1. Introduction

Energy has always been an eternal topic in the process of continuous social and economic development. Coal has long been the main source of energy consumption and is irreplaceable from some perspectives, and nowadays it is still one of the main consumption energy sources worldwide[1-4]. As shallow coal resources are mined out, the geological conditions of deep coal seams are complex, and coal reservoirs are generally characterized by low porosity, low permeability and high non-homogeneity, thus seriously restricting coal mining[4-9]. Therefore, to dispose of coal mine gas and the physical and mechanical properties of the coal rock mass has been the focus of attention and a hot spot of research[10, 11]. Mine gas (coalbed methane) is not only a major source of disaster in coal mines, but also a high quality and efficient clean energy source. As an associated energy source of coal, the efficient exploitation of coal bed methane is of great significance to solve the energy shortage and mine gas disaster[12-14].

The technology of increase reservoir permeability has been the focus of attention, and many scholars have been conducting research in this area using different technical means[

15]. With the development of coal seam fracturing technology, waterless coal seam fracturing technology has received wide attention as an emerging technology. Liquid nitrogen is used as a medium to inject into the coal seam, cause the stress difference between minerals, the freezing and swelling force generated by the freezing of liquid water phase change, resulting in new cracks in the coal seam and achieving the purpose of increasing permeability. Some research results have shown that this technology can have significant effects. Mcdaniel et al. performed some work on coalbed methane production and showed that liquid nitrogen can effectively increase the permeability of coal seams[

16]. Grundmann et al. produced 8% more gas by fracturing shale logs with liquid nitrogen compared to conventional methods[

17]. A large number of scholars have conducted studies on this subject. Winkler et al. showed that water in the pores, fractures, and joints of rocks plays a dominant role in freeze-thaw cycle damage[

18]. Chu et al. studied the pore fracture structure damage evolution law, physical and mechanical properties, and permeability evolution characteristics of coal bodies under different freezing time and number of freeze-thaw cycles of liquid nitrogen by means of experimental and theoretical analysis, and revealed the mechanism of damage effect of liquid nitrogen freeze-thaw on coal from two perspectives: thermal stress and freeze-thaw action[19, 20]. Takarli et al. conducted an extensive experimental study on the microstructural changes in granite during freeze-thaw cycles[

21]. McDaniel et al. showed that the violent temperature shock effect formed by liquid nitrogen injection into the CBM reservoir caused physical changes in the fracture wall, which could prevent the hydraulic fracture and thermally induced fracture from completely closing under the closure stress, and would create thermally induced microfractures orthogonal to the hydraulic fracture[

16].

The effects of liquid nitrogen on the structural and permeability properties of rock have been studied above, and many important conclusions have been obtained. However, the temperature of liquid nitrogen is so low that the direct treatment of rocks with liquid nitrogen produces many complex changes, and the effects caused by the thermal stress effect between minerals cannot be distinguished from those caused by the freezing and swelling forces of the water phase change. Therefore, in this study, freeze-thaw disposal of coal samples was carried out at -18°C and room temperature. The influence factors produced by ultra-low temperature liquid nitrogen on coal are removed, and the influence of freezing and swelling force of water on the mechanics and permeability evolution law of coal rocks is studied. This experimental study provides a theoretical basis for the study of the mechanism of reservoir seepage, and increase permeability under multi-field coupling conditions. This is an important guideline for the power disaster control of deep coal mining and unconventional gas extraction to improve recovery.

2. Experimental preparation and method

2.1. Rock Description and Specimen Preparation

The study area of this work is Baijiao coal mine of Sichuan Coal Group Furong Company, Gongxian County, Yibin City, Southwest China. The coal quality is anthracite with natural density between 1.53 and 1.64 g/cm

3, and the mineral composition of the coal samples is mainly kaolinite, quartz, calcite, etc[

22]. The coal samples used in the test were taken from the same mining face, and the selected intact large coal blocks with good homogeneity were wrapped and sealed with polyethylene cling film and transported to the indoor laboratory for further processing. The large coal was drilled into a cylinder of 50mm diameter by a special sampling machine, and then the cylindrical coal was cut into 100mm length by a cutting machine, and finally polished into φ×h=50mm×100mm standard specimens with section non-parallelism and non-verticality less than 0.02mm (

Figure 1). The made standard coal sample is sealed with polyethylene film and stored in a cool place.

Before the test, the standard coal samples were divided into dry group, water-saturated group and experimental group, where the dry group was put in a dryer at 60℃ and weighed once at an interval of 6h until the weight of the specimen no longer changed; The water-saturated group is to put the coal sample in the vacuum bottle which has been tested for sealing, fill the vacuum bottle with water so that the water completely covers the coal sample, then install the sealing piston for vacuuming, and weigh the sample once at an interval of 6h until the weight of the sample no longer changes; The experimental group was to place the coal samples completed with full water in a thermostat at -18℃ for 24h, and then take them out and place them in room temperature water for 24h. There was no big difference in appearance of the rock samples in each group before and after the treatment.

2.2. Three-axis test equipment

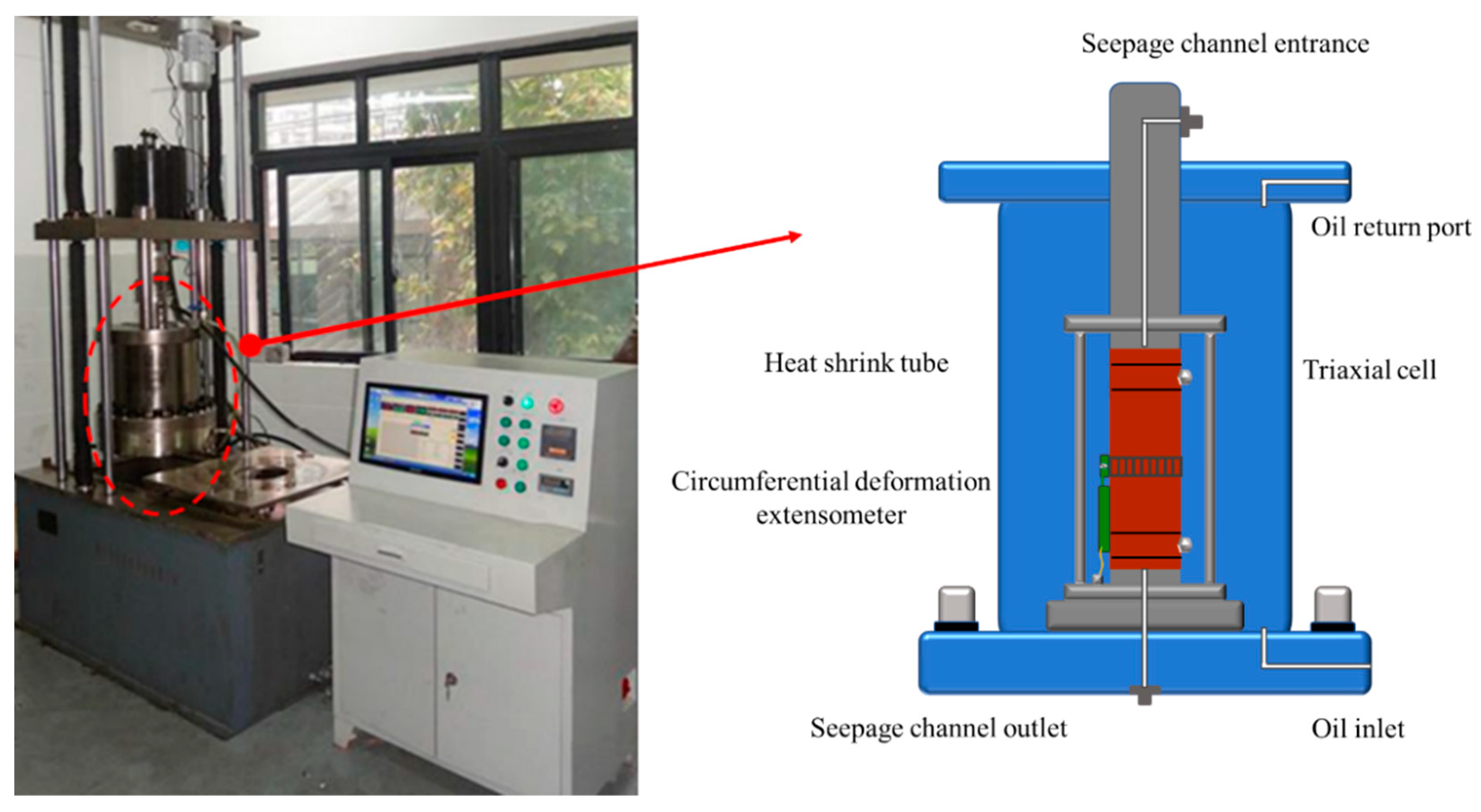

In this study, fracturing and seepage experimental system for multi-physical field and multiphase coupling of porous media (THM-2) developed by Chongqing University, as shown in

