1. Introduction

Tree plantations are intensively managed crops designed for the sustainable and competitive supply of a whole range of wood based products [

1] such as: pulp, paper, clothing, furniture and building structures. According to [

2] wood product demand will increase from 2.3 to 3.1 billion m³ roundwood equivalent between 2020 and 2050. In plantation forestry, the management of harvesting residue offers a major challenge to replanting. From an operational point of view, residue management is a key component of soil nutrient management and forest fire prevention [

3,

4,

5]. There are several ways in which harvesting residues can be managed, such as burning, broadcasting, mulching, or collecting for energy use. The choice of the most suitable residue management method depends on a number of factors, such as terrain, weather, available markets and residue load [

1].

In South Africa, out of a total annual area of 41 869 ha surveyed, burning (78%) is the most common way to manage harvesting residues followed by broadcasting with 11% and mulching 8% [

6]. Burning is a preferred option because it is relatively cheap when compared to mechanical treatments such as mulching and chopper rolling [

7]. Broadcasting is the process of distributing residues left on site after harvesting [

8]. Broadcasting offers the benefits of retaining nutrients and minimizing water and soil loss [

1]. Furthermore broadcasting can improve soil structure, increase nutrient availability and promote soil biodiversity, all of which contribute too healthy plant growth [

9]. Mulching (or mastication) offers the same benefits, but accrues them even faster because it accelerates residue decomposition [

10]. On top of that, mulching also achieves a faster reduction of fuel loads and a more effective removal of physical hindrance to replanting [

11]. There are no general work quality references for mulching and operators default to “company standards”[

12], which can prescribe reduction into medium or fine size fragments. Mulching into fine particles can only be achieved by multiple passes, with a strong impact on costs. The cost of mulching should be weighed against its benefits, including better accessibility, increased soil moisture, reduced nutrient loss, lower fire risks and optimum soil cover. In particular, a mulched residue layer represents an effective barrier against soil erosion [

13,

14].

In South Africa, residue management is being modernized through the adoption of mulchers, with the primary objective of removing the high risks associated with burning. Unsuitable burning conditions are exacerbated by extreme and unpredictable weather events (climate change) and made increasingly expensive due to growing labour cost. Even though broadcasting may be a viable alternative for residue management, it is labour intensive and retains the full residue (fuel) load. Very little information is available on the use of mulchers and on their effect on fuel load reduction and distribution. The goal of this study is to compare manual broadcasting and mulching as alternatives for the management of harvesting residues in pine plantations. The comparison was based on the following key performance indicators: (1) productivity (2) costs and (3) work quality (i.e., size reduction effect).

2. Materials and Methods

2.1. Study site

The study was conducted in Tsitsikamma, in the Eastern Cape province of South Africa. The stand was a

Pinus elliottii plantation established at a 3.5 X 3.5 m spacing. The plantation was clearcut at the age of 14 years and yielded 1 031 m

