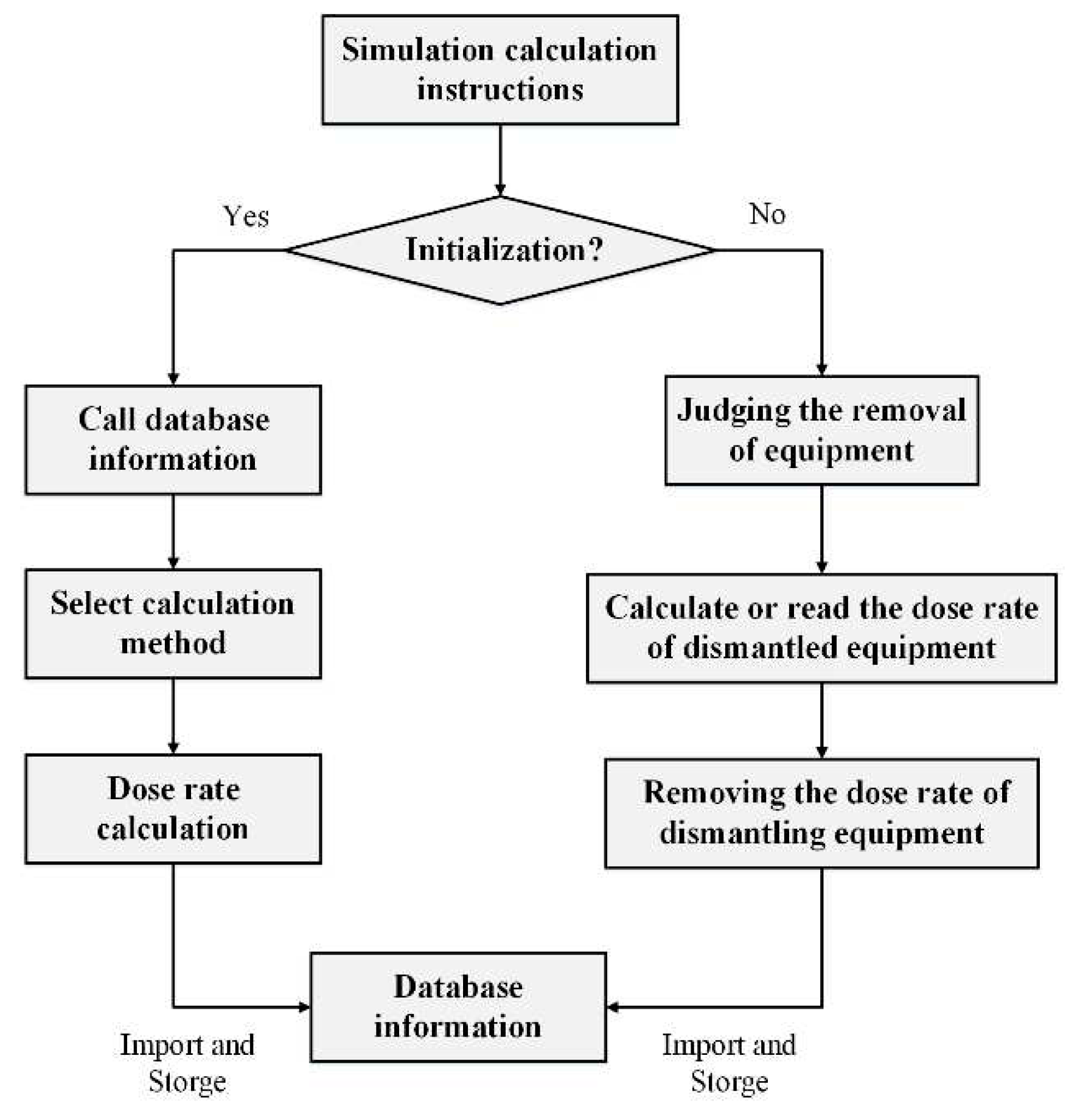

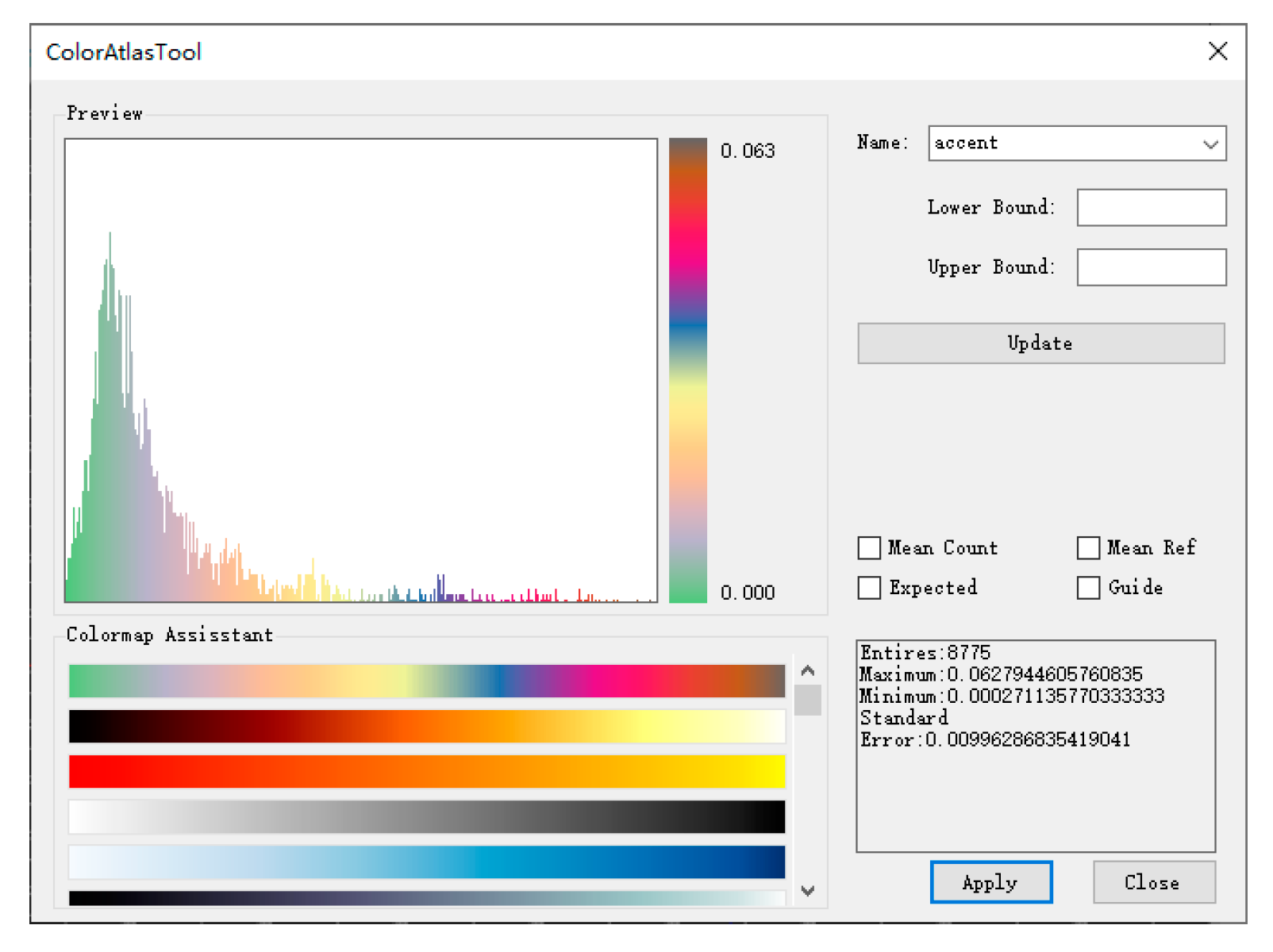

University of South China has developed a rapid and accurate calculation MCPK program for three-dimensional radiation fields and visualization display. This program uses the coupled MCNP5 Monte Carlo code and point kernel method to calculate the dose fields distribution [

25], solving the shortcomings of long calculation time and insufficient calculation accuracy in shielding calculations. It can achieve rapid and accurate calculation of dose fields. The MCPK program mainly includes a database module (capable of customizing information such as scenes, devices, and source items), a radiation field calculation module (using Monte Carlo method and point kernel methods), a visualization display module (visualizing geometric scenes and dose fields), and an interface program module (realizing the connection of all calculation processes). The core module of MCPK is the self-developed point kernel calculation program, which establishes various material accumulation factors based on ICRP data, the database of line attenuation coefficient, photon fluence and conversion coefficient from air kerma in free air to ambient dose equivalent of rays in some elements and materials. At the same time, in terms of shielding of different materials, the geometric identification process of shielding materials and thickness through which rays pass (Brep, the Boundary representation method) is considered, which ensures the accuracy and speed of radiation field calculation. The 3D visualization module is mainly developed based on the AnyCAD platform. AnyCAD is a visualization plug-in developed based on Open CASCADE, which is responsible for the display of 3D models and the rendering of radiation exposure fields during the visualization operation. At the same time, the MCPK code can achieve dynamic calculation of decontamination and dismantling dose fields, which can be seen in

Figure 2.42.

Figure 10.

3D radiation field display in MCPK code system.

Figure 10.

3D radiation field display in MCPK code system.

In addition, North China Electric Power University has developed a TORT-MCNP three-dimensional coupling program system [

26,

27,

28], which is based on the discrete ordinate method (SN) and Monte Carlo method (MC) coupling to calculate the dose field. Combining the advantages of SN method in solving deep penetration problems and the advantages of MC method in simulating complex geometry, the TORT-MCNP program system is divided into four main modules: SN calculation module, SN-MC interface module, MC custom source sampling module and MC calculation module.