Figure 2. The system consists of a mainframe, electro-hydraulic servo hydraulic pump station, pneumatic and hydraulic pressure supply system, measurement and control system, etc. The test equipment can provide a maximum axial pressure of 1000 kN and a maximum confining pressure of 60 MPa, and is capable of using two specimen sizes (φ50 mm×100mm and φ100mm×200 mm) for the test. The displacement monitoring system can monitor the axial and radial displacements, and the maximum axial and radial displacements are 60 mm and 12 mm, respectively. The system can simulate porous media (coal, sandstone, etc.) in different ground stress, different mining stress, different temperature, different fluid pressure and other multi-field coupling conditions, and can carry out uniaxial and triaxial mechanical tests, hydraulic fracturing tests, seepage tests and other research, with high reliability and accuracy[23, 24].

2.3. Test method and loading path

To explore the influence of freeze-thaw on the permeability characteristics of coal, we conducted the CO

2 seepage experiments on three different states of coal specimens (dry, saturated, freeze-thaw) under two confining pressures (5MPa, 15MPa). The testing procedure is as shown in

Table 1 and is described specifically as follows:

Step 1: Place the standard coal specimen on the lower loading plate (the specimen is concentric with the loading plate). Install O-ring seals on the corresponding pressure rods and loading plates. Use heat-shrinkable tubes to cover the rock and loading plates. Apply heat with a heat gun to ensure a perfect coupling with the O-ring seal and create a pre-seal. Then use clamps for further sealing to prevent any gas leakage during the experiment (sometimes evenly apply silicone gel on the side of the specimen to form a soft gel layer of about 1 mm, which is effective in preventing damage to the heat-shrinkable tubes for rocks with large surface pores). Install a radial displacement sensor at the middle of the specimen and ensure it is in good working condition. Use a sample car to transport the prepared specimen into the top part of the triaxial pressure chamber. Lower the triaxial pressure chamber and install the sealing screws of the triaxial pressure chamber.

Step 2: Apply a preload of 0.5kN axial stress on the specimen as a pre-stress to stabilize the rock sample. Then fill the triaxial pressure chamber with hydraulic oil and close the oil inlet valve. Load the axial stress to 10kN (30 kN) at a rate of 0.1kN/s while increasing the confining pressure inside the triaxial chamber to 5MPa (15 MPa) at a rate of 0.05MPa/s simultaneously. Maintain the stress stability.

Step 3: Inject CO2 into the specimen from one end along the axial direction with a pressure of 1.5MPa. Attach a pressure gauge to the other end of the specimen and wait until the pressure reading reaches 1.5MPa before proceeding to the next step.

Step 4: Replace the pressure gauge at the outlet end with a high-precision flow meter. Keep the confining and axial pressures constant. Monitor the flow meter reading until it stabilizes and then start recording data. Meanwhile, load the axial stress at a rate of 0.002mm/s until fracture.

3. Experimental results and analysis

3.1. Mechanical response characteristics of the coal in different states under two confining pressures

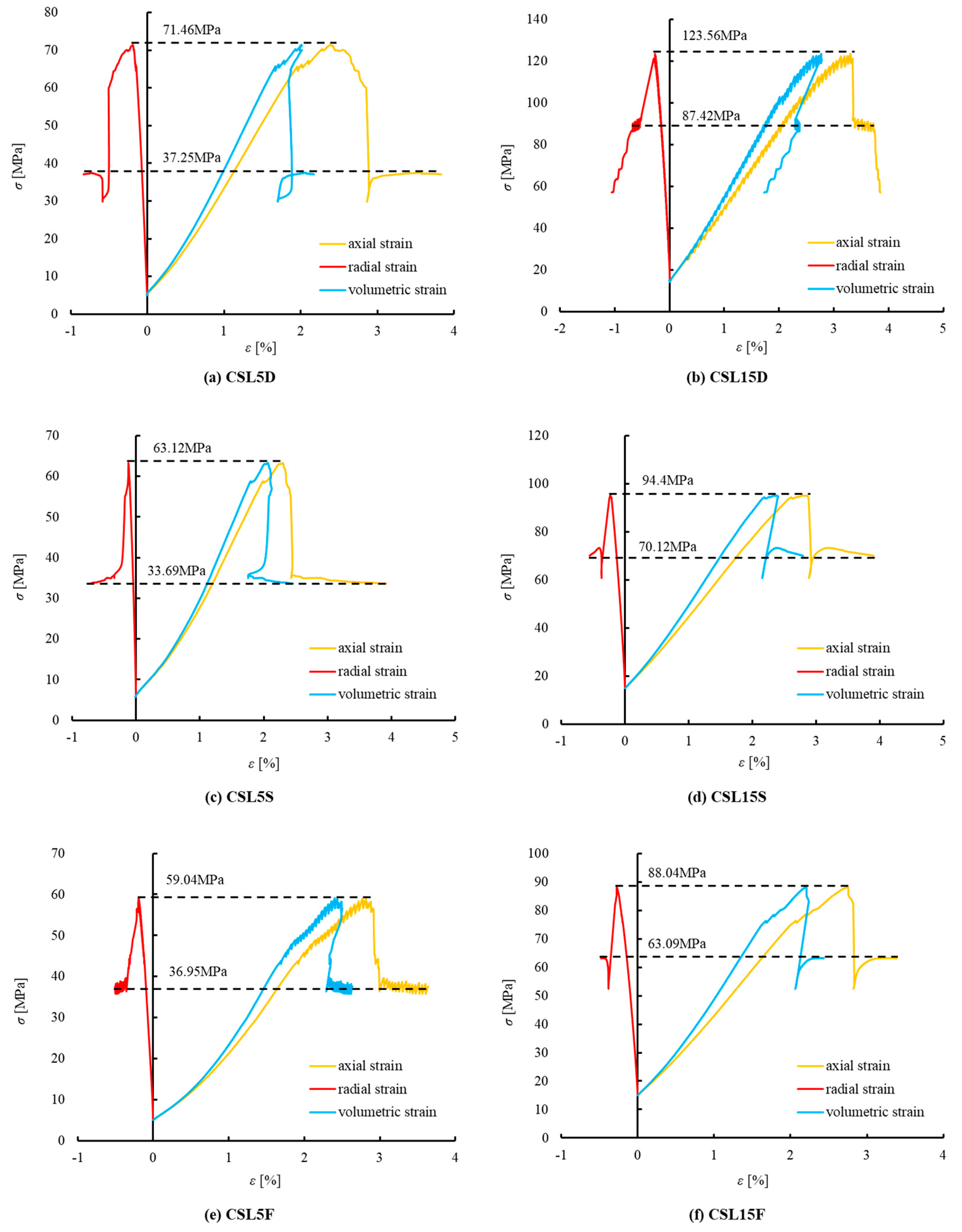

The stress-strain curves of the coal specimens in three states under two different confining pressures are shown in

Figure 3. The stress-strain characteristics of the coal are in accordance with the general rock mechanics test law: the specimens show four stages of compression density (this process is not obvious under high confining pressure), elastic deformation, plastic rupture, and fracture in the triaxial compression process. The triaxial compressive strength and residual strength of the specimens under low confining pressure were much larger than the specimens under high confining pressure. As the axial loading proceeds, positive strains are generated in the axial direction and negative strains are generated in the radial direction, and there is a process of volume increase (expansion) after the fracture of the specimens. By comparing the test results under the two confining pressure conditions, it was found that the coal in dry state had the highest strength and the coal that had been frozen and thawed had the lowest strength. The strength of the saturated specimen was 63.12 MPa under the 5 MPa confining pressure condition, which was 11.67% lower compared to the strength of the dry coal; The strength of the freeze-thawed specimen was 59.04 MPa, which was 17.38% lower compared to the dry coal strength. The strength of the saturated specimen was 94.4 MPa under the confining pressure of 15 MPa, which was 23.6% lower than that of the dry coal; The strength of the freeze-thaw specimen is 88.04 MPa, which is 28.75% lower than that of the dry coal.