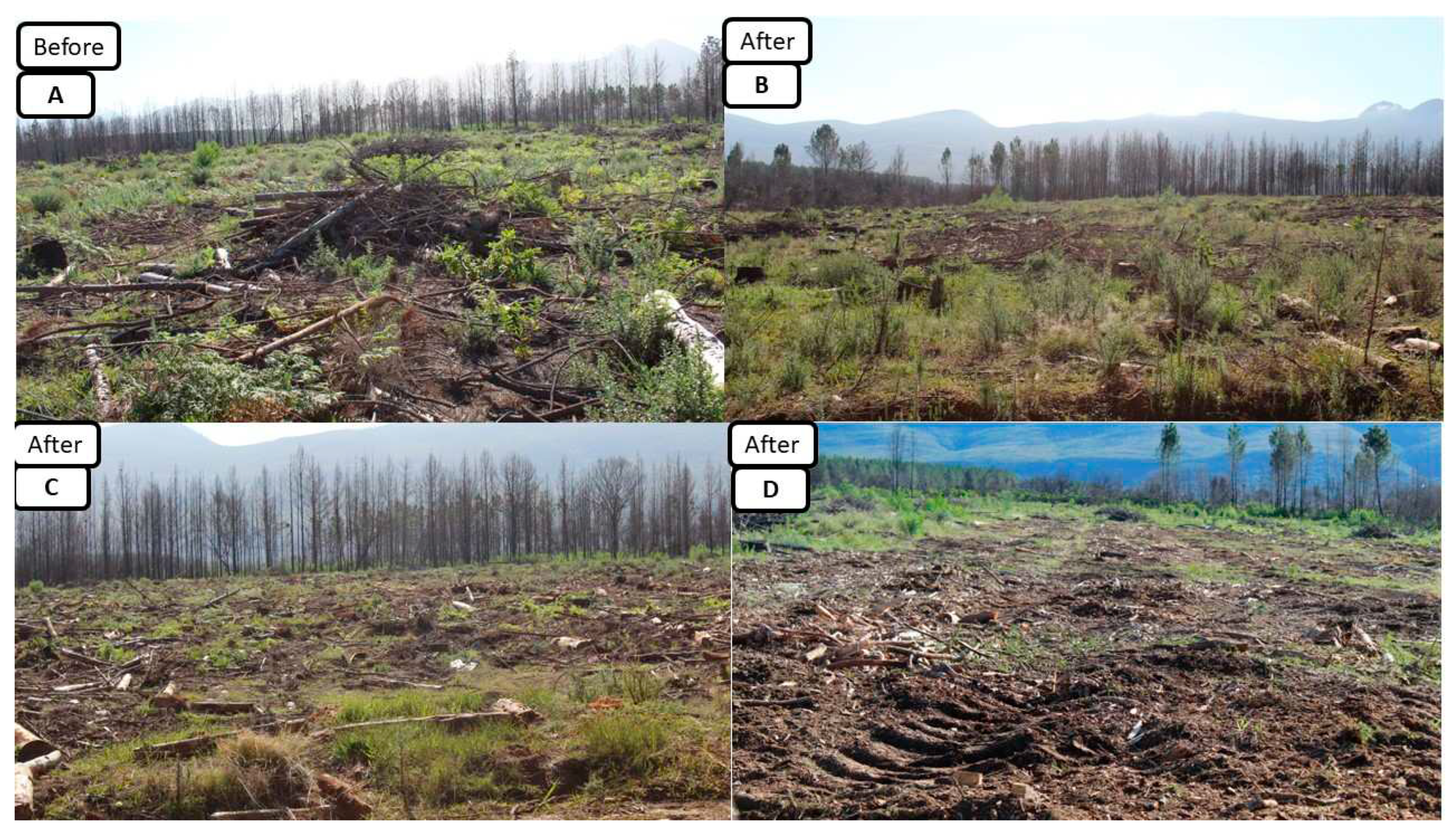

3/ha. Harvesting was carried out according to the mechanized cut-to-length method, using a harvester and a forwarder. The terrain was flat, with a slope gradient ranging from 0% to 10%. Residues were left in piles, spread across the compartment. Three methods of residue management were used, as follows: manual method (broadcasting), semi-mechanised method (manual broadcasting followed by mulching with a forestry-fitted farm tractor) and fully mechanised method (purpose-built mulcher). The three methods are depicted on

Figure 1.

Table 1 gives the specifications of the carrier and the attachments used in this study.

2.2. Experimental design

Three (3) treatments (manual broadcasting, semi mechanised and fully mechanised) were observed on the site and replicated four (4) times, each time on a plot measuring 30 m x 150 m. The resulting 12 plots were distributed randomly across the same compartment, their corners being marked with white painted pegs. Plot length and width were determined with a measuring wheel.

2.3. Residue load assessment

Prior to treatment application, the residue load on each plot was estimated by selecting two representative residue piles, manually separating branches and stem wood, and then weighing the two fractions on a portable scale. To the purpose, residues were cut to pieces with a chainsaw, so that they would fit into a bucket. The resulting weight per pile was then multiplied by the number of piles on the respective plot. Moisture content was also determined, according to the gravimetric method. This was done separately for the two fractions, from each sample pile.

2.4. Productivity assessment

Researchers used a stopwatch to determine the time taken to complete each plot. Furthermore, elemental time studies were conducted to determine the distribution of work time among different functional tasks. Manual broadcasting was performed by a team of five workers, and therefore the researcher conducted the elemental time study according to the activity sampling technique. The researcher recorded at one-minute intervals what activity was conducted by each worker at that moment, among the following four options: walk, broadcast, stand and delays. This was done for both the manual and the semi-mechanized methods.

Given that only one mechanical unit was working at one time (farm tractor-based mulcher or purpose-built mulcher), with those machines the elemental time study was applied as a classic cycle study. In that case, time was measured using a Trimble handheld computer, running the dedicated UMT manager time study software. Therefore, the time studies of those machines split the work cycle into the following work elements:

Move: Begins when the wheels of the machine start moving, and the head is not engaged and stops when the wheels stop, and the head is put on the ground to start engaging

Mulch: Begins when the mulching head is put on the ground and the mulcher starts moving and stops when the mulcher picks up the mulching head and starts turning.

Turn: Begins when the mulcher picks up the head and starts turning and stops when the mulching head is put on the ground and the mulcher starts moving

The same machine operators were used throughout the study.

2.5. Work quality assessment

After mulching, work quality was sampled at six (6) points per study plot. Collection points consisted of 1x1 m squares located 20m from each other and placed in a zig-zag pattern. All the fragments present on each square were collected, and their length was measured with a measuring tape. Fragments were then allocated to one of the following four length classes: <20 cm; 20-50 cm; 51-100 cm; >100 cm. Biomass reduction for the fully mechanised mulching was further assessed using sieves to get the particle size distribution of the medium and fine materials.

2.6. Cost assessment

Costs were calculated using an industry accepted silviculture costing model developed by the South African Contractor’s Association Costing (SAFCA). The assumptions information regarding machine purchase price and running costs (e.g., fuel and oil consumption and maintenance) of the machines were obtained from the machine suppliers and contractors. The interest rate used was 9% as it was the prime lending rate when the study was undertaken in July 2022 [

15]. General labour rates were obtained from the current government gazette wage rates in the South African forestry industry [

16].

Table 2 illustrates the main cost assumptions for the machines used in the study.

2.7. Data analysis

Data analysis aimed at determining and comparing the operational productivity, costs, and work quality of the three residue management methods. Descriptive statistics were used to guide detailed analysis. Given the relatively small sample size and the violation of the normality assumption, comparisons were conducted with non-parametric techniques. In particular, the significance of any differences between three or more groups were tested using the Kruskal-Walli’s test, while differences between two groups were tested using the Mann-Whitney U test (SAS Institute Inc. 1999). Statistical significance was assumed for α < 5%.

3. Results

3.1. Productivity and costs

The analysis of test conditions (surface area, number of residue piles, biomass load per hectare and percentage stem wood) did not show any significant differences among treatments

Table 3. The mean sample plot area for all treatments was 0.424 ha and the mean number of pine residue piles per plot was 16. The estimated residue load ranged between 12 and 14 oven-dry tons per hectare (ODT/ha). Stem wood proportion averaged 61% of those amounts. The average stump volume for the plots was 8.16m

3/ha.

Broadcasting only (manual method) required 16 h/ha while broadcasting in preparation for tractor mulching (semi-mechanized method) required 14 h/ha. Therefore, the cost incurred was quite similar; 400 ZAR/ha for broadcasting only and 350 ZAR/ha for the broadcasting in preparation for the tractor. Those differences were small and deprived of any statistical significance.

When comparing the two mulching techniques (farm tractor-based vs. purpose-built), it was found that mulching took less than half as many machine hours when applied with purpose-built equipment (1.5h) rather than with an adapted farm tractor (3.5h). However, the latter was much more expensive to own and operate and the cost per hectare was significantly different between the two techniques: 4 083 ZAR/ha and 3 267 ZAR/ha respectively. However, the purpose-built machine could cope with piled residues and therefore its use did not require prior manual broadcasting as in the case of the farm tractor-based mulcher. The latter was less powerful and was mounted on the rear of the tractor, and therefore needed to drive over the residues, which could not be piled too high. Working with piled residues, the purpose-built mulcher had to perform a second pass to achieve good work quality. The second pass was significantly faster than the first one, as it dealt with semi-processed material

Table 4.