3.2. The permeability evolution characteristics of coal in different states under two confining pressures

This section reports the permeability evolution characteristics of the coal in different states under different confining pressures, and the flow rate of gas through the specimen is recorded during the test. Since we temporarily disregarded the effect of temperature and the whole experiment was conducted at a constant temperature in this study (the indoor laboratory temperature is about 20°C), the transport of CO

2 inside the coal can be regarded as a constant temperature laminar flow. This satisfies the basic conditions of Darcy’s law[

25], and the expression used to calculate the permeability is given by Eq. (1):

where k is the effective permeability, m

2; Q is the gas seepage flow, m

3/s; P

0 is the standard atmospheric pressure (about 0.1 MPa), MPa; μ is the CO

2 gas dynamic viscosity, 1.4932×10

−11 MPa s; L is the length of the specimen, m; P1 is the inlet gas pressure (1.5 MPa), MPa; P

2 is the outlet gas pressure (0.1 MPa), MPa; A is the effective area of gas seepage, m

2.

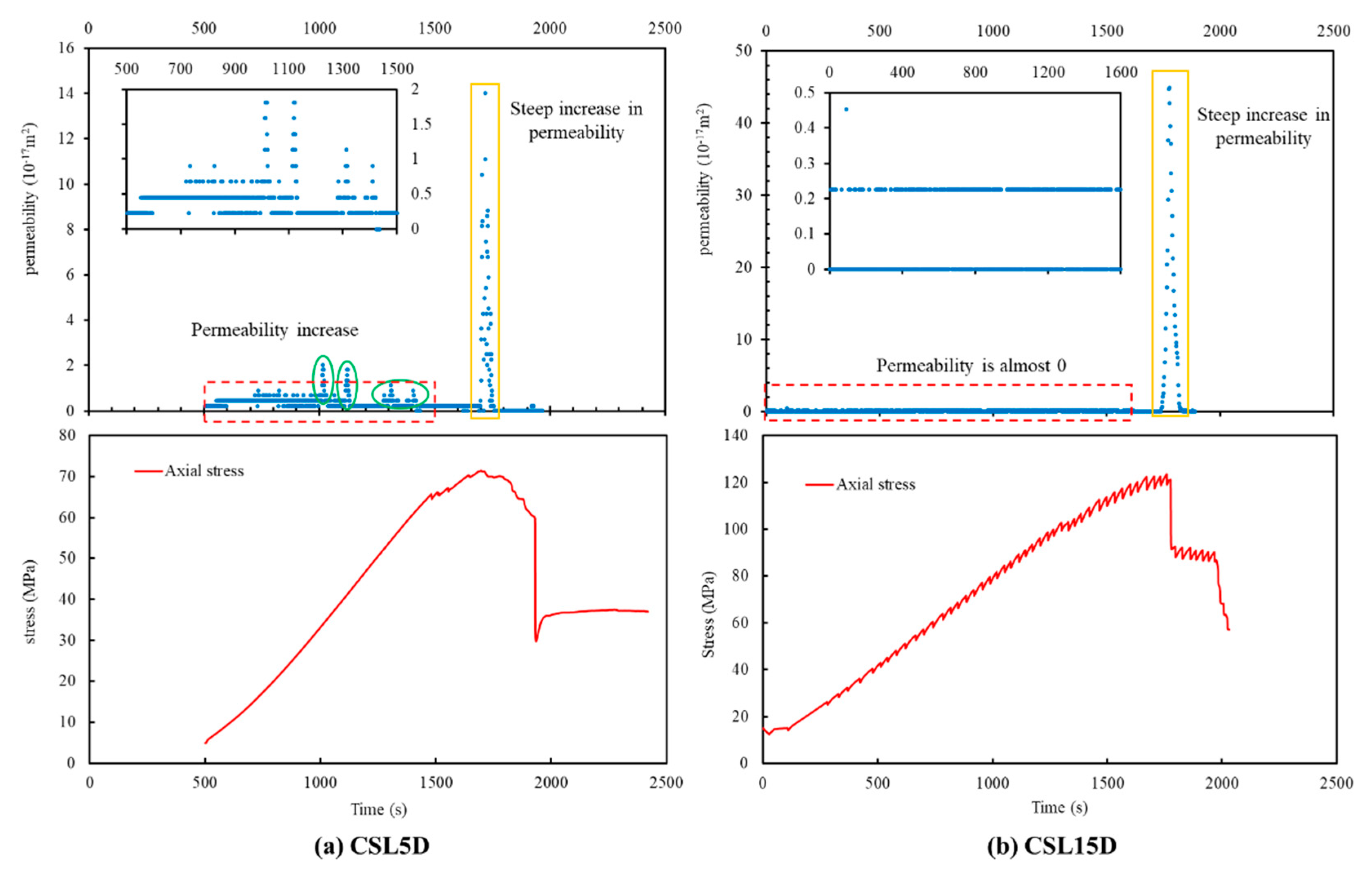

The permeability evolution curves of dry coal under two confining pressures (5MPa,15MPa) are shown in

Figure 4. The permeability of the coal rock specimens under low confining pressure (5MPa) is approximately 0.2 to 1×10

-17m

2 at the early stage of loading. As the test proceeds, the axial stress gradually increases and several brief increases in permeability (marked by green circles) occur, increasing to 0.6-2×10

-17m

2. Note that each brief increase in permeability is quickly followed by a decrease to the initial value before the increase. At the peak of the axial stress, the specimen breaks down and the permeability suddenly increases steeply (marked by the yellow rectangle), at which point the magnitude of the increase exceeds that of any previous increase (by an order of magnitude, with a maximum value of 14.03×10

-17m

2), and as the test proceeds, the permeability quickly returns to its initial size at the post-peak stage of the test. Under high confining pressure (15 MPa) conditions, the permeability of the coal specimens ranged from roughly 0-0.23×10

-17m

2. At the beginning of the loading, the initial permeability had a significant decrease compared to the low confining pressure test conditions. As the test proceeded the axial stress gradually increased and the permeability did not change significantly. Until the axial stress reached the peak specimen fracture, the permeability suddenly increased steeply (marked by yellow rectangle) to 44.81×10

-17m

2 and quickly returned to the size at the beginning of the test.

Numerous studies have shown that triaxial permeability tests will decrease the permeability of the rock at the initial stage due to the pore and cracks being compressed. As the test proceeds (the crack extension phase), the increase in permeability response results from increased pore size and crack due to increased rock damage, and importantly, the damage is an irreversible process. The above test results do lead to a different conclusion.