Therefore, if the manual method (broadcasting only) is replaced by either the semi-mechanized or the fully mechanised methods (broadcasting plus mulching or mulching only) residue management cost incurs an 8-10-fold increase from 400 ZAR/ha to approximately 4100 ZAR/ha for the purpose-built mulcher and 3 300 ZAR/ha for the tractor respectively. Furthermore, it was found that there is significant difference (p-value 0.0209) between the cost incurred by the semi-mechanized 3 267 ZAR/ha and the fully mechanized methods 4 083 ZAR/ha.

3.2. Work quality

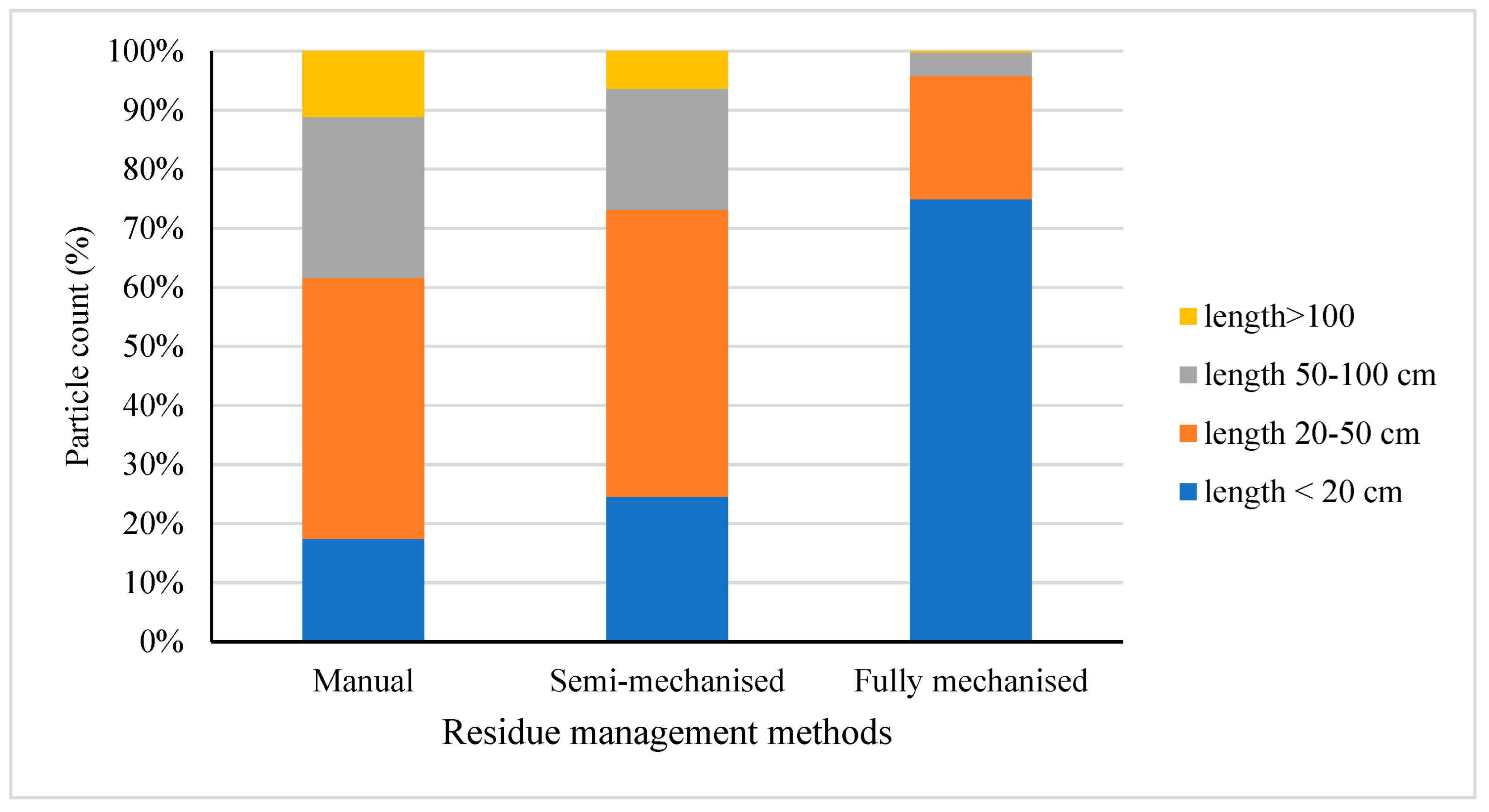

The fully mechanised method (i.e., mulching residues with a purpose-built machine) achieved the strongest size reduction: median particle size was 12, 31 and 39 cm for the fully mechanized, the semi-mechanized and the manual methods, respectively.

A better appreciation of work quality is achieved by examining the particle size distribution graphs for the three treatments

Figure 2. With the fully mechanised method over 70% of the fragments were shorter than 20 cm. In contrast, most fragments (49%) produced with the semi-mechanized and the manual method were included within the 20 to 50 cm length class. Overall, the fully mechanized method obtained a much better size reduction compared with the semi-mechanized method. Indeed, the semi-mechanized method yielded half as many fragments longer than 1 m, compared with the manual method – that is: 5% vs. 10% of the total. However, the fully mechanized method yielded none.

Figure 3 illustrates the before and after biomass distribution by treatments on the plots.

Furthermore, samples taken from the fully mechanised method were passed through sieves of width between >5cm and >40cm and the results on

Table 5 shows that more fine materials were produced when residues were mulched in the residue piles compared to in between the residue piles. This assessment was conducted to understand the fuel load distribution after mechanically mulching in areas with residue piles versus none. Due to the residues being long and not entirely broken down in the manual (broadcasting) and semi mechanised (broadcasting with tractor mulcher) sieving was impossible. There was no significant difference (

p-value 0.7150) between the two methods of work quality assessment for the fully mechanised method, therefore when using the fully mechanised mulcher the work quality produced when mulching on areas with residue piles and no piles is relatively the same.

4. Discussion

The study was conducted to determine the productivity, cost, and work quality of three residue management methods. The purpose of residue management is to reduce and redistribute the fuel load for better accessibility and reduction of fire risks. According to [

17] fuel treatments modify and affect species structure, composition, availability, distribution, fuel moisture and surface -wind behavior. Moreover, methods used in silviculture to alter fuel load and continuity decrease the treated area’s vulnerability to fires.

4.1. Fully mechanised method

The fully mechanised system, applied with a purpose-built machine, was the most productive, requiring 1.47 h/ha (two passes) and costing 4 083 ZAR/ha. The second pass was necessary to achieve the desired work quality, according to company standards. When observing a similar wheeled mulcher (Tigercat M726G) working in broadcasted pine pulpwood harvest residues [

18] found that time consumption was 2.90 h/ha and cost 6 165 ZAR/ha. The cost difference between the two studies amounts to 2 069 ZAR/ha. Both studies took place in stands previously planted with pine species (

Pinus elliottii vs Pinus patula), characterized by flat terrain (0-10% vs 0-12%); both sites were previously harvested according to the mechanised cut-to-length method, using a harvester and a forwarder. The main difference seems to be with slash distribution, which had been piled in the case of this study and left broadcast in the case of the study by [

16]. This may lead to the conclusion that a powerful frontal mulcher works best with piled residues: concentration does not exceed the available power capacity, while it avoids idle maneuvering and piecemeal work. An additional study of mulching in Ponderosa pine (

Pinus lambertiana) stands may offer further corroboration to the general validity of our figures, since it estimates time consumption at 1.9 h/ha, which is well within range of this study [

19]. As to mulching cost, most of the existing references available on the subject come from the United States, under a very different economic environment; those studies report costs most commonly included between 5500 and 7500 ZAR/ha, or between 300 and 400 USD/acre [

20,

21,

22].

Slash quantities, size, composition, and proximity to soil affect the speed with which residue is mineralized. Mulching speeds up the rate of decomposition and offers a safer alternative to burning [

23]. Furthermore, mulching guarantees a better soil cover, which mitigates soil temperature, avoiding extremes during both Summer and Winter [

24]. Finally, mulched residues prevent excessive evaporation and maintain favorable soil moisture conditions, thereby promoting plant health and sustained growth.