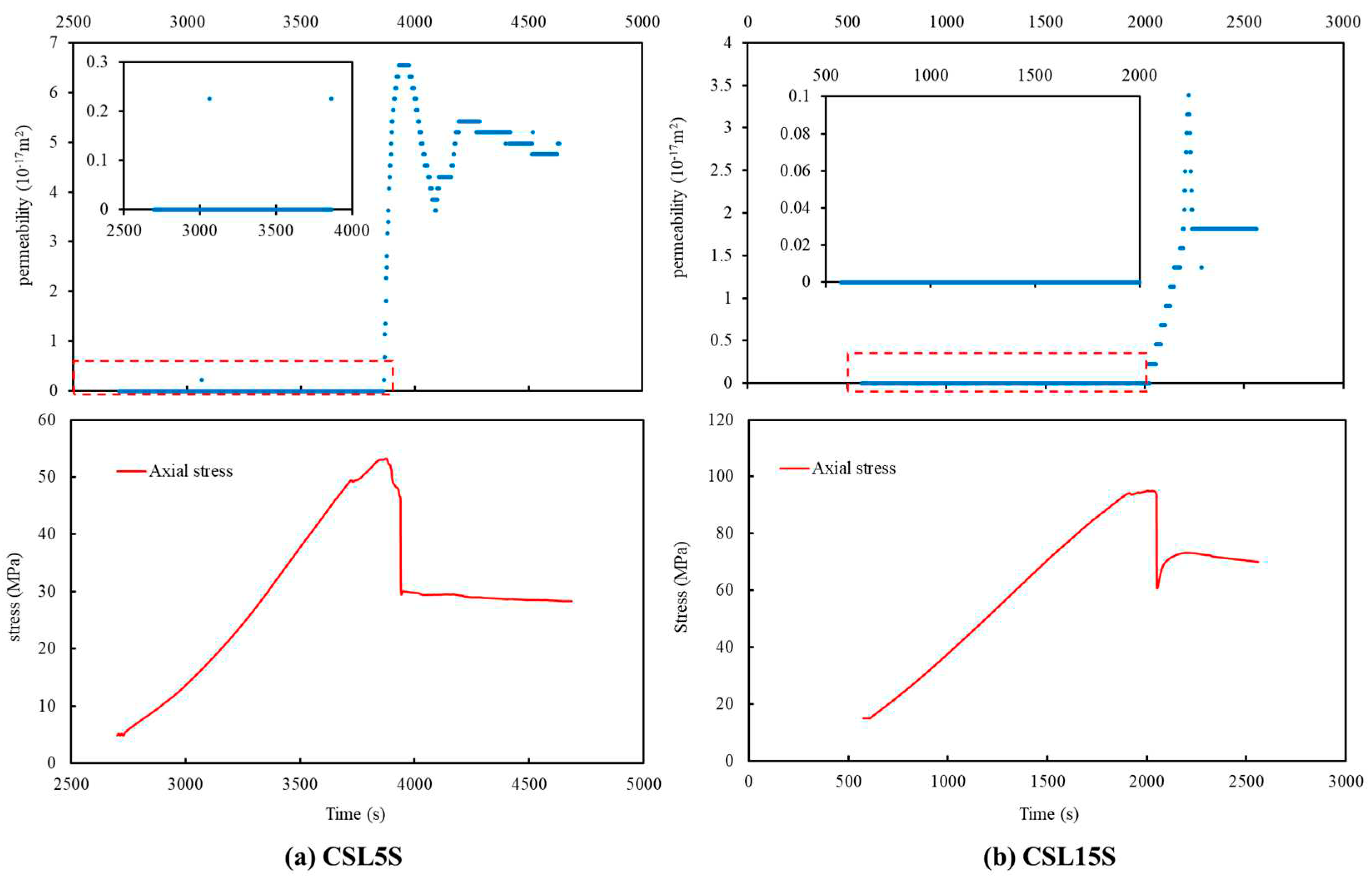

The permeability evolution curves of saturated coal under two confining pressures (5MPa,15MPa) are shown in

Figure 5. The permeability of the coal specimens under low confining pressure (5MPa) is 0 at the early stage of loading. As the test proceeds the axial stress gradually increases, the permeability of the coal rock specimen is 0 at most and 0.23×10

-17m

2 at a few times. At the peak of the axial stress, the specimens were fractured and the permeability gradually increased to 6.56×10

-17m

2 and then gradually decreased. As the test proceeded, the permeability increased for a period followed by a steady decrease in the post-peak phase, during which the residual stress after the peak remained essentially constant. At high confining pressure (15 MPa), the permeability of the coal specimen is stabilized at 0. At the early stage of loading, the seepage channel is completely blocked compared to the presence of a small amount of gas seepage under low confining pressure test conditions. As the test proceeded the axial stress gradually increased and the permeability did not improve significantly. Until the axial stress was about to reach the peak when the specimen was fractured, the permeability first increased steadily and then accelerated to 3.4×10

-17m

2 and soon decreased to a stable value of 1.81×10

-17m

2.

Compared with the test results of dry coal, the permeability of saturated coal is significantly better under the same stress conditions. Under the action of pore water and stress, the seepage channels of the coal are completely closed and the permeability is almost zero. This is the problem of many low-permeability coal seams, which will lead to difficulties in coalbed methane extraction and utilization and mine gas disaster management. And the permeability of saturated coal is obviously lower when the coal rock specimen is damaged by compression. This indicates that the presence of pore water not only affects the permeability of natural pore throats, microfractures and joints in coal seams, but also affects the permeability of artificially generated macrocrack. Hydraulic fracturing techniques and other methods of fracturing coal seams to increase permeability can also be greatly limited by the presence of pore water.

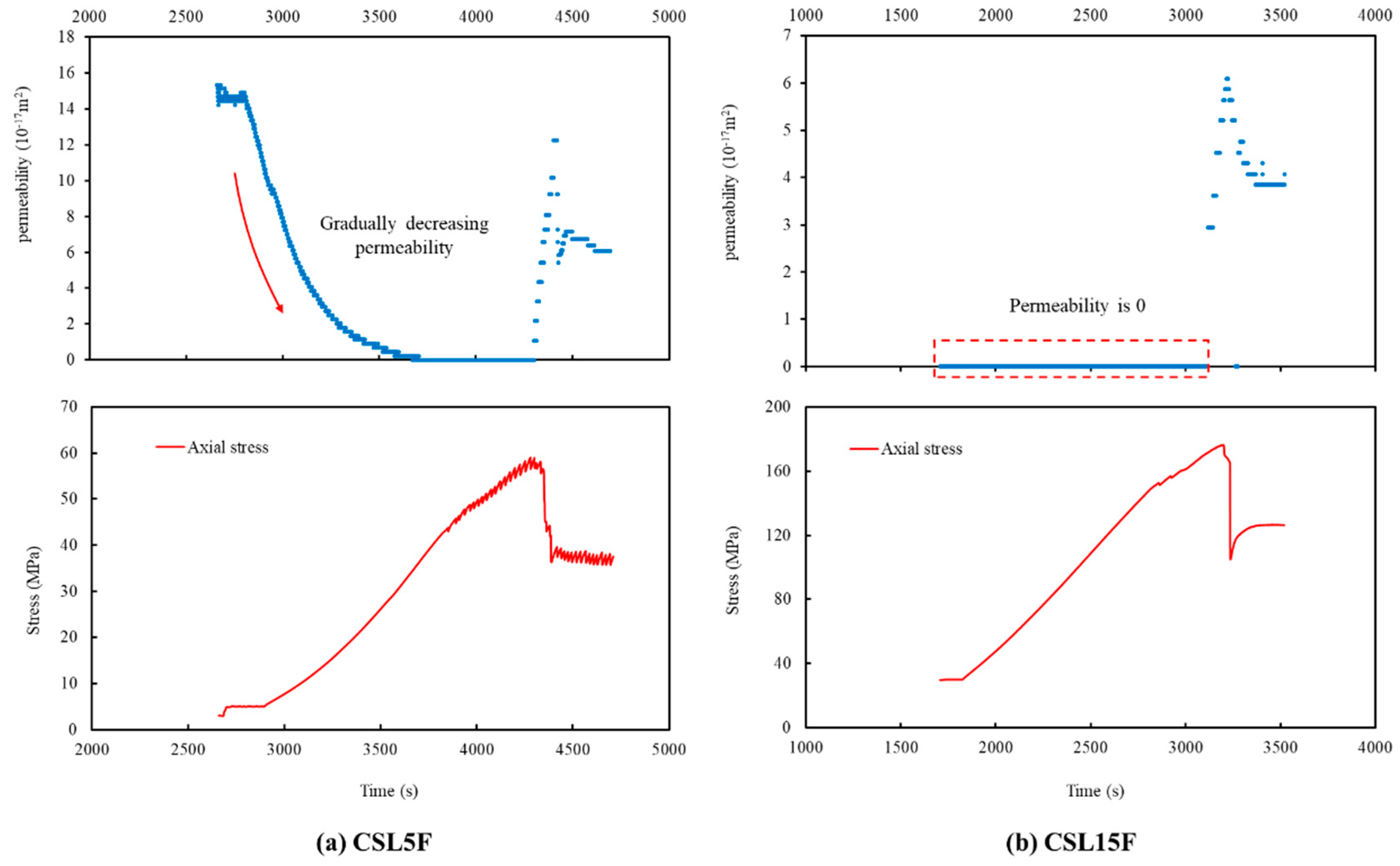

The permeability evolution curves of the coal after freeze-thawing at two confining pressures (5MPa,15MPa) are shown in

Figure 6. The permeability of the coal specimens under the low confining pressure (5MPa) is 14.68×10

-17m

2 at the early stage of loading. As the test proceeds the axial stress gradually increases and the permeability of the coal specimen gradually decreases to 0. At the peak of the axial stress, the specimen was fractured and the permeability gradually increased to 12.24×10

-17m

2, and then gradually decreased. As the test proceeded (in the post-peak phase), the permeability was consistent with the characteristics of saturated coal, with a period of increase followed by a steady decrease, during which the post-peak residual stress remained essentially constant. Under high confining pressure (15 MPa), the permeability of the coal specimens is stabilized at 0 at the early stage of loading, indicating that the seepage channels generated by freeze-thaw action are completely blocked under the stress. As the test proceeded the axial stress gradually increased and the permeability did not improve significantly. Until the axial stress was about to reach the peak specimen fracture, the permeability first increased steadily and then accelerated to 5.88×10

-17m

2, and finally decreased gradually to a stable value of 3.85×10

-17m

2.