Figure 2 show the work quality of the fully mechanised method: most fragments were reduced to a length of 12 cm after two passes. That is a good result, since fragment size falls between that of medium and fine chips. Furthermore, work quality for the fully mechanised method was assessed using sieves

Table 5: results complement each other in terms of more materials falling within the class of medium to fine particles. [

12] indicates that mulching at a normal intensity result in a fuel bed with fuels (surface and aerial) processed into chipped debris. [

25] supports this by mentioning that mulching as a treatment alters the fuel load covering the forest floor. Moreover, slash management properly carried out could contribute to forest ecosystem maintenance by limiting nutrient losses and allowing nutrient release to synchronize with stand requirements [

23].This gives an indication that the fully mechanised system is adequately capable of performing this task.

4.2. Semi-mechanised method

Results for the semi-mechanised method show that there is a slight change in residue form as broadcasting was combined with tractor mulching. Median fragments length reaches 31 cm after one pass of the tractor mulcher. A study conducted by [

26]compared the productivity and costs of a harvester collecting and comminuting apple pruning residues and traditional mulching. The working conditions included a row spacing of 3.2m and it was observed on an average area of 19 m

2 over 3 to 5 plots. Time consumption was found to be 2.43 h/ha and cost 2 858 ZAR/ha. In the current study the semi-mechanised method incurred a time consumption of 3.58 h/ha and costs of 3 267 ZAR/ha. This is expected since the mulching was not observed on similar conditions (forest compartment vs apple orchard). The residues mulched were different in terms thickness, length, and arrangement: the forest stand presented a higher residue load and larger slash components compared to the apple orchard. Taking that into account, however, the cost is notably different (409 ZAR/ha). The working conditions of the tractor mulcher were improved considering the initial broadcasting that took place prior to mulching. The work quality of the semi-mechanised mulching had more of its residues particles after mulching in the class between 20-50cm.

4.3. Manual method.

Manual broadcasting incurred the lowest cost (400 ZAR/ha) among the three methods observed in this study. It also achieved the poorest work quality, as residues sized had been minimally reduced and the prevalent fragment length was 39 cm, with a relatively large proportion of elements longer than 1 m – which could prove a significant hindrance to future soil preparation and planting work. [

27] mention that the extensive use of fire for harvesting residue disposal contributes to nutrients loss and erosion and leaching. Therefore, broadcasting is more efficient than burning, both in financial and environmental terms: it requires less work, maintains soil cover and minimizes nutrient leaching [

28]. Broadcasting is likely more efficient than windrowing, because windrowed residues is slower to mineralize and does not offer the same soil cover benefits [

23].

From this study it can be gathered mechanised mulching is the most suitable method for the reduction and distribution of slash to reduce the potential of a fire spreading rapidly and improved accessibility on a site. Moreover, productivity for fully mechanised mulching was not influenced adversely by the amount and arrangement of the residues. The number of residue piles and their arrangement in each plot did not seem to change the mulching consistency of the fully mechanised mulcher thus the quality was similar throughout the plot. Semi-mechanised mulching productivity was much lower due to limited maneuverability. With this method, the mulcher was carried on the back of a farm tractor and therefore it was not possible to treat piled residues. Even if the tractor had attempted to mulch the residue piles driving in the reverse gear, the mulcher would have not done a good job as it had been designed for working with a tractor in the forward gear range, straddling the residues. Therefore, slash had to be broadcast first, and mulching required travelling the whole surface of the plot, not just driving to the piles. That was far less efficient, which combined with the lower power of the tractor to limit overall productivity. As a result, residue management cost was as less than the purpose-built mulcher with poor work quality produced while for the purpose-built mulcher the cost was higher with excellent work quality.