4. Discussion

To discuss the evolution of permeability in coal specimens under different states (dry, saturated, freeze-thaw) and to reveal the mechanism of freeze-thaw damage on the permeability evolution of coal and the gas migration law within coal when stress changes occur during mining activities. This part focuses on the discussion of the theoretical evolution of coal deformation and macroscopic permeability of the specimens to explain the observed experimental phenomena.

4.1. Analysis of strain variation rate and stress variation rate of coal

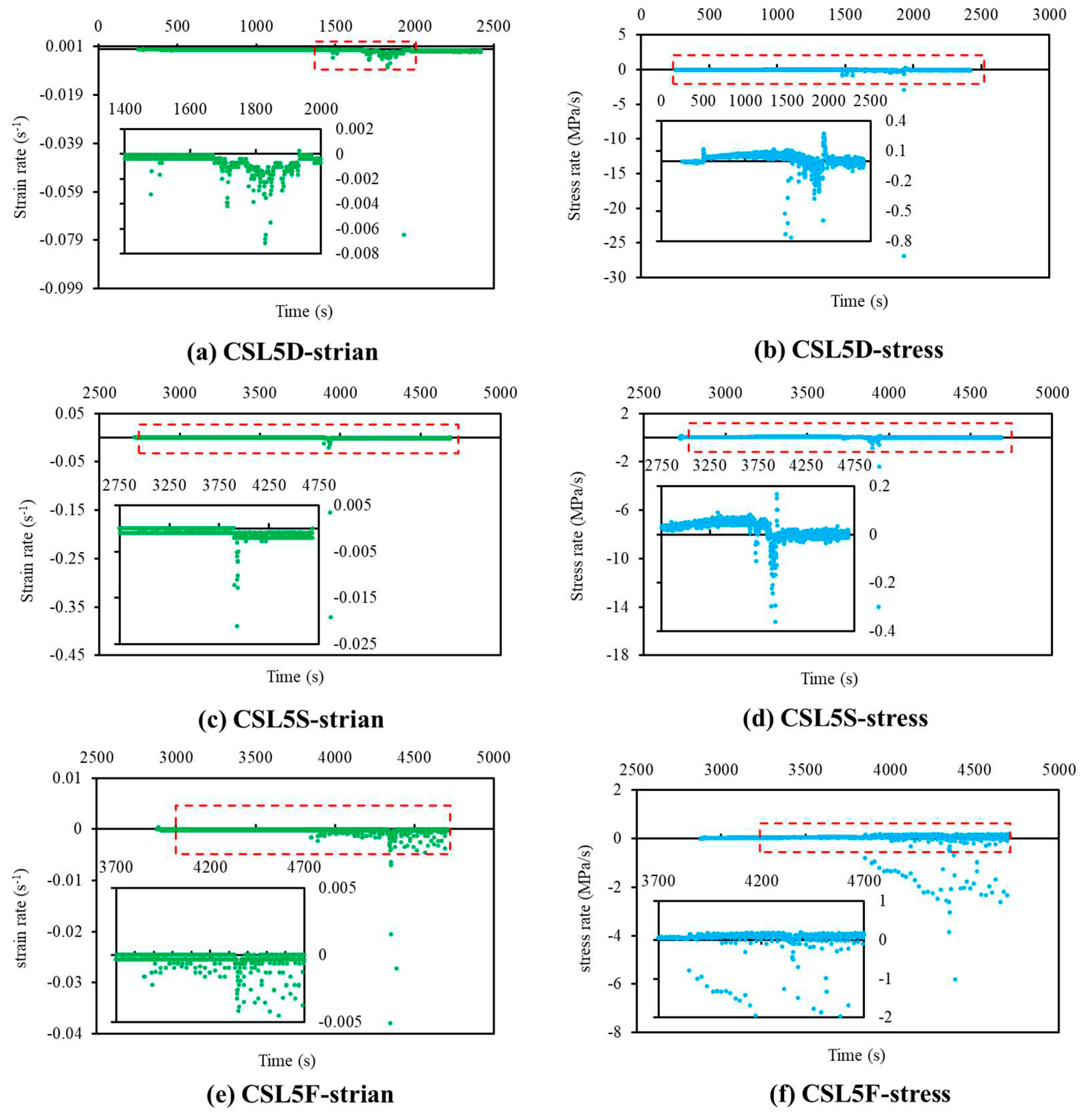

As shown in

Figure 7, the curves represent the relationship between radial strain rate, axial stress variation rate, and time for different states coal specimens under low confining pressure (5MPa) condition. The stress variation rate of dry coal and water-saturated coal are relatively consistent. Under the condition of constant axial displacement loading testing, the stress variation rate initially increases and then decreases, ultimately turning into a negative value at the point of fracture, and remains relatively unchanged after the peak. For freeze-thawed coal, the stress rate becomes negative before fracture, with the smallest variation rate observed during the pre-peak stage. This indicates that under the effects of thermal stress and freeze expansion force, a significant amount of damage is generated, while under the action of expansion force, the pore throat enlarges, resulting in better plastic behavior of the freeze-thawed coal.

The radial strain variation rate reflects the deformation, pore deformation, and crack caused by the Poisson effect. At the initial loading stage, all three states of coal exhibit a stable and relatively small radial strain variation rate (expansion). At this stage, the primary factor influencing the behavior is the Poisson’s ratio of the coal specimens and the mechanical properties of the pore throat. As the testing proceeds, the freeze-thawed coal shows the characteristics of accelerated expansion first, followed by the dry coal. This is attributed to the cumulative effect of crack. Until the formation of macroscopic cracks, the radial strain variation rate of the specimens under all three states increases significantly.

These findings indicate that the presence of water-saturated and freeze-thaw actions both have an impact on the physical structure and mechanical properties of coal pores. The presence of pore water inhibits radial deformation of the rock, reduces the bearing capacity of the pores, and thereby affects the axial load-bearing capacity of the rock. Furthermore, freeze-thaw actions promote radial deformation of the rock.

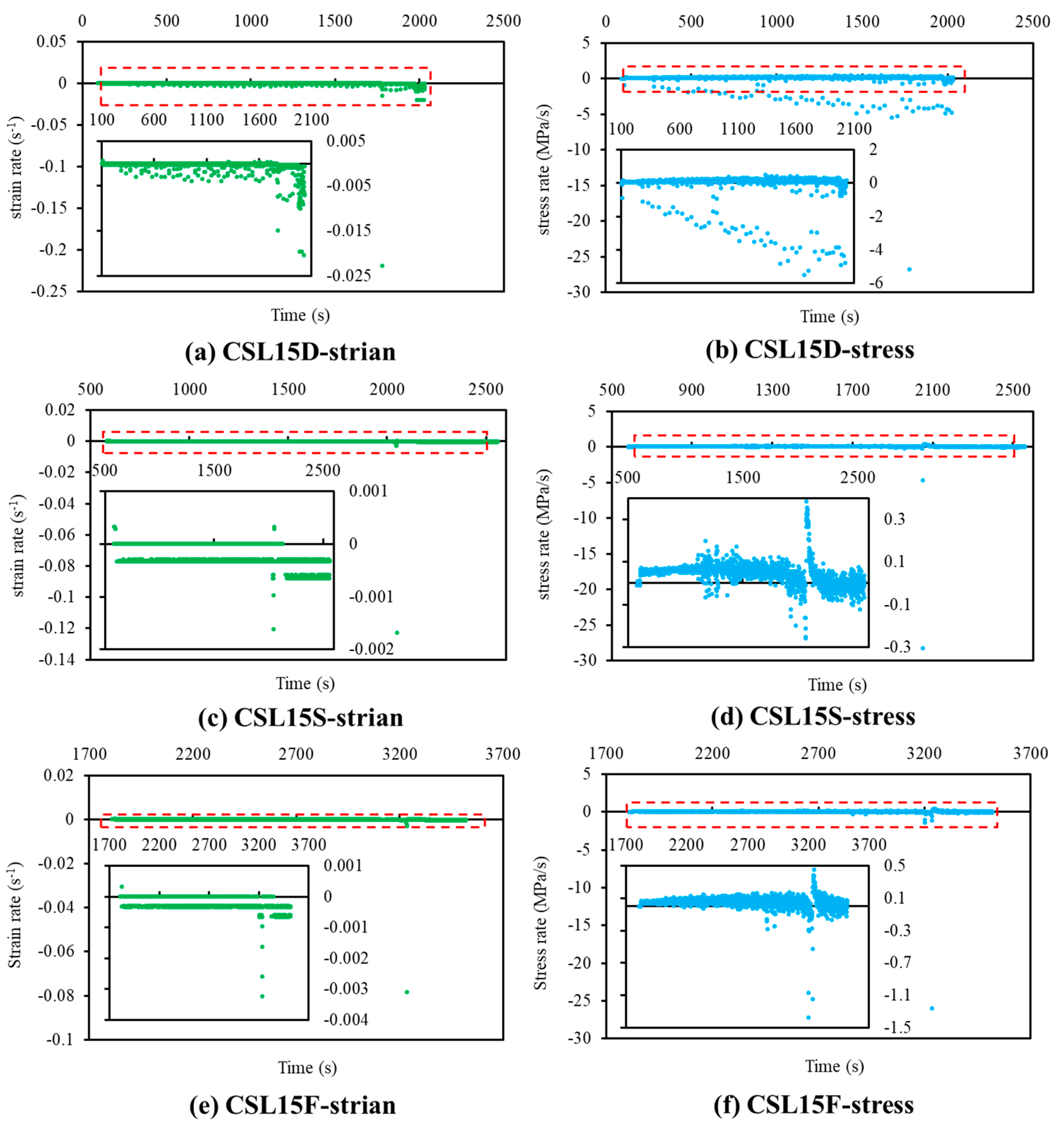

The curves of radial strain and axial stress variation rate versus time for coal specimens with different conditions under high confining pressure (15 MPa) are shown in

Figure 8. The stress variation rate of coal in the three states gradually increases at the beginning of loading, and the stress variation rate starts to show negative values as the test proceeds, which means that the stress appears to decrease under the condition of axial constant displacement loading, indicating that damage to the specimen has occurred. This phenomenon appears earliest in dry coal, and freeze-thaw coal appear almost when they enter the plastic deformation before fracture. This indirectly confirms that freeze-thaw coal has additional damage before loading.

The rate of radial strain variation is much greater in dry coal compared to coal in other states, and the presence of water reduces the Poisson’s ratio of the coal, while the freeze-thaw action seems to increase the Poisson’s ratio of the coal, but this effect is still smaller under high confining pressure conditions. The overall trend of strain variation rate for dry coals continued to decrease throughout the test, which indicates that radial expansion is increasing. In contrast, saturated and freeze-thaw coal expand to a maximum at the moment of fracture and then return to their original rates.

4.2. Analysis of the mechanism of coal permeability evolution

Based on the above experimental phenomena, the reasons affecting the deformation and evolution of permeability of coal specimens need to be discussed. Coal formations have natural pores formed under long-term diagenesis and geological processes, but these pores are often insufficient to meet the gas migration requirements during production. These pores gradually close under stress (referred to as the pore crack compaction stage in the initial loading), resulting in reduced permeability and entering the elastic stage. The differences in specimen pore structure and state also lead to different performances.

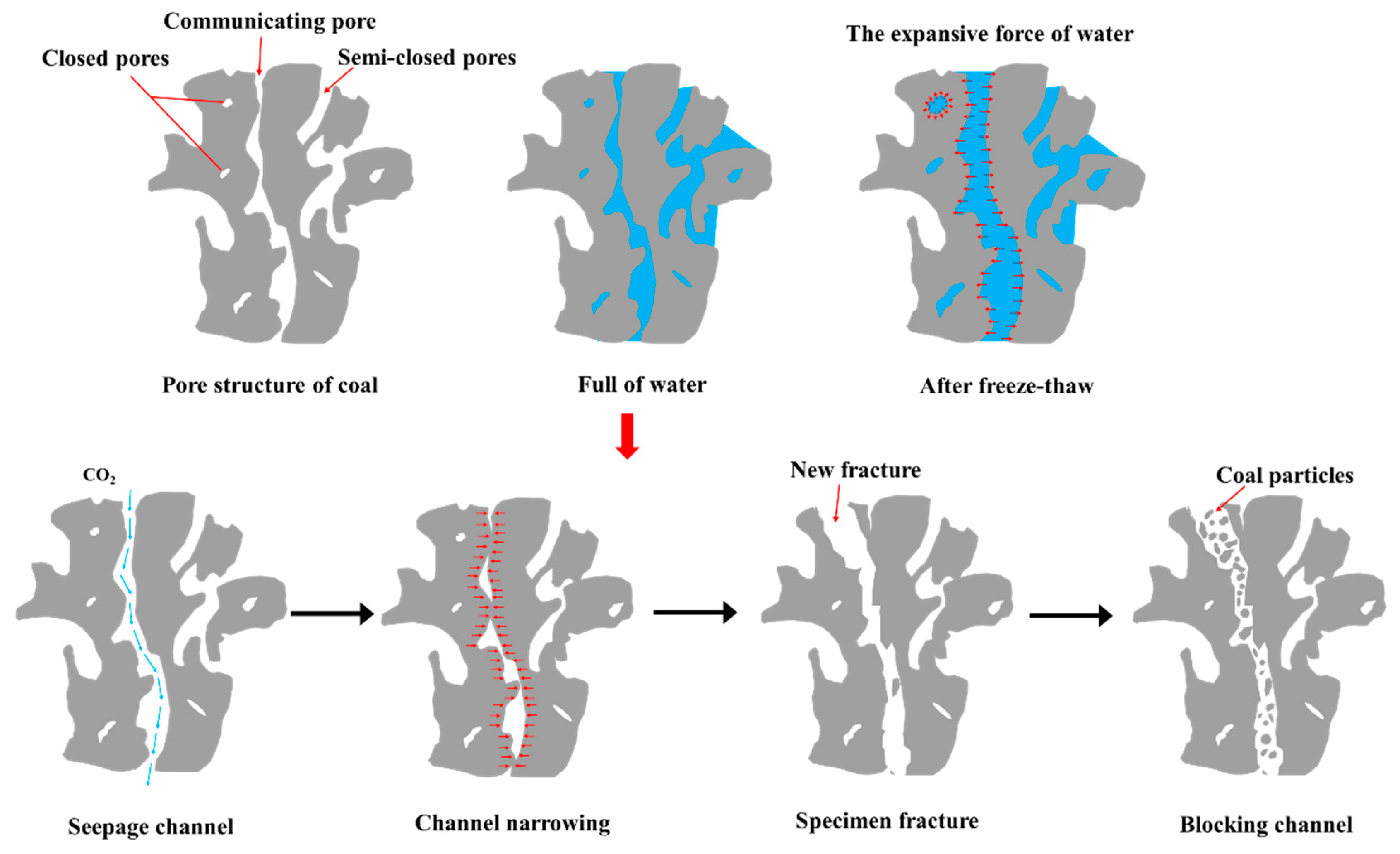

When there is no water in the coal pores, connected pores consisting of pores, throat channels, fractures, joints, cleavage planes, and bedding planes become gas flow channels. Those disconnected closed pores and semi-closed pores become potential gas flow channels. As shown in

Figure 9, under the influence of stress, flow channels gradually narrow or even close, resulting in reduced permeability or even loss of gas permeability. When the stress further increases, microcracks gradually initiate, and at this time, the permeability will increase. As the testing progresses, the damage intensifies, and the detachment of rock particles around the pores causes blockages in the flow channels, leading to a reduction in permeability. Until the specimen fractures and macroscopic cracks are formed, the experimental results show that under the influence of stress, these macroscopic cracks quickly become blocked.