5. Conclusion

The goal of this study was to determine the productivity of three methods for dealing with harvesting residues on pine stands. Furthermore, the study determined the work quality and the costs associated with residue management. Fuel load redistribution was best achieved by the fully mechanised method, which offered the highest work quality in the shortest time but with the highest costs. On the other hand, manual broadcasting alone (no mulching) was the cheapest method, even if it achieved the lowest work quality and required the longest time. Introducing a low-investment tractor mulcher after manual broadcasting resulted in a large increment of treatment cost and a modest improvement of work quality. Therefore, this solution is best avoided. Managers are then left to decide between a cheap solution offering an average work quality and an expensive solution offering an excellent work quality: there is no in-between. Further studies should investigate the impact of work quality on following management steps, in order to determine how much of the additional cost incurred with mulching is recovered through more efficient replanting. Similarly, the same comparisons could be conducted on other plantation types, such as eucalyptus and acacia harvested stands.

Author Contributions

Conceptualization, M.M.R. and H.M.Z.; methodology, M.M.R. and R.S. formal analysis, R.S.; Resources M.M.R.; writing – original draft preparation, H.M.Z.; writing – review and editing, M.M.R. and R.S.; visualization, H.M.Z. and M.M.R. supervision, M.M.R.; funding acquisition, M.M.R.

Data availability statement

Data can be obtained from the authors upon reasonable request.

Acknowledgments

The authors acknowledge MTO (grower company), silviculture contractors and their staff who enabled the research to be conducted. FP&M SETA and the Nelson Mandela University are acknowledged for providing funding for the research.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Eckert, M.; Gaigher, R.; Pryke, J.S.; Samways, M.J. Short-term arthropod recovery in Eucalyptus plantations after harvesting is not affected by different residue management practices. Forest Ecology and Management 2023, 537, 120973. [Google Scholar] [CrossRef]

- FAO. Global forest sector outlook 2050: Assessing future demand and sources of timber for a sustainable economy – Background paper for The State of the World’s Forests 2022. FAO Forestry Working Rome, 2022.

- Xu, H.; Latta, G.; Lee, U.; Lewandrowski, J.; Wang, M. Regionalized life cycle greenhouse gas emissions of forest biomass use for electricity generation in the United States. Environmental Science & Technology 2021, 55, 14806–14816. [Google Scholar]

- Franco, C.R.; Page-Dumroese, D.S.; Archuleta, J. Forest management and biochar for continued ecosystem services. Journal of Soil and Water Conservation 2022, 77, 60A–64A. [Google Scholar] [CrossRef]

- Skovsgaard, J.P.; Johansson, U.; Holmström, E.; Tune, R.M.; Ols, C.; Attocchi, G. Effects of thinning practice, high pruning and slash management on crop tree and stand growth in young even-aged stands of planted silver birch (Betula pendula Roth). Forests 2021, 12, 225. [Google Scholar] [CrossRef]

- Ramantswana, M.M.; Brink, M.P.; Little, K.M.; Spinelli, R.; Chirwa, P.W. Current status of technology-use for plantation re-establishment in South Africa. Southern Forests: a Journal of Forest Science 2020, 82, 313–323. [Google Scholar] [CrossRef]

- Ndlovu, N.; Little, K.M.; Titshall, L.; A., R.C. Site preperation and vegetation management impacts on Pinus patula growth and rotation end productivity in South Africa. Australian Forestry 2019, 82, 107-115.

- Norris, C. Site preparation options for South African forestry soils. 1995.

- Li, Y.; Li, Z.; Chang, S.X.; Cui, S.; Jagadamma, S.; Zhang, Q.; Cai, Y. Residue retention promotes soil carbon accumulation in minimum tillage systems: Implications for conservation agriculture. Science of the Total Environment 2020, 740, 140147. [Google Scholar] [CrossRef] [PubMed]

- Mechergui, T.; Pardos, M.; Jhariya, M.K.; Banerjee, A. Mulching and weed management towards sustainability. Ecological intensification of natural resources for sustainable agriculture 2021, 255–287. [Google Scholar]

- Fornwalt, P.J.; Rocca, M.E.; Battaglia, M.A.; Rhoades, C.C.; Ryan, M.G. Mulching fuels treatments promote understory plant communities in three Colorado, USA, coniferous forest types. Forest Ecology and Management 2017, 385, 214–224. [Google Scholar] [CrossRef]

- Hvenegaard, S. Mulching productivity in black spruce fuels: productivity as a function of treatment intensity. FP Innovations: Edmonton, AB, Canada 2019, 14.