When the coal is full of water, the pore space inside the specimen is occupied by water, and the passage originally for the gas to pass through is obstructed by water, which makes the permeability of the coal further reduced. Under the action of stress, the pore water pressure increases, making it more difficult for the gas to pass through. When the specimen is fractured to produce macroscopic cracks, the presence of pore water at this time can effectively prevent the coal particles from blocking the channel this situation. Therefore, the freeze-thaw coal makes the pore fissure space larger and more conducive to the formation of channels.

As a material with many pores and cracks, which is the key to the permeability of coal[

26]. The permeability evolution pattern of dry, saturated water and freeze-thawed coal in axially loaded tests will be discussed. Therefore, the permeability model shown in Eq. (2) is included in the scope repertoire of the discussion. This model was proposed by Shi et al.[27, 28] and is known as the S&D model.

where

is the cleat volume compressibility,

is the axial stress;

is the initial stress.

In Eq. (2), the cleat volume compressibility was extended to the fracture compressibility, and the fracture compressibility

Cf is described as a constant in this model. Existing studies, however, have found that fracture compressibility is not constant but changes with varying stress conditions. The permeability of coal specimens progressed through elastic and plastic stages, with the permeability decreasing and then increasing. The reason for the decrease in permeability in the elastic stage is due to the extrusion of the pore throat, and the reason for the increase in permeability in the plastic stage is due to the expansion of cracks, and the value of

Cf is changed[29, 30]. In simple terms, fracture compressibility is a function of stress, as shown in Eq. (3):

where

is the mean equivalent fracture compressibility;

is the initial equivalent fracture compressibility;

is the declining rate of equivalent fracture compressibility with increasing stress.

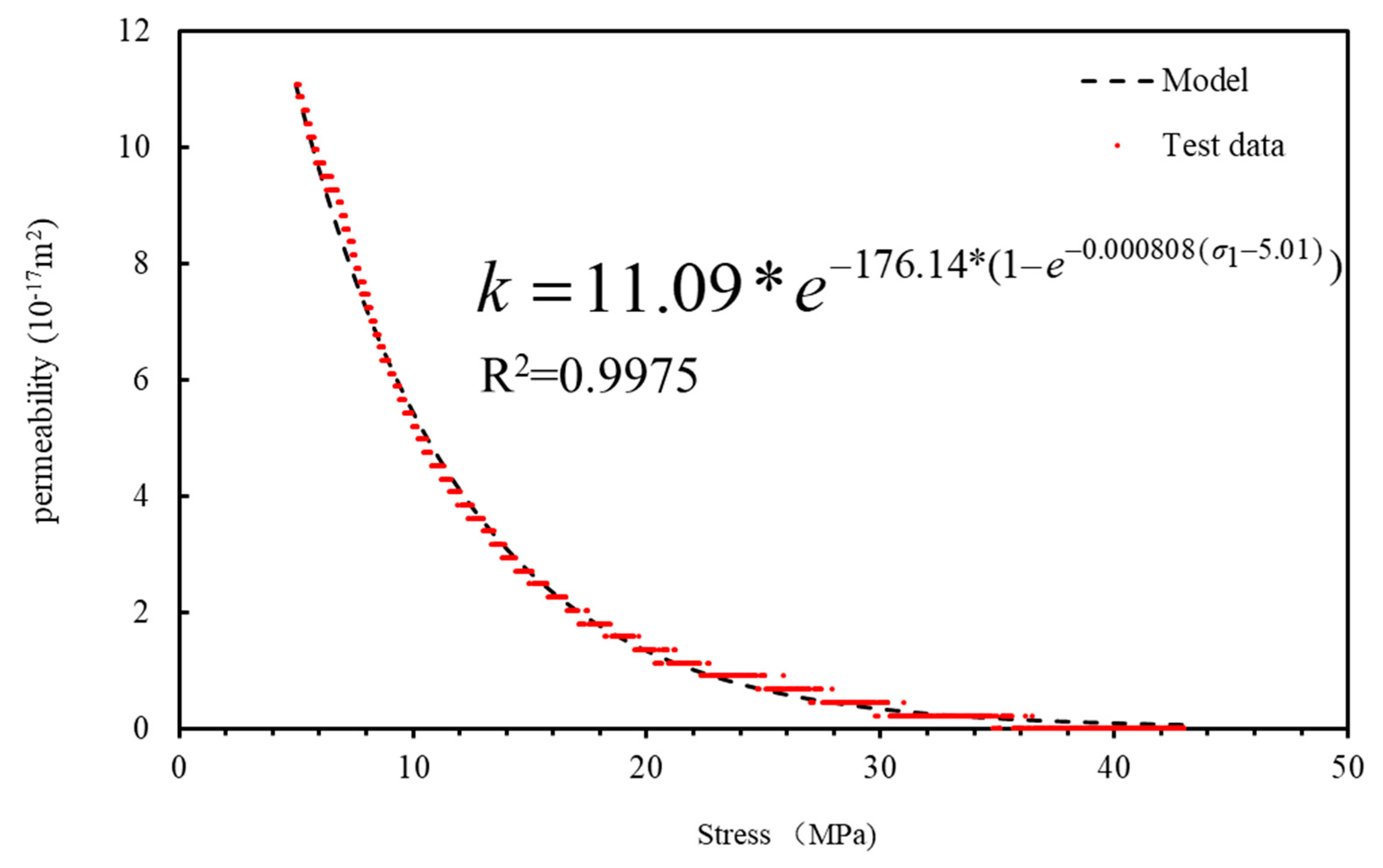

The evolution law of permeability of frozen-thawed coal with axial stress under 5 MPa confining pressure is selected for discussion, and the results are shown in

Figure 10. The permeability of the coal tends to be close to 0 when the axial pressure of 5 MPa gradually increases to 40 MPa. The R

2 of 0.9975 is obtained by fitting the results, indicating that the freeze-thaw coal can be well fitted with the S&D model. During this period of testing, the pores and cracks the coal involved in the seepage channels, which are either natural or artificial, gradually close to blockage.

5. Conclusion

Self-developed percolation equipment (THM-2) was used for testing, and the mechanical and permeability characteristics of coal in three different states under different confining pressure conditions were studied, and the influence law of freeze-thaw on the mechanical and permeability characteristics of coal was systematically analyzed, and the following conclusions were obtained:

1. The triaxial compressive strength of dry coal rock specimens is the highest and the triaxial compressive strength of freeze-thaw coal rock specimens is the lowest under the conditions of the same surrounding pressure (5 MPa, 15 MPa) and permeability pressure (1.5 MPa CO2).

2. The Cracking and fracture process produce fine coal particles will block the seepage channels, which is an important reason for the decrease of permeability. But pore water will mitigate channel blockage caused by this factor.

3.The presence of pore water in coal rock specimens will greatly reduce the permeability of coal rock, and freeze-thawing will improve this result to some extent.

4. The permeability of coal rock after freeze-thaw damage is still consistent with the S&D model.

Acknowledgments

The authors gratefully acknowledge the financial support from National Natural Science Foundation of China (Grant No. 52104209;52174084), National Key R&D Program of China (No. 2022YFB3706605), Sichuan Science and Technology Program (No.2023NSFSC0919) and Postdoctoral R&D Program of Sichuan University (No. 2023SCU12122). The author would also like to thank the anonymous reviewers for their comments that help rove the manuscript.

References

- Li, C. ; Xie HP; Gao MZ; Chen L; Zhao L; Li CB; Wu NH; He ZQ; JN, L., Novel designs of pressure controllers to enhance the upper pressure limit for gas-hydrate-bearing sediment sampling. Energy, 2021; 227, 120405. [Google Scholar]

- He, ZQ; Xie, HP; Gao, MZ; Chen, L; Yu, B; Hu, YQ; JP, Y. Design and Verification of a Deep Rock Corer with Retaining the In Situ Temperature. Advances in Civil Engineering, 2020; 2020, 1–13. [Google Scholar] [CrossRef]

- He, ZQ; Yang, Y; Yu, B; Yang, JP; Jiang, XB; Tian, B; Wang, M; Li, XY; Sun, SQ; H, S. Research on properties of hollow glass microspheres/epoxy resin composites applied in deep rock in-situ temperature-preserved coring. Petroleum Science, 2022; 19, 720–730. [Google Scholar] [CrossRef]

- HP, X. , Research review of the state key research development program of China:Deep rock mechanics and mining theory. Journal of China coal society 2019, 44, 1283–1305. [Google Scholar]

- Xie, HP; Gao, MZ; Zhang, R; Peng, GY; Wang, WY; AQ, L. Study on the Mechanical Properties and Mechanical Response of Coal Mining at 1000 m or Deeper. Rock Mechanics and Rock Engineering, 2018; 52, 1475–1490. [Google Scholar] [CrossRef]

- Xie, HP; Li, C; He, ZQ; Li, CB; Lu, YQ; Zhang, R; Gao, MZ; F, G. Experimental study on rock mechanical behavior retaining the in situ geological conditions at different depths. International Journal of Rock Mechanics and Mining Sciences, 2021; 138. [Google Scholar] [CrossRef]

- Xie, HP; Liu, T; Gao, MZ; Chen, L; Zhou, HW; Ju, Y; Gao, F; Peng, XB; Li, XJ; Peng, RD; Gao, YN; Li, C; He, ZQ; Yang, MQ; ZY, Z. Research on in-situ condition preserved coring and testing systems. Petroleum Science, 2021; 18, 1840–1859. [Google Scholar]

- Xie, HP; Lu, J; Li, CB; Li, MH; MZ, G. Experimental study on the mechanical and failure behaviors of deep rock subjected to true triaxial stress: A review. International Journal of Mining Science and Technology, 2022; 32, 915–950. [Google Scholar] [CrossRef]

- Lu, J.; Jiang, C.; Jin, Z.; Wang, W.; Zhuang, W.; Yu, H. , Three-dimensional physical model experiment of mining-induced deformation and failure characteristics of roof and floor in deep underground coal seams. Process Safety and Environmental Protection 2021, 150, 400–415. [Google Scholar] [CrossRef]

- Lu, J. , GuangzhiZhang, DongmingGao, HengLi, CunbaoLi, Minghui, True triaxial strength and failure characteristics of cubic coal and sandstone under different loading paths. International Journal of Rock Mechanics and Mining Sciences, 2020; 135. [Google Scholar]

- Lu, J.; Huang, G.; Gao, H.; Li, X.; Yin, G. , Mechanical Properties of Layered Composite Coal–Rock Subjected to True Triaxial Stress. Rock Mechanics and Rock Engineering, 2020; 53. [Google Scholar] [CrossRef]

- J, L.; DM, Z.; G, H.; X, L.; H, G.; GZ, Y. , Effects of loading rate on the compound dynamic disaster in deep underground coal mine under true triaxial stress. International Journal of Rock Mechanics and Mining Sciences 2020, 134. [Google Scholar]

- Lu, J.; Yin, G.; Gao, H.; Li, X.; Zhang, D.; Deng, B.; Wu, M.; Li, M. , True Triaxial Experimental Study of Disturbed Compound Dynamic Disaster in Deep Underground Coal Mine. Rock Mechanics and Rock Engineering 2020, 53, 2347–2364. [Google Scholar] [CrossRef]

- Li, C; Pei, JL; Wu, NH; Liu, GK; Huang, W; Dai, ZX; Wang, R.; Chen, ZF; WC, L. Rotational failure analysis of spherical-cylindrical shell pressure controllers related to gas hydrate drilling investigations. Petroleum Science, 2022; 19, 789–799. [Google Scholar] [CrossRef]

- Lu, J.; Xie, H.; Li, M.; Li, C.; Gao, M.; Shang, D.; Li, J. , Effect of microwave radiation on mechanical behaviors of tight fine sandstone subjected to true triaxial stress. International Journal of Rock Mechanics and Mining Sciences, 2022; 152, 152. [Google Scholar] [CrossRef]

- Mcdaniel, B. W.; Grundmann, S. R.; Kendrick, W. D.; Wilson, D. R.; Jordan, S. W. , Field Applications of Cryogenic Nitrogen as a Hydraulic Fracturing Fluid. Jpt Journal of Petroleum Technology 1998, 50, 38–39. [Google Scholar]

- Grundmann, S. R.; Rodvelt, G. D.; Dials, G. A.; Allen, R. E. , Cryogenic Nitrogen as a Hydraulic Fracturing Fluid in the Devonian Shale. Society of Petroleum Engineers 1998. [Google Scholar] [CrossRef]

- Winkler, E. M. , Frost damage to stone and concrete: geological considerations. Engineering Geology 1968, 2, 315–323. [Google Scholar] [CrossRef]

- Chu, Y.; Zhang, D. , Study on the pore evolution law of anthracite coal under liquid nitrogen freeze-thaw cycles based on infrared thermal imaging and nuclear magnetic resonance. Energy Science & Engineering, 2019. [Google Scholar] [CrossRef]

- Chu, Y.; Sun, H.; Zhang, D.; Yu, G. , Nuclear magnetic resonance study of the influence of the liquid nitrogen freeze-thaw process on the pore structure of anthracite coal. Energy Science and Engineering, 2020; 8. [Google Scholar] [CrossRef]

- Takarli, M.; Prince, W. , Permeability and P-wave velocity change in granitic rocks under freeze–thaw cycles. Geomechanics & Geoengineering, 2007; 2, 227–234. [Google Scholar] [CrossRef]

- J, L.; GZ, Y.; DM, Z.; H, G.; CB, L.; MH, L. , True triaxial strength and failure characteristics of cubic coal and sandstone under different loading paths. International Journal of Rock Mechanics and Mining Sciences 2020, 135. [Google Scholar]

- Gao, H.; Zhang, Z.-L.; Lu, J.; Zhang, Z.-T. , Experimental study on the mechanism of water affecting the permeability characteristics of sandstone. Thermal Science 2023, 27, 581–589. [Google Scholar] [CrossRef]

- Guangzhi Yin, W. L. , Jiang Xu, Minghui Li, Weizhong Wang, Development and application of fracturing and seepage experimental system for multi-physical field and multiphase coupling of porous media. Chinese Journal of Rock Mechanics and Engineering 2016, 35, 2853–2861. [Google Scholar]

- Gao, H; Zhang, DM; Lu, J; Yin, GZ; MY, W. Experimental Study on Influence of Intermediate Principal Stress on the Permeability of Sandstone. Transport in Porous Media, 2020; 135, 753–778. [Google Scholar] [CrossRef]

- Lu, J. , GuangzhiDeng, BozhiZhang, WeizhongLi, MinghuiChai, XiuweiLiu, ChaoLiu, Yubing, Permeability characteristics of layered composite coal-rock under true triaxial stress conditions. Journal of natural gas science and engineering 2019, 66. [Google Scholar]

- Li, M.; Yin, G.; Xu, J.; Cao, J.; Song, Z. , Permeability evolution of shale under anisotropic true triaxial stress conditions. International Journal of Coal Geology 2016. [Google Scholar] [CrossRef]

- Chen, D.; Pan, Z.; Ye, Z. , Dependence of gas shale fracture permeability on effective stress and reservoir pressure: Model match and insights. Fuel 2015, 139, 383–392. [Google Scholar] [CrossRef]

- Seidle, J. P.; Jeansonne, M. W.; Erickson, D. J. In Application of Matchstick Geometry To Stress Dependent Permeability in Coals, SPE Rocky Mountain Regional Meeting, 1992; 1992.

- Gale, J. F. W.; Reed, R. M.; Holder, J. , Natural fractures in the Barnett Shale and their importance for hydraulic fracture treatments. AAPG Bulletin 2007, (4), 91. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).