- Lopes, A.R.; Prats, S.A.; Silva, F.C.; Keizer, J.J. Effects of ploughing and mulching on soil and organic matter losses after a wildfire in Central Portugal. Cuadernos de investigación geográfica/Geographical Research Letters 2020, 303-318.

- Abrantes, J.R.; Prats, S.A.; Keizer, J.J.; de Lima, J.L. Effectiveness of the application of rice straw mulching strips in reducing runoff and soil loss: Laboratory soil flume experiments under simulated rainfall. Soil and Tillage Research 2018, 180, 238–249. [Google Scholar] [CrossRef]

- Resbank. Key statistics. Available online: https://www.resbank.co.za/en/home/what-we-do/statistics/key-statistics (accessed on 15 July).

- labour, D.o.e.a. The National Minimum Wage, a tool to close the wage gap and to overcome poverty. 2023.

- Piqué, M.; Domènech, R. Effectiveness of mechanical thinning and prescribed burning on fire behavior in Pinus nigra forests in NE Spain. Science of the total environment 2018, 618, 1539–1546. [Google Scholar] [CrossRef] [PubMed]

- Mahadeo, L. Understanding the system and supply chain effects of two residue management treatments in pine and eucalyptus plantations. 2022.

- DeLasaux, M.J.; Hartsough, B.R.; Spinelli, R.; Magagnotti, N. Small parcel fuel reduction with a low-investment, high-mobility operation. Western Journal of Applied Forestry 2009, 24, 205–213. [Google Scholar] [CrossRef]

- Coulter, E.D.; Coulter, K.; Mason, T. Dry forest mechanized fuels treatment trials project. In Proceedings of the Proc. 25th Annual Council on Forest Engineering Meeting; Auburn, AL, 2002.

- Halbrook, J.; Han, H.-S.; Graham, R.T.; Jain, T.B.; Denner, R. Mastication: A fuel reduction and site preperation alternative. In Proceedings of the Proc. July, 2006 Council On Forest Engineering (COFE) meeting, Coeur d'Alene, ID, 2006.

- Vitorelo, B.; Han, H.-S.; Varner, J. Masticators for fuel reduction treatment: equipment options, effectiveness, costs, and environmental impacts. In Proceedings of the Proceedings of the 2006 Council on Forest Engineering (COFE) meeting, Lake Tahoe, CA, 2009.

- Belleau, A.; Brais, S.; Paré, D. Soil nutrient dynamics after harvesting and slash treatments in boreal aspen stands. Soil Science Society of America Journal 2006, 70, 1189–1199. [Google Scholar] [CrossRef]

- Frame, C. Reducing Fuels through Mulching Treatments: What are the Ecological Effects? 2011.

- Battaglia, M.A.; Rocca, M.E.; Rhoades, C.C.; Ryan, M.G. Surface fuel loadings within mulching treatments in Colorado coniferous forests. Forest Ecology and Management 2010, 260, 1557–1566. [Google Scholar] [CrossRef]

- Nati, C.; Boschiero, M.; Picchi, G.; Mastrolonardo, G.; Kelderer, M.; Zerbe, S. Energy performance of a new biomass harvester for recovery of orchard wood wastes as alternative to mulching. Renewable Energy 2018, 124, 121–128. [Google Scholar] [CrossRef]

- Chamshama, S.; Lupala, Z. Effect of post-harvest Cupressus lusitanica slash management on early growth of Pinus patula at Shume, Lushoto, Tanzania. Tanzania Journal of Forestry and Nature Conservation 2012, 82, 13–21. [Google Scholar]

- Fernández, C.; Vega, J.A.; Gras, J.M.; Fonturbel, T.; Cuinas, P.; Dambrine, E.; Alonso, M. Soil erosion after Eucalyptus globulus clearcutting: differences between logging slash disposal treatments. Forest Ecology and Management 2004, 195, 85–95. [Google Scholar] [CrossRef]

|

Disclaimer/Publisher’s Note: The statements, opinions and data contained in all publications are solely those of the individual author(s) and contributor(s) and not of MDPI and/or the editor(s). MDPI and/or the editor(s) disclaim responsibility for any injury to people or property resulting from any ideas, methods, instructions or products referred to in the content. |

© 2023 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).